Environment-friendly chromium-free leather retanning method

A chrome-free retanning and environment-friendly technology, applied in small raw hide/big raw hide/leather/fur treatment, small raw hide/big raw hide/leather skin/fur chemical treatment, dyeing method, etc., can solve the problem of easy deformation and leather surface Poor filling uniformity, poor flatness, poor durability, etc., to achieve the effect of improving softness, improving wastewater treatment efficiency, and improving fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of concrete steps of the method for environment-friendly chromium-free retanning leather are as follows:

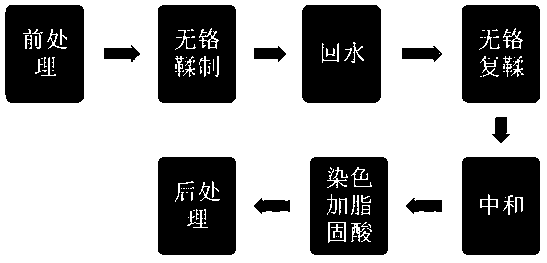

[0032] Include the following steps in turn: pretreatment → chrome-free tanning → backwater → chrome-free retanning → neutralization → dyeing, fatliquoring, acid fixation → post-treatment; specifically,

[0033] The pre-treatment process includes: based on the quality of the bare hide, add 120% of water at 25°C and 2% of ammonia-free deliming agent in the drum, rotate for 70 minutes, then add 0.3% softening enzyme, rotate for 40 minutes, and the final bath liquid The pH is 7.5, drain, pickle and wash with water.

[0034] The chrome-free tanning process is: based on the quality of bare hide, add 40% water at 25°C to the drum and rotate for 10 minutes; add 2% silicone modified polyurethane resin and rotate for 60 minutes; add 8% zirconium-aluminum-titanium Rotate for 160 minutes with polymetallic compound tanning agent; then add 0.3% alkali-raising agent and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com