Manufacturing method for improving softness of tissue paper

A manufacturing method and technology of household paper, applied in the direction of textiles and papermaking, etc., can solve the problems of loss of strength, inability to obtain softness and strength of paper products, etc., and achieve improved satisfaction, softness and hand feeling, and low softness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

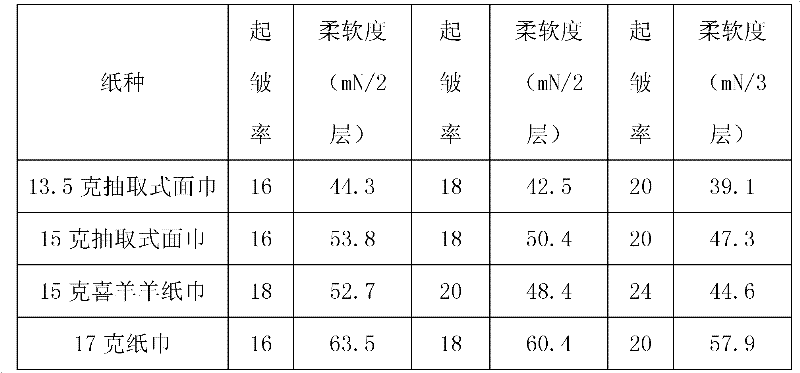

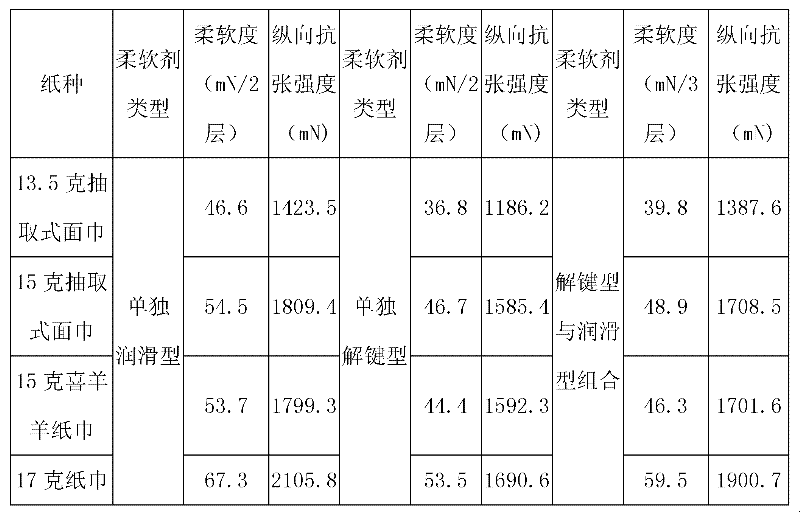

Examples

Embodiment Construction

[0014] The manufacturing method for improving the softness of tissue paper of the present invention includes the steps of material selection, beating, filling, papermaking, scraping and pressing drying, and also includes selection and addition of a softener.

[0015] During the above material selection process, the raw materials and their weight contents are respectively 30%-40% of Canadian high-quality softwood kraft pulp, 30%-40% of Indonesian high-quality acacia fluff pulp, and 30%-30% of Brazilian high-quality eucalyptus fluff pulp. 40%.

[0016] During the above-mentioned beating steps, the pulp is decomposed by the deflaker before being refined by the refiner, and the concentration range of the pulp after decompression is controlled at 4.5% to 4.8%. The proportion of chemical, control the viscosity increase coefficient in the range of 1.2 to 1.3.

[0017] During the scraping process above, use the sharp-angled surface of the scraper to contact the surface of the dryer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com