Patents

Literature

126results about How to "Light touch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Desulfurization gypsum-based thermal insulation mortar and preparation method thereof

The invention relates to a desulfurization gypsum-based thermal insulation mortar and a preparation method of the mortar, belonging to the technical fields of solid waste comprehensive utilization and building material. The desulfurization gypsum-based thermal insulation mortar comprises the components in parts by weight: 1000 parts of desulfurization gypsum, 3-10 parts of white cement, 350-450 parts of glass beads, 5-15 parts of redispersible latex powder, 1-5 parts of wood fiber, 5-25 parts of sepiolite fiber, 1.5-5 parts of polypropylene (PP) fiber, 1-8 parts of polyvinyl alcohol, 1-5 parts of hydrophobic agent, 0.4-3 parts of retarder, 1-5 parts of water reducing agent and 2-6 parts of thickening agent. The desulfurization gypsum-based thermal insulation mortar is convenient to transport and has very strong thermal insulation performance and fireproof performance.

Owner:上海复培新材料科技有限公司

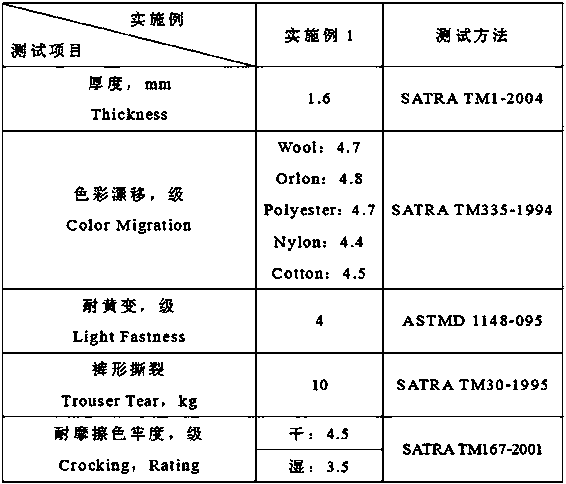

Prepn of superfine fiber sofa leatherette

The present invention belongs to the field of leather-making technology. By selecting superfine fiber non-woven fabric as base cloth, and through polishing, gigging, dyeing, softening, strippable paper molding and post tanning, the leather product is obtained. The strippable paper molding includes the surface layer spreading, the middle layer spreading, the adhered layer spreading, extruding to adhere the adhesive layer to the base cloth, stoving and stripping. The said process can make sofa leatherette with high resistance to acid, alkali, chemicals, light, wear and hydrolysis and high color fastness.

Owner:龙口市欣鑫超纤皮革有限公司

Terylene fine-denier triangle super bright FDY filament and preparation method thereof

InactiveCN101139741AGood flexibilityFeel goodFilament/thread formingMonocomponent polyesters artificial filamentMaterials scienceFilament yarn

The invention discloses a terylene fine denier triangular super-glossy FDY filament and relevant preparation method, and belongs to the technical field of terylene fibers. During the course of filature preparation, the invented fine denier triangular super-glossy terylene filament can lower filature speed, shorten calm zone distance and milden air blow cooling conditions; meanwhile, the fiber adopts nozzle oiling mode to improve oiling position, in order to successfully prepare fine denier triangular super-glossy FDY terylene filament with denier no more than 0.7dtex, fiber corss section similar to regular triangle and super-bright glossy. The terylene filament has advantages of extremely perfect flexibleness, excellent hand feeling, and moreover, the product is characterized by fewer broken filament, fewer short ends, more uniform yarn more stable quality.

Owner:JIANGSU HENGLI CHEM FIBER

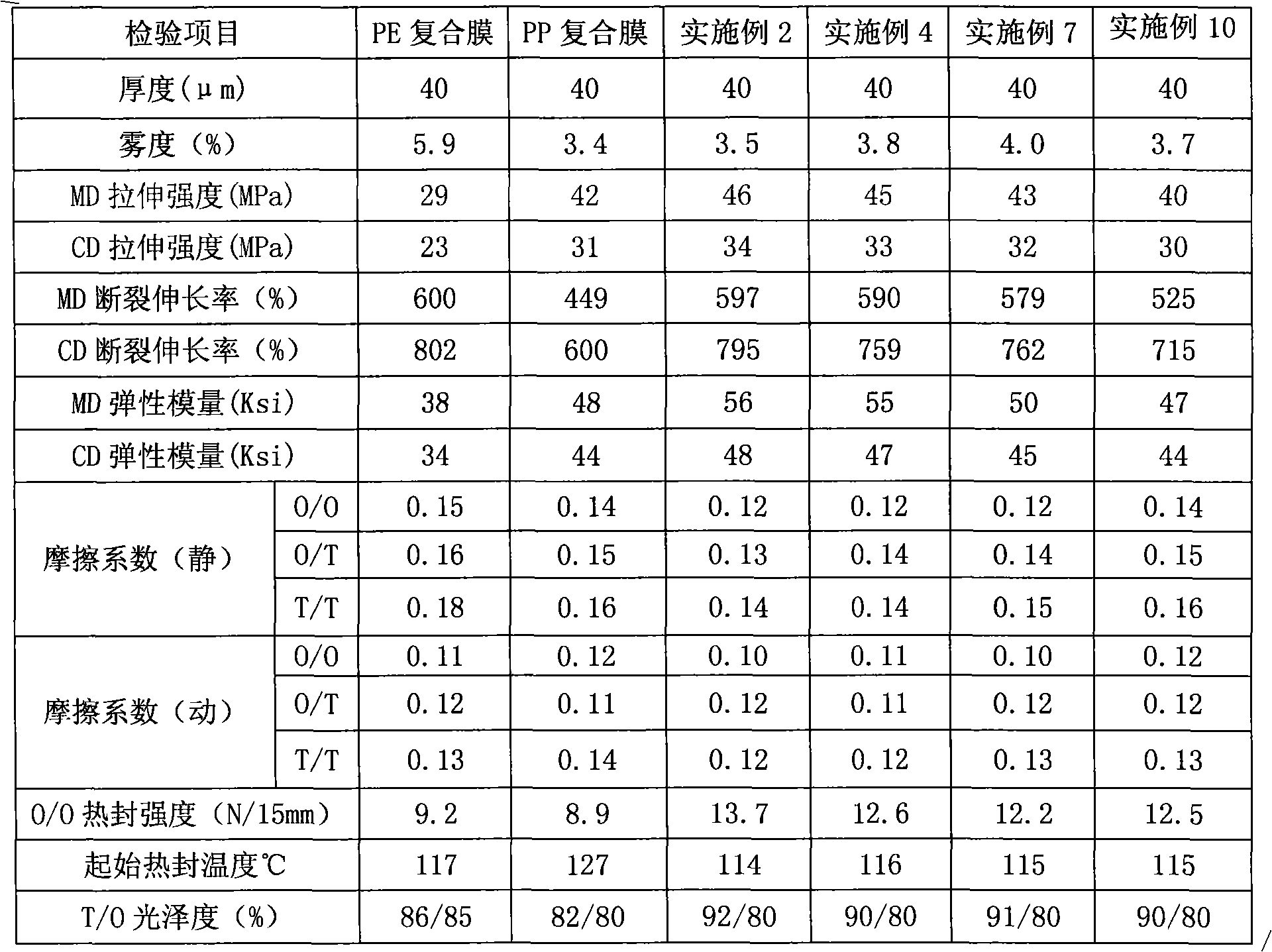

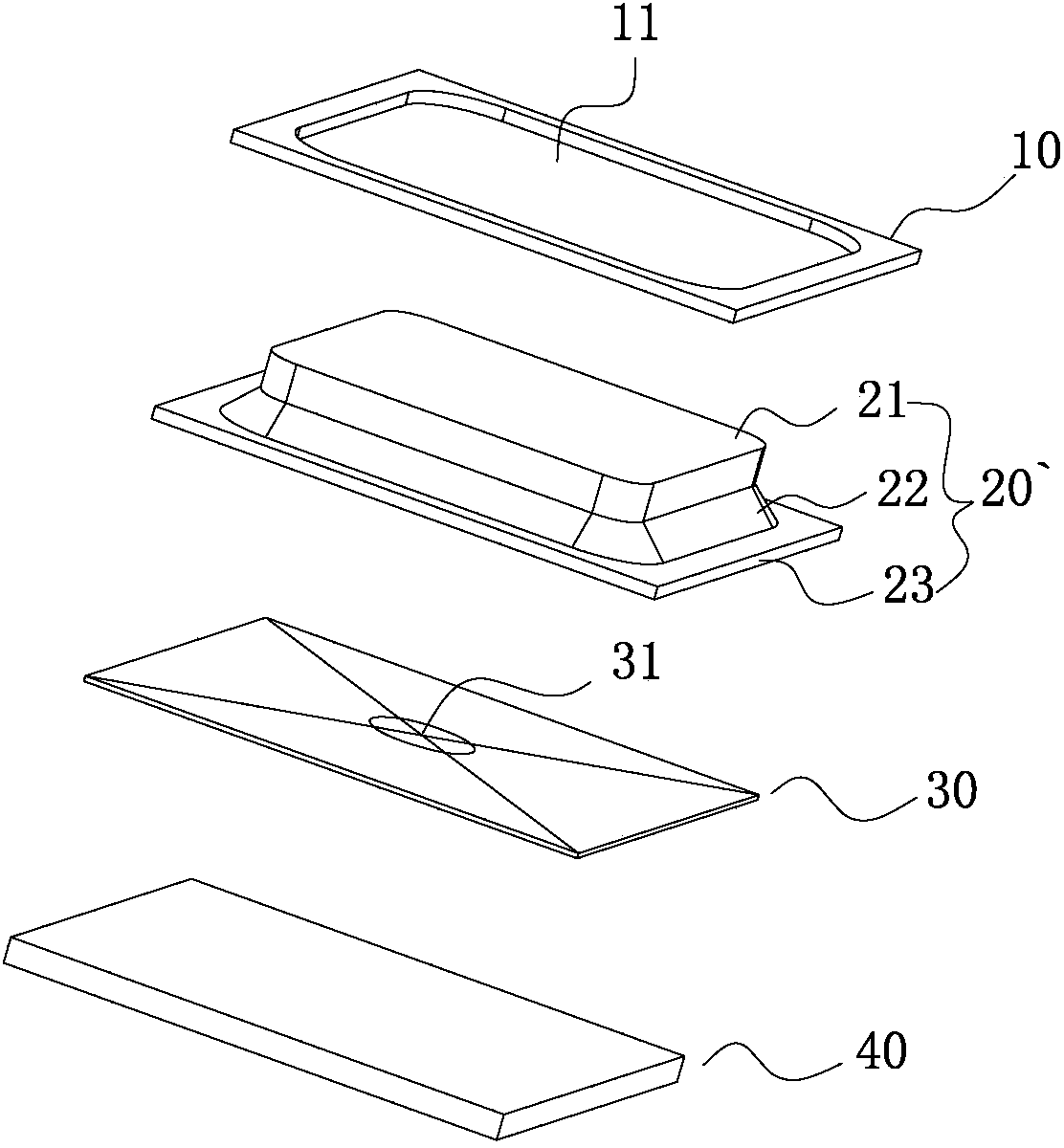

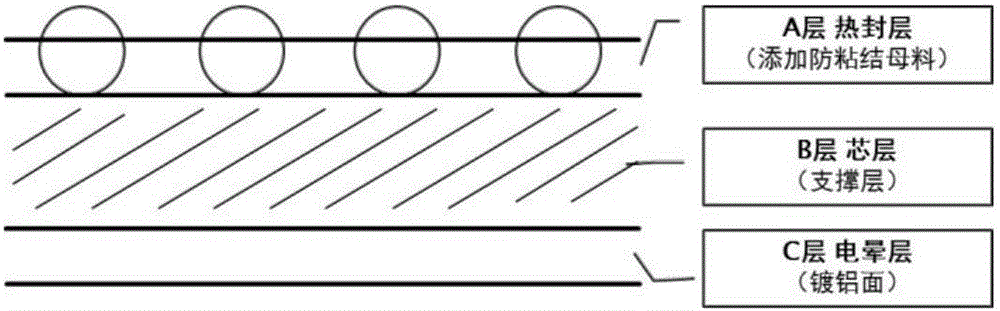

Multifunctional casting polyolefine firmness-increasing film

InactiveCN101659142ALower surface resistance valueProduce anti-static effect of plastic filmFlexible coversWrappersCompound aPolyolefin

The invention relates to a multifunctional casting polyolefine firmness-increasing film which is formed by compounding a heat sealing layer, a core layer and a corona layer. The corona layer or the heat sealing layer mainly comprises the following components in portions by weight: 100 portions of polyethylene resin, 10-60 portions of compatilizer, 0.1-0.5 portion of anti-blocking agent and 0.1-0.5portion of slipping agent; and the core layer mainly comprises the following components in portions by weight: 100 portions of polypropylene resin and 0.1-1.1 portions of nucleating agent. The multifunctional casting polyolefine firmness-increasing film has the characteristics of low temperature, favorable heat sealing performance, high firmness, high elastic modulus and the like, not only combines the advantages of polyethylene and polypropylene films, but also overcomes the defects of polyethylene or polypropylene composite films, is widely applied for packing facial tissues, foods and other products, and is particularly suitable for quick and automatic package of products.

Owner:湖北慧狮塑业股份有限公司

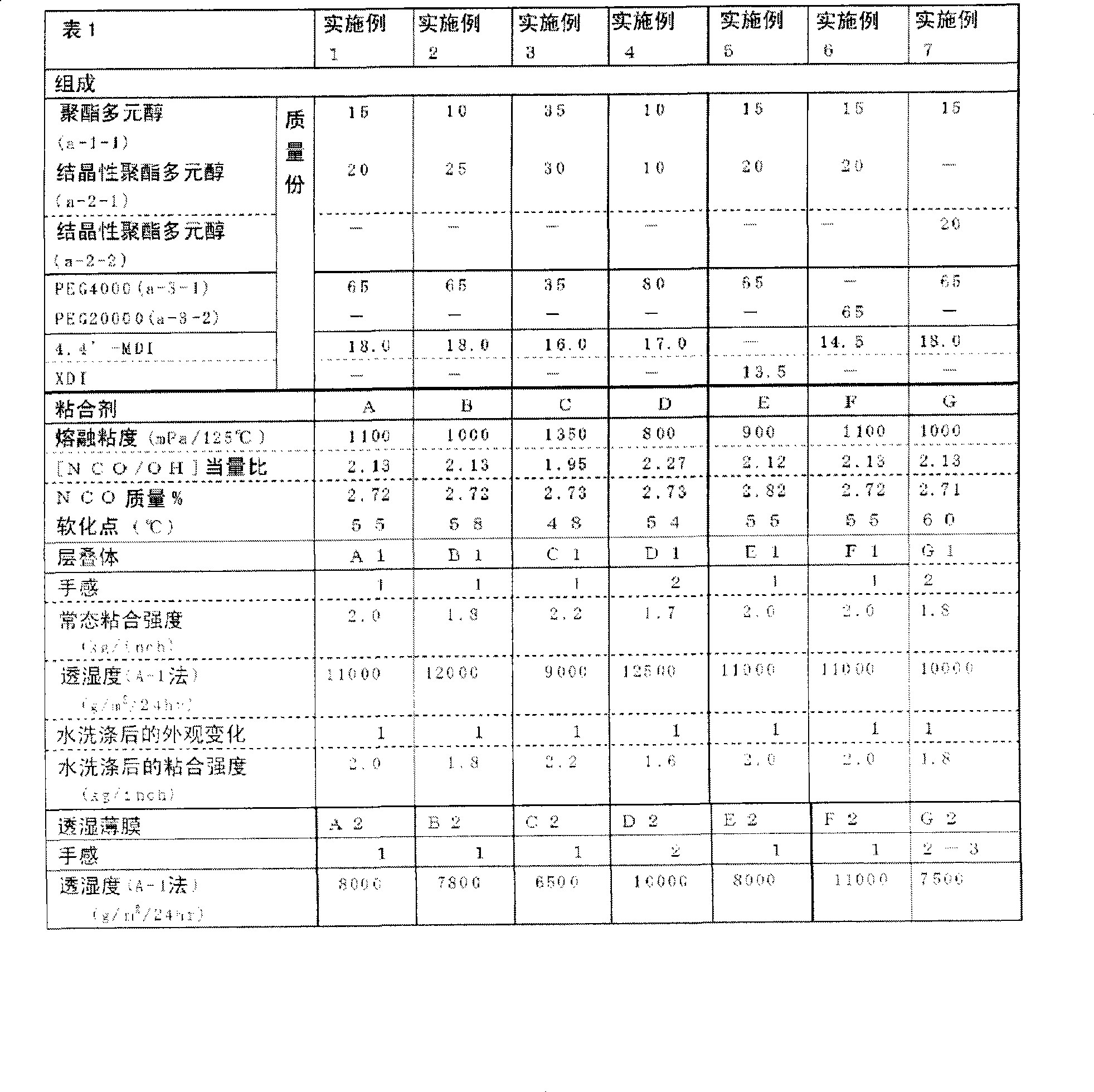

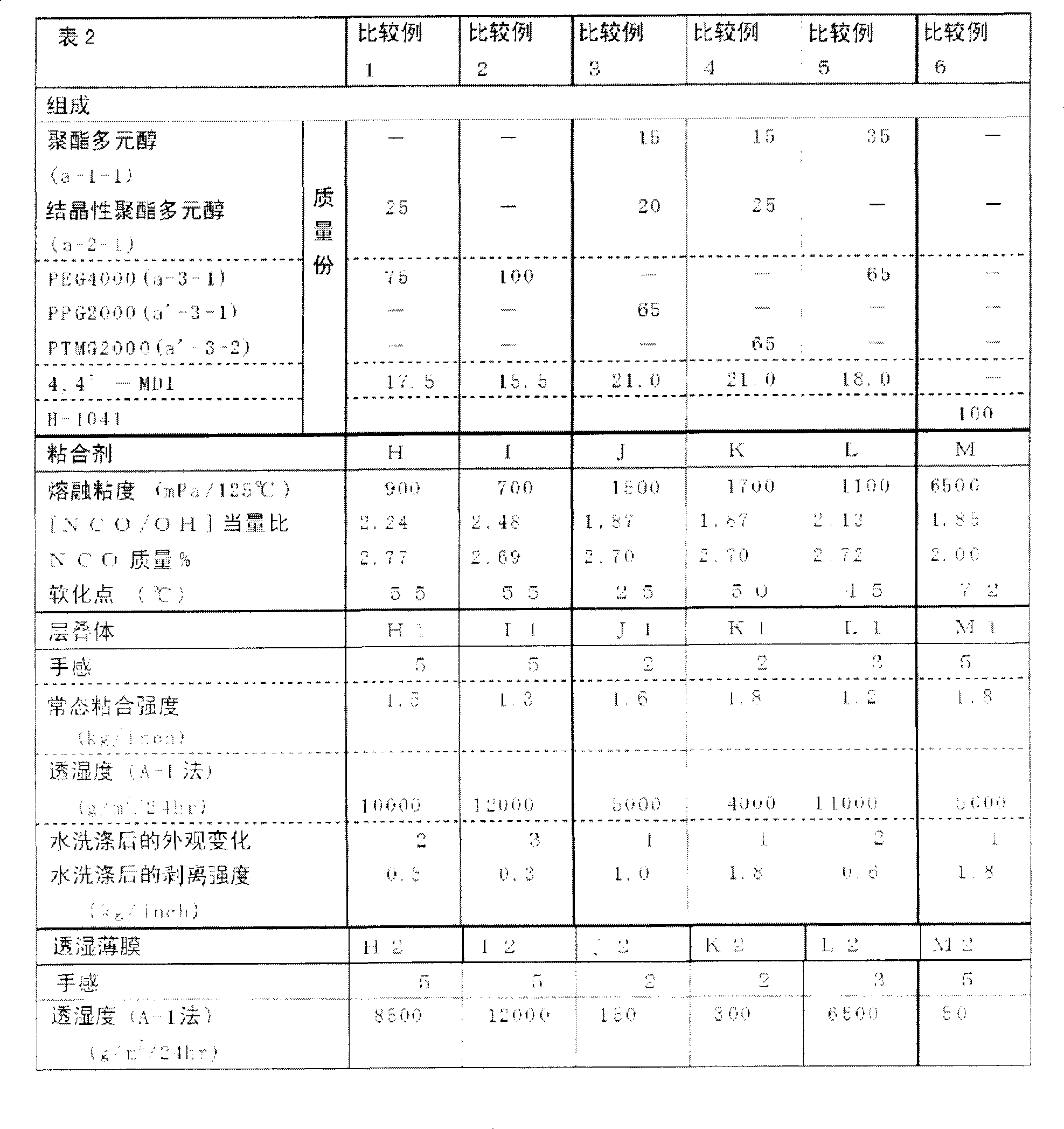

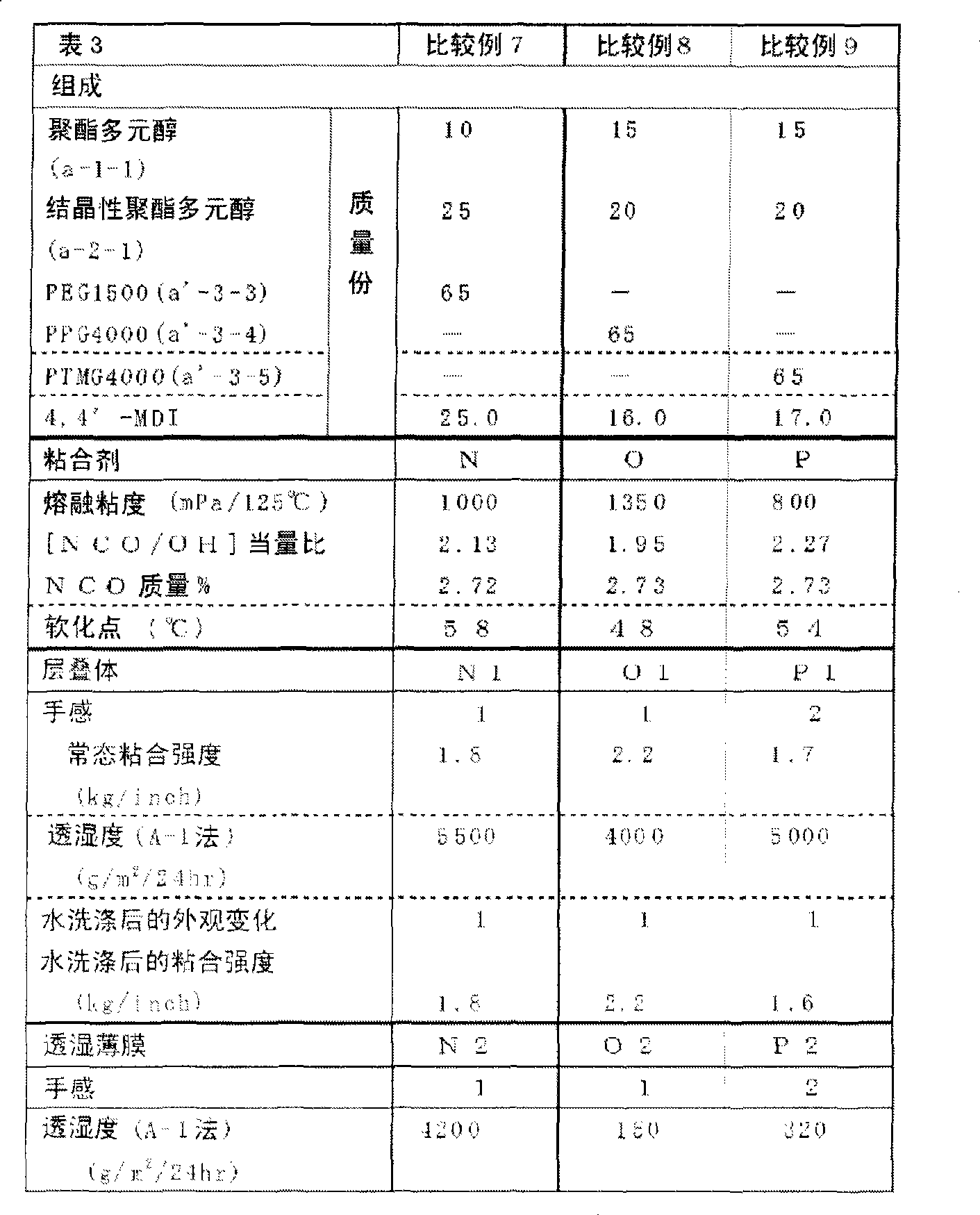

Moisture-curable polyurethane hot-melt adhesive, laminates made with the same, and moisture-permeable film

ActiveCN101547991AImprove use valueHigh strengthPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyesterMilitary Uniforms

A moisture-curable polyurethane hot-melt adhesive containing a urethane prepolymer obtained by reacting a polyol (A) which comprises a polyester polyol (a-1) obtained by reacting a polyol prepared by the addition of bisphenol A with an alkylene oxide with both an aliphatic polycarboxylic acid and an aromatic polycarboxylic acid, a crystalline polyester polyol (a-2), and a polyoxyethylene glycol (a-3) having a number-average molecular weight of 2000 to 25000 with a polyisocyanate (B); and a moisture-permeable film, which are suitable for the production of sport wear, raincoats, shoes, fireman uniforms, military uniforms, and so on.

Owner:DIC CORP

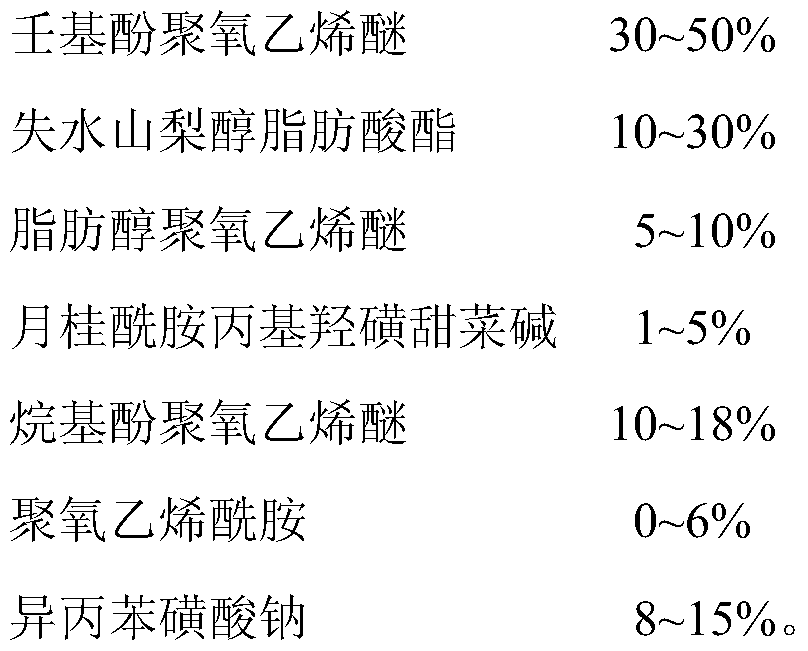

Multifunctional softener and preparation method for same

ActiveCN103321053AImprove biological activityPromote degradationFibre treatmentWater soluble chitosanAqueous solubility

The invention provides a multifunctional softener and a preparation method for the same. The multifunctional softener is composed of amino silicon oil, a compound emulsifier, water-soluble chitosan and water, wherein amino silicon oil is added in the compound emulsifier, and the mass ratio of the amino silicon oil to the compound emulsifier is 1:(0.2-0.8); then the water-soluble chitosan is added, and the added amount is 1-8% of the mass of the mixed solution of the amino silicon oil and the compound emulsifier; finally, water is added, and the mass of water is 10-50% of the total mass of the mixed solution aforementioned. The preparation method comprises the following steps of: preparation for the water-soluble chitosan, preparation for the compound emulsifier, and preparation for the multifunctional fabric softener. The multifunctional integrated softener obtained after compounding has all the excellent characteristics of modified chitosan on the basis of a soft function. Compared with the existing softener with an anti-bacterial function, the preparation process flow is simple, a complex configuration process is not required, and industrialized production is easy to realize.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Method for ash-free and no-sulfurizing alkaline liming treatment for making pigskin leather

InactiveCN1900321AImprove leather yieldGood power savingPre-tanning chemical treatmentChemistrySodium sulphide

The no-ash and no-sodium sulfide liming process for making pigskin leather features its greatly reduced pollution, and no use of pollutant sodium sulfide, sodium hydrosulfide and lime makes it easy to treat exhausted waste water. Compared with conventional technological process, the present invention has the advantages of no deposit, reduced waste water exhaust, short production period, saving in material and lowered comprehensive cost.

Owner:SICHUAN UNIV

Crisp and elastic finishing agent for afterfinish of textile as well as preparation method and use method of finishing agent

The invention provides a crisp and elastic finishing agent for afterfinish of textile as well as a preparation method and a use method of the finishing agent. The crisp and elastic finishing agent is prepared from raw materials in percentage by weight as follows: 9%-11% of acrylate monomers, 15%-20% of vinyl monomers, 0.1%-1% of cation monomers, 1%-2% of a crosslinking agent, 0.1%-0.3% of a cation emulsifier, 0.05%-1% of an acidic auxiliary liquid, 0.1%-1% of polyether monomers, 0.2%-0.6% of a nonionic emulsifier, 0.05%-0.1% of a water-soluble initiator and 60%-70% of deionized water. The crisp and elastic finishing agent for afterfinish of textile can endow the textile with excellent water resistance, crispness and elasticity.

Owner:苏州联胜化学有限公司

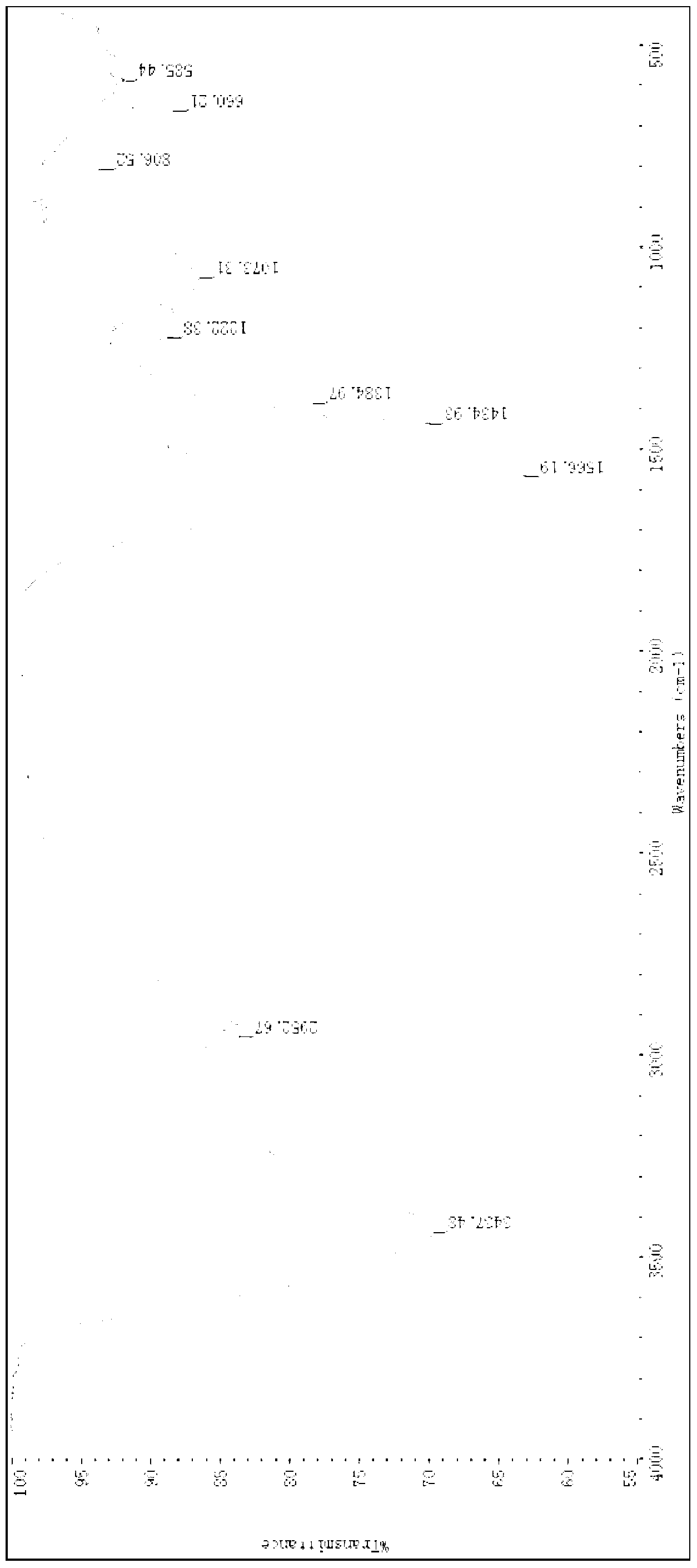

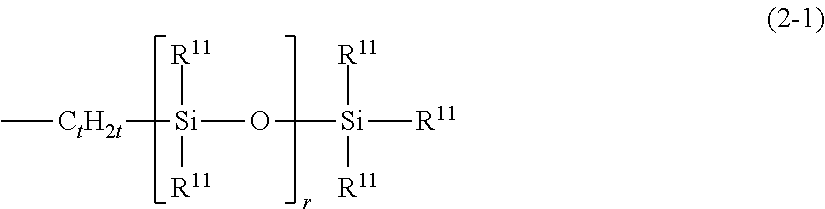

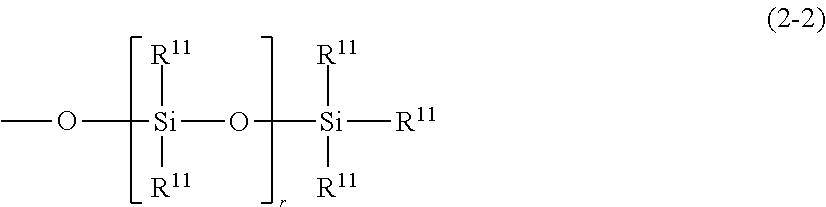

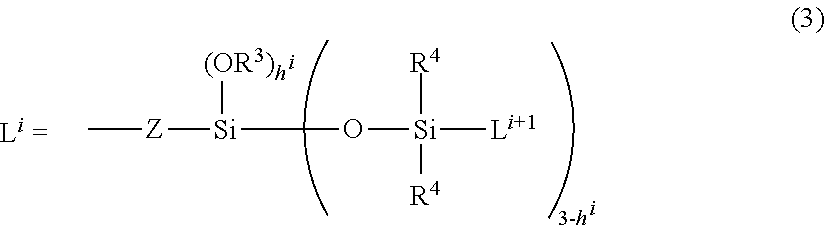

Organopolysiloxane and use thereof as surfactant, powder treatment agent, thickening agent of oil-based raw material or gelling agent. gel and emulsion compositions, as well as, preparations for external use and cosmetics comprising the same

InactiveUS20130210930A1Smooth sensationLight touchBiocideCosmetic preparationsChemical structureSilylene

The present invention provides a co-modified organopolysiloxane having a specified chemical structure in which a sugar alcohol-modified group and a silylalkyl group having a siloxane dendron structure, and optionally a long-chain hydrocarbon group are present. The co-modified organopolysiloxane is blended, as a surfactant, a powder treatment agent, a gelling agent or the like, or as a cosmetic raw material together with powder (s), oil agent (s) or the like, in a preparation for external use, and in particular, a cosmetic.

Owner:DOW CORNING TORAY CO LTD

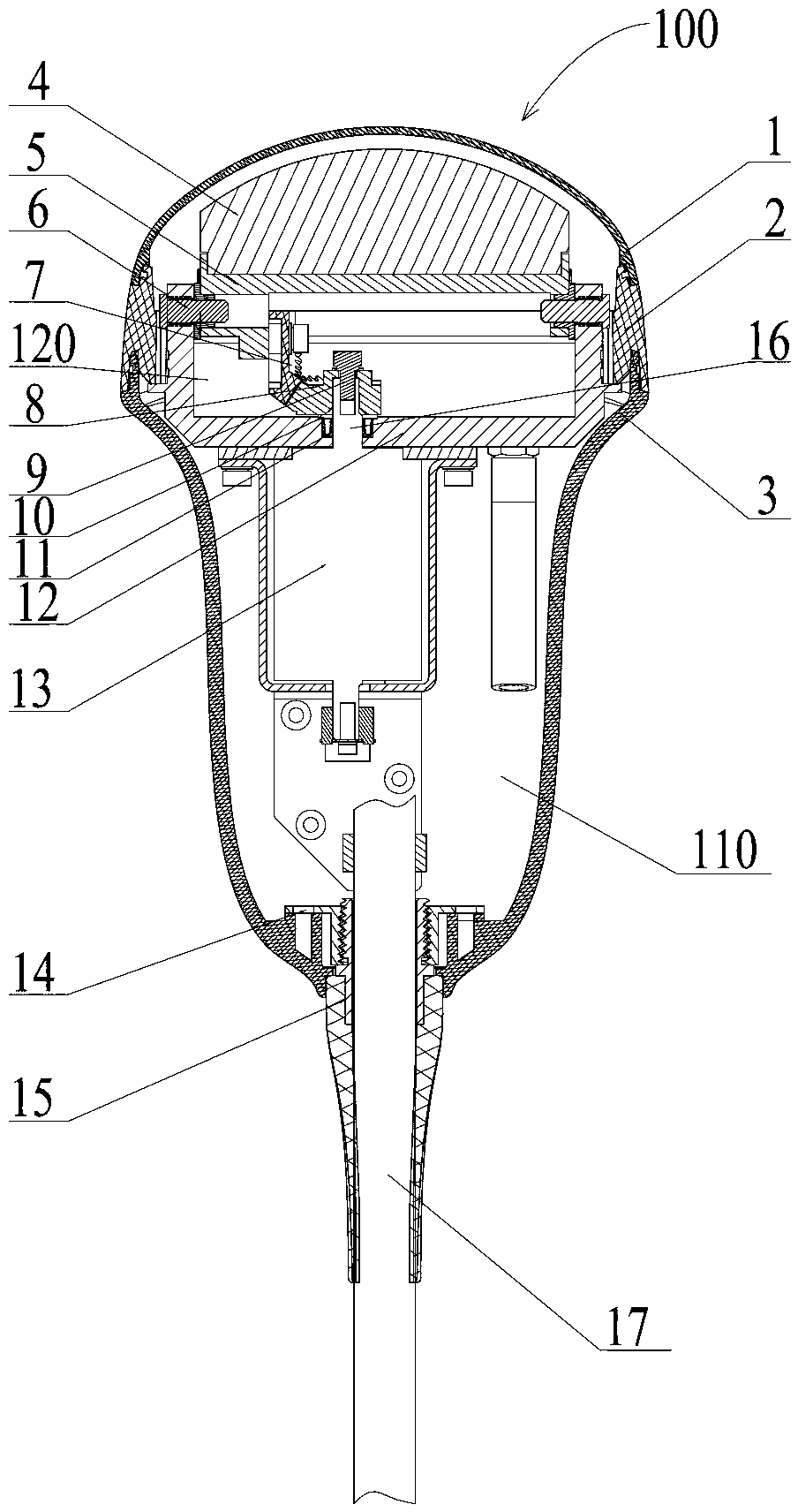

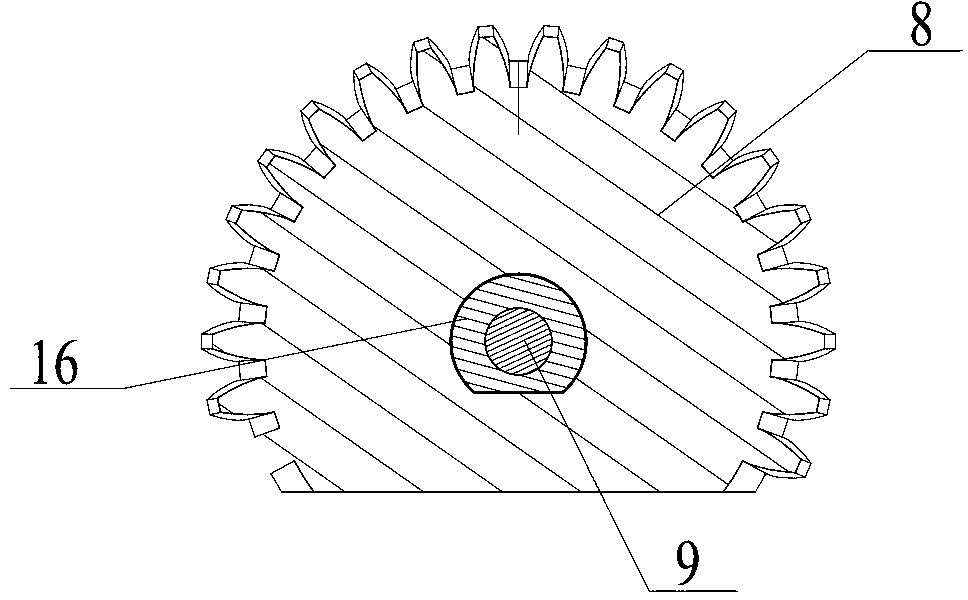

Ultrasonic scanning probe

InactiveCN102988081ASimple structureCompact structureUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsUltrasound imagingTransducer

The invention relates to a probe and in particular relates to an ultrasonic scanning probe, belonging to the technical field of ultrasonic image-forming equipment. According to the technical scheme provided by the invention, the ultrasonic scanning probe comprises a housing, wherein a probe main body is arranged in the housing; a transducer base which is rotatably connected is arranged in the probe main body; a transducer is arranged on the transducer base; a swinging drive mechanism for driving the transducer base and the transducer to swing in the probe main body is arranged on the probe main body; the swinging drive mechanism comprises a drive motor, wherein a drive bevel gear is arranged at the end part, getting out of the output shaft of the probe main body, of the drive motor; and the drive bevel gear is engaged with a driven bevel gear on the transducer base. The ultrasonic scanning probe has a simple structure and a small size, is light, and can guarantee that the transmitted motor output power is enough to enable the transducer to realize swing-scanning within a large-angle range.

Owner:WUXI CHUDIAN TECH

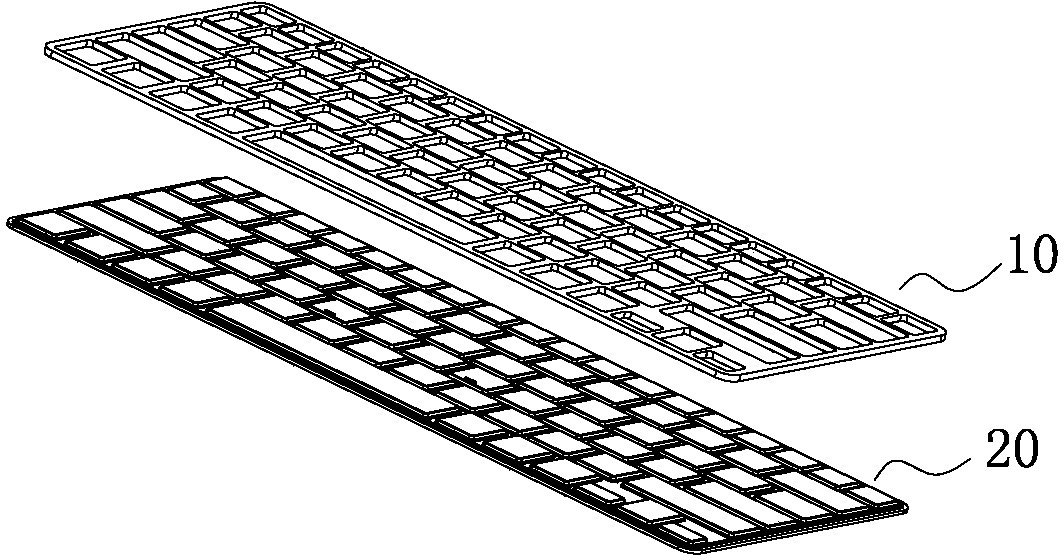

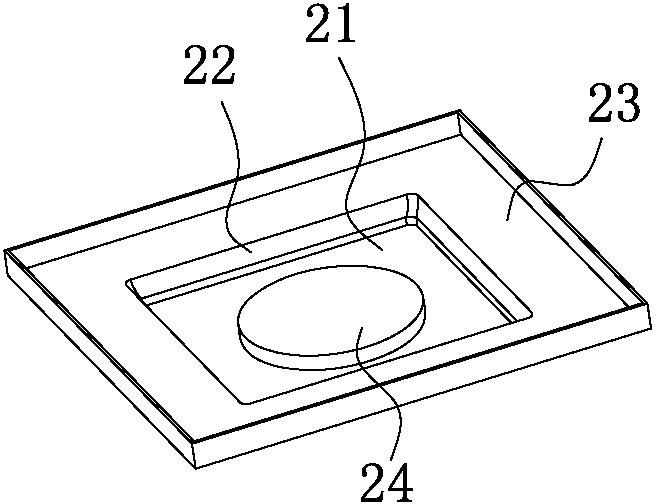

Thin keyboard composed of soft rubber parts and hard rubber parts

ActiveCN103413711AAvoid deformationOvercome the defect of being easily deformed and unable to recover from deformationElectric switchesRubber materialEngineering

Owner:深圳源创塑胶电子科技有限公司

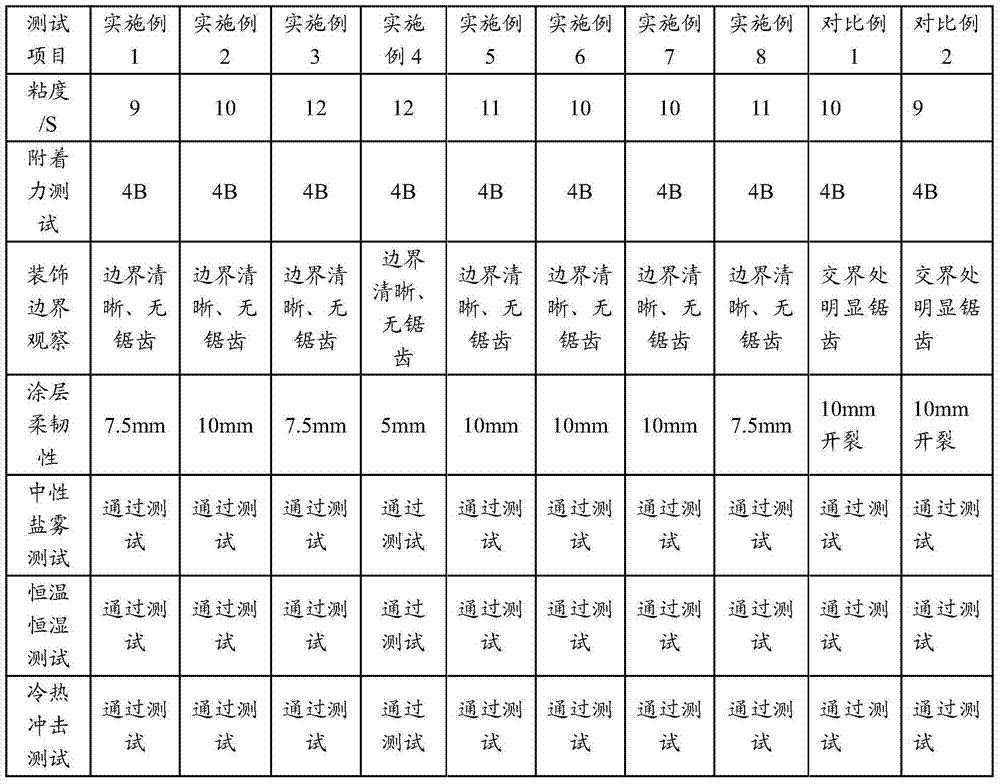

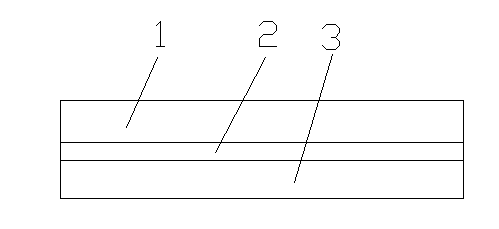

Modified UV paint and preparation method thereof

InactiveCN104745068AImprove adhesionImprove brittlenessPolyurea/polyurethane coatingsEpoxy resin coatingsOligomerThermoplastic polyurethane

The invention relates to a modified UV paint and a preparation method thereof, and belongs to the field of coating. The modified UV paint comprises the following components in percentage by weight: 20-40% of an oligomer, 5-30% of thermoplastic polyurethane resin, 1-10% of a diluent monomer, 30-50% of a diluent, 0.1-5% of an additive and 0.5-5% of a light initiator. The invention further discloses a preparation method of UV paint and an application of the coating. The coating has good performance, is subjected to spray coating on the surface of an integral seamless product of metal and plastic or glass and plastic, is stripped off by an adhesive tape to achieve excellent decoration and performance protection of paint on the plastic position, is not left on glass or plastic and has a clear boundary with the metal and the plastic or with the glass and the plastic without generating a hand feeling.

Owner:BYD CO LTD

Multifunctional Chinese hemp and ceiba compounded lifesaving and warm keeping fabric

The invention discloses multifunctional Chinese hemp and ceiba compounded lifesaving and warm keeping fabric. The fabric is characterized in that anti-flaming and moisture conducting surface fabric is formed by interweaving the following constituent in percent by weight: 50 percent of interweaving regenerate polyester fiber RepreveFR with a permanent anti-flaming function, 30 percent of Chinese hemp fiber, 20 percent of wool mixed 14.5tex anti-flaming and moisture conducting dry yarn and 20D spandex yarn, then is prepared into elastic polar fleece fabric through knitting, open ball wool and anti-pilling treatment; interlayer fabric adopts a porous waterproof and moisture permeable film; inner layer fabric is formed by interweaving the following constituent in percent by weight: 20 percent of ceiba fiber, 70 percent of antibacterial nylon yarn, and 10 percent of Porel mixed moisture absorbing heating fiber spun 14.5tex yarns and 20D spandex yarn; inner layer ceiba fabric, surface layer Chinese hemp fabric are compounded and connected with interlayer porous polyurethane elastic waterproof and moisture permeable film fiber on special compound equipment, so as to form the multifunctional Chinese hemp and ceiba compounded lifesaving and warm keeping fabric.

Owner:JIHUA 3542 TEXTILE CO LTD

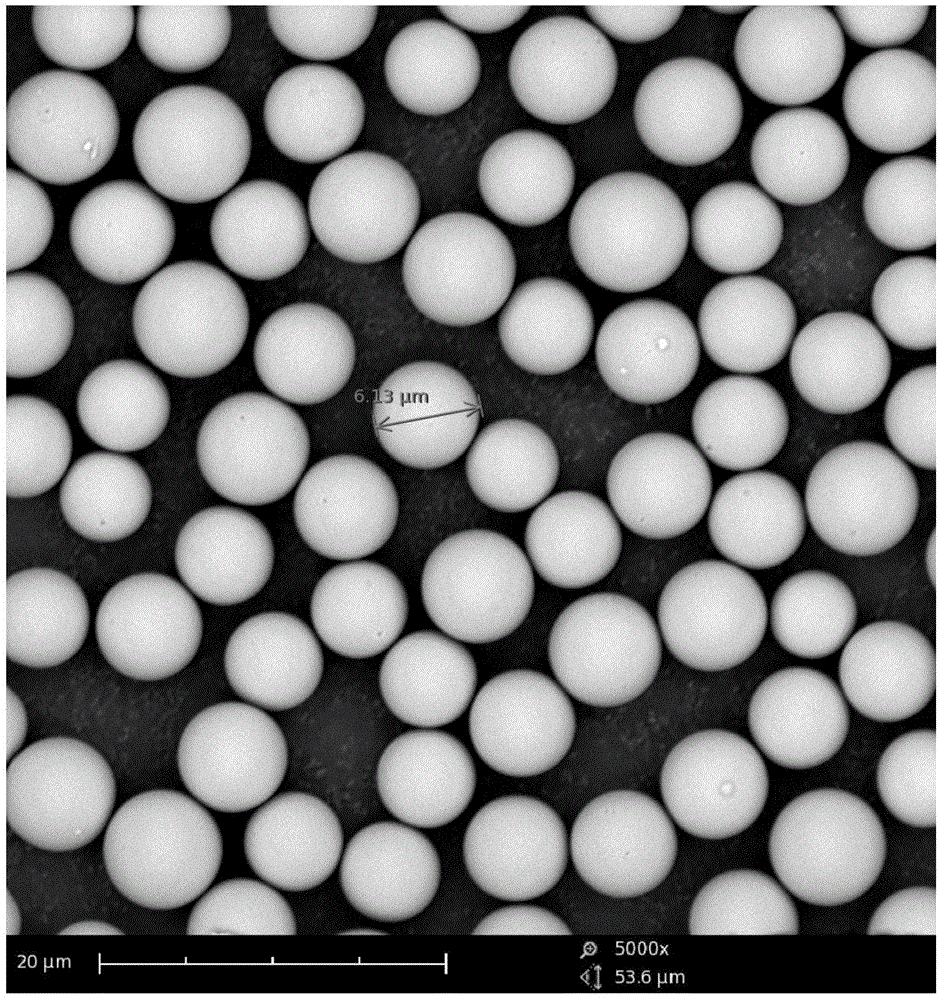

Low-friction coefficient anti-bonding master batch special for metallized base film and preparation method thereof

ActiveCN106519455ADoes not affect heat sealing temperatureDoes not affect heat sealing performanceMetallised filmPolypropylene

The invention relates to a low-friction coefficient anti-bonding master batch special for a metallized base film and a preparation method thereof. The low-friction coefficient anti-bonding master batch mainly comprises, by weight, 90-95 parts of polypropylene resin and 5-10 parts of polymethylsesquisiloxane-polyphenylsilsesquioxane. The polymethylsesquisiloxane-polyphenylsilsesquioxane is a ladder polymer with R3SiO terminated. The molecular formula of the polymethylsesquisiloxane-polyphenylsilsesquioxane is [CH3SiO1.5]n-[PhSiO1.5]m, wherein n is 5-8 and m is 2-5. According to the preparation method, an anti-sticking agent is added by means of side feeding through precision electronic weight loss scales, and pelleting is performed after melt blending by means of the special double-screw process. By the adoption of the method, the problem that no slipping agent (master batch) can be added into the metallized film and thus the friction coefficient is high and the problem that the low friction coefficient is required under the condition that no migration slipping agent can be added into an aluminum laminated film are effectively solved. The friction coefficient of the obtained metallized base film is lowered to 0.4 or below from 0.8 or above, the slipping property is good, no migration happens, and the product surface is not greasy, high in glossiness, resistant to abrasion, lasting and effective.

Owner:SHANTOU BEST SCI & TECH

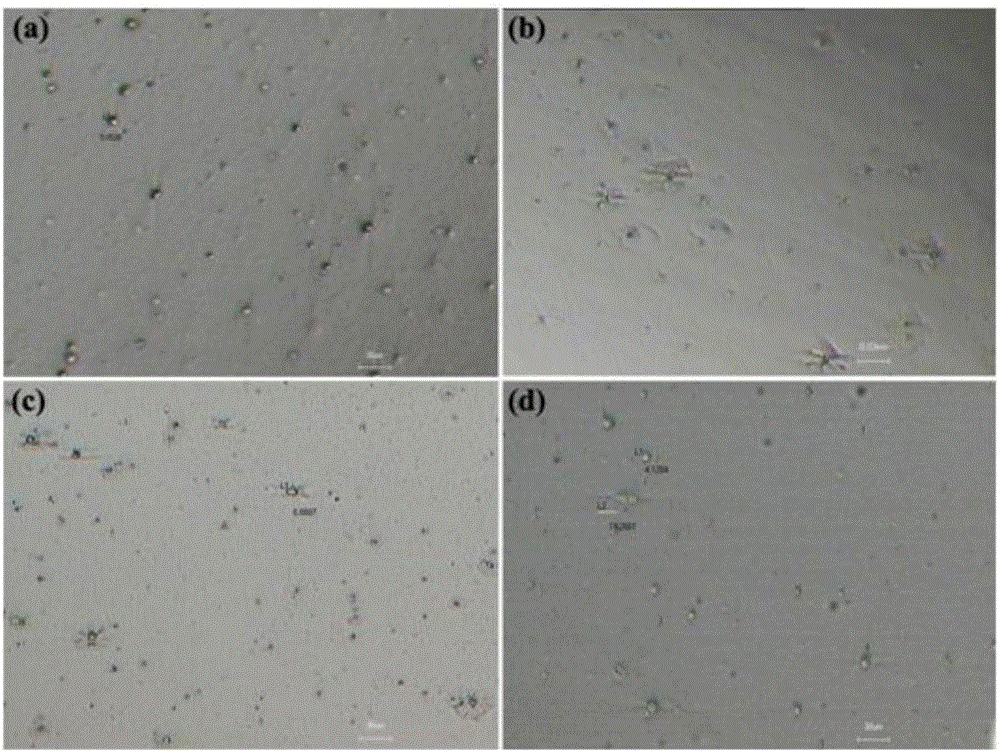

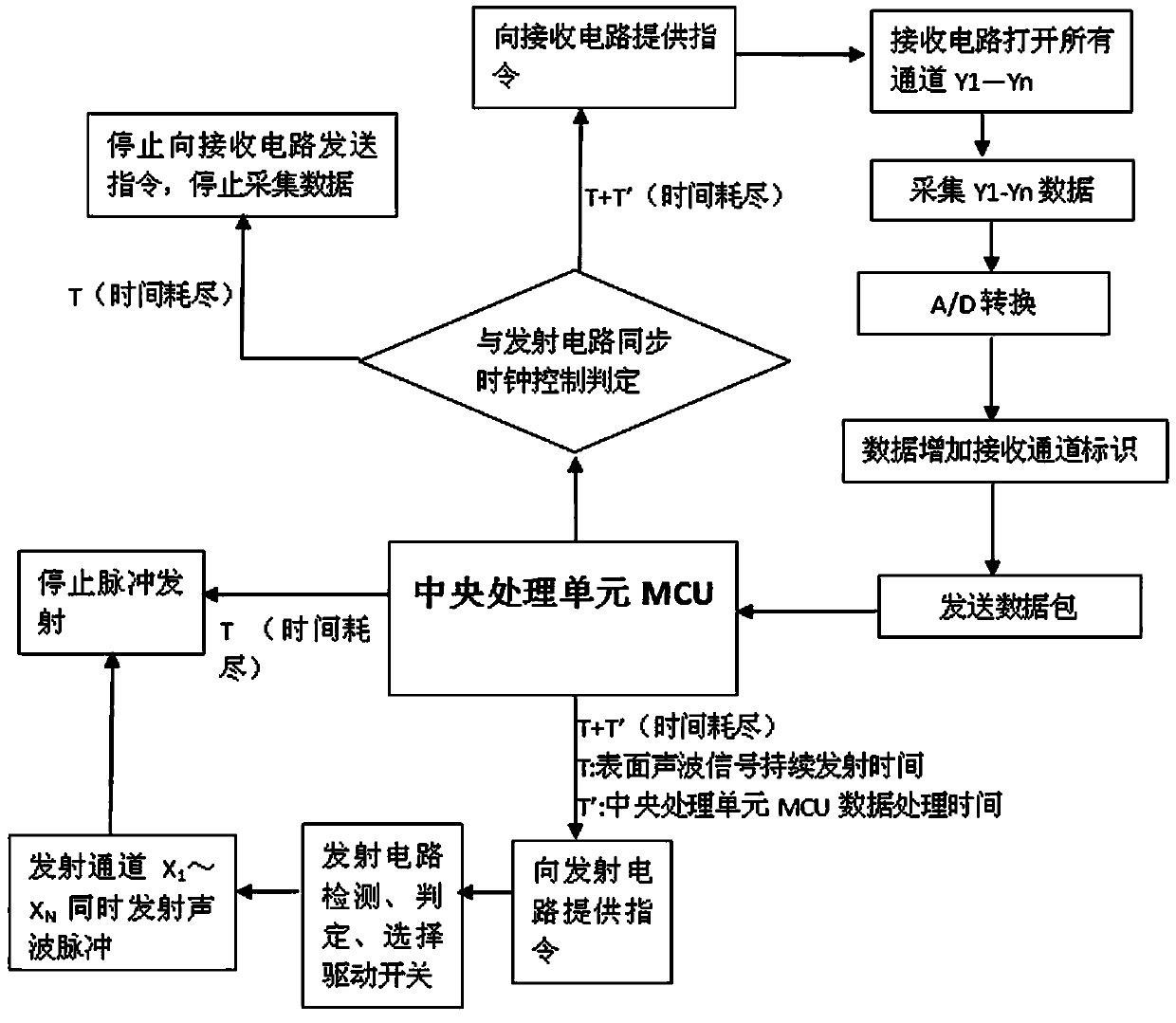

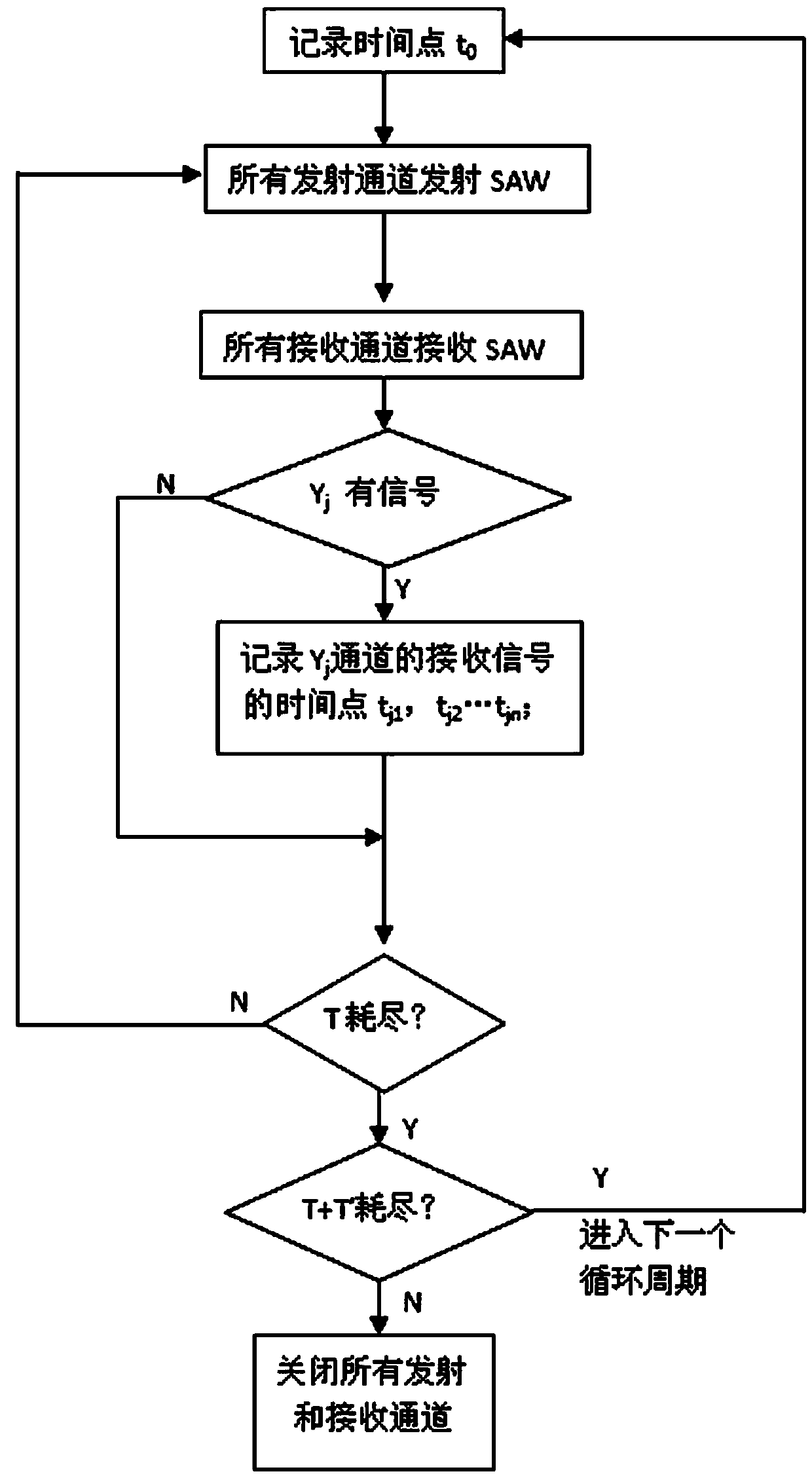

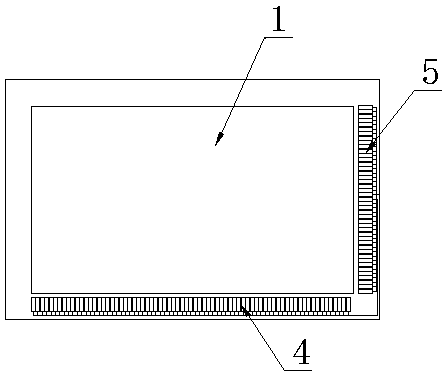

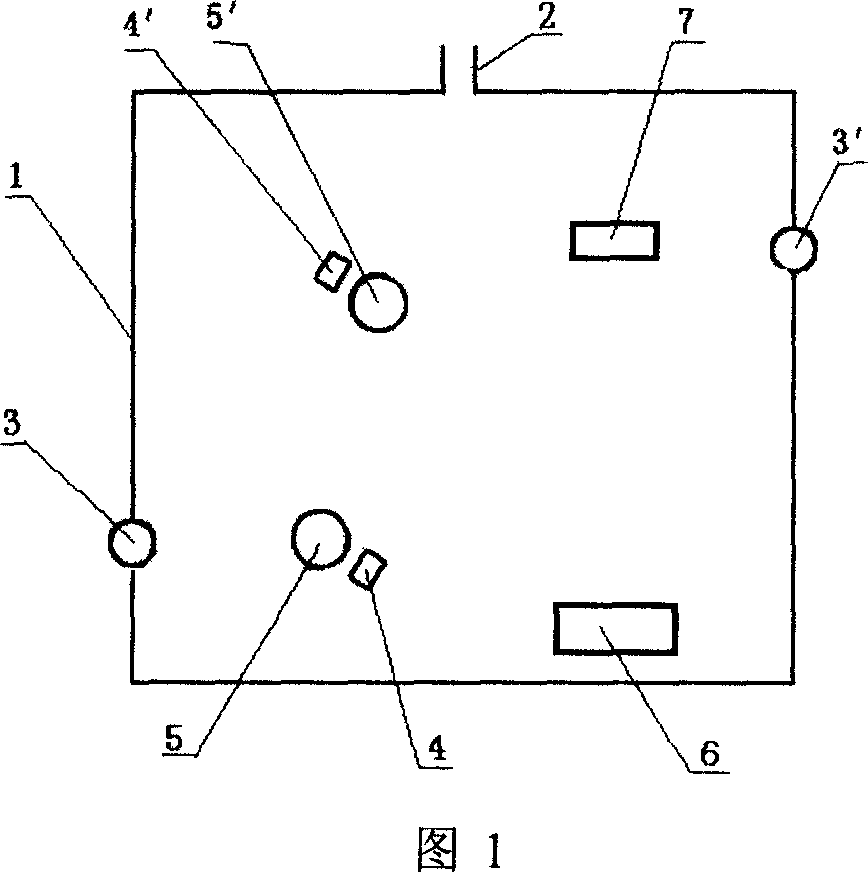

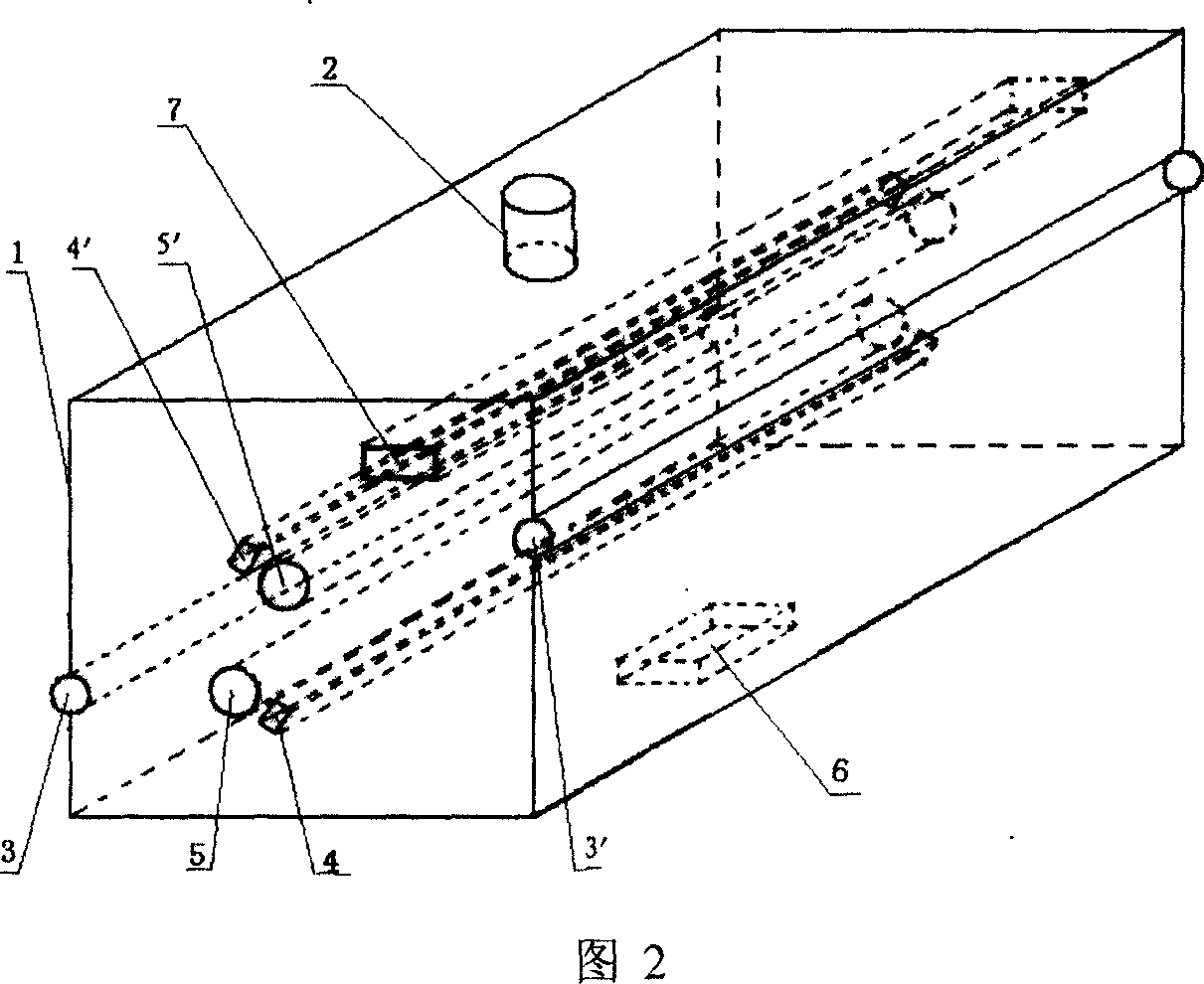

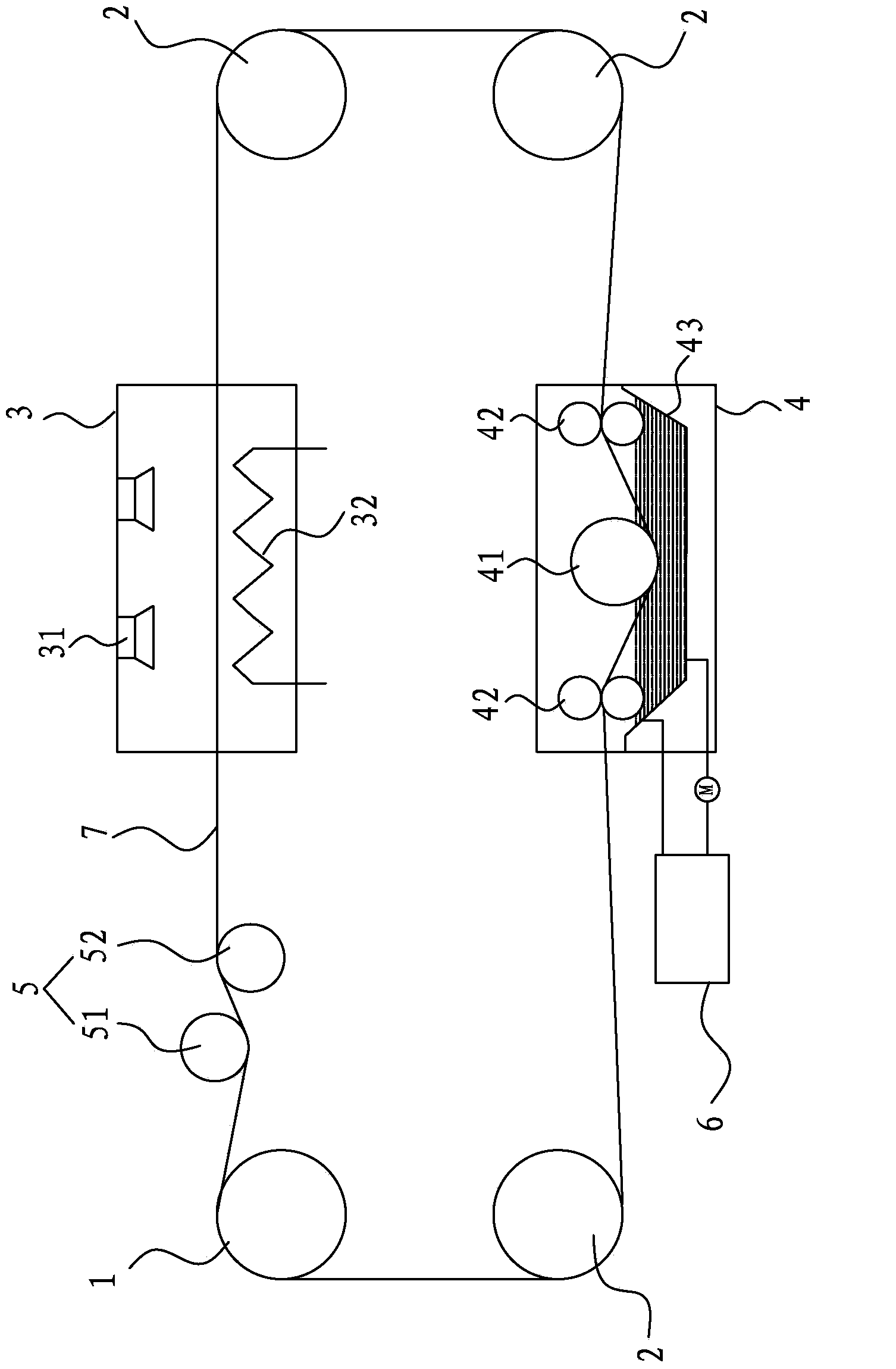

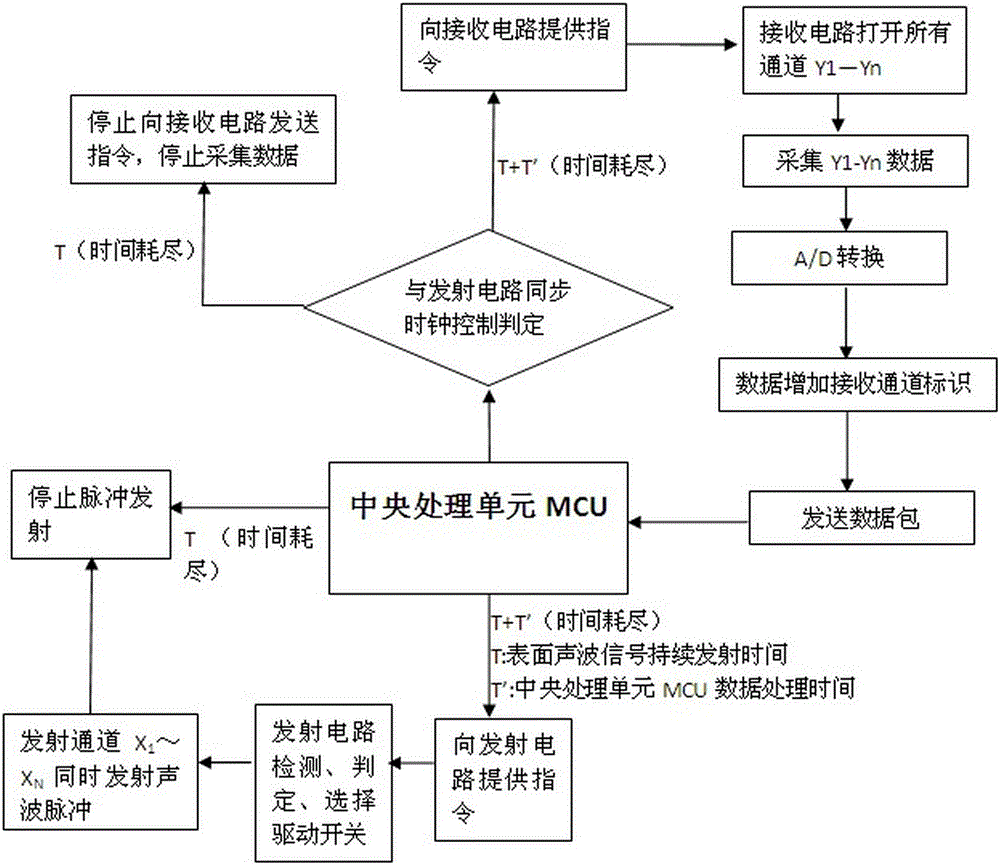

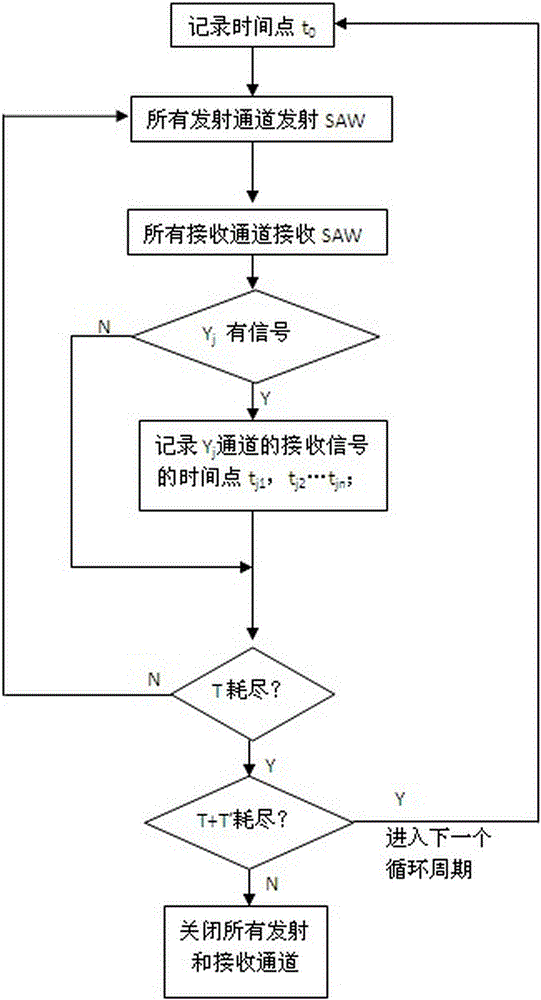

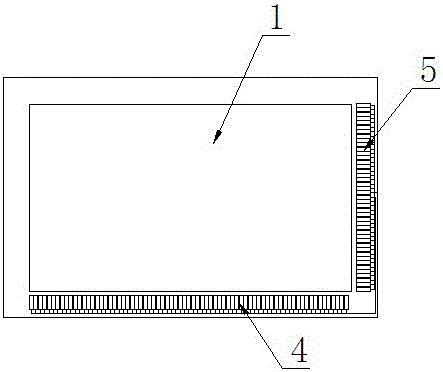

Method for realizing multi-point real touch on surface acoustic wave touch screen

ActiveCN103472960AStrong signalStable touch performanceInput/output processes for data processingMicroprocessor control unitSurface acoustic wave sensor

The invention discloses a method for realizing multi-point real touch on a surface acoustic wave touch screen. The method comprises the following steps that (1), a group of transmitting transducer arrays or receiving transducer arrays are at least arranged on the X axis or the Y axis; (2), a transmitting circuit drives transmitting transducers to transmit a surface acoustic wave signal, and a receiving circuit controls receiving transducers to receive the surface acoustic wave signal; (3), when a touch body touches the surface acoustic wave touch screen, the surface acoustic wave signal reaches the receiving transducers after being reflected by the touch body; when the surface acoustic wave signal intensity is greater than a set threshold value, the receiving circuit sends the surface acoustic wave signal to an MCU (microprocessor control unit), and the MCU determines the coordinates of the touch body. By the method, the multi-point real touch response of two or more points is realized, ghost points are eliminated fundamentally, and moreover, the touch response of unlimited points in a touch area can be really realized by the conventional process.

Owner:GENERAL TOUCH CO LTD

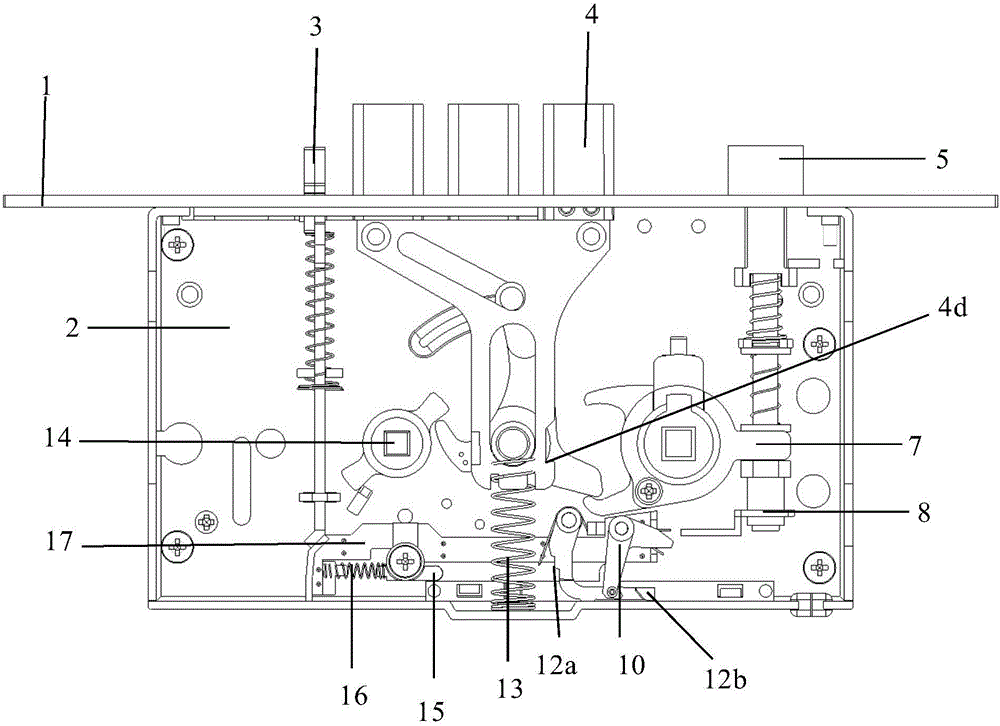

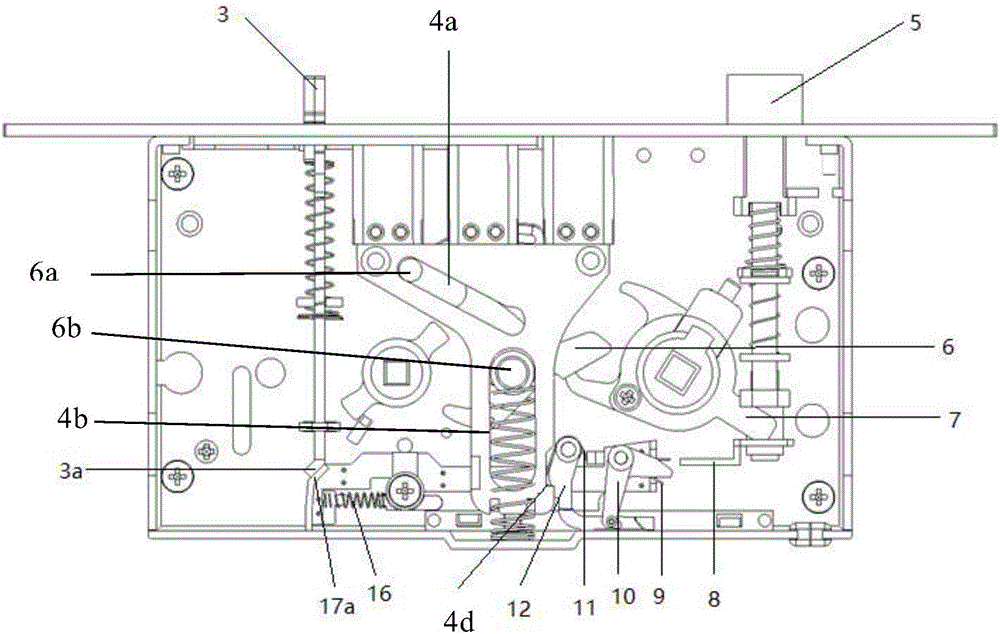

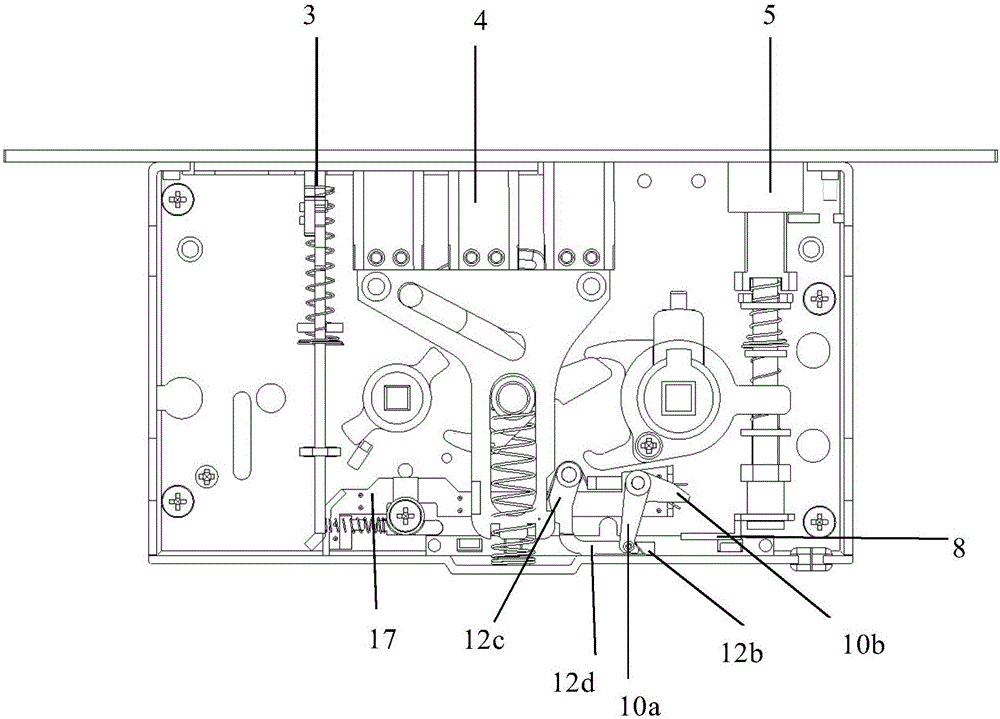

Dead bolt pop-up device

The invention discloses a dead bolt pop-up device. When a door is closed, a dead bolt can be triggered to pop up automatically and synchronously through cooperation of a state bolt assembly and a latch bolt assembly. The dead bolt pop-up device is provided with a dead bolt check piece, a latch bolt dial driving piece, a sliding plate, a first spring, a second spring and a third spring, wherein the dead bolt check piece is used for clamping and locking the dead bolt to enable the dead bolt to be in a retracted state; the latch bolt dial driving piece can drive the dead bolt check piece to carry out clamping and locking so that the dead bolt can pop up; the sliding plate is used for driving the latch bolt dial driving piece to move towards a latch bolt when the state bolt assembly retracts, and driving the latch bolt dial driving piece to move opposite to the latch bolt when the state bolt assembly stretches; the first spring is connected with the sliding plate and is in a natural state when the state bolt assembly stretches; the second spring is connected with the dead bolt check piece and is in a natural state when the dead bolt is clamped and locked; and the third spring is connected with the latch bolt dial driving piece and is not in a natural state when the latch bolt dial driving piece applies driving force to the dead bolt check piece.

Owner:ALLEGION SECURITY TECH CHINA

Special anti-wrinkle flame retardant finishing agent of wool hat

InactiveCN107938356AGuaranteed StrengthAvoid yellowingBiochemical fibre treatmentAnimal fibresWrinkle skinRare earth

The invention discloses a special anti-wrinkle flame retardant finishing agent of a wool hat. The finishing agent comprises the following raw materials in parts by weight: 20-38 parts of waterborne polyurethane emulsion, 2-10 parts of organic silicon emulsion, 1-5 parts of sodium cyanate, 3-8 parts of hydrogen peroxide, 1-5 parts of dicyandiamide, 2-10 parts of chitosan, 3-10 parts of mixed plantextracting solution, 2-10 parts of beta-cyclodextrin, 0.1-0.8 parts of cyclodextrin, 1-5 parts of organic acid, 1-4 parts of oxidized alginate, 2-10 parts of oxidized sodium carboxymethyl cellulose, 2-10 parts of rare earth oxide sol, 1-4 parts of hexa(4-aminophenoxy)cyclotriphosphazene and 1-5 parts of a hydrophilic surfactant. The special anti-wrinkle flame retardant finishing agent provided bythe invention has the advantage that the wool hat can be endowed with excellent wrinkle resistance and fire retardance.

Owner:安徽中福毛纺制帽有限公司

Cotton loose fiber dyeing method

InactiveCN1528975ASmall chromatic aberrationReduce lossDyeing processLiquid/gas/vapor fibres/slivers/rovings treatmentFiberChemistry

The invention discloses a dyeing process method for loose fiber of cotton, sliver, and cotton roll. It includes changes the traditional process of spinning-before-dyeing into the one of dyeing-before-spinning. The method uses azo dyes to dye the loose cotton, the dyed loose cotton is colorful cotton with five colors, the color includes red, yellow, brown and black. It can be produced without special appliances, especially applies to small industry, the color difference of the product is small, the product is soft, pluffy, it solves the problem of color floating, fading, contaminating, cotton joint, bad color firm rate. It reduces yarn back, high speed cone winding process.

Owner:余姚久丰染色厂有限公司

Pretreating equipment for improving yarn sizing performance

The present invention relates to a pretreatment equipment capable of on-line improving yarn sizing performance for sizing machine. Said pretreatment equipment can be mounted between the warping beam frame of sizing machine and size box, and is formed from the following several portions: box body, guiding roller, high-voltage discharge heads, ozonator, UV irradiation device and sealing rubber-covered roll. Said invention also provides the working principle of said pretreatment equipment and its operation method.

Owner:WUHAN TEXTILE UNIV

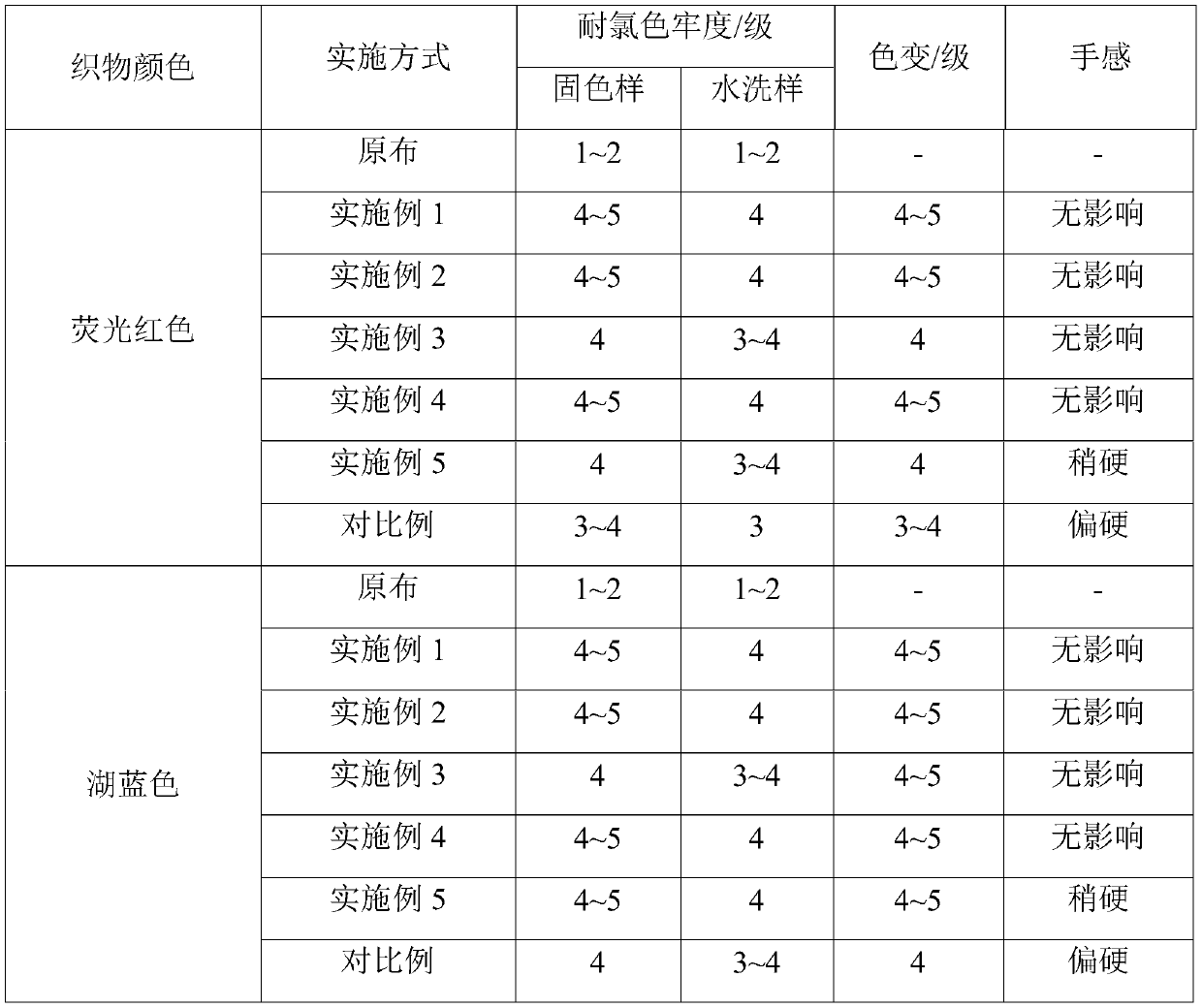

Environment-friendly chlorine-resistant color fixing agent, and preparation method and application thereof

PendingCN110735338AImprove color fastness to chlorine waterAvoid destructionDyeing processFunctional monomerDye molecule

The invention discloses an environment-friendly chlorine-resistant color fixing agent, and a preparation method and application thereof. The chlorine-resistant color fixing agent comprises, by mass, 35-40% of chlorine-resistant intermediates, 0.1-1.0% of chelating agent, 0.5-5% of deoxidants and the balance of water. Proper functional monomers having high reactive activity with chlorine are selected and then composited into the chlorine-resistant color fixing agent, the environment-friendly chlorine-resistant color fixing agent reacts with active chlorine preferentially, damage of the active chlorine to a dye molecule color development system is reduced, and accordingly, the chlorine water resistance and color fastness of dyed textiles are improved.

Owner:东莞市中纺化工有限公司

Portable garment fabric

The invention discloses a portable garment fabric, which comprises an ecological cotton fabric, wherein the ecological cotton fabric consists of warp yarns and weft yarns, the warp yarns adopt perle, the weft yarns adopt tiger cashmere, the diameter of the perle is 14.5 mum, the fiber number is 72 dtex, the diameter of the tiger cashmere is 12 mum, the fiber number is 144 dtex, the density of the warp yarns is 7 pieces / cm, and the density of the weft yarns is 13 pieces / cm. Therefore the prepared portable garment fabric has the advantages that the hand feeling is smooth, the portable garment fabric is portable, the drape effect is very high, and woven cloth achieves the effect of sufficient toughness.

Owner:常熟市碧溪新区吴市卓艺家纺厂

Dry type polyurethane resin for cold pressing and preparation method thereof

ActiveCN103467691AImprove rigidityProtect from oxidative decompositionFibre treatmentAlcoholAntioxidant

The invention discloses a dry type polyurethane resin for cold pressing and a preparation method thereof. The dry type polyurethane resin for cold pressing comprises the raw materials including diisocyanate, a polyol compound, a small molecular dihydric alcohol chain extender, a catalyst, an antioxidant, auxiliaries and a terminator. In the process of synthesizing the polyurethane resin, the rigid polyol compound and small molecular dihydric alcohol are selected, so that the rigidity of the resin can be improved, and the patterns can be well molded after the resin is embossed, and the patterns are prevented from rebounding; the antioxidant is added into the resin, so that the resin is protected from oxygenolysis when the resin is made into leather and embossed, and the patterns are full and natural after the resin is embossed, and the hand feel and the leather brightness are little changed before and after the resin is embossed.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

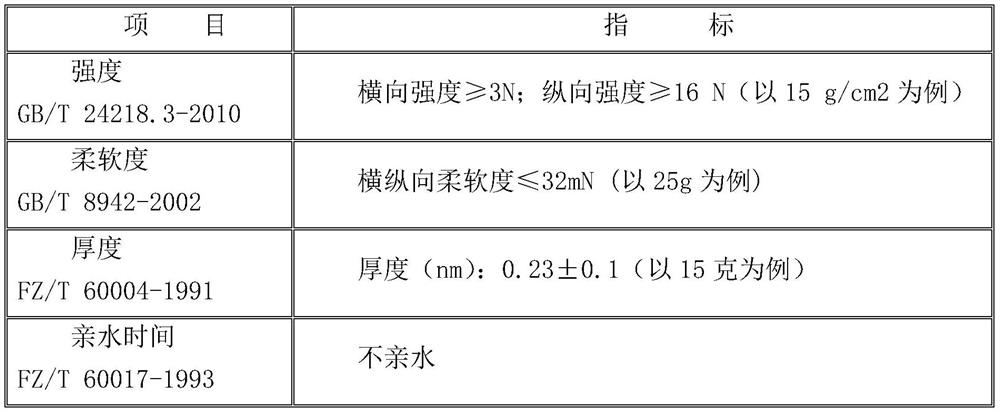

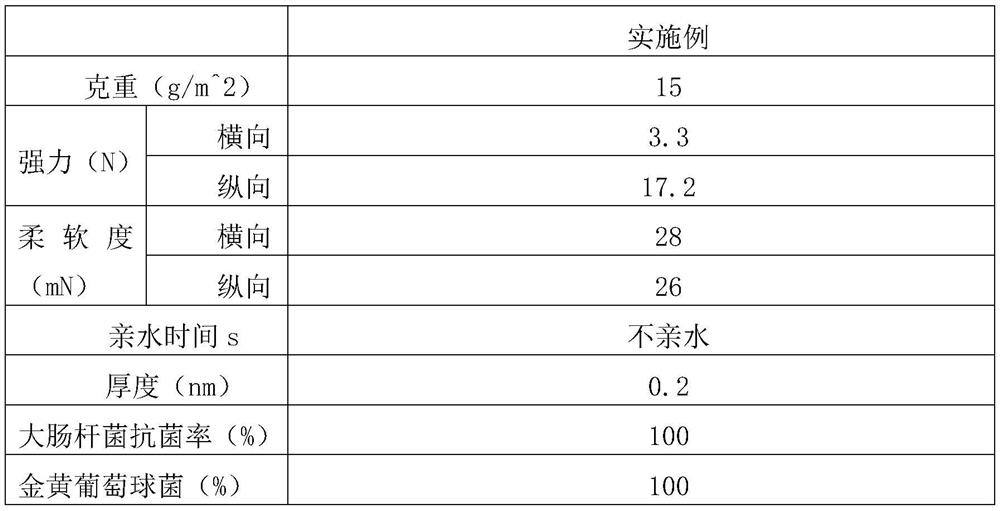

Silky through-air thermal bonded nonwoven and manufacturing method thereof

InactiveCN111663243AReasonable formulaReduce voidsBiochemical fibre treatmentHeating/cooling textile fabricsPolymer scienceNonwoven fabric

The invention provides a silky through-air thermal bonded nonwoven and a manufacturing method thereof. The silky through-air thermal bonded nonwoven is made of a PE / PET sheath-core composite fiber with a concentric structure, and a sheath layer material of the PE / PET sheath-core composite fiber is PE and a core layer material is PET; the PE / PET sheath-core composite fiber comprises a first component and a second component; the first component is a PE / PET composite fiber with a thickness of 1.5D, a length of 38mm, and a sheath-core ratio of 50 / 50, and the second component is a PE / PET compositefiber with a thickness of 1.2D, a length of 38mm, and a sheath-core ratio of 50 / 50, wherein the mass ratio of the first component to the second component is 2:8. According to the silky through-air thermal bonded nonwoven and the manufacturing method thereof provided by the invention, more than 70% of the fiber arrangement of the prepared silk-soft hot-air nonwoven fabric is longitudinal arrangement, thus the silky through-air thermal bonded nonwoven has excellent silky feeling, is extremely skin-friendly, and has an excellent antibacterial effect; and the manufacturing method is simple, the flexibility is high, and has a good development prospect.

Owner:JIANGSU SHENGFANG NANO MATERIAL TECH CO LTD

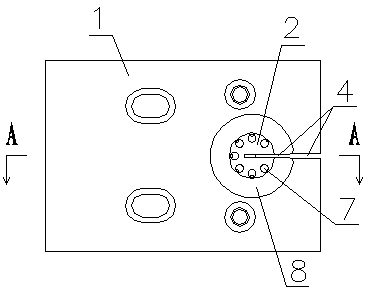

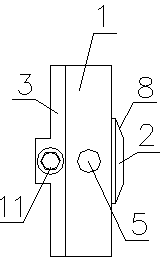

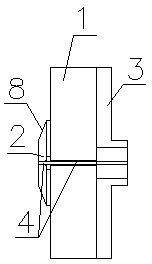

Positioned water spray device of reciprocating wire cut electrical discharge machining

ActiveCN103639557AStable sprayingStable processingElectrical-based auxillary apparatusInlet channelSpray nozzle

The invention discloses a positioned water spray device of a reciprocating wire cut electrical discharge machining. The device comprises a water spray plate and a spray nozzle mounted in the water spray plate, wherein connected wire grooves are formed in one side of each of the water spray plate and the spray nozzle; a liquid inlet channel is arranged in the water spray plate; and the spray nozzle is provided with a liquid guide groove connected with the liquid inlet channel as well as a plurality of spray holes connected with the liquid guide groove. The device is characterized in that the water spray end of the spray nozzle is located outside an end surface of the water spray plate, and a chamfer is arranged on the spray nozzle end surface outside all the spray holes. The positioned water spray device has the advantages of absence of chip accumulation in the spray nozzle, stable processing and small wire electrode buffeting range, and improves the surface accuracy of workpieces and product quality effectively.

Owner:自贡市嘉特数控机械制造有限公司

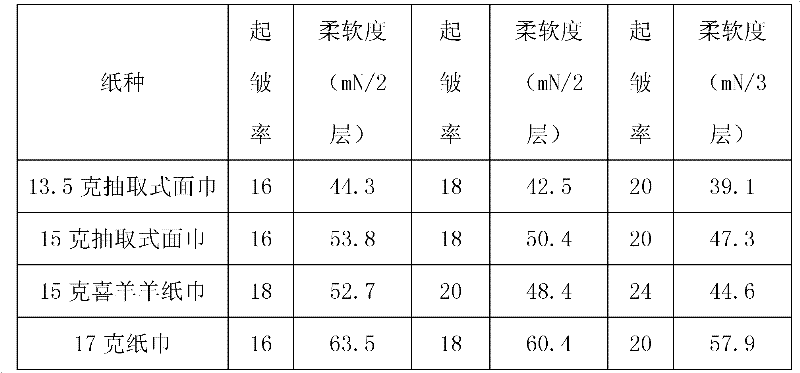

Manufacturing method for improving softness of tissue paper

The invention discloses a manufacturing method for improving the softness of tissue paper. The method comprises the following steps of: sorting, pulping, filling, making paper, scraping the paper, squeezing and drying, and also comprises a step of selecting and adding a softener, wherein a fluffer and refiner series connection free pulping method is adopted and the range of a tackifying coefficient is strictly controlled in the pulping process, and an appropriate scraper angle is selected and the crepe ratio of the paper is adjusted in the paper scraping process. Compared with the prior art, the method has the advantages that: the softness and handfeel of a paper product are obviously improved while the paper product has high strength, the softness of paper towel raw paper is lower, the handfeel of the raw paper is better and the strength of the paper product is slightly influenced when processing conditions are met, and the satisfaction of a consumer with the product is obviously improved.

Owner:WEIANJIE CARE PROD CHINA CO LTD

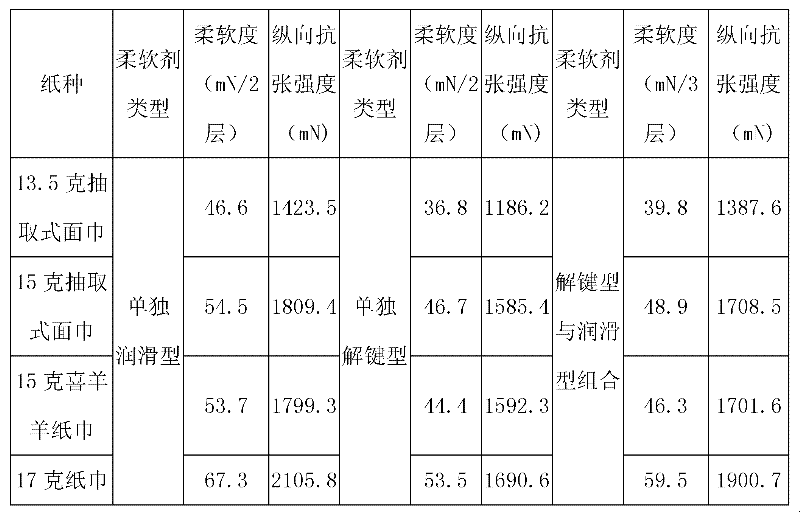

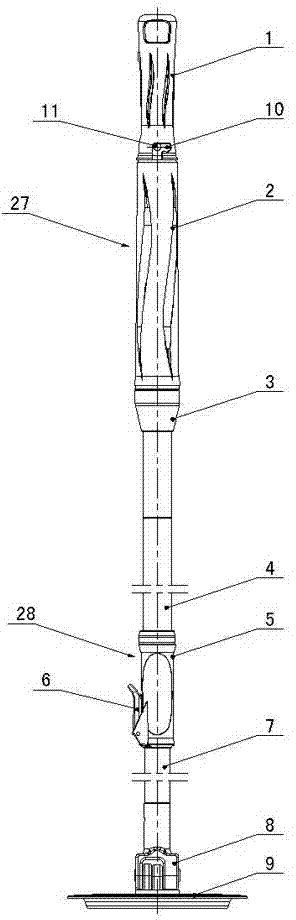

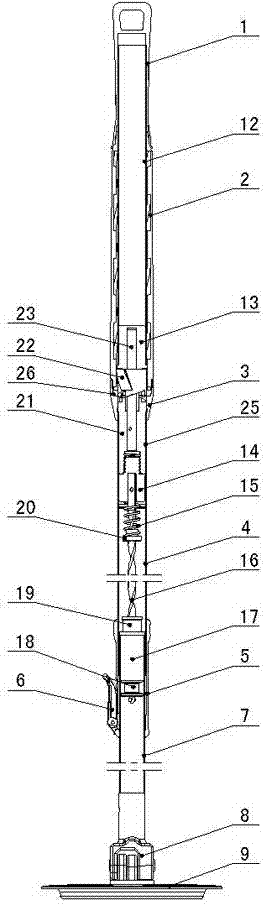

Hand-pressing type two-speed rotating mop

The invention discloses a hand-pressing type two-speed rotating mop which comprises a handle (1), an upper rod (12), a middle rod (4), a first-speed driving mechanism (28), a lower rod (7) and a mop assembly (9). The handle (1) is fixed to the upper rod (12), and the first-speed driving mechanism (28) is connected between the middle rod (4) and the lower rod (7). When the handle (1) is pressed down, the first-speed driving mechanism (28) drives the mop assembly (9) to rotate at first speed. A second-speed driving mechanism (27) is connected between the upper rod (12) and the middle rod (4). When the first-speed driving mechanism (28) and the lower rod (7) are locked, the handle (1), the upper rod (12), the middle rod (4), the first-speed driving mechanism (28) and the lower rod (7) are connected into a whole. When the second-speed driving mechanism (27) is pressed down, the mop assembly (9) is driven to rotate at second speed. By the adoption of the structure, the hand-pressing type two-speed rotating mop has the advantages of being simple and reasonable in structure, light and convenient to operate and use, good in cleaning and dehydrating effect, low in production cost and long in service life, rotating at different speeds during cleaning and dehydrating, and the like.

Owner:周高扬

Anti-wrinkle pretreatment method for composite fabric lining

InactiveCN103966794ALight touchContinuation of stabilityTextile shapingPretreatment methodClosed loop

The invention provides an anti-wrinkle pretreatment method for a composite fabric lining. The method comprises the following steps: preparing an anti-wrinkle pretreatment device comprising a frame, as well as a driving device, a driving roller, a driven roller, a setting chamber, an impregnation chamber, a tension control device, a refrigeration device and an electric control system which are arranged on the frame according to an assembly line closed loop, clamping and fixing the lining on a conveyer belt, and rotating the conveyer belt at a linear velocity of 10-25 meters per minute so as to enable the lining to sequentially passes through the tension control device, the setting chamber, the impregnation chamber and an extrusion roller, and performing cyclic treatment; setting the temperature of the setting chamber at 70-90 DEG C, and setting the humidity as relative humidity of 35-40 percent, wherein the impregnation liquid is purified water at the temperature of 4-10 DEG C; performing cyclic treatment on the lining on the conveyer belt for 12-20 hours, and compounding the lining and other fabrics into the composite fabric. The composite fabric is used for collars, cuffs and pocket flaps of clothing or cases, and the overall stability and stiffness of the composite fabric are preserved for a long time.

Owner:FUJIAN DALIYA CLOTHING TECH

A method for realizing multi-point real touch on a surface acoustic wave touch screen

ActiveCN103472960BStrong signalStable touch performanceInput/output processes for data processingMicroprocessor control unitSurface acoustic wave sensor

The invention discloses a method for realizing multi-point real touch on a surface acoustic wave touch screen. The method comprises the following steps that (1), a group of transmitting transducer arrays or receiving transducer arrays are at least arranged on the X axis or the Y axis; (2), a transmitting circuit drives transmitting transducers to transmit a surface acoustic wave signal, and a receiving circuit controls receiving transducers to receive the surface acoustic wave signal; (3), when a touch body touches the surface acoustic wave touch screen, the surface acoustic wave signal reaches the receiving transducers after being reflected by the touch body; when the surface acoustic wave signal intensity is greater than a set threshold value, the receiving circuit sends the surface acoustic wave signal to an MCU (microprocessor control unit), and the MCU determines the coordinates of the touch body. By the method, the multi-point real touch response of two or more points is realized, ghost points are eliminated fundamentally, and moreover, the touch response of unlimited points in a touch area can be really realized by the conventional process.

Owner:GENERAL TOUCH CO LTD

White anti-yellowing cow split leather and manufacturing method thereof

ActiveCN110938717AFeel plumpFeel roundTanning treatmentPre-tanning chemical treatmentPulp and paper industryBiology

The invention relates to white anti-yellowing cow split leather and a manufacturing method thereof, and belongs to the technical field of leather manufacturing. The manufacturing method of the white anti-yellowing cow split leather comprises the following steps that wet blue leather is sequentially subjected to rewetting, primary retanning, alkali extraction, secondary retanning, primary dyeing, main fat liquoring, secondary dyeing, plate pasting, drying, softening, buffing and drum milling, and the white anti-yellowing cow split leather is obtained. The white cow split leather prepared by theinvention is free of powder falling in the use process, high in quality and excellent in performance.

Owner:漳州香洲皮革有限公司

Modified UV paint and preparation method thereof

The invention relates to a modified UV paint and a preparation method thereof, and belongs to the field of coating. The modified UV paint comprises the following components in percentage by weight: 20-40% of an oligomer, 5-30% of thermoplastic polyurethane resin, 1-10% of a diluent monomer, 30-50% of a diluent, 0.1-5% of an additive and 0.5-5% of a light initiator. The invention further discloses a preparation method of UV paint and an application of the coating. The coating has good performance, is subjected to spray coating on the surface of an integral seamless product of metal and plastic or glass and plastic, is stripped off by an adhesive tape to achieve excellent decoration and performance protection of paint on the plastic position, is not left on glass or plastic and has a clear boundary with the metal and the plastic or with the glass and the plastic without generating a hand feeling.

Owner:BYD PRECISION MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com