Silky through-air thermal bonded nonwoven and manufacturing method thereof

A technology of nonwoven fabrics and manufacturing methods, applied in the field of nonwoven fabrics, can solve problems such as limited application range and single components, and achieve the effects of wide application prospects, reasonable and simple formula, and excellent antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

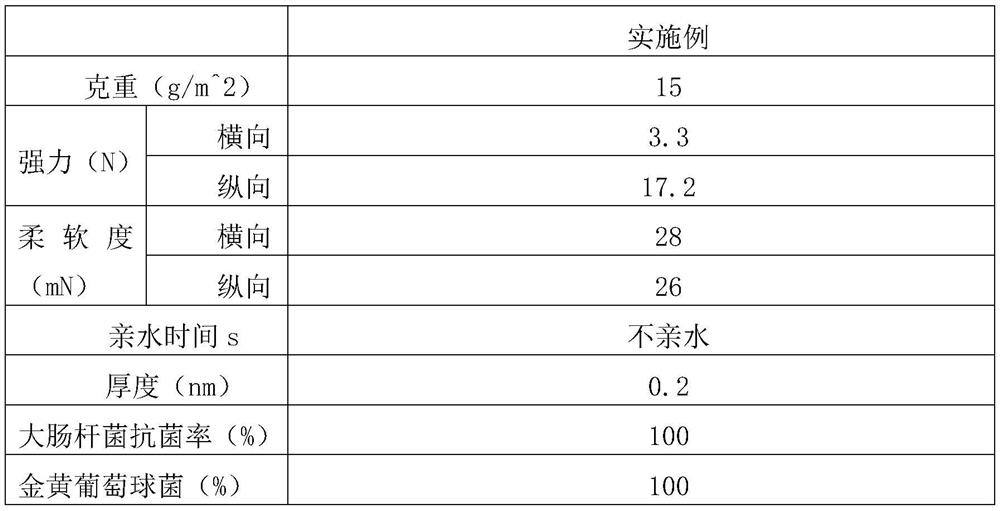

Examples

Embodiment

[0043] The manufacture method of described silk soft hot-air nonwoven fabric, comprises the following steps:

[0044] (1) Feeding: put the first component and the second component of the opened cotton bale into No. A fiber is put into the opener according to the ratio stated in the formula;

[0045] (2) Opening and blending: the opening machine loosens the agglomerated above-mentioned fibers, then sends the opened fibers into the cotton mixing box, and fully mixes the fibers;

[0046] (3) Carding: the mixed fiber is sent into a carding machine for sufficient carding, and the fiber is carded into a monofilament and spread into a uniform fiber web;

[0047] (4) Hot air bonding: Send the above-mentioned fiber web into a hot air oven, through the hot air flow inside the hot air oven, the hot air flow penetrates the fiber web to heat the fibers, the cortex material PE absorbs a certain amount of heat and produces melting flow recrystallization, the fiber Self-adhesive reinforceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com