Pretreating equipment for improving yarn sizing performance

A pretreatment and equipment technology, applied in the direction of ultrasonic/sonic fiber treatment, etc., can solve problems such as refractory degradation, deterioration of water solubility, and environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The pretreatment equipment and treatment process of the present invention will be described in detail below in conjunction with the accompanying drawings.

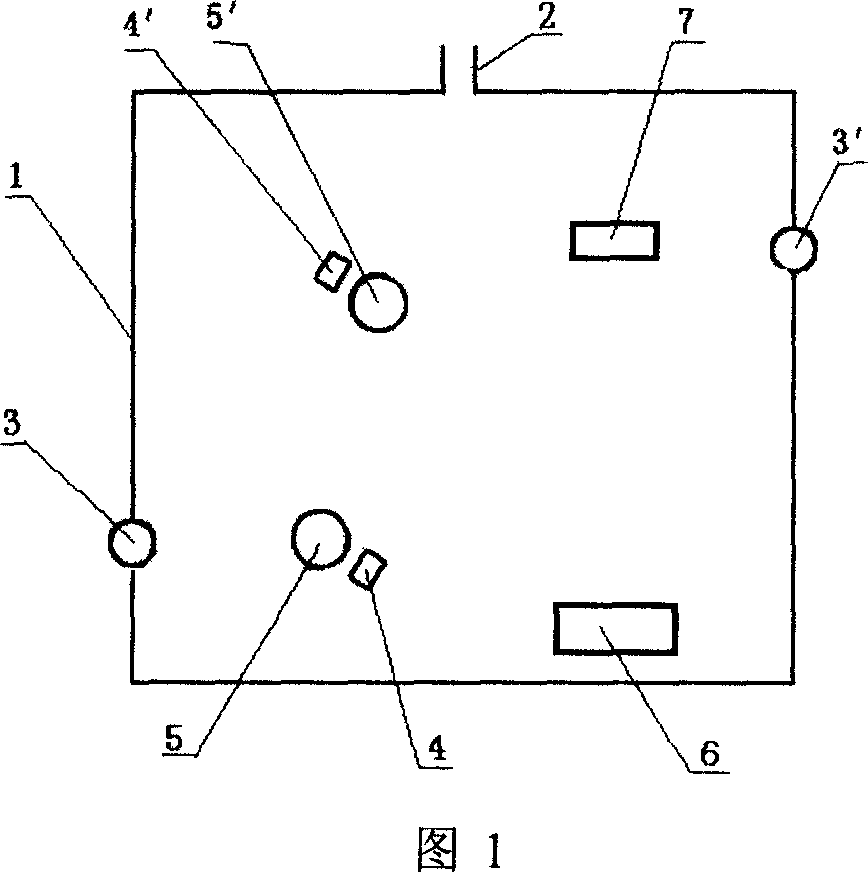

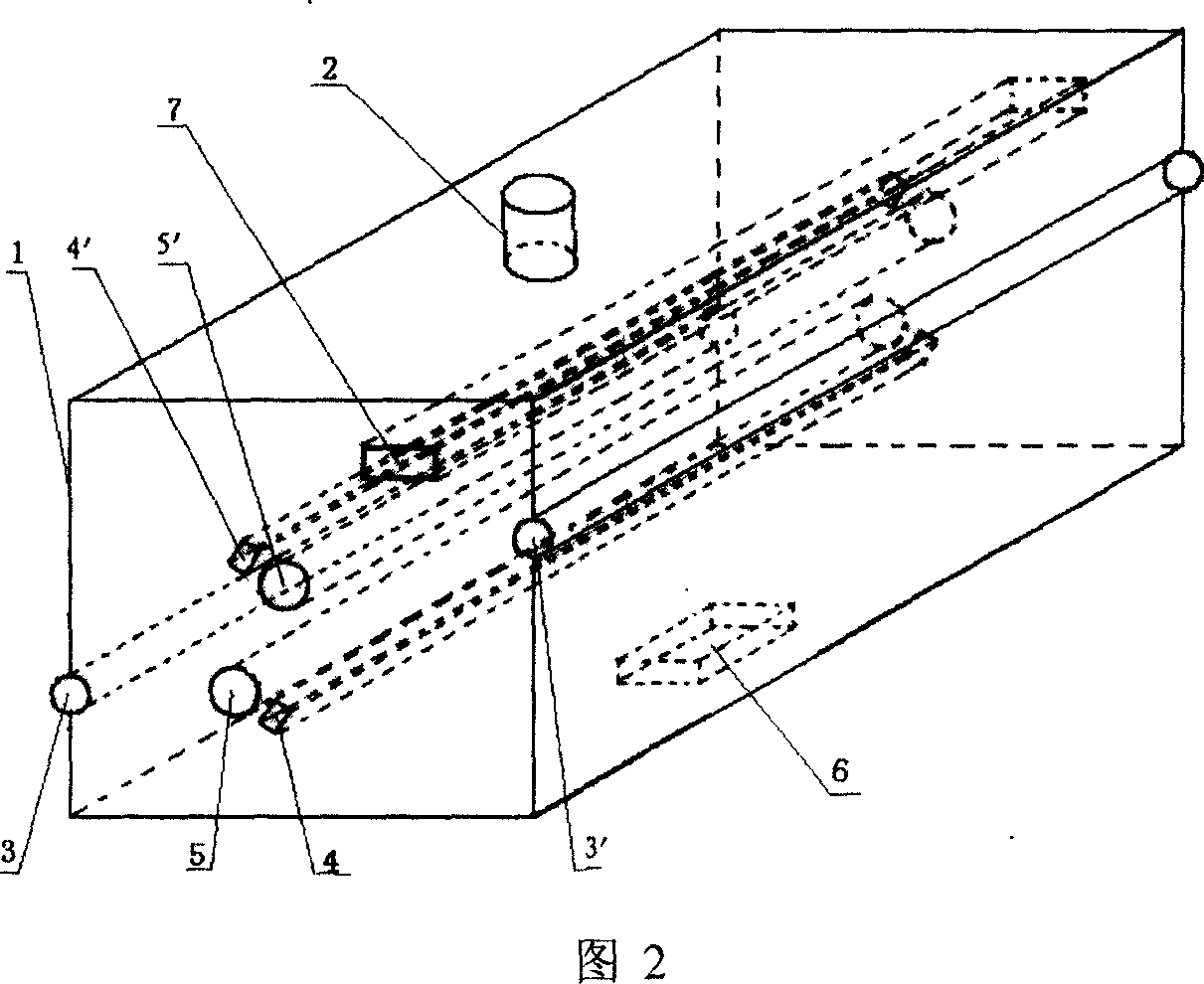

[0011] See accompanying drawing 1, accompanying drawing 2.

[0012] The pretreatment equipment of the present invention is composed of a box body 1, guide rollers 5, 5', high-voltage discharge heads 4, 4', ozone generator 6, ultraviolet irradiation device 7 and sealing rubber rollers 3, 3'.

[0013] Sealing rubber rollers 3, 3' are respectively fixedly installed on the two opposite walls of the box body 1, and the two ends of the guide rollers 5, 5' installed in the box body are respectively fixedly installed on the two side walls of the box body 1, from The yarn drawn on the warping beam advances along the route formed by the rubber seal roller 3, the guide roller 5, the guide roller 5' and the rubber seal roller 3'.

[0014] The high-voltage discharge heads 4, 4' fixedly installed in the box body 1 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com