White anti-yellowing cow split leather and manufacturing method thereof

A production method and a technology of resistance to yellowing, applied in dyeing method, leather impregnation, small raw hide/large raw hide/leather/fur treatment, etc. Rich tones, good light fastness, fade-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

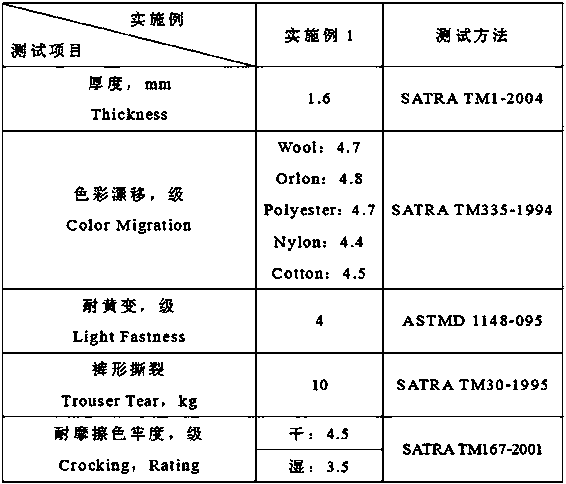

Embodiment 1

[0051] The preparation method of white anti-yellowing cow split leather comprises the following steps:

[0052] The wet blue leather is subjected to rewetting → primary retanning → alkaline extraction → secondary retanning → primary dyeing → main fatliquoring → secondary dyeing → laminating → drying → softening → smoothing → drumming, specifically:

[0053] Step 1, rehumidification: put the wet blue hide in the drum, add 200% water, 0.2%-0.4% rehumidifier Usabang W, and 0.5% degreasing Youshabang OC, run for 60min, add 1.0% acid softening enzyme TJ-A489, 1.0% ammonium bisulfate, run for 120min, add 0.5% formic acid, run for 40min, add 1.5% anti-spot agent TJ-A9811, Run for 60 minutes, add 1.0% oxalic acid, run for 60 minutes, drain, add 300% water, wash with water and drain to get wet leather;

[0054] Step 2, primary retanning: according to the mass percentage of wet blue leather, add 100% water and 0.5% formic acid into the drum, adjust the pH to 2.8-3.2, run for 40 minutes...

Embodiment 2

[0061] The preparation method of white anti-yellowing cow split leather comprises the following steps:

[0062] The wet blue leather is subjected to rewetting → primary retanning → alkaline extraction → secondary retanning → primary dyeing → main fatliquoring → secondary dyeing → laminating → drying → softening → smoothing → drumming, specifically:

[0063] Step 1, rehumidification: put the wet blue hide in the drum, and add 150% water, 0.2% rehumidifying agent Ushabang W, and 0.4% degreaser Ushabang in sequence according to the mass percentage of the wet blue hide Bang OC, run for 55min, add 0.8% acid softening enzyme TJ-A489, 0.8% ammonium bisulfate, run for 115min, add 0.4% formic acid, run for 35min, add 1.4% anti-spot agent TJ-A9811, run for 55min, Add 0.9% oxalic acid, run for 55 minutes, drain, add 250% water, wash with water and drain, and get wet leather;

[0064] Step 2, primary retanning: according to the mass percentage of wet blue leather, add 95% water and 0.4% ...

Embodiment 3

[0071] The preparation method of white anti-yellowing cow split leather comprises the following steps:

[0072] The wet blue leather is subjected to rewetting → primary retanning → alkaline extraction → secondary retanning → primary dyeing → main fatliquoring → secondary dyeing → laminating → drying → softening → smoothing → drumming, specifically:

[0073] Step 1, rehumidification: put the wet blue hide in the drum, and add 250% water, 0.4% rehumidifying agent Ushabang W, and 0.6% degreaser Ushabang in sequence according to the mass percentage of the wet blue hide Bang OC, run for 65min, add 1.2% acid softening enzyme TJ-A489, 1.2% ammonium bisulfate, run for 125min, add 0.6% formic acid, run for 45min, add 1.6% anti-spot agent TJ-A9811, run for 65min, Add 1.1% oxalic acid, run for 65 minutes, drain, add 350% water, wash with water and drain, and get wet leather;

[0074] Step 2, primary retanning: according to the mass percentage of wet blue leather, add 105% water and 0.6%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com