Method for producing water-based polyurethane synthetic leather

A technology of water-based polyurethane and production methods, which is applied in the direction of chemical instruments and methods, layered products, textiles and papermaking, etc., which can solve the problems of large-scale products, such as the regulation of foaming effect and the control of product quality, ingredients and process steps To solve problems such as cumbersomeness and environmental hazards for operators, achieve the effect of full hand feeling, broad market application prospects, good air permeability and hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

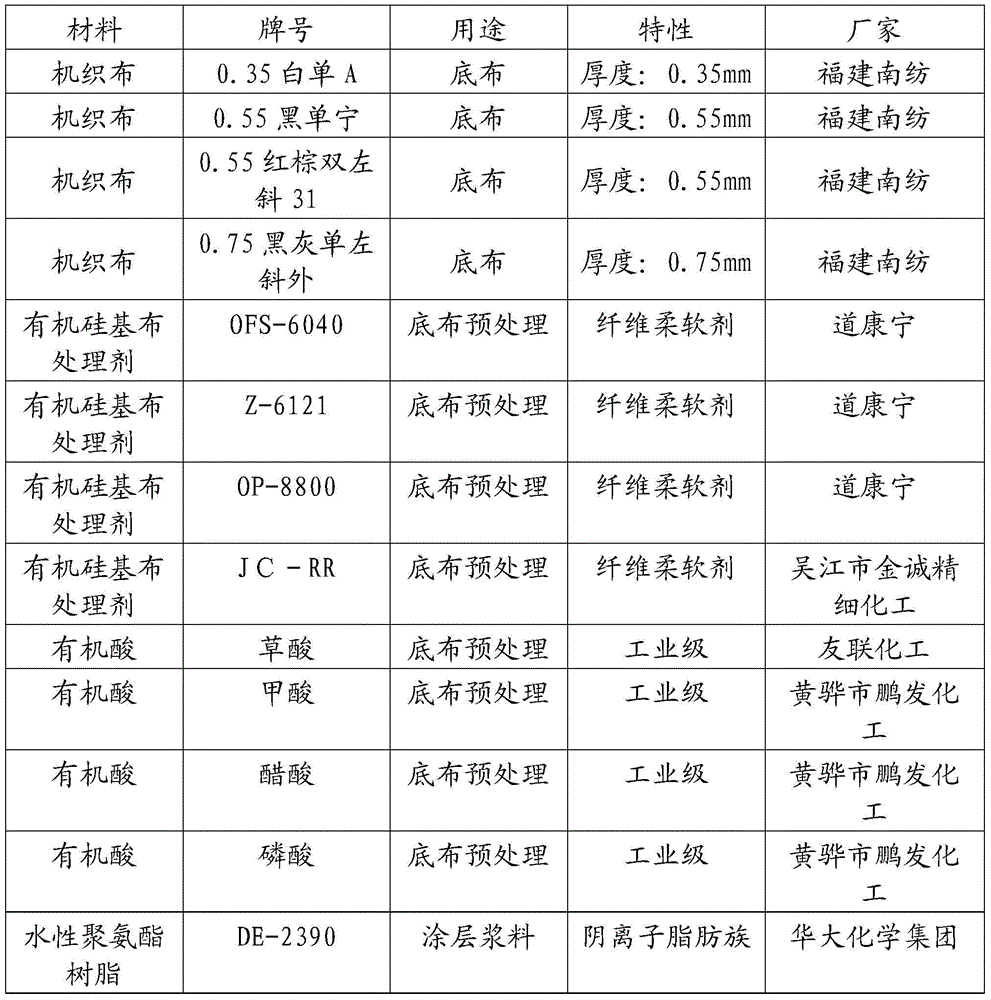

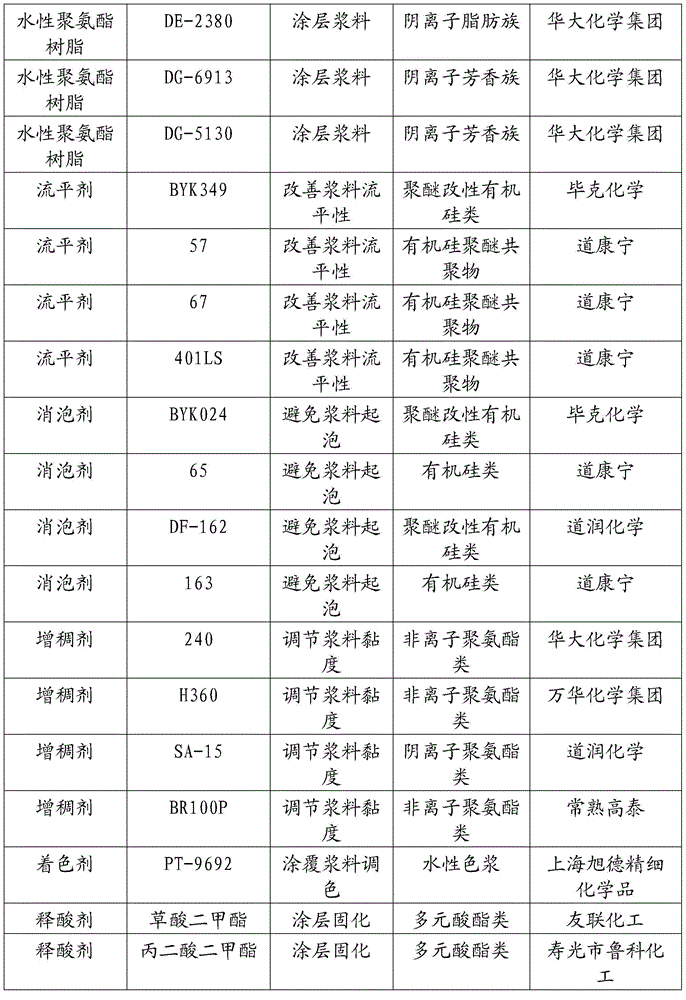

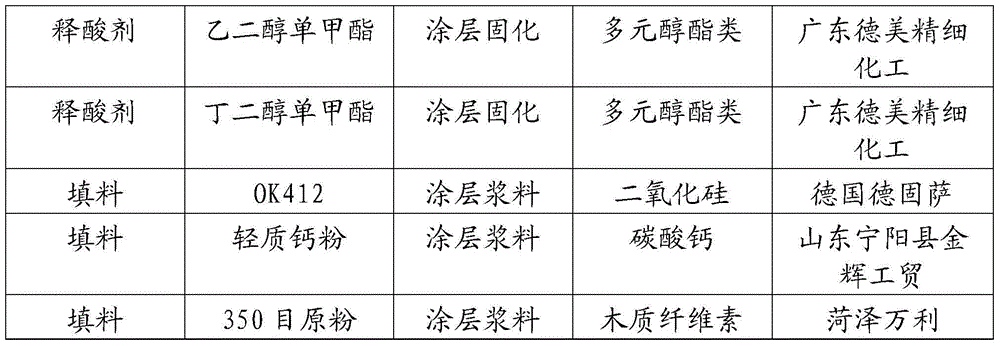

[0056] 1. Materials and reagents

[0057] 1) The base fabric is made of Fujian Nanfang Co., Ltd. 0.35 white sheet A, thickness: 0.35mm.

[0058] 2) The formulation of base cloth treatment liquid is as follows in Table 2:

[0059] Table 2 Formula of base fabric treatment liquid

[0060]

[0061] 3) The formula of water-based polyurethane slurry is shown in Table 3:

[0062] Table 3 Waterborne polyurethane slurry formula

[0063]

[0064] The preparation method of the water-based polyurethane slurry is as follows: mix the raw materials according to Table 3, and obtain them after being uniformly stirred by a high-speed machine.

[0065] 2. Preparation method

[0066] (1) Moisture conditioning finishing of the base cloth: impregnate the base cloth in the base cloth treatment solution, and control the impregnated liquid rate of the base cloth to 50% through the gap between the rolls and the pressure;

[0067] (2) Coating of water-based slurry: The water-based polyurethan...

Embodiment 2

[0071] 1. Materials and reagents

[0072] 1) The base fabric is 0.55 black tannin of Fujian Nanfang Co., Ltd., thickness: 0.55mm.

[0073] 2) The formulation of the moisture-conditioning finishing agent solution for the base cloth is as follows in Table 4:

[0074] Table 4 Formula of substrate treatment liquid

[0075]

[0076] 3) The formula of water-based polyurethane slurry is shown in Table 5:

[0077] Table 5 Waterborne polyurethane slurry formula

[0078]

[0079]

[0080] The preparation method of the water-based polyurethane slurry is as follows: mix the raw materials according to Table 5, and obtain them evenly by high-speed mechanical stirring.

[0081] 2. Preparation method

[0082] (1) Moisture conditioning finishing of the base cloth: impregnate the base cloth in the base cloth treatment solution, and control the liquid-carrying rate of the base cloth after the impregnation through the roll gap and pressure to 70%;

[0083] (2) Coating of water-based...

Embodiment 3

[0087] 1. Materials and reagents

[0088] 1) The base fabric is Fujian Nanfang Co., Ltd. 0.55 red brown double left diagonal 31, thickness: 0.55mm.

[0089] 2) The formulation of the moisture-conditioning finishing agent solution for the base cloth is shown in Table 6:

[0090] Table 6 Formula of substrate treatment liquid

[0091]

[0092] 3) The formula of water-based polyurethane slurry is shown in Table 7:

[0093] Table 7 Waterborne polyurethane slurry formula

[0094]

[0095]

[0096] The preparation method of the water-based polyurethane slurry is as follows: mix the raw materials according to Table 7, and obtain them evenly by high-speed mechanical stirring.

[0097] 2. Preparation method

[0098] (1) Moisture conditioning finishing of the base cloth: impregnate the base cloth in the base cloth treatment solution, and control the impregnated liquid rate of the base cloth to 80% through the gap between the rolls and the pressure;

[0099] (2) Coating of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com