Polyurethane resin for hydrolysis-resistant sofa leather and preparation method thereof

A technology of polyurethane resin and sofa leather, which is applied in the field of ten-year hydrolysis-resistant polyurethane resin for sofa leather and its preparation, which can solve the problems of degradation, cracking and peeling strength of the leather surface, and achieve soft hand feeling, improved softness and increased polarity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The raw material composition (unit kg) is as follows:

[0043] Polytetrahydrofuran ether glycol 700

[0044] Polycarbonate diol 220

[0045] Ethylene glycol 68

[0046] 4,4-Diphenylmethanediamine 5

[0047] 4,4-Diphenylmethane diisocyanate 395.5

[0048] Catalyst MB20 0.2

[0049] Antioxidant 1010 2.0

[0050] water repellant 15

[0051] N,N-Dimethylformamide 3615

[0052] Polytetrahydrofuran ether glycol is a polyether polyol with a number average molecular weight of 2000±200g / mol.

[0053] Polycarbonate diol is a polycarbonate polyol with a number average molecular weight of 2000±200g / mol.

[0054] Its preparation method is as follows:

[0055]1. Put 35% of the total weight of polyether and polycarbon polyol mixture and N,N-dimethylformamide into the reaction kettle for mixing, stir for 10 minutes and then put 172.5kg of 4,4-diphenylmethane Diisocyanate (MDI) reaction, so that the molar ratio of the hydroxyl group in the polyether and polycarbonate polyol mi...

Embodiment 2

[0062] The raw material composition (unit kg) is as follows:

[0063] Polytetrahydrofuran ether glycol 620

[0064] Polycarbonate diol 300

[0065] Ethylene glycol 65

[0066] 4,4-Diphenylmethanediamine 10

[0067] 4,4-Diphenylmethane diisocyanate 389.7

[0068] Catalyst MB20 0.2

[0069] Antioxidant 2246 2.0

[0070] water repellant 15

[0071] N,N-Dimethylformamide 3600

[0072] Polytetrahydrofuran ether glycol is a polyether polyol with a number average molecular weight of 2000±200g / mol.

[0073] The polycarbonate diol is a polycarbon polyol with a number average molecular weight of 2000±200 g / mol.

[0074] Its preparation method is as follows:

[0075] 1. Put 35% of the total weight of the polyether and polycarbon polyol mixture and N,N-dimethylformamide into the reaction kettle for mixing, stir for 10 minutes and then put in 172.5 kg of 4,4-diphenylmethane Diisocyanate (MDI) reaction, so that the molar ratio of the hydroxyl group in the polyether and polycarbona...

Embodiment 3

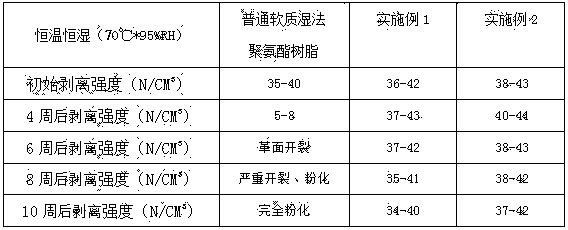

[0081] In order to verify that the ten-year hydrolysis-resistant sofa leather of the present invention is made of polyurethane resin, the synthetic leather not only feels soft, plump, and has good elasticity, but also can meet the requirements of constant temperature and humidity (70°C*95%RH) and the peel strength can still be retained after ten weeks. More than 90%, compare the resin prepared in the above examples 1-2 with the ordinary soft low modulus wet polyurethane resin, and make a sample into wet-process crust leather to test its peeling performance, (wherein the formula for proofing is: DMF: 120 , S-7: 2, S-8I: 1, lignin: 20, resin 100, color paste: 2, the unit is KG) The results are shown in the following table:

[0082]

[0083] After testing, the wet-laid crust made of ordinary soft low-modulus wet-type polyurethane resin has soft hand feeling, good fullness and elasticity; the wet-laid crust made of the polyurethane resin prepared in Examples 1 and 2 of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com