Ultraviolet light solidified water born paint in use for leather or leatheroid

A water-based coating, artificial leather technology, applied in polyurea/polyurethane coatings, coatings, textiles and papermaking, etc., to achieve smooth coating, good feel and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

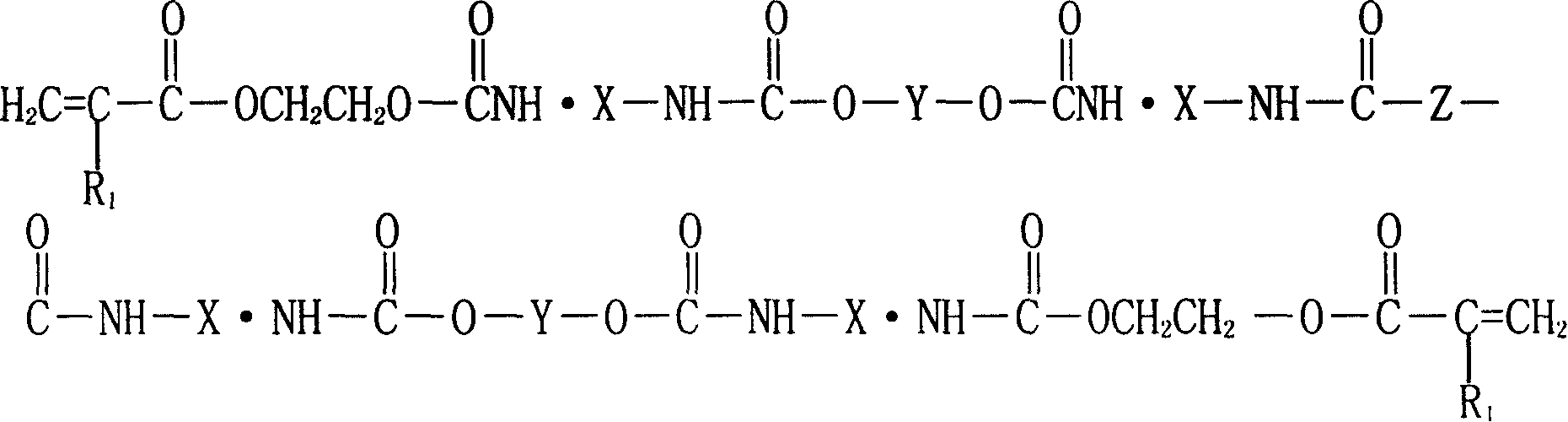

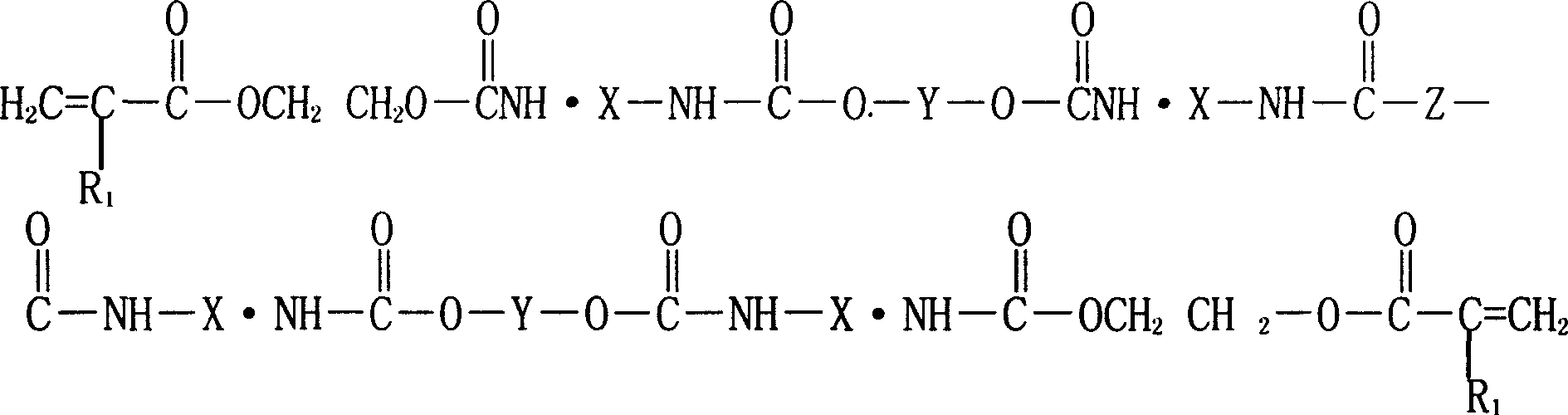

AI Technical Summary

Problems solved by technology

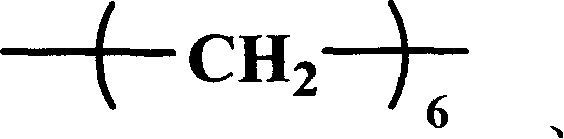

Method used

Image

Examples

Embodiment 1

[0038] Waterborne Aromatic Urethane Acrylate (A-1) 35%

[0039] Ethoxylated Trimethylolpropane Triacrylate 6%

[0040] Deionized water 55%

[0041] 4'-(2-Hydroxyethoxy)-2-hydroxy-2-methylpropiophenone 4%

[0042] After mixing the above-mentioned components in proportion, stir at 40-50°C for about 0.5 hours, filter with a 200-mesh filter cloth and pack, then the UV-curable leather or artificial leather water-based coating of the present invention is obtained. Spray the coating on artificial PU leather, level it at 50°C for 3 minutes, and measure its performance after being cured by ultraviolet light. The results are shown in Table 1.

Embodiment 2

[0044] Waterborne Aromatic Urethane Acrylate (A-1) 40%

[0045] Polyethylene Glycol Acrylate 5%

[0046] Deionized water 50%

[0047] 4'-(2-Hydroxyethoxy)-2-hydroxy-2-methylpropiophenone 5%

[0048] The sample preparation method is the same as in Example 1, and the properties of the coating film are shown in Table 1.

Embodiment 3

[0050] Waterborne Aliphatic Urethane Acrylate (A-2) 48%

[0051]Deionized water 45%

[0052] 4'-(2-Hydroxyethoxy)-2-hydroxy-2-methylpropiophenone 5%

[0053] 1-Hydroxy-1-cyclohexylbenzophenone 2%

[0054] The sample preparation method is the same as in Example 1, and the properties of the coating film are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com