Anti-wrinkle pretreatment method for composite fabric lining

A composite fabric and pretreatment technology, which is applied in fabric surface trimming, textiles and papermaking, etc., can solve the problems of soft lining, poor hand feeling, and reduced fiber activity, and achieve wrinkle resistance, thermoplasticity and dimensional stability, and fiber The effect of low moisture regain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and examples, so as to fully understand the present invention.

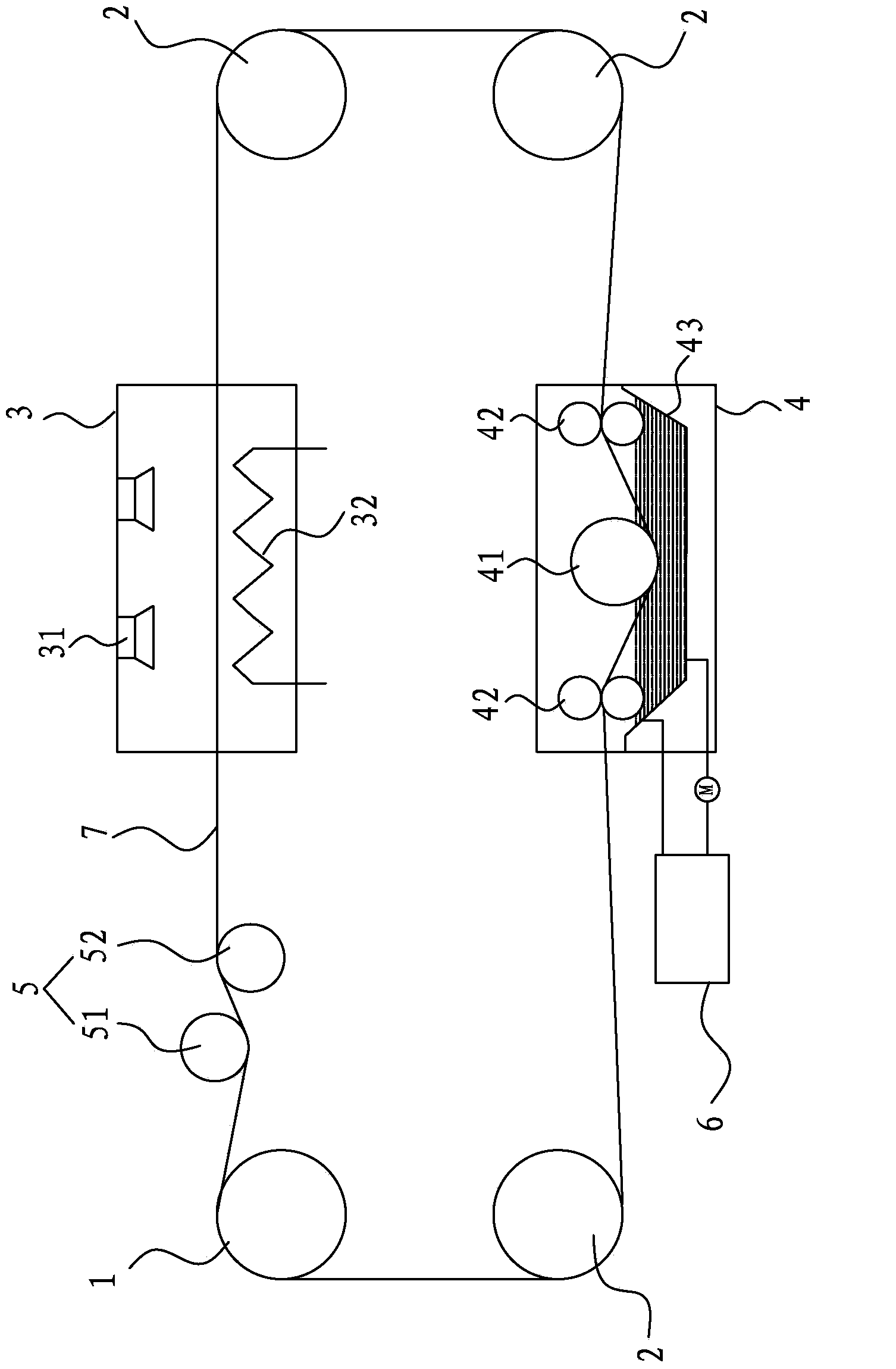

[0015] In order to pretreat the anti-wrinkle of the composite fabric lining, it is first necessary to prepare an anti-wrinkle pretreatment device, refer to figure 1 , the device includes a frame (not shown in the figure) and a driving device (not shown in the figure) respectively arranged on the frame, a driving roller 1, a driven roller 2, a shaping chamber 3, an impregnation chamber 4, a tension control device 5, refrigeration device 6 and electrical control system (not shown in the figure), wherein, the frame is roughly a panel structure, which is used to fix and support other components, and the drive device is a servo drive The servo motor controlled by the controller, the driving roller 1 and the driven roller 2 are respectively connected to the output shaft of the servo motor thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com