Hand-pressing type two-speed rotating mop

A rotary mop, hand-pressed technology, applied in the field of cleaning and sanitary appliances, can solve the problems of high production cost, slow starting speed, difficult assembly, etc., and achieve the effect of guaranteed service life, moderate speed and flexible rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

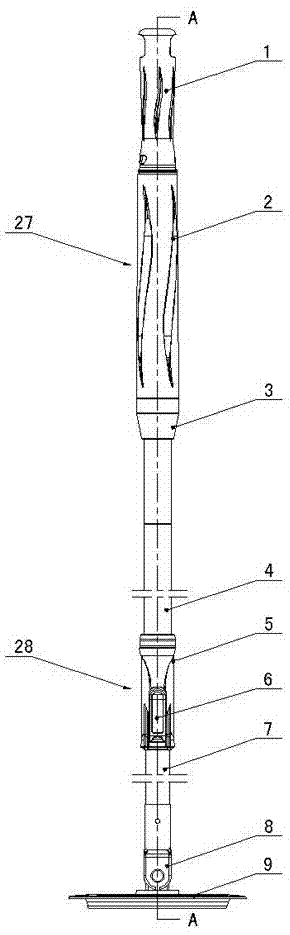

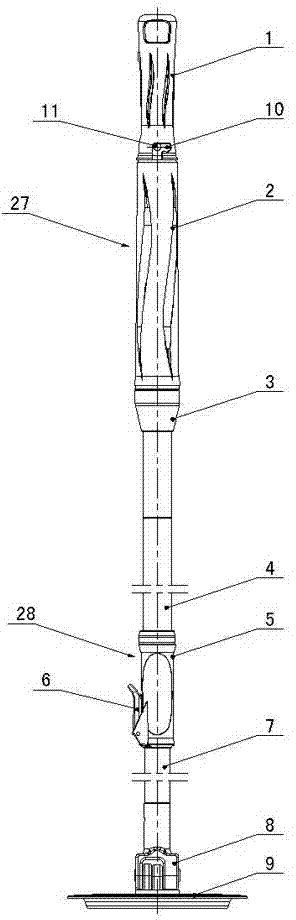

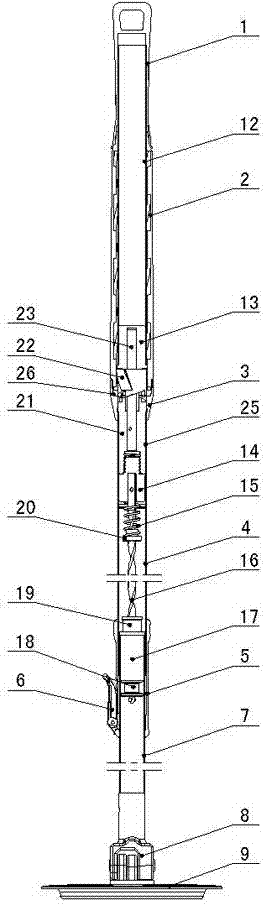

[0021] Figure 1 to Figure 4 As shown, the present invention creates a specific embodiment of a hand-pressed two-speed rotary mop, which includes a handle 1, an upper rod 12, an intermediate rod 4, a first speed drive mechanism 28, a lower rod 7, a connector 8, a mop Component 9, the handle 1 is fixed on the upper rod 12, the first speed driving mechanism 28 is connected between the middle rod 4 and the lower rod 7, when the handle 1 is pressed down, the first speed driving mechanism 28 drives the mop assembly 9 through the lower rod 7 Rotate at the first speed; the second speed drive mechanism 27 is connected between the upper rod 12 and the middle rod 4. When the first speed drive mechanism 28 and the lower rod 7 are locked, the handle 1, the upper rod 12, the middle rod 4 1. The first speed driving mechanism 28 and the lower rod 7 are connected as one, and when the second speed driving mechanism 27 is pressed down, the lower rod 7 drives the mop assembly 9 to rotate at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com