Environment-friendly chlorine-resistant color fixing agent, and preparation method and application thereof

A color-fixing agent and chlorine-resistant technology, which is applied in the field of textile dyeing and finishing, and can solve the effects of color change, handle and washability of textiles that are not mentioned, rare, and chlorine-resistant color fastness, etc. problems, achieve the effect of improving the color fastness to chlorine water, little influence of color and light, and good washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

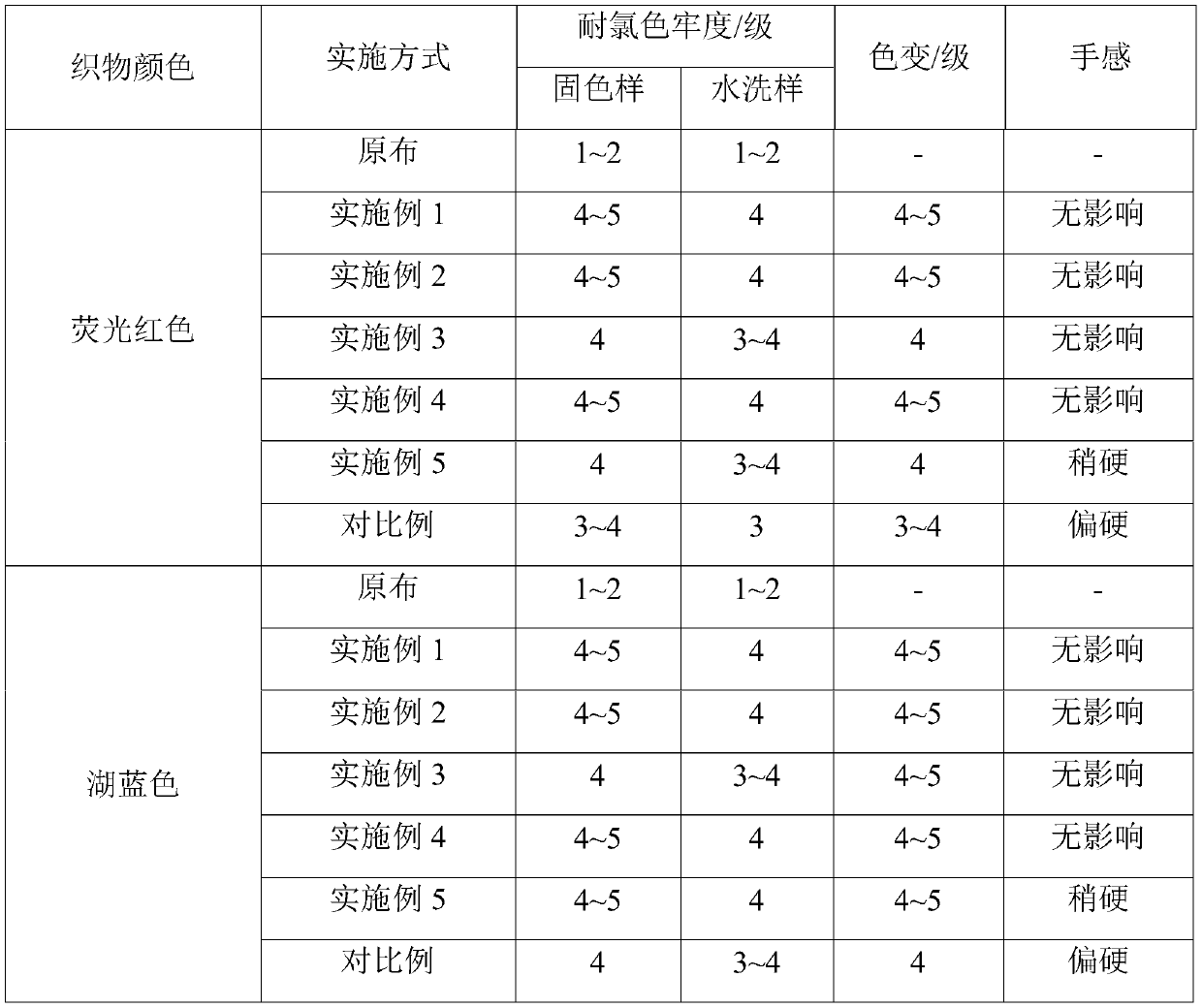

Examples

Embodiment 1

[0042] Add 11.82 grams of diethylenetriamine, 2.5 grams of N,N-dimethylaniline and 0.32 grams of diethylamine into a three-necked flask with a condenser, a thermometer and a balance feeder, and after stirring for 30 minutes, dropwise add 23.36 grams of epoxy Chloropropane, the rate of addition is 5ml / min, after the drop is completed, it is incubated at 25°C for 4 hours; then the temperature is raised to 75°C, and the reaction is continued for 3 hours; 59.4 grams of deionized water, 0.6 grams of citric acid and 2 grams of citric acid are added Carbohydrazide, stirred for 0.5 hours, and after cooling, the environment-friendly cationic chlorine-resistant color-fixing agent was obtained.

[0043] The environment-friendly cationic chlorine-resistant color-fixing agent prepared in this example is composed of 38% chlorine-resistant intermediate, 0.6% chelating agent citric acid, 2% oxygen scavenger carbohydrazide and 59.4% deionized water. Among them, in the chlorine-resistant interm...

Embodiment 2

[0045] Add 12.48 grams of diethylenetriamine and 2.85 grams of dodecyldimethyl tertiary amine into a three-necked flask with a condenser, a thermometer and a balance feeder. After stirring for 10 minutes, add 24.67 grams of epichlorohydrin dropwise, and the dropwise speed The rate is 6ml / min; after dripping, keep the reaction at 25°C for 3 hours; then raise the temperature to 55°C, and continue the heat preservation reaction for 5 hours; add 58.7 grams of deionized water, 0.8 grams of citric acid and 0.5 grams of hydrazine acetate, and stir for 0.5 Hours, after cooling, the environment-friendly cationic chlorine-resistant color fixing agent is obtained.

[0046] The environment-friendly cationic chlorine-resistant color-fixing agent prepared in this example is composed of 40% chlorine-resistant intermediate, 0.8% chelating agent citric acid, 0.5% oxygen scavenger hydrazine acetate and 58.7% deionized water. Wherein, in the chlorine-resistant intermediate, the molar ratio of po...

Embodiment 3

[0048] Add 10.1 grams of diethylenetriamine and 3.75 grams of dodecyldimethyl tertiary amine into a three-necked flask with a condenser, a thermometer and a balance feeder, and stir for 20 minutes; add 22.65 grams of epichlorohydrin dropwise, and dropwise The rate is 5ml / min; after the drop is completed, it is incubated at 30°C for 4 hours; then the temperature is raised to 65°C, and the reaction is continued for 4 hours; gram of carbohydrazide, stirred for 1 hour, and cooled to obtain an environment-friendly cationic chlorine-resistant color-fixing agent.

[0049]The environment-friendly cationic chlorine-resistant color-fixing agent prepared in this example is composed of 36.5% chlorine-resistant intermediate, 0.3% chelating agent carboxyethylthiosuccinic acid, 3.5% oxygen scavenger carbohydrazide and 59.7% deionized water . Wherein, in the chlorine-resistant intermediate, the monomer molar ratio of polyamine monomer: monoamine monomer: epichlorohydrin monomer is 1:0.18:2.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com