Patents

Literature

31results about How to "Shade effect is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medium temperature type three-primary-color disperse dyes

ActiveCN103073918AGood sublimation fastnessEasy to liftOrganic dyesDyeing processDisperse dyeDistillation

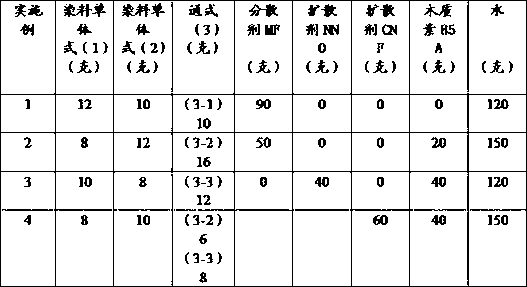

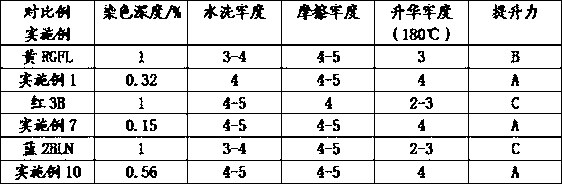

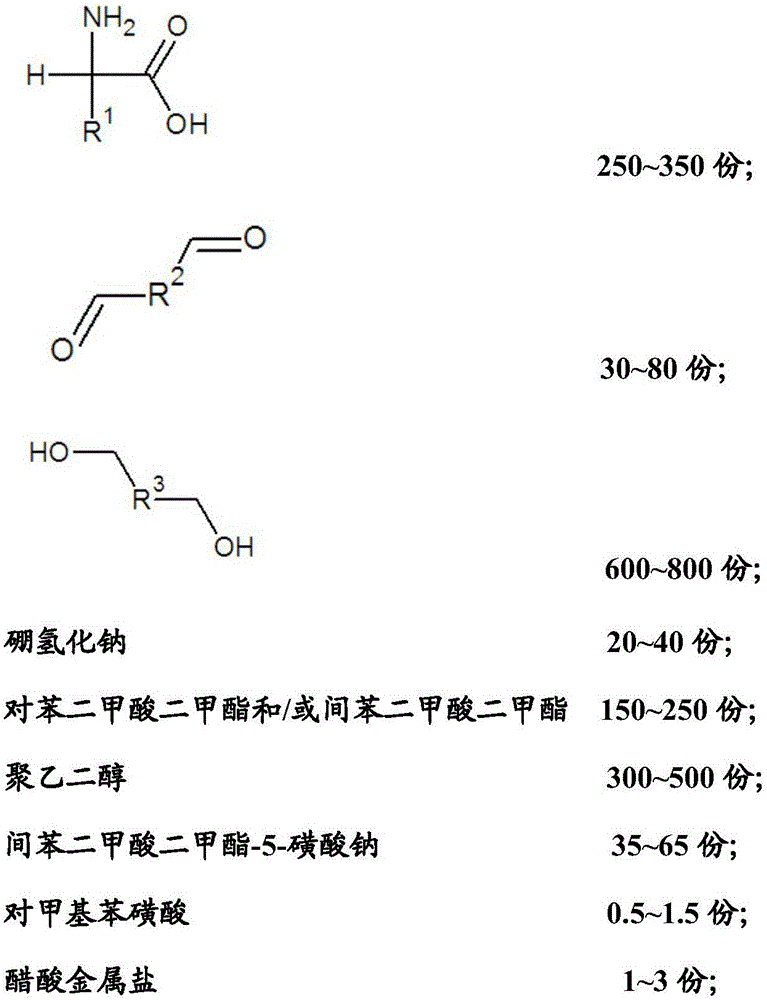

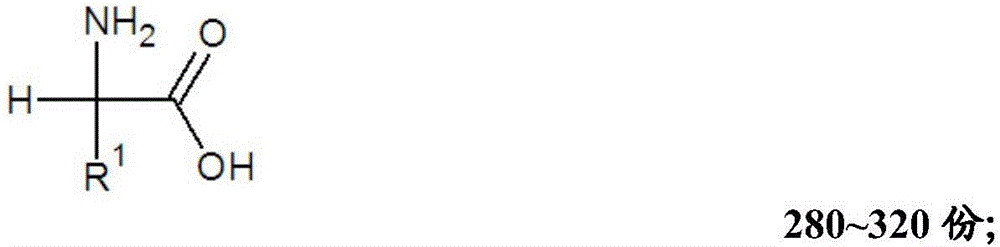

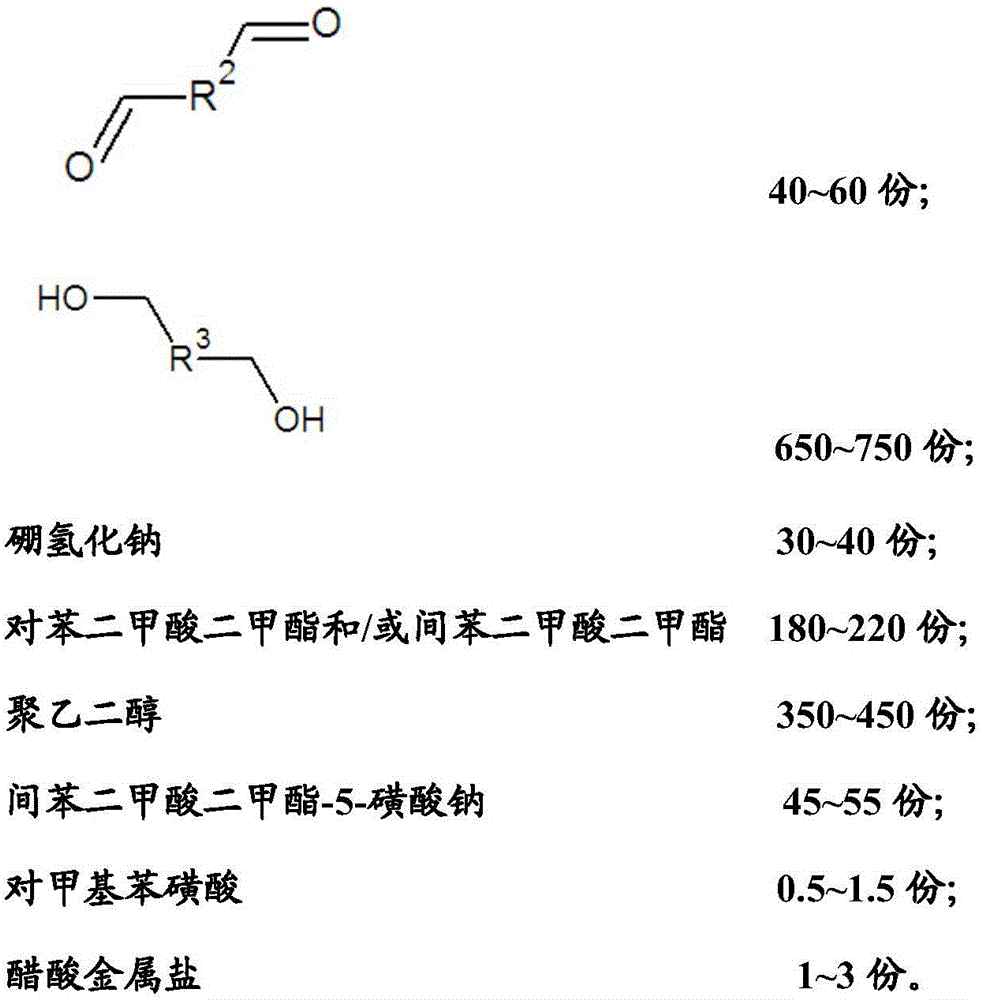

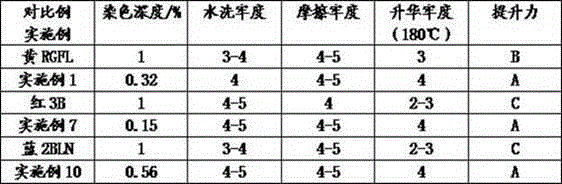

The invention discloses a group of medium temperature type three-primary-color disperse dyes. A yellow disperse dye is a mixture formed by 5-20 % of compound shown by a chemical formula (1), 5-40 % of compound shown by a chemical formula (2) and 5-40 % of compound shown by a chemical general formula (3) in percentage by weight; a red disperse dye comprises one or more monomers in a compound shown by a chemical general formula (4); and a blue disperse dye comprises one or more monomers in a compound shown by a chemical general formula (5). The medium temperature type three-primary-color disperse dyes disclosed by the invention have the advantages as follows: medium temperature type three primary colors beautiful in colored lights and high in intensities; the colored lights of the medium temperature type three primary colors are similar to the original three primary colors; the medium temperature type three-primary-color disperse dyes have the advantages of perfect compatibility, high lifting force, distillation, excellent fastness and the like during dyeing and are a group of medium temperature type three-primary-color disperse dyes with excellent comprehensive performances.

Owner:JIANGSU YABANG DYE

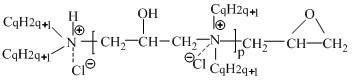

Textile printing and dyeing pigment color fixing agent and preparation method thereof

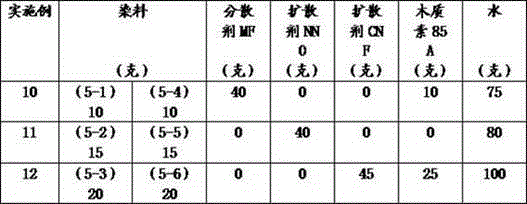

InactiveCN103343464AGood color fixing effectShade effect is smallDyeing processTextile printerEngineering

The invention relates to a textile printing and dyeing pigment color fixing agent and a preparation method thereof. The textile printing and dyeing pigment color fixing agent mainly comprises acrylic ester, epichlorohydrin, organic siloxane, 2.2-azodi(2-methopropoxy acid)polyvinyl polypyrrolidone, dicyandiamide and deionized. The textile printing and dyeing pigment color fixing agent has a good color fixing effect on textiles which are dyed by pigments and small influences on textile colored lights, free formaldehyde is not generated in a synthetic process, and the textile printing and dyeing pigment color fixing agent belongs to an environment-friendly color fixing agent.

Owner:ZHANGJIAGANG DONGFANG SPECIAL DYEING

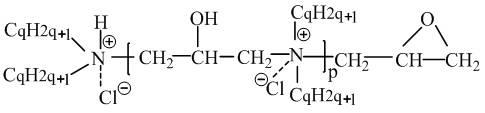

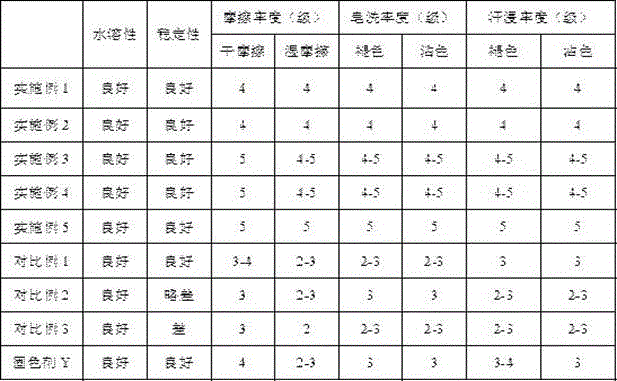

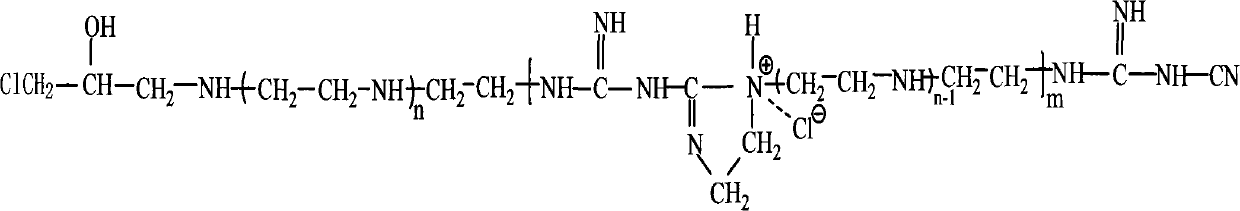

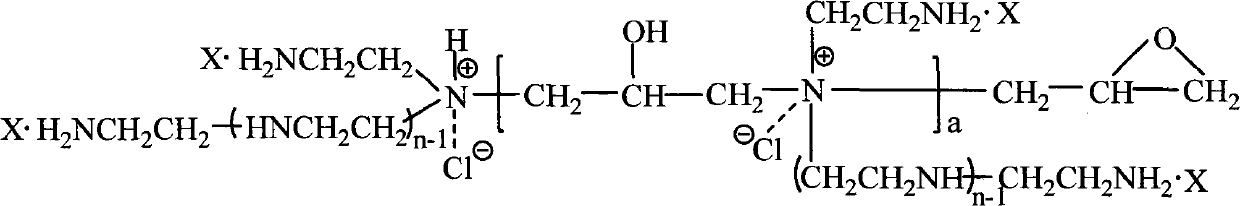

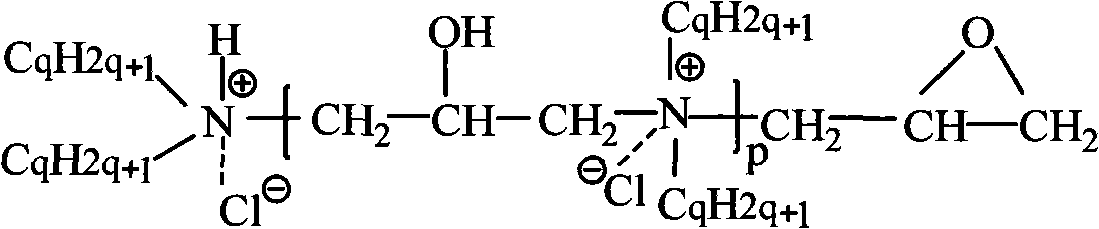

Formaldehyde-free fixing agent for active dye

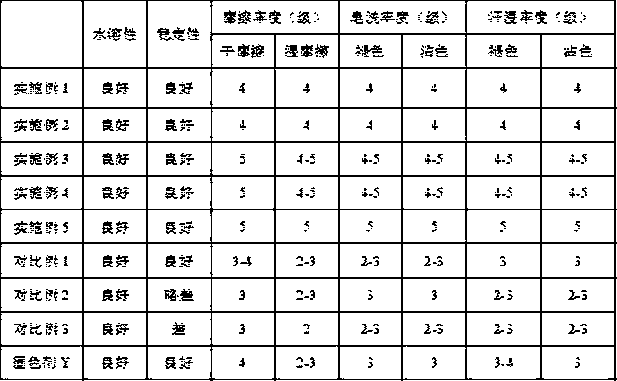

InactiveCN102493232AHigh color fastnessLow water solubilityDyeing processPolymer chemistryFormaldehyde free

The invention discloses a formaldehyde-free fixing agent for an active dye. The formaldehyde-free fixing agent is prepared by compounding 2 to 4 compounds. The formaldehyde-free fixing agent has reactive functional groups and high cationic property, can effectively improve the dry rubbing fastness, wet rubbing fastness and color fastness to washing of fabrics dyed by the active dye, and has a little influence on the color tone of the fabrics.

Owner:SUZHOU UNIV

Dyeing wastewater recycling method

The invention discloses a dyeing wastewater recycling method. The method is characterized by including the following steps that a high-polymer disperse agent and water are added into disperse dye filter cake for grinding, and filtering is conducted to obtain liquid disperse dye; the liquid disperse dye is weighed, water is added to prepare a dye bath, then a fiber material is immersed in dyeing equipment for dyeing, then the fiber material is taken out of the dyeing equipment, and after drying is conducted, a dyed fiber material is obtained; dyeing wastewater obtained after dyeing is conductedis reused for multiple times, the dyeing wastewater is returned to the step 2 as water used for the dye bath, and the step 2 is repeated to dye the fiber material. According to the dyeing wastewaterrecycling method, the high-polymer disperse agent is used for replacing conventional sodium sulfonate dispersion agents, not only is the dyeing effect good, but also washing is not needed, and the dyevat wastewater can be recycled, so that printing and dyeing wastewater discharge is greatly reduced.

Owner:ZHEJIANG SHANYU TECH CO LTD

Color fixing agent for wool fiber

The invention discloses a color fixing agent for wool fiber. The color fixing agent consists of the following components in parts by mass: 1-2 parts of sodium polyacrylate, 30-35 parts of epoxy chloropropane, 80-90 parts of absolute ethyl alcohol, 1-2 parts of oleoyl amino acid sodium, 10-15 parts of epoxy chloropropane, 7-9 parts of hydroquinone and 8-9 parts of sodium hydroxide. The color fixing agent for wool fiber has a good color fixing effect on a wool fiber fabric in dyeing by using a dye, has little influence on the color and lustre of the fabric and is free of free formaldehyde in a synthesis process.

Owner:常熟市爱博尔服饰有限公司

Dye-fixing agent for wool fiber and preparation method thereof

The invention relates to a dye-fixing agent for a wool fiber and a preparation method thereof. The dye-fixing agent for the wool fiber mainly comprises hydroquinone, epoxy chloropropane, a catalyst, absolute ethyl alcohol and sodium hydroxide. The dye-fixing agent for the wool fiber has a good dye-fixing effect on wool fiber fabrics after dyeing the dyestuff, has slight influence on color of the fabrics and belongs to an environment-friendly dye-fixing agent, and free formaldehyde in the synthetic process is avoided.

Owner:ZHANGJIAGANG DONGFANG SPECIAL DYEING

Reduction clearing method used for synthetic fiber

InactiveCN106592284AShade effect is smallHigh color fastnessDyeing processCleansing AgentsPhotochemistry

The invention relates to a reduction clearing method used for synthetic fiber. The reduction clearing method comprises the steps of adding dyed synthetic fiber into reductive cleaning liquid, raising the temperature to 70-80 DEG C, maintaining the temperature and conducting reaction for 10-20 min, discharging water, afterwards, adding water, raising the temperature to 70-80 DEG C, maintaining the temperature and conducting reaction for 5-15 min, and accomplishing the reduction clearing. According to the reduction clearing method used for synthetic fiber, through the coordinative use of a reductive cleaning agent and sodium carbonate, under the condition that the influence on color shade of a shell fabric is small, color fastness of the shell fabric is improved; in addition, the reduction clearing method is simple and easy to control.

Owner:DUPLUS CHEM OF ZHANGJIAGANG CITY

Environment-friendly type synthetic tannin color fixing agent as well as preparation method and application thereof

The invention discloses an environment-friendly type synthetic tannin color fixing agent as well as a preparation method and application thereof. The color fixing agent is a synthetic tannin color fixing agent prepared from the following raw materials in percentage by mass: 15-30% of a phenol compound, 10-30% of an aromatic sulfonic acid compound, 1-5% of a catalyst, 5-15% of a formaldehyde solution, 0.5-2% of a chelating agent, 0.5-3% of a modifier, 1-4% of a dispersant and the balance of water. When being applied to color fixation of chinlon and blended fabrics, the synthetic tannin color fixing agent disclosed by the invention has the advantages of being good in acid resistance stability, small in color change, good in color fastness, and the like.

Owner:东莞市中纺化工有限公司 +1

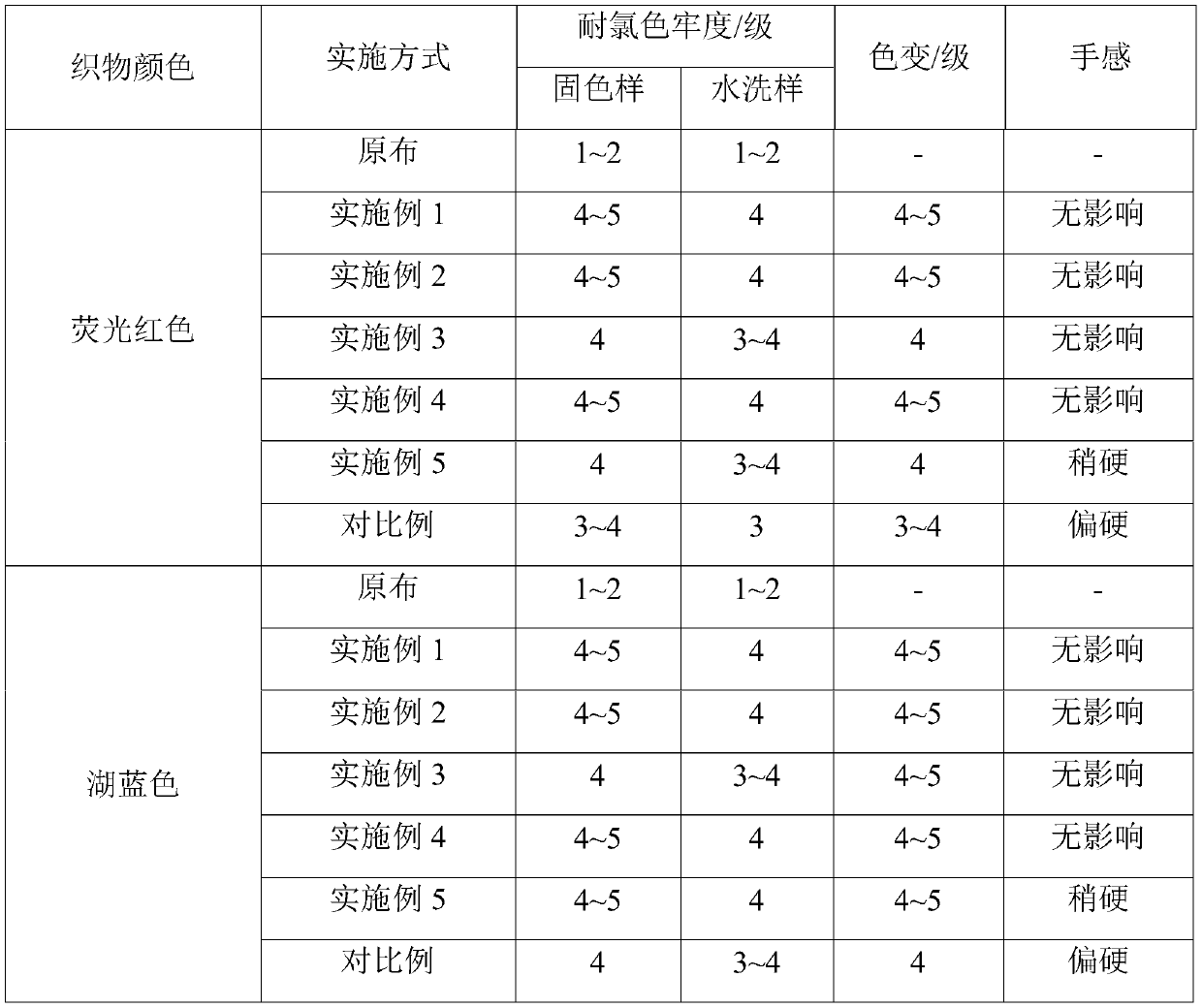

Environment-friendly chlorine-resistant color fixing agent, and preparation method and application thereof

PendingCN110735338AImprove color fastness to chlorine waterAvoid destructionDyeing processFunctional monomerDye molecule

The invention discloses an environment-friendly chlorine-resistant color fixing agent, and a preparation method and application thereof. The chlorine-resistant color fixing agent comprises, by mass, 35-40% of chlorine-resistant intermediates, 0.1-1.0% of chelating agent, 0.5-5% of deoxidants and the balance of water. Proper functional monomers having high reactive activity with chlorine are selected and then composited into the chlorine-resistant color fixing agent, the environment-friendly chlorine-resistant color fixing agent reacts with active chlorine preferentially, damage of the active chlorine to a dye molecule color development system is reduced, and accordingly, the chlorine water resistance and color fastness of dyed textiles are improved.

Owner:东莞市中纺化工有限公司

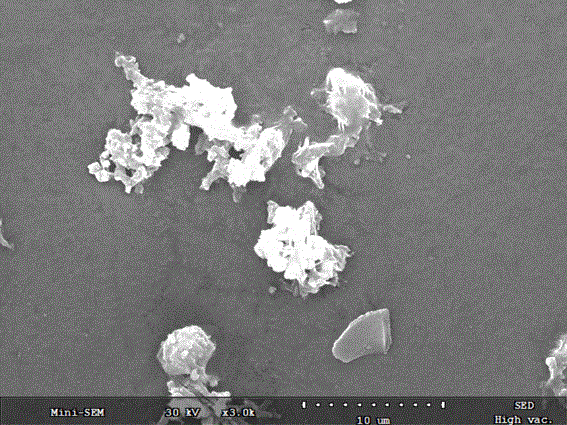

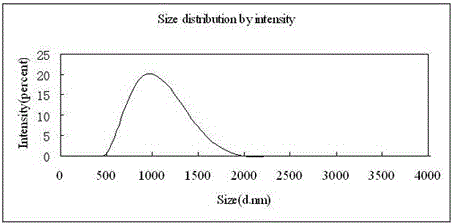

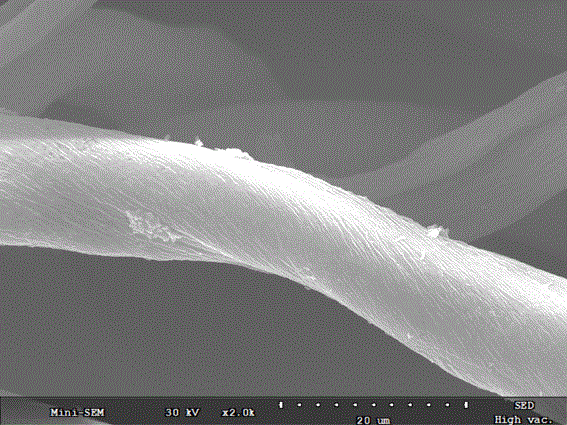

Preparation method and apparition of wet rubbing fastness improver containing copper microcapsules

The invention relates to a preparation method and an apparition of a wet rubbing fastness improver containing copper microcapsules. The preparation method comprises the following steps: (1), silane modified ultrafine copper nanopowder is prepared; (2), the ultrafine copper nanopowder is ground and dried to constant weight; (3), the dried ultrafine copper nanopowder, 2,2'-azodiisobutyronitrile, divinyl benzene, butyl acrylate, methyl methacrylate and distilled water are mixed uniformly, tricalcium phosphate is added, and the mixture is subjected to ultrasonic vibration to obtain a dispersing liquid; (4) the dispersing liquid is placed into a flask with four necks to be subjected to heating, micro-suspension polymerization, heating and curing, and a product is washed with excessive hydrochloric acid solution and then washed to neutral to obtain the wet rubbing fastness improver containing the copper microcapsules. The prepared wet rubbing fastness improver containing the copper microcapsules can improve the wearability of fabric dyed with reactive dye, and the preparation method has the characteristics of simplicity, low cost, little time and labor investment, low toxicity of synthetic raw materials and reduction of environmental pollution.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

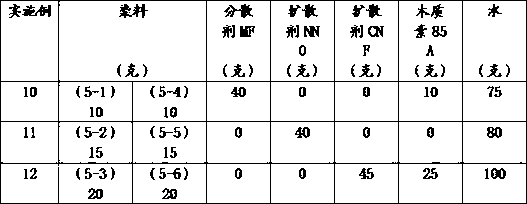

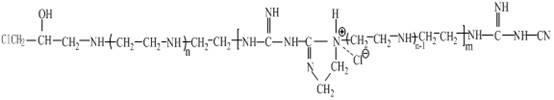

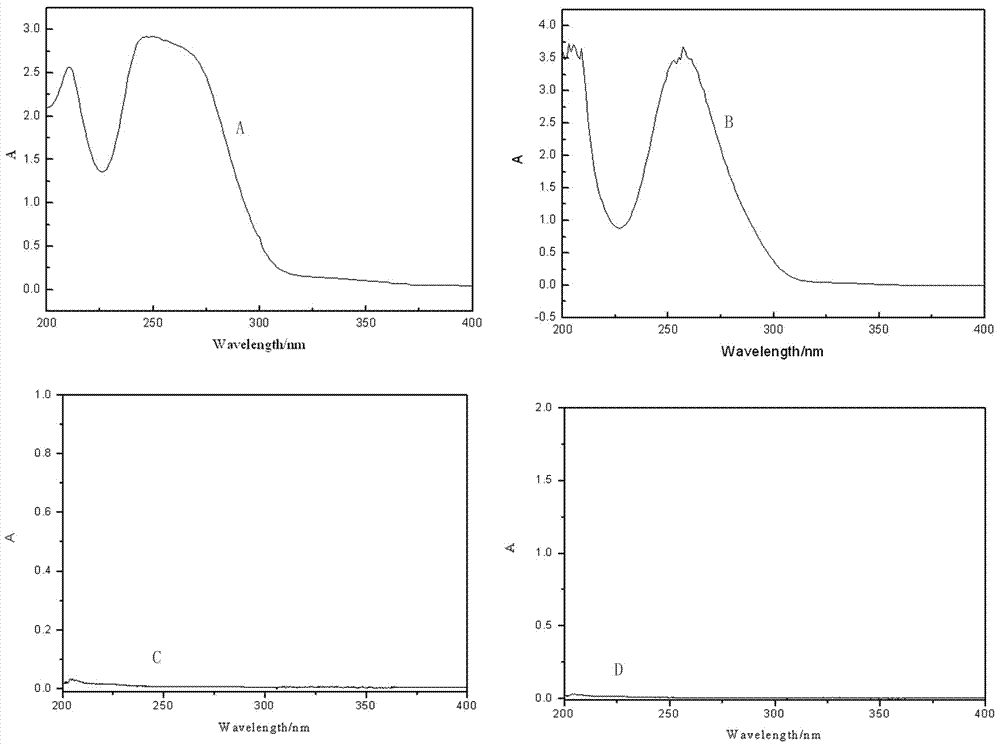

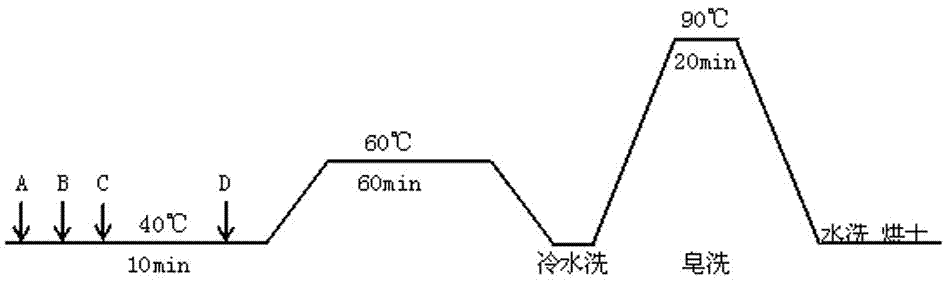

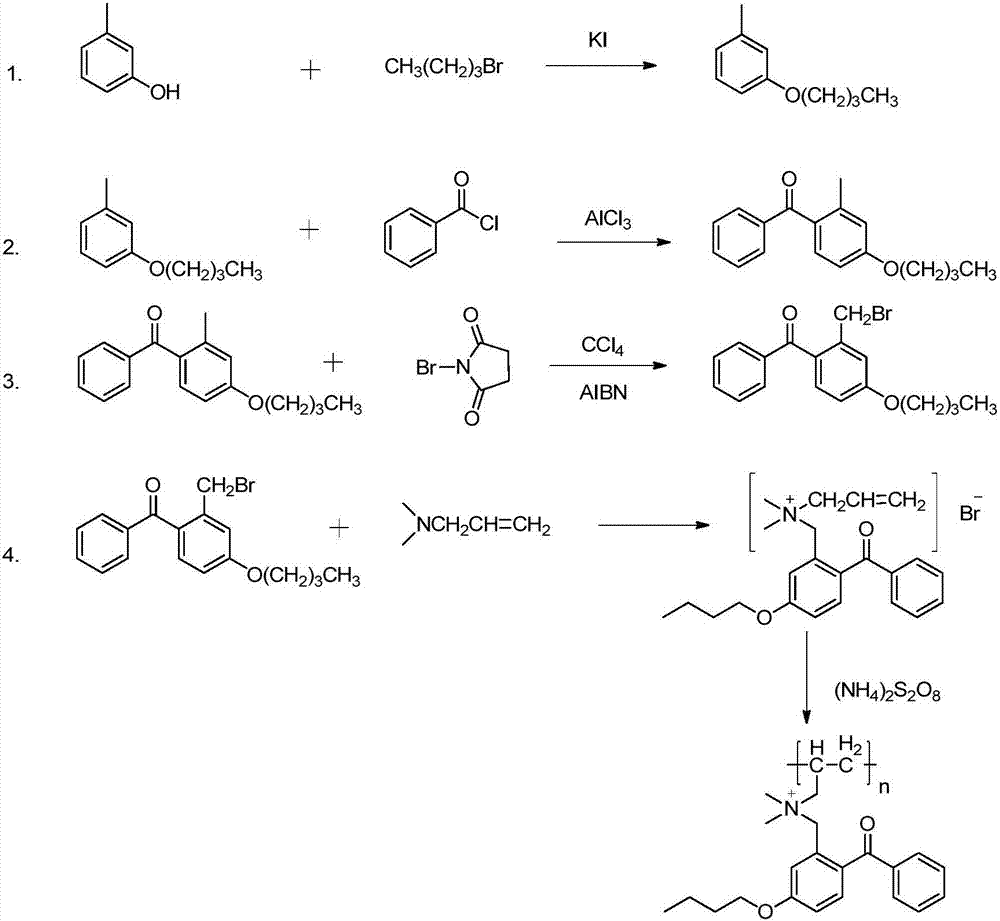

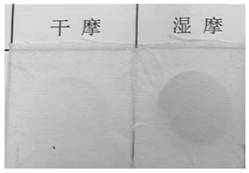

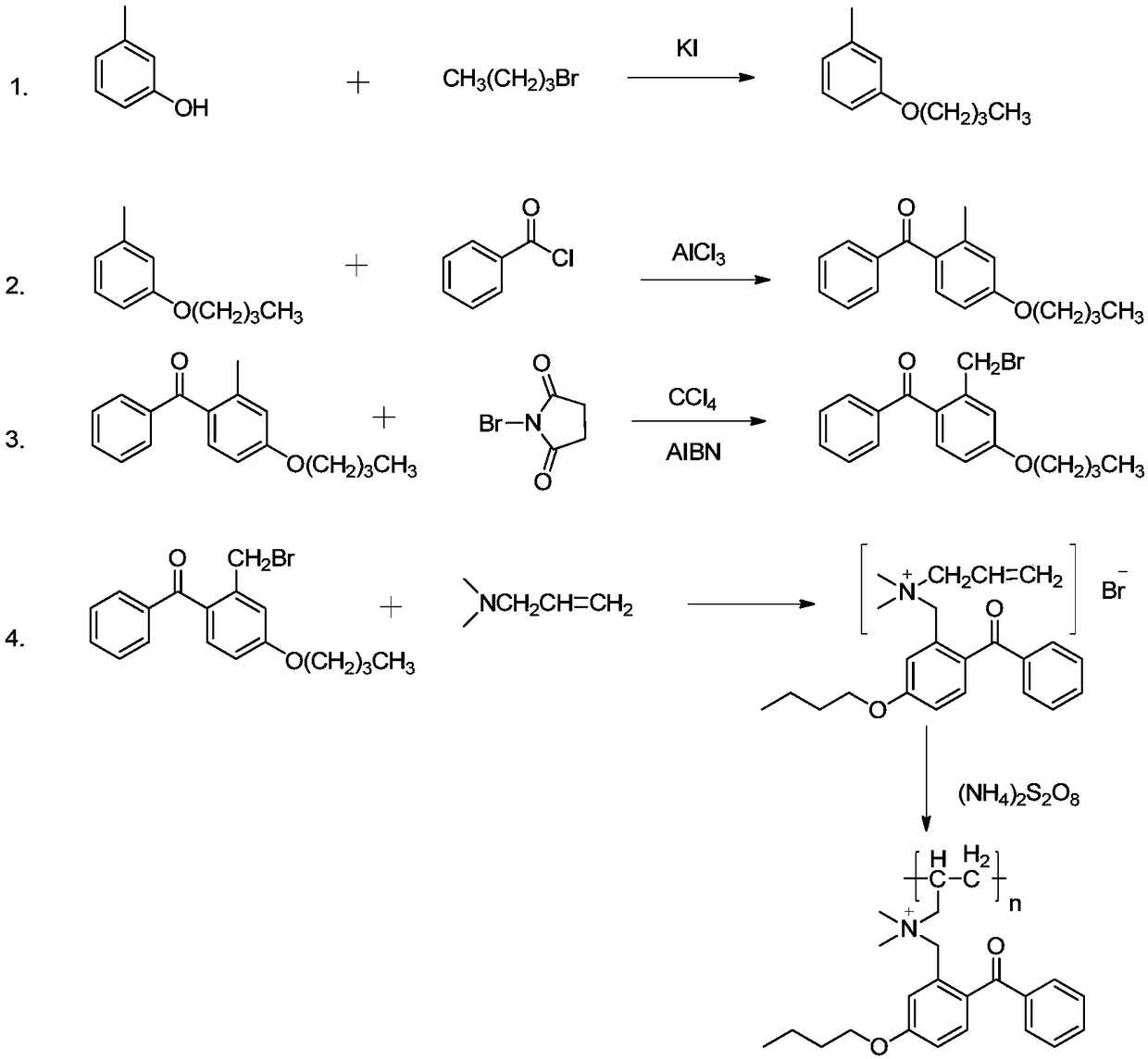

Poly-dimethylallyl (2-benzoyl-5-n-butoxypolyethylene phenyl) ammonium bromide synthesis method and dye-fixing agent

The invention discloses a poly-dimethylallyl (2-benzoyl-5-n-butoxypolyethylene phenyl) ammonium bromide synthesis method and a dye-fixing agent. According to the method, a molecule is acquired by the aid of a chemical synthesis mode and contains reactive groups, quaternary ammonium salt groups, ultraviolet absorbing groups, benzophenone groups and double-bond groups, the double-bond groups are polymerized to obtain a macromolecular compound containing more than two functional groups, a structure of a synthesis substance is represented, and the macromolecular compound is used for the dye-fixing agent (dyeing and finishing additive) of reaction dye dyeing processes. The dye-fixing agent saves energy, reduces emission and consumption on section of dye-fixing processes, sunlight fastness and ultraviolet protection factors of dyed fabrics can be improved, a common commodity dye-fixing agent does not have the performance, the comprehensive dye-fixing effect of the dye-fixing agent reaches or is superior to that of the commodity dye-fixing agent, so that the dye-fixing agent has high practical values and can be effectively applied to enterprise production.

Owner:周口科技职业学院

A preparing method of a sensitive color fixing agent and the fixing agent

InactiveCN106948196AHigh color fastnessImprove dry and wet rubbing fastnessDyeing processFixative/StainChemistry

A preparing method of a sensitive color fixing agent and the fixing agent are disclosed. During preparation, methyl ethyl ketone peroxide and a 6-hydroxy-2-naphthoic acid solution are mixed, heated and stirred; dimethylformamide is added into the mixture; the mixture is heated and stirred; then a tris(nonylphenyl)phosphite solution is added into the mixture; and the mixture is stirred at 110-112 DEG C for 20-25 min, then stirred at 65-70 DEG C for 50-55 min and cooled to room temperature to obtain the fixing agent. Under interactions of raw materials, the fixing agent has advantages of high dyeing fastness, capability of significantly increasing dry and wet rubbing fastness and water-washing color fastness, and the like. Hue changes do not occur substantially during color fixing of dye for sensitive colors such as turquoise blue and cobalt blue. The fixing agent is free of formaldehyde and is environmentally friendly. A production process is simple. The fixing agent does not influence chlorine fastness, light fastness or perspiration fastness of dyed fabrics, influences of color fixing treatment on fabrics by the fixing agent are low, and chromatic aberration can be controlled to be the 4-5 level. Treated fabrics have good color fixing effects and an influence on hand feeling is low.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

Fabric color fixing agent

ActiveCN104179044AGood color fixing effectShade effect is smallDyeing processDistilled waterEngineering

The invention provides a fabric color fixing agent. The fabric color fixing agent consists of the following components in parts by weight: 4-6 parts of sodium silicate, 8-10 parts of epichlorohydrin, 9-11 parts of acryloyl chloride, 2-3 parts of octadecyl dimethyl amine and 30-35 parts of distilled water. The invention also provides a preparation method of the fabric color fixing agent. The preparation method comprises the following steps: mixing sodium silicate, epichlorohydrin and distilled water according to a mixing ratio, slowly heating to 50-55 DEG C under a stirring condition, adding acryloyl chloride and octadecyl dimethyl amine according to a mixing ratio, heating to 60-65 DEG C, stirring for 2-3 hours, and cooling to normal temperature, thereby obtaining the fabric color fixing agent. Compared with the prior art, the fabric color fixing agent has a very good color fixing effect on the dyed wool fabric and just slightly affects the shade of the fabric.

Owner:汕头市澄海区瑞胜毛织有限公司

Dyeing substitution alkali for cellulose fiber reactive dyes

The invention discloses dyeing substitution alkali for cellulose fiber reactive dyes. The dyeing substitution alkali comprises sodium bicarbonate, sodium hydroxide, borax and sodium acetate. The dyeing substitution alkali disclosed by the invention can enable the dye to dye uniformly, the obtained color is deeper, the color fastness after dyeing is better, and the influence on color light is smaller.

Owner:SUZHOU INST OF TRADE & COMMERCE

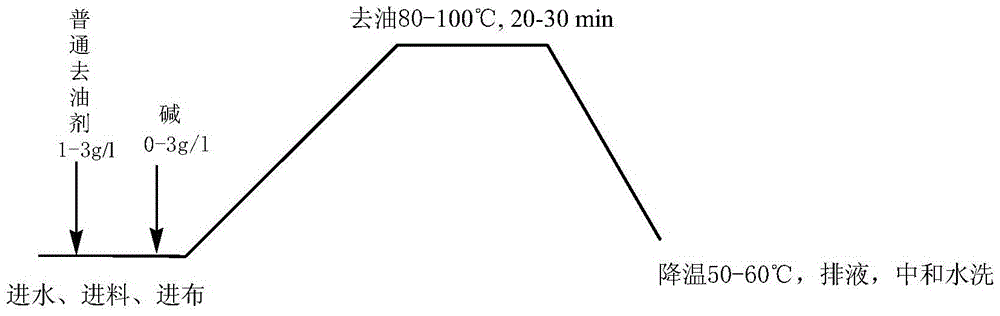

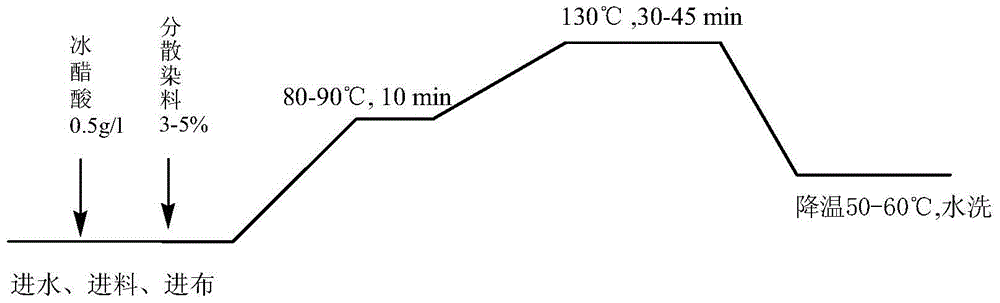

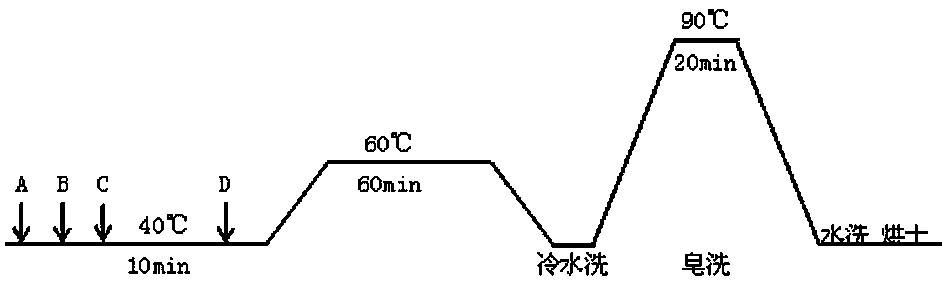

Method for improving color fastness of polyester cotton

The invention discloses a method for improving color fastness of polyester cotton. The method comprises the following steps of polyester dyeing, acid reduction, cotton dyeing, soaping, vat discharging, dewatering, scutching and setting. A novel polyester soaping agent is adopted to replace a traditional polyester cotton two-bath soaping method, so that reduction cleaning is omitted, soaping after cotton dyeing is only needed, water and energy are saved, and environment friendliness is achieved; disperse dye floating color attached to polyester and cotton fibers can be efficiently removed by using the novel soaping agent for soaping after cotton dyeing, so that various fastness such as soaping fastness and friction fastness can be improved; and the novel soaping agent can tolerate an anhydrous sodium sulphate aqueous solution and a sodium carbonate aqueous solution with relatively high concentrations, has good chelating property on metal ions, does not belong to dangerous goods, does not have potential safety hazards such as flammable and explosive properties, does not contain prohibited substances such as APEO, is environment-friendly, greatly improves the production efficiency, and realizes energy conservation and emission reduction.

Owner:JIHUA 3543 KNITTING CLOTHING

Preparing method of novel acidic dye-fixing agent for seamless underwear and prepared dye-fixing agent

ActiveCN106544905AImprove color fixationStrong alkali resistance and high temperature resistanceDyeing processAlcoholDibutyltin oxide

The invention discloses a preparing method of a novel acidic dye-fixing agent for seamless underwear and the prepared dye-fixing agent. The preparing method comprises the steps of mixing bisphenol S, dibutyltin oxide and an alkanolamide solution, conducting heating and stirring processing on the mixture, then adding hexamethyldisilazane into the mixture, and conducting cooling and stirring processing on the mixture, wherein the mass ratio of bisphenol S to dibutylin oxide to hexamethyldisilazane is (28-36):(1-5):(5-13) and the volume ratio of hexamethyldisilazane to the alkanolamide solution is 1:(6-8); adding a citric acid solution into the mixture, and stirring the mixture at the temperature of 62 DEG C, wherein the volume ratio of hexamethyldisilazane to the citric acid solution is 1:(15-17); dropwise adding an isomeric alcohol ethoxylate solution into the mixture, conducting stirring processing on the mixture at the temperature of 55 DEG C, and lowering the temperature to a normal temperature so as to obtain the novel acidic dye-fixing agent. According to the preparing method of the novel acidic dye-fixing agent for seamless underwear and the prepared dye-fixing agent, the dye-fixing agent is free of formaldehyde, excellent in color fixation effect, and very strong in alkali resistance and high temperature resistance; the dye-fixing agent has no influence on bright hues of reactive dyes; the dye-fixing agent is free of color change, has no influence on chlorine fastness, light fastness and perspiration fastness of dye materials, is green and environmentally friendly, and is suitable for industrialized production.

Owner:江西德盛精细化学品有限公司

Formaldehyde-free color-fixing agent of active dye

The invention discloses a formaldehyde-free color-fixing agent of an active dye, which is prepared with 2-4 compounds. The formaldehyde-free color-fixing agent comprises a reactive functional group, has high cationic performance, and can effectively improve the dry rubbing fastness, wet rubbing fastness, color fastness to washing of the fabric dyed with the active dye. Moreover, the formaldehyde-free color-fixing agent has little effect on the color light of the fabric.

Owner:SUZHOU UNIV

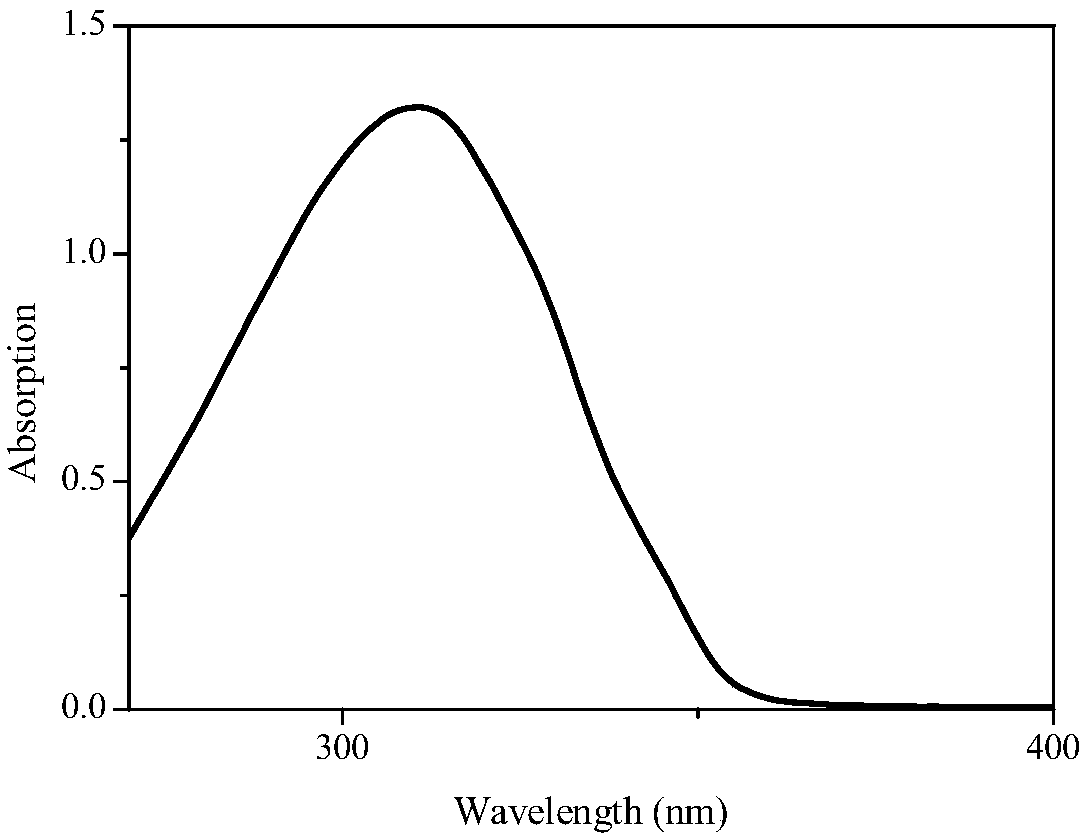

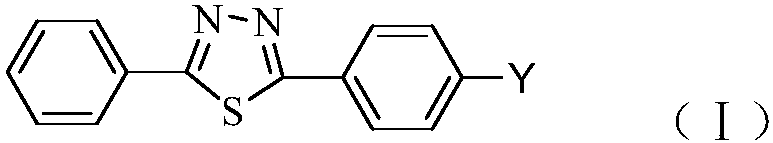

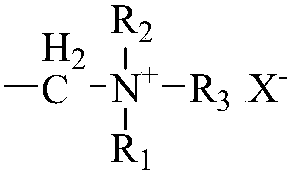

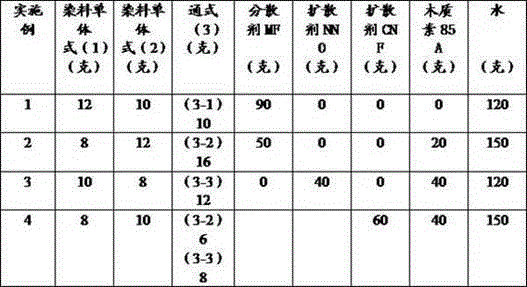

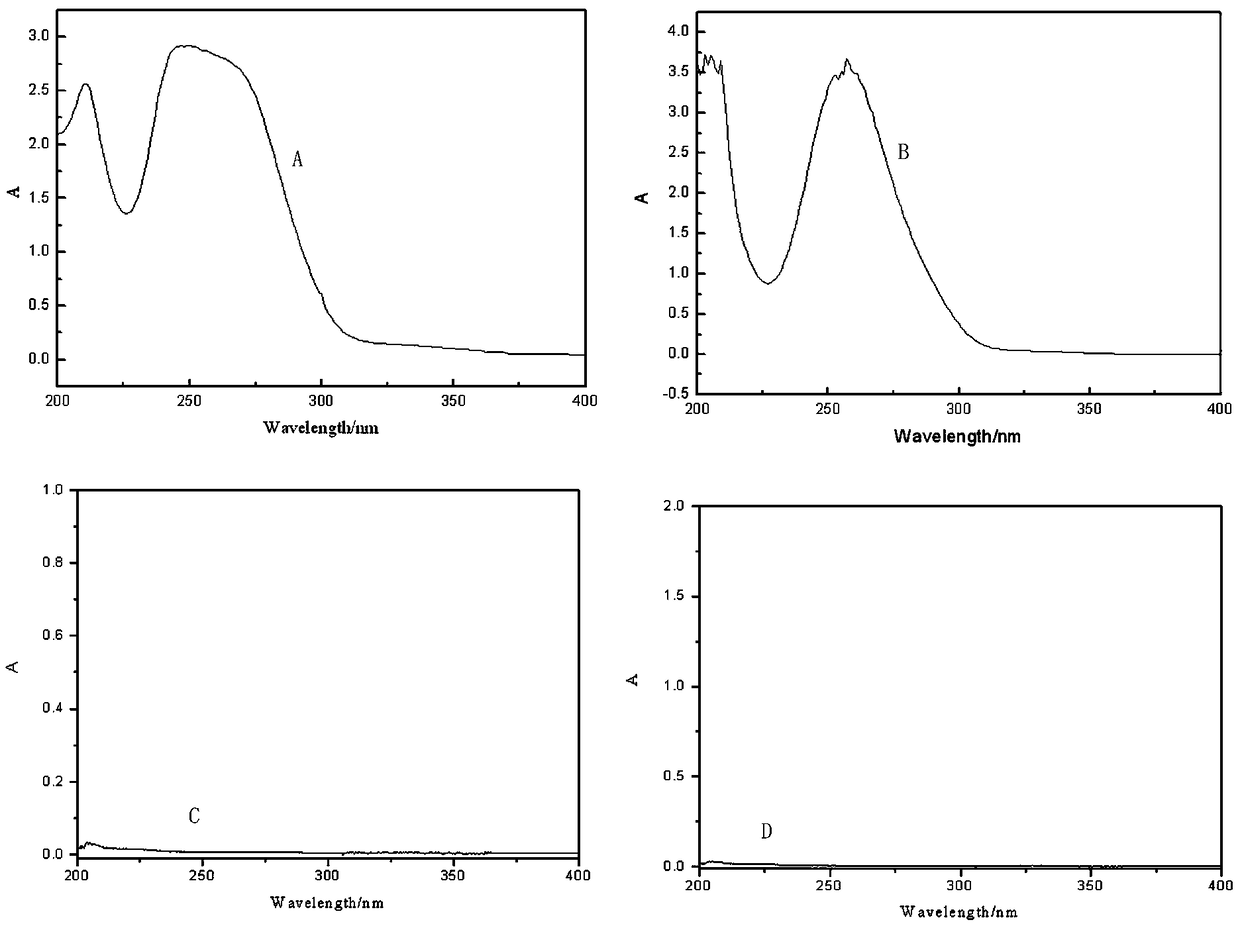

A kind of preparation method and application of multifunctional ultraviolet absorber

ActiveCN106543098BStrong absorption capacityShade effect is smallOrganic chemistryFibre typesDisperse dyeEscherichia coli

The invention relates to a preparation method and application of a multifunctional ultraviolet absorbent for terylene. The general structural formula of the absorbent is as follows: formula, wherein Y is a quaternary ammonium salt group. According to the preparation method and application of the multifunctional ultraviolet absorbent for terylene disclosed by the invention, the dyeing mode of the ultraviolet absorbent to terylene is similar to disperse dyes, and fabrics can be subjected to anti-ultraviolet finishing by using a high-temperature and high-pressure exhausting method and can also be dyed with the disperse dyes in the same bath; the finished fabrics not only have good anti-ultraviolet properties, but also have the effects of killing or inhibiting Gram-positive bacteria and Gram-negative bacteria represented by staphylococcus aureus and Escherichia coli; and meanwhile, the fabrics have good anti-static function.

Owner:CHANGZHOU UNIV

A group of medium temperature three primary color disperse dyes

ActiveCN103073918BGood sublimation fastnessEasy to liftOrganic dyesDyeing processEnvironmental resistanceDisperse dye

The invention discloses a group of medium temperature type three-primary-color disperse dyes. A yellow disperse dye is a mixture formed by 5-20 % of compound shown by a chemical formula (1), 5-40 % of compound shown by a chemical formula (2) and 5-40 % of compound shown by a chemical general formula (3) in percentage by weight; a red disperse dye comprises one or more monomers in a compound shown by a chemical general formula (4); and a blue disperse dye comprises one or more monomers in a compound shown by a chemical general formula (5). The medium temperature type three-primary-color disperse dyes disclosed by the invention have the advantages as follows: medium temperature type three primary colors beautiful in colored lights and high in intensities; the colored lights of the medium temperature type three primary colors are similar to the original three primary colors; the medium temperature type three-primary-color disperse dyes have the advantages of perfect compatibility, high lifting force, distillation, excellent fastness and the like during dyeing and are a group of medium temperature type three-primary-color disperse dyes with excellent comprehensive performances.

Owner:JIANGSU YABANG DYE

Environment-friendly non-ionic surfactant for high-temperature level dyeing of superfine fiber fabric

The invention discloses an environment-friendly non-ionic surfactant for high-temperature level dyeing of a superfine fiber fabric. The surfactant is prepared from the following components in parts by weight of 10 to 20 parts of dimethyl diallyl ammonium chloride, 4 to 10 parts of xylanase, 3 to 9 parts of JFC, 2 to 6 parts of Bugong tea saponin, 4 to 8 parts of poly(acrylamide-co-diallyl dimethyl ammonium chloride), 2 to 6 parts of graphene oxide, 4 to 8 parts of sodium potassium tartrate, 6 to 12 parts of N-alkyl betaine and 8 to 14 parts of deionized water. The preparation process is simple, the prepared surfactant can be used for an optimized modification process of the superfine fiber fabric, the dye uptake is greatly improved, the dyeing wastewater amount is reduced, and the environment is protected.

Owner:南通宏申化工有限公司

A preparation method of an acidic color-fixing agent for seamless underwear and the prepared color-fixing agent

ActiveCN106544905BImprove color fixationStrong alkali resistance and high temperature resistanceDyeing processAlcoholDibutyltin oxide

The invention discloses a preparing method of a novel acidic dye-fixing agent for seamless underwear and the prepared dye-fixing agent. The preparing method comprises the steps of mixing bisphenol S, dibutyltin oxide and an alkanolamide solution, conducting heating and stirring processing on the mixture, then adding hexamethyldisilazane into the mixture, and conducting cooling and stirring processing on the mixture, wherein the mass ratio of bisphenol S to dibutylin oxide to hexamethyldisilazane is (28-36):(1-5):(5-13) and the volume ratio of hexamethyldisilazane to the alkanolamide solution is 1:(6-8); adding a citric acid solution into the mixture, and stirring the mixture at the temperature of 62 DEG C, wherein the volume ratio of hexamethyldisilazane to the citric acid solution is 1:(15-17); dropwise adding an isomeric alcohol ethoxylate solution into the mixture, conducting stirring processing on the mixture at the temperature of 55 DEG C, and lowering the temperature to a normal temperature so as to obtain the novel acidic dye-fixing agent. According to the preparing method of the novel acidic dye-fixing agent for seamless underwear and the prepared dye-fixing agent, the dye-fixing agent is free of formaldehyde, excellent in color fixation effect, and very strong in alkali resistance and high temperature resistance; the dye-fixing agent has no influence on bright hues of reactive dyes; the dye-fixing agent is free of color change, has no influence on chlorine fastness, light fastness and perspiration fastness of dye materials, is green and environmentally friendly, and is suitable for industrialized production.

Owner:江西德盛精细化学品有限公司

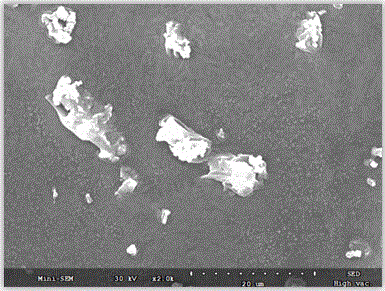

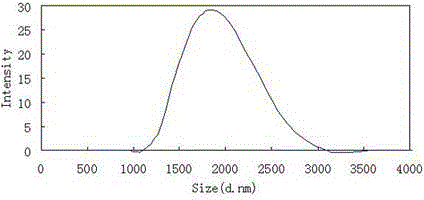

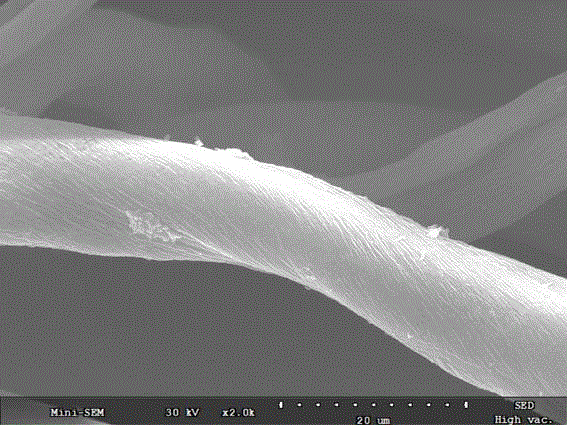

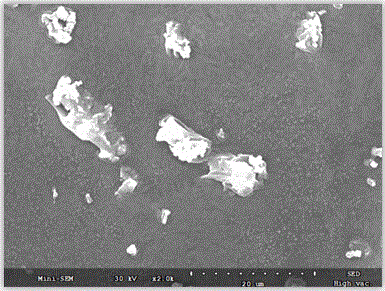

Preparation method and application of copper microcapsule wet rubbing fastness improving agent

The invention relates to a preparation method and an apparition of a wet rubbing fastness improver containing copper microcapsules. The preparation method comprises the following steps: (1), silane modified ultrafine copper nanopowder is prepared; (2), the ultrafine copper nanopowder is ground and dried to constant weight; (3), the dried ultrafine copper nanopowder, 2,2'-azodiisobutyronitrile, divinyl benzene, butyl acrylate, methyl methacrylate and distilled water are mixed uniformly, tricalcium phosphate is added, and the mixture is subjected to ultrasonic vibration to obtain a dispersing liquid; (4) the dispersing liquid is placed into a flask with four necks to be subjected to heating, micro-suspension polymerization, heating and curing, and a product is washed with excessive hydrochloric acid solution and then washed to neutral to obtain the wet rubbing fastness improver containing the copper microcapsules. The prepared wet rubbing fastness improver containing the copper microcapsules can improve the wearability of fabric dyed with reactive dye, and the preparation method has the characteristics of simplicity, low cost, little time and labor investment, low toxicity of synthetic raw materials and reduction of environmental pollution.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

A kind of environment-friendly synthetic tannin fixing agent and its preparation method and application

ActiveCN108442150BGood stability in hard waterNo condensationDyeing processColour fastnessPtru catalyst

The invention discloses an environment-friendly type synthetic tannin color fixing agent as well as a preparation method and application thereof. The color fixing agent is a synthetic tannin color fixing agent prepared from the following raw materials in percentage by mass: 15-30% of a phenol compound, 10-30% of an aromatic sulfonic acid compound, 1-5% of a catalyst, 5-15% of a formaldehyde solution, 0.5-2% of a chelating agent, 0.5-3% of a modifier, 1-4% of a dispersant and the balance of water. When being applied to color fixation of chinlon and blended fabrics, the synthetic tannin color fixing agent disclosed by the invention has the advantages of being good in acid resistance stability, small in color change, good in color fastness, and the like.

Owner:东莞市中纺化工有限公司 +1

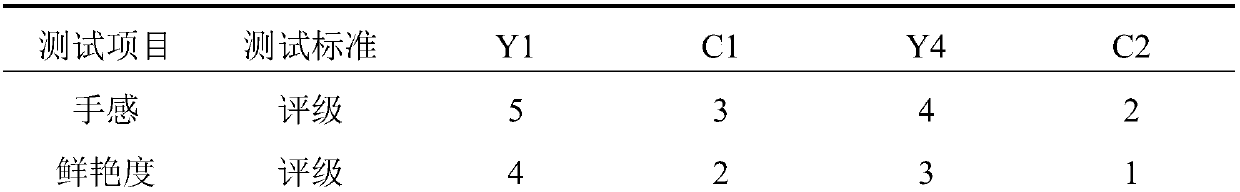

Yilun printed fabric and its printing method

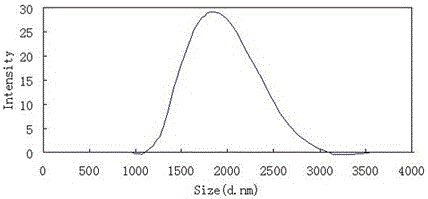

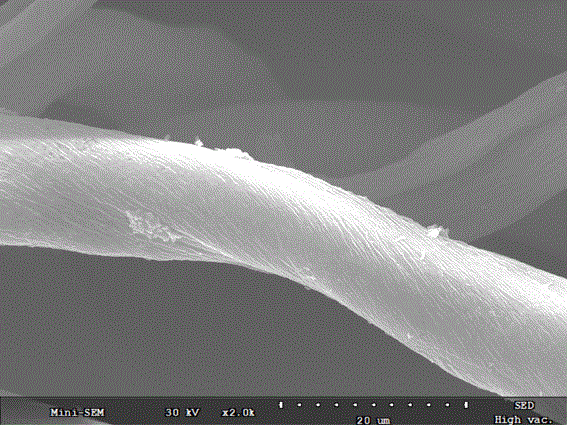

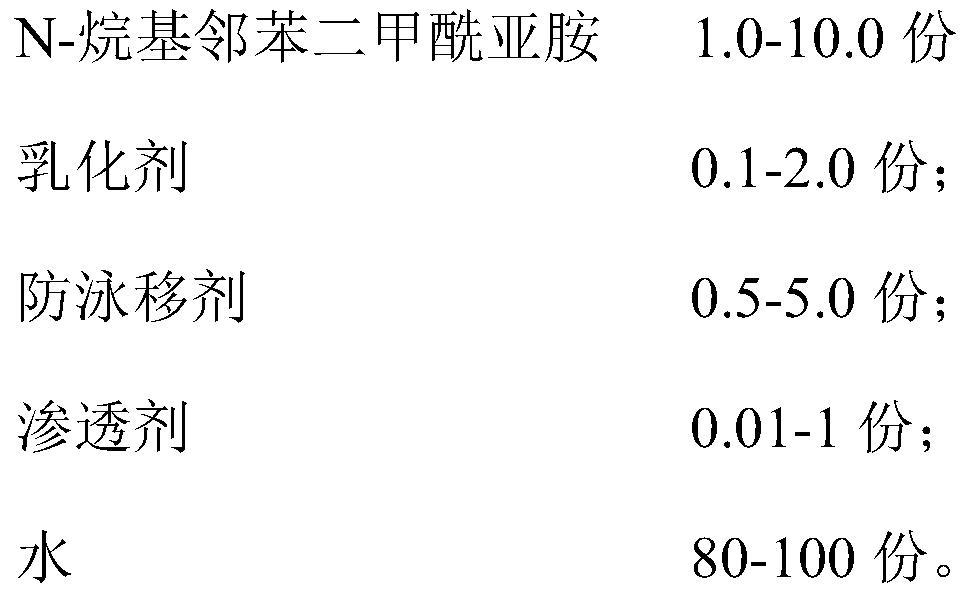

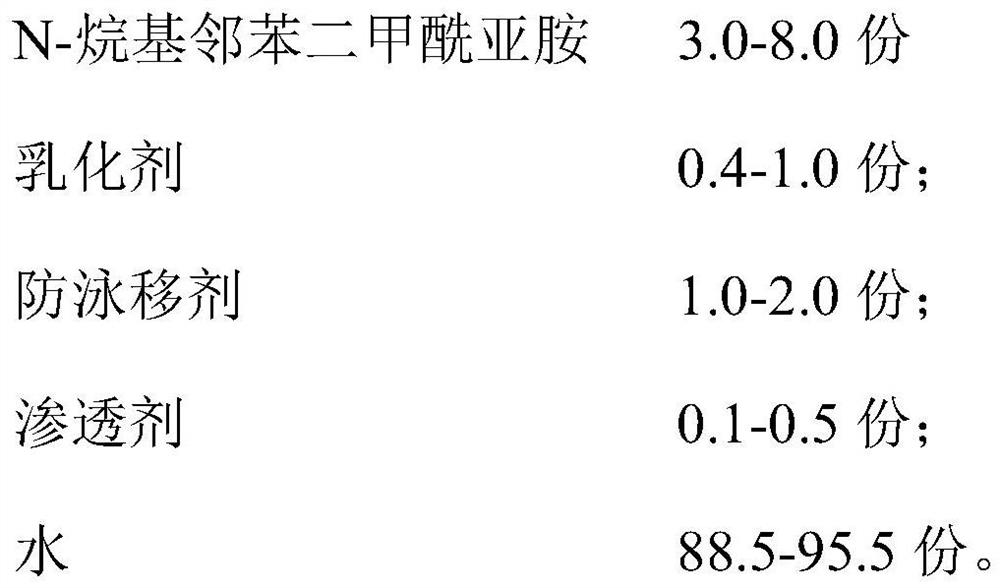

The invention relates to a Yilun printed fabric and a printing method thereof. The printing method includes the following steps: arranging the Yilun gray cloth in the pretreatment solution for padding, taking it out and drying it; adopting the printing method of thermal sublimation transfer printing to print the dried Yilun gray cloth, the The transfer temperature in thermal sublimation transfer printing is 160°C-175°C; the gray cloth after printing is subjected to reduction cleaning, color fixation and baking to obtain it; the pretreatment liquid contains the following components in parts by weight: N ‑Alkyl phthalimide 1.0‑10.0 parts; emulsifier 0.1‑2.0 parts; anti-migration agent 0.5‑5.0 parts; penetrant 0.01‑1 part; water 80‑100 parts. The invention breaks through the limitation that Yilun fabric cannot be digitally printed with disperse dye ink and then heat transferred due to the limitation of temperature. The color fastness and color depth of printing can meet the high-end needs of the market.

Owner:广东康派环创科技有限公司

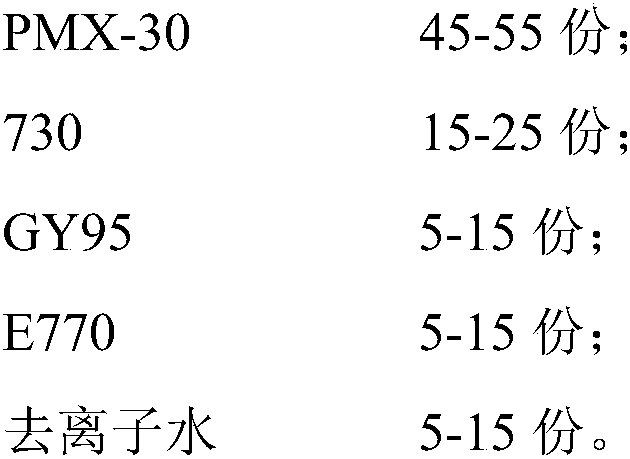

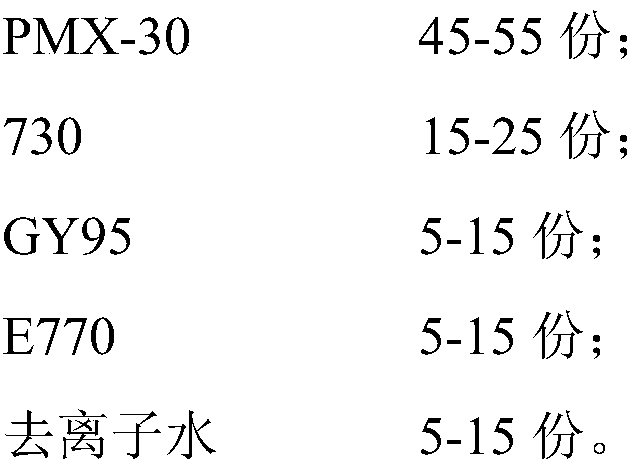

All-around brightener for denim fabric as well as preparation method and application of all-around brightener

ActiveCN109537293AImprove brightening effectHigh glossGrip property fibresTextile treatment by spraying/projectingWaxWater based

The invention relates to an all-around brightener for denim fabric as well as a preparation method and application of the all-around brightener. The all-around brightener is prepared from the following components and content: 45 to 55 parts of dimethyl silicone oil emulsion PMX-30, 15 to 25 parts of block silicone emulsion 730, 5 to 15 parts of glycerol GY95, 5 to 15 parts of water-based wax emulsion E770 and 5 to 15 parts of deionized water. The all-around brightener for the denim fabric is prepared by uniformly stirring raw materials, heating, filtering with a filter screen and discharging.Compared with the prior art, the all-around brightener provided by the invention is fluffier, softer and slipperier, darker and clearer in luster, and does not stick to hands after drying. The denim fabric treated by the all-around brightener has higher elasticity and tensile strength; in addition, the all-around brightener can be diluted with normal temperature water before being used, so the operation is simpler and more energy-saving.

Owner:FIBER CHEM BIOLOGICAL CHEM

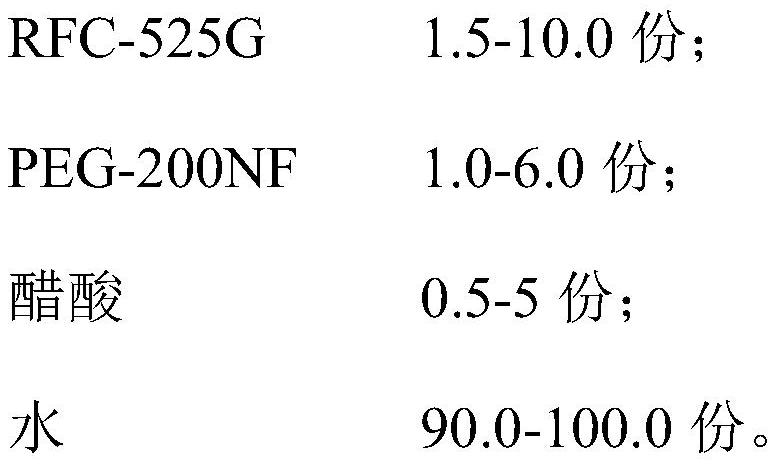

A kind of preparation method of environment-friendly acid dye fixing agent

ActiveCN103497286BImprove color fixationNot easy to fadeDyeing processPotassium persulfateAcetic acid

The invention discloses a preparation method of an environment-friendly acidic dye fixing agent. The method comprises the steps that: 1.5 parts of a dimethylamine aqueous solution is added into a four-neck reaction flask; nitrogen is delivered in for protection; stirring is started, and the temperature is increased to 30 DEG C; an epichlorohydrin solution is started to be dropped; dropping is finished within 1h, and the temperature is controlled at 55-60 DEG C; when epichlorohydrin adding is finished, a reaction is allowed for 2h under maintained temperature; 1.5 parts of butyl acrylate and 0.1 parts of a 30% potassium persulfate solution are dropped within 1h; the temperature is controlled at 80 (+ / - 3) DEG C, and a reaction is allowed for 3h; 1 part of a methacrylic acid solution is dropped within 1h; a reaction is allowed for 3h under a temperature of 85 (+ / -3) DEG C; the product is cooled to room temperature; and the pH value is regulated to 5-6 by using acetic acid, such that a light yellow transparent liquid is obtained. With the technical scheme provided by the invention, the process is easy to apply in production. After treatment, silk fabric has good color fixing effect, and is prevented from fading after washing.

Owner:GUANGDONG ZHAN FENG FINE CHEM CO LTD

A kind of preparation method and application of ecological copper wet rubbing fastness improving agent

ActiveCN104844756BImprove stabilityLow toxicityDyeing processVegetal fibresWater bathsPotassium persulfate

The invention relates to a preparation method and the application of an ecological copper wet rubbing fastness improver. The method comprises the following steps: (1) preparing copper superfine powder modified by C12 alkyl sulfonate; (2) grinding and drying the copper nano superfine powder until the weight is constant; (3) uniformly mixing the dried copper superfine powder with butyl acrylate, methyl methacrylate and emulsifier n-hexadecane, adding a sodium dodecyl benzene sulfonate emulsifier water solution, uniformly stirring, and then performing ultrasonic dispersion in a water bath with the temperature of 0-4 DEG C for 200s to obtain a corresponding emulsion; (4) putting the emulsion into a four-neck flask, raising the temperature to 70 DEG C, adding a potassium persulfate initiator, and then reacting for 5-6 hours to obtain the ecological copper micro-capsule type wet rubbing fastness improver. The wearability of reactive dyeing fabric is improved, and the method has the characteristics that the method is simple, the cost is low, the time input and the human input are low, synthetic raw materials are low in toxicity, and the environmental pollution is reduced.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

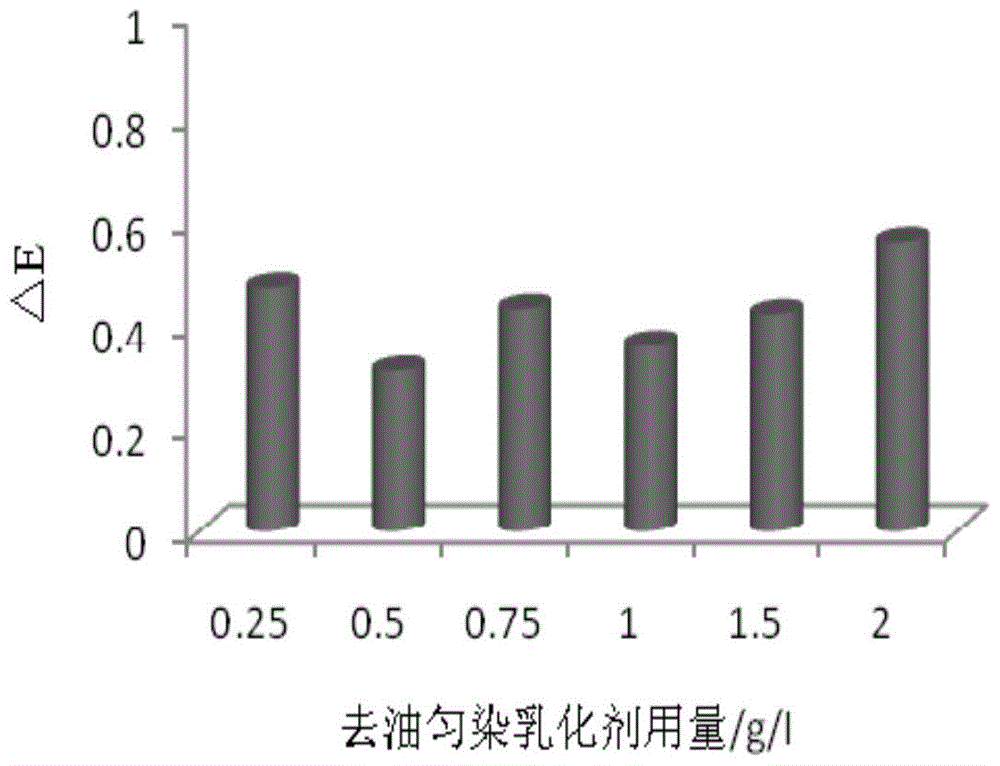

A kind of degreasing and leveling compound emulsifier and its application

ActiveCN104674574BShade effect is smallReduce surface tensionDyeing processPentaerythritolCis-Butenedioic Acid

Owner:传化智联股份有限公司 +1

A fabric fixative

ActiveCN104179044BGood color fixing effectShade effect is smallDyeing processPolymer scienceDistilled water

The invention provides a fabric color fixing agent. The fabric color fixing agent consists of the following components in parts by weight: 4-6 parts of sodium silicate, 8-10 parts of epichlorohydrin, 9-11 parts of acryloyl chloride, 2-3 parts of octadecyl dimethyl amine and 30-35 parts of distilled water. The invention also provides a preparation method of the fabric color fixing agent. The preparation method comprises the following steps: mixing sodium silicate, epichlorohydrin and distilled water according to a mixing ratio, slowly heating to 50-55 DEG C under a stirring condition, adding acryloyl chloride and octadecyl dimethyl amine according to a mixing ratio, heating to 60-65 DEG C, stirring for 2-3 hours, and cooling to normal temperature, thereby obtaining the fabric color fixing agent. Compared with the prior art, the fabric color fixing agent has a very good color fixing effect on the dyed wool fabric and just slightly affects the shade of the fabric.

Owner:汕头市澄海区瑞胜毛织有限公司

Synthetic method and color-fixing agent of polydimethylallyl (2-benzoyl-5-n-butoxyphenyl) ammonium bromide

The invention discloses a poly-dimethylallyl (2-benzoyl-5-n-butoxypolyethylene phenyl) ammonium bromide synthesis method and a dye-fixing agent. According to the method, a molecule is acquired by the aid of a chemical synthesis mode and contains reactive groups, quaternary ammonium salt groups, ultraviolet absorbing groups, benzophenone groups and double-bond groups, the double-bond groups are polymerized to obtain a macromolecular compound containing more than two functional groups, a structure of a synthesis substance is represented, and the macromolecular compound is used for the dye-fixing agent (dyeing and finishing additive) of reaction dye dyeing processes. The dye-fixing agent saves energy, reduces emission and consumption on section of dye-fixing processes, sunlight fastness and ultraviolet protection factors of dyed fabrics can be improved, a common commodity dye-fixing agent does not have the performance, the comprehensive dye-fixing effect of the dye-fixing agent reaches or is superior to that of the commodity dye-fixing agent, so that the dye-fixing agent has high practical values and can be effectively applied to enterprise production.

Owner:周口科技职业学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com