A kind of preparation method and application of ecological copper wet rubbing fastness improving agent

A technology of wet rubbing fastness and improving agent, which is applied in the field of preparation of wet rubbing fastness improving agent, can solve the problems of low rubbing fastness, high production cost, dye falling off on fabrics, etc., achieve less time and manpower input, improve Consumption performance, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation and application of the ecological copper wet rubbing fastness improving agent of present embodiment 1 may further comprise the steps:

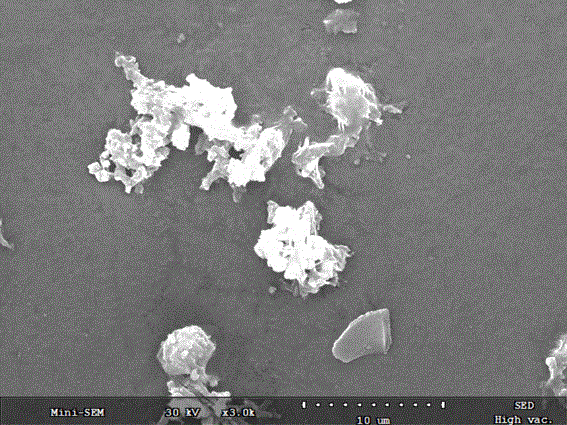

[0027] (1) Weigh 200mL of 0.05mol / L sodium dodecylsulfonate into a four-neck flask, add 17.6gL-ascorbic acid and stir thoroughly (stirring speed 500 rpm) and raise the temperature to 80°C, measure 0.5mol / L Put 200mL of copper sulfate pentahydrate in a separatory funnel, add all drops at a rate of 60 drops per minute at 80°C and continue to stir for 3 hours. After cooling down, 7g of reddish-brown copper ultrafine powder is obtained. All drugs in this reaction are analyzed Pure, the water used is distilled water;

[0028] (2) Grind the reddish-brown copper ultrafine powder collected in step (1), wash with distilled water twice, and then dry in an oven at 85°C for 2 hours;

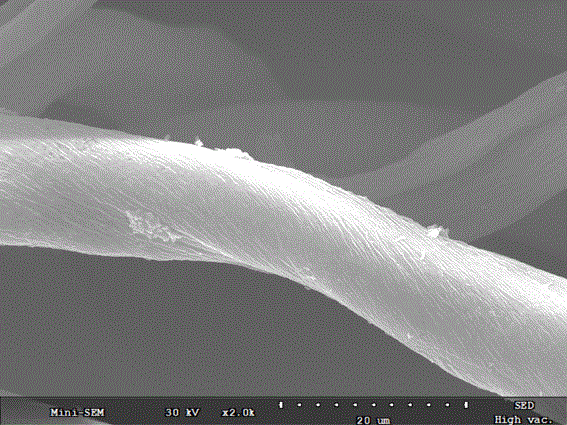

[0029] (3) Mix 1g of reddish-brown copper ultrafine powder dried in step (2) with 10g of butyl acrylate (BA), 10g of methyl methacrylate (MMA) and 0....

Embodiment 2

[0032] The preparation and application of the ecological copper wet rubbing fastness improving agent of present embodiment 2 may further comprise the steps:

[0033] (1) Weigh 100mL of 0.05mol / L sodium dodecylsulfonate into a four-neck flask, add 8.8gVc and stir thoroughly (stirring speed 500 rpm) and heat up to 80°C, measure 0.5mol / L pentahydrate Copper sulfate 100mL was placed in a separatory funnel, and the rate of 60 drops per minute at 70°C was all added dropwise, and then the stirring reaction was continued for 3 hours. After cooling down, 3g of reddish-brown copper nanometer powder was obtained. All drugs in this reaction were analytically pure , the water used is distilled water;

[0034] (2) Grind the reddish-brown copper nanometer ultrafine powder collected in step (1), wash with distilled water twice, and then dry in an oven at 85°C for 2 hours;

[0035] (3) Mix 3g of reddish-brown copper ultrafine powder dried in step (2) with 10g of butyl acrylate (BA), 10g of me...

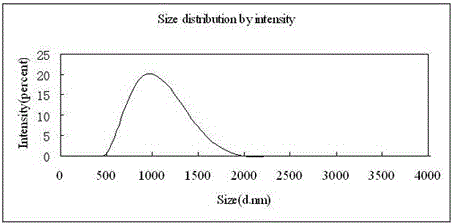

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com