Poly-dimethylallyl (2-benzoyl-5-n-butoxypolyethylene phenyl) ammonium bromide synthesis method and dye-fixing agent

A technology of polydimethylallyl and n-butoxyphenyl, which is applied in the dyeing field of printing and dyeing auxiliaries, can solve problems such as complex methods, many by-products, and environmental pollution, and achieve good comprehensive effects, saving usage, and The effect of low rolling ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

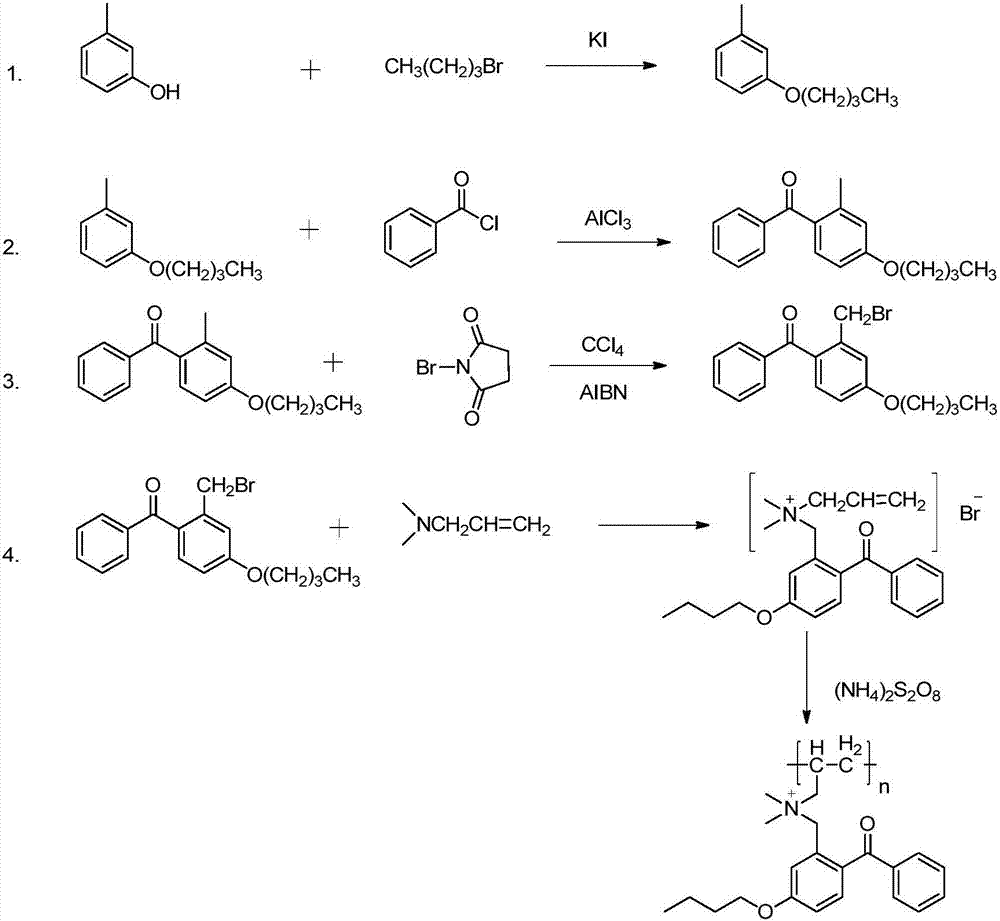

[0032] Polydimethylallyl (2-benzoyl-5-n-butoxyphenyl) ammonium bromide synthetic route is:

[0033]

[0034] 1) Synthesis of 3-n-butoxytoluene

[0035] Add 10.8g of m-cresol, 11.2g of potassium hydroxide, 4.0g of potassium iodide and 120ml of absolute ethanol in a 250ml dry three-necked flask, and when the water bath is heated to 80°C, slowly add 28ml of bromobutane dropwise with a dropping funnel, The reflux reaction was continued, and TLC was tracked and detected until the reaction was completed. A large amount of solid appears, add 80ml of distilled water to dissolve it, transfer the reaction solution into a separatory funnel, separate the upper organic layer, wash twice with distilled water, extract the remaining organic phase in the aqueous phase with ethyl acetate, and combine the two For the organic phase, use a rotary evaporator to distill off the crude product of the solvent. The crude product was separated and purified by flash column chromatography to obtain a ...

Embodiment 2

[0075] A color-fixing agent containing an ultraviolet absorbing group, the color-fixing agent is made by adding the prepared polydimethylallyl (2-benzoyl-5-n-butoxyphenyl) ammonium bromide After mixing in a mixed solvent of ethanol and distilled water, the pH of the system is adjusted to neutrality to obtain the product. The product is a light yellow transparent liquid (hereinafter referred to as "self-made auxiliary agent"). Wherein, the ratio of the polydimethylallyl (2-benzoyl-5-n-butoxyphenyl)ammonium bromide to the mixed solution is 1g: (10-20) ml: the mixed solution The ratio of ethanol and distilled water is 1: (1~2).

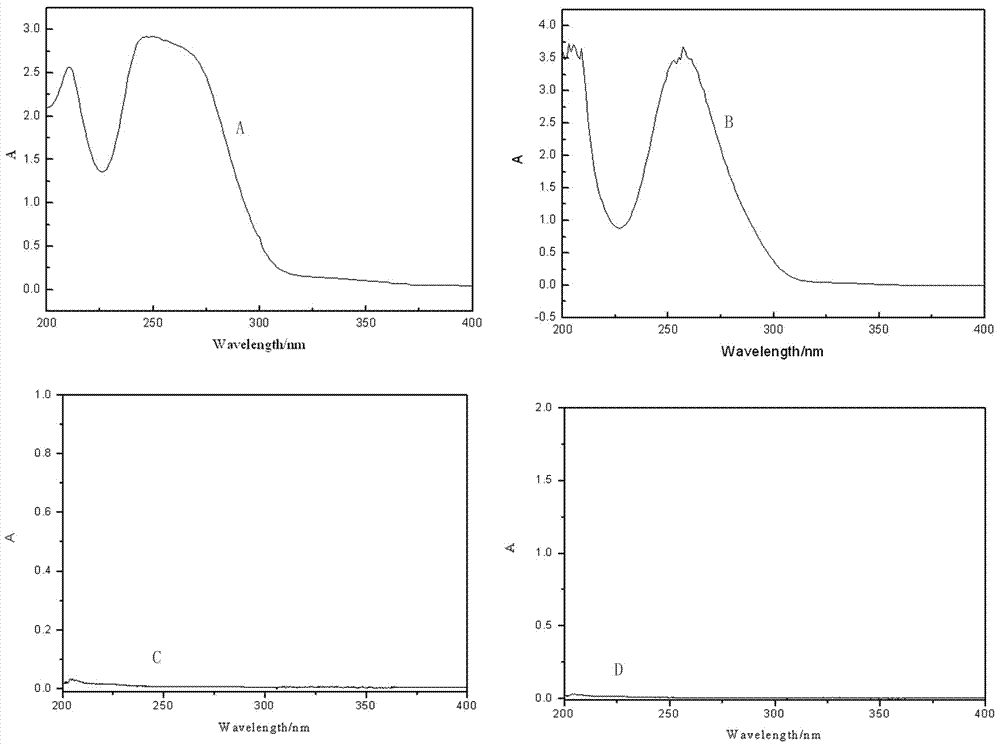

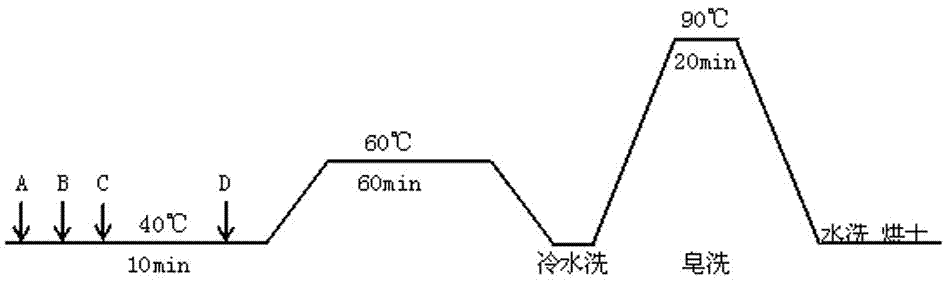

[0076] Performance Testing

[0077] 1. Test results of basic performance indicators of self-made additives

[0078] Test the color-fixing performance of self-made auxiliaries and commercial color fixing agents to investigate whether the self-made auxiliaries can meet the actual application requirements. Observe the appearance of the self-made auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com