Patents

Literature

92results about How to "Evenly dyed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Capability verification sample for detection of textile color fastness to rubbing and preparation method thereof

InactiveCN104007061AEvenly dyedEasy to preparePreparing sample for investigationUsing mechanical meansColour fastnessRubbing

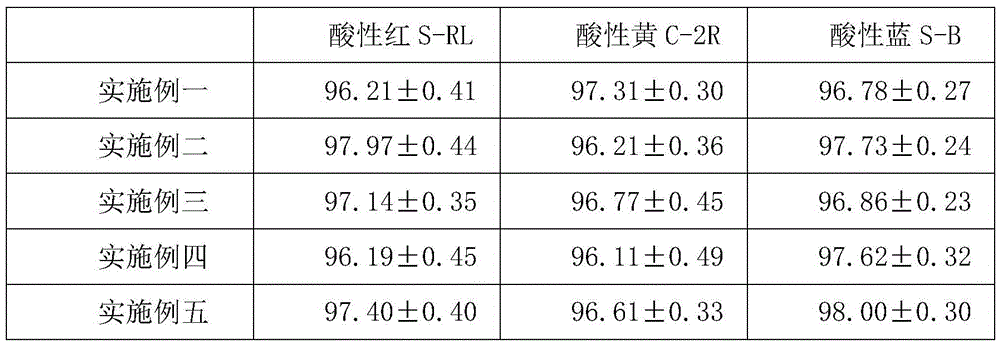

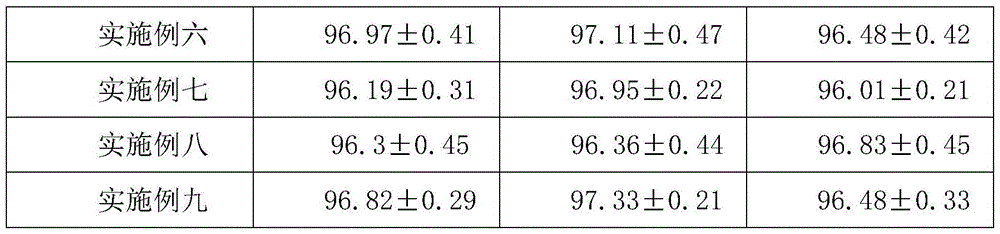

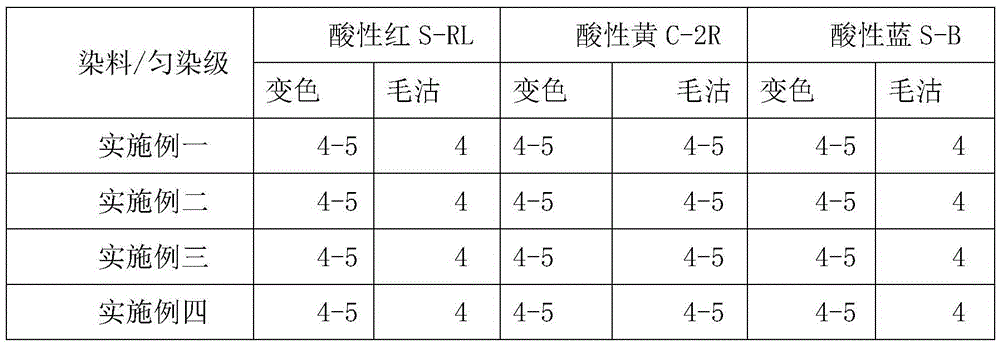

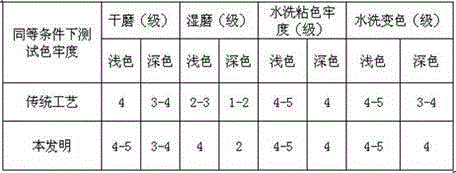

The invention discloses a capability verification sample for detection of textile color fastness to rubbing and a preparation method thereof. The capability verification sample is prepared by reactive dye or direct dye-based dying of pure cotton woven plain or twill bleached grey cloth. A test according to GB / T3920-2008 textile color fastness and color fastness to rubbing proves that color fastness to dry rubbing and color fastness to wet rubbing are in a range of 2-5 level, the existing daily detection range of color fastness to rubbing in the textile and clothing field is covered, and capability evaluation of different laboratory detection projects or laboratory quality control use is realized. The preparation method of the capability verification sample has simple processes, a high yield and high practicality. The capability verification sample can be stored and transported at a normal temperature and has uniformity and stability according with the CNAS-GL03 capability verification sample uniformity and stability evaluation guide requirements.

Owner:INSPECTION & QUARANTINE TECH CENT OF CHONGQING ENTRY EXIT INSPECTION & QUARANTINE BUREAU

Proficiency testing sample for measuring color fastness to perspiration of textile and preparation method of sample

InactiveCN103954744AEvenly dyedLow color fastness to acid perspirationPreparing sample for investigationTextile testingStainingPerspiration

The invention discloses a proficiency testing sample for measuring the color fastness to perspiration of a textile and a preparation method of the sample. The proficiency testing sample is formed by dyeing a piece of pure cotton weaving tabby bleaching grey cloth by adopting an active dye or a direct dye, the detection result of the color fastness to acidic perspiration (which comprises an original sample discoloration level number, a cotton lining staining level number and a wool lining staining level number) is within 2 level-5 level and contains the daily detection range of the color fastness to acidic perspiration in the field of existing textile clothing, and the proficiency assessment of the detection items of different laboratories or the quality control usage of the laboratories can be realized. The preparation method of the proficiency testing sample has the advantages of easiness and convenience for operation, high success rate and high practicability; the prepared proficiency testing sample can be stored and transported at normal temperature and meets the uniformity and stability assessment guide requirement of a CNAS0GL03 proficiency testing sample in the aspects of uniformity and stability.

Owner:INSPECTION & QUARANTINE TECH CENT OF CHONGQING ENTRY EXIT INSPECTION & QUARANTINE BUREAU

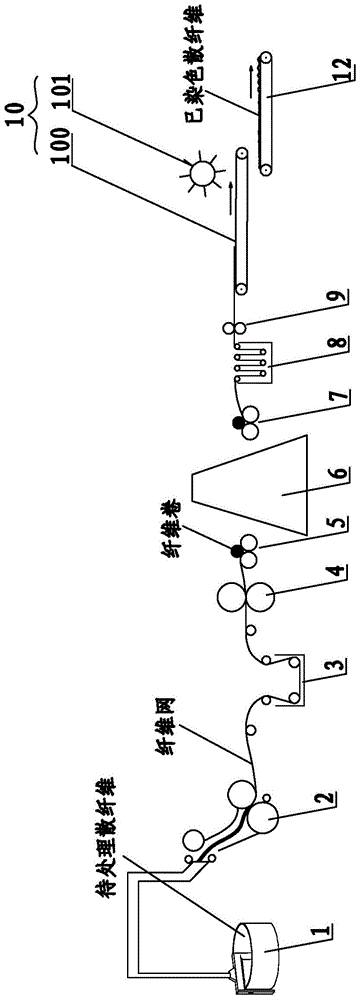

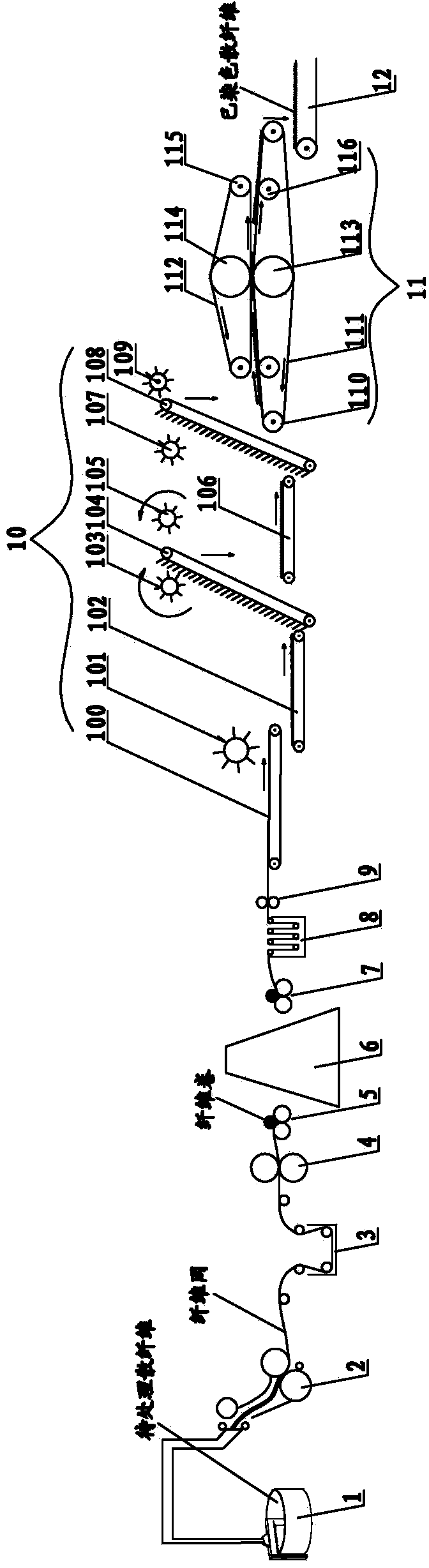

Loose fiber dyeing process

ActiveCN103911782AEvenly dyedConvey evenlyTextile treatment machine partsLiquid/gas/vapor fibres/slivers/rovings treatmentFiberPolymer science

The invention relates to a loose fiber dyeing process and belongs to technical field of fiber dyeing. The process sequentially includes: grabbing cotton, forming nets, soaking, mangling, forming rolls, cold piling, unrolling, washing, squeezing, splitting, spreading and drying. Squeezed loose fibers are fed to the spreading procedure after splitting, the loose fibers are squeezed at the squeezing force of 3-15kg / cm<2> under the premise of not damaging the fibers, the squeezed dyed fibers are directly fed through a lower conveying belt to an eight-cage dryer or a loose fiber high-frequency dryer for drying. By the process, the defects that continuous production cannot be performed and machining efficiency is low in conventional technologies are overcome, the defects that of uneven dyeing, low drying efficiency, large energy consumption and the like when the loose fibers are dried in a net structure are overcome, fiber damage is low during processing, and the quality of the finished fibers is guaranteed.

Owner:SHAOXING GUOZHOU TEXTILE NEW MATERIAL

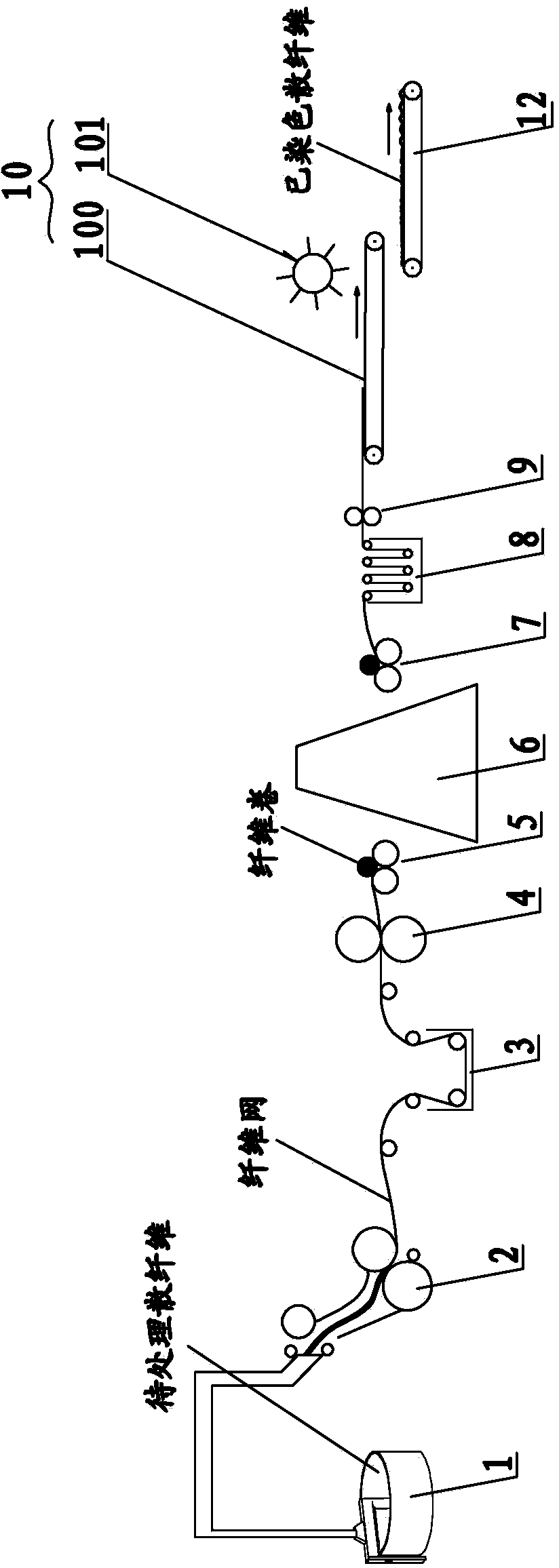

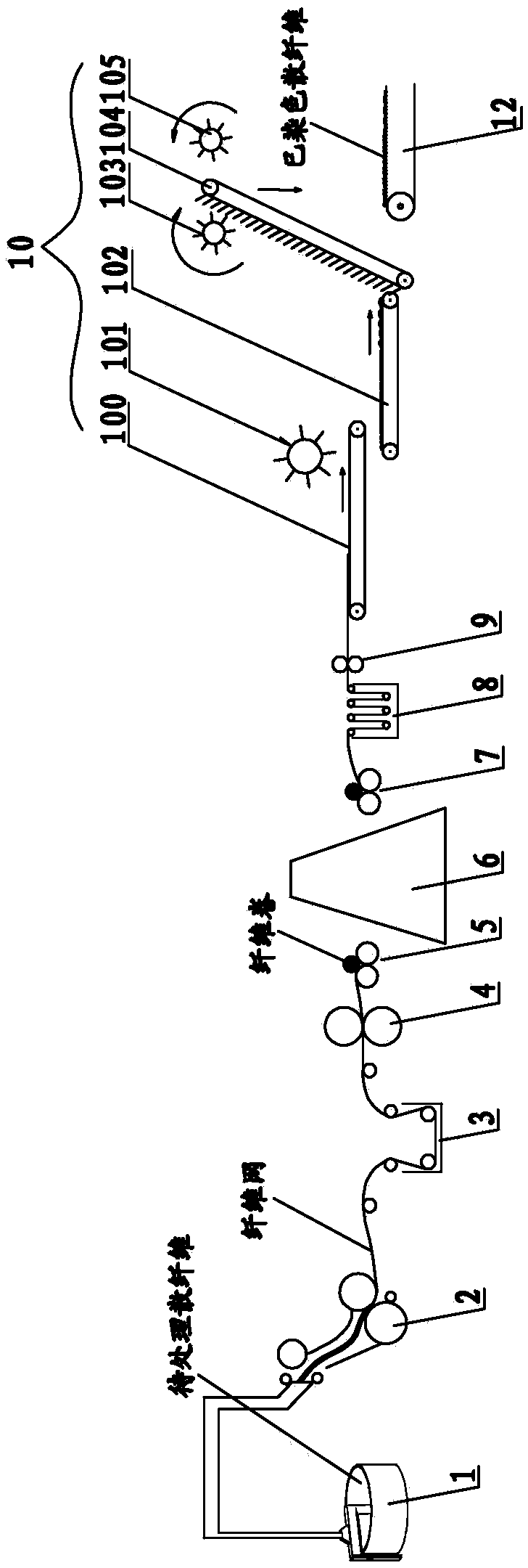

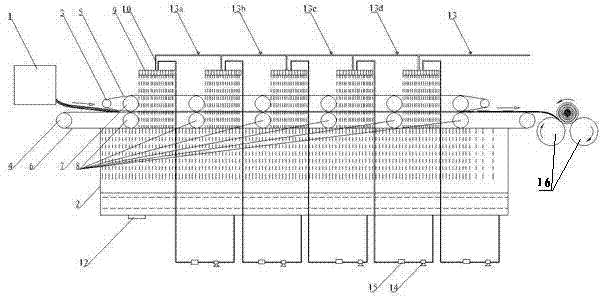

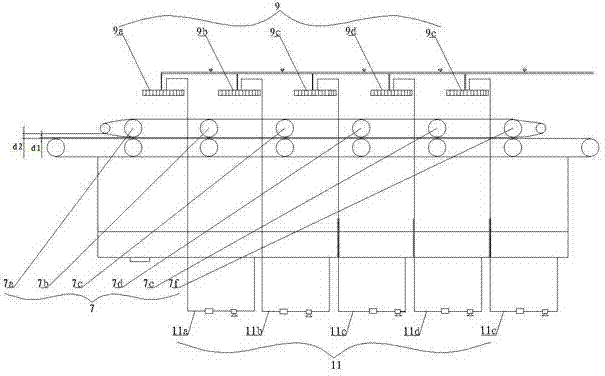

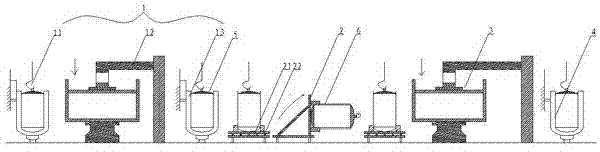

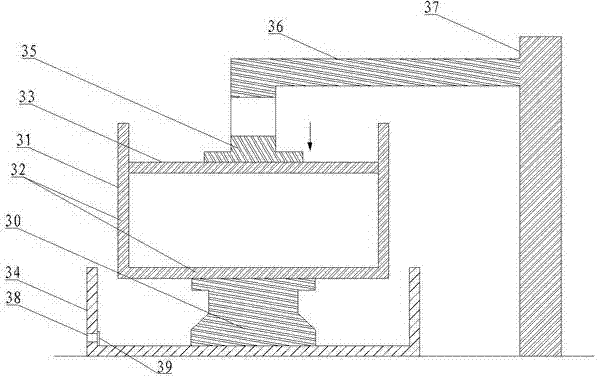

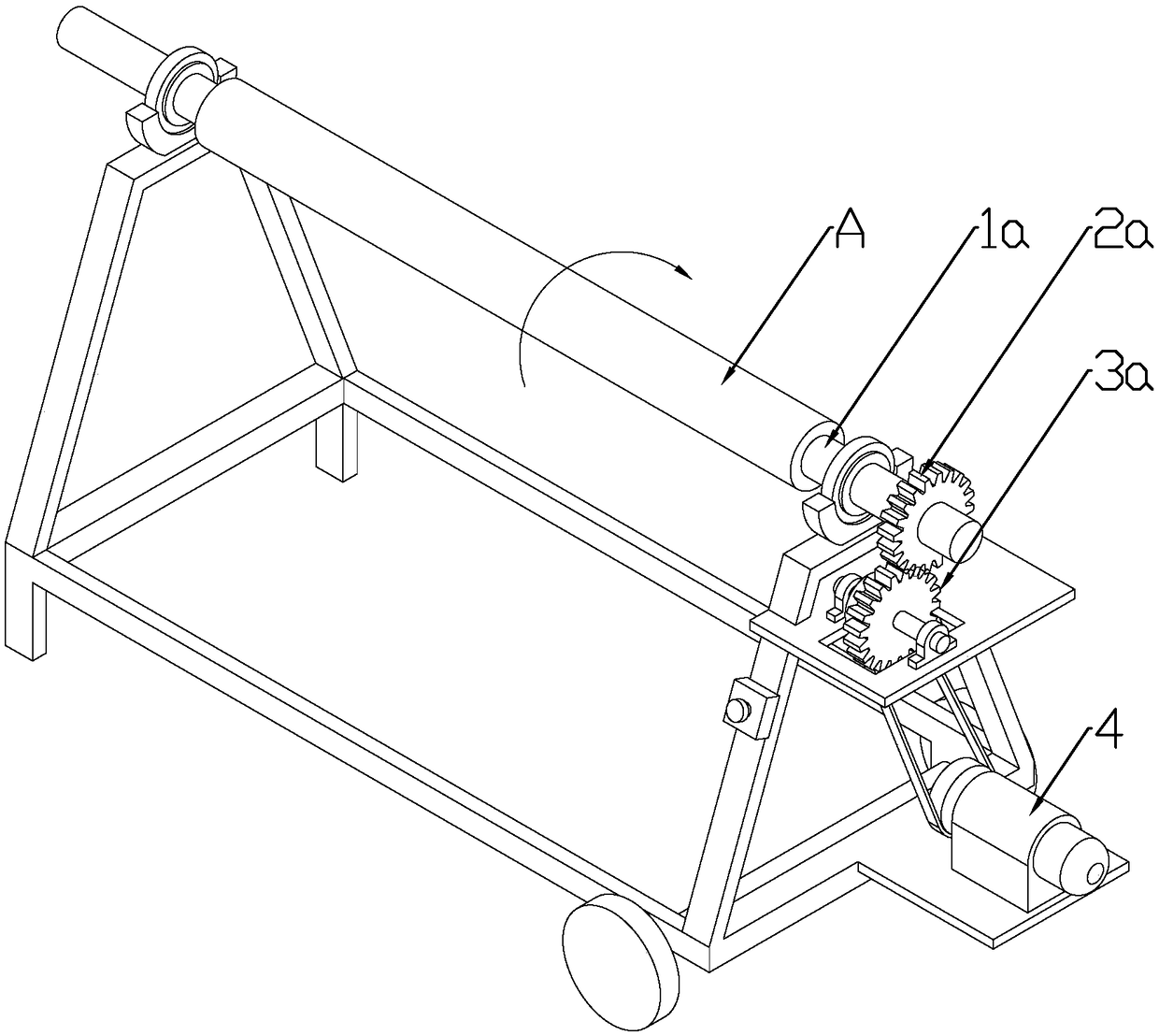

Loose stock dyeing device

ActiveCN103882637AEvenly dyedConvey evenlyTextile treatment machine partsLiquid/gas/vapor fibres/slivers/rovings treatmentFiberProcess efficiency

The invention relates to a loose stock dyeing device and belongs to the technical field of stock dyeing devices. The loose stock dyeing device comprises a cotton grabbing device, a net forming device, a steeping device, a mangle device, a coiling device, a cold-batch fixation device, a uncoiling device, a washing device, a squeezing device, a splitting device and a drying device, wherein the cotton grabbing device, the net forming device, the steeping device, the mangle device, the coiling device, the cold-batch fixation device, the uncoiling device, the washing device, the squeezing device, the splitting device and the drying device are sequentially arranged. A loose stock net after squeezing is sent to the splitting device to be split and sent to the drying device to be dried. According to the technical scheme, the defects that continuous production cannot be performed and processing efficiency is low in the prior art are overcome, and the defects that dyeing is uneven, drying efficiency is low and energy consumption is large in drying loose stock with a net-shaped structure are overcome. In the processing process, stock damage is little, and the quality of finished stock products is ensured.

Owner:SHAOXING GUOZHOU TEXTILE NEW MATERIAL

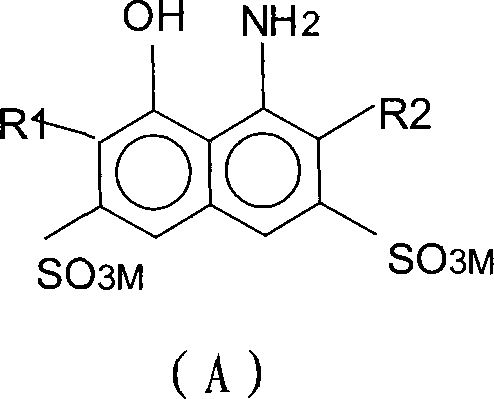

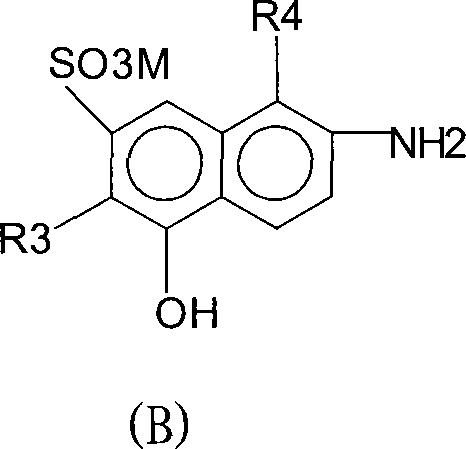

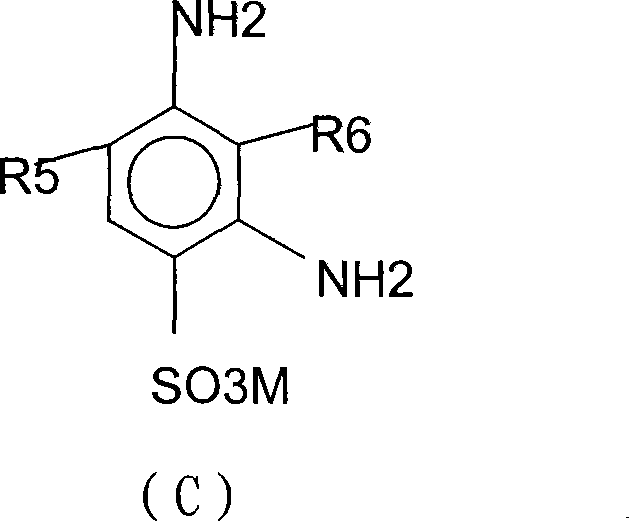

Reactive dye composition and preparing process and application thereof

InactiveCN101143972AHigh color fixing rateGood synchronization of dyeingOrganic dyesDyeing processCelluloseOil water

The invention discloses an active dye composition, which includes compound as showed in formula (A), formula (B), formula (C) and formula (D) and additive. 4 components of the active dye composition of the invention active dye composition are medium temperature dye, wherein the oil-water ratio, dye curve, affinity to cellulose, degree of dyeing, color fixing rate, sensitivity to salt and base, effect on bath ratio and sensitivity to temperature are very close. The composition has good dyeing synchronism and level dyeing property, and much higher color fixing rate, thereby being applicable for dip dyeing, continuous dyeing, cold dome, and printing and embossing of cellulose or protein fiber.

Owner:ZHEJIANG RUIHUA CHEM

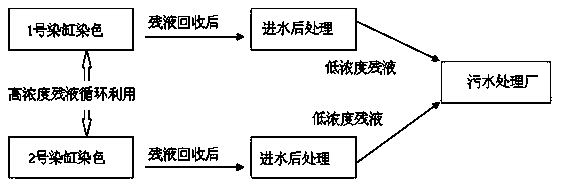

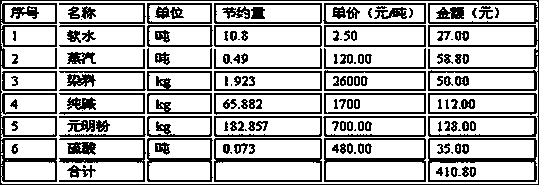

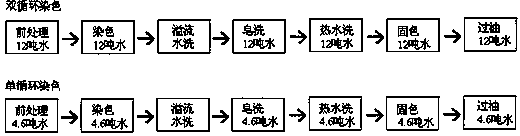

Residual liquid dyeing process of cheese

ActiveCN103741526AReduce consumptionEmission reductionTextile treatment machine arrangementsDyeing processYarnPulp and paper industry

The invention provides a residual liquid dyeing process of cheese in order to reduce the dye consumption for cheese dyeing. The residual liquid dyeing process is characterized in that a dye vat No.1 and a dye vat No.2 are connected through a pump, after yarns in the dye vat No.1 are dyed for the first time, a dyeing solution is pumped into the dye vat No.2, and after the yarns in the dye vat No.2 are dyed, the dyeing solution is returned to the dye vat No.1 to dye undyed yarns; the dyeing solution is recycled for dyeing between the dye vat No.1 and the dye vat No.2 according to the method; and after the dyeing solution is exhausted each time, a post-processing stage is entered, the dyed yarns are taken out after the post-processing is completed, and the undyed yarns are hung to wait for the import of the dyeing solution. According to the residual liquid dyeing process disclosed by the invention, the water consumption and sewage discharge are reduced from the source, resource consumption and environment pollution are reduced, and the cyclic utilization of resources and clean production are realized.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

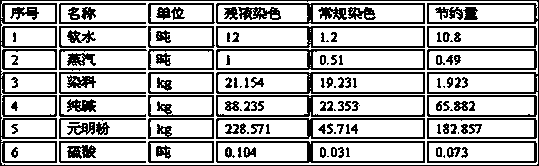

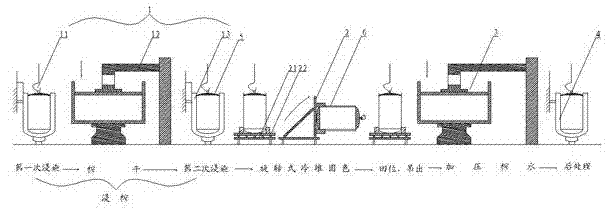

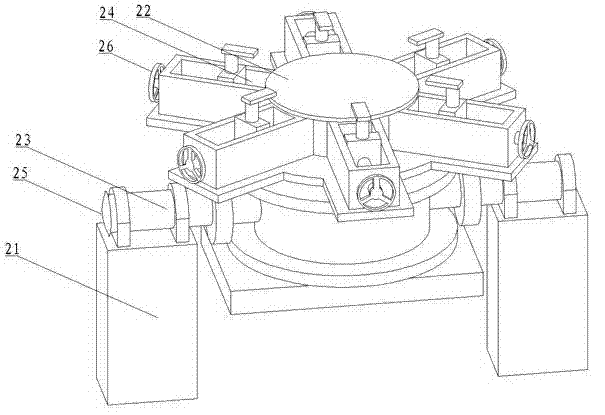

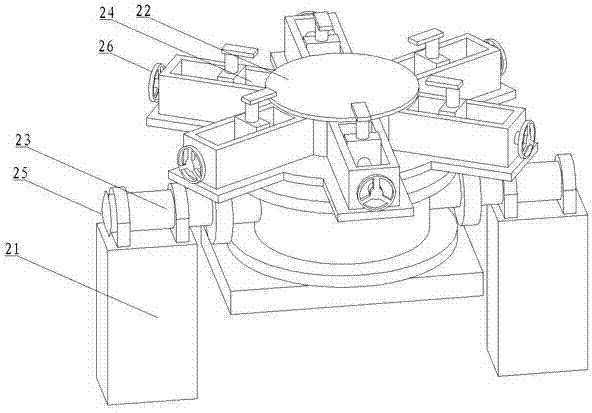

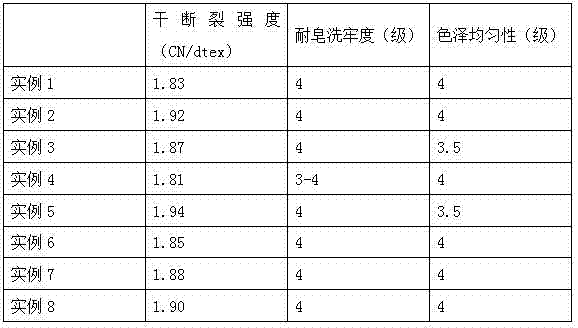

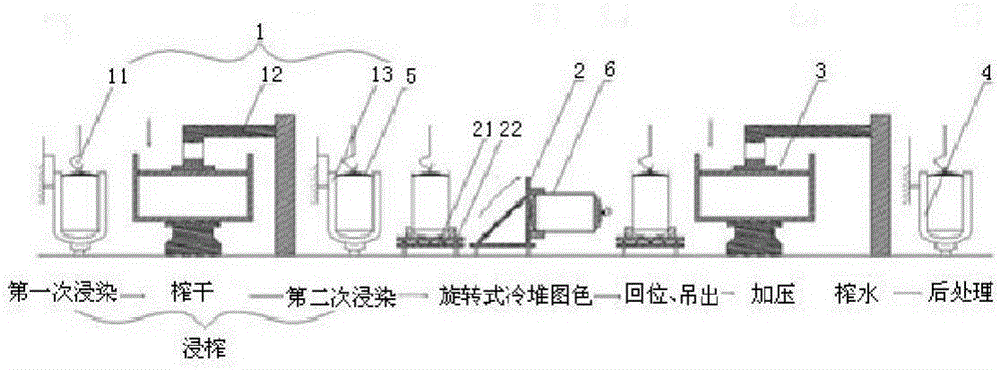

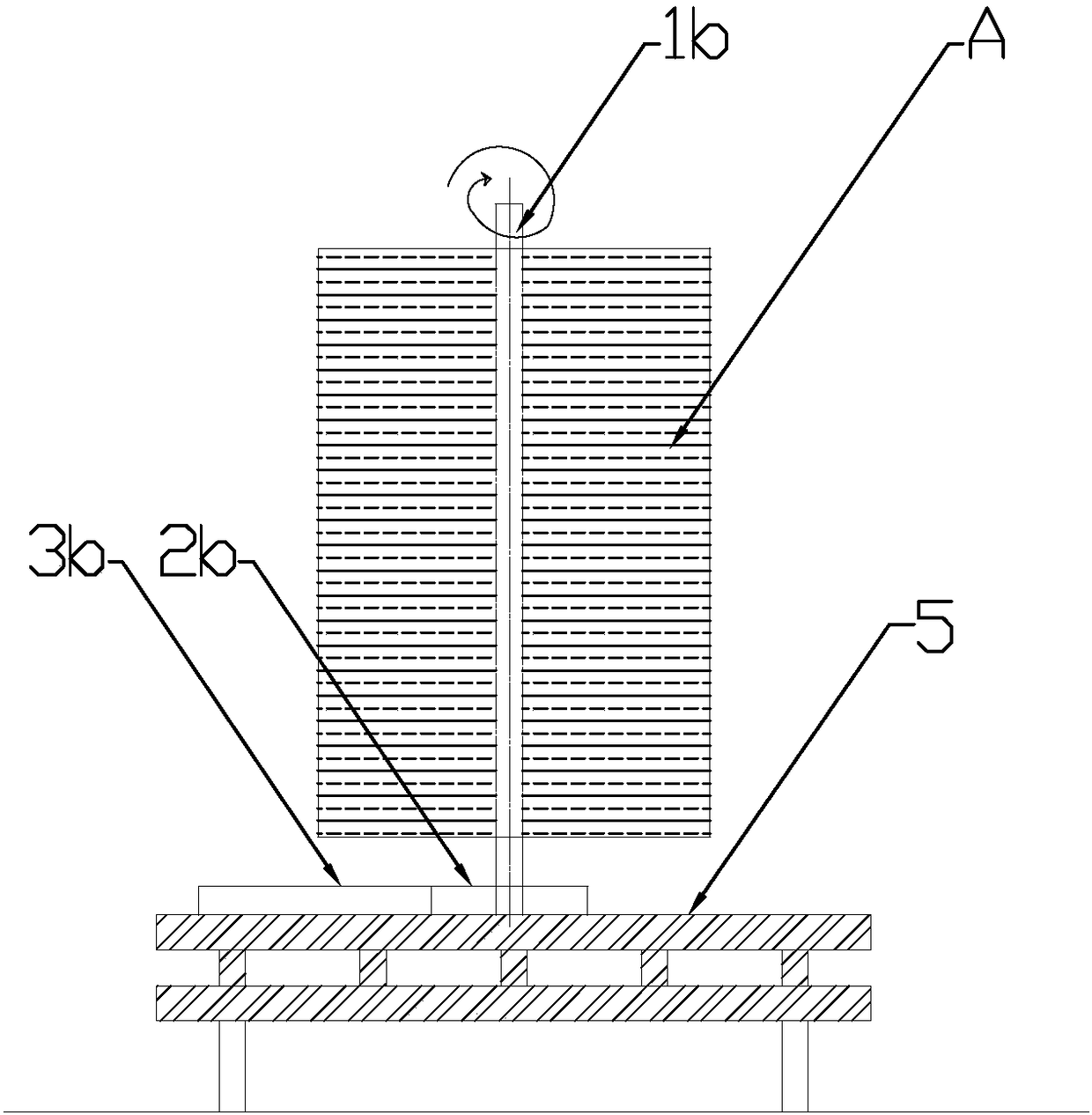

Cold-pad batch dyeing process for loose fibers

ActiveCN103774363AEvenly distributedPromote absorptionTextile treatment machine arrangementsLiquid/gas/vapor treatment of definite length materialsFiberPolymer science

The invention belongs to the technical field of loose fiber dyeing and relates to cold-pad batch dyeing process for loose fibers. The cold-pad batch dyeing process for loose fibers comprises the steps of soaking and squeezing, rotating type cold-patch treatment, pressing and water squeezing and post-treatment. The loose fibers are soaked and squeezed in a twice soaking and once squeezing mode, the rotating type cold-patch treatment is then conducted, the loose fibers are pressed and water is squeezed out after the rotating type cold-patch treatment is conducted, and after the water and dye in a loose fiber cake or loose fibers are squeezed out, the loose fiber cake or loose fibers are sent for post-treatments of drying and the like. The cold-pad batch dyeing process for loose fibers is applied to cold-pad batch dyeing of the loose fibers and has the advantages of being uniform in dyeing, small in water consumption and the like. In addition, procedures are simple.

Owner:绍兴国周针织科技有限公司

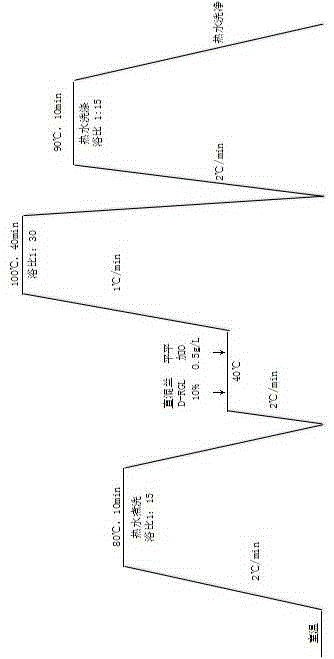

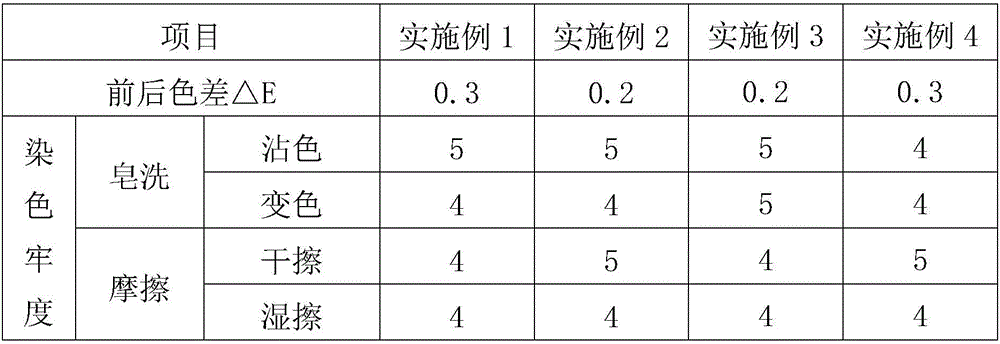

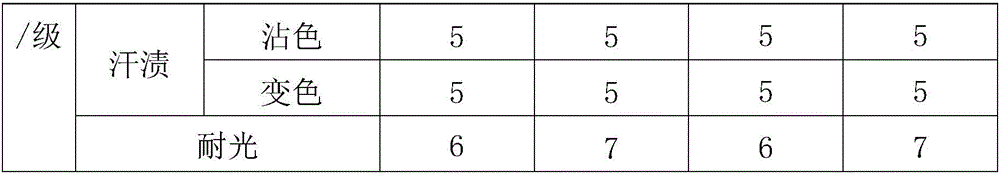

Dyeing method for improving color fastness to light of osier

InactiveCN107486908AImprove color fastness to lightEnhanced photooxidative stabilityRadiation/waves wood treatmentWood treatment detailsVolumetric Mass DensityBinding force

The invention belongs to the technical field of osier dyeing, in particular to a dyeing method for improving color fastness to light of osier. The method specifically comprises the following steps of (1) osier pretreatment and (2) osier dyeing. The permeation of a coloring agent is effectively improved, the degree of aggregation of dye molecules is higher, crosslinking binding between the dye molecules and the ingredients of osier is prompted, the binding force is high, leachability resistance is good, the electronic cloud density of azo group hydrogen atoms is reduced, the shielding effect on azo groups is achieved, the photooxidation resistance stability of the azo groups in the structure of the dye molecules is improved, and finally, the color fastness to light of a dye is improved; and furthermore, osier is evenly dyed and has good color fastness to water, the difference between the color of the interior and the color of the exterior of osier is small, osier is evenly dyed without stains, and is bright and glossy, and the quality of the wickerwork made of osier is effectively improved.

Owner:安徽阜南县万家和工艺品有限公司

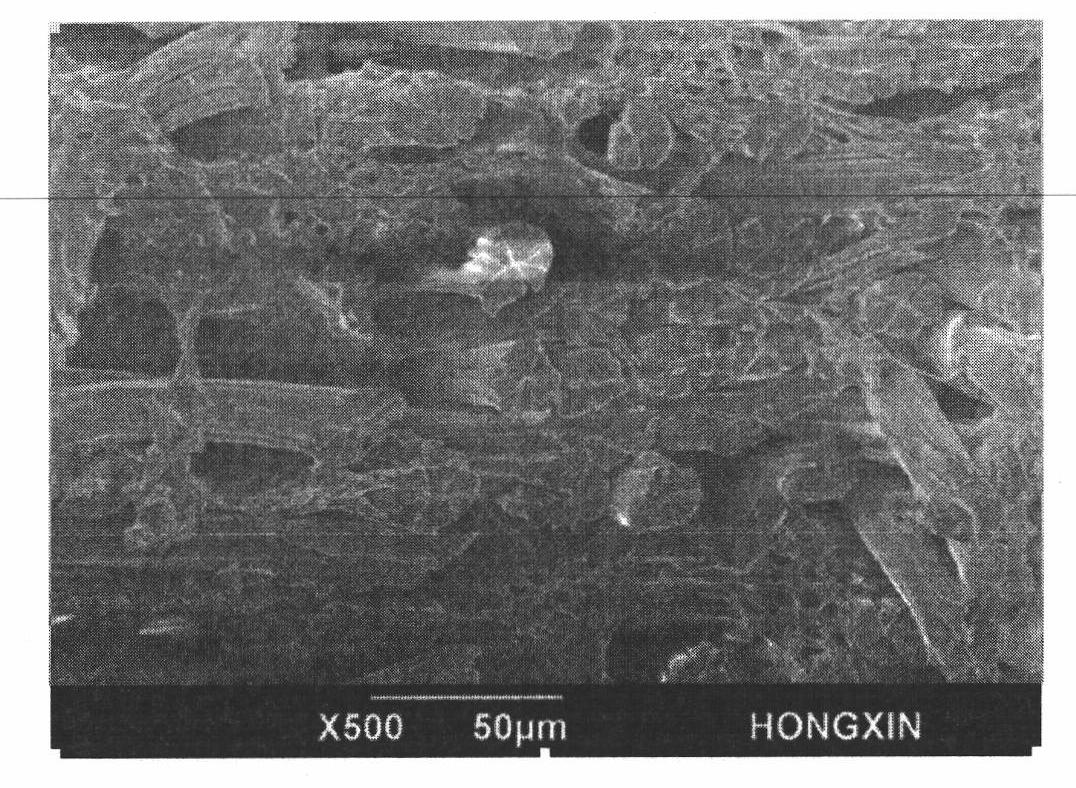

Dyeing method of artificial leather

The invention provides a dyeing method of artificial leather, comprising: providing superfine fibre PU synthetic leather composed of superfine fibre non-woven fabric and polyurethane impregnated in the superfine fibre non-woven fabric, wherein the superfine fibre non-woven fabric is prepared from superfine fibre, and the superfine fibre comprises polyester superfine fibre and polyamide superfine fibre; adding the superfine fibre PU synthetic leather into dye bath filled with the dye containing the following components for dyeing; the dye comprises the following components in percentage by weight: 63-78% of acidic dye, 13-29% of disperse dye and the balance of metal complex dye; and dyed superfine fibre PU synthetic leather is dried after being washed by water. The dyeing method of the invention realizes the simultaneously and evenly dye of polyester fibre, polyarmide fibre and polyurethane in the superfine fibre PU synthetic leather, and prepared superfine fibre PU synthetic leather not only has proper stiffness and softness but also has abundant color.

Owner:厦门象屿兴泓超细材料有限公司

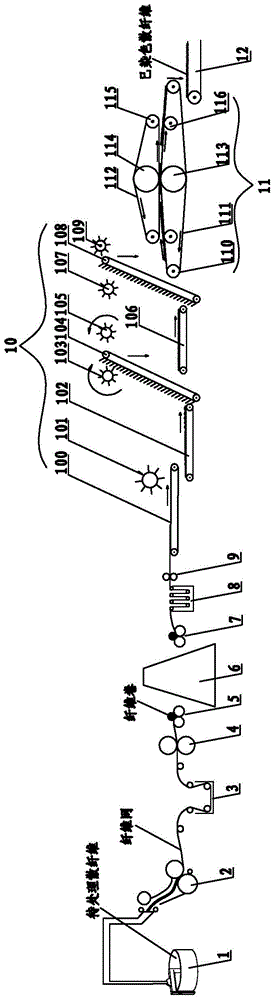

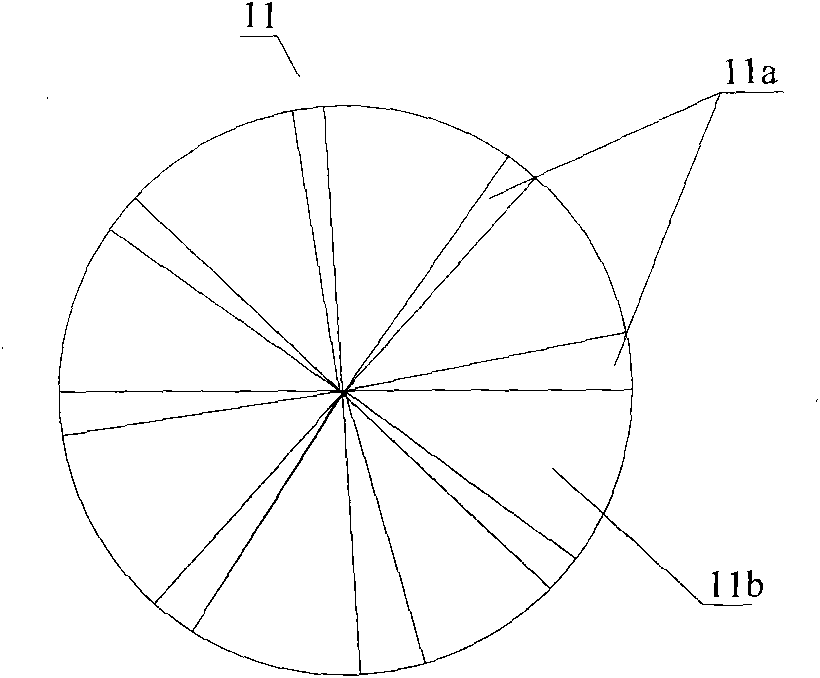

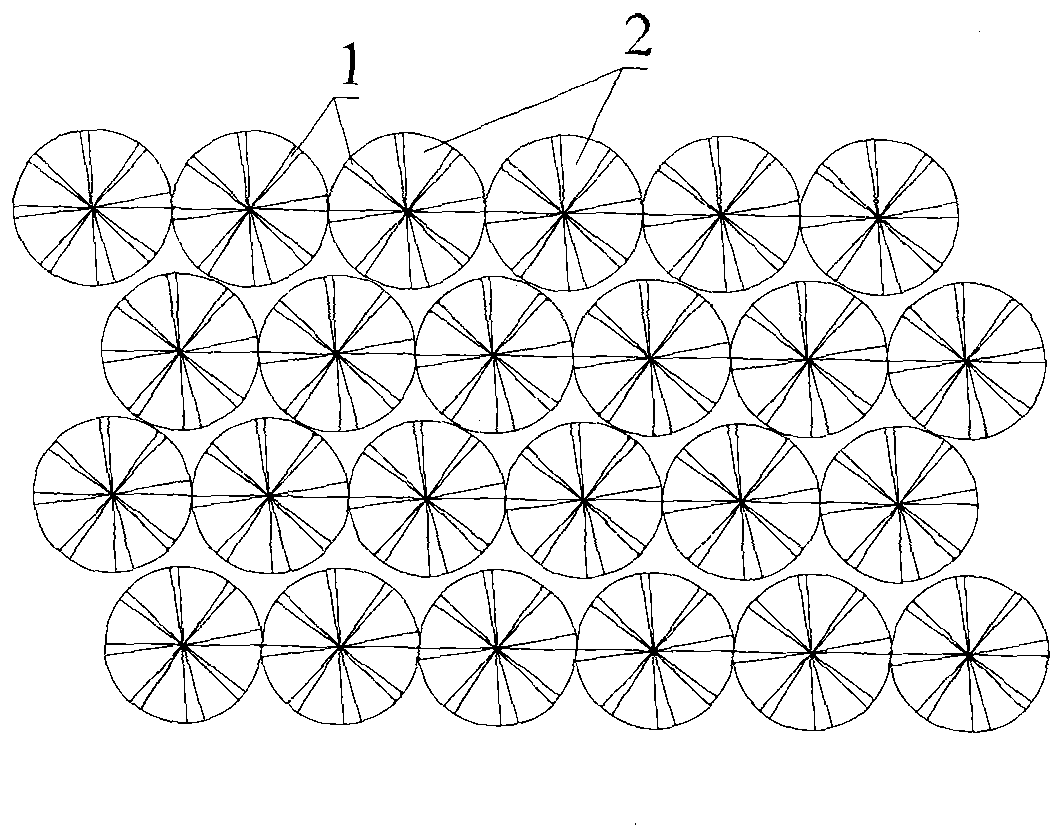

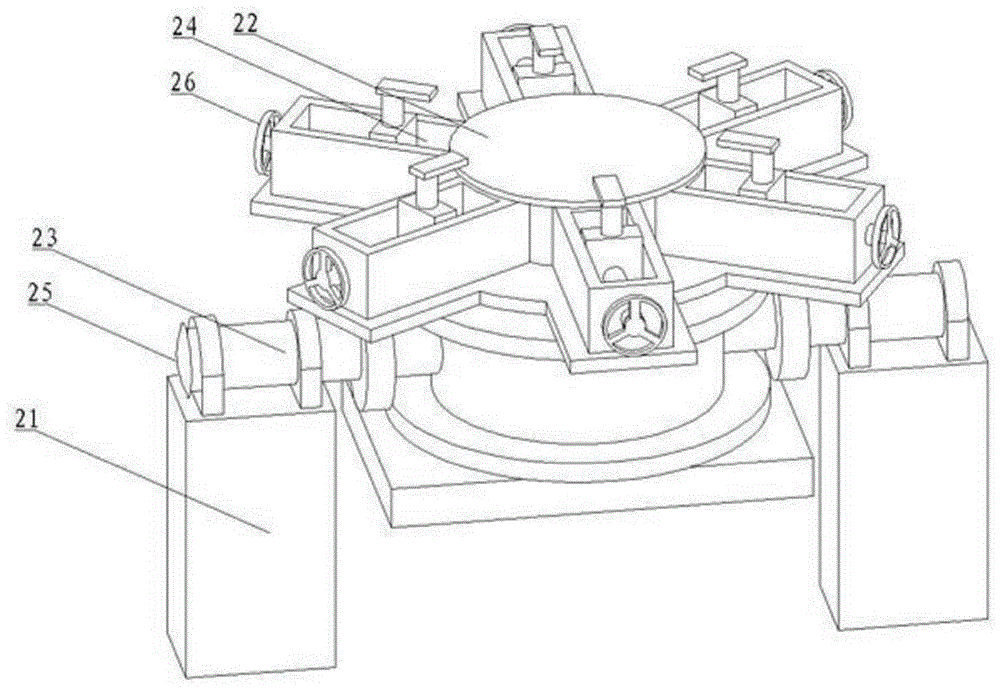

Spray-rolling type loose fiber dyeing machine

ActiveCN103774360AFast absorptionFacilitated DiffusionLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsFiberMechanical engineering

The invention relates to a spray-rolling type loose fiber dyeing machine, and belongs to the technical field of loose fiber dyeing. The spray-rolling type loose fiber dyeing machine comprises a transmission component and a spray component. The transmission component comprises a pair of upper drive rollers and a pair of lower drive rollers. The upper drive rollers and the lower drive rollers are sleeved with an upper guide belt and a lower guide belt respectively to be used in a cooperative mode. The upper guide belt is provided with a first leak hole, the upper guide belt and the lower guide belt operate synchronously, a plurality of upper rollers are arranged in an upper guide belt loop, and a plurality of lower rollers matched with the upper rollers to be used are arranged in a lower guide belt loop. The upper guide belt and the lower guide belt are matched with the upper rollers and the lower rollers to achieve synchronous clamping transportation of the loose fibers. The spray component comprises a dyeing liquid pipe and sprayer heads. One end of the dyeing liquid pipe is communicated with dyeing liquid, the other end of the dyeing liquid pipe is connected with the sprayer heads, the sprayer heads are located above the upper guide belt between adjacent upper rollers, and the dyeing liquid in the dyeing liquid pipe is sprayed downwards onto the loose fibers through the sprayer heads. By means of the spray-rolling type loose fiber dyeing machine, continuous production can be carried out, cost can be lowered to 1 / 3-1 / 5 of that in the prior art.

Owner:SHAOXING JINYU TEXITLE NEW TECH CO LTD

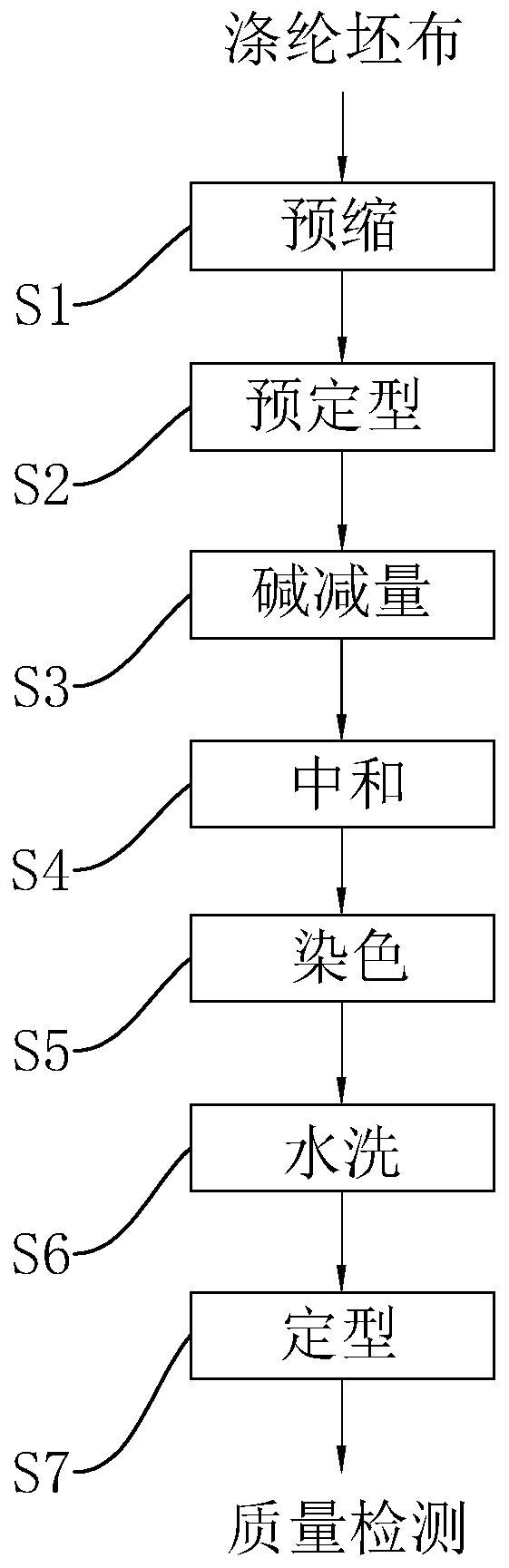

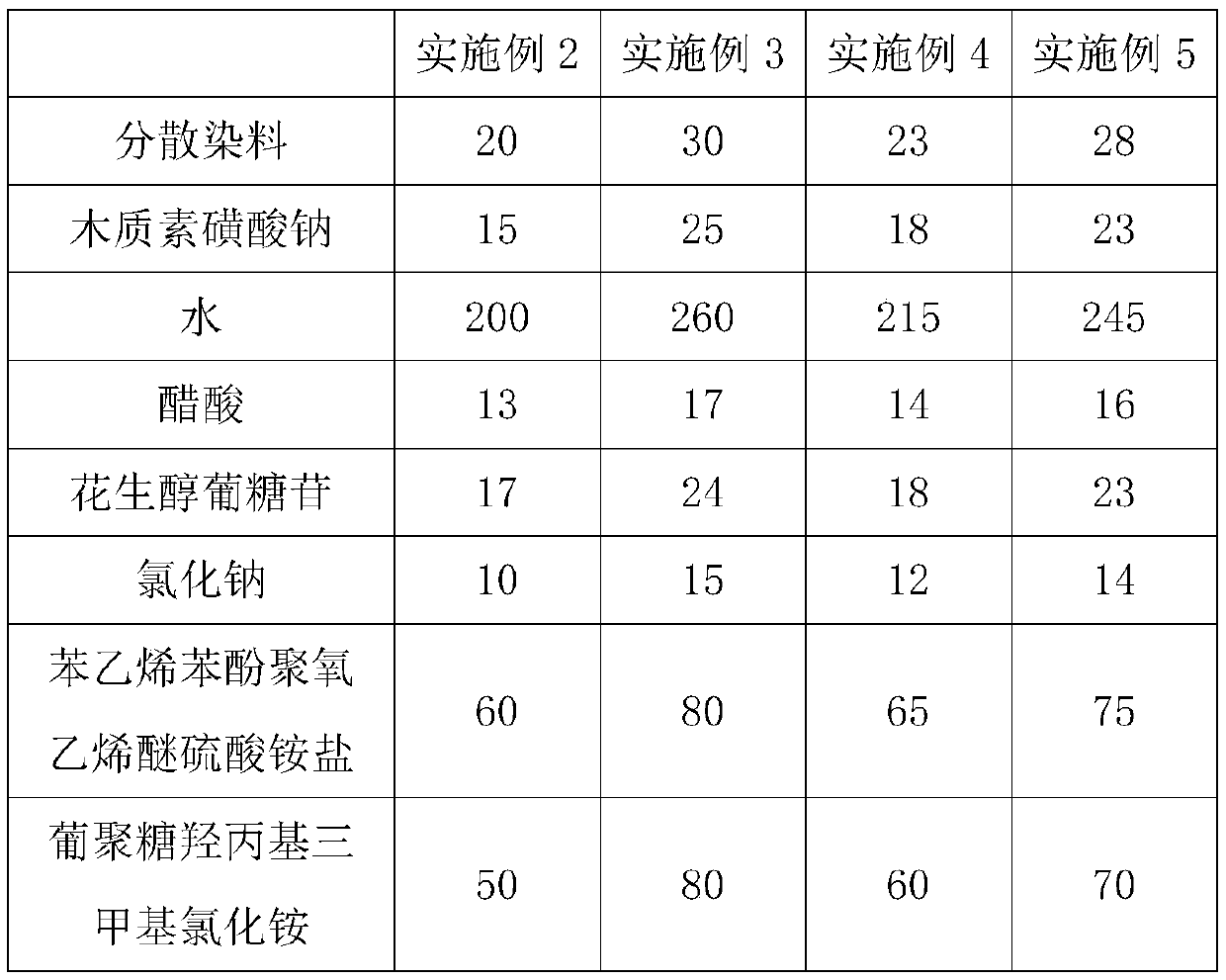

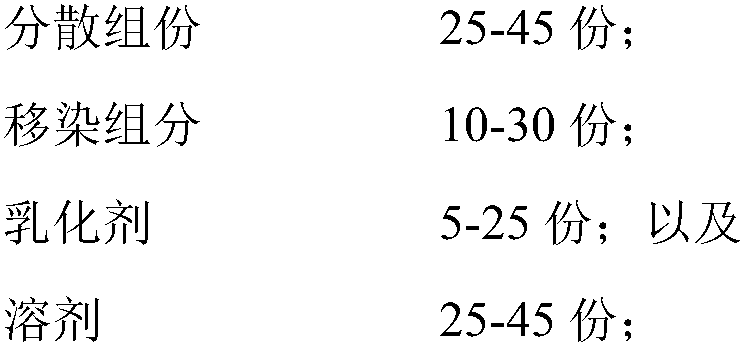

Dyeing process of heavy-twist polyester fabric with high color fastness

The invention relates to the technical field of polyester fabric processing and discloses a dyeing process of heavy-twist polyester fabric with high color fastness. Gray fabric is treated through steps as follows: S1, preshrinking; S2, pre-setting; S3, alkali peeling; S4, neutralization; S5, dyeing: the gray fabric subjected to neutralization treatment in S4 is dyed, and dye for dyeing is preparedfrom raw materials in parts by weight as follows: 20-30 parts of disperse dyes, 15-25 parts of sodium lignin sulfonate, 200-260 parts of water, 13-17 parts of acetic acid, 17-24 parts of arachidyl glucoside, 10-15 parts of sodium chloride and 60-80 parts of styrene phenol polyoxyethylene ether ammonium sulfate; S6, water washing; and S7, setting: the heavy-twist polyester fabric with high color fastness is prepared after S7 is implemented. Arachidyl glucoside and styrene phenol polyoxyethylene ether ammonium sulfate are added to the dye, so that the color fastness of the dyed polyester fabriccan be improved.

Owner:浙江新益印染有限公司

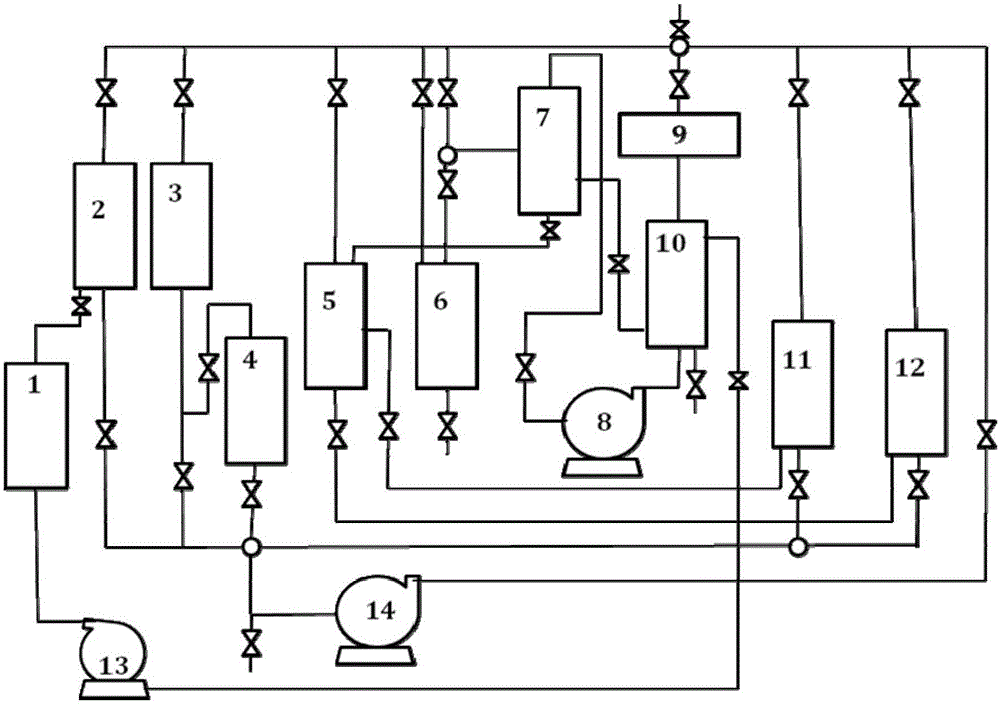

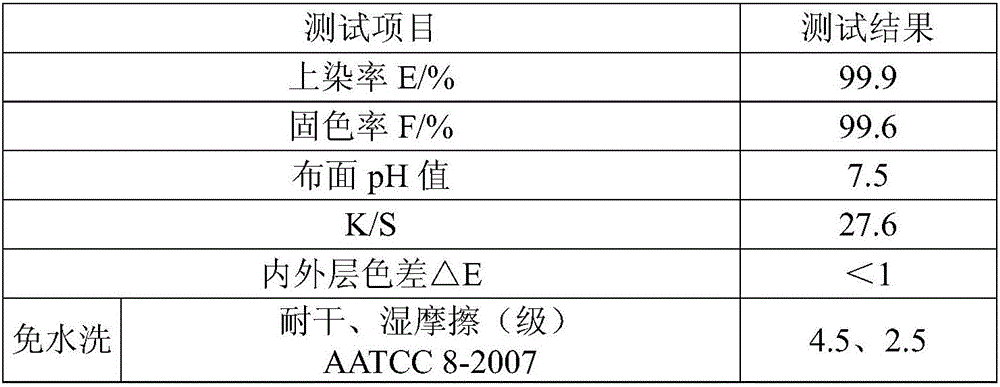

Washing-free non-aqueous-solvent dyeing device and method adopting activated dye

InactiveCN106065520AEvenly dyedRealize recyclingTextile treatment containersTextile treatment machine arrangementsDyeingCompound (substance)

The invention provides a washing-free non-aqueous-solvent dyeing device and method adopting activated dye. According to the dyeing device, an assistant heating pipe is respectively communicated with a main dyeing cylinder and an air pump; a first feeding hole and a first discharging hole of the main dyeing cylinder are respectively communicated with a main pump; the main dyeing cylinder is also communicated with a first condenser; a second feeding hole and a second discharging hole of a chemical material tank are respectively communicated with the main pump; the chemical material tank is also communicated with a liquid storage tank; the liquid storage tank is communicated with the main pump; a dispenser is respectively communicated with the main pump, the first condenser, a polar solvent storage tank and a nonpolar solvent storage tank; the first condenser is communicated with a second condenser; the second condenser is communicated with the air pump; the polar solvent storage tank and the nonpolar solvent storage tank are respectively communicated with the main pump; a steam heating tube and a first clamp cover filled with condensate water are arranged in the main dyeing cylinder; a chemical stirring device is arranged in the chemical material tank; a second clamp cover filled with condensate water is arranged in the liquid storage tank; a first sewage discharging hole is formed in the bottom of the liquid storage tank.

Owner:GUANGDONG ESQUEL TEXTILES

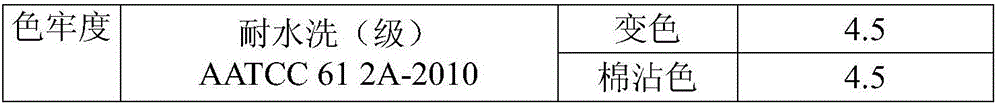

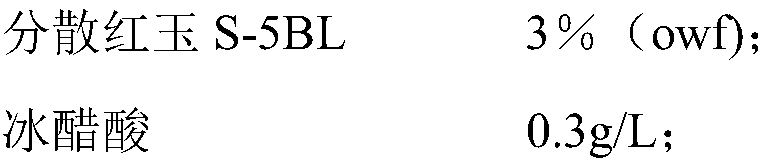

Disperse dye dyeing defect preventing agent and preparation method thereof

The invention provides a disperse dye dyeing defect preventing agent and a preparation method thereof. The disperse dye dyeing defect preventing agent is prepared from the following raw materials in parts by mass: 25-45 parts of disperse component, 10-30 parts of transfer dyeing component, 5-25 parts of an emulgator and 25-45 parts of a solvent. The disperse dye dyeing defect preventing agent is applicable to disperse dyeing of polyester and blended fabrics thereof under the conditions of high temperature and high pressure, and has the outstanding dispersion and transfer dyeing capabilities ondisperse dye, so that the dye can easily diffuse and evenly migrate from the dye liquor into the interior of fiber, and the problem of dyeing defect and color light shifting in the dyeing process canbe avoided.

Owner:苏州联胜化学有限公司

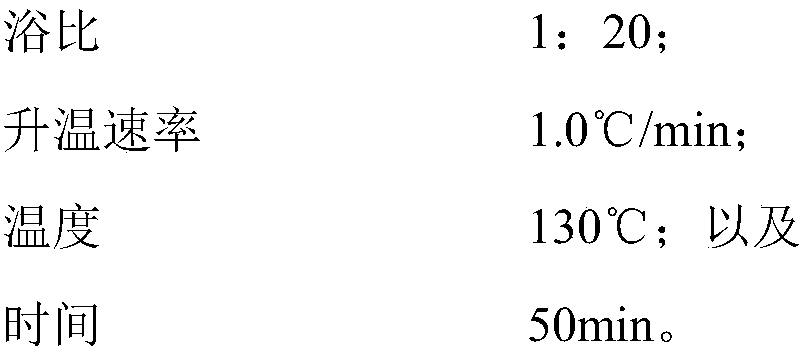

Unidirectional circulation dyeing process for cheese

ActiveCN103726244ALess power consumptionAvoid layer differenceTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentDyeingEngineering

The invention provides an unidirectional circulation dyeing process for cheese. The unidirectional circulation dyeing process for the cheese is characterized in that a single circulation mode is adopted by dyeing liquor, and the dyeing liquor is driven to circulate from the interior of the cheese to the exterior of the cheese through the changing of the rotating speed of a main pump in a dyeing vat. According to the unidirectional circulation dyeing process for the cheese, a dyeing pulse technique and a spray technique are adopted to change a circulation mode of the dyeing process as single outflow dyeing, only half or even lower water level of raw materials are soaked by the dyeing liquor, dyeing can be carried out, the bath ratio can be lowered to 1:3, and production water consumption can be reduced greatly.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

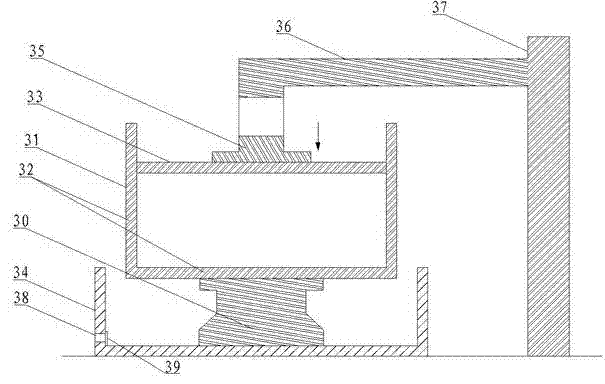

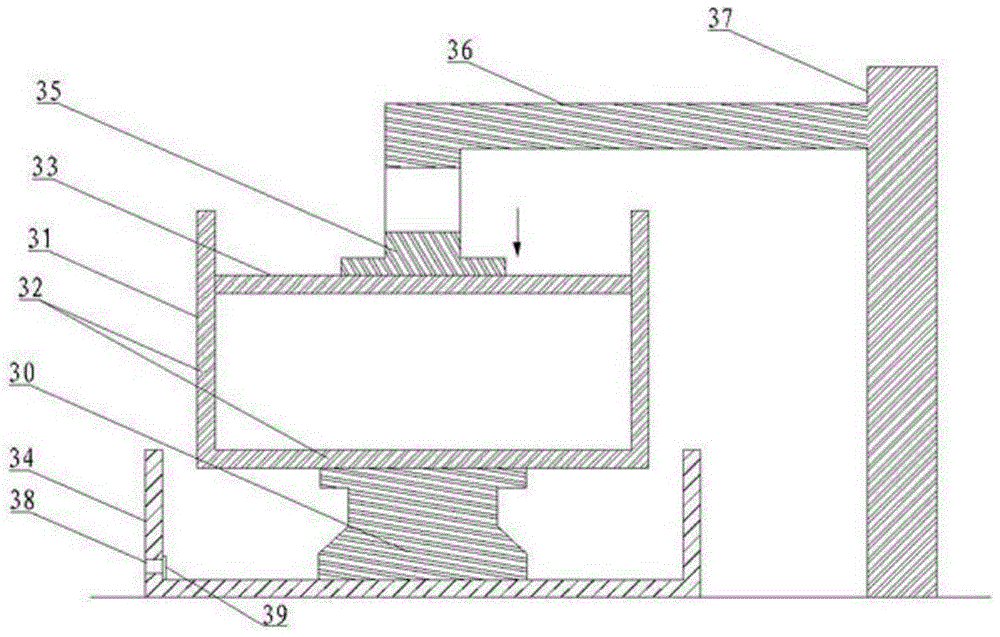

Wringer suitable for loose fiber or loose fiber cake dehydration

InactiveCN103774367AReduce the difficulty of washingReduce water consumptionLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor textile treatmentPistonPower component

The invention relates to a wringer suitable for loose fiber or loose fiber cake dehydration and belongs to the technical field of loose fiber dyeing. The wringer comprises a base, a cylindrical cylinder body and a top plate. The cylindrical cylinder body is arranged on the base. A leakage hole is formed in the cylindrical cylinder body. The top plate is movably connected with the cylindrical cylinder body. The upper portion of the top plate is connected with a pressure component. A power component drives the top plate to carry out piston motion in the cylindrical cylinder body, so that moisture in loose fibers in the cylindrical cylinder body is squeezed out. The wringer is used for loose fiber cold rolling stack dyeing and has the advantages that dyeing is even, the amount of used water is small, and procedures are simple.

Owner:绍兴国周针织科技有限公司

Cow leather dyeing process

InactiveCN104499319AImprove color fixationEvenly dyedTanning treatmentDyeing processPulp and paper industryDye uptake

The invention relates to a cow leather dyeing process, belonging to the technical field of dyeing processing of leather materials. A preparation process comprises the following steps: returning water, namely adding water and industrial salt into a rotary drum; controlling baume degree; stripping leather; sequentially adding a de-greasing agent and baking soda in sequence after stripping the leather; rotating and adjusting pH; discharging a solution and carrying out a retanning procedure; after retanning, filling and adding grease; and then discharging water, washing with water and discharging from the drum. The process has the advantages that the use amount of dyes is few, the dye absorptivity is greatly improved and the environment pollution is alleviated; the plumpness of deep-color dyes and the brightness of light-color dyes can be effectively improved; and the cow leather dyeing process has the advantages in the aspects of dyeing rate, leveling property, permeability, color fastness and the like.

Owner:GUANGDONG FION LEATHER CO LTD

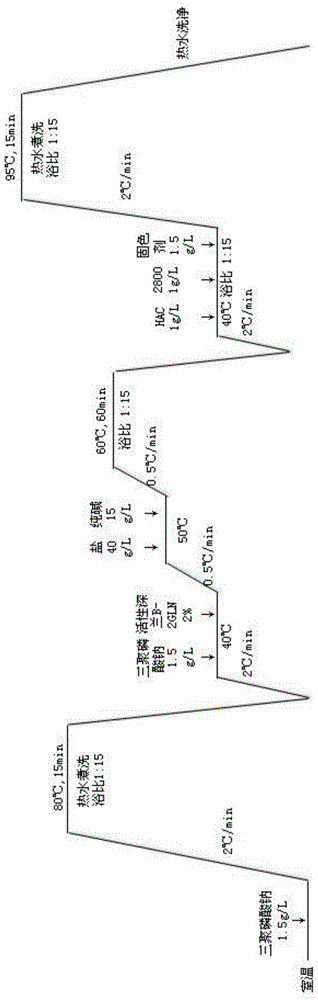

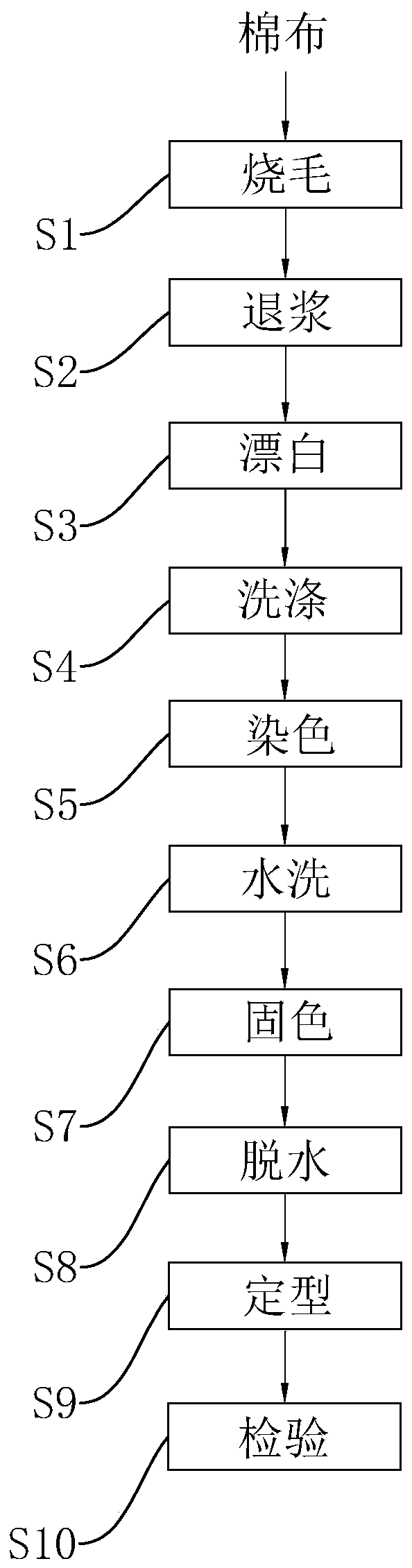

Dyeing technology for cotton cloth

InactiveCN110512444AImprove permeabilityImprove bindingDry-cleaning apparatus for textilesDyeing processCotton clothEngineering

The invention relates to the technical field of textile dyeing and finishing, and discloses a dyeing technology for a cotton cloth. The method for treating a cotton cloth gray fabric comprises the following steps of S1, performing singeing on the gray fabric; S2, performing resizing; S3, performing bleaching; S4, performing washing; S5, performing dyeing, wherein the gray fabric obtained after treatment in S4 is dyed, dyes adopted during dyeing are prepared from, by weight, 35-50 parts of active dyes, 7-10 parts of sodium carbonate, 3.5-5 parts of anhydrous sodium sulphate, 20-30 parts of a leveling agent, 5-8 parts of acetic acid, 11-23 parts of magnesium sodium silicate, 7-13 parts of imidazolidinyl urea, 2-5 parts of copper chloride and 80-110 parts of water; S6, performing washing; S7,performing color fixing; S8, performing dehydrating; S9, performing sizing, wherein after sizing in S9 is performed, the dyed cotton cloth is obtained. By adding magnesium sodium silicate and imidazolidinyl urea into dyes, active dyes can be promoted to continuously permeate cotton fiber, the imidazolidinyl urea can improve the combining capability of the active dyes and the cotton fiber, and finally the color fastness of the dyed cotton cloth is improved.

Owner:HANGZHOU XINSHENG PRINTING & DYEING

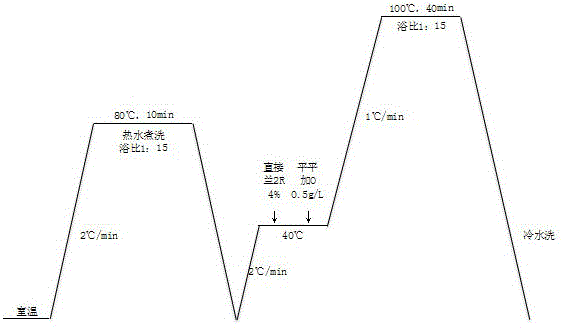

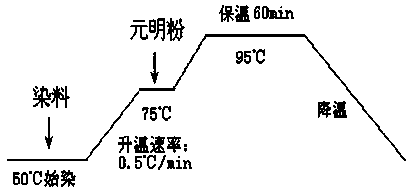

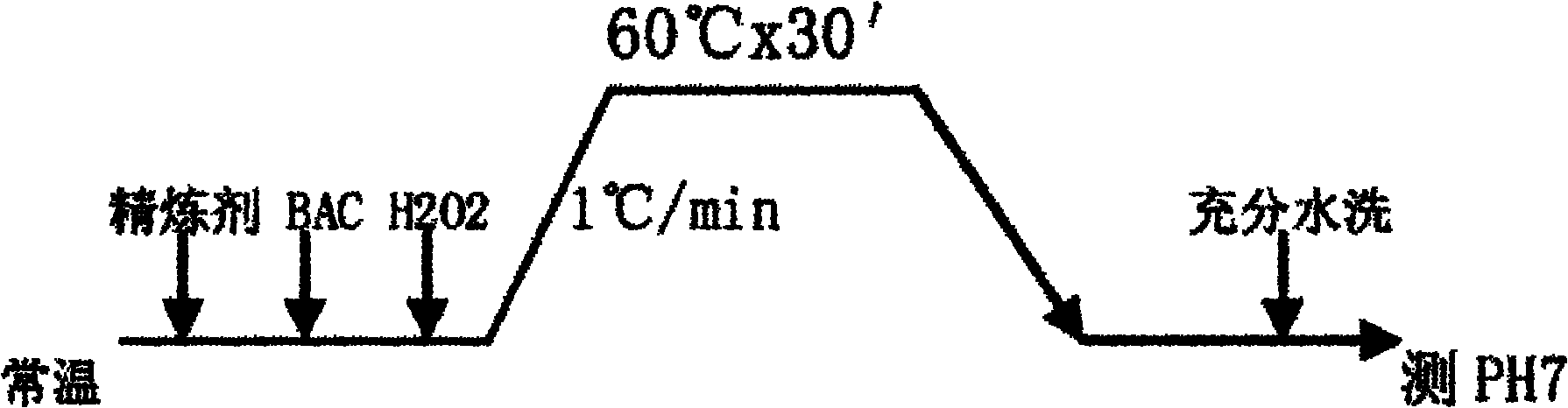

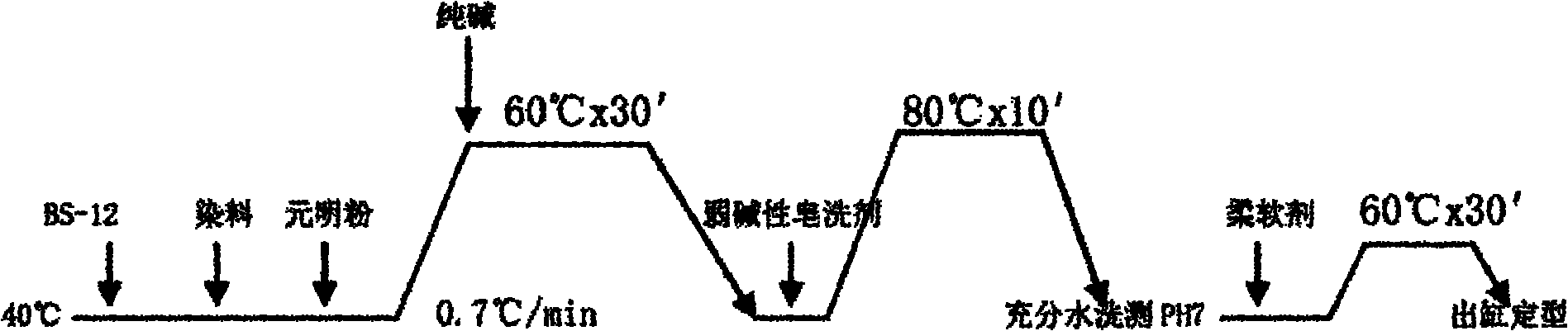

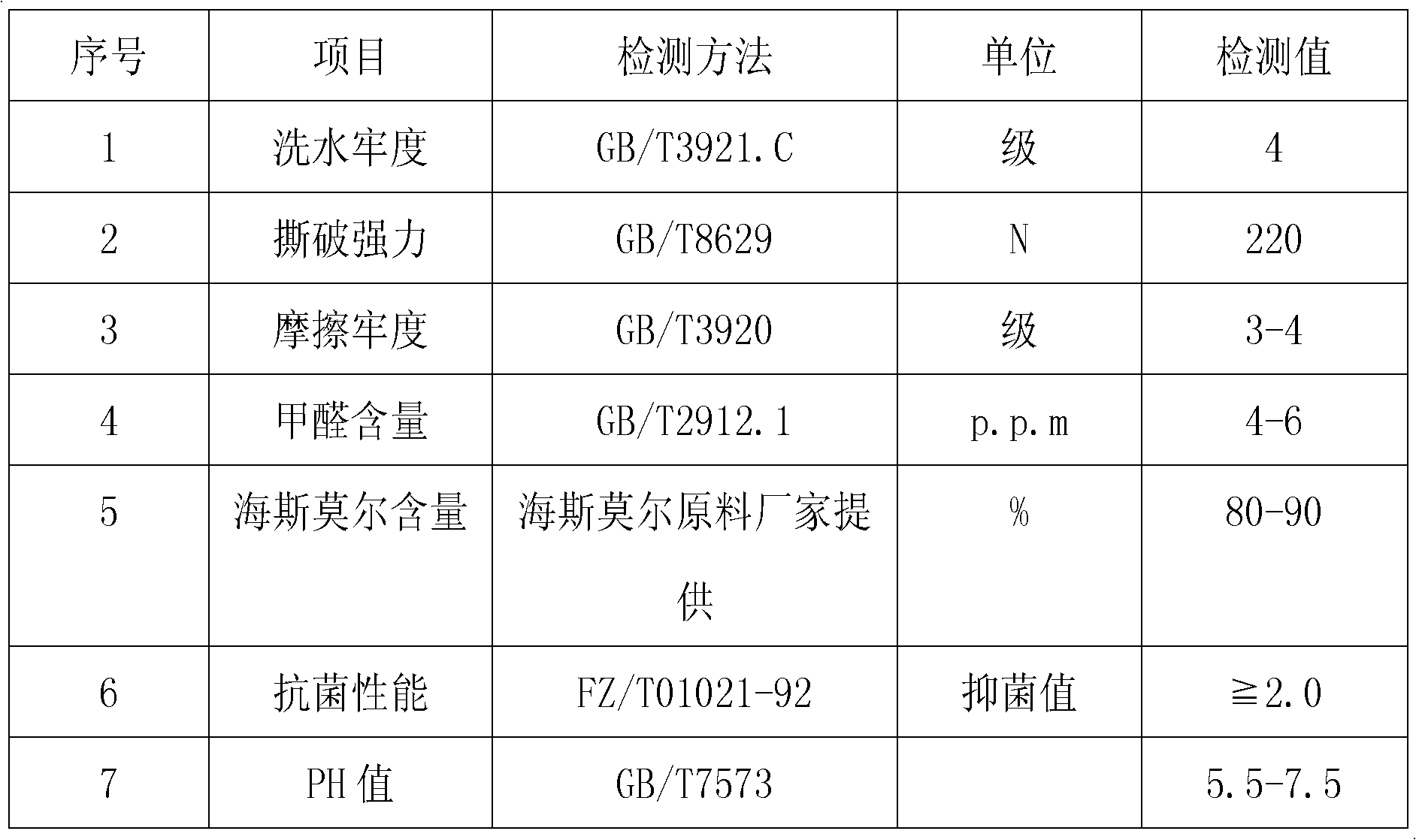

Dyeing and finishing technology for Hismer blended fabric

ActiveCN102115975AGood moisture absorptionGood moisturizing effectDyeing processVegetal fibresSURFACTANT BLENDEthylene

The invention designs a dyeing and finishing technology for a Hismer blended fabric, which mainly comprises a pretreatment process and a dyeing process and specifically comprises the following steps: firstly, placing a Hismer blended fabric into a mixed solution containing a refining agent, an anionic surfactant BAC and hydrogen peroxide, treating for 30 minutes at the temperature of 60 DEG C, and then carrying out pretreatment; during dyeing, adding an amphoteric surfactant BS-12 into a dyeing bath at 40 DEG C; then placing the Hismer blended fabric into a dyeing tank, slowly adding divinylsulfone reactive dyes and a dyeing assistant in batches, and fixing color for 30 minutes at the temperature kept to be 60 DEG C in the presence of alkalescence with the pH of 9-10; after color fixing, adding an alkalescent soaping agent and soaping by preserving the temperature to be 80 DEGC, and sufficiently washing in water till the pH value is 7 after the soaping is finished; and finally, treating with a neutral cationic softening agent for 30 minutes by preserving the temperature to be 60 DEG C so as to soften the Hismer blended fabric, taking the fabric out of the dyeing tank after a handfeel requirement is met, and sizing.

Owner:ZHEJIANG JIAMING DYEING & FINISHING CO LTD

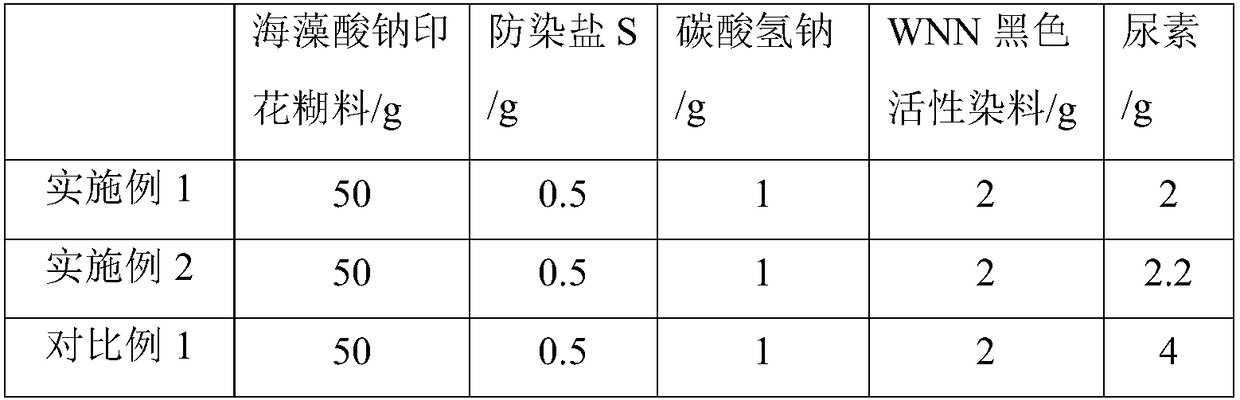

Sodium alginate, and preparation method and application of sodium alginate

The invention discloses sodium alginate, and a preparation method and an application of sodium alginate. The preparation method of sodium alginate comprises the steps of adding sorbitol after a neutralization procedure, and performing mixing, granulation, drying and grinding to form a final product. Prepared sodium alginate has the advantages of good appearance, high rheological property and the like; a preparation technology is simple and easy to implement and popularize; a PVI (polyvinyl isobutyl ether) value of printing paste of sodium alginate is 0.65-0.73; defects such as blade streaks and mesh clogging during printing can be effectively reduced; a formula of the printing paste of sodium alginate comprises sorbitol; fixation between a dye and a fabric can be promoted; the fabric is dyed uniformly; the color yield and fastness of the printing are increased, so that the consumption of urea in the printing can be reduced; the rheological property of sodium alginate can also be improved; the generation of the printing defects is reduced; the printing of the fabric is uniform; a color is bright; and a pattern is clear.

Owner:QINGDAO BRIGHT MOON SEAWEED GROUP

Neutral leveling agent for dyeing wool fiber with acid dye

The invention discloses a neutral leveling agent for dyeing wool fiber with an acid dye, and belongs to the field of dyeing auxiliary application. The neutral leveling agent is prepared from, by weight, 0.01-0.02 part of chrysophanol, 0.1-0.5 part of 2-methyl naphthalene, 12-13 parts of fatty amine polyoxyethylene ether, 14-16 parts of hydroxybiphenyl sodium salt and 160-200 parts of water. By means of the neutral leveling agent, the damage to wool fiber protein can be effectively reduced, and the quality of wool fabric is improved; meanwhile, good dyeing dispersity is achieved, wool fiber can be uniformly dyed with the acid dye, use is convenient, and high market popularization value is achieved.

Owner:SUZHOU INSILK CO LTD

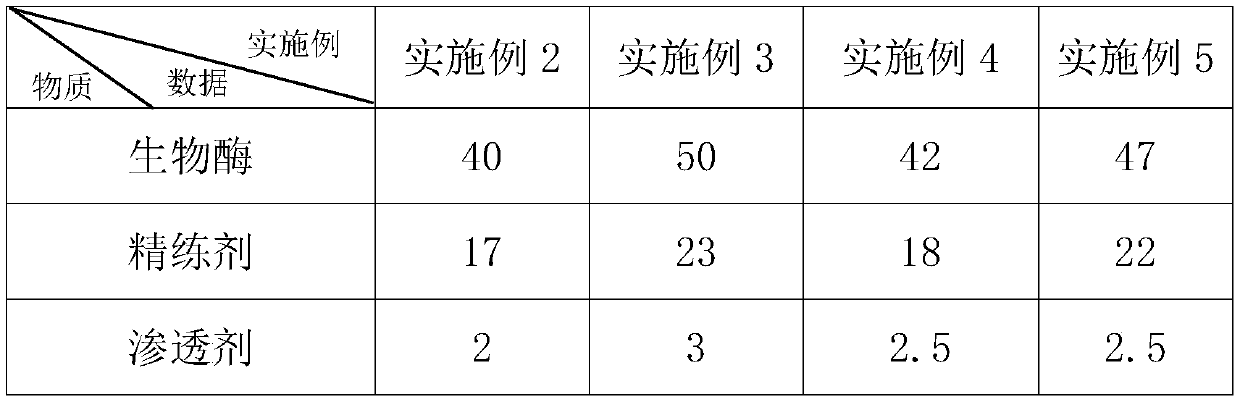

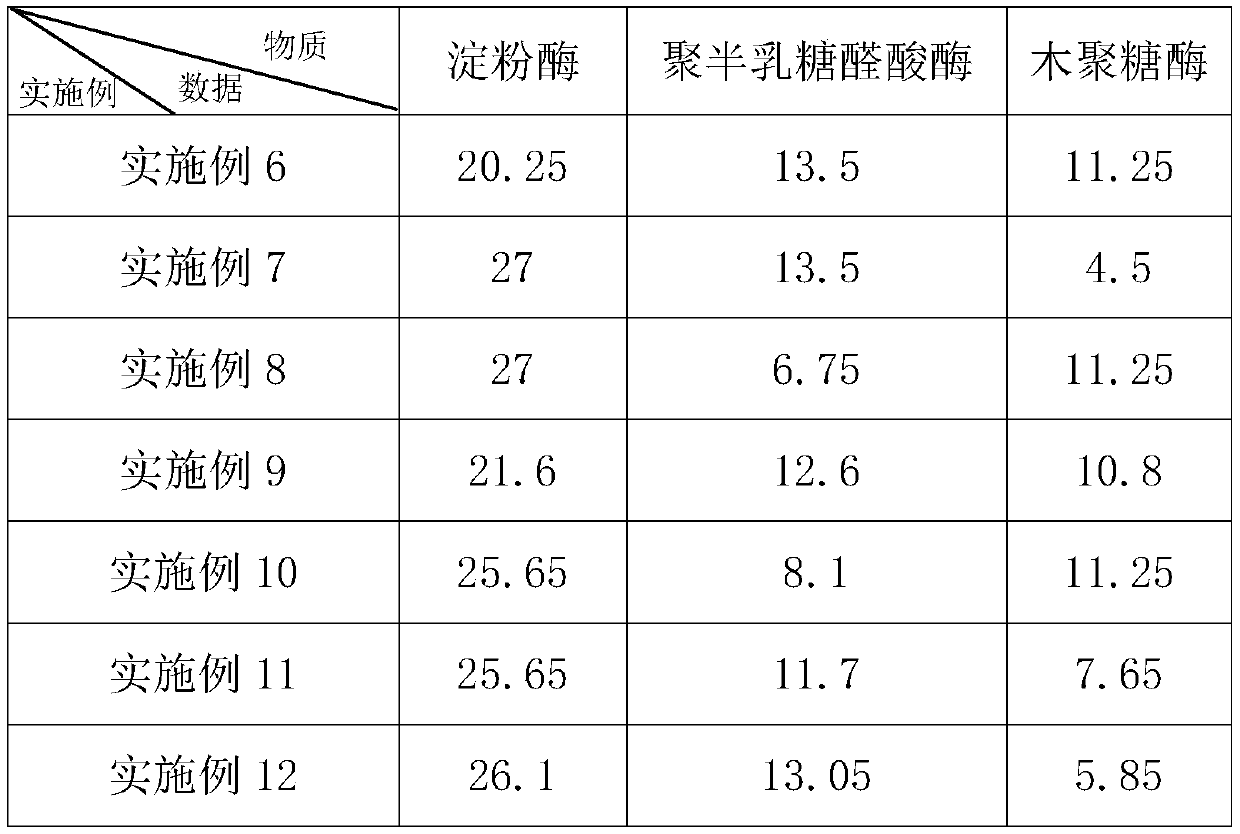

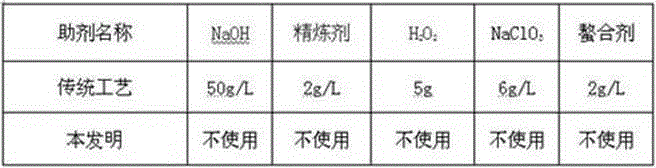

Pre-treatment process of textile fabric

ActiveCN105155282AImprove dyeing effectEfficient decompositionBiochemical fibre treatmentBleaching apparatusWastewaterBiological agent

The invention relates to a pre-treatment process of a textile fabric. The pre-treatment process comprises: a step of clear water boiling, a step of biological agent immersion, and a step of pre-treatment of dyeing in an overflow tank. The step of biological agent immersion comprises: adding a biological agent, citric acid, and glucose into the textile fabric; adjusting the pH value to 4.5-5.0; and immersing the textile fabric at a constant temperature in a range of 35-39 DEG C for 8-12 days, wherein the biological agent is a plant ferment consisting of brown sugar, fruits, and water. A preparation method of the plant ferment includes fermenting brown sugar, fruits, and water in the absence of light for 2.5-3.5 months in a sealed environment. Since the biological agent is added, pectin and lignin in linen fiber can be effectively decomposed. Compared with a traditional process, the pre-treatment process is saved in water, power, and gas. Discharge of waste water is greatly reduced due to no addition of a printing and dyeing auxiliary, thereby satisfying the requirement of environment protection and energy saving.

Owner:SHAOXING CITY KEQIAO DISTRICT DELONG CLOTH

Wet short steaming pad dyeing process adopting vat dye microcapsules

ActiveCN106012376AImprove stabilityImprove dyeing effectTextile treatment containersTextile treatment machine arrangementsColour fastnessPh buffering

The invention discloses a wet short steaming pad dyeing process adopting vat dye microcapsules. The wet short steaming pad dyeing process comprises procedures as follows: S1, padding and rolling in a dyeing : to-be-dyed fabric is padded in the dyeing for double padding and double rolling, and the dyeing is prepared from 0.1%-10% (owf) of the vat dye microcapsules, 1-20 g / L of thiourea dioxide, 1-3 g / L of a pH buffering agent, 1-3 g / L of a penetrant and 5-30 g / L of an accelerator; S2, padding and rolling in an alkaline : the to-be-dyed fabric obtained through treatment in S1 is directly padded and rolled in the alkaline for single padding and single rolling, and the alkaline is prepared from 5-30 g / L of caustic soda and 0-10 g of sodium dithionite; S3, reduction and steaming: saturated steam is used for rapid steaming; S4, oxidization: hydrogen peroxide is adopted for oxidation. By means of the wet short steaming pad dyeing process adopting the vat dye microcapsules, the level dyeing property and the color fastness are remarkably improved, the process is simple and energy is saved.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

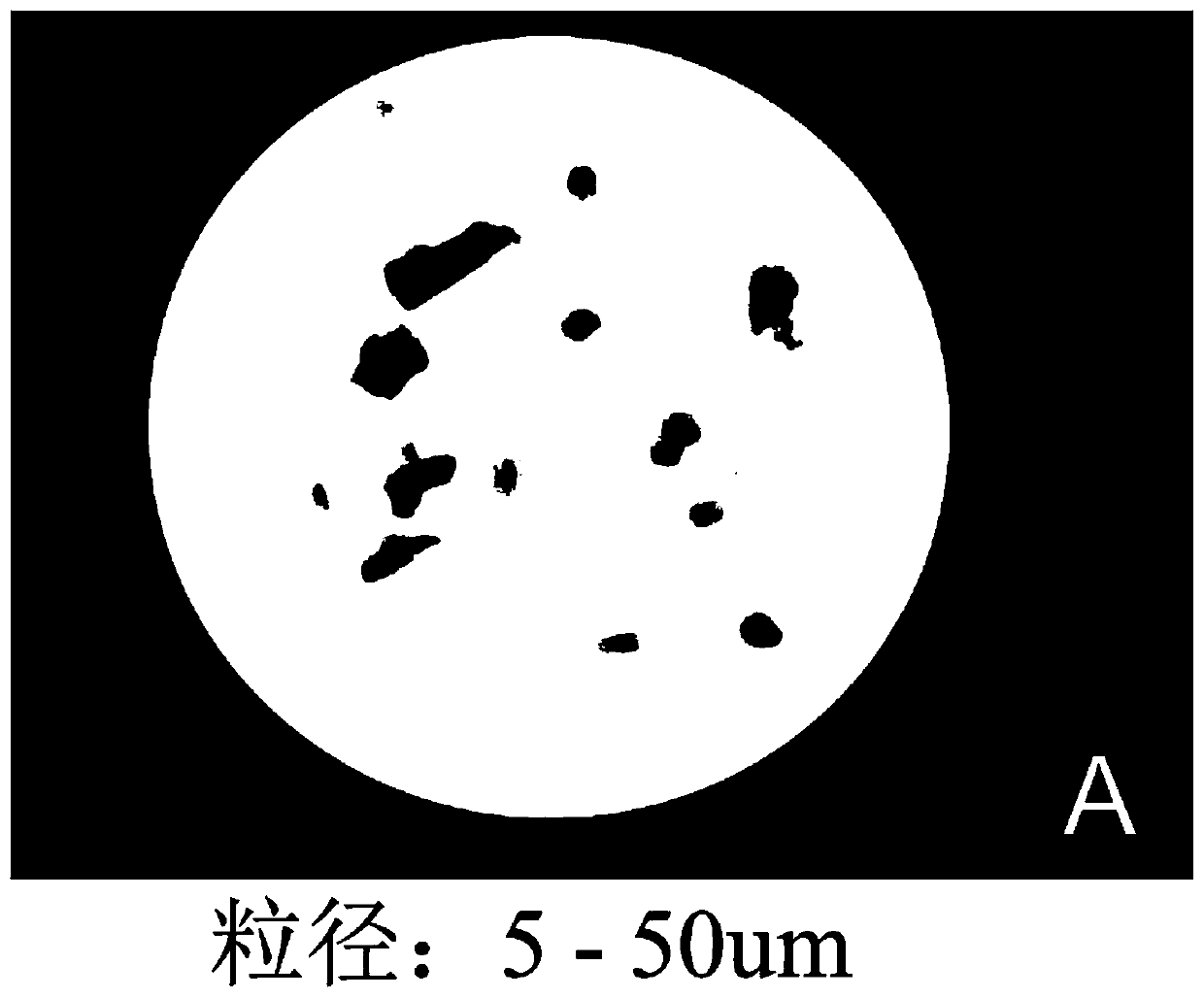

Method for producing dye through textile waste materials to dye fabric

The invention provides a method for producing a dye through textile waste materials to dye fabrics. The method includes the following steps that fiber grinding is conducted on the textile waste materials, and fiber powder is obtained; cationization process is conducted on fabrics by using cationic finishing agent, and to-be-dyed fabrics are obtained; the obtained fiber powder is used as the dye todye the to-be-dyed fabrics, and the fiber-power-dyed fabrics are obtained. According to the method of fiber grinding, grinding can be effective, the fiber powder with small particle diameter, lower granularity and uniform distribution, dyeing of the fiber powder is facilitated in the follow-up dyeing process, and the degree of dyeing is increased; according to the method for producing the dye through the textile waste materials to dye the fabrics, through the technology for treating processing, uniformity of dyeing, the degree of dyeing and color fastness are improved, and amount of the fiberpowder is further decreased greatly; and according to the method for producing the dye through the textile waste materials to dye the fabrics, cyclic utilization of fibers and the dye can be achieved, and the pollution on environment caused by a large amount of the wasted fibers is reduced.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

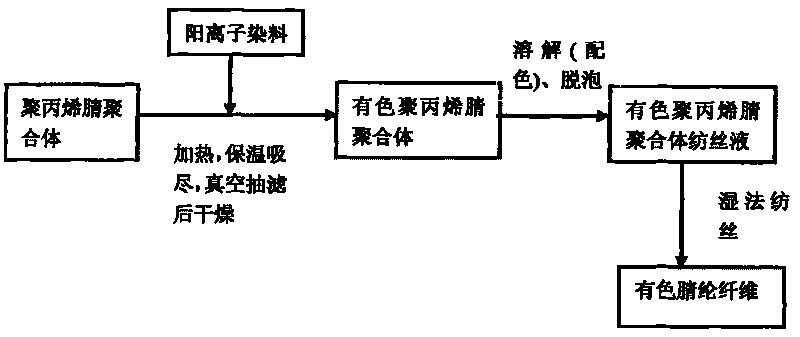

Production process of colored viscose filament yarns

ActiveCN102808232AEvenly dyedReduce secondary pollutionMonocomponent cellulose artificial filamentCellulose/protein filament chemical after-treatmentPolymer scienceSpinning

The invention relates to a production process of colored viscose filament yarns, and belongs to the technical field of the production and the manufacturing of the colored viscose filament yarns, particularly the manufacturing of the colored viscose filament yarns by using a before-spinning solution dyeing method. By using the production process, through improving color paste solution preparation, colored viscose preparation and spinning dyeing formation, a novel reducing agent is not introduced anymore; the production investment and the secondary pollution of the reducing agent are reduced; by using the production process, a dye paste solution is directly reduced by directly utilizing a reducing environment in a viscose; the reducing agents such as sodium hydrosulfite are not introduced anymore; production working procedures are decreased; the production cost is reduced; meanwhile, by using the production process, an oxidant is used in a targeted way; all reduced dyes can also carry out uniform dyeing; the product quality is improved; and the color range of a product is broadened.

Owner:YIBIN GRACE +2

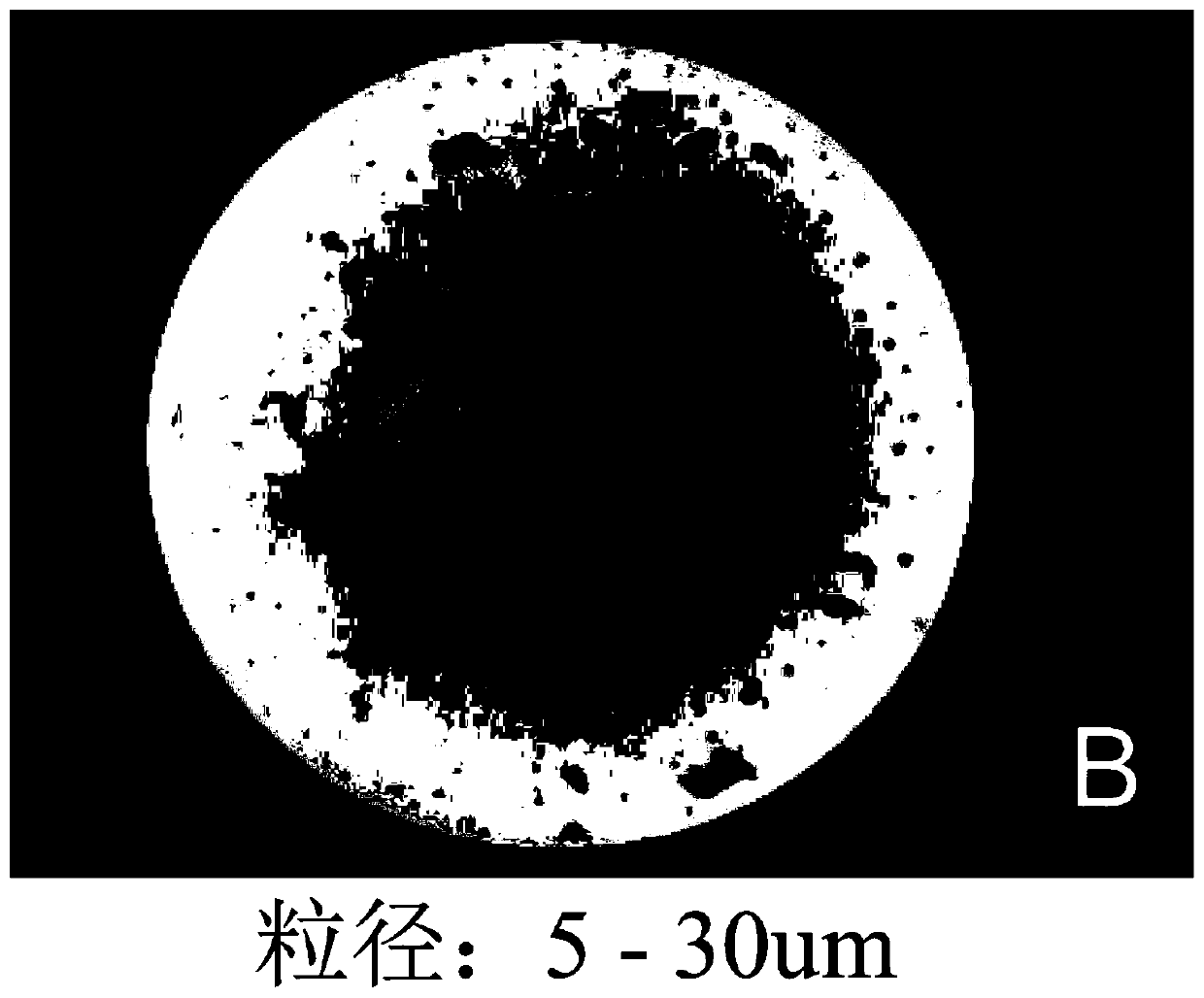

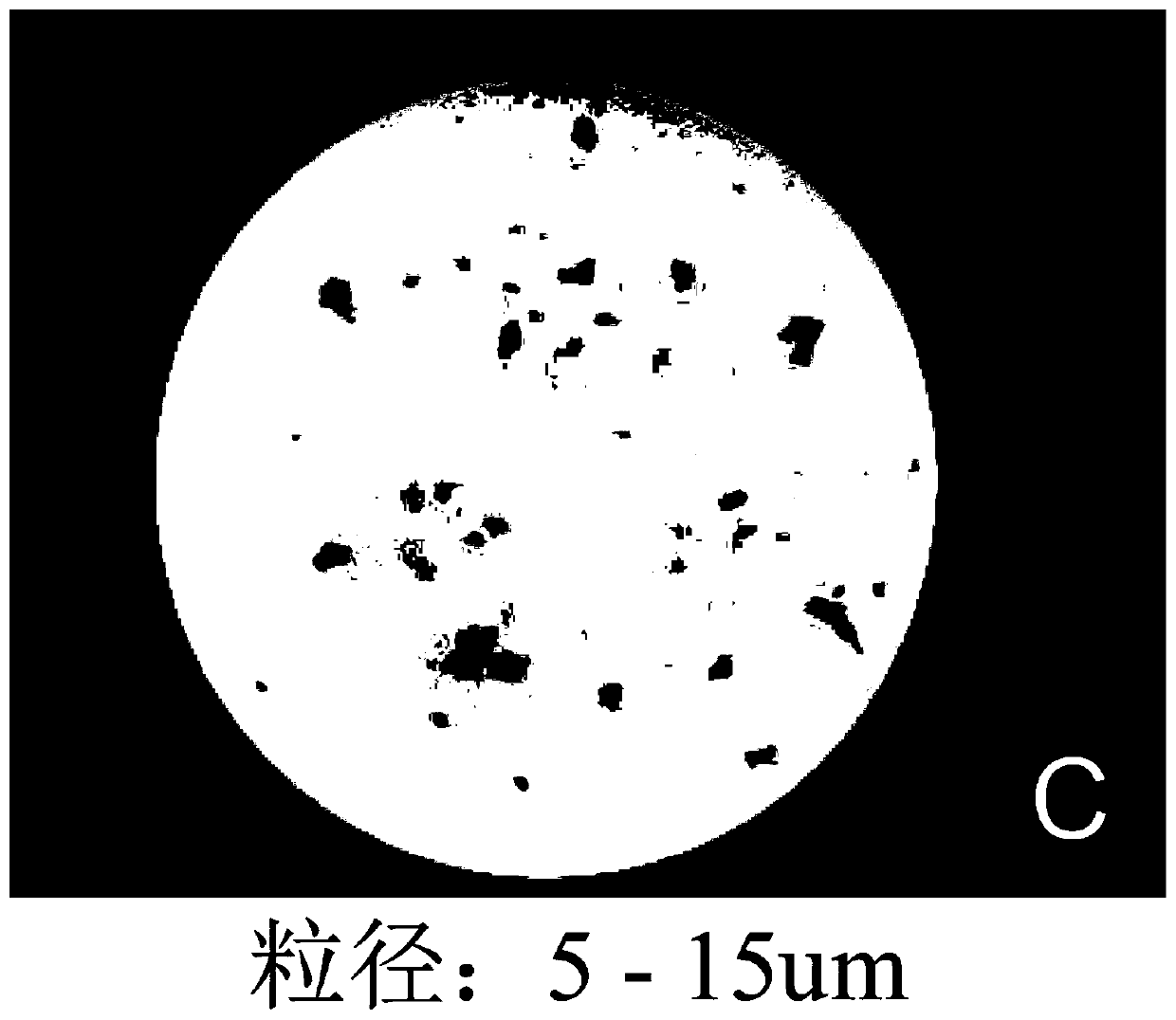

Cold-pad batch dyeing process of loose fibers

InactiveCN105671833ASmall particlesImprove dye uptakeTextile storage in superimposed formLiquid/gas/vapor removalFiberCavitation

The invention provides cold-pad batch dyeing process of loose fibers. The process comprises following steps: supersonic wave dyeing through pressing extraction, rotary cold-batch, water extraction through pressurization and aftertreatment. In the ultrasonic treatment, dyes are placed into an ultrasonic dyeing machine for increasing temperature. After supersonic waves are started, carboxylic carbon nanospheres and levelling agents are added and stirred for dyeing by putting loose fibers.Due to effect of acoustic cavitation of supersonic waves, loose fibers maintain their smaller particle with dispersibility not affected by temperature control. The manufacturing process is simple and helps save water and cost. Meanwhile, carboxylic carbon nanospheres and physical absorption and hydrogen bond combination performance of dyes as well as chemical effect of active groups of carboxylic carbon nanospheres, combination degree of dyes and loose fibers is increased and therefore dye rate is improved and up to more than 95%.

Owner:朱忠良

Preparation method of dispersing dye microcapsule

InactiveCN1216949CControl the rate of diffusionGood sustained release effectOrganic dyesMicroballoon preparationDisperse dyeAdjuvant

The present invention provides a method for preparing disperse dye microcapsule by utilizing melamine resin performed polymer and ethylene monomer as monomer for forming microcapsule well material and adopting in-situ polymerization. The wall material has good slowly-releasing property, centralized grain size distribution (generally, the grain size is 2-14 micrometer), small dose of adjuvant. It can control release of dye, can be used for dyeing and multiple transfer printing of polyester fabrics, and can raise utilization rate of dye and reduce pollution.

Owner:SHANGHAI WOODGE TEXTILE TECH

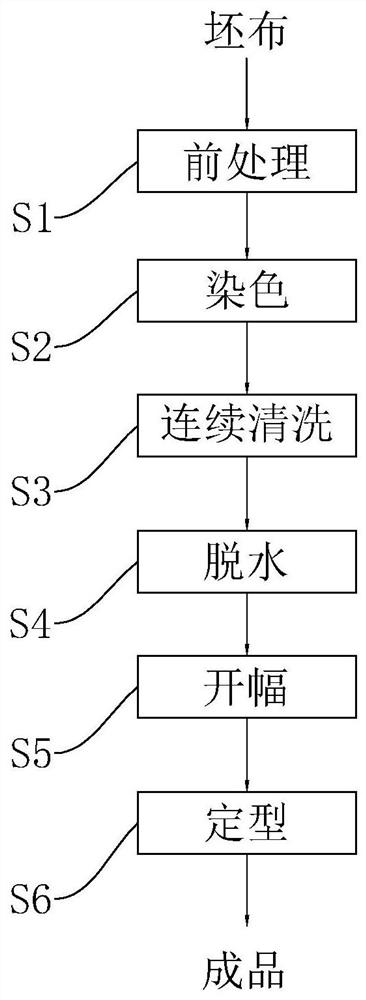

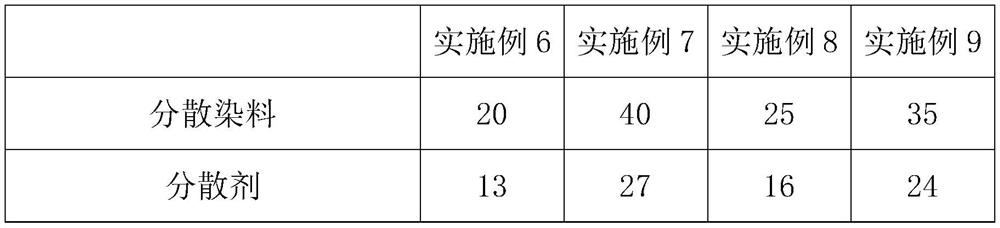

Dyeing process of polyester fabric

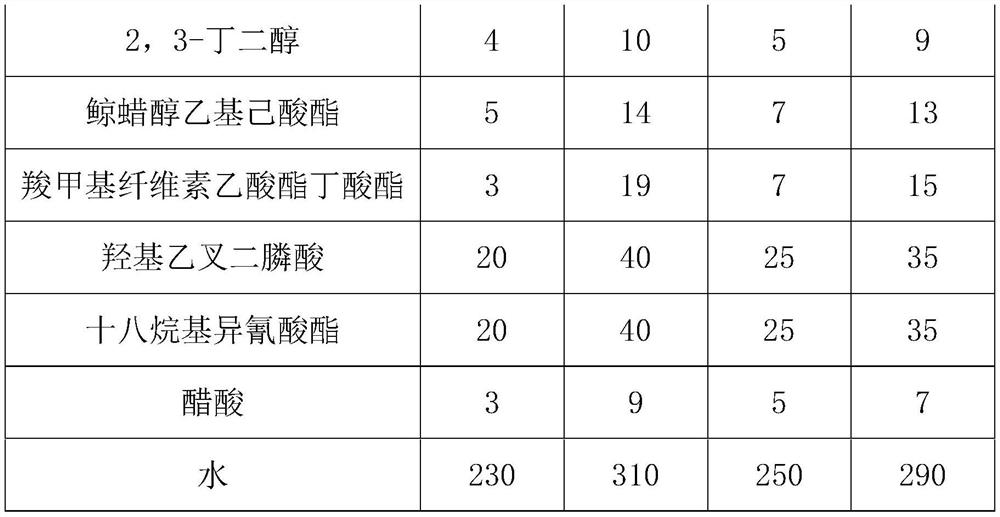

The application relates to the technical field of fabric dyeing and finishing, and discloses a dyeing process for polyester fabrics. A polyester grey fabric is subjected to the following operations: S1: pretreatment; S2: dyeing, namely, dyeing the grey fabric after the treatment in S1, wherein a dye used for dyeing comprises the following components in parts by weight: 20-40 parts of a disperse dye, 13-27 parts of a dispersant, 4-10 parts of 2,3-butanediol, 5-14 parts of cetyl ethyl hexanoate, 3-19 parts of carboxymethyl cellulose acetate butyrate, 20-40 parts of hydroxyethylidene diphosphonicacid, 20-40 parts of octadecylisocyanate, 3-9 parts of acetic acid and 230-310 parts of water; S3: continuous cleaning, namely, continuously cleaning the grey fabric after the treatment in S2; S4: dehydration; S5: scutching; and S6: setting; and the grey fabric after the setting in S6 is a dyed polyester fabric. The color fastness of polyester fabric dyeing can be improved.

Owner:诸暨市泓宇化纤漂染有限公司

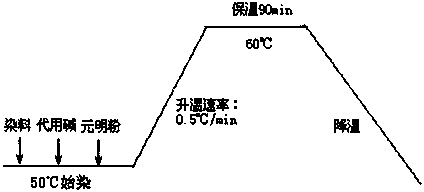

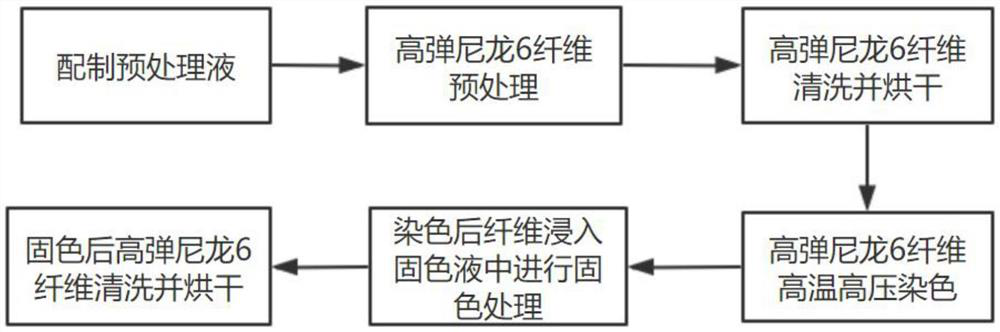

Dyeing method capable of improving dyeing performance of high-elastic nylon 6 fibers

PendingCN113073482AFully dyedImprove color fixationDyeing processColour fastnessEnvironmentally friendly

The invention discloses a dyeing method capable of improving the dyeing performance of high-elastic nylon 6 fibers. The method comprises the steps of dyeing pretreatment, a dyeing process and a color fixing process. According to the dyeing method, the dyeing performance of the high-elastic nylon 6 fibers can be effectively improved, the dyeing rate, the fixation rate, the K / S value and the level dyeing performance of the fibers are remarkably improved, and the washing color fastness, the rubbing color fastness and the light color fastness of fabric are improved. The process is simple and efficient, the usage amount of dye can be remarkably reduced, the method is environmentally friendly, the adopted reagent is efficient in dyeing, bright in color and not prone to fading, and the efficient and lasting dyeing effect can be achieved. On the basis that the dyeing performance of the high-elastic nylon 6 fibers is enhanced, the simplicity, high efficiency and environmental friendliness of the dyeing process are further improved, and wide application of the high-elastic nylon 6 fibers and fabric can be promoted.

Owner:绍兴市柯桥区东纺纺织产业创新研究院

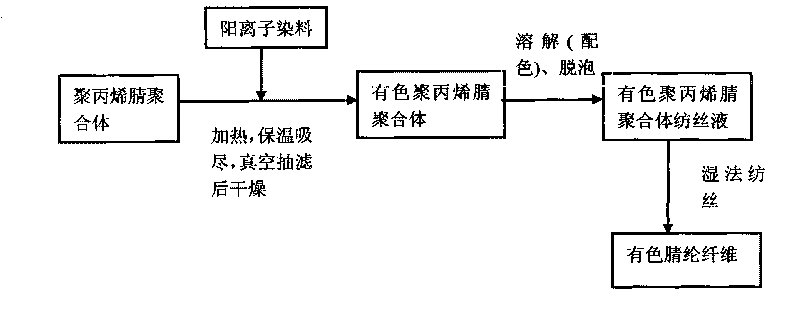

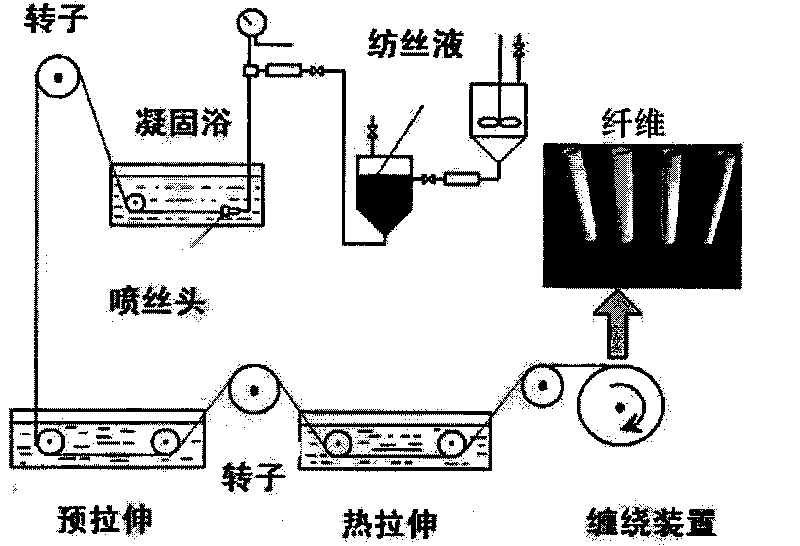

Method for preparing colored polyacrylonitrile fibers

InactiveCN101709514AEasy to prepareLow costMonocomponent synthetic polymer artificial filamentWet spinning methodsPolymer scienceSodium thiocyanate

The invention relates to a method for preparing colored polyacrylonitrile fibers, which comprises the following steps: (1) mixing water-soluble cationic dye, powder or slurry polyacrylonitrile polymer and water, adjusting the pH value of the mixture to 2 to 6, heating the mixture to between 95 and 100 DEG C, preserving the heat, and drying the mixture; (2) dissolving the dried mixture in solution of sodium thiocyanate to obtain spinning stock solution of the colored polyacrylonitrile fibers, and defoaming the solution at the temperature of between 40 and 80 DEG C; and (3) treating the defoamed spinning stock solution through conventional wet spinning to obtain the colored polyacrylonitrile fibers. The method of the invention is simple, has low cost and light pollution, and is suitable for industrialized production.

Owner:DONGHUA UNIV

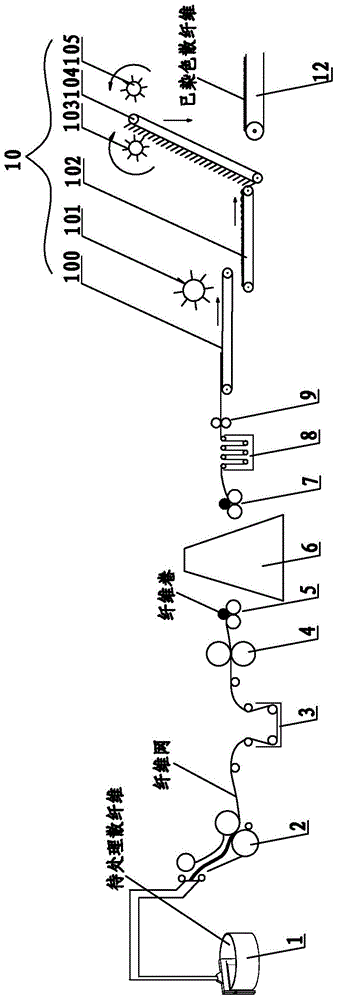

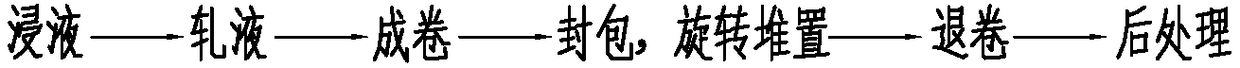

Cooling stacking technology

PendingCN108547096AAvoid uneven distributionEvenly dyedTextile storage in superimposed formFiberEngineering

The invention relates to a cooling stacking technology, and belongs to the technical field of loose stock dyeing. To-be-processed loose fibers, fiber webs or similar materials are subjected to immersion, liquid squeezing and rolling, after rolling, the loose fibers, the fiber webs or the similar materials are packaged in a closed environment, rotating and stacking are carried out, after the rotating and stacking are completed, unrolling is performed, and the loose fibers, the fiber webs or the similar materials are subjected to the next process. The technology is applied to the cooling stacking color fixation of the loose fibers, fiber webs or similar materials, and has the advantages of uniform dyeing, continuous processing and the like.

Owner:绍兴国周针织科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com