Proficiency testing sample for measuring color fastness to perspiration of textile and preparation method of sample

A proficiency test and perspiration-resistant technology, applied in the field of light industrial textiles, can solve the problems of low color fastness level and high difficulty, and achieve the effect of simple preparation method and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Select the base fabric: choose a pure cotton woven plain bleached gray fabric with a smooth surface and no defects. The parameters of the gray fabric are: warp density 288 threads / 10cm, weft density 160 threads / 10cm, warp and weft yarn count 40~ 60Ne, the weight per square meter is 120-180g / ㎡, and the width is 144cm.

[0041] (2) Select the dyeing method: overflow dyeing method, using SME30 overflow dyeing machine.

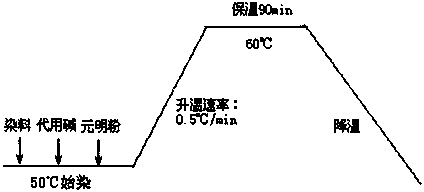

[0042] (3) Choose dye and formula: choose direct red 4G. The formula of Direct Red 4G is: Direct Red 4G: 6.5% (o.w.f), Pinpingjia O: 0.5%, Yuanmingfen: 5g / L, the dyeing process curve is shown in figure 1 .

[0043] (4) Dyeing: The bath ratio is 1:30, and the dyeing process is as follows: base fabric preparation → pretreatment → dyeing → washing → dehydration → drying, tentering and shaping → cloth inspection and rolling.

[0044] 1) Base fabric preparation: cut the base fabric according to the length required for sample preparation on the open-width ...

Embodiment 2

[0058] (1) Select the base fabric: choose a pure cotton woven plain bleached gray fabric with a smooth surface and no defects. The parameters of the gray fabric are: warp density 288 threads / 10cm, weft density 160 threads / 10cm, warp and weft yarn count 40~ 60Ne, the weight per square meter is 120-180g / ㎡, and the width is 144cm.

[0059] (2) Select the dyeing method: overflow dyeing method, using SME30 overflow dyeing machine.

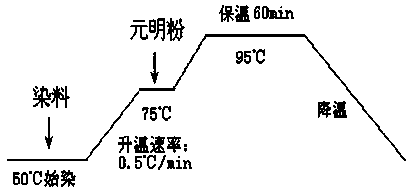

[0060] (3) Choose dye and formula: choose reactive red 3BSN. The formula of reactive red 3BSN is: reactive red 3BSN: 4% (o.w.f), substitute alkali: 2.0%, sodium sulfate: 50g / L, the dyeing process curve is shown in figure 2 .

[0061] (4) Dyeing: The bath ratio is 1:30, and the dyeing process is as follows: base fabric preparation → pretreatment → dyeing → washing → dehydration → drying, tentering and shaping → cloth inspection and rolling.

[0062] 1) Base fabric preparation: cut the base fabric according to the length required for sample preparatio...

Embodiment 3

[0076] (1) Select the base fabric: choose a pure cotton woven plain bleached gray fabric with a smooth surface and no defects. The parameters of the gray fabric are: warp density 288 threads / 10cm, weft density 160 threads / 10cm, warp and weft yarn count 40~ 60Ne, the weight per square meter is 120-180g / ㎡, and the width is 144cm.

[0077] (2) Select the dyeing method: overflow dyeing method, using SME30 overflow dyeing machine.

[0078] (3) Choose dye and formula: choose direct frozen yellow G. The formula of direct frozen yellow G is: direct frozen yellow G: 6% (o.w.f), Pingpingjia O: 0.8%, Yuanming powder: 5g / L, the dyeing process curve is shown in figure 1 .

[0079] (4) Dyeing: The bath ratio is 1:30, and the dyeing process is as follows: base fabric preparation → pretreatment → dyeing → washing → dehydration → drying, tentering and shaping → cloth inspection and rolling.

[0080] 1) Base fabric preparation: cut the base fabric according to the length required for sample ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com