Dyeing method capable of improving dyeing performance of high-elastic nylon 6 fibers

A technology of dyeing performance and dyeing method, which is applied in the field of dyeing technology of high-elastic nylon 6 fiber, and can solve the problems of poor level dyeing, low dyeing rate, low color fastness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

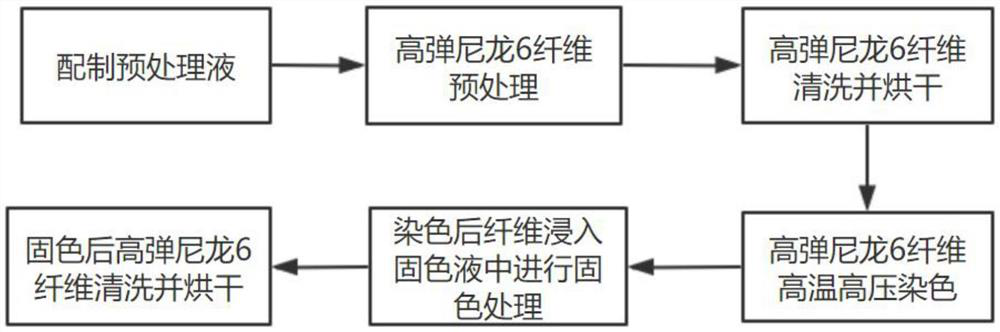

Image

Examples

Embodiment 1

[0026] A dyeing method for improving the dyeing performance of high-elastic nylon 6 fibers. The specific steps are: before the high-elastic nylon 6 fibers are dyed with acid dyes, first select 4g / L glacial acetic acid and 3g / L acid penetrant, and use a volume ratio of 3: 1 Mix evenly, adjust the pH value to 2 to prepare the pretreatment solution, immerse the fiber in the pretreatment solution, raise the temperature of the pretreatment solution to 100°C, keep it warm for 30 minutes, cool the pretreatment solution to room temperature, take out the fiber, wash and dry it with warm water Dry; the pretreated fiber is immersed in the acid dye solution in the autoclave according to the liquor ratio of 10:1, and the autoclave is heated to 80°C, while the pressure in the autoclave is increased to 150kPa, and the dye solution is kept warm for 40min , then cool the dyeing solution to room temperature, open the autoclave to take out the fiber, and then carry out water washing, soaping, wat...

Embodiment 2

[0028] Before the high-elastic nylon 6 fiber is dyed with acid dyes, first select 4g / L glacial acetic acid and 4g / L acid penetrant, mix them uniformly at a volume ratio of 5:1, and adjust the pH value to 2 to prepare a pretreatment solution. Immerse in the pretreatment solution, raise the temperature of the pretreatment solution to 100°C, keep it warm for 30 minutes, cool the pretreatment solution to room temperature, take out the fiber, wash it with warm water, and dry it; the pretreated fiber is immersed in an autoclave at a bath ratio of 15:1 In the acid dye solution in the acid dyeing solution, the autoclave is heated to 80°C, and the pressure in the autoclave is raised to 150kPa at the same time, and the dye solution is kept warm for 50 minutes, and then the temperature of the dye solution is cooled to room temperature, and the autoclave is opened to take out the fiber and then carry out sequentially It is washed, soaped, washed, and dried to obtain dyed high-elastic nylon...

Embodiment 3

[0030] Before the high-elastic nylon 6 fiber is dyed with acid dyes, first select 5g / L glacial acetic acid and 4g / L acid penetrant, and mix them uniformly at a volume ratio of 5:1, and adjust the pH value to 2 to prepare a pretreatment solution. Immerse in the pretreatment solution, raise the temperature of the pretreatment solution to 100°C, keep it warm for 30 minutes, cool the pretreatment solution to room temperature, take out the fiber, wash it with warm water, and dry it; the pretreated fiber is immersed in an autoclave at a bath ratio of 20:1 In the acid dye solution in the acid dyeing solution, the autoclave is heated to 80°C, and the pressure in the autoclave is increased to 170kPa at the same time, and the dye solution is kept warm for 50 minutes, and then the temperature of the dye solution is cooled to room temperature, and the autoclave is opened to take out the fiber and then carry out sequential treatment. It is washed, soaped, washed, and dried to obtain dyed hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com