Anti-precipitation elastic jacquard screen fabric printing device and process

A kind of dyeing equipment and anti-sedimentation technology, which is applied in the direction of textile material equipment configuration, textile material treatment, textile processing machine accessories, etc., can solve the problems of finished product difference, dyeing effect reduction, etc., achieve safe and convenient use, and avoid dyeing. Sufficient and guaranteed stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

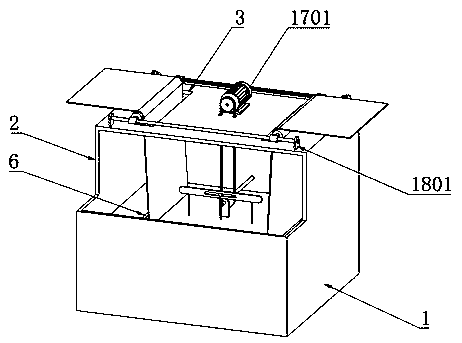

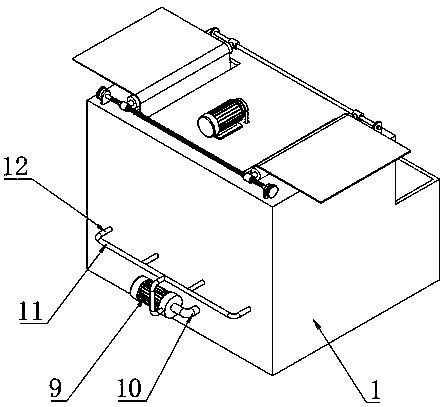

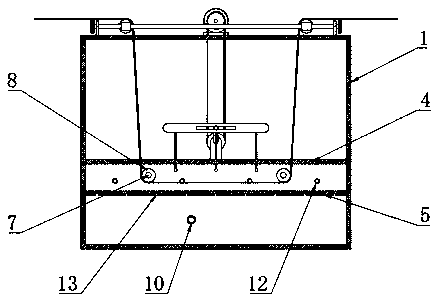

[0055] Embodiment 1: as Figure 1-9 As shown, the present invention provides a technical solution, a kind of elastic jacquard mesh dyeing equipment that can prevent precipitation, including a dyeing vat 1, and an observation notch 2 is provided at the top end of the dyeing vat 1, which is convenient for users to observe, and The top of the dyeing vat 1 is symmetrically opened with a first cloth inlet notch 3 to realize the entry of the jacquard mesh. The inner bottom of the dyeing vat 1 is welded with a top partition plate 4, and the inner bottom of the dyeing vat 1 corresponds to the top partition. The lower part of the board 4 is welded with a bottom partition 5, and the top of the top partition 4 corresponds to the first cloth feeding notch 3, and a second cloth feeding notch 6 is opened through it, so that the jacquard mesh enters the top partition 4 and the bottom partition plate 5, the top partition plate 4 bottom one side part is all welded with the mounting plate 19 at...

Embodiment 2

[0067] Embodiment 2: as Figure 10 Shown, a kind of elastic jacquard mesh dyeing process specifically comprises the following steps:

[0068] An elastic jacquard mesh dyeing process specifically comprises the following steps:

[0069] S1. Refining: Put the elastic jacquard mesh to be dyed into the refining agent to reduce the surface tension of the elastic jacquard mesh;

[0070] S2. Connecting the guide cloth: seam the wetted elastic jacquard mesh with the guide cloth;

[0071] S3. Dyeing: Pull the guide cloth to drive the elastic jacquard mesh to be dyed to be soaked in the dyeing solution for dyeing;

[0072] S4. Extrusion: the dyed elastic jacquard mesh passes through two extrusion rollers to squeeze out excess dyeing liquid;

[0073] S5. Drying: pass the dyed elastic jacquard mesh through a fabric dryer;

[0074] S6. Screening: screening the dyed elastic jacquard mesh;

[0075] S7. Rolling: the elastic jacquard mesh that has passed the dyeing is collected into a roll...

Embodiment 3

[0078] Embodiment 3: as Figure 10 Shown, a kind of elastic jacquard mesh dyeing process specifically comprises the following steps:

[0079] An elastic jacquard mesh dyeing process specifically comprises the following steps:

[0080] S1. Refining: Put the elastic jacquard mesh to be dyed into the refining agent to reduce the surface tension of the elastic jacquard mesh;

[0081] S2. Connecting the guide cloth: seam the wetted elastic jacquard mesh with the guide cloth;

[0082] S3. Dyeing: Pull the guide cloth to drive the elastic jacquard mesh to be dyed to be soaked in the dyeing solution for dyeing;

[0083] S4. Extrusion: the dyed elastic jacquard mesh passes through two extrusion rollers to squeeze out excess dyeing liquid;

[0084] S5. Drying: pass the dyed elastic jacquard mesh through a fabric dryer;

[0085] S6. Screening: screening the dyed elastic jacquard mesh;

[0086] S7. Rolling: the elastic jacquard mesh that has passed the dyeing is collected into a roll. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com