Patents

Literature

149results about How to "Prevent back and forth movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

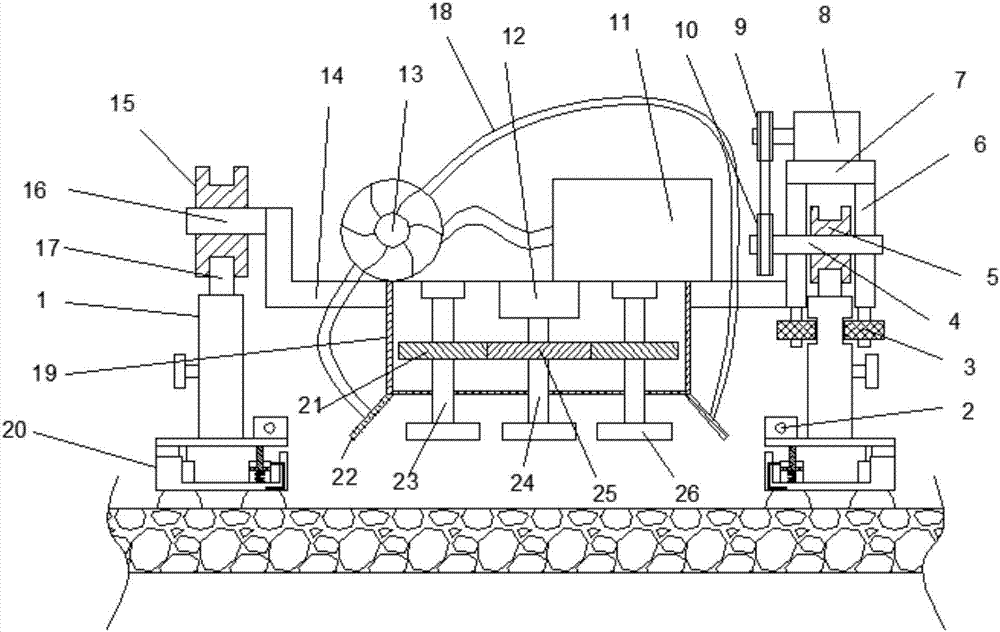

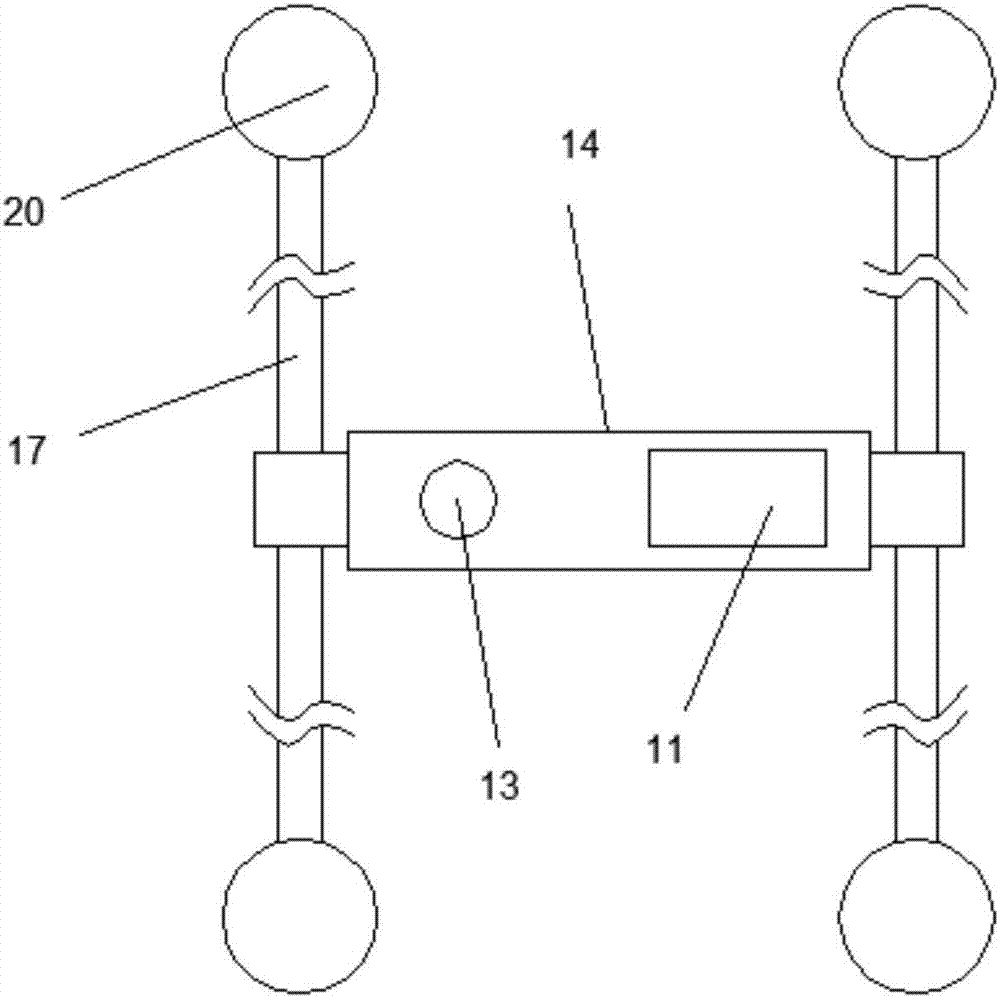

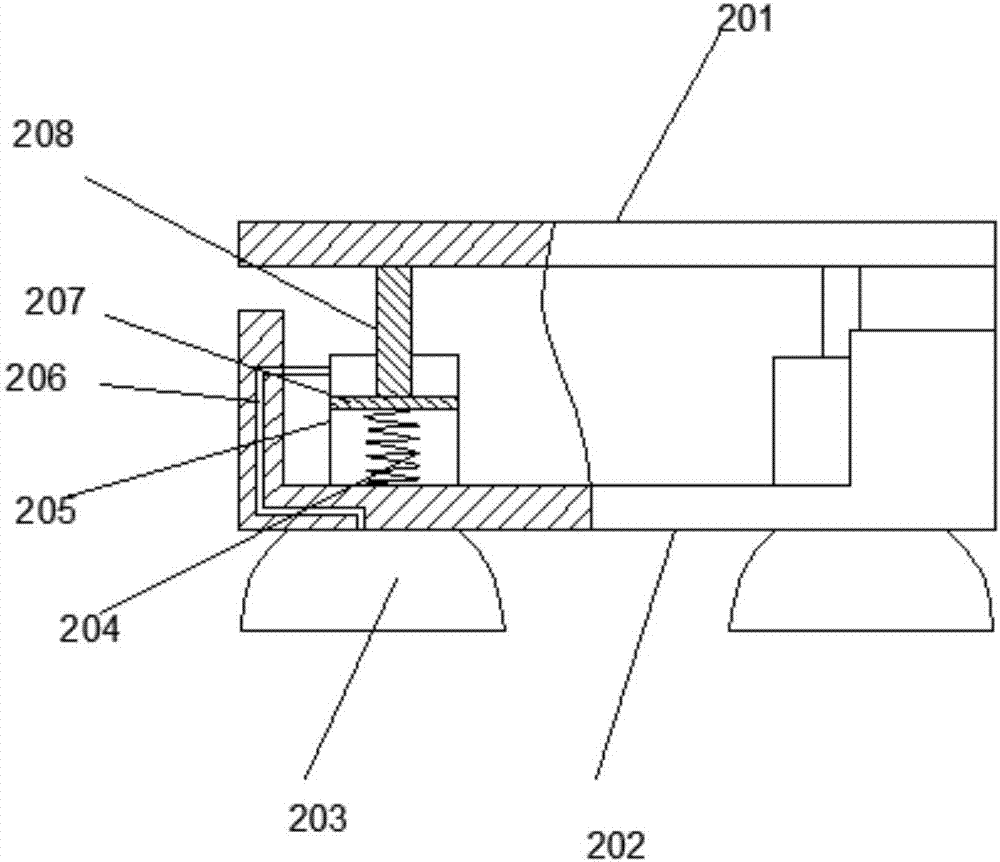

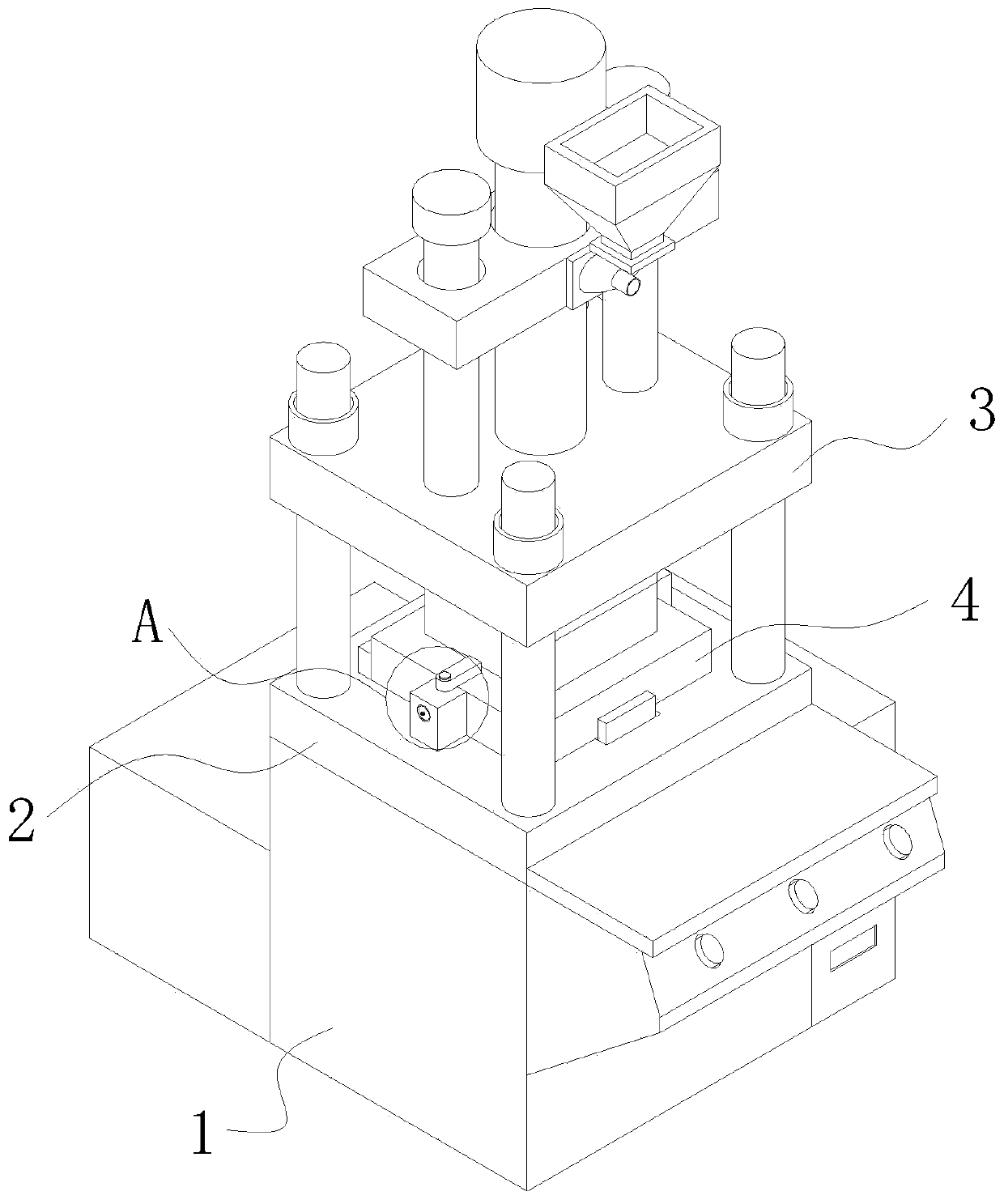

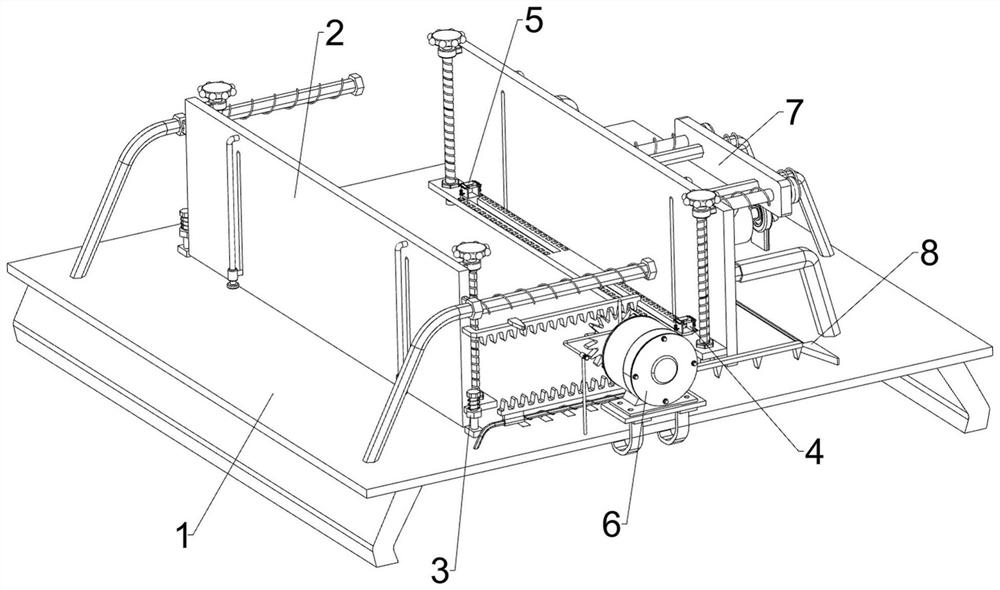

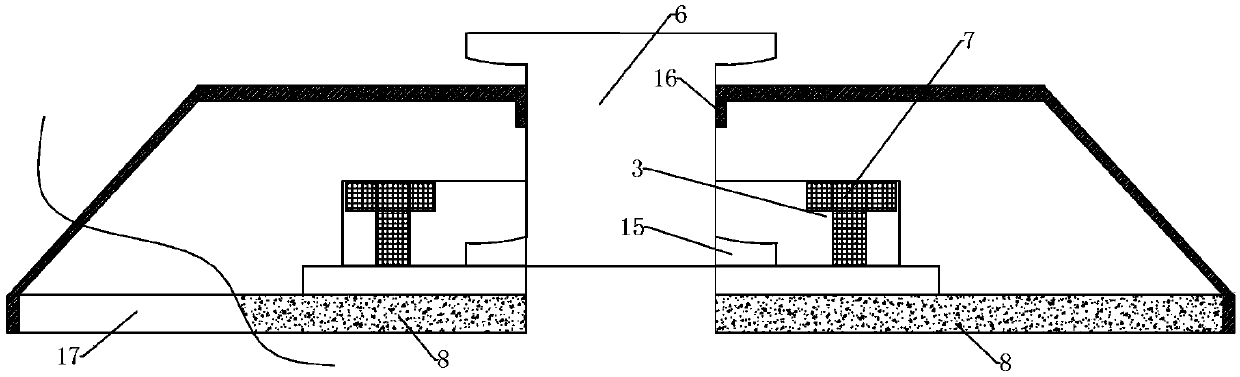

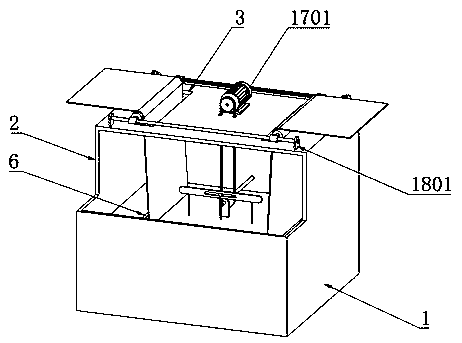

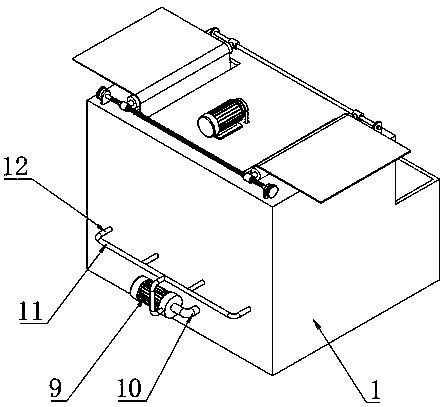

Polishing device for dustless building grounds

InactiveCN107097110AReasonable structureInnovative designGrinding carriagesGrinding work supportsAgricultural engineeringDrive shaft

The invention discloses a polishing device for dustless building grounds. The polishing device comprises an extension column; the upper end of the extension column is connected with limiting bars; the upper end of the limiting bar on the left side is connected with a driven walking wheel; the middle part of the driven walking wheel is connected with a driven shaft; the upper end of the limiting bar on the right side is connected with a driving walking wheel; the middle part of the driving walking wheel is connected with a driving shaft; limiting frames are connected to two ends of the driving shaft; the upper ends of the limiting frames are connected with a mounting plate; the upper end of the mounting plate is connected with a walking motor; the left end of the walking motor is connected with a driving belt wheel; the lower end of the driving belt wheel is connected with a driven belt wheel through a belt; a walking frame is connected between the driven shaft and the limiting frame on the left side; the middle part of the walking frame is connected with a driving box; the lower end of the driving box is connected with a dust sucking cover; and the lower end of the extension column is connected with a fixed base. The polishing device satisfies the polishing demands on the building grounds, prevents workers from being supported by a polishing machine to polish, reduces the labor intensity of construction workers, meanwhile, improves the polishing efficiency of the building grounds, and is high in practicability.

Owner:CHANGSHA WUDAO IND DESIGN CO LTD

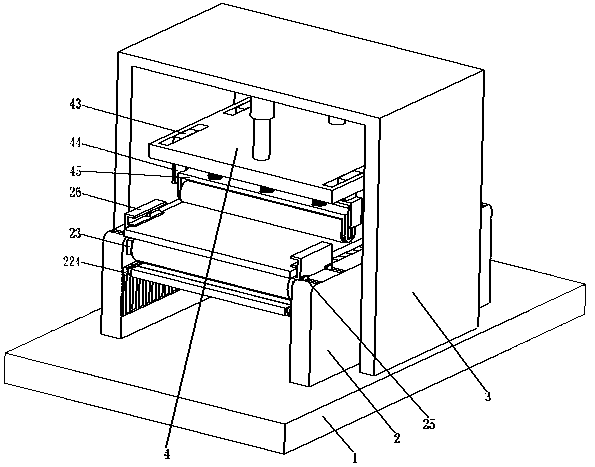

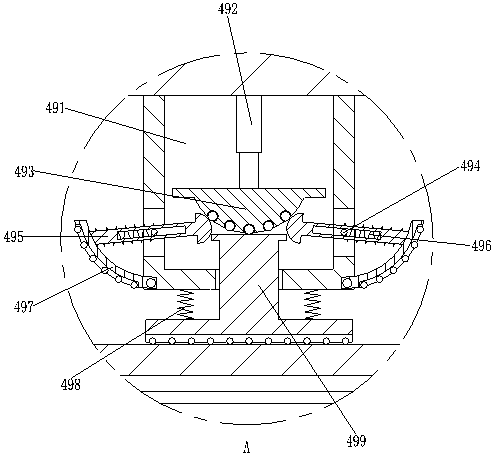

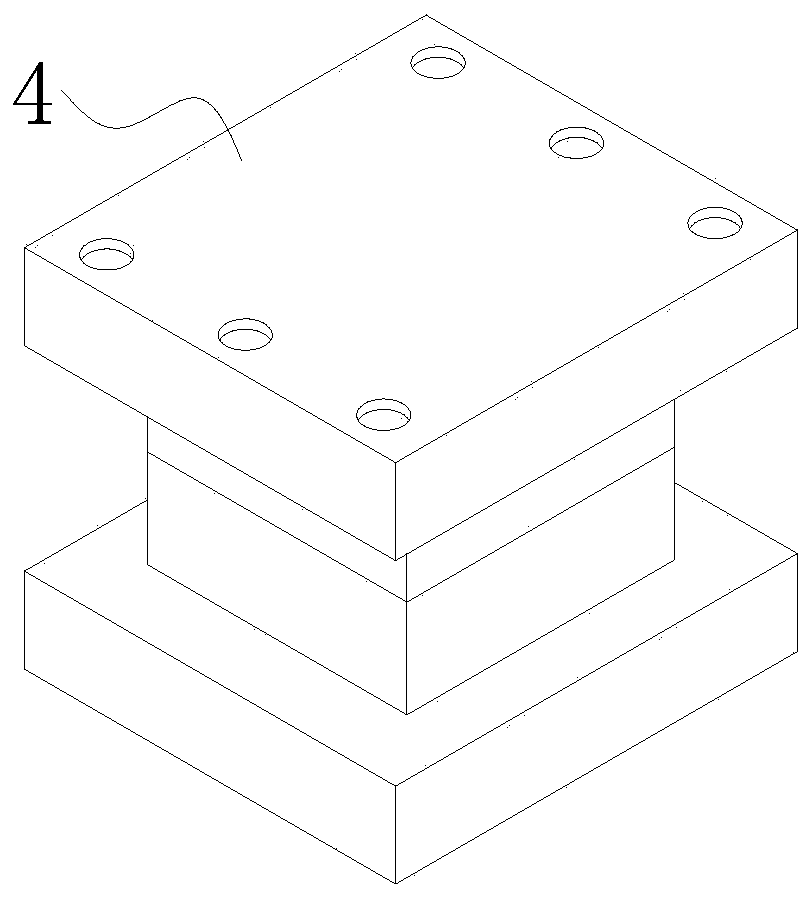

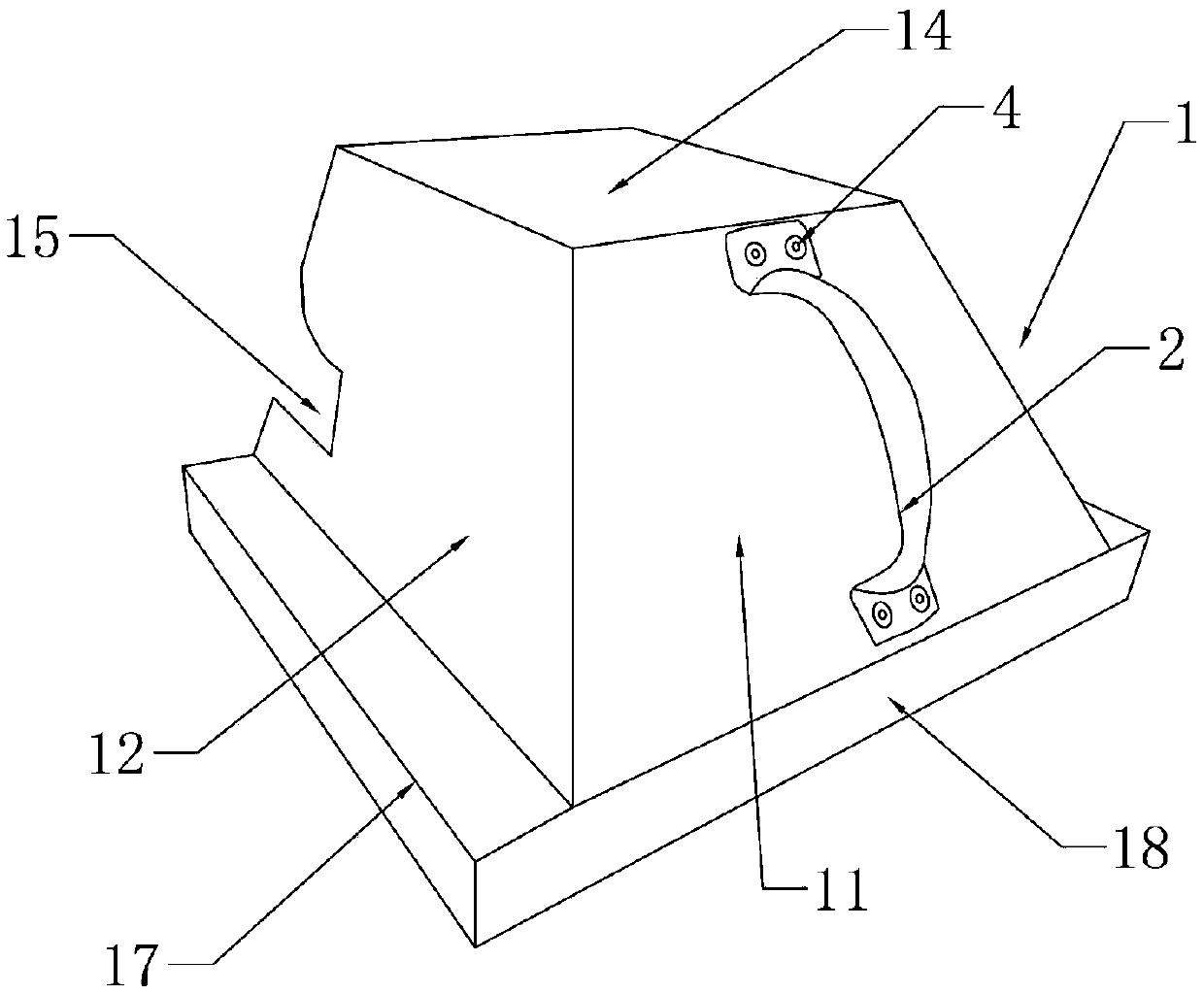

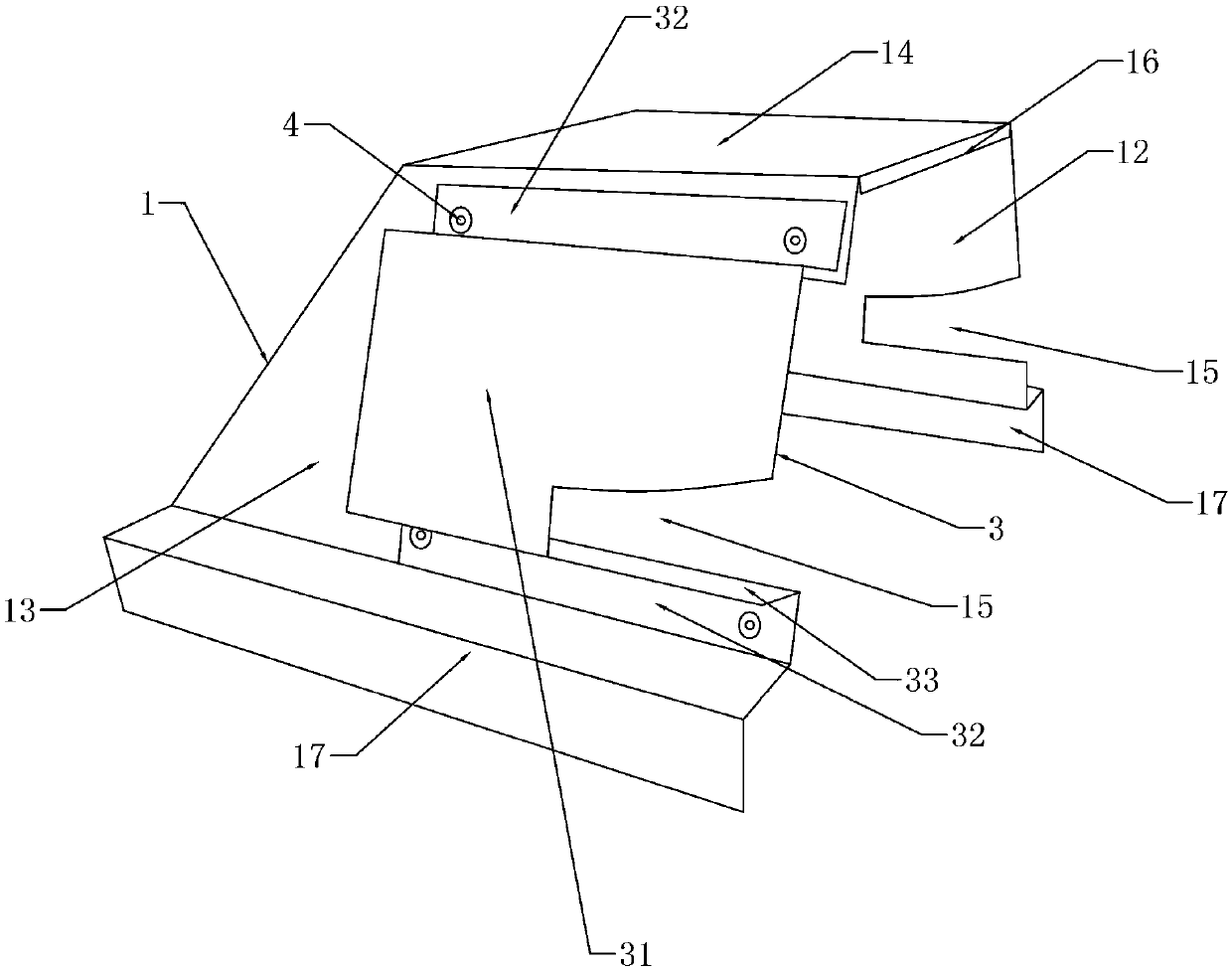

Plate bending and forming device

ActiveCN110814100AImprove protectionAvoid crackingMetal-working feeding devicesPositioning devicesWater leakagePunching

The invention provides a plate bending and forming device which comprises a bottom plate, a lower supporting device, a U-shaped frame and a bending device. The lower supporting device is installed atthe middle portion of the upper end of the bottom plate, the U-shaped frame is installed at the middle portion of the bottom plate, the bending device is arranged on the U-shaped frame, and the bending device is located over the lower supporting device. The plate bending and forming device solves the problems that as a plate which is generated by direct punching at present and has certain radian,deformation is caused due to sudden stress, and consequently cracks are prone to being caused at the bending deformation position of the plate; breaking, water leakage and the like of the plate in theusing process are caused; and the deforming plate which is generated through direct punching at present is fixed in all directions, consequently the thickness of the bending position of the plate inthe punching and bending processes is decreased, and the service life of the plate in the later period is influenced.

Owner:湖南省龙昊重工科技有限公司

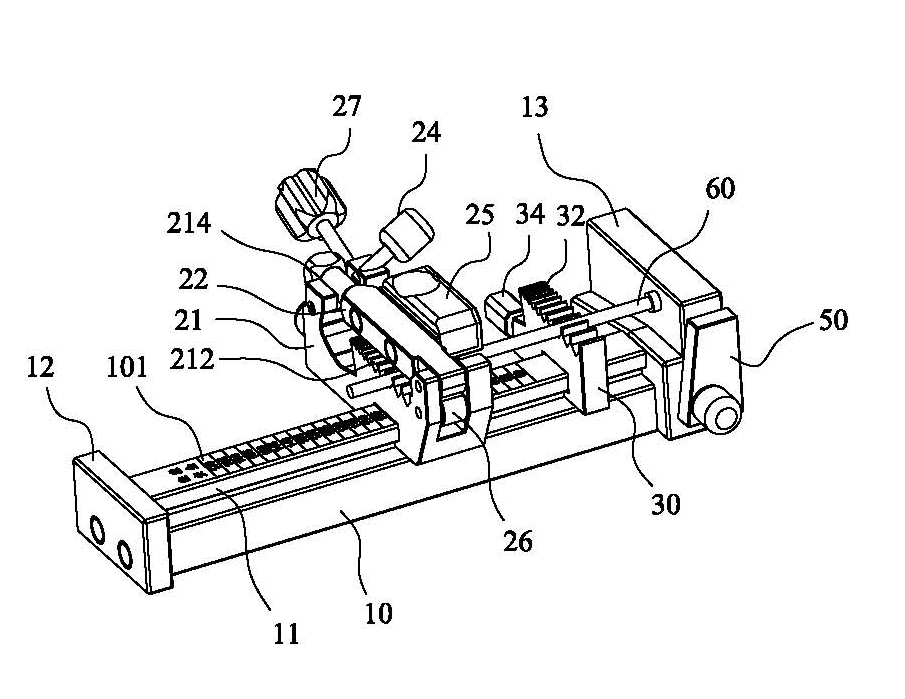

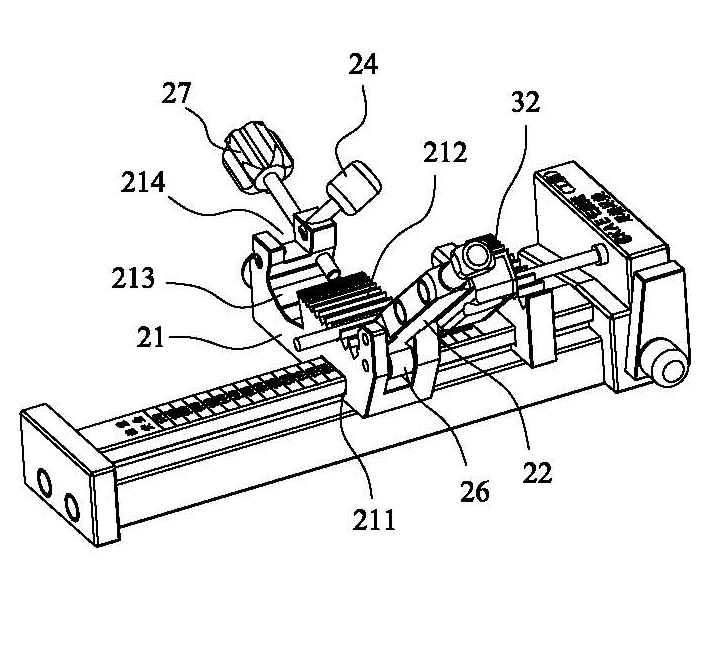

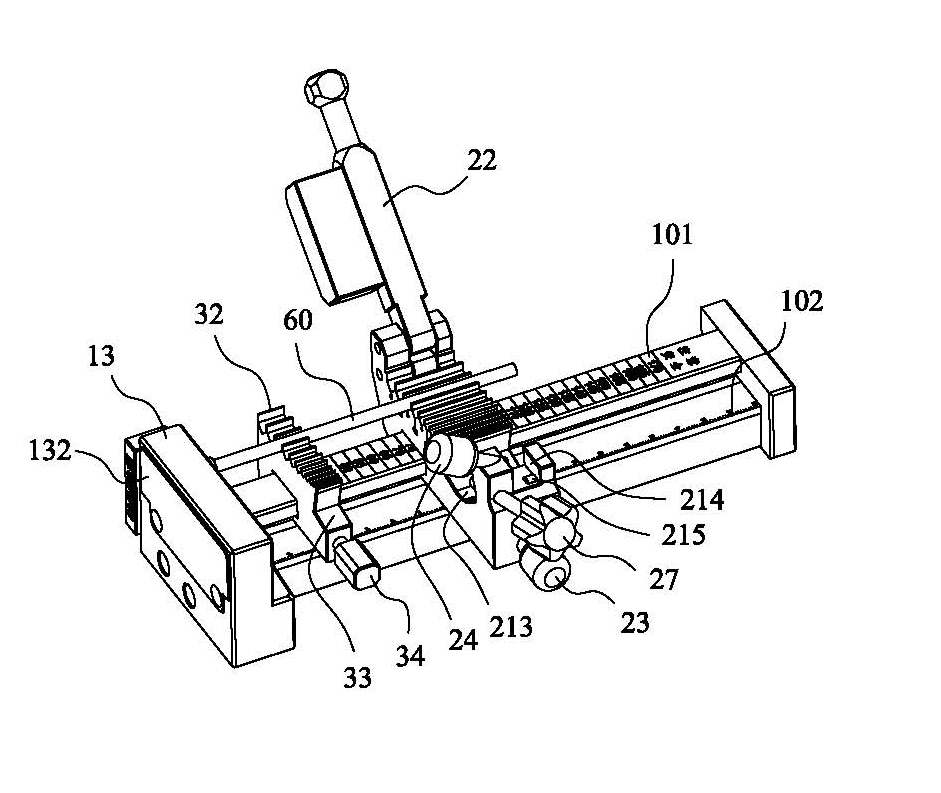

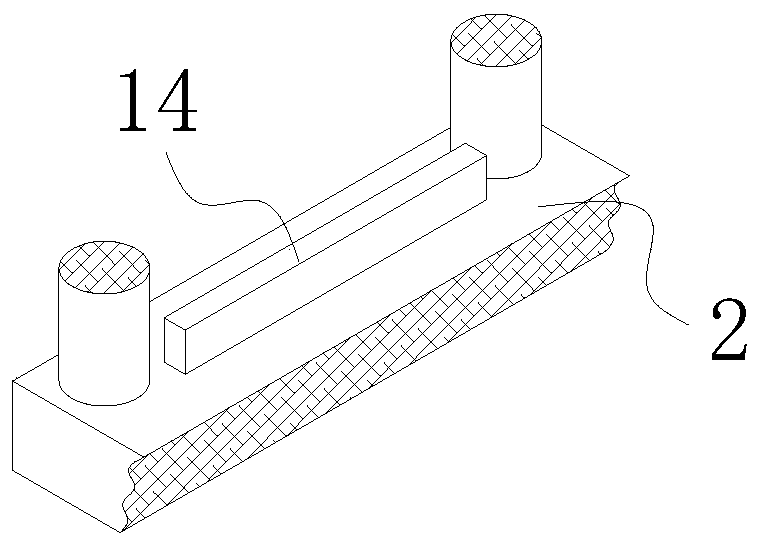

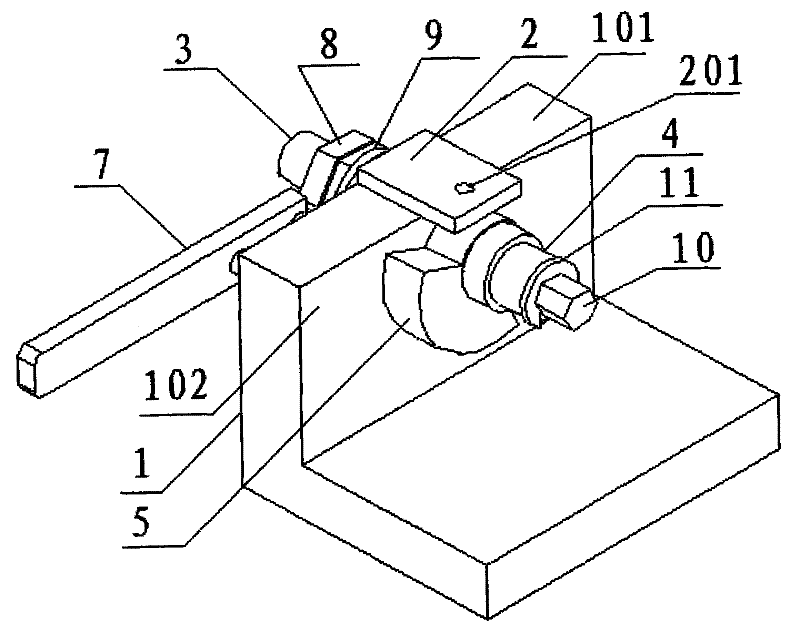

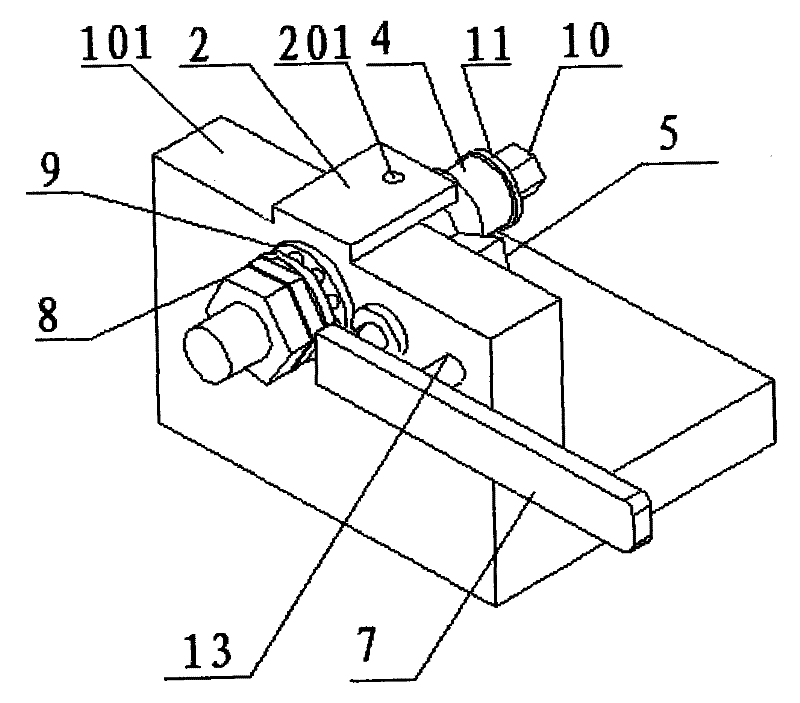

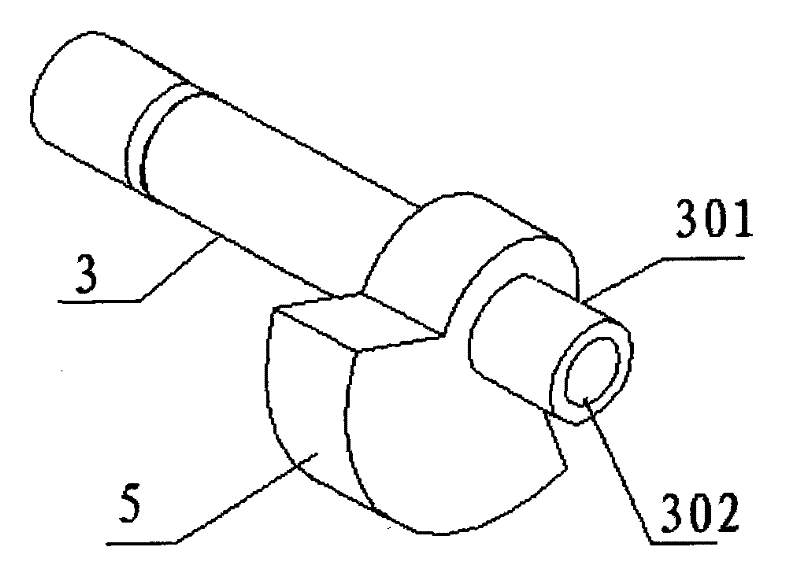

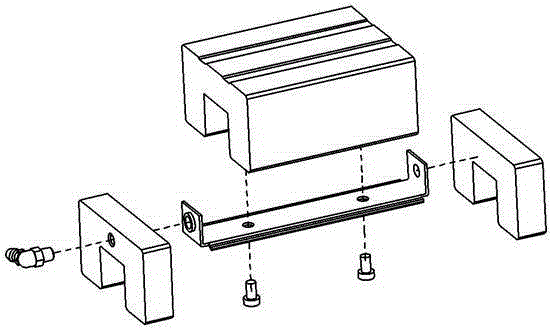

Special gripper for location on cutting of thimble

InactiveCN102039533APrevent back and forth movementEasy to adjustPositioning apparatusMetal-working holdersOperation modeEngineering

The invention discloses a special gripper for the location on the cutting of a thimble, comprising a base, a gripping device and a support slide block. The base is provided with a straight-line slide rail, the straight-line slide rail is provided with scales, a rear suck board is arranged at the rear end of the straight-line slide rail and is used for fixing the tail end of the thimble, a magnet is arranged in the rear suck board, the gripping device comprises a slide seat and a batten, and the slide seat and the support slide block can be connected on the slide rail in a freely sliding manner. In the invention, the root of the thimble is fixed by the adsorption function of the magnet in an adsorption manner, the free tail end of the thimble is gripped and the middle rear part of the thimble is located by the gripping device and the support slide block, and the positions of the gripping device and the support slide block can be regulated in a sliding manner; therefore, the thimble can be effectively prevented from moving back and force to ensure the precision of the thimble cutting in the length direction; meanwhile, the special gripper is more convenient for people to precisely regulate the working positions of the gripping device and the support slide block by matching with the scales on the slide rail; and the overturn type structure design of the batten provides more efficient operation mode for operators to change the thimble.

Owner:东莞市康捷塑胶模具有限公司

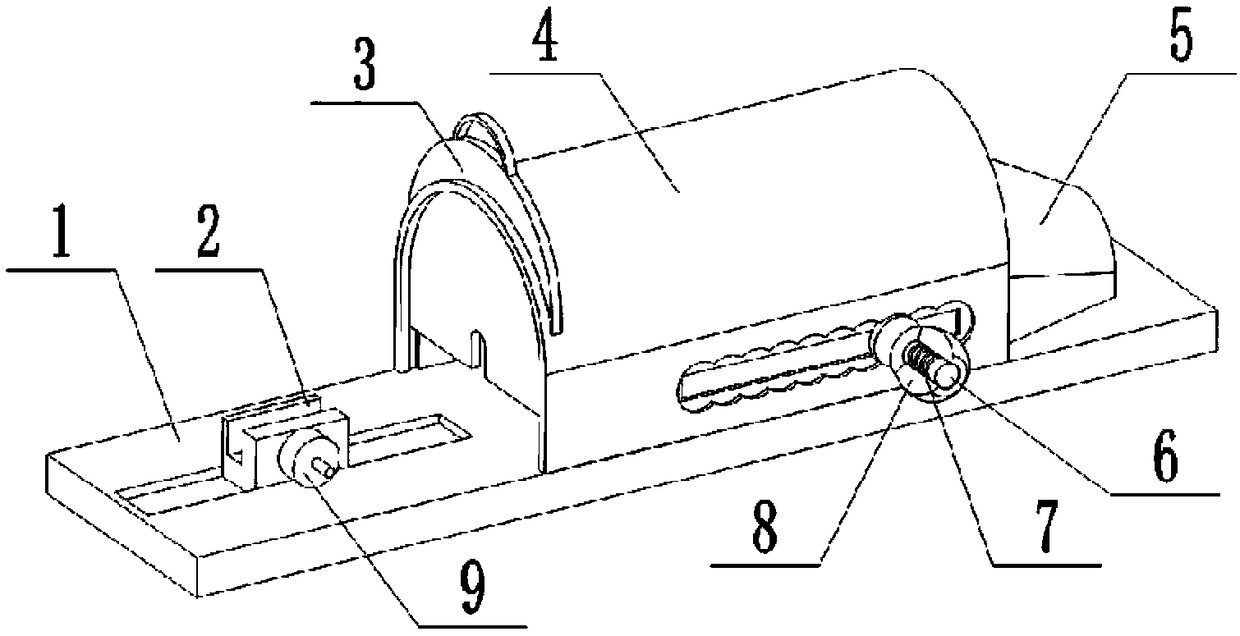

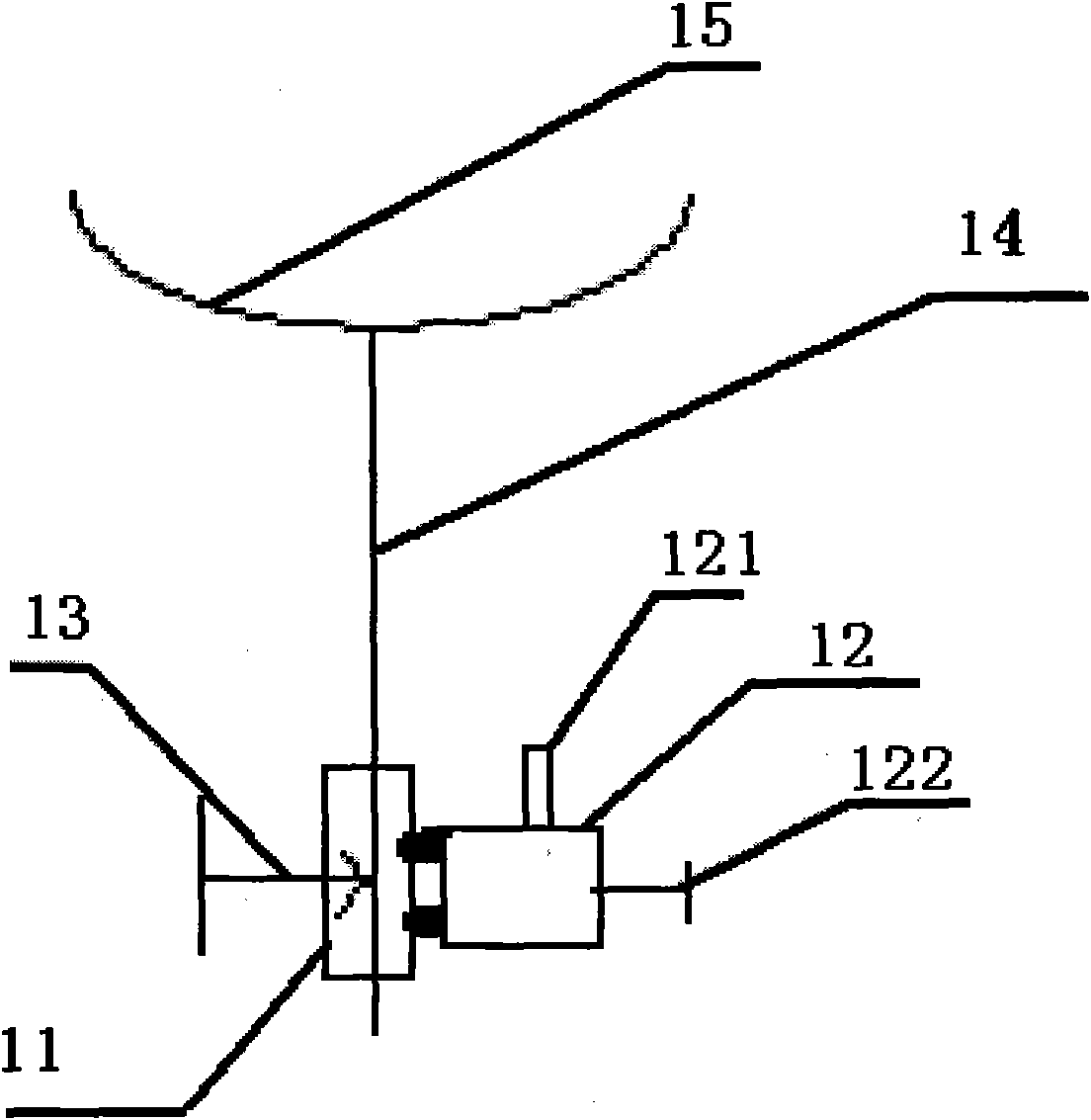

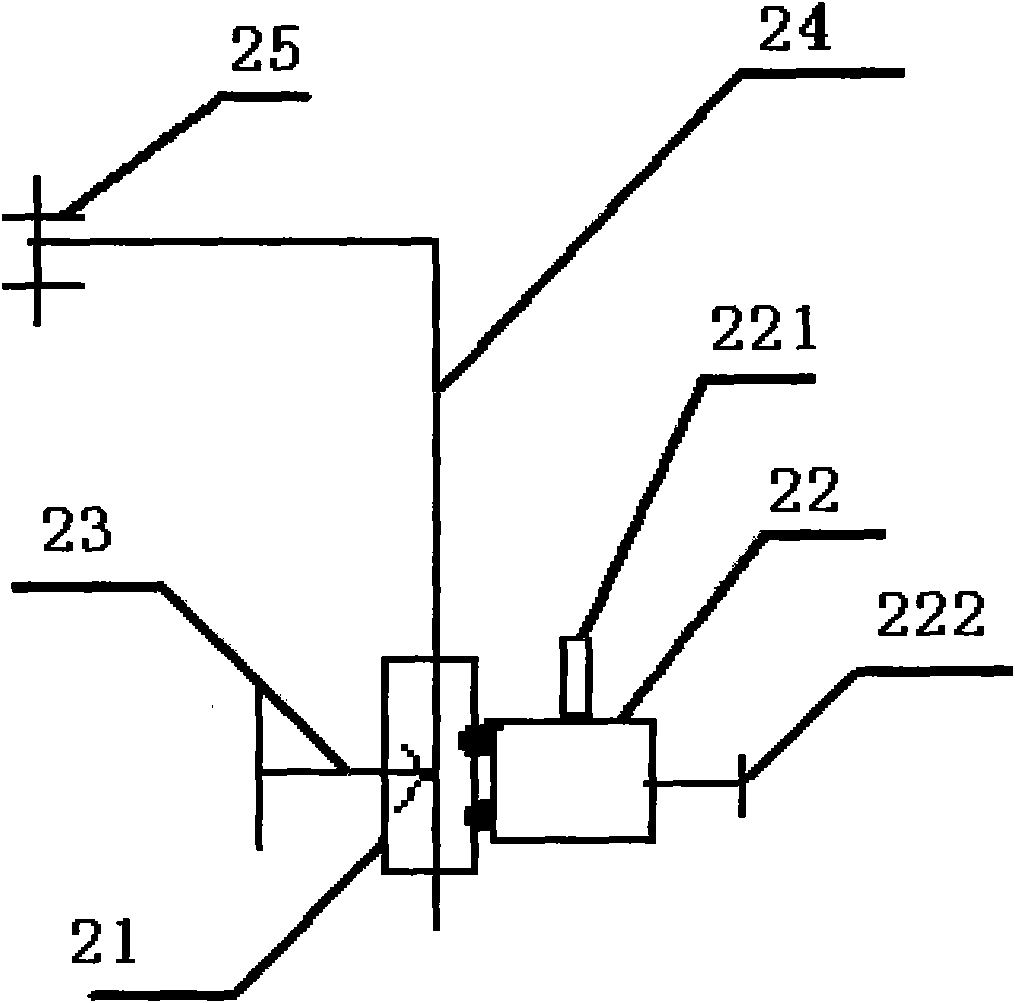

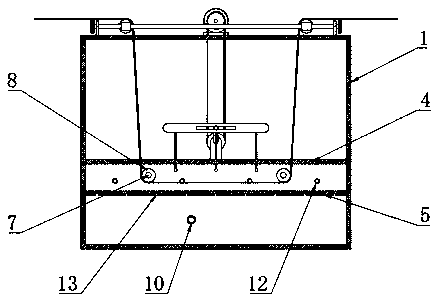

Adjustable fixator for mouse tail-vein injection

The invention relates to the field of animal medical experiment instruments, in particular to an adjustable fixator for mouse tail-vein injection, comprising a base, a tail-holding slider, a cold light, a fixing barrel, an adjusting cover, a connection device and a retainer; the base is provided with a rectangular groove; the tail-holding slider is arranged in the rectangular groove; the cold light is mounted on the tail-holding slider; the fixing barrel is mounted on the upper surface of the base; the adjusting cover is mounted in the front of the fixing barrel through the connection device;the retainer is mounted at the rear end of the fixing barrel. The adjustable fixator for mouse tail-vein injection allows a mouse to be precisely fixed, allows its size to be adjusted according to thebody size of the mouse, and allows the mouse state to be observed to ensure injection precision.

Owner:SHENYANG JIANZHU UNIVERSITY

Automobile steering knuckle forging process

InactiveCN104550621ALow costGood cleaning effectRailway componentsVehicle componentsStructural engineeringManufacturing engineering

The invention discloses an automobile steering knuckle forging process and relates to the field of production of automobile accessories. The automobile steering knuckle forging process includes steps of feeding, initially heating, making blank, successively heating, bending and molding a terminal, hot trimming, hot treating and blasting. The feeding process effectively solves the quality problem caused by impurities in materials by roughly cleaning the surface, removing the impurities and finely cleaning. The automobile steering knuckle forging process is simple, convenient, low in cost and very good in cleaning effect. By cooling in two stages and separately making the blank and bending, forged parts are filled easily without fold lines, and the problem of burrs is solved by polishing. By normalizing and annealing, metal is uniformly distributed, product strength is improved, and quality, reliability and safety of products are effectively improved.

Owner:丹阳市米可汽车零部件厂

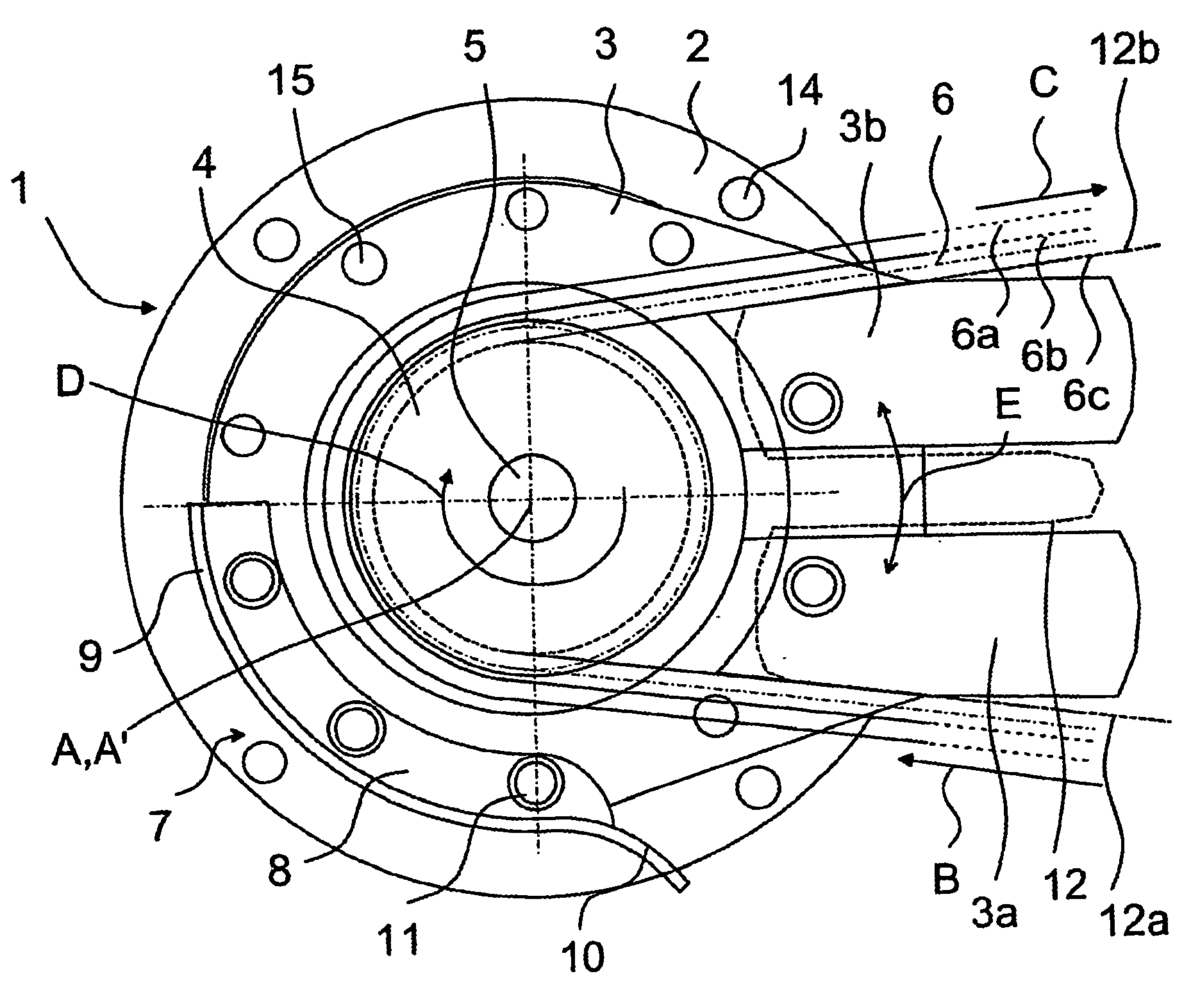

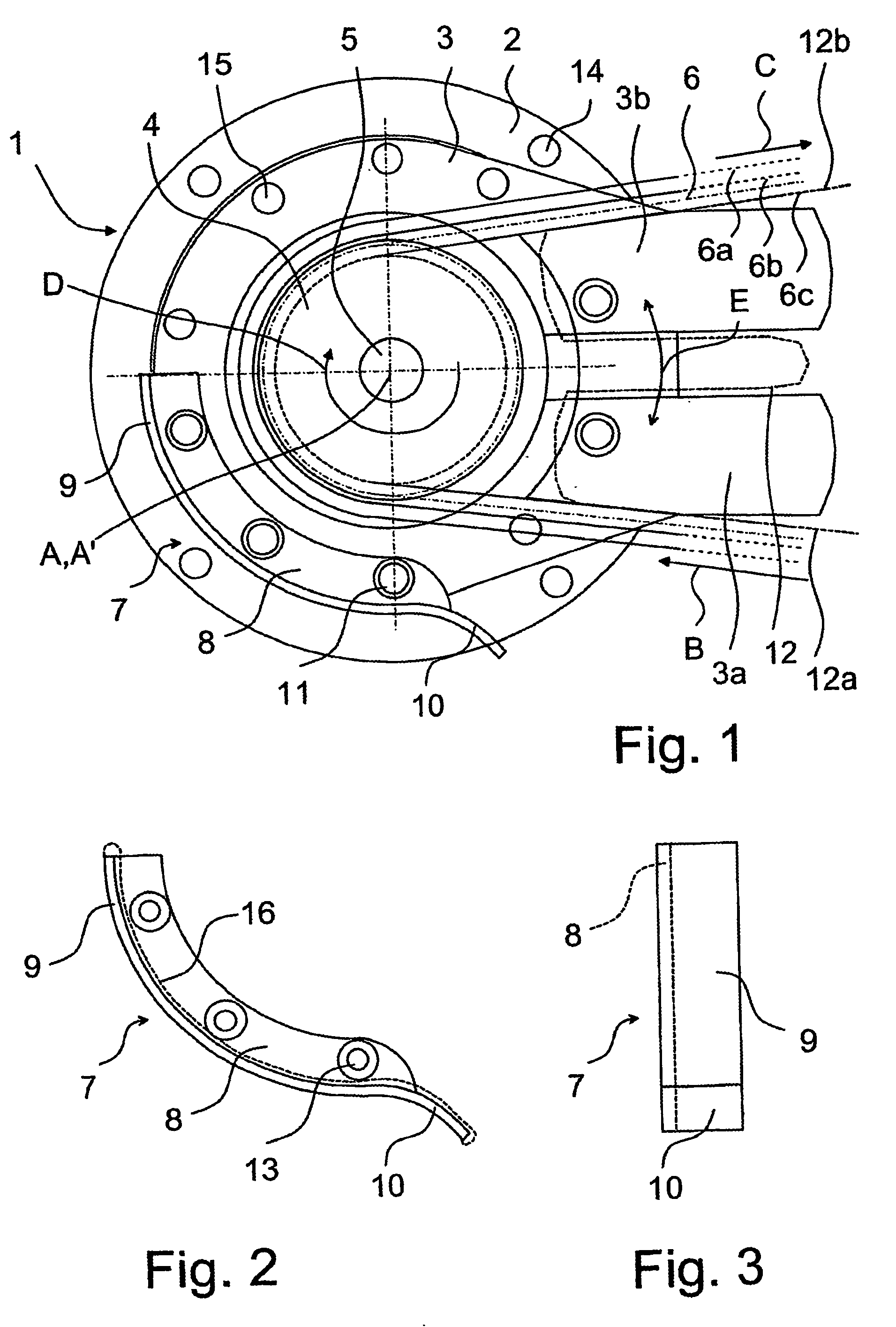

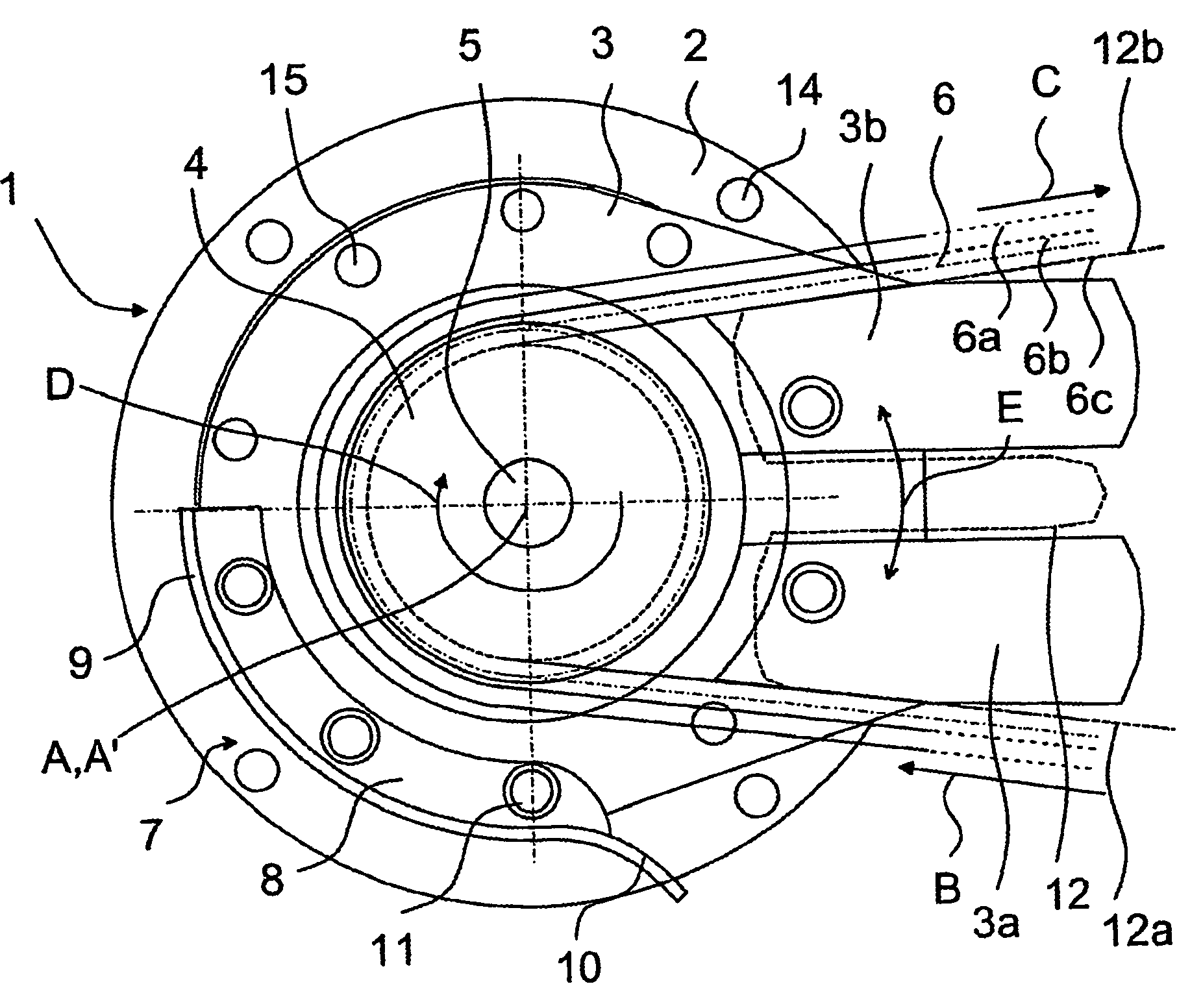

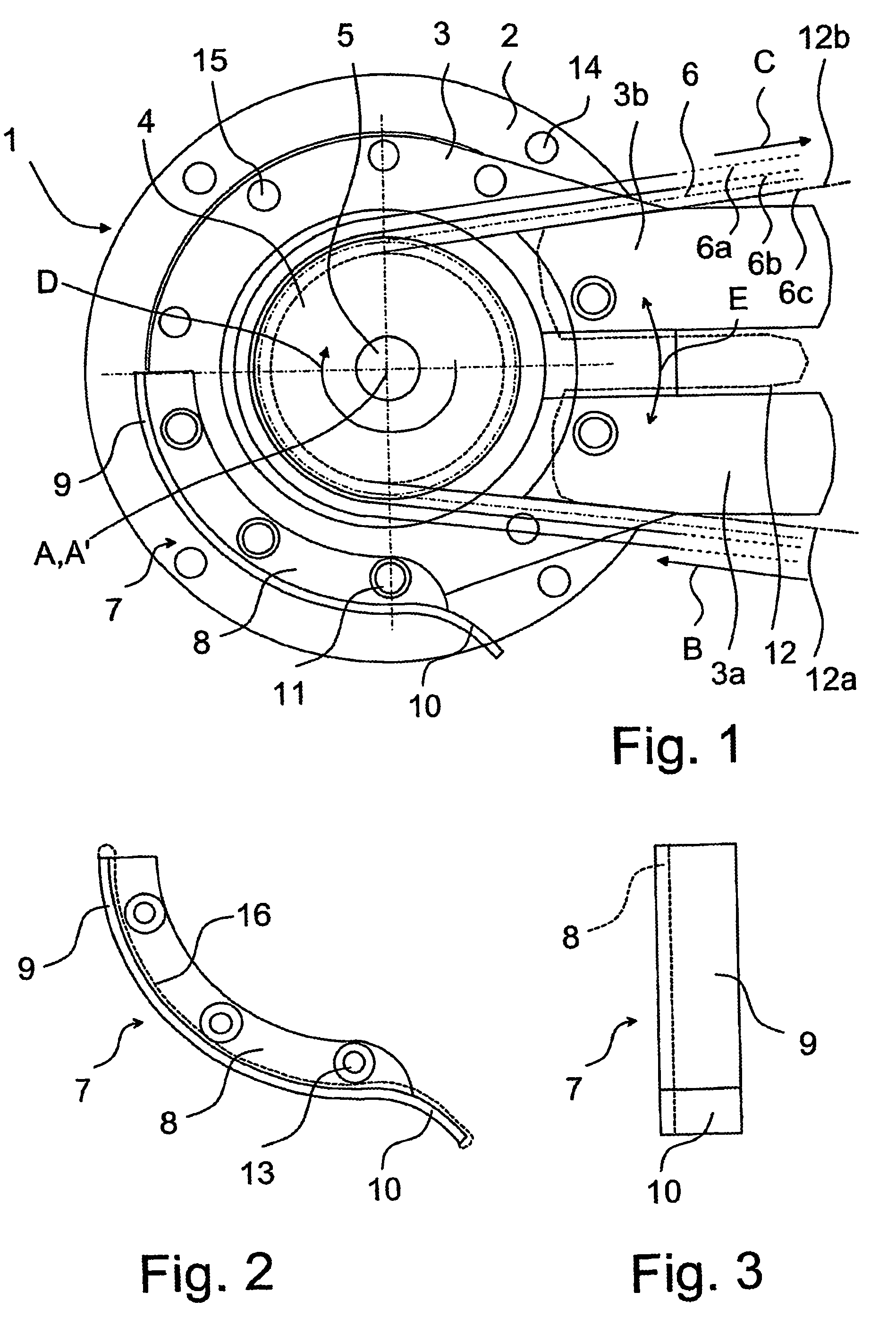

Sawing device and its safety system for precaution of a breaking saw chain

ActiveUS20060107804A1Prevent back-and-forth movementPart is not preventedMetal sawing devicesMulti-purpose machinesControl mannerEngineering

Method and safety device for a breaking saw chain, wherein the safety device comprises a protective wall positioned in the vicinity of the drive gear drawing the saw chain in such a manner that it is capable of receiving the movement of the tail of the broken saw chain and to guide said tail in a controlled manner with the rest of the saw chain into the desired direction, wherein at the same time the strong swinging movement of said tail is prevented, and said protective wall is fastened to movable members that are arranged to hold the protective wall in the correct location during sawing in relation to the saw chain whose incoming direction varies during the operation. In particular, the protective device is placed in a sawing apparatus comprising a frame part, a holder for a guide bar, means for driving the saw chain and for performing the sawing, as well as means for moving the protective wall in phase with the guide bar holder, wherein said means are preferably implemented by using the guide bar holder.

Owner:JOHN DEERE FORESTRY OY

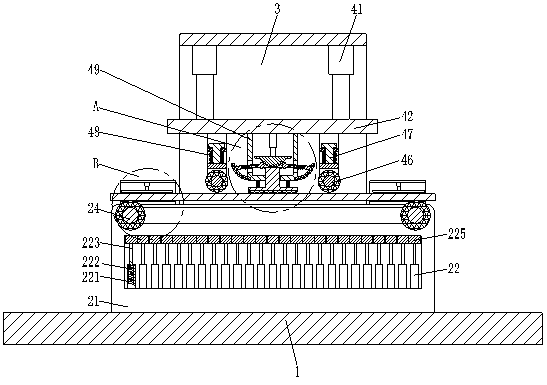

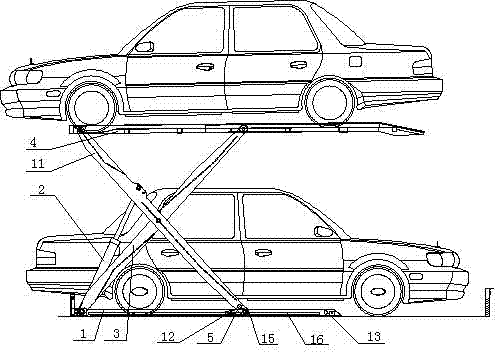

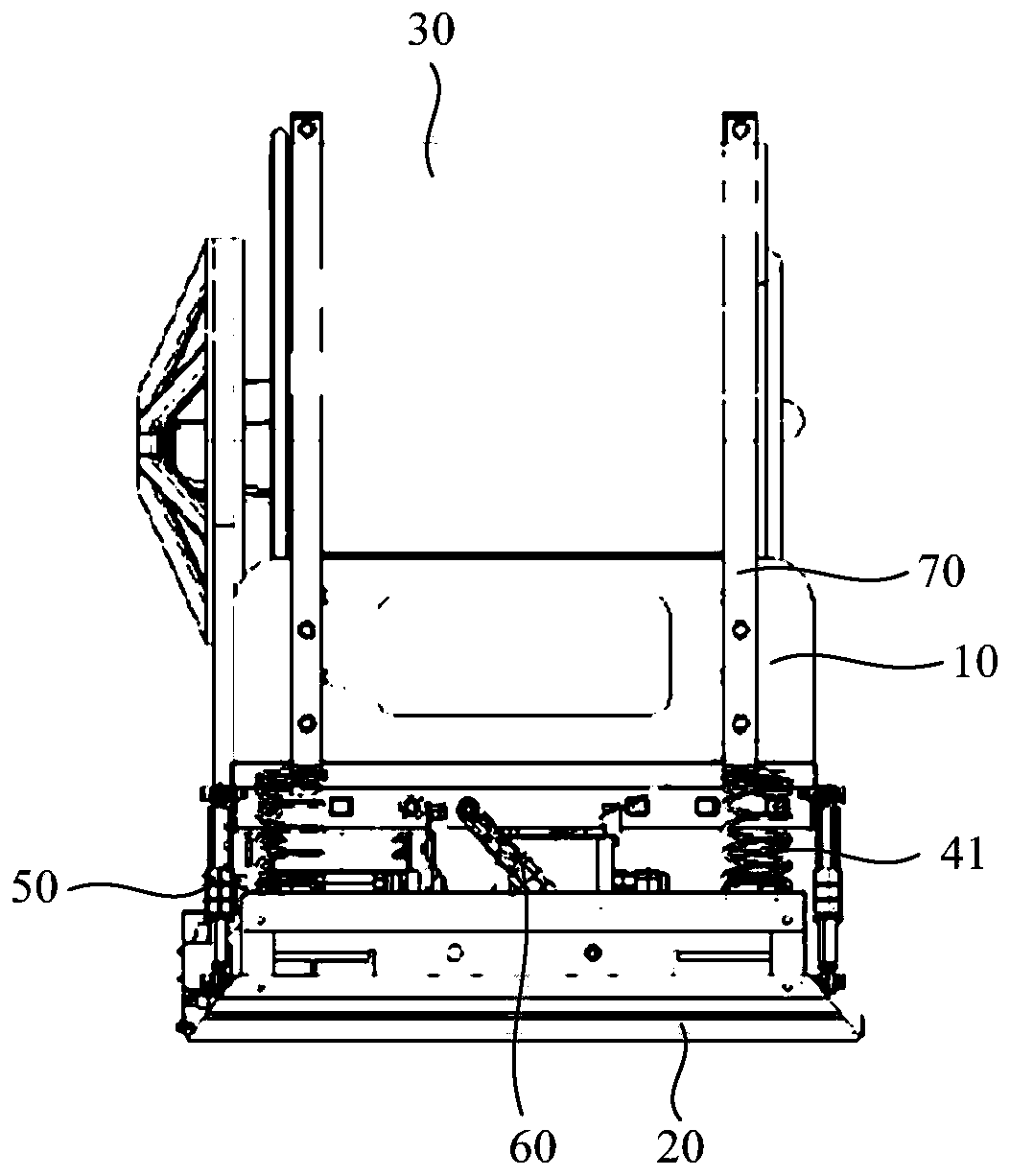

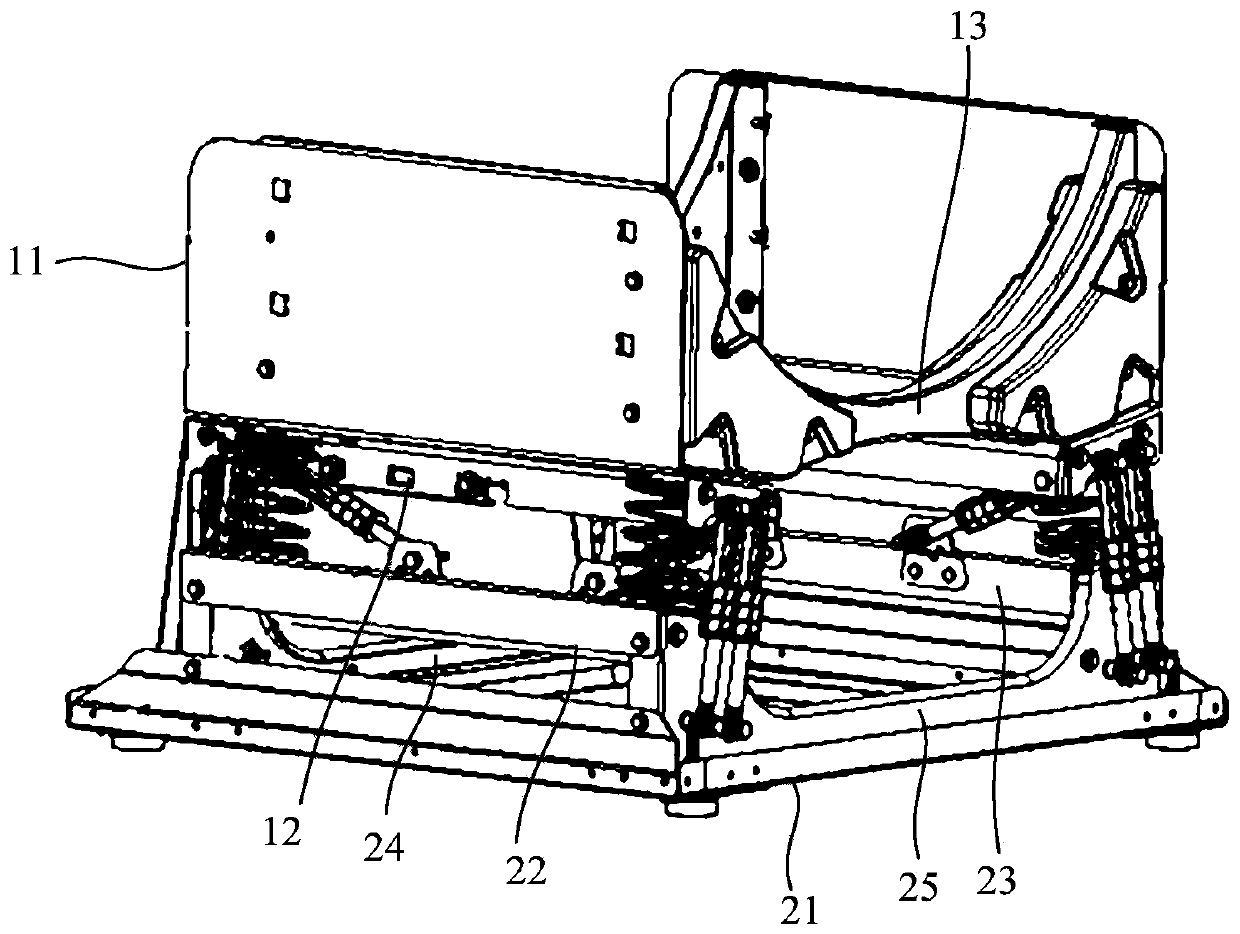

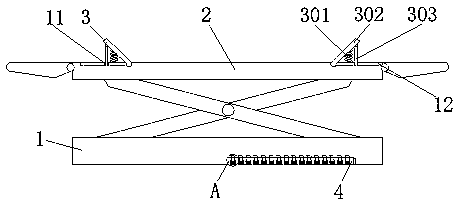

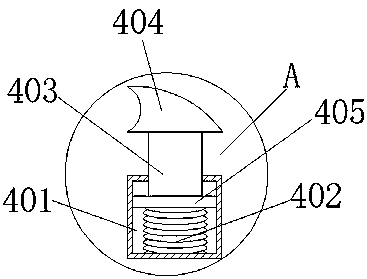

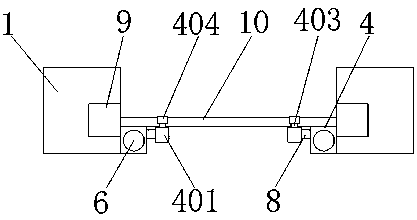

Scissors-type simple lifting utility garage

The invention provides a scissors-type simple lifting utility garage comprising a base, hydraulic cylinders, scissors supports, a carrying plate, and a mechanical safety hook interlocking device. The hydraulic cylinders and the scissors supports are arranged on two sides of the base. Each scissors support comprises a first pillar and a second pillar; the pillars are movably connected in the middle to form an X shape; one end of the second pillar is movably connected to the carrying plate through a roller; the other end of the second pillar is provided with a third roller; the rollers are arranged in rail channels. The scissors-type simple lifting utility garage occupies small area, multiplied cars can be parked on the scissors-type simple lifting utility garage and are convenient and safe to access, the parking difficult is conveniently overcome, an ascent detection switch and a descent detection switch ensure that the cars are safe and reliable to access; by adding the mechanical safety hook interlocking device, the whole frame is prevented from slipping down, namely the carrying plate never descends in normal conditions, and the cars can be safely and reliably stored on the carrying plate.

Owner:WUHU HUITAI SCI & TECH IND

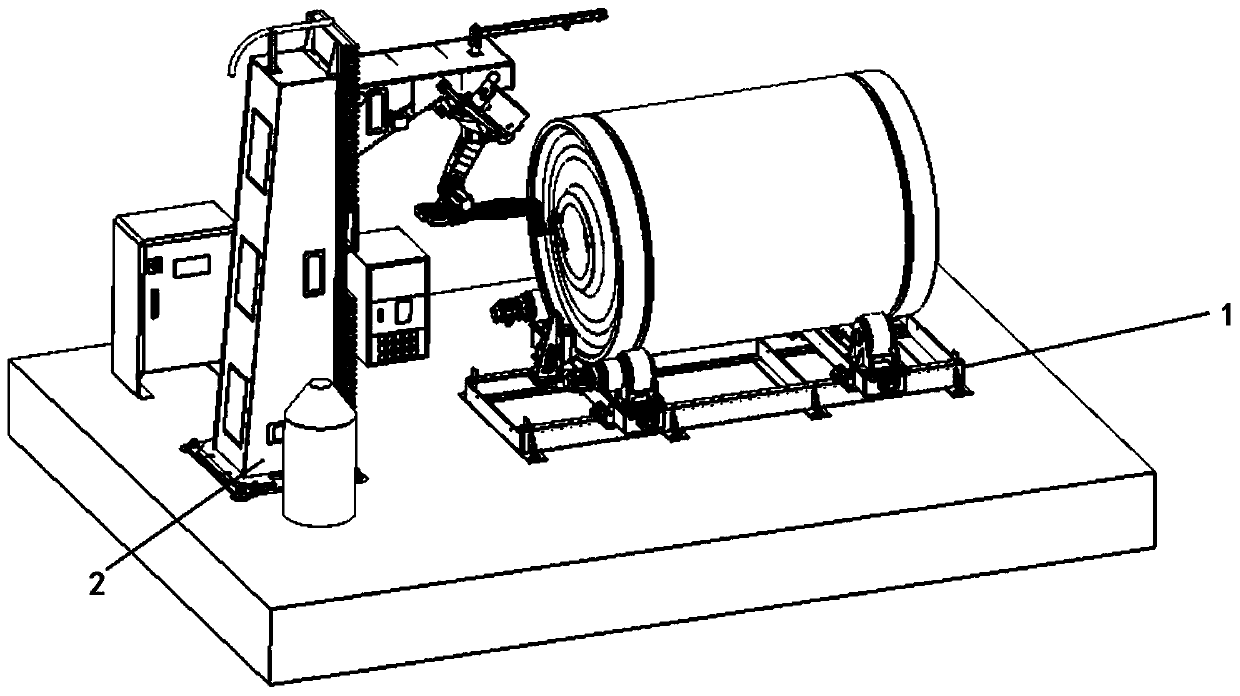

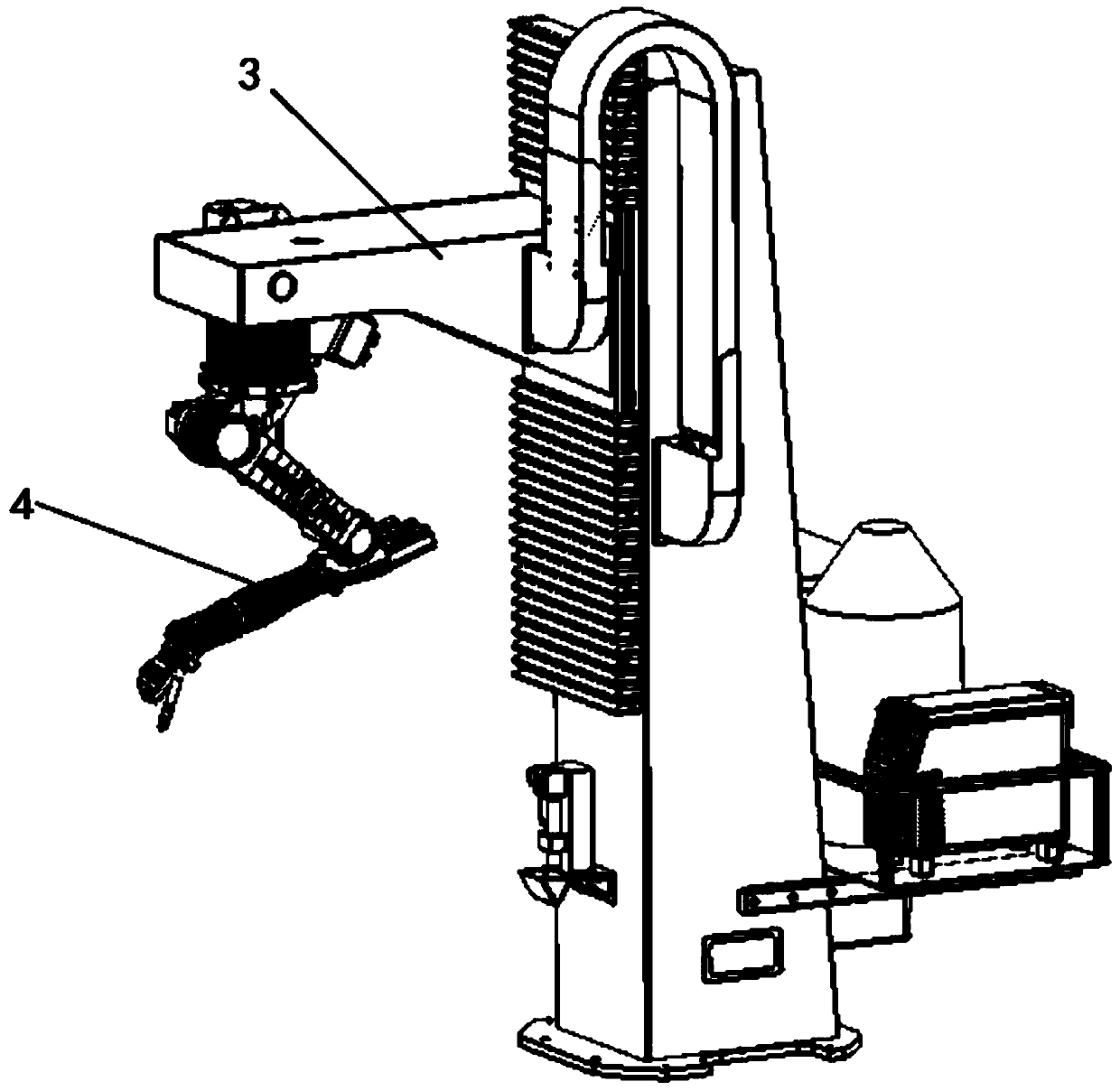

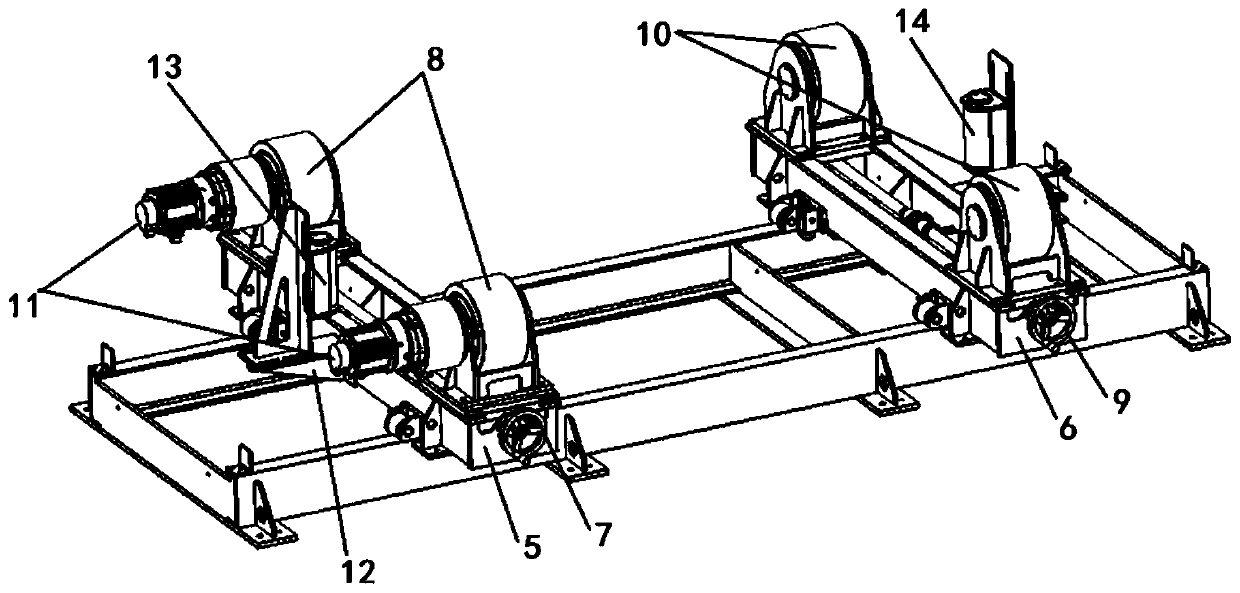

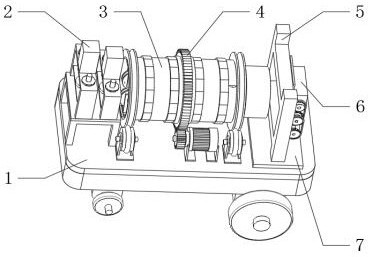

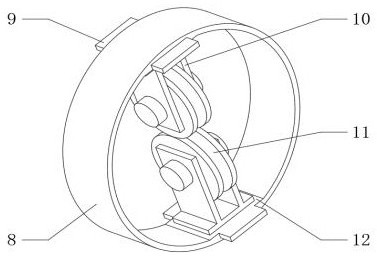

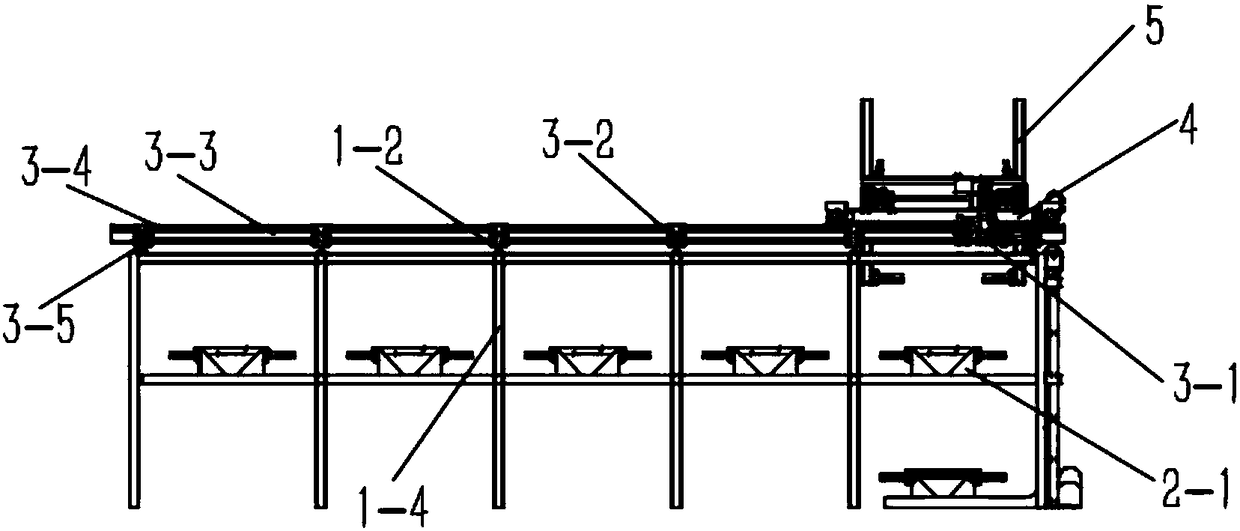

Belt conveyor roller inner wall robot numerical control intelligent welding system

InactiveCN110142540AEasy to weldReduced welding skill requirementsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringHeavy load

The invention provides a belt conveyor roller inner wall robot numerical control intelligent welding system. The belt conveyor roller inner wall robot numerical control intelligent welding system comprises a heavy load roller frame, a C supporting stand column is fixed to one side of the heavy load roller frame, a lifting mechanism is in sliding connection to the C supporting stand column, a welding robot is fixed to the lifting mechanism, the heavy load roller frame comprises a driving roller frame and a driven roller frame, the driving roller frame and the driven roller frame are fixed to the two ends of the heavy load roller frame, the driving roller frame comprises a driving wheel wheel-space adjusting mechanism and two sets of driving wheels located on the two ends of the driving roller frame, the driven roller frame comprises a driven wheel wheel-space adjusting mechanism and two sets of driven wheels located on the two ends of the driven roller frame, the two sets of driving wheels are connected with a servo driving motor. Through the wheel-space adjusting mechanisms, the system adapts to supporting and driven rotation of workpieces with different lengths, when the workpiecediameter and length are changed, workpiece clamping and rotating work can be achieved by adjusting the space between the driving roller frame and the driven roller frame.

Owner:郎溪东奥输送装备科技有限公司

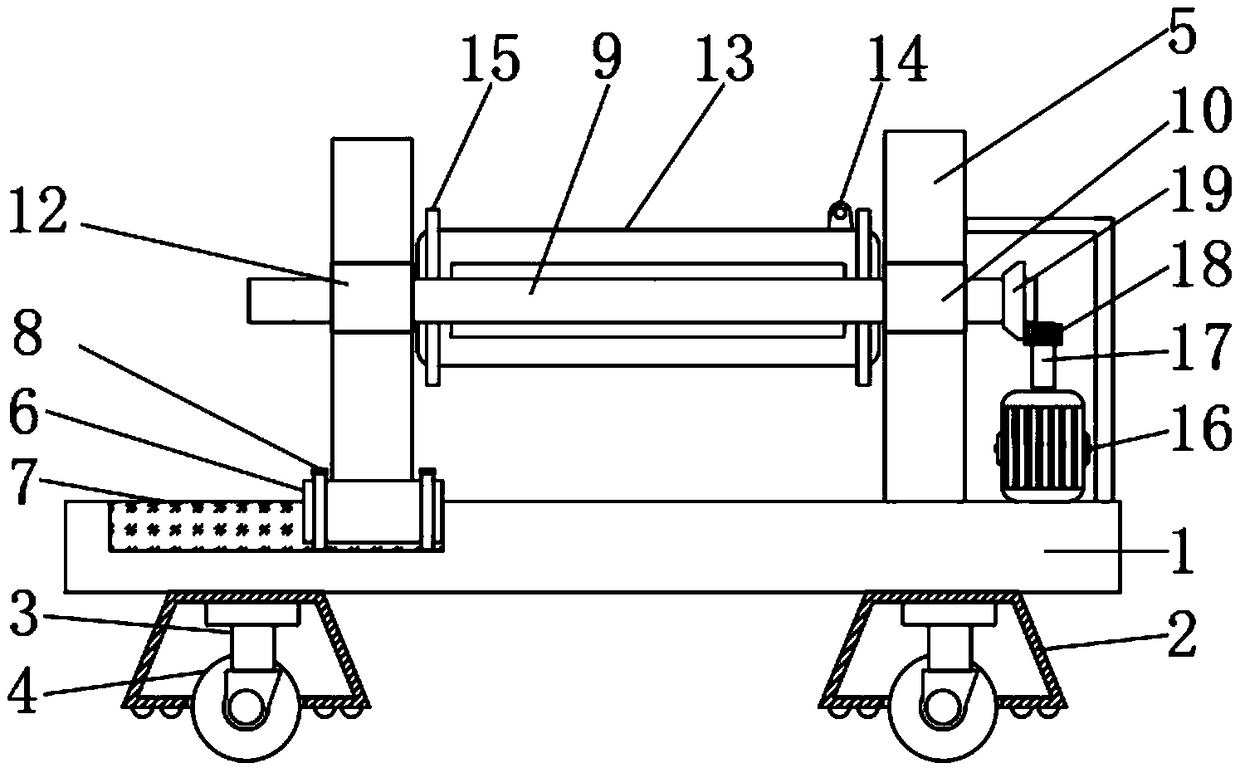

Device facilitating cable winding and dismounting

The invention discloses a device facilitating cable winding and dismounting and belongs to the technical field of power cables. The device comprises a base. Side plates are mounted on the left and right sides of the top of the base correspondingly. A rotary rod is mounted between the two side plates. A second bearing is mounted in the position where the rotary rod and the side plate on the left side are connected. A reel is mounted on the outer wall of the rotary rod in an interference fit mode. A fixing ring is mounted on the outer wall of the top of the right side of the reel. A servo motoris mounted on the right side of the side plate on the right side. A first bevel gear is mounted on the outer wall of a mounting rod. The motor drives the reel to wind a cable, the storing speed is high, labor force is reduced, in addition, storing is uniform, the side plate on the left side slides out through a slide block, then the reel can be taken out, the cable is recovered, and transporting and recovering are facilitated; and rubber abrasion-resistant protrusions at the bottoms of supporting seats reduce abrasion when the supporting seats make contact with the ground, impact force of moving wheels on the ground when hydraulic telescopic rods stretch and retract is reduced, and the service life is prolonged.

Owner:王海平

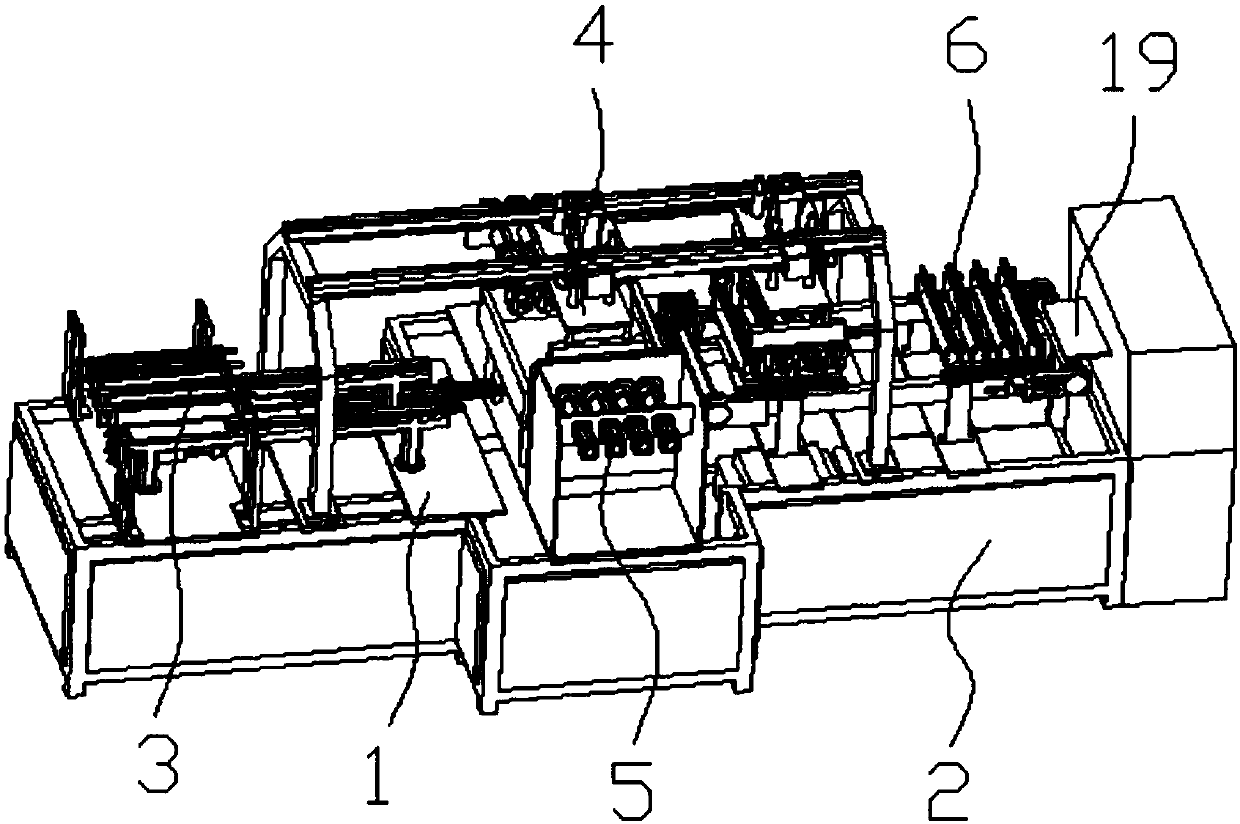

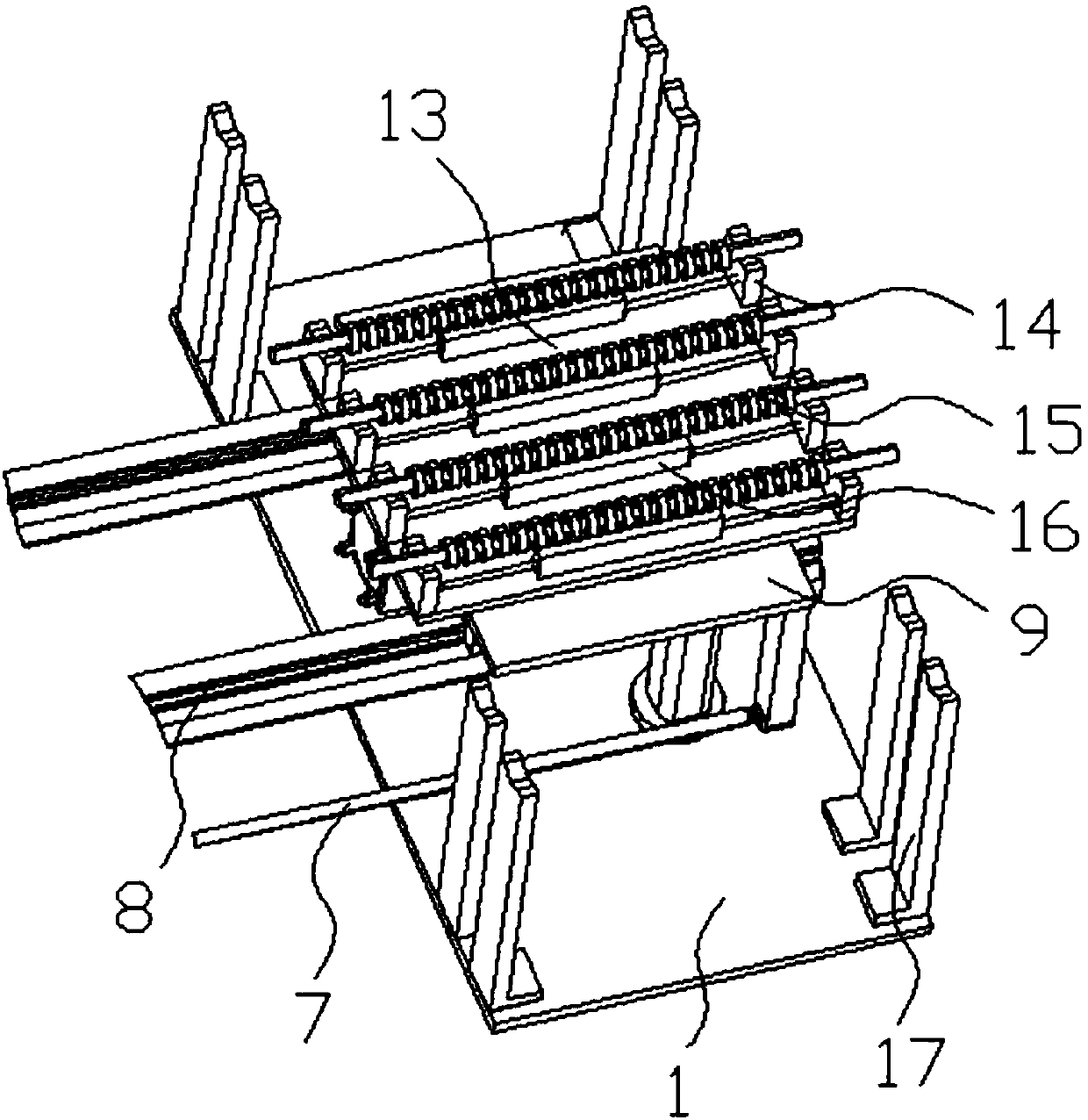

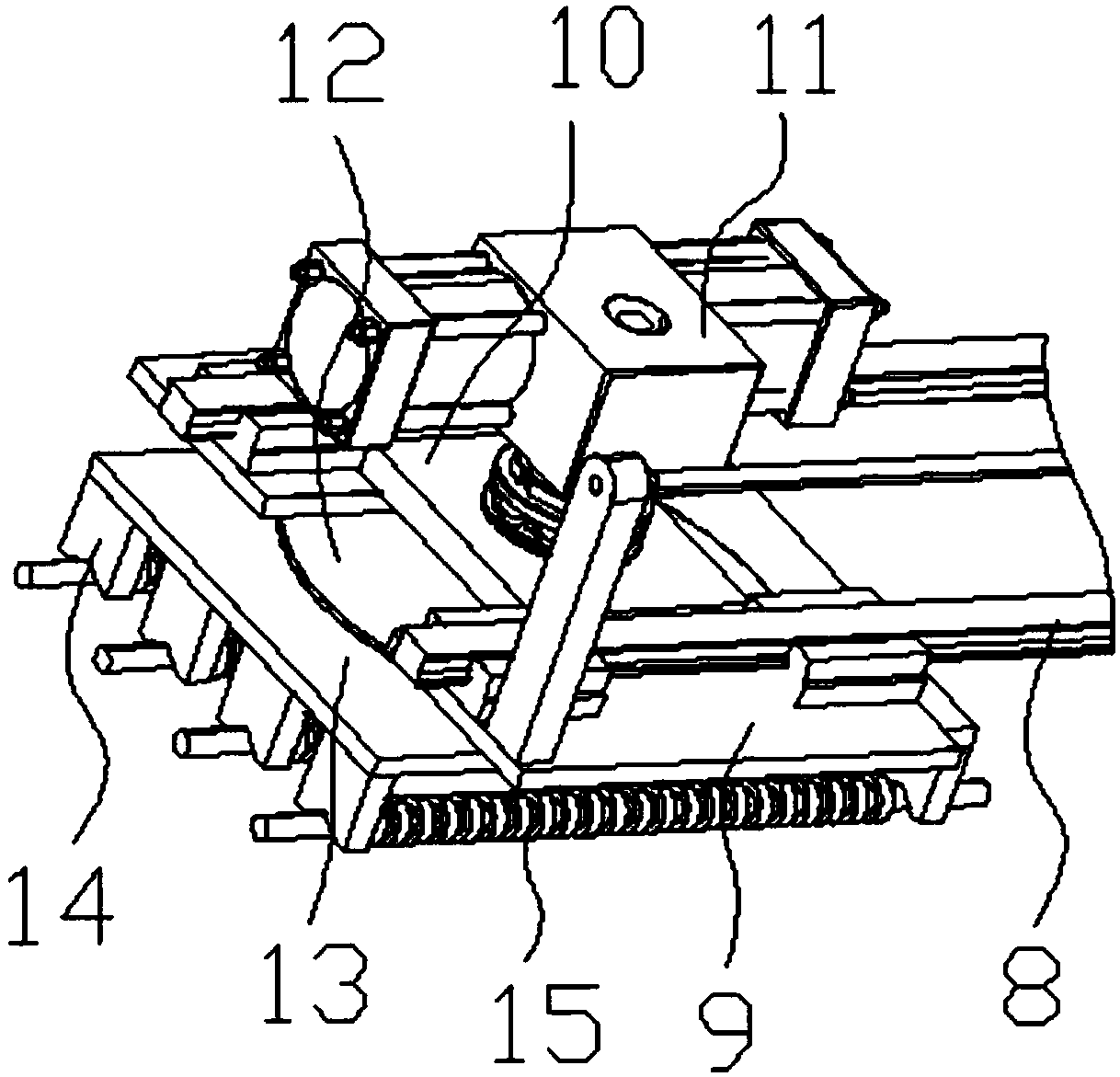

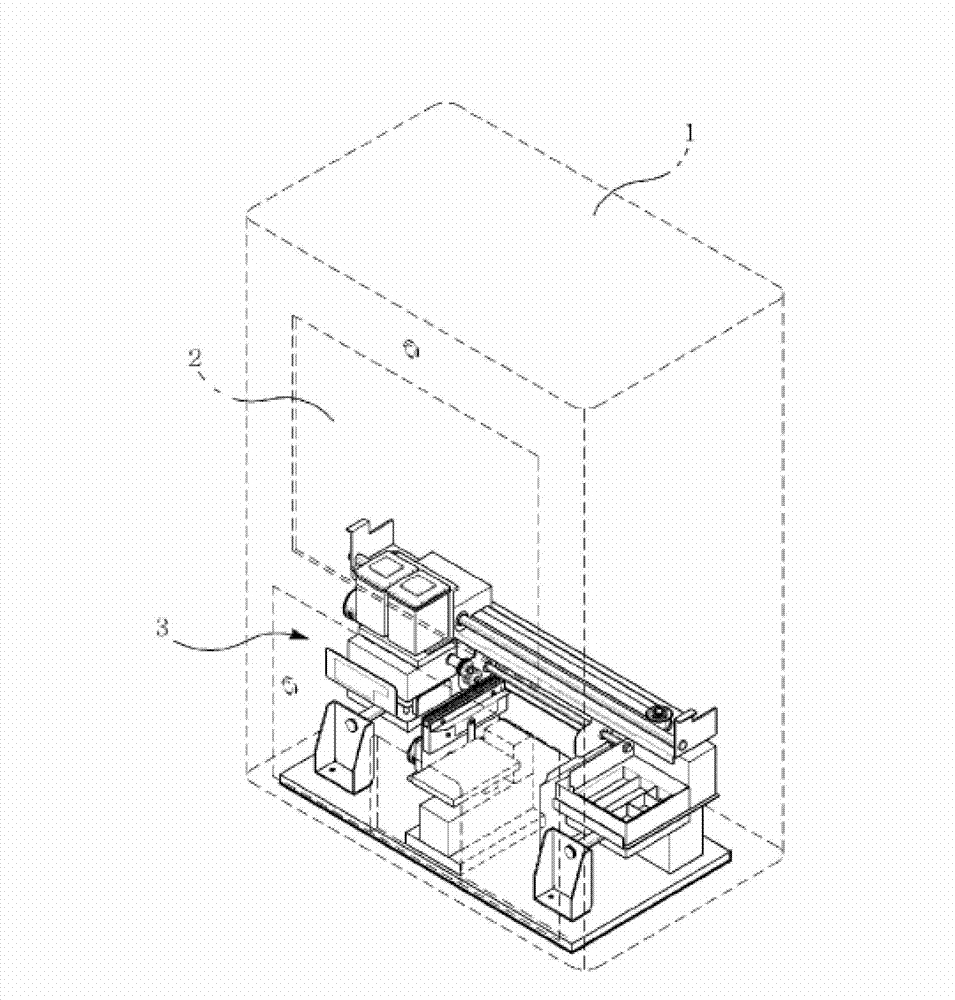

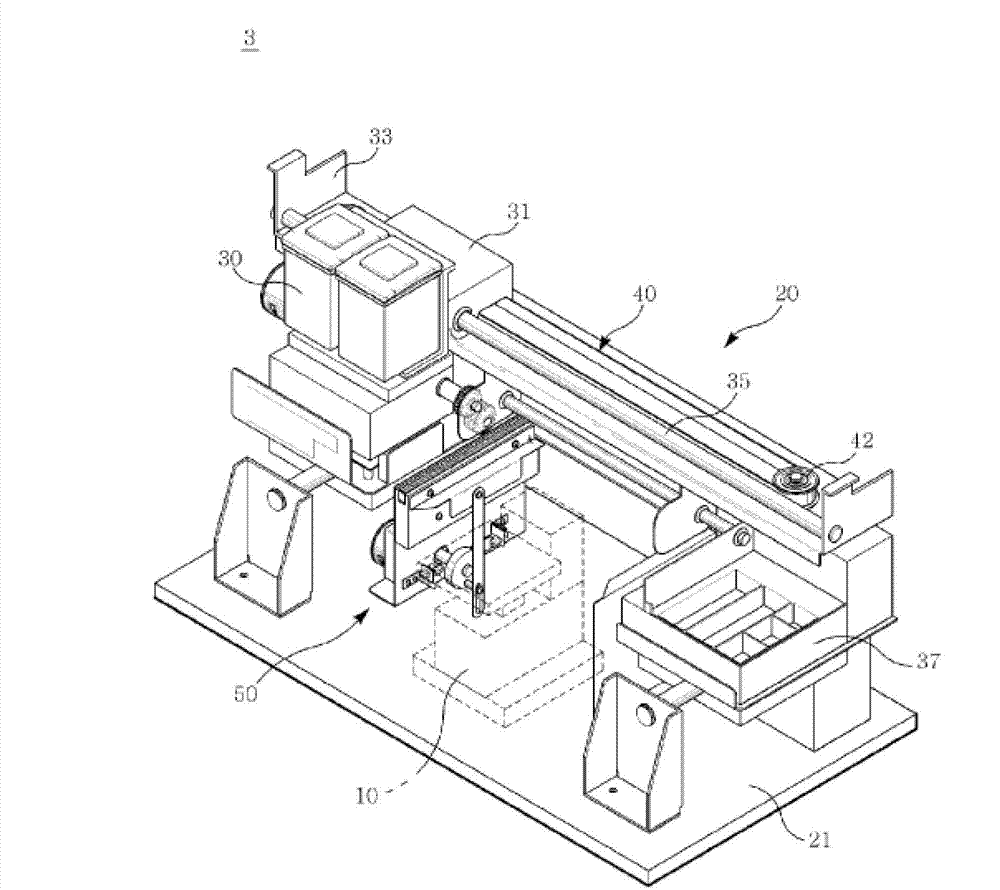

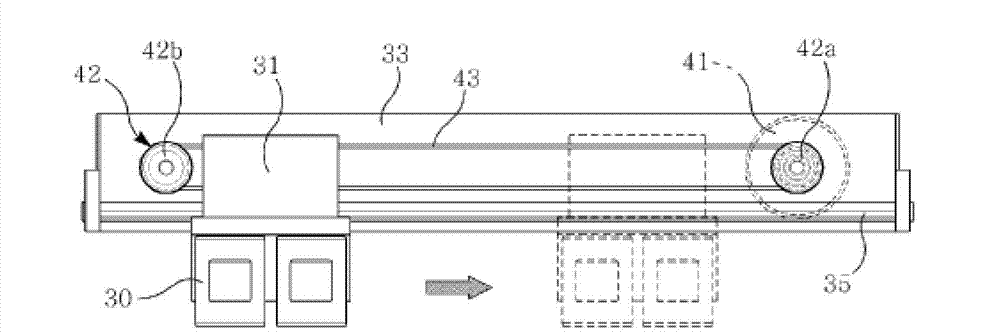

Axis part detection machine with screening and collecting functions

InactiveCN107803351ARealize automatic loading and unloadingImprove the efficiency of detection screening collectionSortingDistribution controlButt joint

The invention relates to an axis part detection machine with screening and collecting functions. The axis part detection machine with the screening and collecting functions comprises a machine frame,a power distribution control cabinet, a detection device, a clamping mechanism, a feeding device and a discharging conveying device. The discharging conveying device comprises two chain conveying device bodies. The tail end of the discharging conveying device is provided with a classified collecting device in a matched mode. The classified collecting device comprises a collecting tank. A collecting opening is formed in the side, close to the discharging conveying device, of the collecting tank. A partition plate is arranged in the middle of the collecting tank. A collecting rotary block is arranged above the partition plate and connected with a collecting rotary motor through a collecting rotary shaft. An unloading collecting block capable of penetrating to the position between the two chain conveying device bodies is arranged on the left side of the collecting rotary block. According to the axis part detection machine with the screening and collecting functions, butt joint between thedetection device and the feeding device as well as between the detection device and the discharging conveying device is achieved through the clamping mechanism, detected products can be classified and collected through cooperation of the discharging conveying device and the rotatable unloading collecting block of the classified collecting device, and the overall efficiency of detection, screeningand collecting is greatly improved.

Owner:CHONGQING TECH & BUSINESS UNIV

Injection mold with good connecting effect

InactiveCN111497146AFirmly connectedImprove the stability of useEngineeringInjection molding machine

The invention discloses an injection mold with a good connecting effect. The injection mold comprises an injection molding device body, and the top of the injection molding device body is fixedly connected with a fixed plate. The top of the fixed plate is fixedly connected with a transmission device, and the bottom of the transmission device is fixedly connected with a mold body. The two sides ofthe top of the fixed plate are fixedly connected with a shell. According to the injection mold, by means of the cooperative use of the injection molding device body, the fixed plate, the transmissiondevice, the mold body, the shell, a compressing mechanism, a limiting mechanism, a positioning mechanism, a limiting groove, a dovetail block, a dovetail groove, a pull ring, a groove body and a limiting plate, the problems that in the actual use process of an existing injection mold, an upper mold is pressed on a lower mold for injection, and therefore the lower mold bears force and is likely togenerate displacement, injection molding flaws are generated, the practicality of an injection molding machine is reduced, and use by a user is inconvenient are solved; and the injection mold with thegood connecting effect has the advantage of improving the use stability of the mold.

Owner:宁波引智信息科技有限公司

Sawing device and its safety system for precaution of a breaking saw chain

ActiveUS7690407B2Prevent back-and-forth movementAvoid partialMulti-purpose machinesChain sawsEngineeringMechanical engineering

Method and safety device for a breaking saw chain. The safety device includes a protective wall positioned in the vicinity of the drive gear drawing the saw chain that is capable of receiving the movement of the tail of the broken saw chain and guiding the broken saw chain and the tail into the desired direction. The protective wall is moved in phase with a guide bar to hold the protective wall in the correct location during sawing in relation to the saw chain.

Owner:JOHN DEERE FORESTRY OY

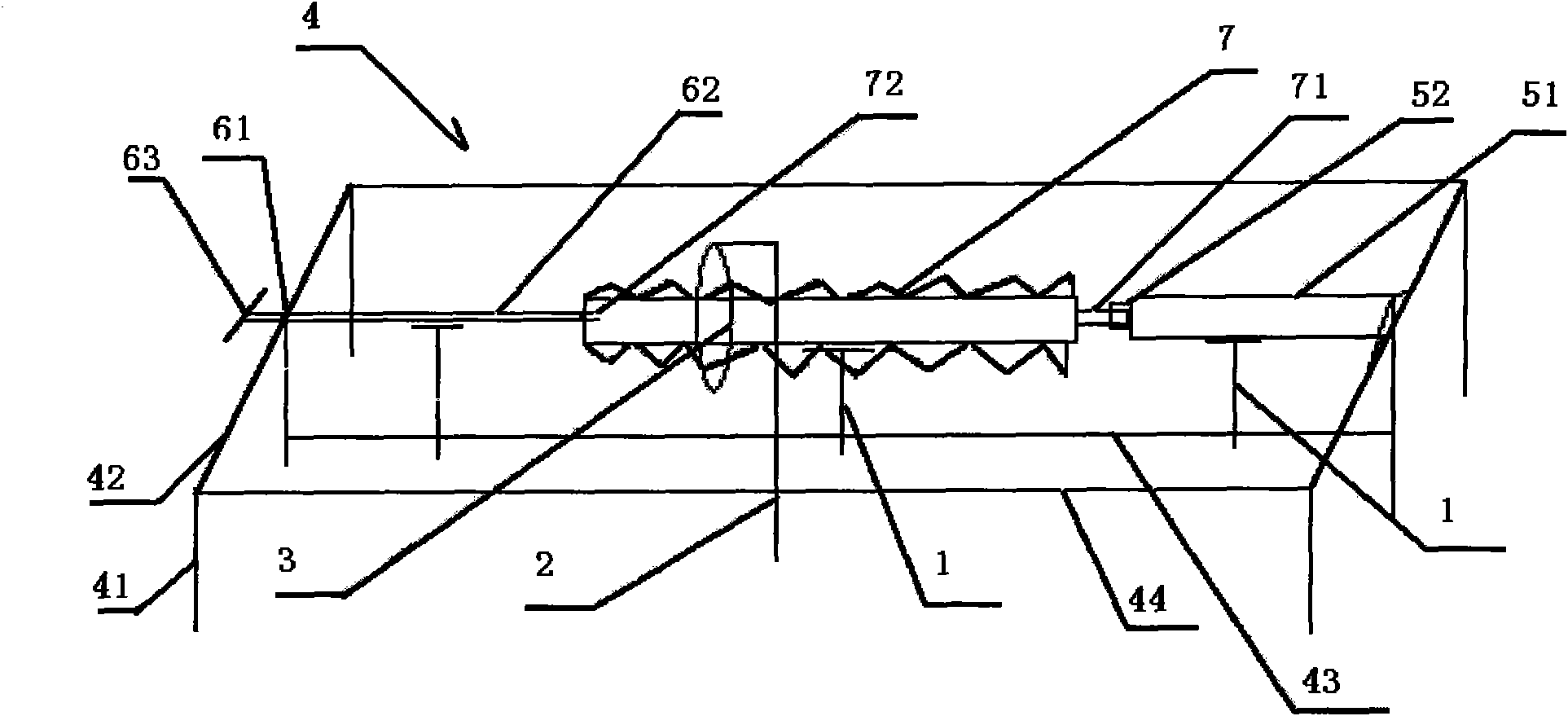

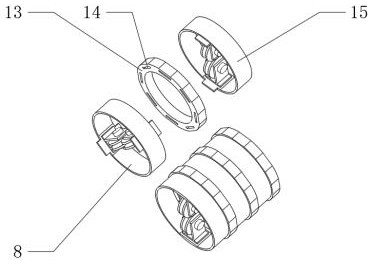

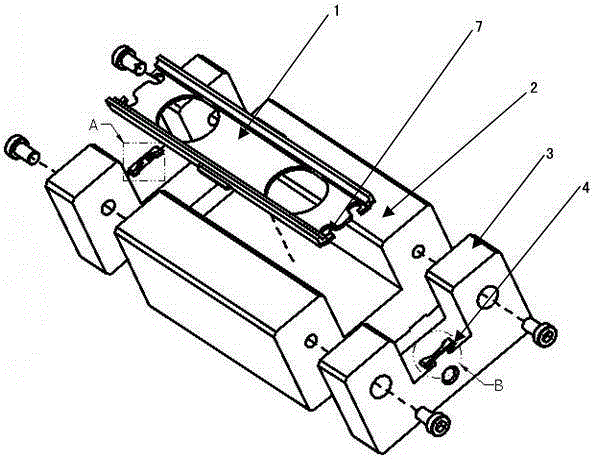

Detaching device for screw rod and threaded element of extruder

The invention provides a detaching device for a screw rod and a threaded element of an extruder, which comprises a frame bracket part, a screw rod sliding bracket part arranged on the frame bracket part, a heating ring sliding bracket part, a screw rod core shaft spline block-sleeve part, a jacking screw rod part and a uniform-temperature heating ring part arranged on the heating ring sliding bracket part. The uniform-temperature heating ring part arranged on the detaching device is used for uniformly heating the screw rod and a threaded block of the extruder, thereby conveniently and stably controlling temperature, protecting technical property of the threaded element, and prolonging the service life of the threaded element. The arranged jacking screw rod part and screw rod core shaft spline block-sleeve part can be used for preventing the screw rod from moving back and forth and rotating during detaching the screw rod, thereby fixing the screw rod and conveniently heating and detaching. By using a metal square tube, the casting cost is saved. The structure is simple and the operation is convenient.

Owner:SHANGHAI KINGFA SCI & TECH

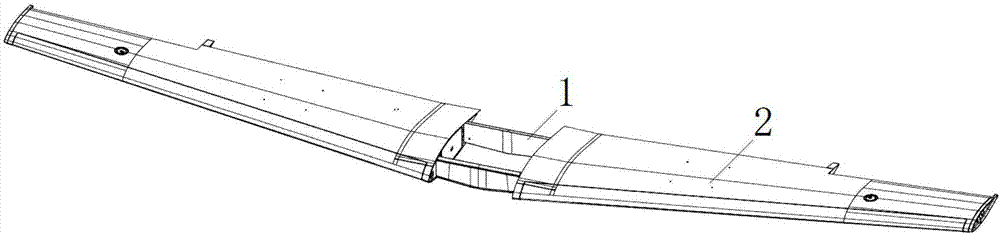

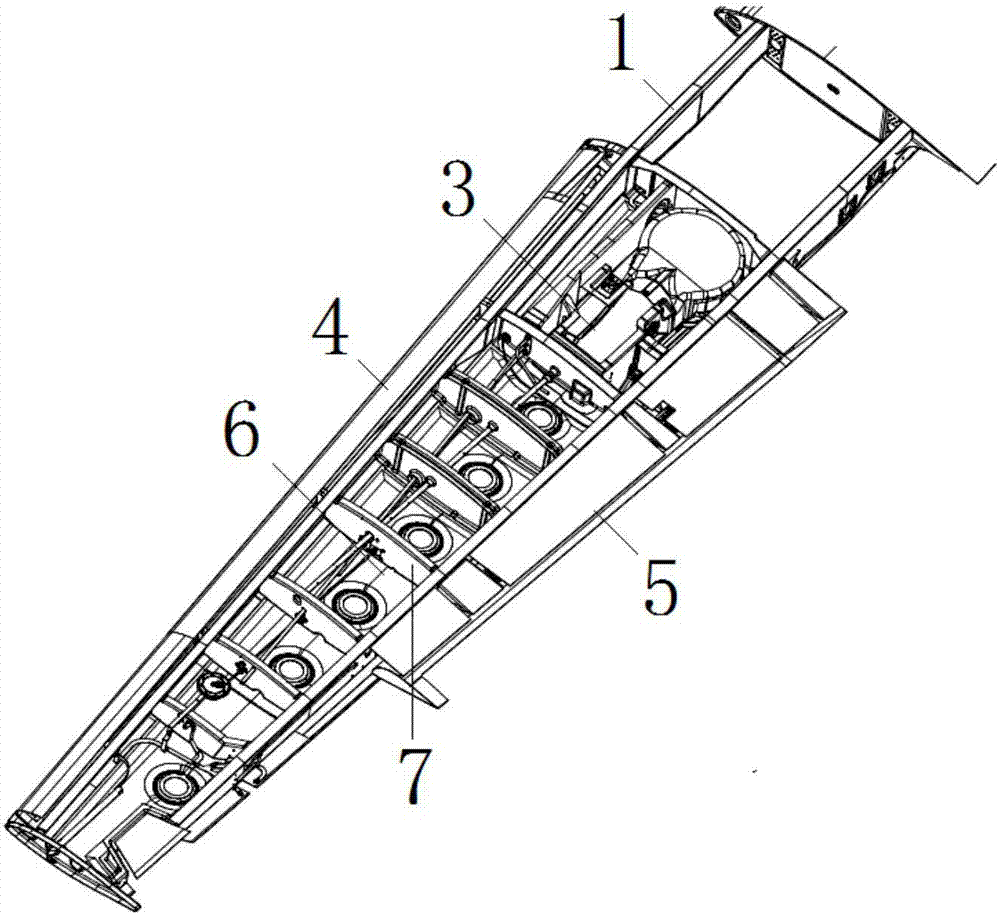

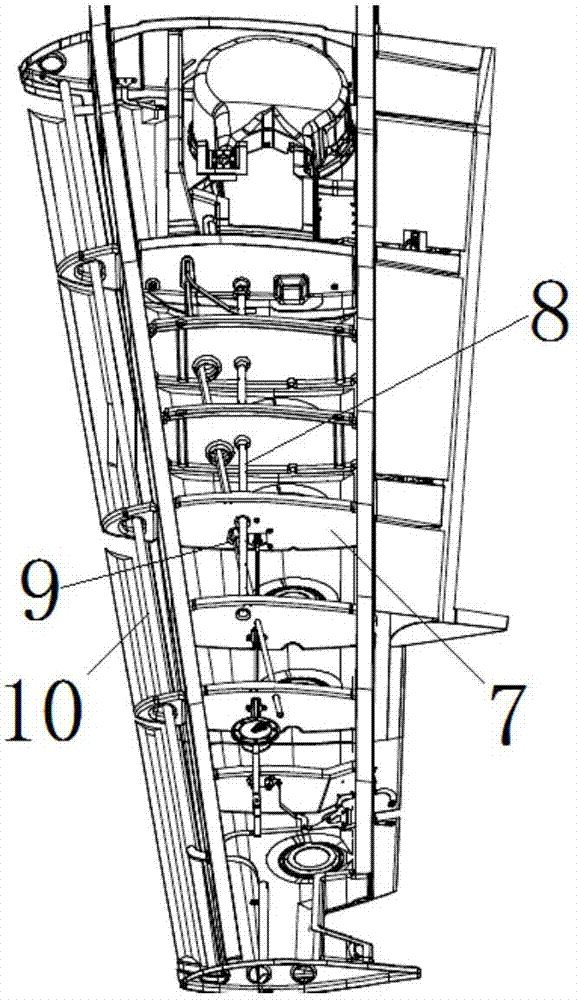

Wing oil box

PendingCN107264817AReasonable structural designPrevent back and forth movementPower plant fuel tanksReciprocating motionStructural engineering

The invention discloses a wing oil box. The wing oil box comprises wing beams. The wing beams are double-wing beams arranged in a front-back abreast mode. A sealed whole wing oil box is vertically formed through a sealing plate between the double-wing beams. The oil box is divided into a group of areas in the length directions of the wing beams through a set of baffles arranged abreast in the whole wing oil box. The adjacent areas communicate with one another through communicating holes formed in the baffles. According to the wing oil box, the structural design is reasonable, the whole wing oil box is divided into the several areas through the baffles, all the areas communicate with one another through the communicating holes, reciprocating motion of fuel oil of the wing fuel oil box is prevented when a plane is unstable, the stability of flying of the plane is ensured, the ends of the baffles are connected with the wing beams, and the structural strength of a wing is improved.

Owner:芜湖中科飞机制造有限公司

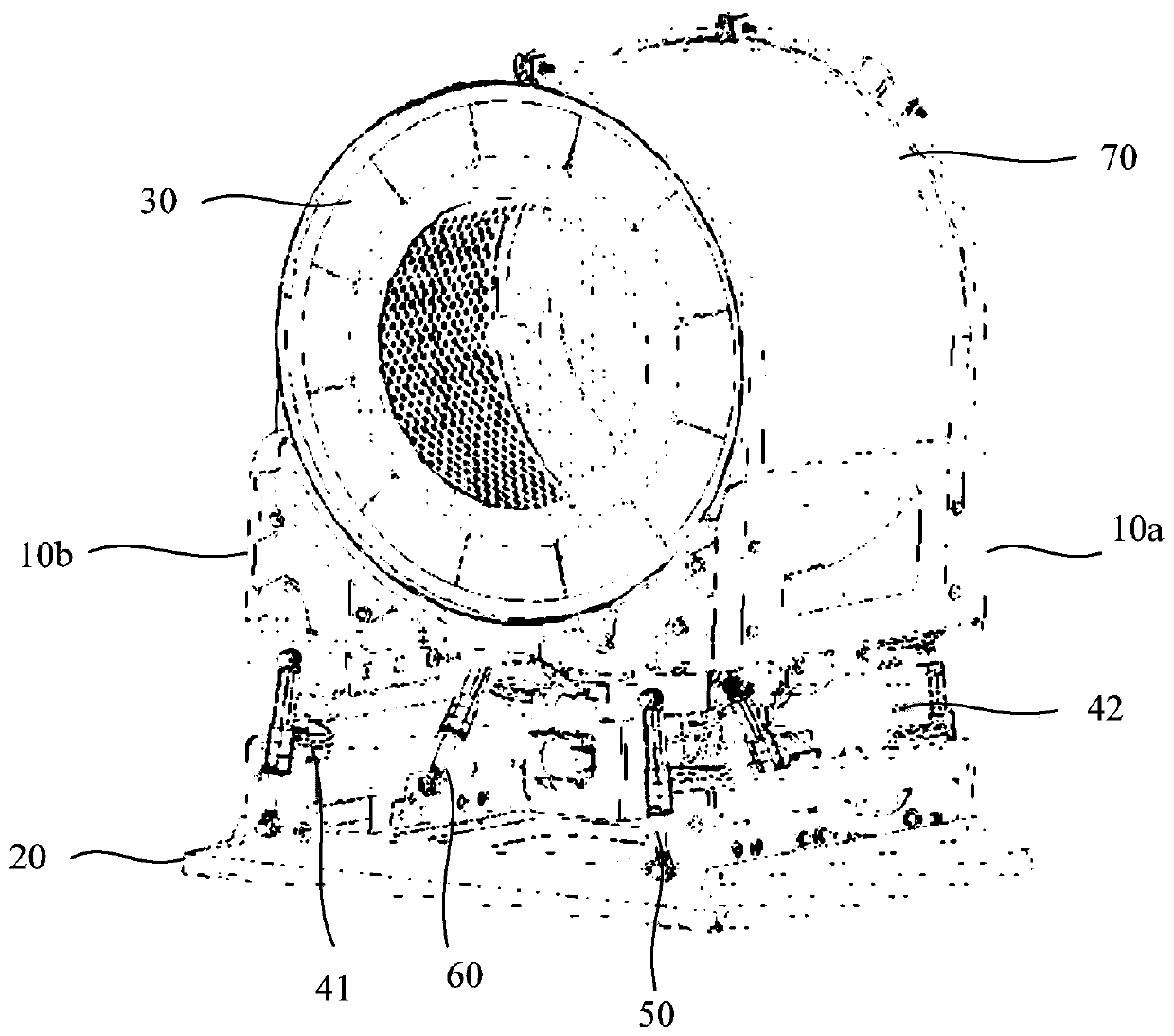

Damping seat and roller washing machine

PendingCN111058238AReduced risk of collisionReduce noiseOther washing machinesTextiles and paperLaundry washing machineDamper

The invention provides a damping seat and a roller washing machine, belongs to the technical field of roller washing machines, and aims to solve the vibration and movement problems of an outer barrel.The damping seat comprises a bottom frame and a supporting frame; the bottom frame is fixed in a box body of the roller washing machine, the supporting frame is used for bearing the outer barrel, andfirst dampers and pressure springs are symmetrically arranged on the left side and the right side of the bottom frame in the axial direction of the outer barrel and are used for providing vertical support for the supporting frame; second dampers are arranged on the left side and the right side between the bottom frame and the supporting frame in a staggered manner, one ends of the second dampersare connected to the bottom frame, and the other ends of the second dampers are connected to the supporting frame; and the supporting frame is provided with at least one fastening belt, one ends of the fastening belts are connected to one side of the supporting frame, the other ends of the fastening belts are connected to the other side of the supporting frame, and the fastening belts are tightlyattached to the outer wall of the outer barrel. The damping seat and the roller washing machine provided by the invention can reduce the risk of collision between the outer barrel and the box body, thereby improving the operation safety and reducing the noise.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

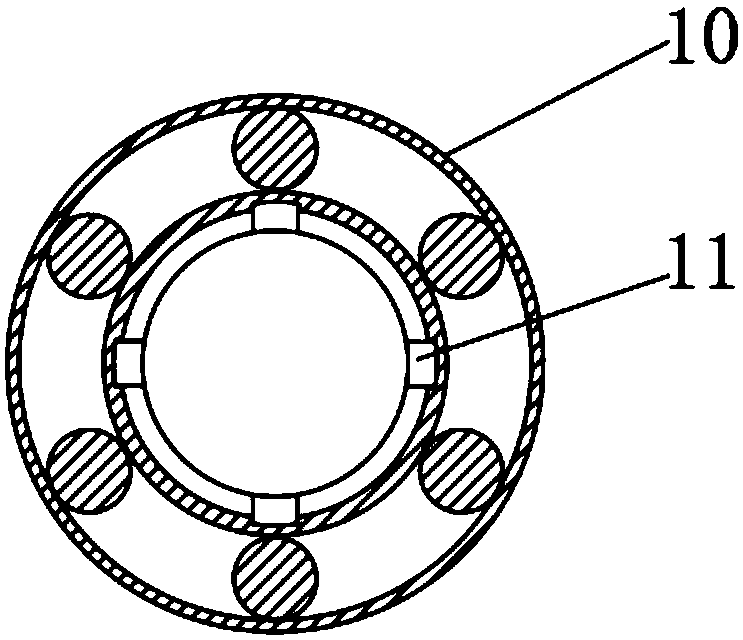

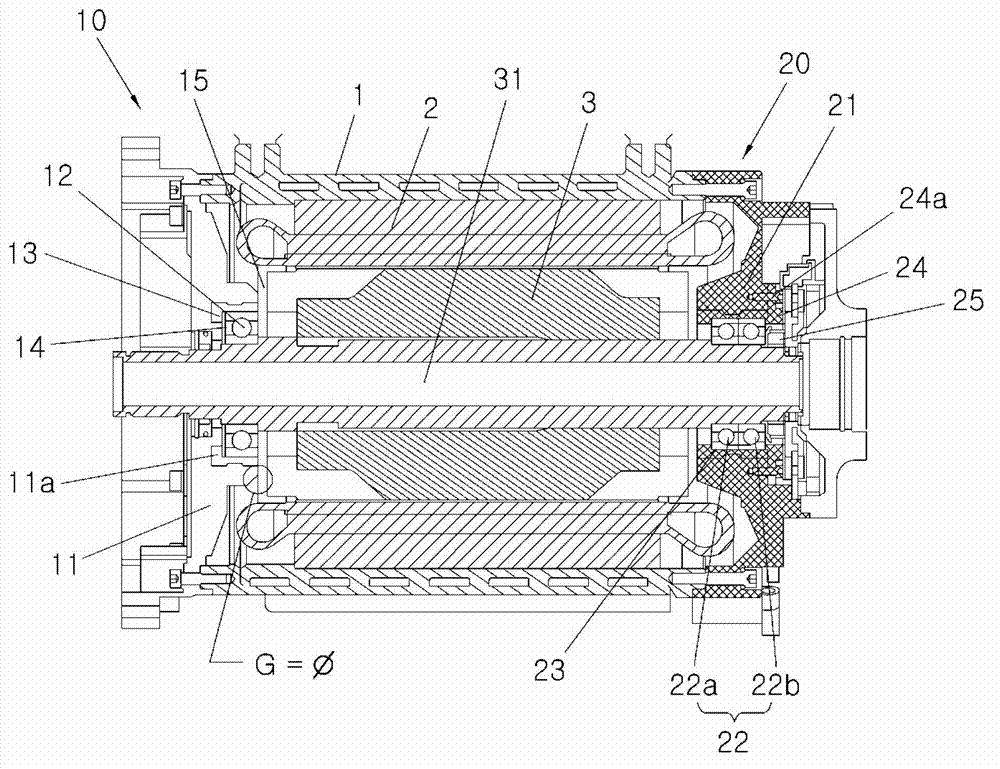

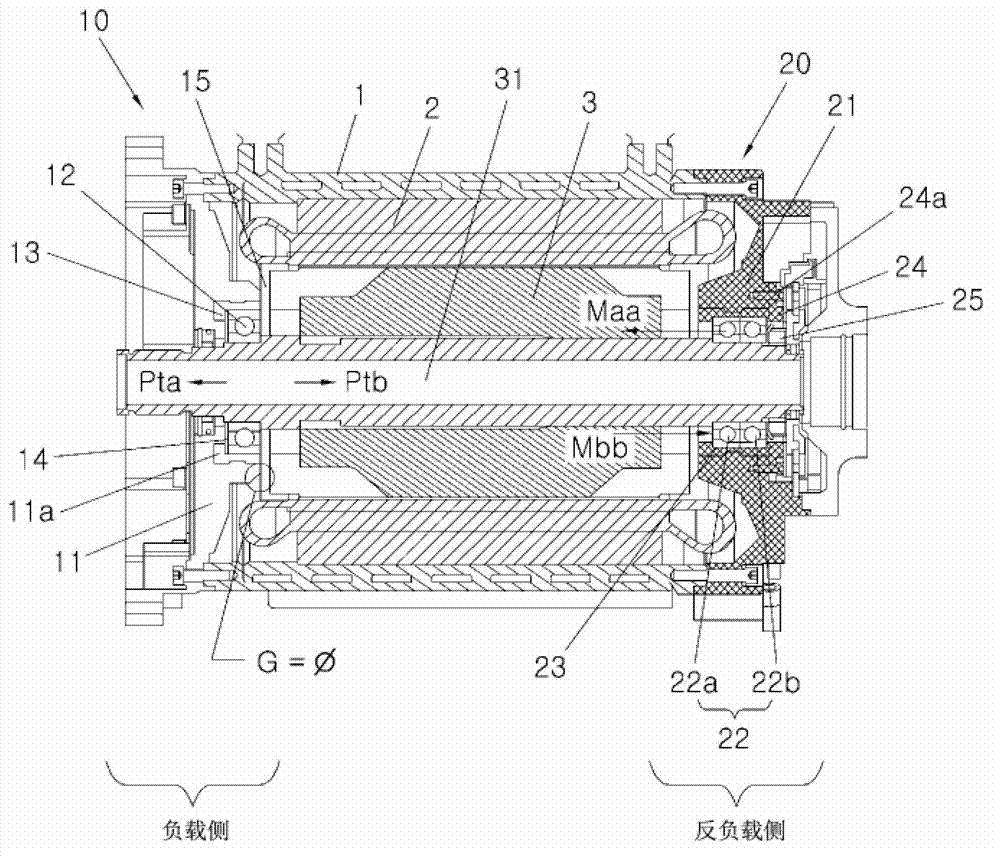

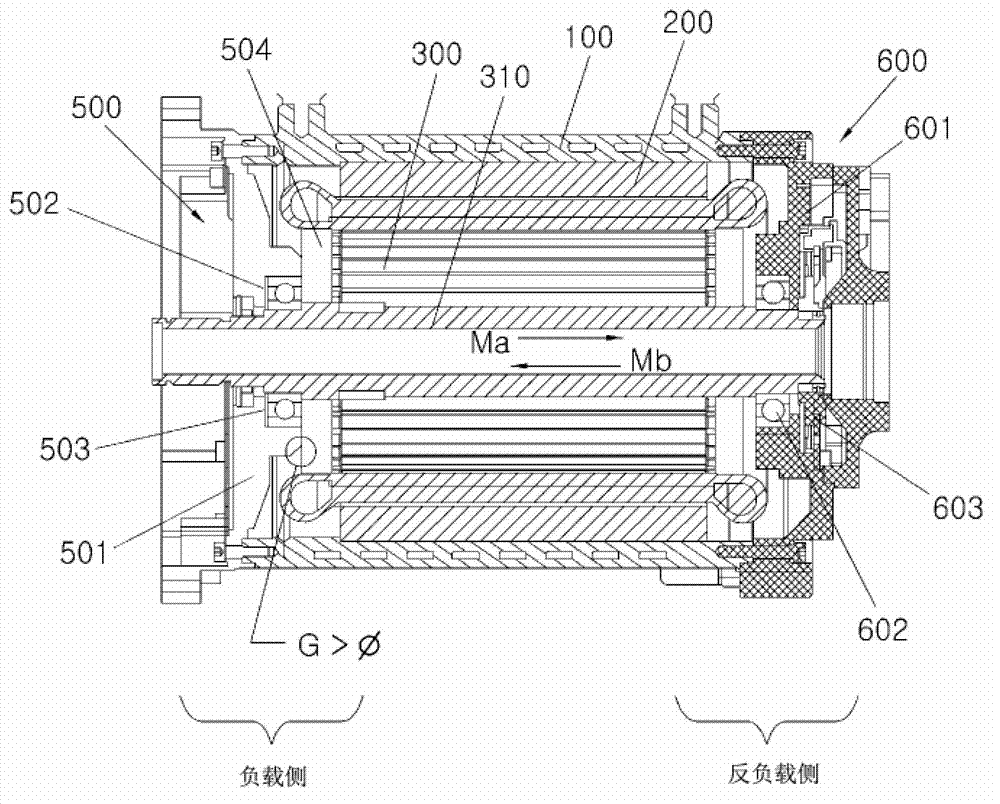

Traction motor

InactiveCN102904367APrevents motor noise and vibrationImprove quality and reliabilitySupports/enclosures/casingsTraction motorEngineering

The invention relates to a traction motor which uses an anti-load side supporting part (20), a supporting part of one side of a rotary shaft (31), as a reference site to fix the rotary shaft (31). Therefore, even if the rotary direction of the motor is changed, the rotary shaft (31) does not move back and forth, thereby greatly reducing noise and vibration of the motor. A load side supporting part (10) used as a supporting part of the opposite side can support thermal expansion movement of the rotary shaft (31), so that the rotary shaft (31) can realize the thermal expansion movement even if an end gap (G) considering the thermal expansion of the rotary shaft is not formed.

Owner:HYUNDAI MOBIS CO LTD

Nail art device

InactiveCN103025196APrevent slidingQuality improvementTypewritersRotary pressesComputer moduleDrive motor

Disclosed is a nail art device comprising: a finger holder for fixing a finger; and a printer unit for printing an image on the nail of the finger fixed by the finger holder, wherein the printer unit includes a printer head provided on a printer head frame, a first moving unit for moving the printer head left and right, and a second moving unit for moving the printer head frame forwards and backwards, the second moving unit including a driving motor, a first driving member that is driven by the driving motor, a second driving member that is spaced apart from the first driving member, and facilitates contact by coming into close contact with the first driving member when printing an image on the nail, and simultaneously guides the forward-and-backwawrd movement of the first driving member,; and a second driving member elevating module for elevating the second driving member so that the second driving member comes into close contact with the first driving member when an image is being printed on the nail, and for spacing out the second driving member from the first driving member when an image is not being printed on the nail. The nail art device of the present invention can automatically print an image desired by a user using the first moving unit that moves the printer head left and right, and the second movement unit that moves the printer head frame having printer head front and back.

Owner:李相玲

Straightening device for reinforcing steel bar machining

The invention discloses a straightening device for reinforcing steel bar machining, relates to the technical field of reinforcing steel bar straightening and aims to solve the problem that a transition area is lacked between straightening assemblies. The straightening device specifically comprises a bottom plate and a straightening assembly. A discharging assembly is fixedly connected to the outerwall of the top of the bottom plate, a supporting plate is fixedly connected to the outer wall of the top of the bottom plate, a vertical frame is fixedly connected to the outer wall of the top of the supporting plate, a feeding assembly is fixedly connected to the outer wall of one side of the vertical frame, and a rotating assembly is fixedly connected to the outer wall of the straightening assembly. By arranging the straightening assembly, inserting grooves are evenly distributed in the inner wall of a fixing cylinder, so that the angle of a first sleeve is adjusted and the first sleeve isfixedly connected, then a pressing wheel on a first support rotates in the axis direction to form a transition area, and the problem that in the straightening process, due to poor straightening of aprevious procedure, a reinforcing steel bar collides with internal components of a follow-up device is avoided; and in addition, the angle of the first sleeve can be adjusted to realize multi-directional straightening of the reinforcing steel bar so as to improve the efficiency.

Owner:JIANGSU POWER TRANSMISSION & DISTRIBUTION CO LTD

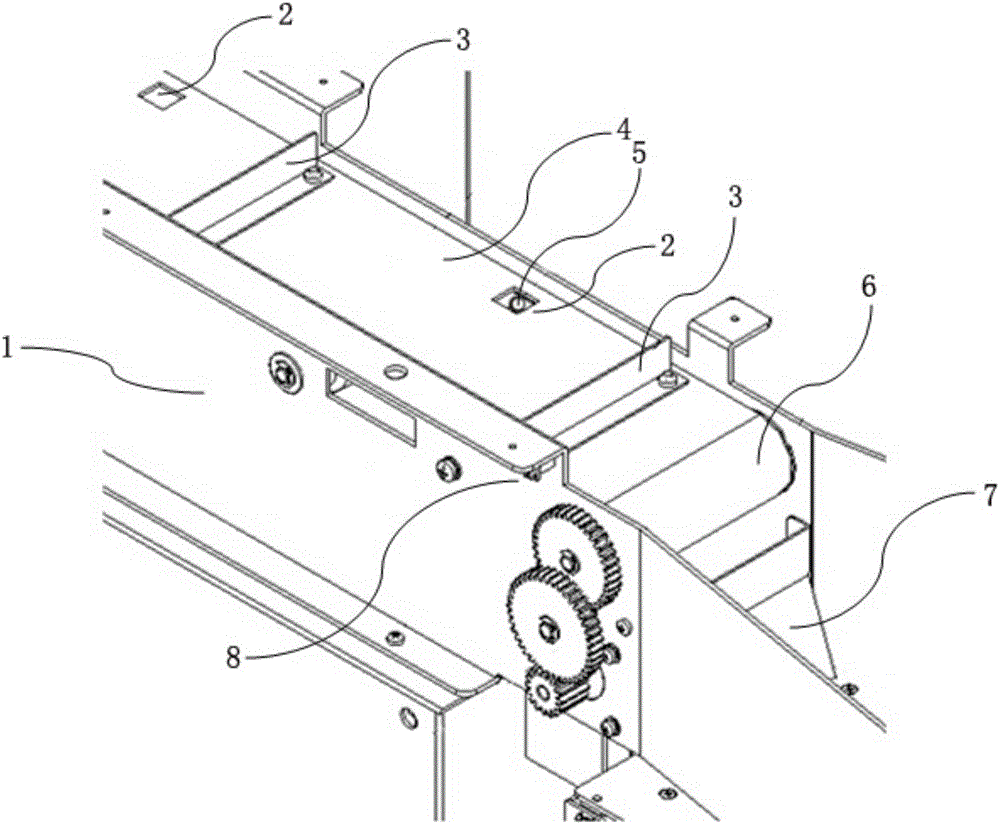

Discharged paper money transport mechanism for wholesale teller machine

PendingCN106251480AThe overall structure is simple and reliableIngenious designCoin/currency accepting devicesPulp and paper industryInductor

The present invention provides a discharged paper money transport mechanism for a wholesale teller machine. The discharged paper money transport mechanism comprises a conveying platform; the conveying platform is provided with a conveyor belt; the conveyor belt is provided with baffles at equal intervals; an induction window is formed on the conveyor belt between every two adjacent baffles; the position of each induction window is corresponding to the position of a corresponding paper money discharging success inductor installed at the tail end of the conveying platform below the conveyor belt; the conveyor belt is supported and driven by a belt roller installed at the tail end of the conveying platform; the tail end of the conveying platform is provided with a conveyor belt position detection sensor; and a paper money fetching groove is arranged below the tail end of the conveying platform. The discharged paper money transport mechanism of the invention has the advantages of simple and reliable overall structure, ingenious design, high working efficiency and high automation degree, and can be widely applied to wholesale bundled paper money and can be popularized and used on a large scale.

Owner:BEIJING HUAXINCHUANGYIN TECH CO LTD

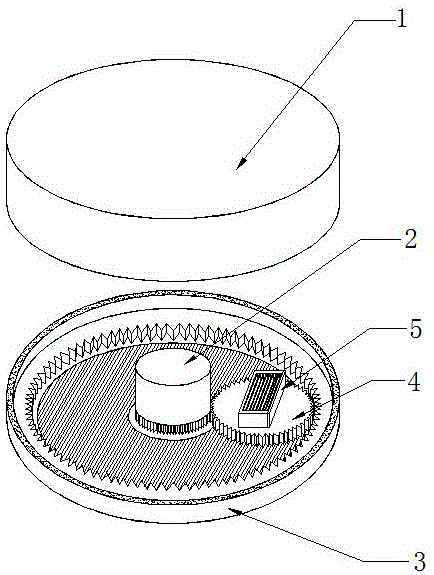

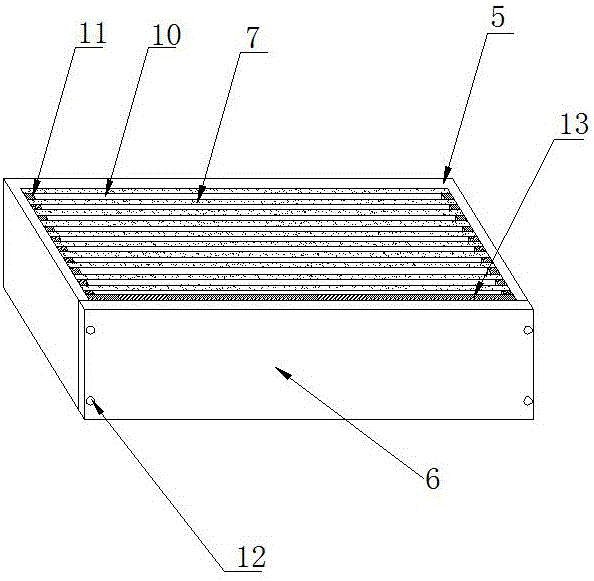

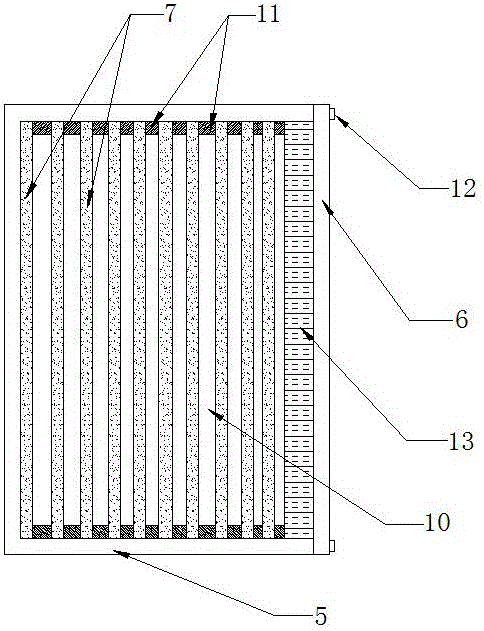

Polishing device for side surface of mobile phone glass

InactiveCN105965344ASave electricityAvoid scratchesEdge grinding machinesGrinding drivesMobile phoneCushion

The invention discloses a polishing device for a side surface of mobile phone glass. The polishing device comprises a grinding head, a rotating shaft, a rotary disc, an epicyclic gear and a loading box, wherein the rotating shaft is mounted in the central position of the rotary disc; sawtooth structures which mesh with the epicyclic gear are arranged on the inner edge of the rotary disc and the outer side of the rotating shaft; the loading box is arranged on the epicyclic gear; three side surfaces and the bottom surface of the loading box are fixed connection structures; the other side surface of the loading box is a movable fixing panel; tooth grooves with uniform intervals are formed in the bottom of the loading box; rubber spacers are arranged at the tops of the tooth grooves; grilles are arranged in the tooth grooves; glass placing grooves are formed between the grilles; and vertical rubber cushion blocks having the same width with the glass placing grooves are arranged at the two ends of the glass placing grooves. On the whole, the polishing device has the advantages that the production efficiency is high, the fixation is firm, and the polishing effect is good, and the phenomenon that the mobile phone glass is broken and scratched during the polishing process can be avoided.

Owner:HENAN COMYOUNG ELECTRONICS

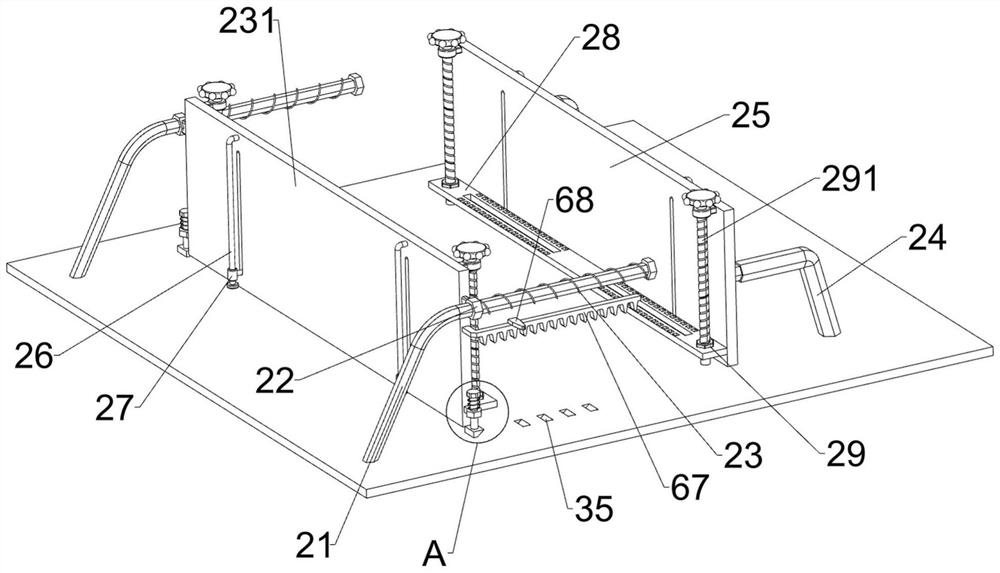

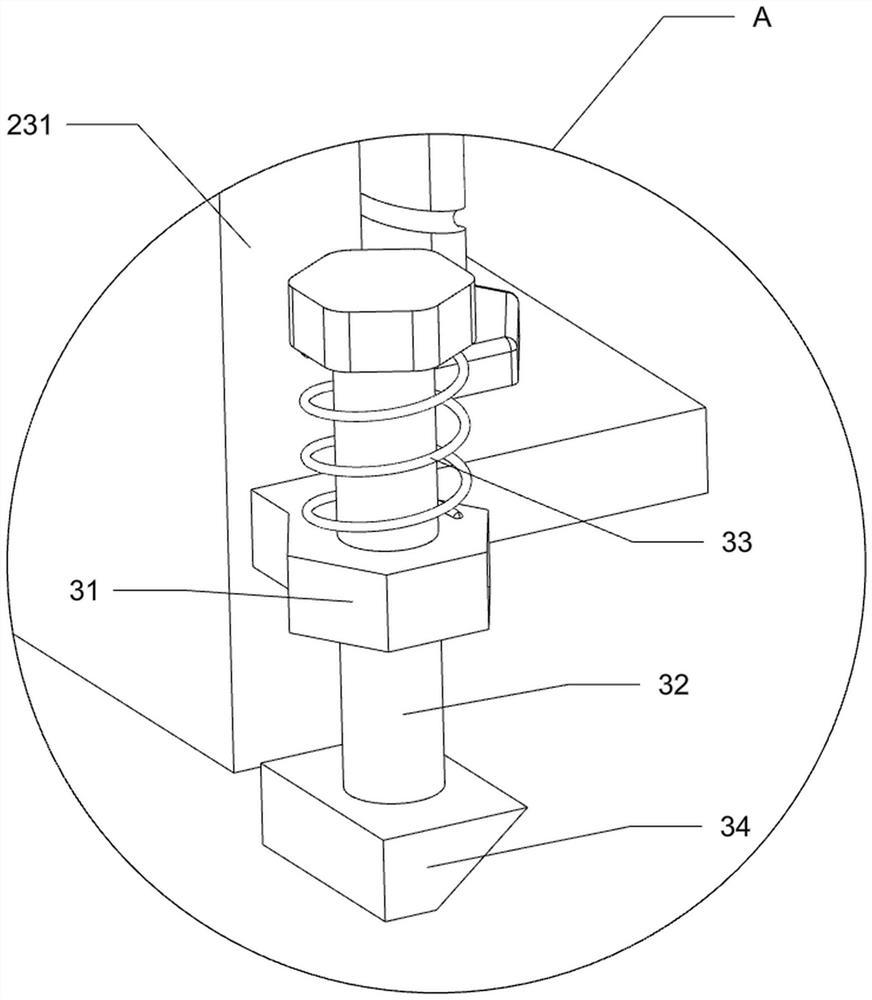

Splicing auxiliary device for furniture production

InactiveCN112975825APrevent back and forth movementImprove work efficiencyWork holdersMetal-working hand toolsEngineeringStructural engineering

The invention relates to a splicing auxiliary device, and particularly relates to a splicing auxiliary device for furniture production. The splicing auxiliary device for furniture production can fix furniture during splicing, does not incline during splicing, and is high in working efficiency and good in quality. The splicing auxiliary device for furniture production comprises a mounting bottom plate, a placing assembly and a clamping assembly, wherein the placing assembly is mounted on the mounting bottom plate and is placed in a sliding mode; and the clamping assembly is mounted on the mounting bottom plate and is clamped in a sliding mode. According to the splicing auxiliary device for furniture production, the furniture needing to be spliced can be placed through the placing assembly, meanwhile, the placing height of the furniture can be adjusted according to needs, the distance can be adjusted according to the needs of people through the clamping assembly, meanwhile, the furniture needing to be spliced can be clamped, the furniture needing to be spliced can be fixed through a fixing assembly, the furniture is prevented from moving front and back during splicing, and a left mounting plate does not need to be pushed manually through a driving assembly.

Owner:东莞市波德莱尔家具设计有限公司

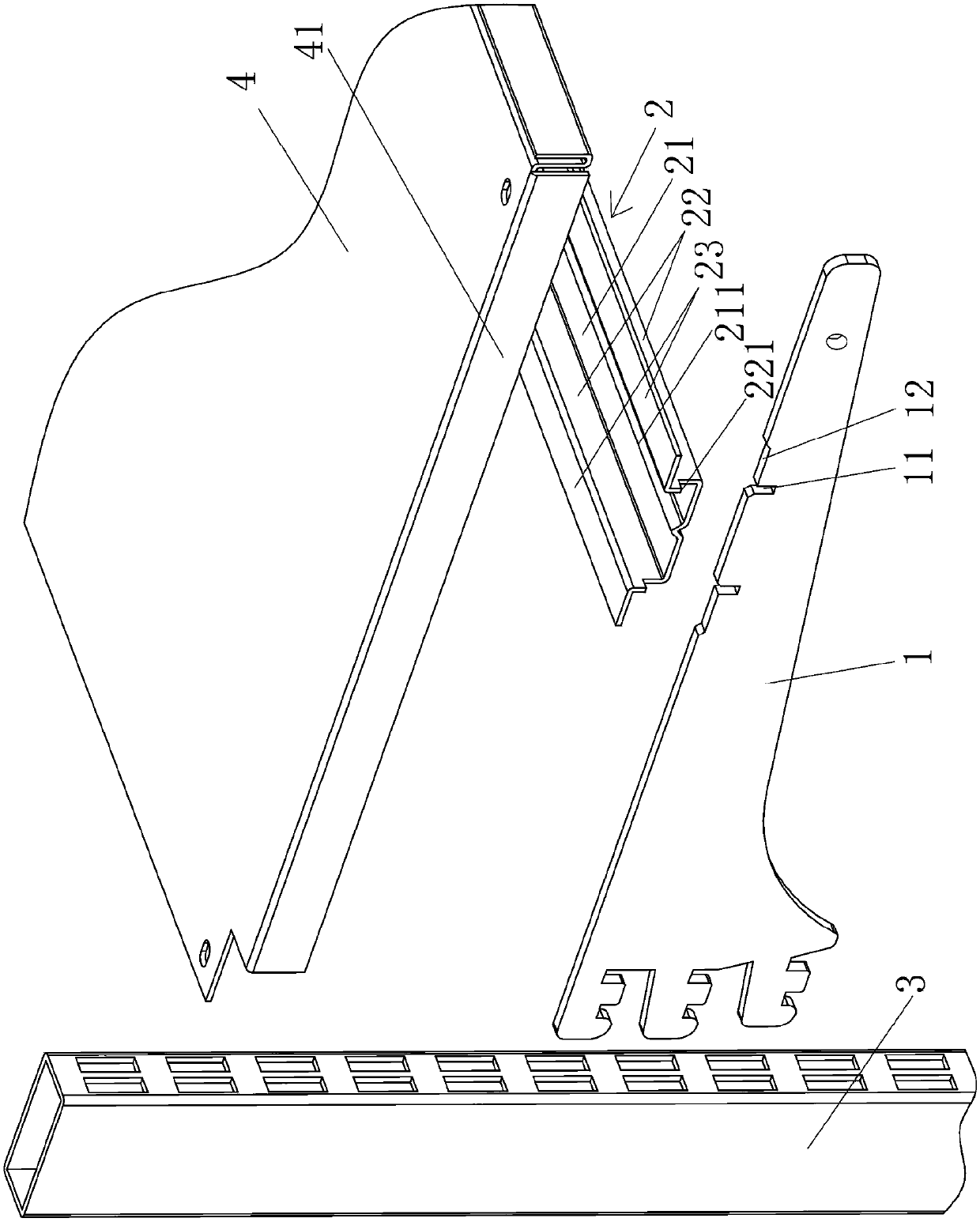

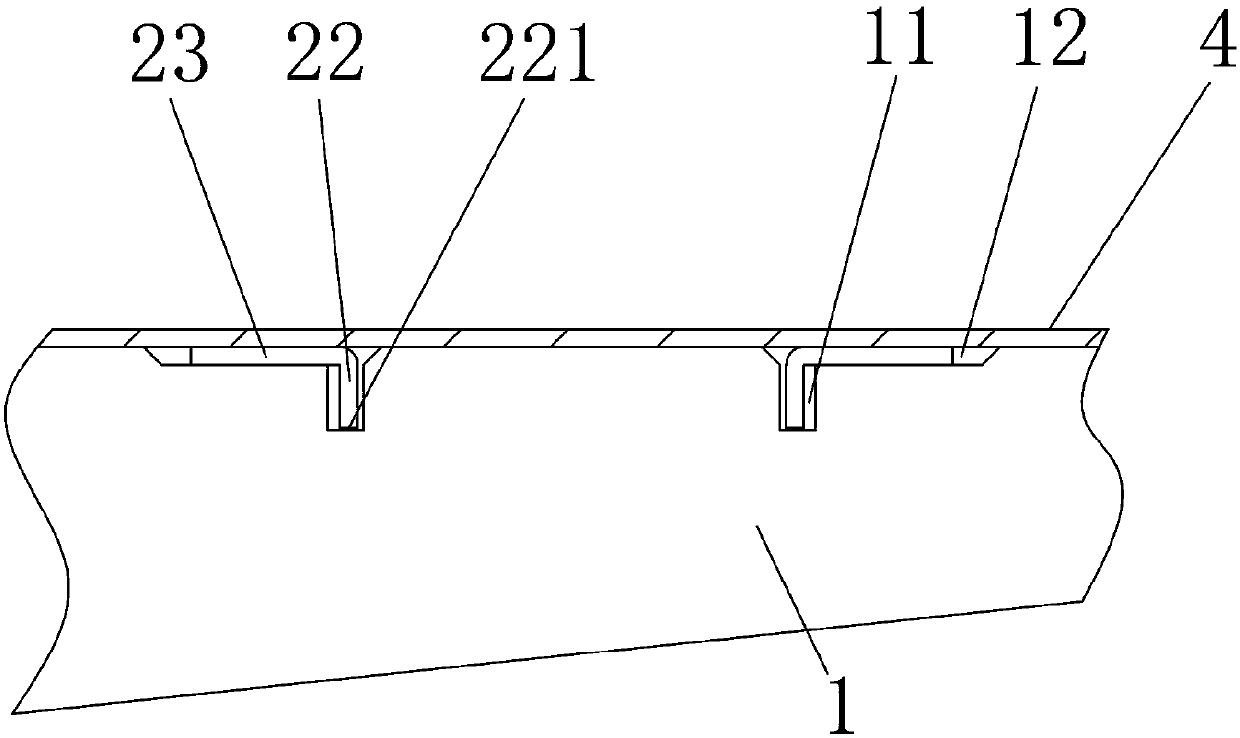

Supporting structure of shelf board for goods shelf

PendingCN107651352APrevent back and forth movementImprove stabilityFurniture partsWork tools storageCantileverUltimate tensile strength

The invention provides a supporting structure of a shelf board for a goods shelf. The goods shelf comprises a stand column and the shelf board. The supporting structure of the shelf board comprises asupporting arm and a shelf board framework. The supporting arm is connected with the stand column in a horizontal overhung arm state to be installed. The shelf board is placed on the supporting arm. The shelf board framework is arranged at the bottom of the shelf board. The two ends, in the length direction, of the shelf board framework are connected and fixed to the supporting arm. The supportingstructure of the shelf board for the goods shelf is characterized in that the shelf board framework comprises a long-strip-shaped reinforcing plate, the side edges on the two sides, in the width direction, of the reinforcing plate are folded upwards to form side plates, the upper end, in the height direction, of each side plate is folded outwards in the length and extends in the length directionto form turned plates used for being attached to the bottom of the shelf board, the portions, located at the two ends in the length direction and located on the upper portion in the height direction,of each side plate are provided with clamping feet protruding towards the supporting arm, the upper end, in the height direction, of the supporting arm is provided with gaps corresponding to the clamping feet in position, and the gaps are used for clamping of the clamping feet. The shelf board can be effectively prevented from moving front and back. The supporting stability and bearing capacity ofthe supporting arm can be improved, and the firmness strength of connection is improved.

Owner:苏州强鸿金属制品有限公司

Shear type lifting machine locking assembly

ActiveCN109319691APrevent fallingImprove securitySafety devices for lifting equipmentsLifting framesGear wheelLocking mechanism

The invention discloses a shear type lifting machine locking assembly. The assembly comprises a base, a first locking mechanism comprises a first resetting spring, an inclined plate and a supporting plate, two ends of the first resetting spring are connected with a lifting machine and the bottom plate of the inclined plate, a rack is arranged on the inner wall of the bottom end of a shell of a second locking mechanism, one side of the rack is connected with an adjusting bolt extending to the outer side of the second locking mechanism, the upper end of the rack is connected with a gear engagedwith the rack, and a limiting block is connected to the top end of the supporting rod. When the lifting machine ascends, a pulley rightwards moves in the base, a connecting rod is locked through the limiting block, the phenomenon that due to sliding, the lifting machine falls can be prevented, the structure is simple, the mechanical motion stability is good, under the effect of the first resettingspring, the inclined plate is ejected, the supporting plate is placed in a clamping groove, the secondary fixing effect is achieved, front and back moving of a vehicle is prevented, safety of the lifting machine is improved, and the accident rate is reduced.

Owner:芜湖高盛液压机电技术有限公司

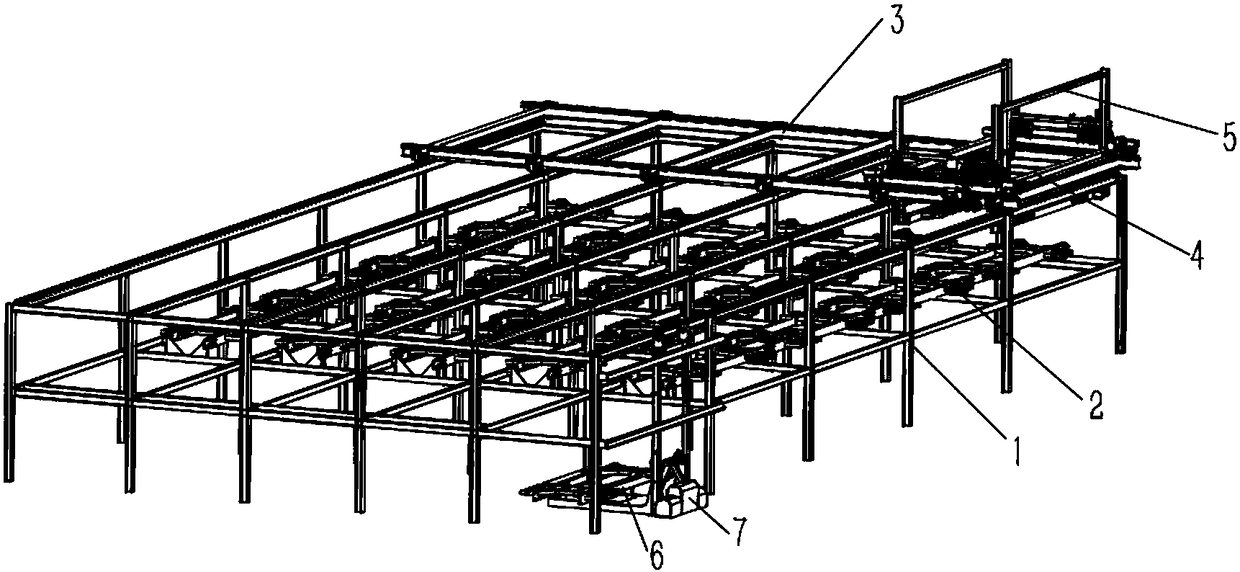

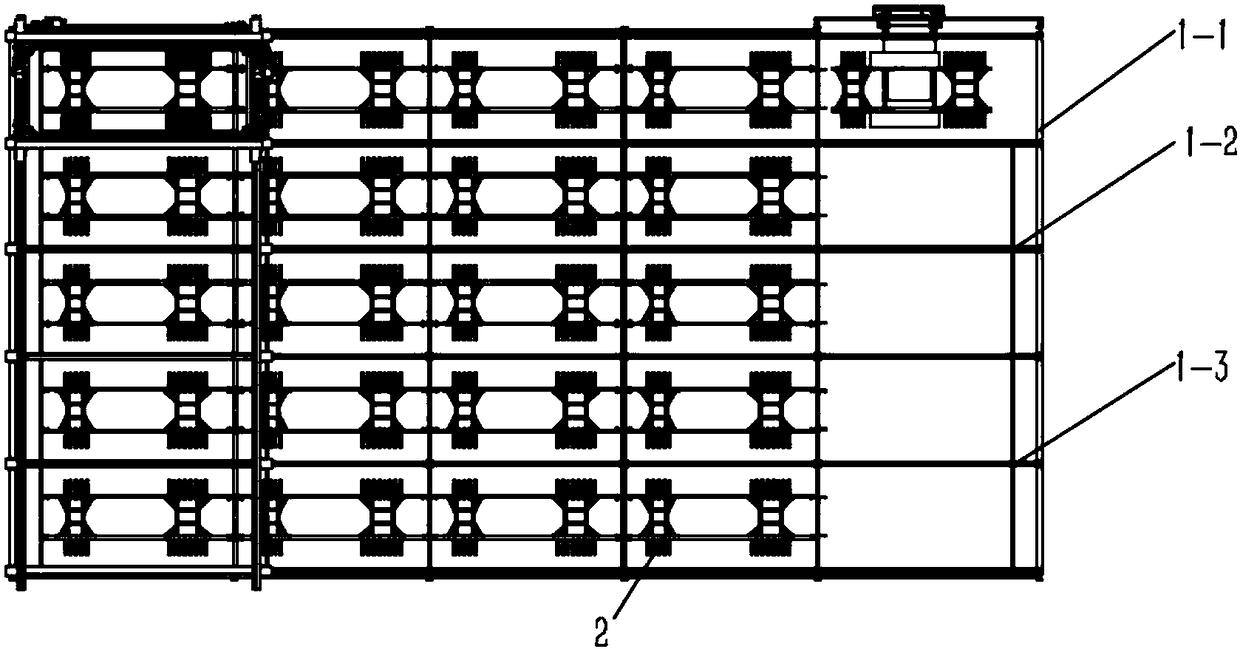

Array comb-teeth type intelligent storage and taking device

PendingCN108131039AThe number of multi-capacity vehiclesAccess to the car is fastParkingsEngineeringIntelligent sensor

The invention belongs to the field of three-dimensional parking equipment and particularly relates to an array comb-teeth type intelligent storage and taking device. The array comb-teeth type intelligent storage and taking device comprises a main-body frame, wherein parking desks are distributed on the main-body frame; the main-body frame comprises longitudinal frame beams and horizontal frame beams; each longitudinal frame beam is provided with a traveling frame guide rail aligned to the central line of the longitudinal frame beam; a traveling frame capable of moving along the traveling frameguide rails is arranged on the traveling frame guide rails; a moving cart capable of moving along the traveling frame is arranged on the traveling frame and is provided with a liftable car taker; a lifting platform driven by a lifting transmission mechanism is arranged in the first row of the main-body frame. The array comb-teeth type intelligent storage and taking device has the beneficial effects that by adoption of comb-teeth connection and a motor transmission structure, parallel storage of a plurality of cars can be realized and the array comb-teeth type intelligent storage and taking device can be applicable to street-crossing or object-crossing places.

Owner:天津知时捷科技发展有限公司

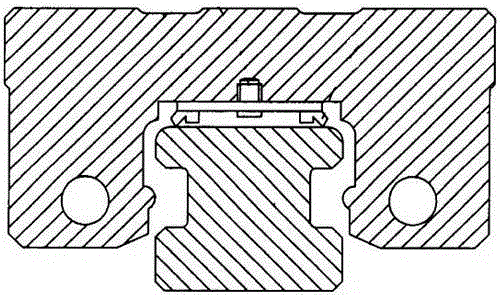

Special fixture for radial porous parts

InactiveCN102528492AAvoid multiple clampingAvoid timePositioning apparatusMetal-working holdersFree stateEngineering

The invention relates to a special fixture for radial porous parts, and the special fixture comprises a base, wherein the base comprises a first plane and a second plane which are vertical to each other, a drilling template is arranged on the first plane, a hole site is formed on the drilling template, and a screw hole and a draw bar hole are formed on the second plane, a screw is rotatably arranged in the screw hole, one end, positioned below the drilling template, of the screw is provided with a locating shaft for installing a part to be processed, the screw is also fixedly provided with a locating block, the locating block is arranged between the locating shaft and the base, a panel, opposite to the base, of the locating block is provided with a plurality of locating pits, a draw bar is rotatably arranged in the draw bar hole, one end of the draw bar is connected to a draw bar handle, the other end of the draw bar is provided with a draw bar contact head which can retract under external action and extend in a free state, the draw bar contact head is arranged at one side, which is provided with the locating block, of the base, and the draw bar contact head is positioned in the locating pits when in the free state. After the fixture is used, the processing efficiency is greatly improved and the product quality is stable.

Owner:JIANGSU WANGONG TECH GRP CO LTD

Novel sleeper component protecting cover

PendingCN109577120APrevent up and down movementPrevent back and forth movementTrack maintainenceEngineeringFree edge

The invention discloses a novel sleeper component protecting cover. The novel sleeper component protecting cover comprises a cover body; the cover body comprises two side surfaces, one top surface andone front surface; a handle is fixed on the front surface of the cover body through a screw; a vertically downward limiting baffle is arranged at the free edge of the top surface; clamping grooves matched with a rail base are formed in the two side surfaces; primary step-shaped base is arranged at the bottoms of the two side surfaces; the base is connected with a front surface extending plate; and the cover body, the base and one side edge of a sleeper form a hollow cavity for accommodating a fastener in a matched manner. According to the novel sleeper component protecting cover, a difficultproblem of component pollution caused by track engineering concrete pouring is solved.

Owner:王国平

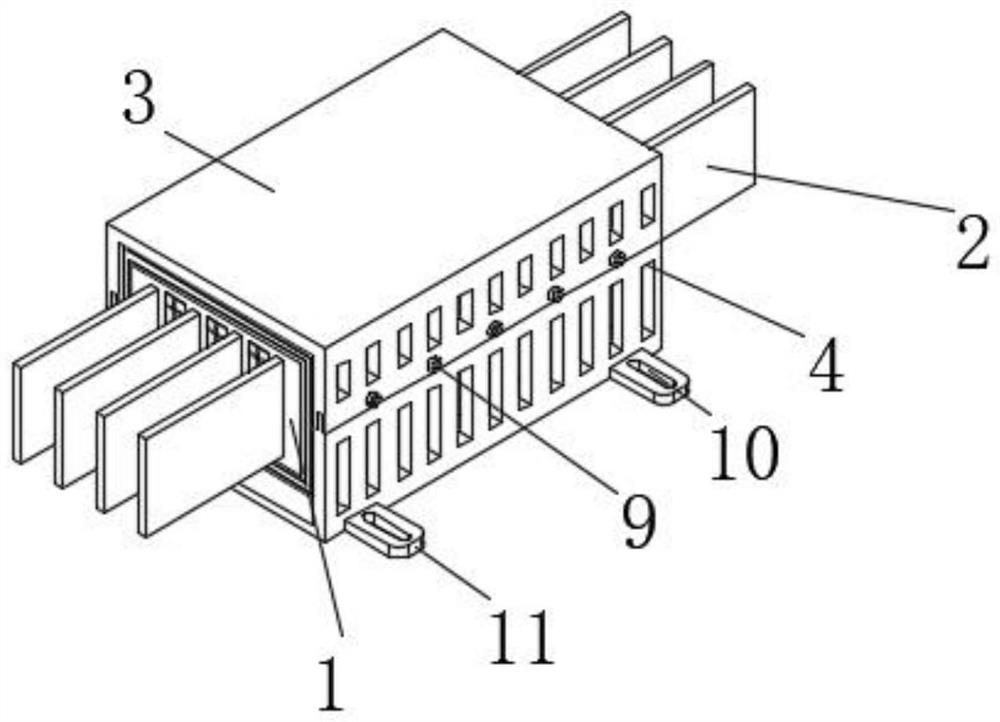

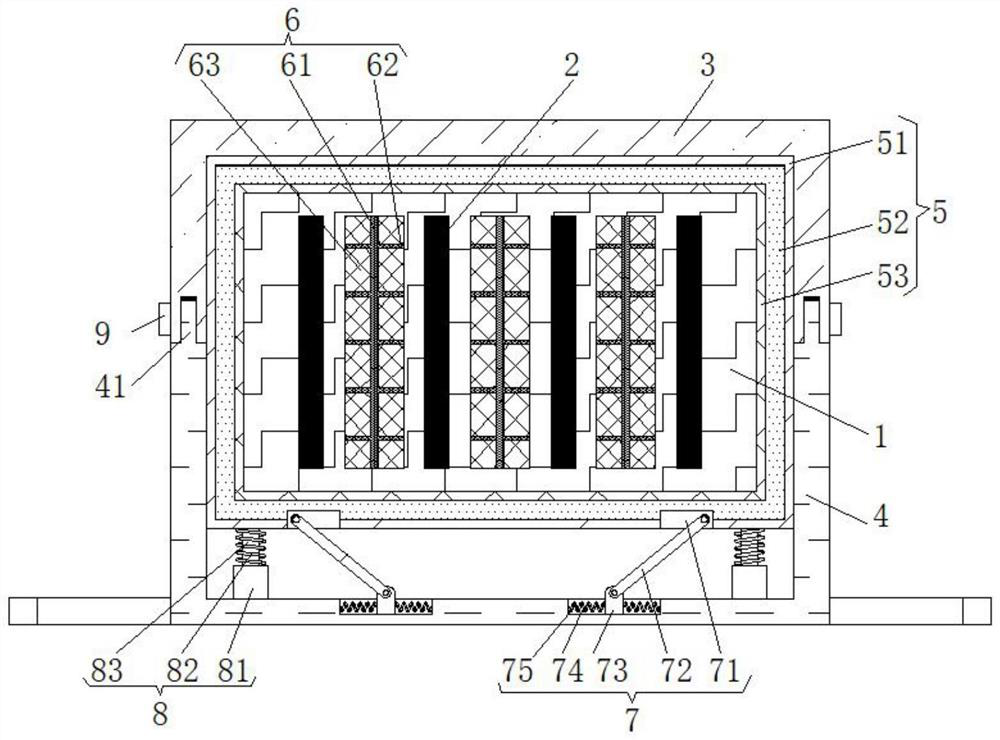

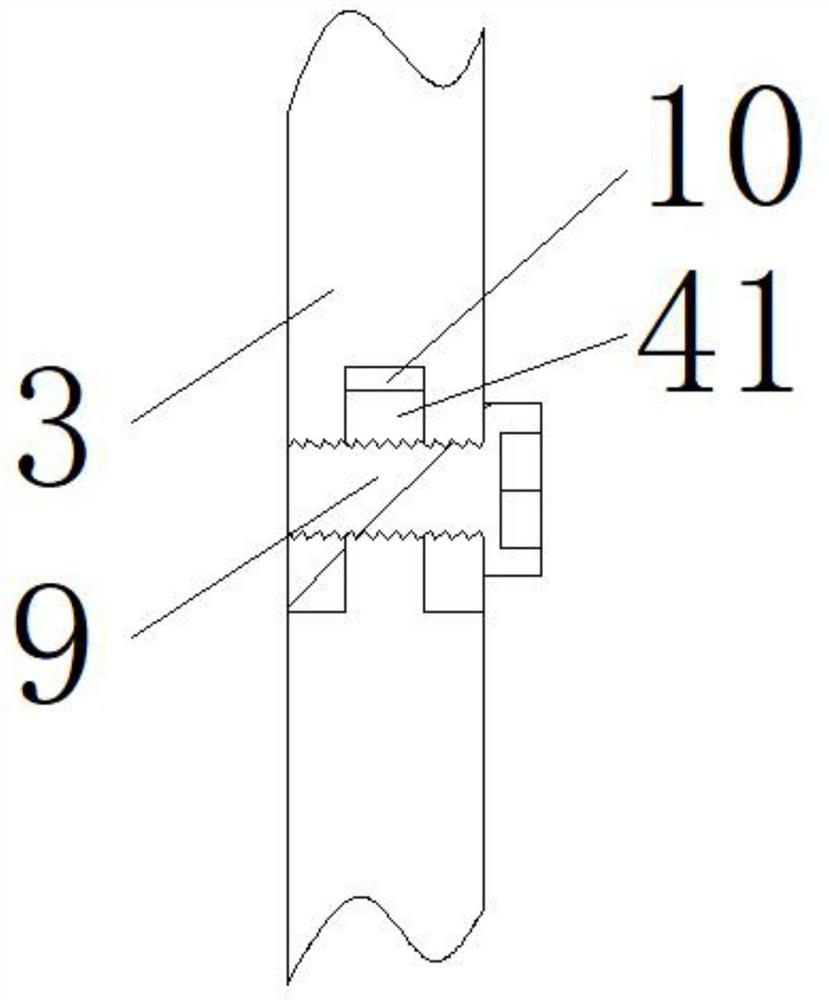

High-protection pouring bus duct

PendingCN111725754AImprove cooling efficiencyAvoid Cooling FeaturesCooling bus-bar installationsTotally enclosed bus-bar installationsStructural engineeringMechanical engineering

Owner:杰铭电气科技(镇江)有限公司

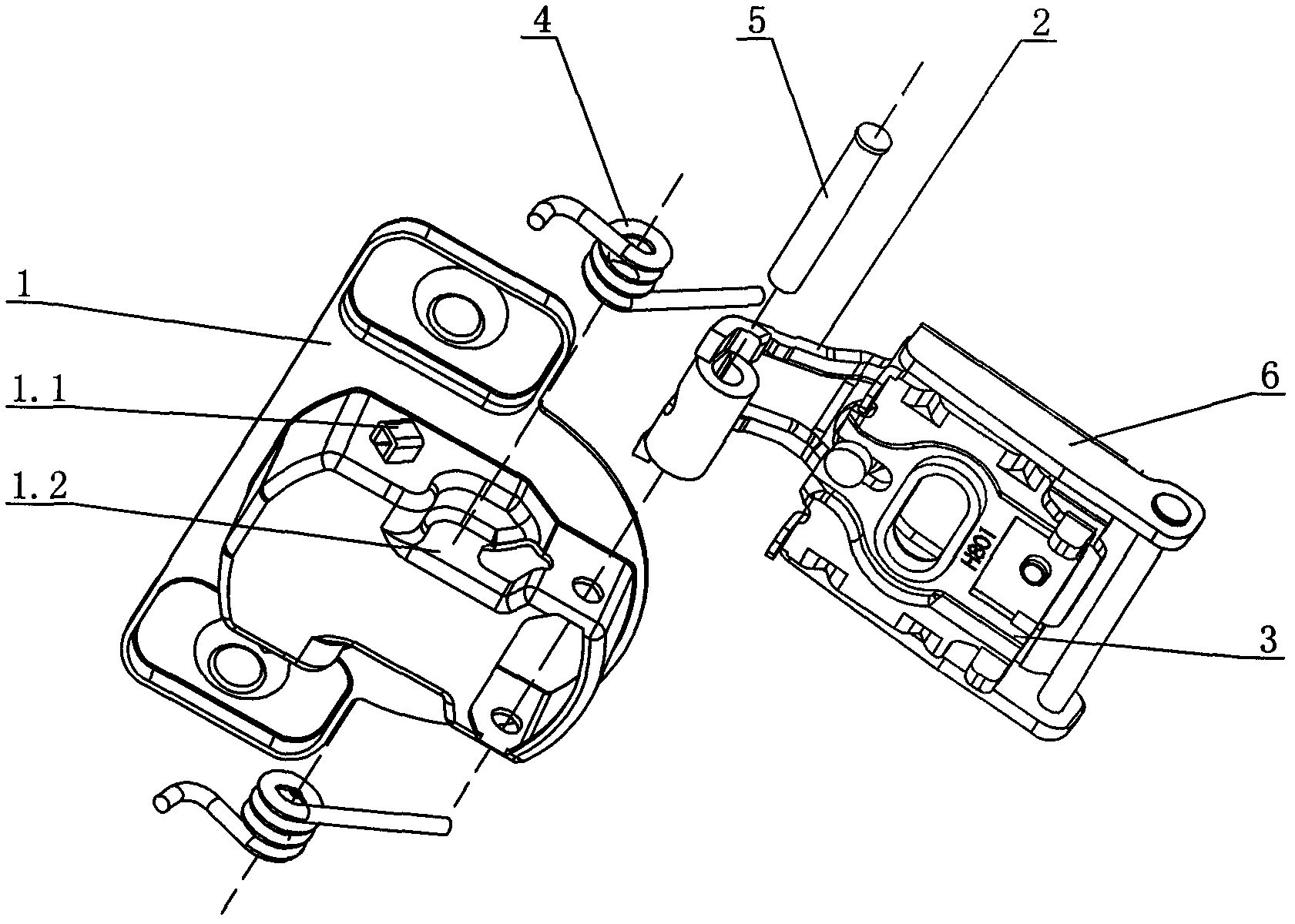

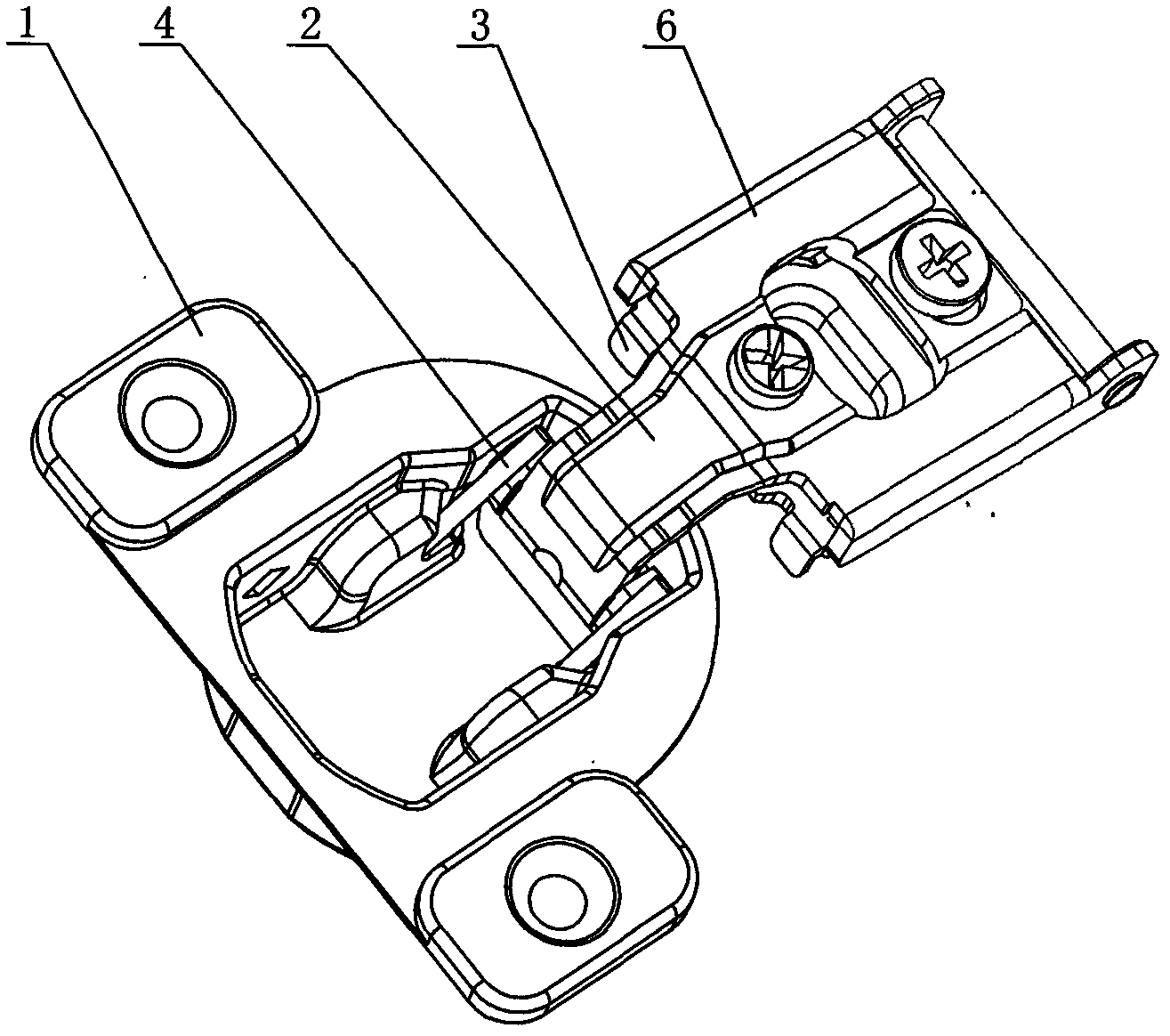

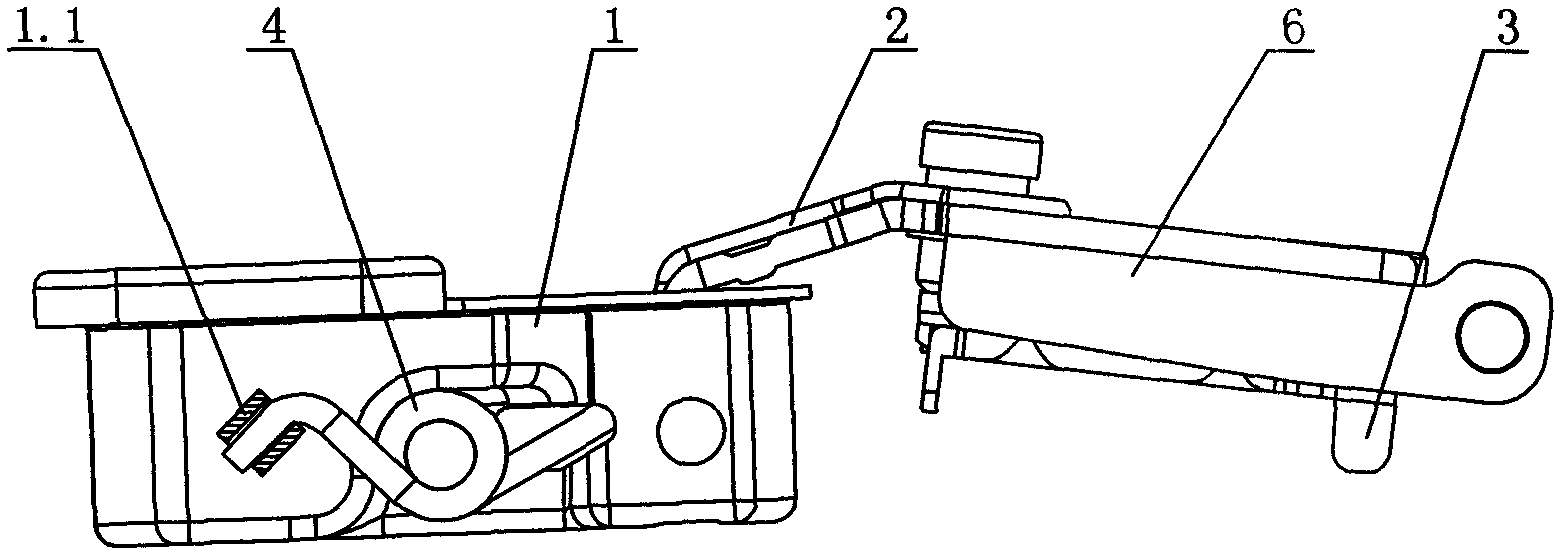

Hinge for furniture

A hinge for furniture comprises a hinge cup seat and a base, wherein the hinge cup seat is arranged on a furniture door body, and the base is arranged on a furniture main body and provided with an adjusting cover plate. The adjusting cover plate is connected with one end of a hinge arm, the hinge cup seat is hinged to the other end of the hinge arm through a torsion spring and a rotating shaft which are arranged on the left side and the right side of the hinge cup seat, buckling positions are arranged on the left side and the right side of the hinge cup seat, one foot of the torsion spring is connected to the buckling positions, and the other foot of the torsion spring abuts against the hinge arm. The buckling positions and the hinge cup seat are formed in an integrated stamping mode, or the buckling positions are arranged on the hinge cup seat in a split mode. The buckling positions are buckling holes or buckling hooks. A recessed accommodating cavity is arranged on the hinge cup seat corresponding to the torsion spring, the torsion spring is placed on the accommodating cavity, and the accommodating cavity is further provided with a blocking portion capable of preventing the torsion spring from moving forwards and backwards. A three-point limiting mode is adopted, forward and backward movement of the torsion spring is effectively prevented, an original shaft for binding the torsion spring is eliminated, a space of a cup body of the hinge cup seat is large, and installation of the hinge is facilitated. The hinge is simple and reasonable in structure, quick to assemble and low in production cost.

Owner:伍志勇

Anti-precipitation elastic jacquard screen fabric printing device and process

ActiveCN110117881AEasy to usePrevent precipitationFibre treatmentLiquid/gas/vapor removal by squeezing rollersEngineeringPrecipitation

The invention discloses an anti-precipitation elastic jacquard screen fabric printing device and process. The device comprises a dye vat, the top end of the dye vat is provided symmetrically in a penetrating mode with a first fabric feeding notch, the inner bottom of the dye vat is provided with a bottom separating plate corresponding to the bottom of a top separating plate, the top end of the topseparating plate is provided with a second fabric feeding notch formed in a penetrating mode and corresponding in position to the first fabric feeding notch, and the middle of each fixing shaft is rotatingly connected in a sleeve mode with a guide roller. The anti-precipitation elastic jacquard screen fabric printing device is scientific, reasonable, safe and convenient to use; dye liquor is pumped out from the bottom of the bottom separating plate by a suction pump and then flows via a liquor inlet branch pipe back to between the top separating plate and the bottom separating plate, jacquardscreen fabrics are driven by the two guide rollers and accordingly can be fully dyed between the two separating plates, and through circular flow of the dye liquor, precipitation between the top separating plate and the bottom separating plate can be avoided, and further insufficient dyeing or poor appearance of the jacquard screen fabrics due to precipitation can be avoided.

Owner:FUJIAN FORTUNES TEXTILE PRINTING & DYEING TECH

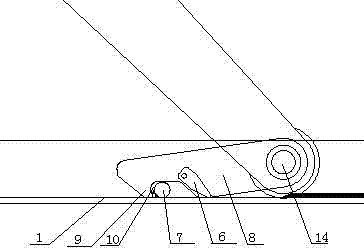

Linear guide slider

ActiveCN103615464BEasy to assemblePrevent back and forth movementLinear bearingsBearing componentsStructural engineeringMechanical engineering

The present invention relates to a linear guide rail, in particular, to an internal sealing sheet for a linear guide rail and a linear guide rail slider. The purpose of the present invention is to provide an internal sealing sheet combined with this structure to achieve convenient and rapid assembly. It includes end caps, sliding seats, and internal sealing sheets. The end caps are arranged at both ends of the sliding seat, and the internal sealing sheet is arranged on the inner side of the sliding seat between the two end covers. The shape of the opening and the end of the internal sealing sheet are set on the end caps. The card is fixed on the end cover through the support body, and the distance between the card openings of the two end covers is slightly smaller than the length of the internal sealing sheet. The distance between the card and the inner side of the sliding seat of the present invention is The distance is matched with the thickness of the internal sealing sheet, so that the internal sealing sheet is fixed more firmly and will not shake.

Owner:青岛祥银传动设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com