Belt conveyor roller inner wall robot numerical control intelligent welding system

A technology of belt conveyor and welding system, applied in the field of machinery, to avoid overheating, facilitate welding, and reduce welding skill requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

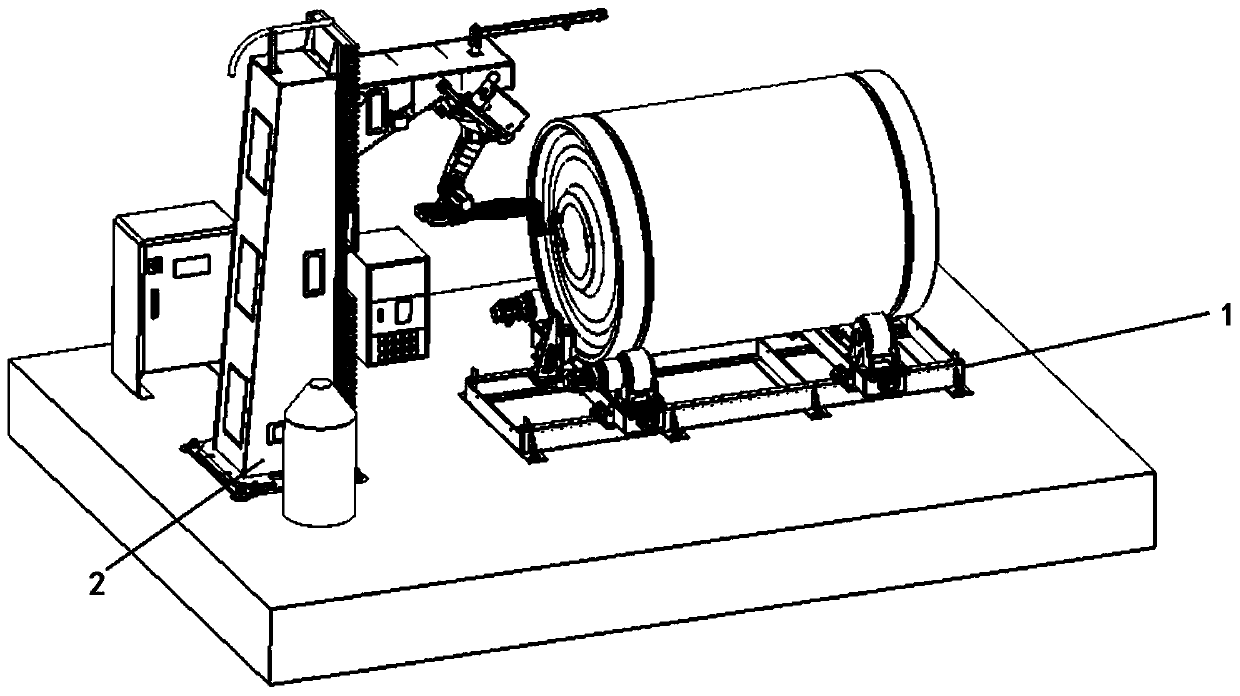

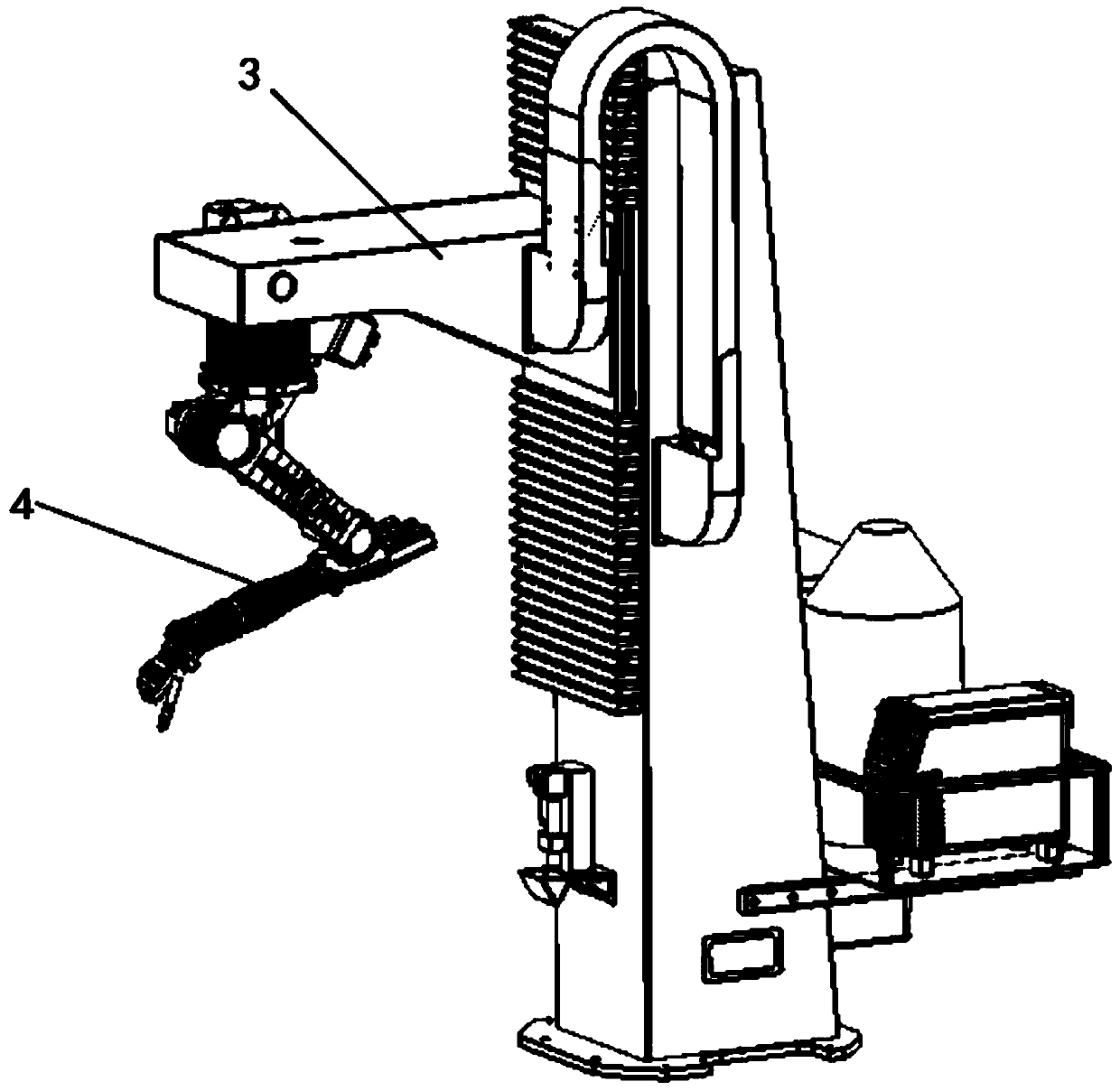

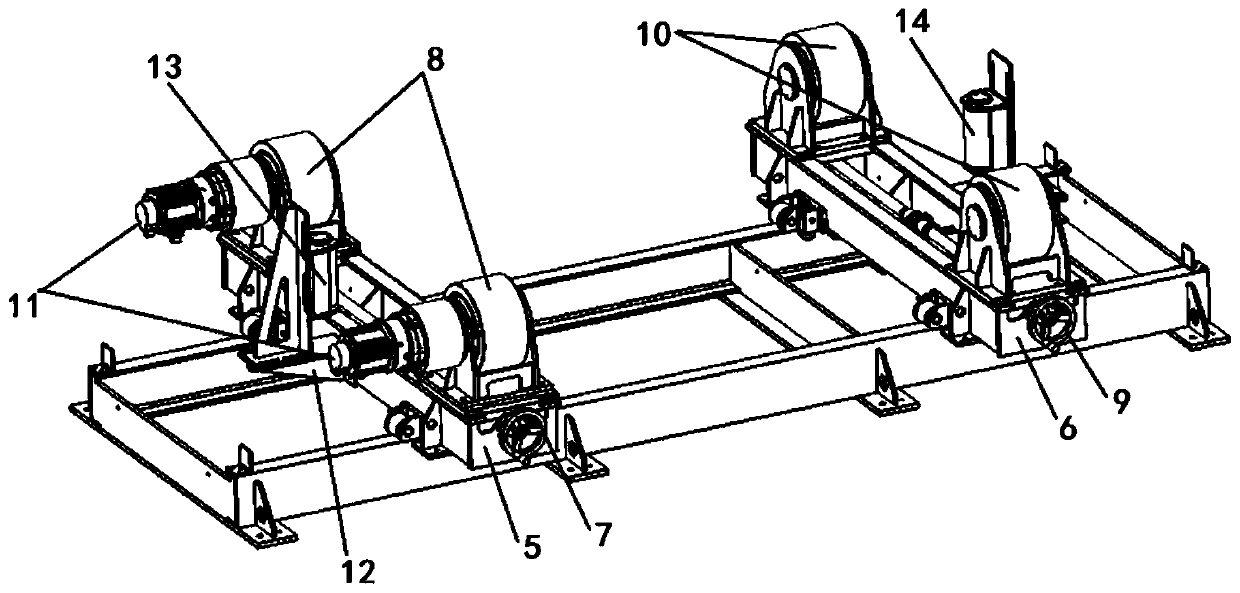

[0033] like Figure 1-Figure 3 As shown, the robot numerical control intelligent welding system for the inner wall of the roller of the belt conveyor includes a heavy-duty roller frame 1, a C-shaped support column 2 is fixed on one side of the heavy-duty roller frame, and a lifting mechanism 3 is slidingly connected to the C-shaped support column. A welding robot 4 is fixed on the mechanism. The heavy-duty roller frame includes a driving roller frame 5 and a driven roller frame 6. The driving roller frame and the driven roller frame are respectively fixed at both ends of the heavy-duty roller frame. The spacing adjustment mechanism 7 and two groups of driving wheels 8 respectively located at the two ends of the driving roller frame, and the driven roller frame includes the driven wheel spacing adjustment mechanism 9 and two groups of driven wheels 10 respectively posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com