Patents

Literature

97results about How to "Mobile stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

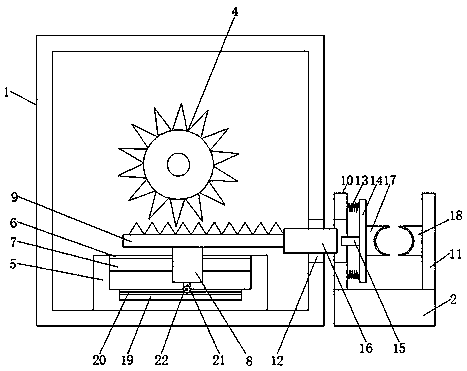

Printer

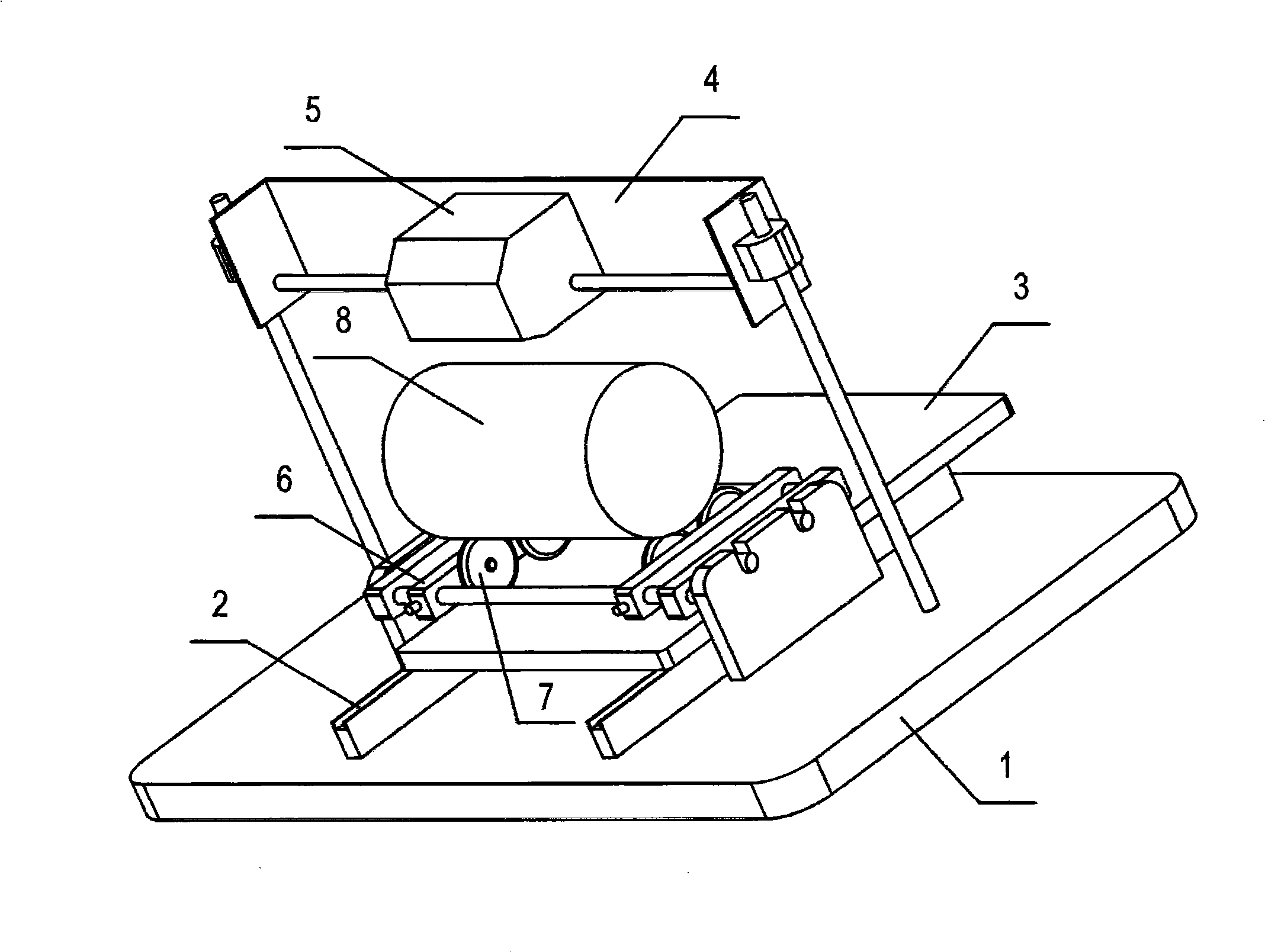

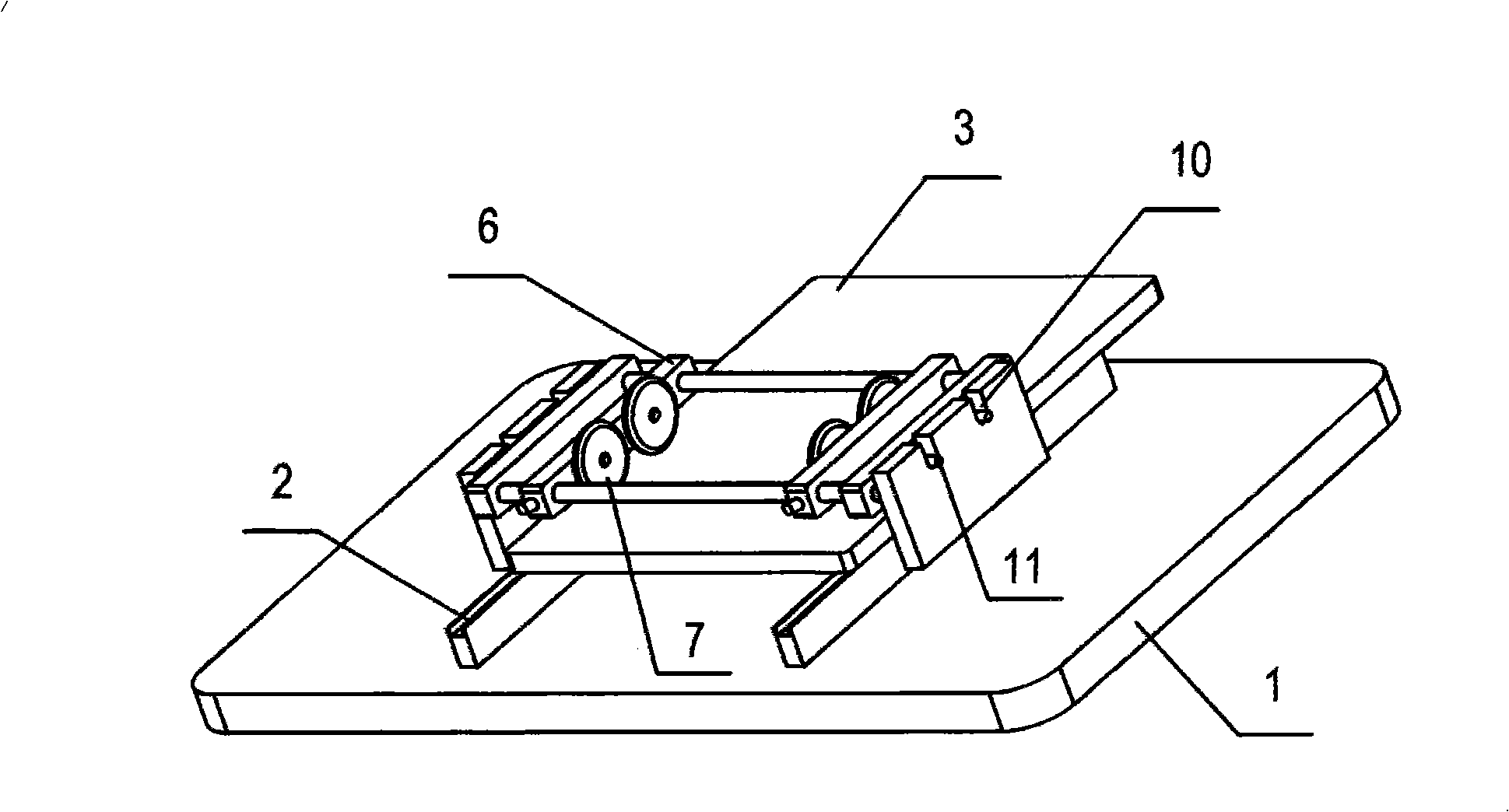

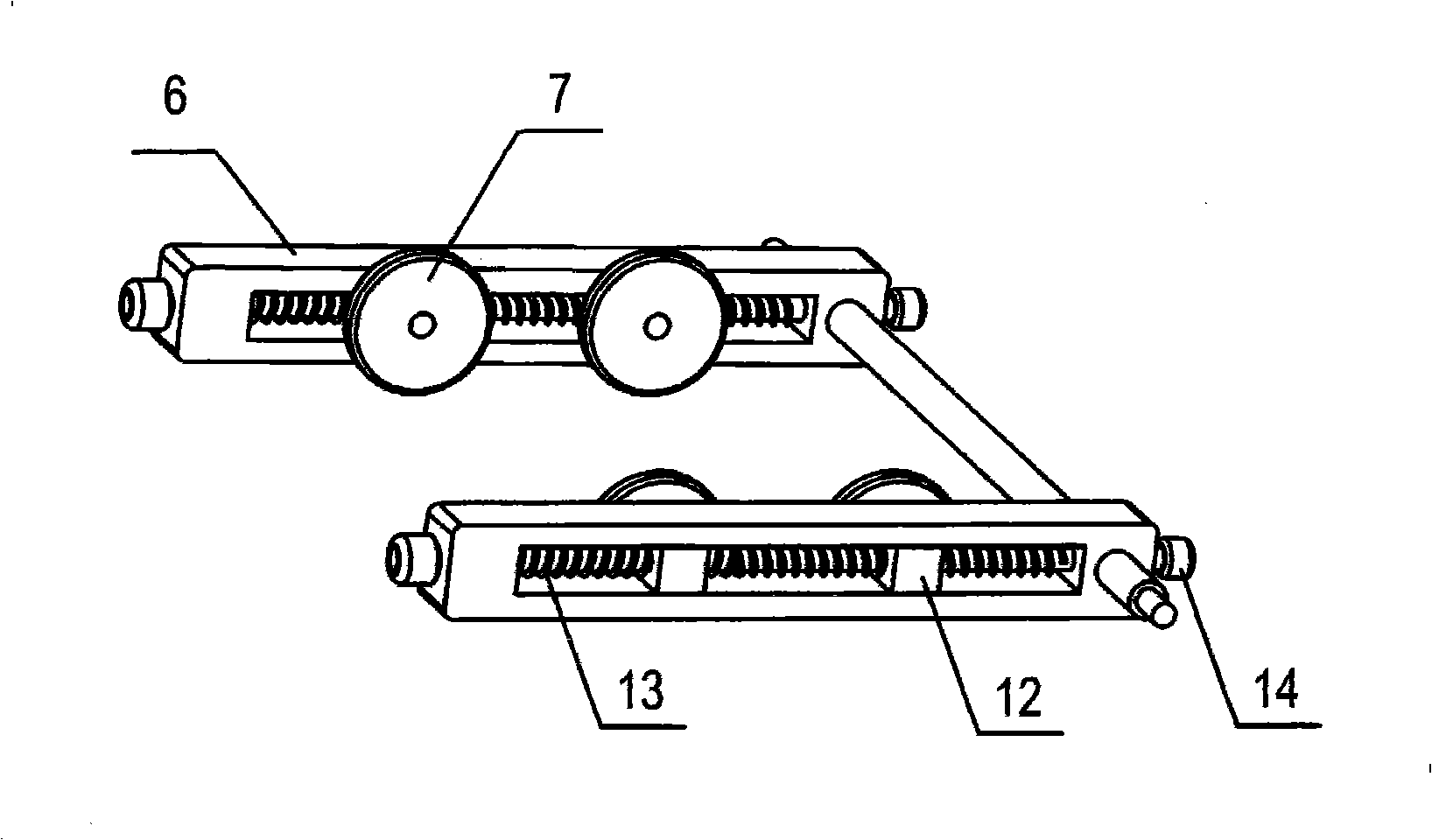

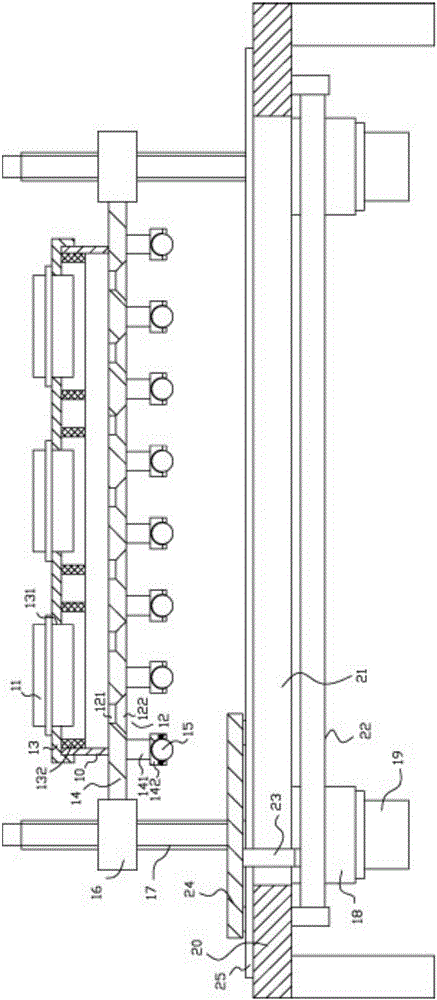

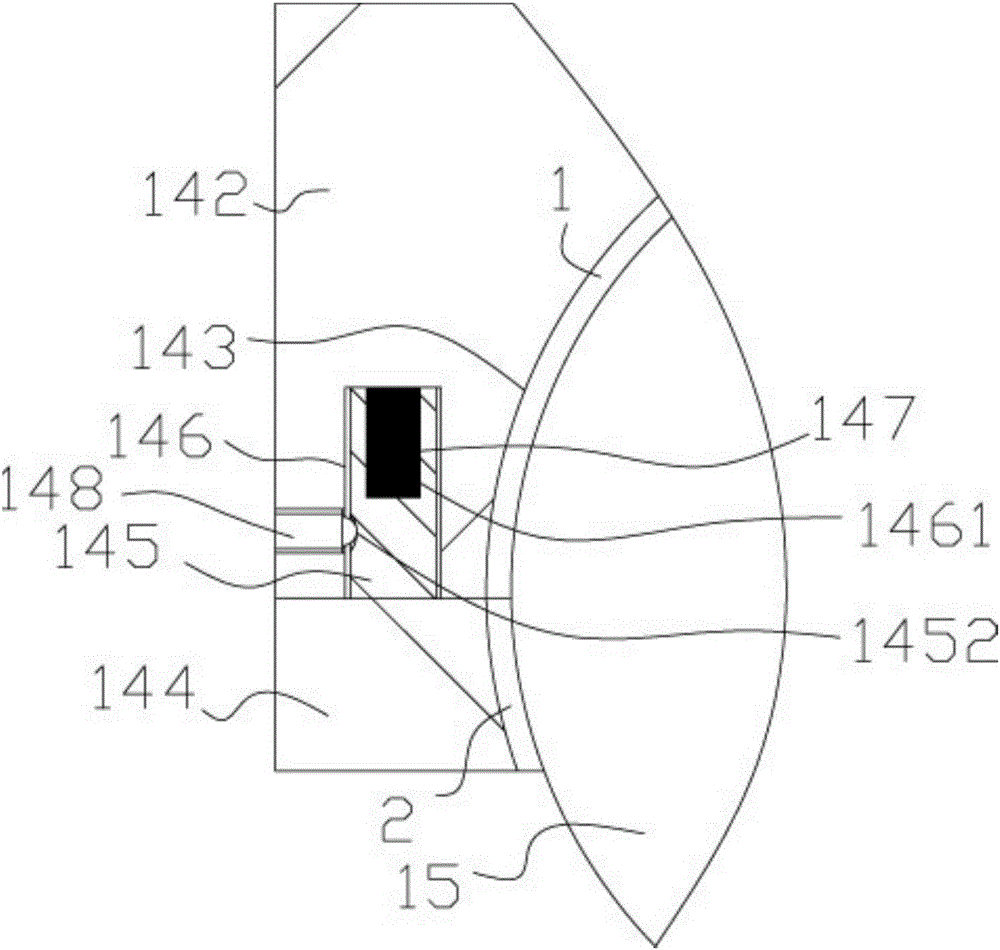

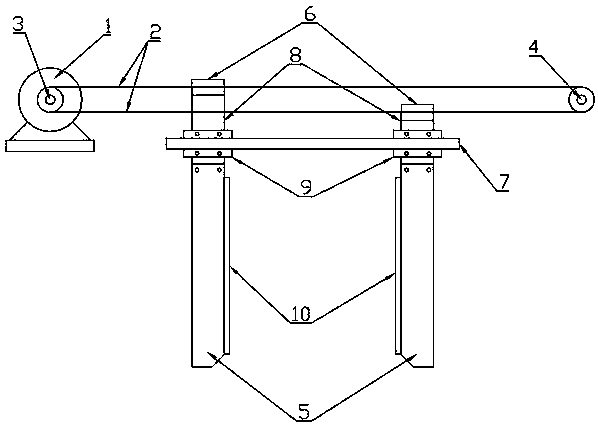

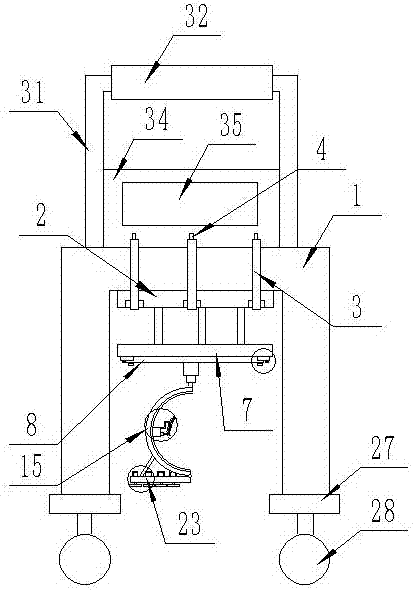

InactiveCN101513799AMobile stabilityAvoid the problem of deviationTypewritersEngineeringFriction force

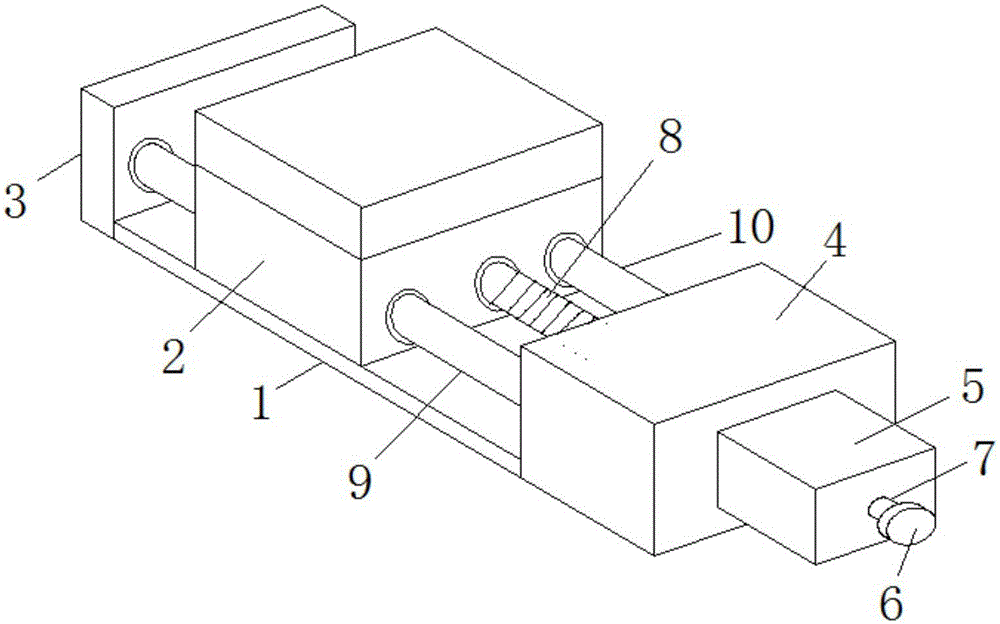

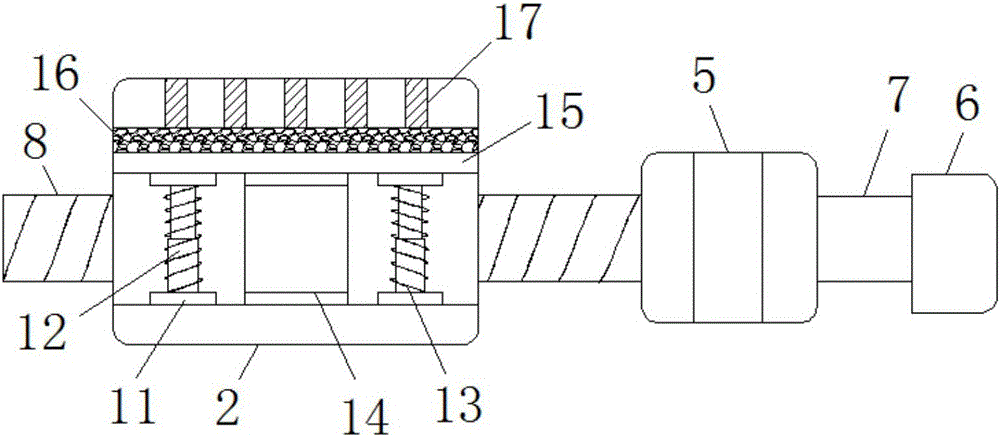

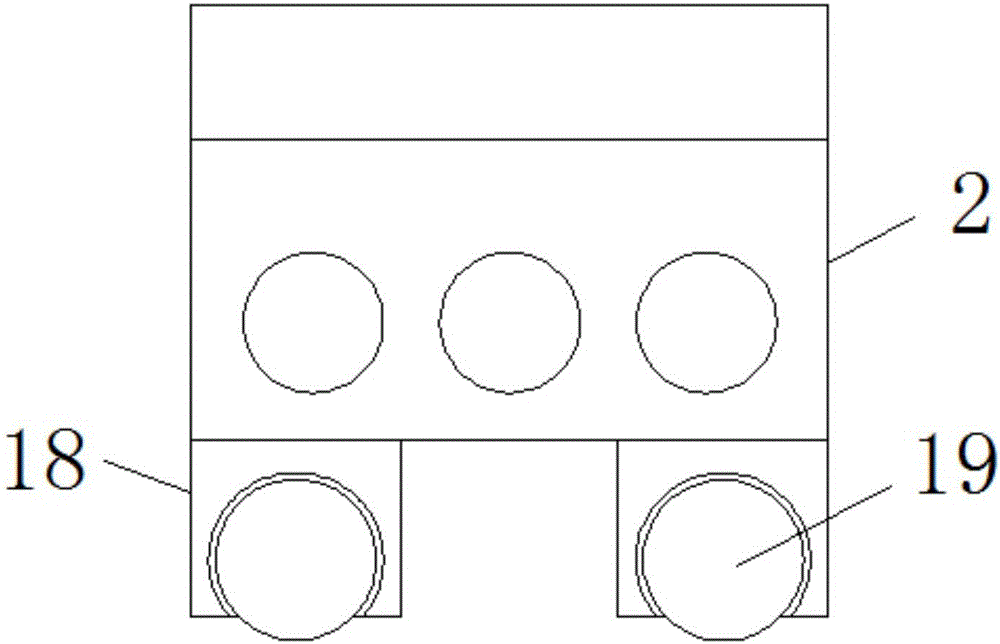

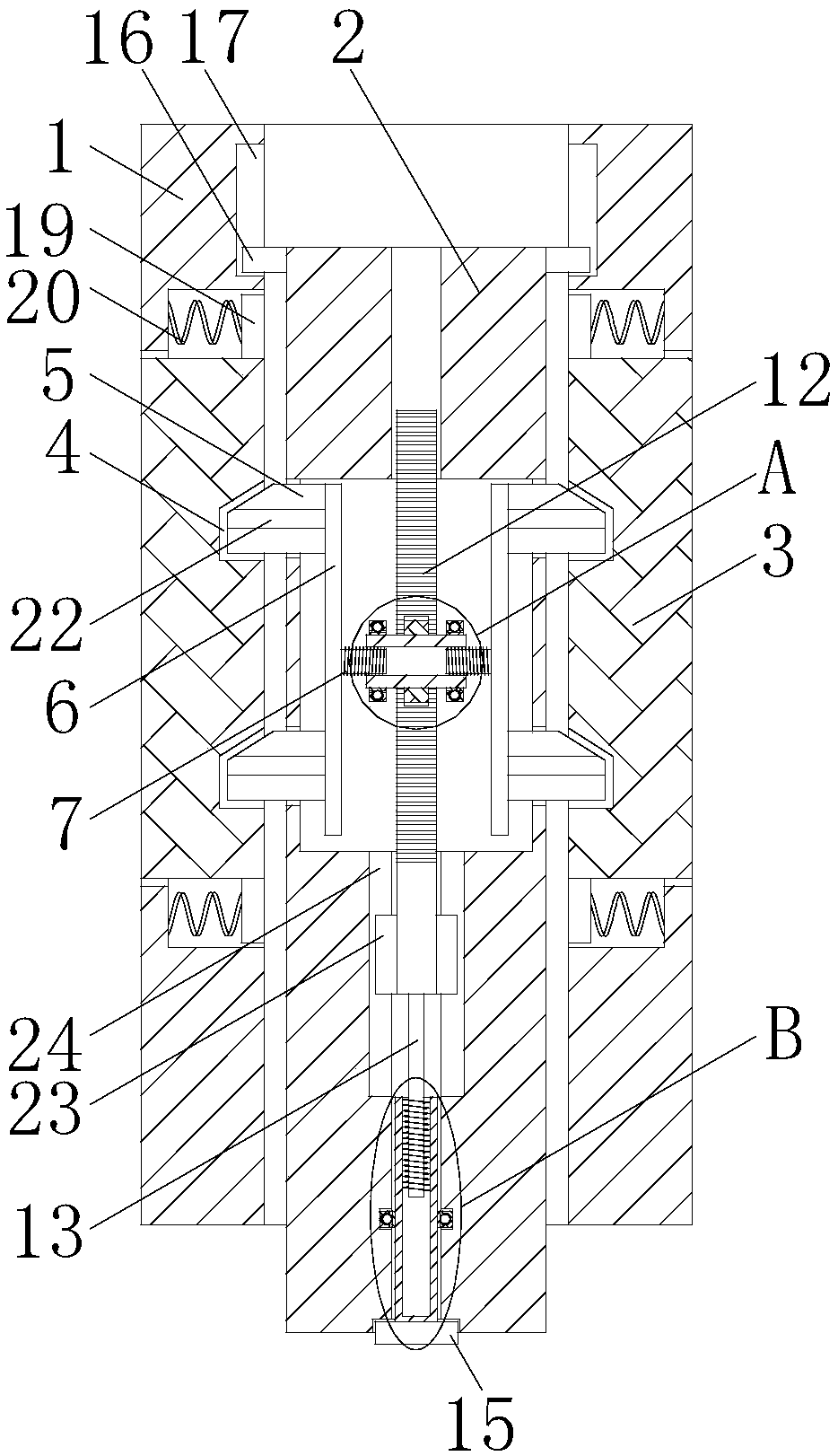

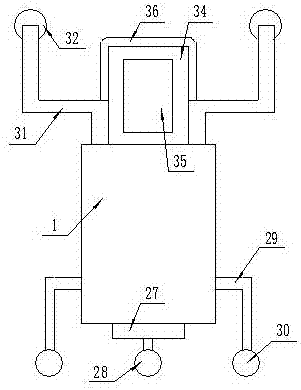

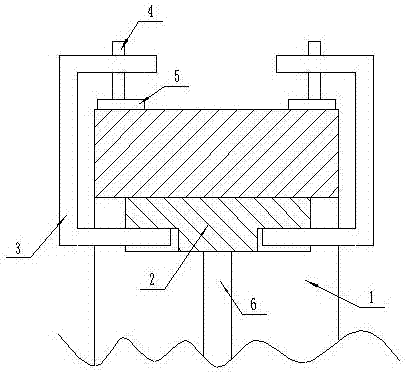

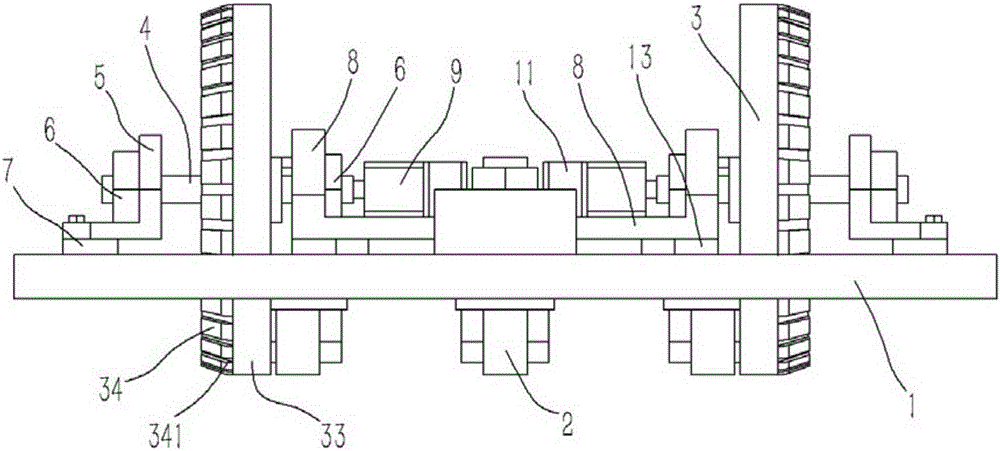

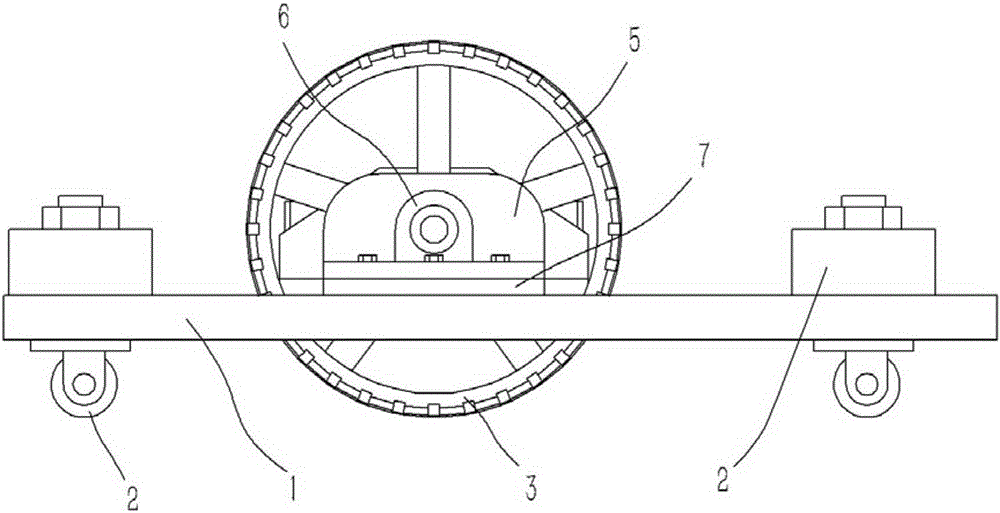

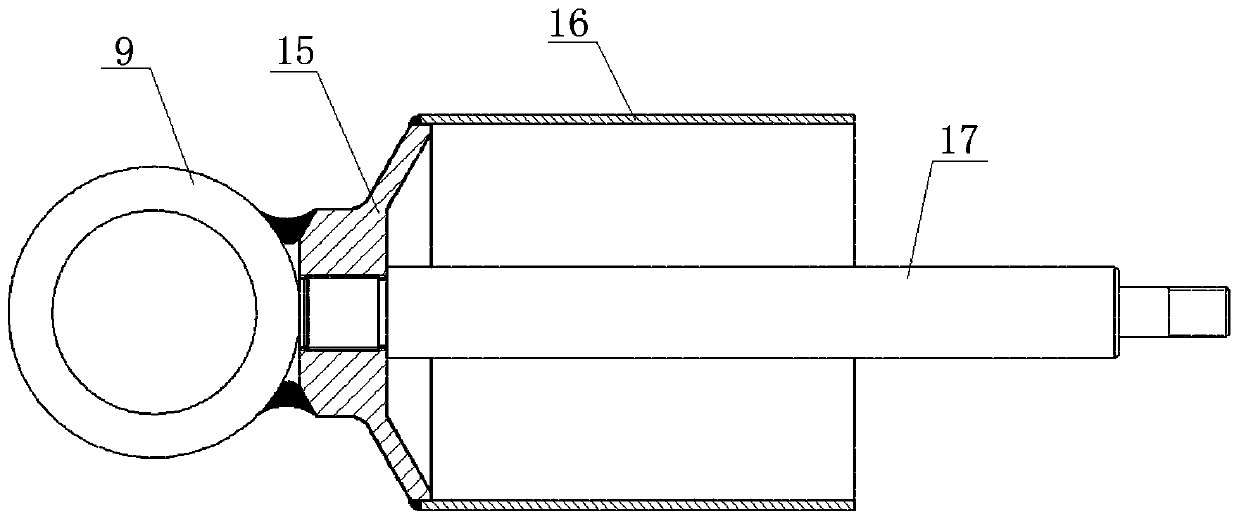

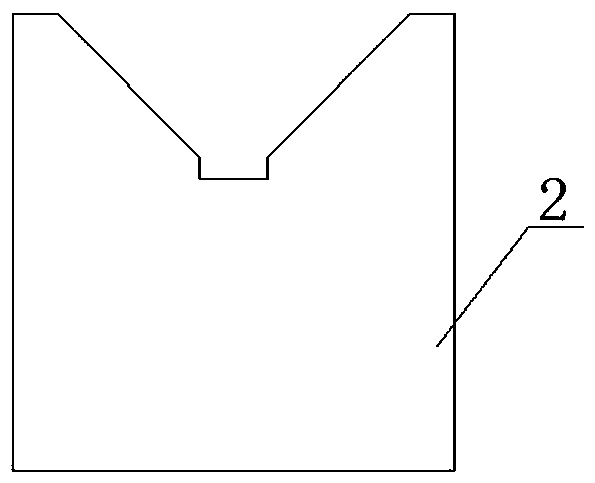

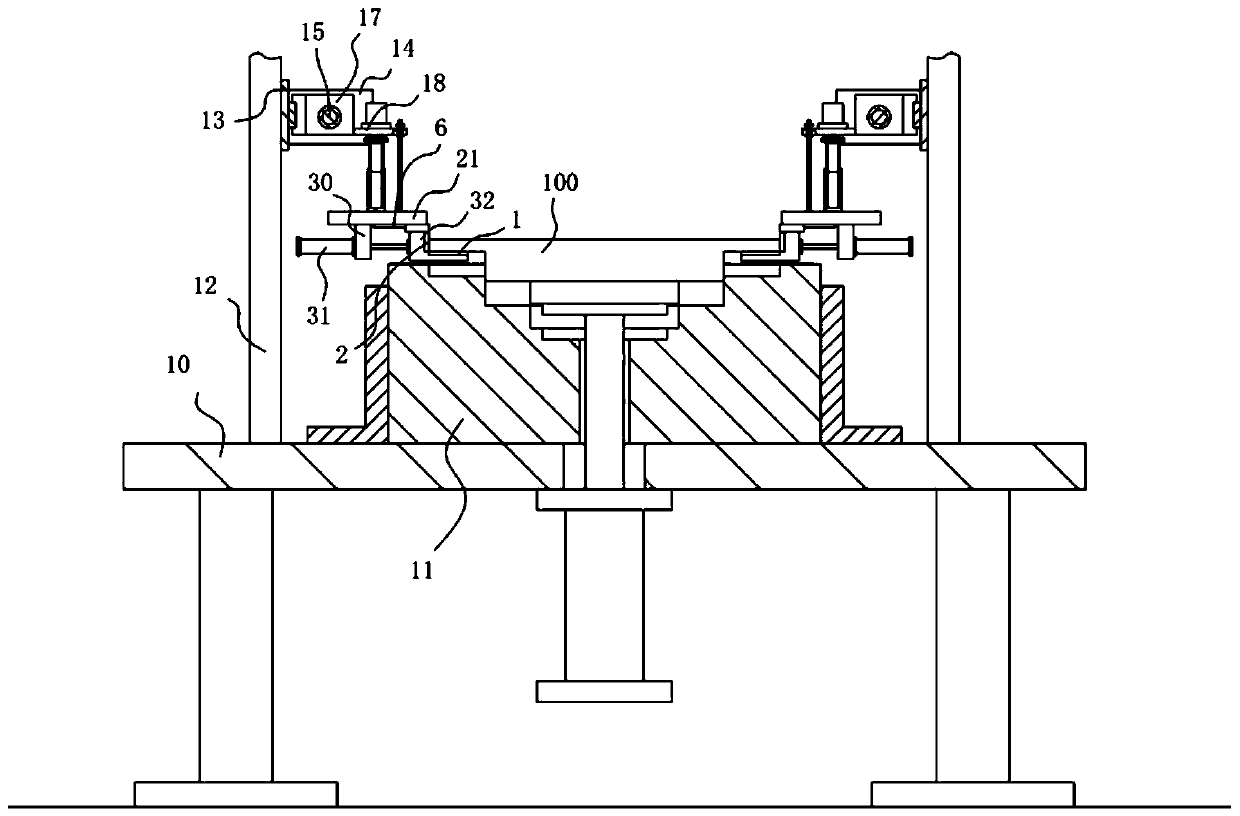

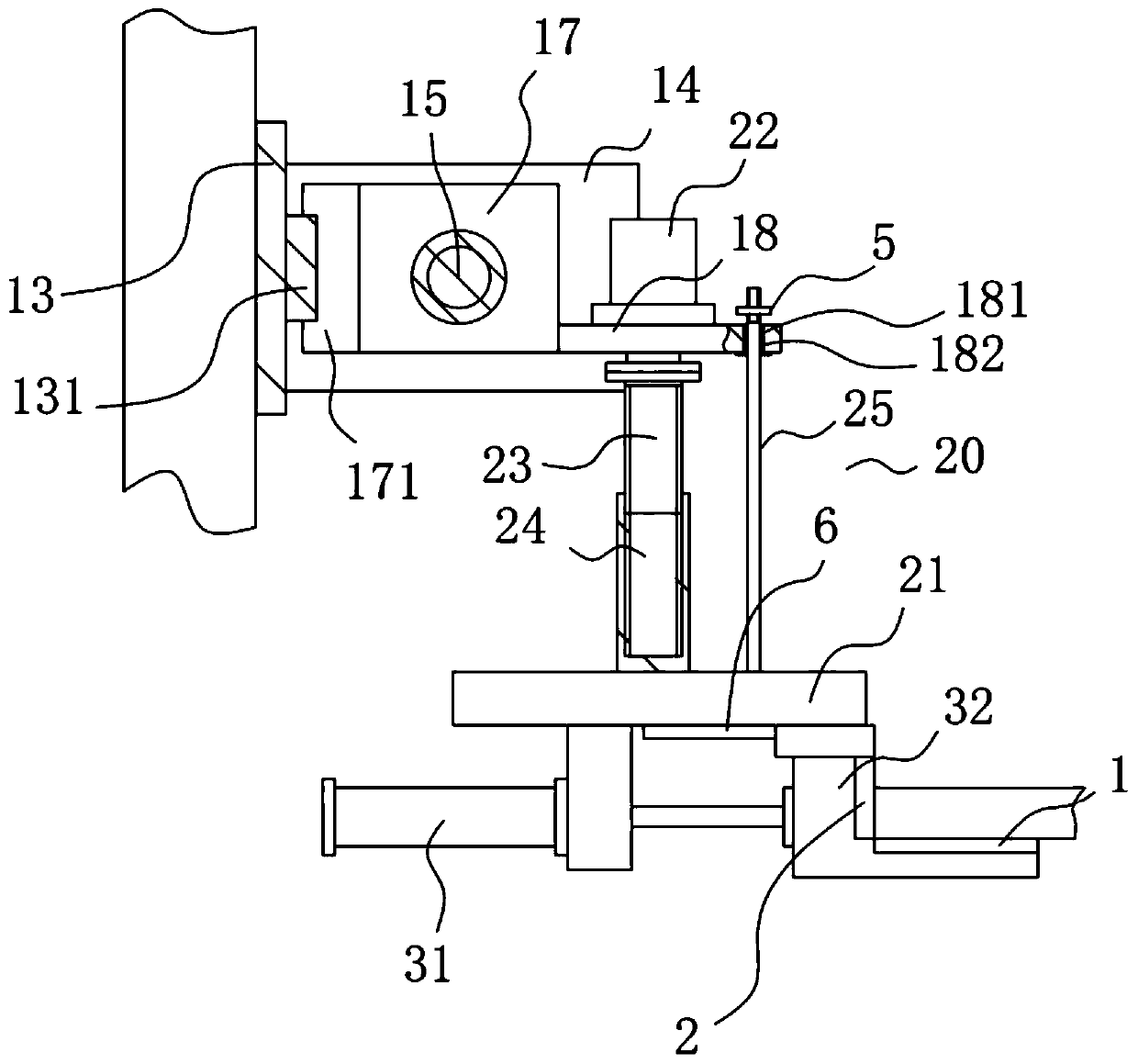

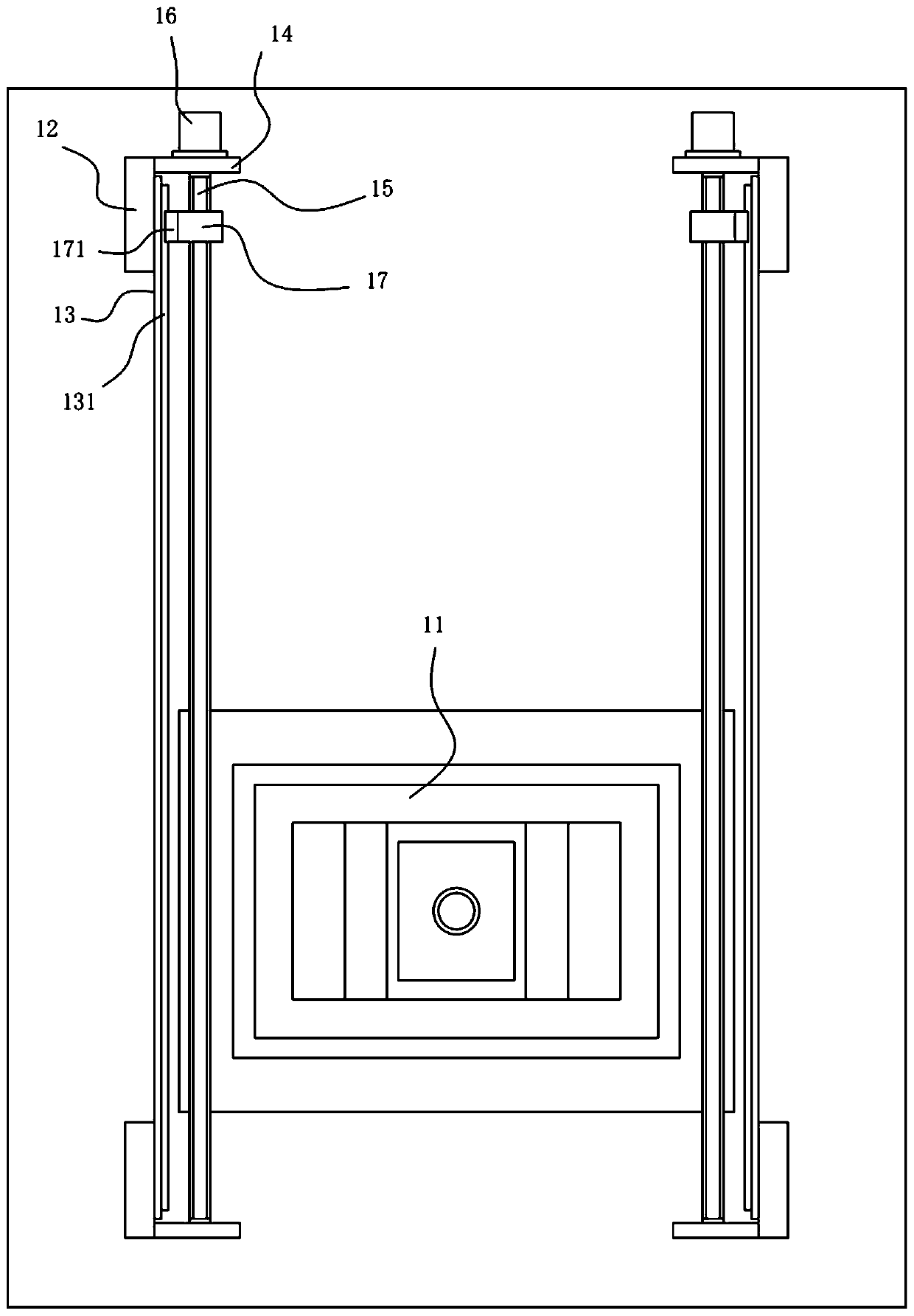

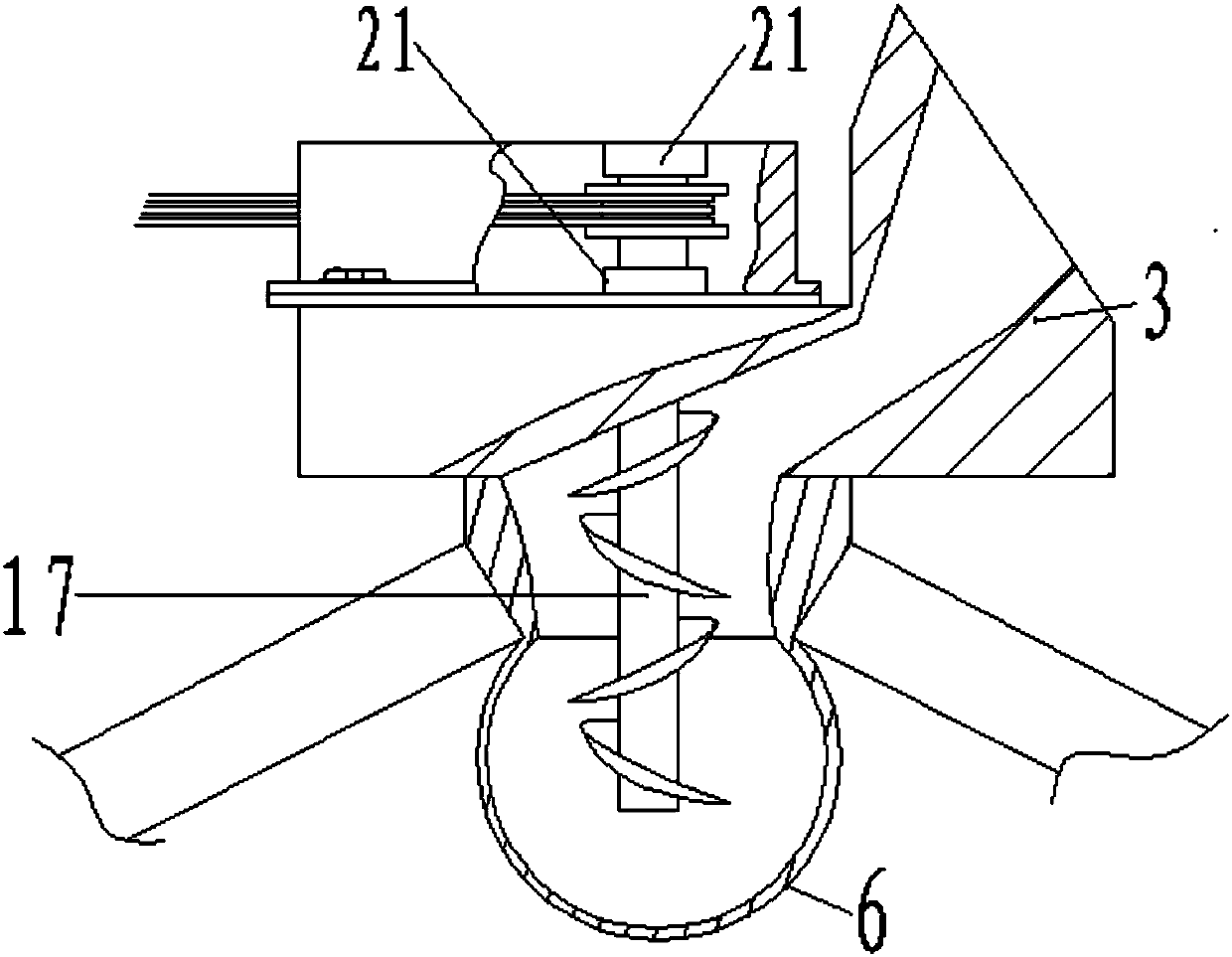

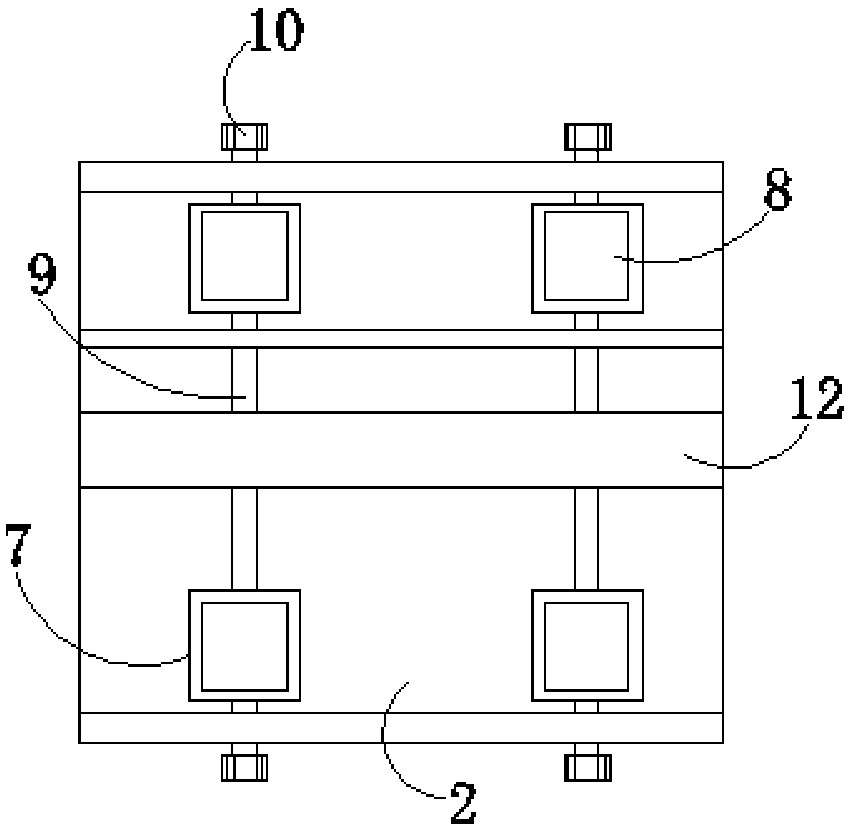

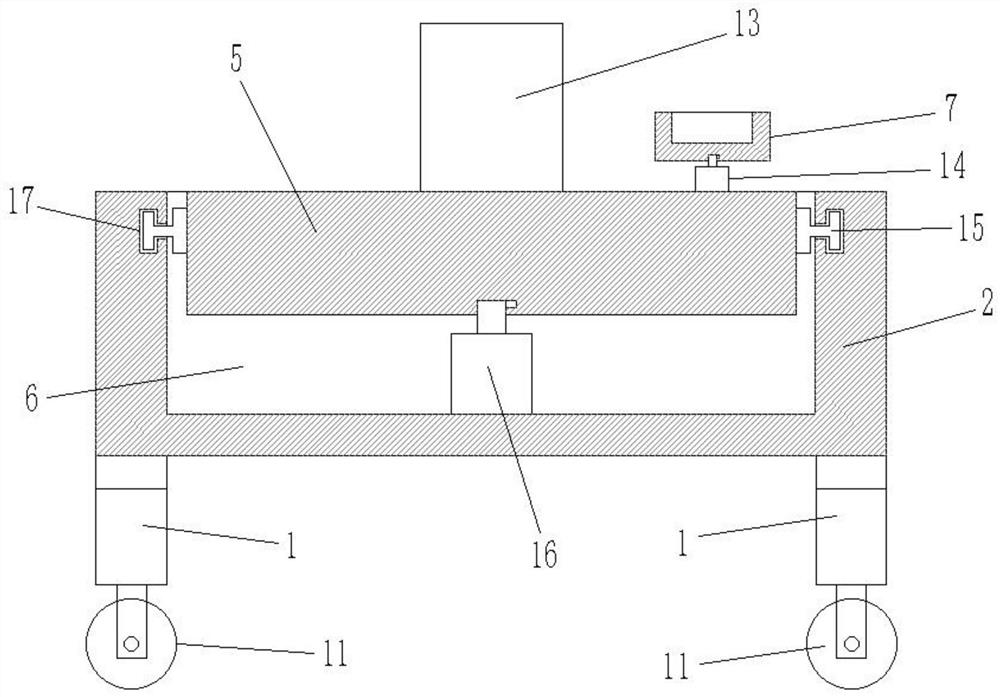

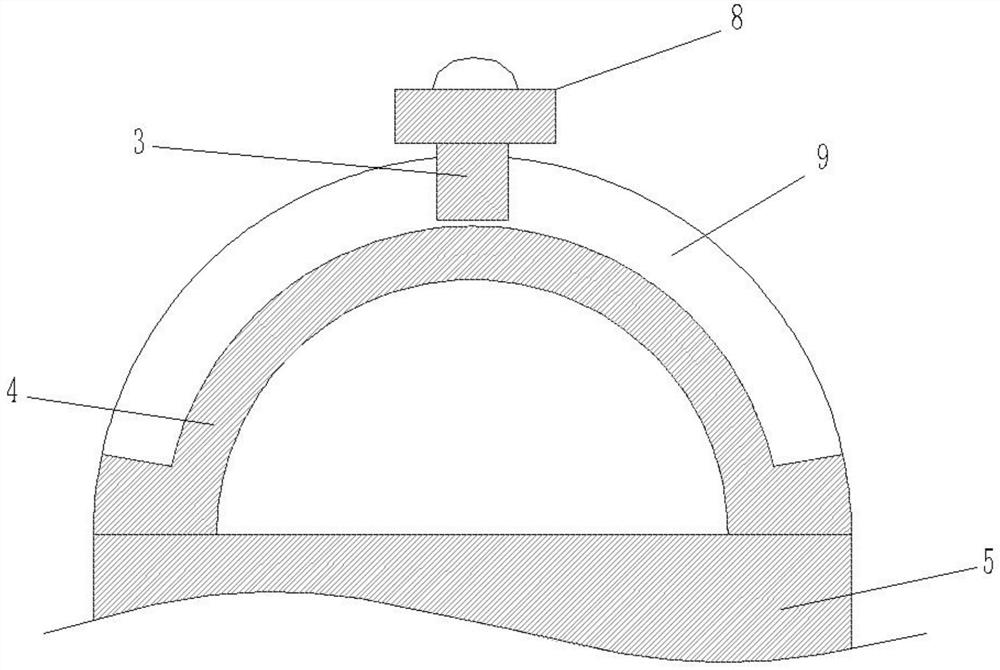

The invention relates to a printer. The printer comprises a base on which a guide rail and a tray longitudinally moving relative to the base along the guide rail are arranged, the upside position of the tray is provided with a printing unit, and the base is provided with a dismountable conversion rack on which at least a pair of parallel roller wheels or rollers rotated by the rolling friction force generated by the surface of the tray when the tray longitudinally moves are arranged. When the conversion rack is not mounted, placing an object on the tray and printing on the plane can be realized; when the conversion rack is mounted, a columnar surface object is placed on the roller wheels or the rollers of the conversion rack, and the friction force generated by moving tray and the roller wheels or the rollers drives the roller wheels or the rollers to rotate, and further drives the columnar printed object to rotate so as to print pictures and texts on the columnar surface line by line. Compared with the prior art, no matter printing on the plane or the columnar surface, the problem that a component for placing the printed object runs unstably does not appear, so that the printer can control the printing quality better.

Owner:QINGDAO UNIQUE PRODS DEV

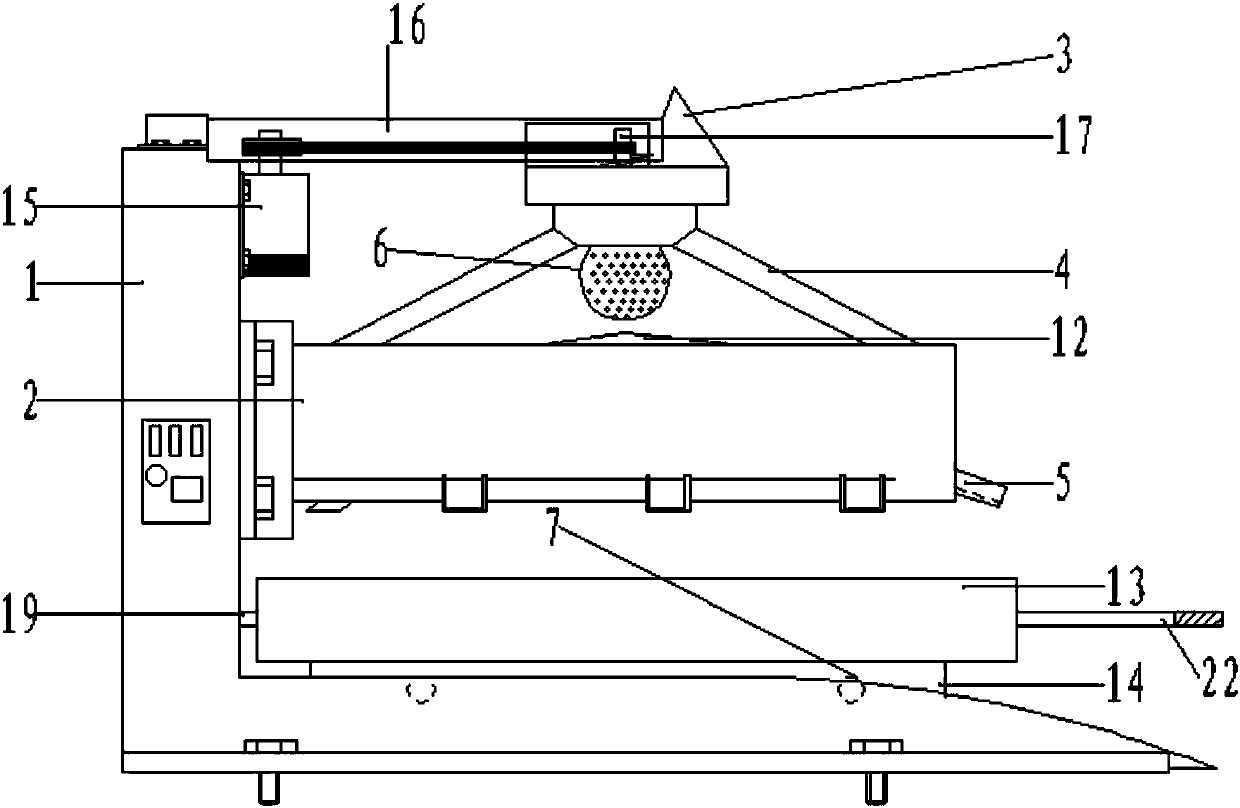

Cylinder-moving conveying type packaging bag drier

InactiveCN106564662AMobile stabilityEasy to disassemble and installDrying gas arrangementsDrying machines with progressive movementsEngineering

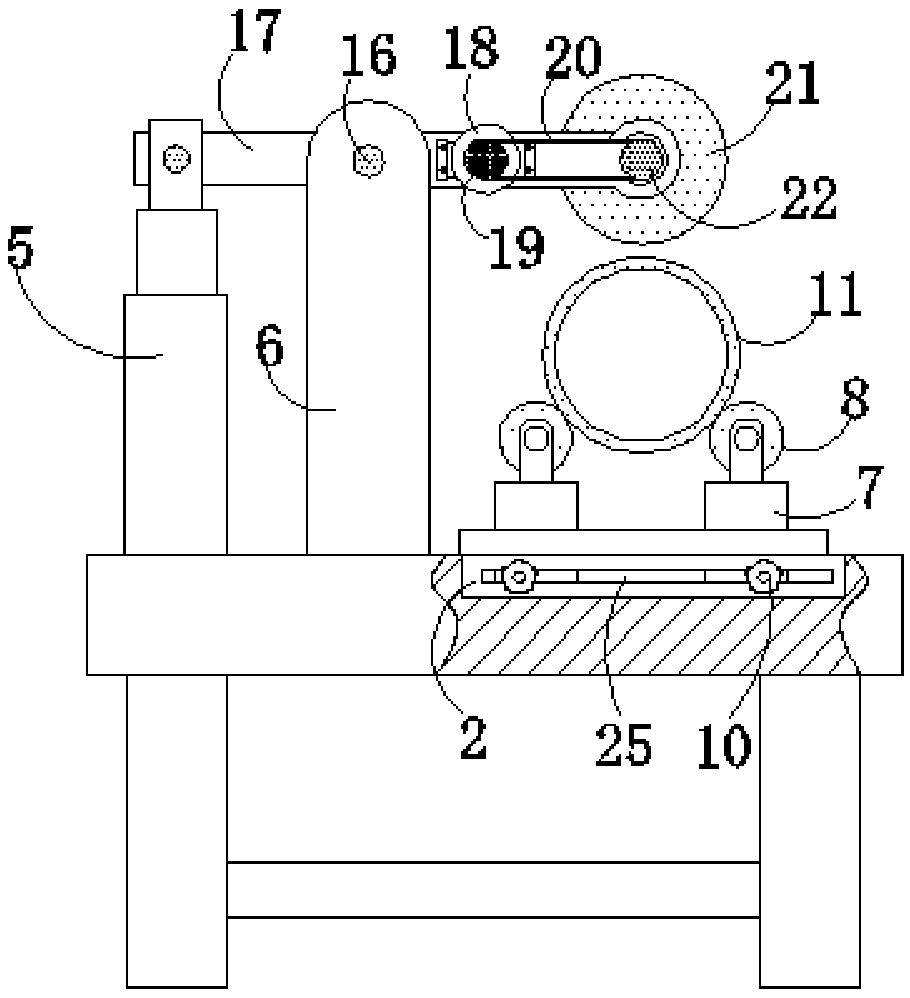

The invention discloses a cylinder-moving conveying type packaging bag drier which comprises a rack and a main board. A transverse moving through groove is formed in the middle of a top plate of the rack, rodless cylinders are fixed to the bottom face of the top plate of the rack, and guiding connection plates are fixed to sliding blocks of the rodless cylinders. Each guiding connection plate upwards stretches out of the transverse moving through groove, and an upper horizontal plate is fixed to each guiding connection plate. Guiding slide blocks are fixed to the left side and the right side of the bottom face of each upper horizontal plate, guiding rails are fixed to the left side and the right side of the top face of the top plate of the rack, sliding grooves are formed in the top faces of the guiding rails, and the guiding slide blocks are inserted into the sliding grooves. Movable connecting blocks are fixed to the left ends and the right ends of the front and back sides of the main board. The rodless cylinders push the upper horizontal plates to move rapidly and stably; meanwhile, heating pipes are fixed to the main board, the main board can move up and down to adjust the vertical positions of the heating pipes, so that heat is adjusted; and the heating pipes are fixed in an insertion mode through mounting blocks and limiting blocks, and the heating pipes are convenient to dismount and mount.

Owner:SHAOXING LITAI TEXTILE TECH CO LTD

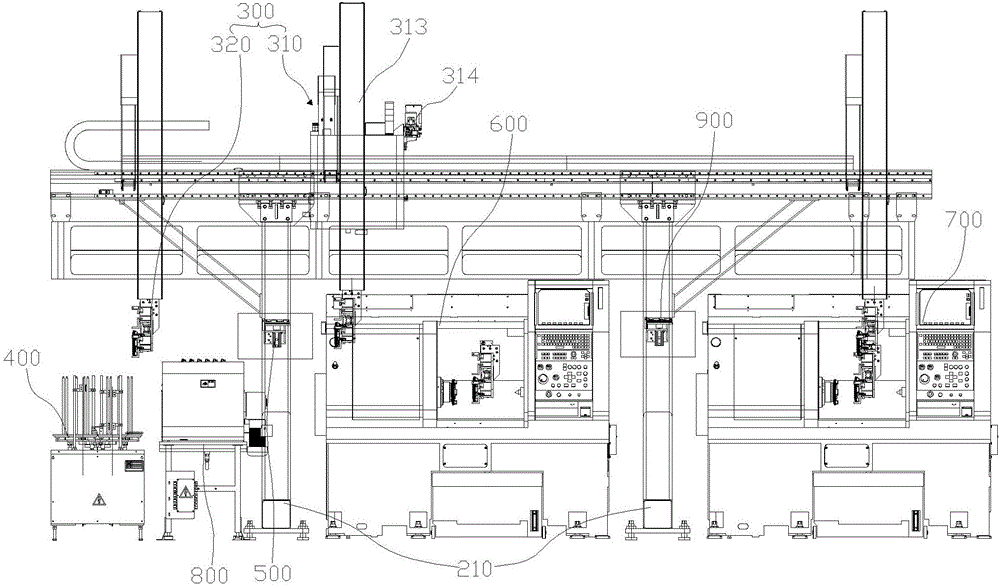

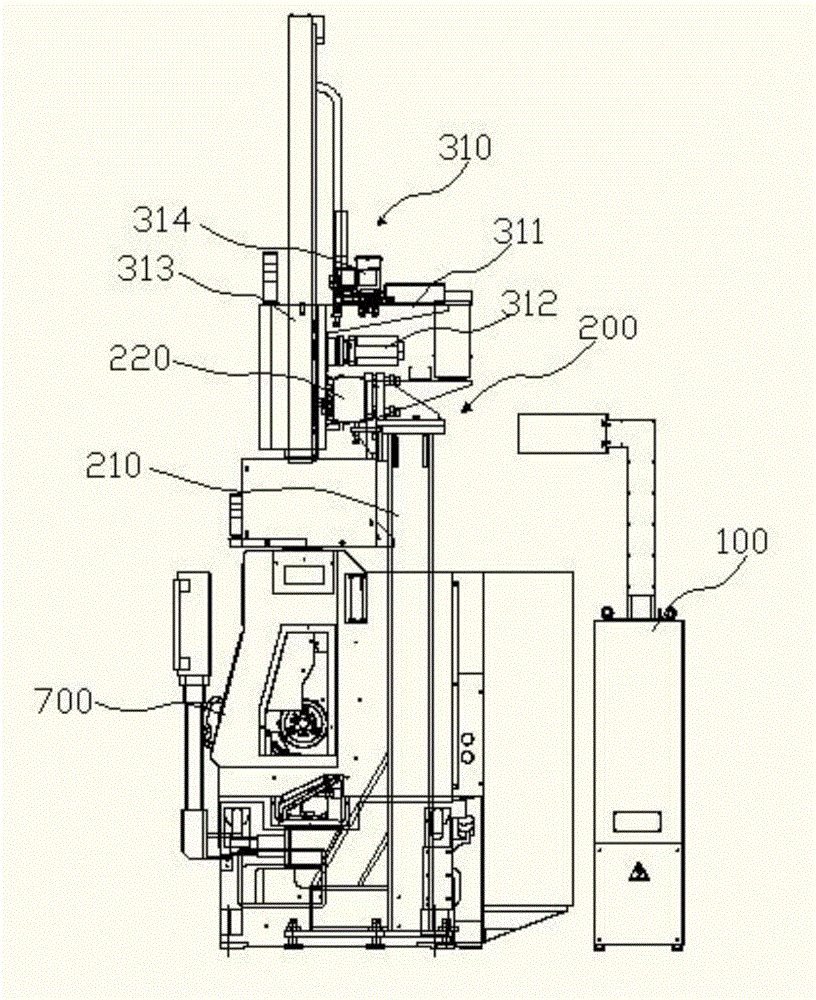

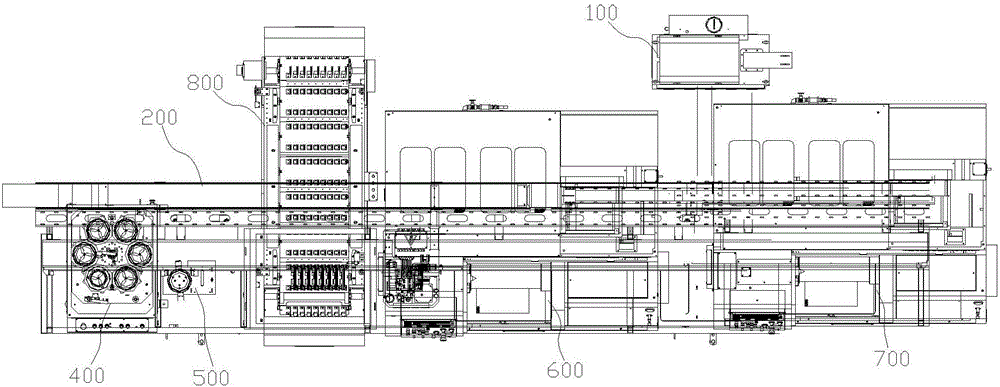

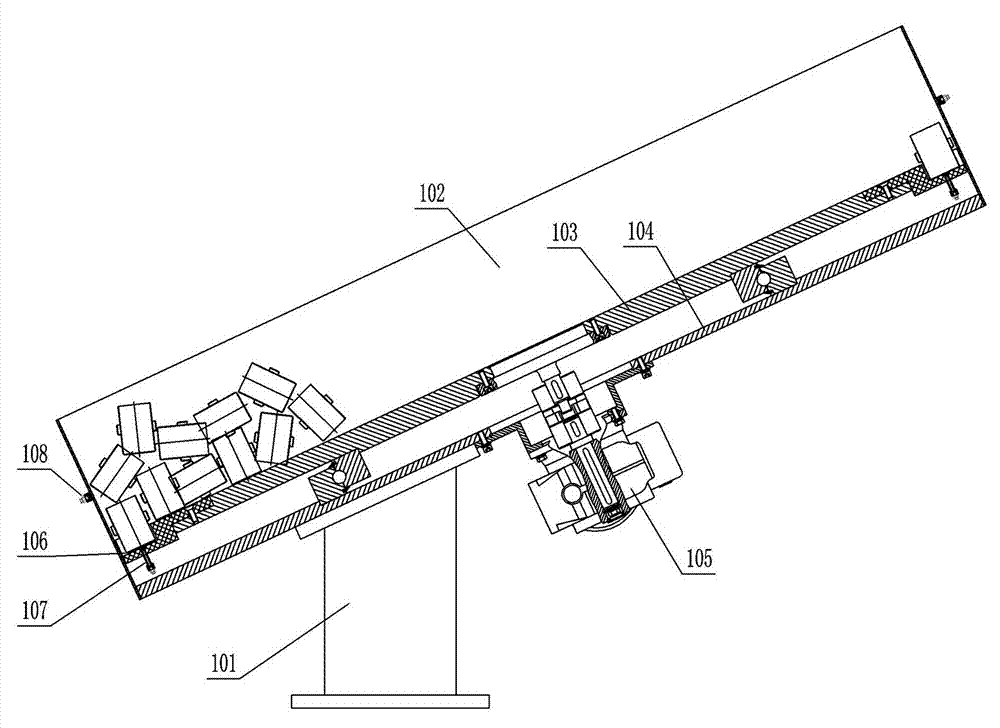

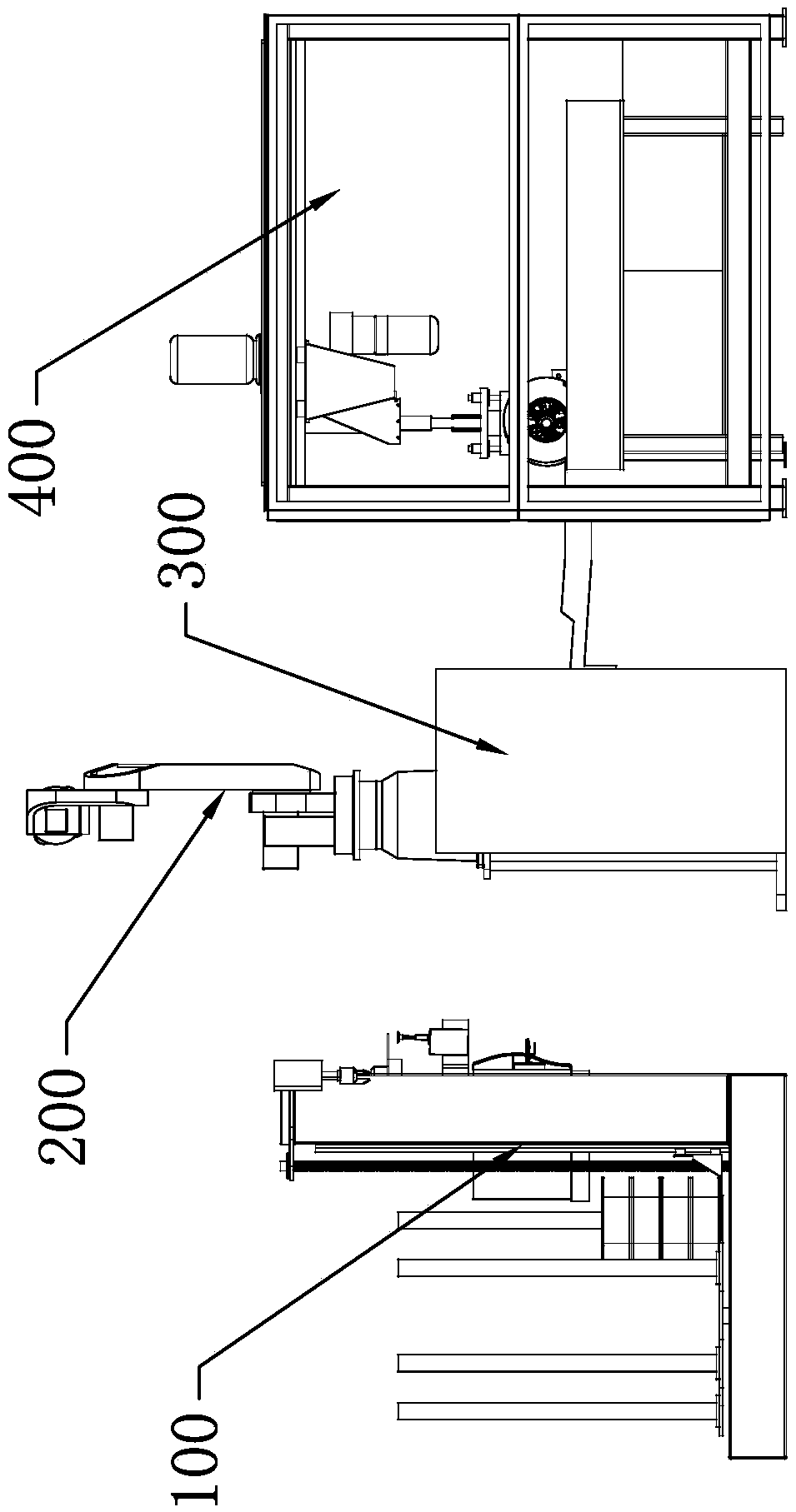

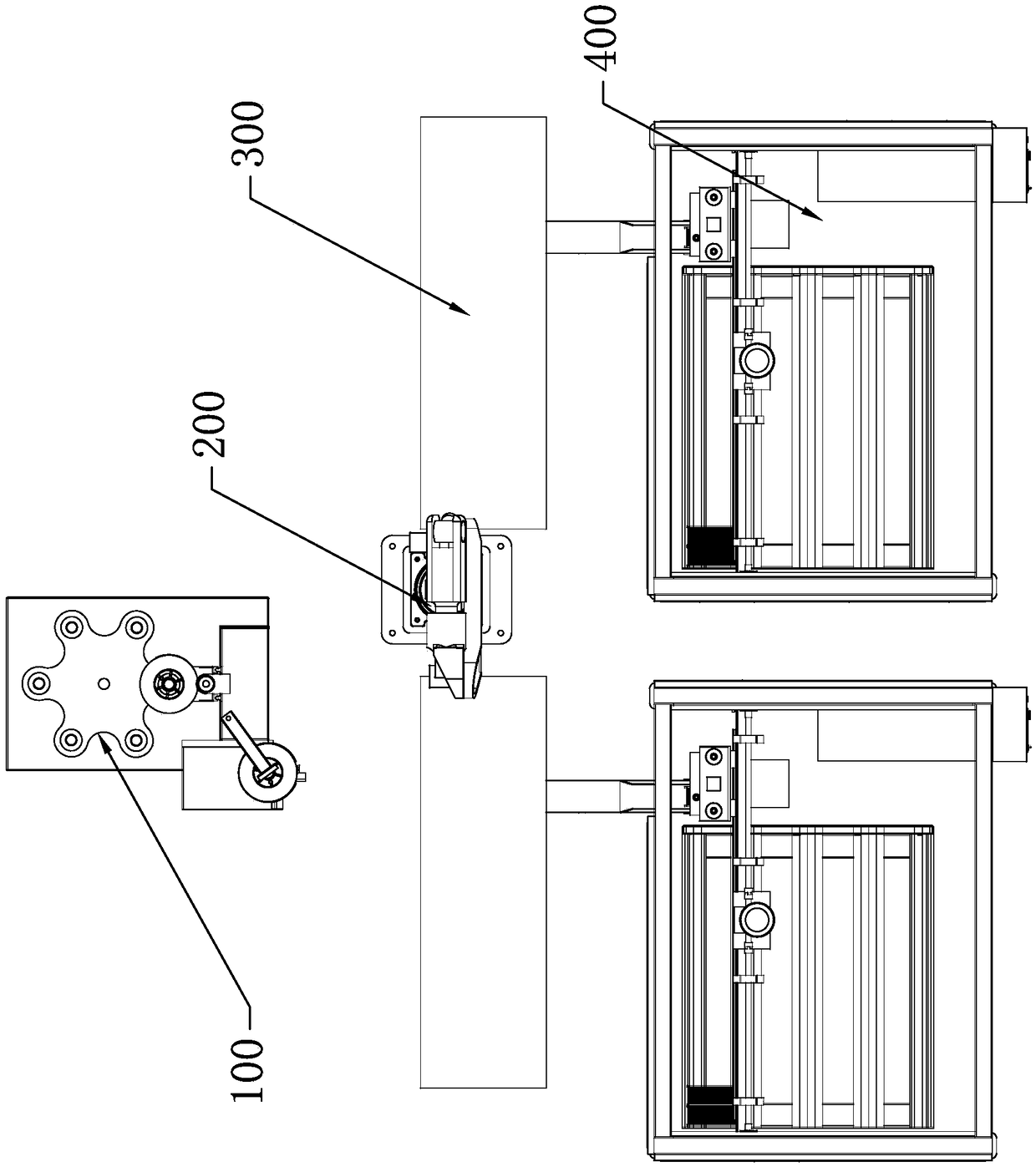

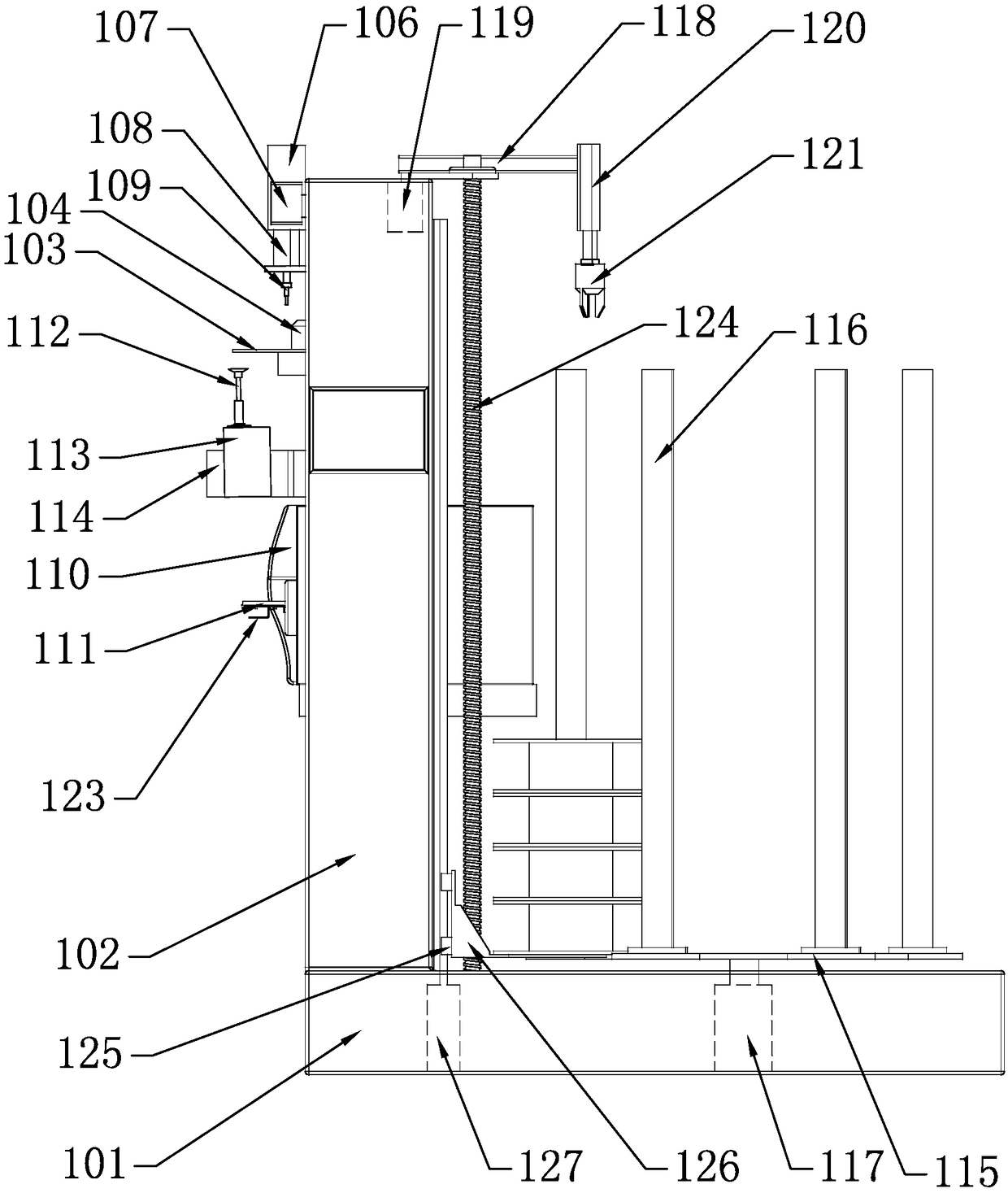

Multifunctional automatic machining line and machining method of multifunctional automatic machining line

ActiveCN106736600AHigh working reliabilityMobile stabilityMeasurement/indication equipmentsOther manufacturing equipments/toolsManufacturing engineeringMachining system

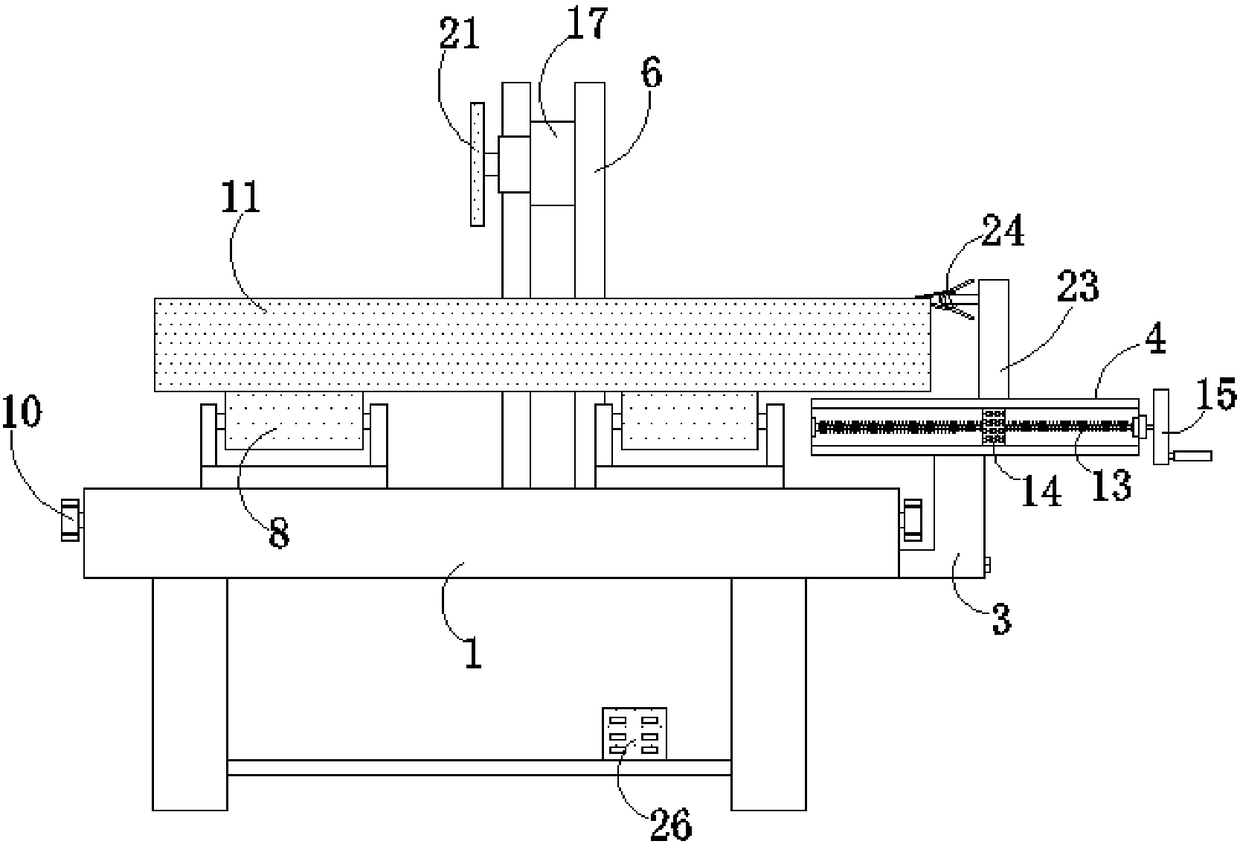

The invention discloses a multifunctional automatic machining line and a machining method of the multifunctional automatic machining line. The multifunctional automatic machining line comprises a control device, a track mechanism, a feeding and discharging device, a machining system, a finished product storage device and a detection device. According to the multifunctional automatic machining line and the machining method, the feeding and discharging device, the machining system, the finished product storage device and the detection device are electrically connected with the control device, meanwhile all the devices are optimally combined and arranged, in this way, automatic machining, from blanks to finished products, of products can be completed automatically, the labor intensity of workers can be saved to the great extent, the human cost is lowered, meanwhile the product machining quality and the production stability can be improved greatly, the production efficiency is improved, the production period is shortened, and the economy of enterprises is increased.

Owner:广东文灿压铸科技有限公司

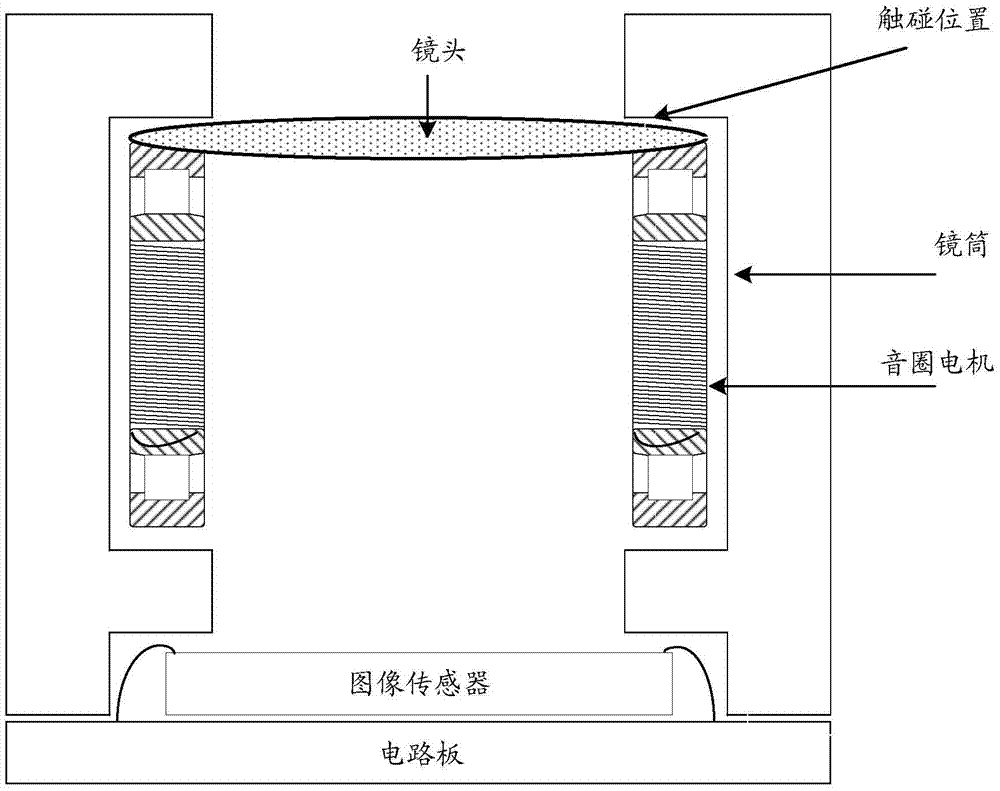

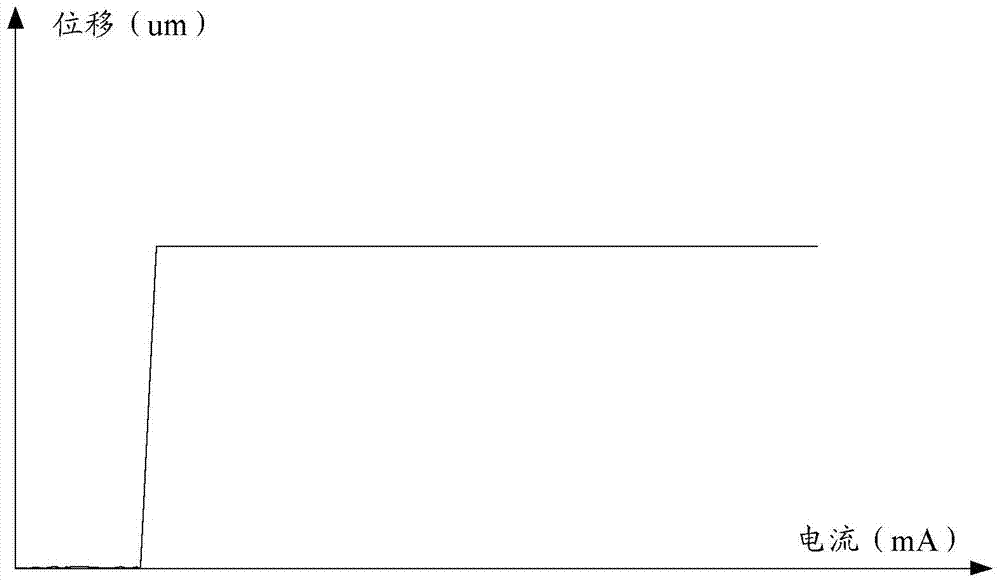

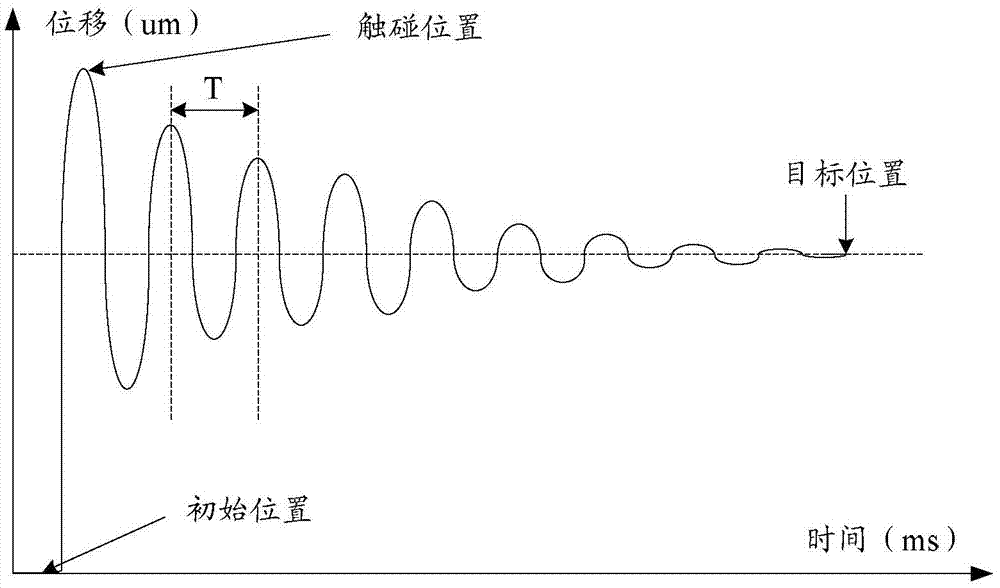

Voice coil motor starting control method and device and camera module group

InactiveCN107040175AMobile stabilityAvoid damped oscillationsDC motor speed/torque controlMountingsCamera moduleVoice coil

The embodiment of the invention discloses a voice coil motor starting control method comprising the steps that a voice coil motor driver is controlled to output starting current to a voice coil motor, wherein the starting current is the minimum current for controlling the voice coil motor to drive a lens component to move; and the voice coil motor driver is controlled to output step increasing driving current with the starting current acting as the initial value, the current step change time acting as the step and the current step change value acting as the step to the voice coil motor according to the acquired current step change time and the current step change value until the voice coil motor is controlled to drive the lens component to move to the target position. The embodiment of the invention also discloses a voice coil motor starting control device and a camera module group.

Owner:XIAN ZHONGXING NEW SOFTWARE

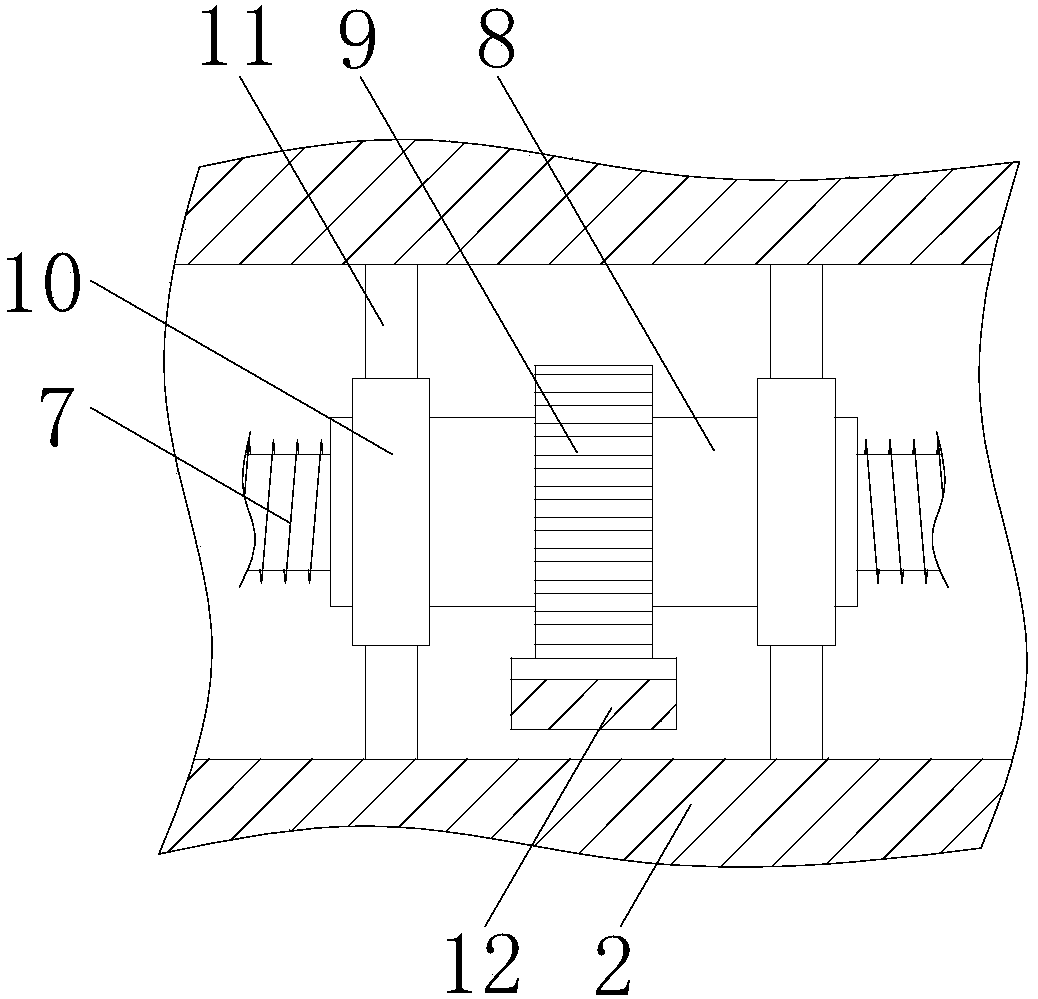

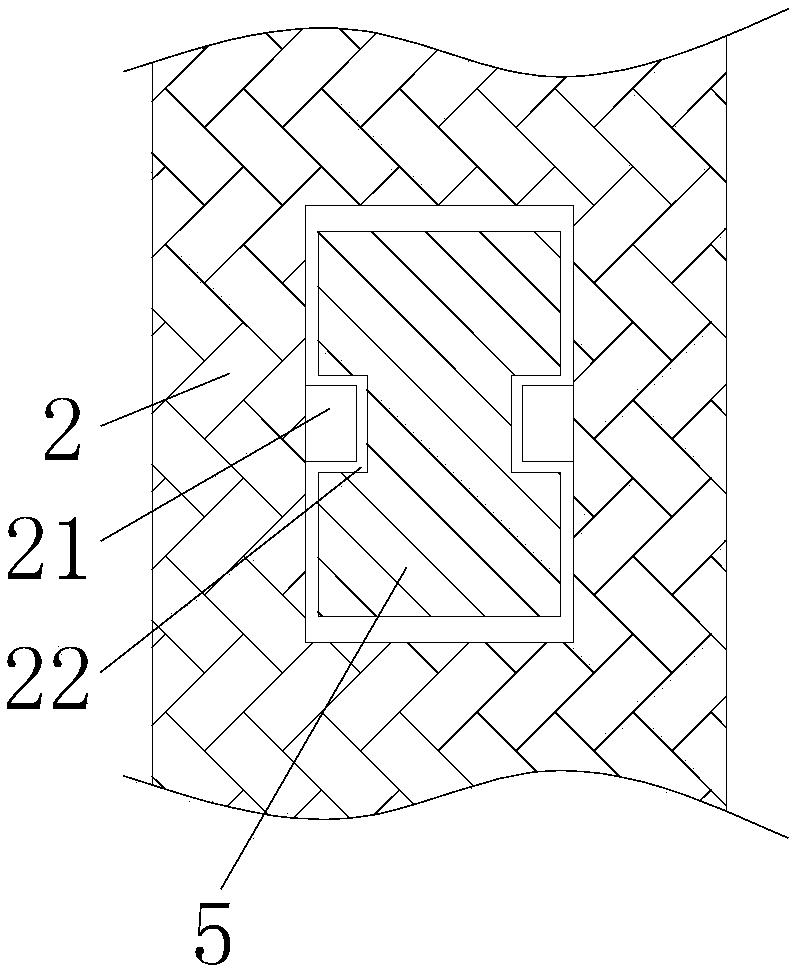

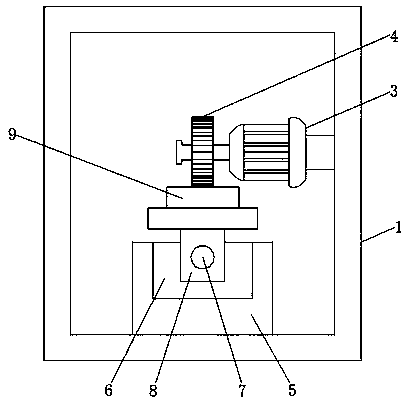

Low-noise precision electric control translation stage

PendingCN106737460AReduce surface frictionMobile stabilityWork benchesMechanical energy handlingEngineeringLow noise

The invention discloses a low-noise precision electric control translation stage which comprises a base, wherein an end plate and a fixing block are arranged at the two ends of the base respectively; a lead screw, a first sliding rail and a second sliding rail are arranged between the end plate and the fixing block; the lead screw penetrates through the fixing block and extends outwards; a coupler is arranged at the extending end of the lead screw; a rotating shaft is arranged at one end, away from the lead screw, of the coupler; a stepping motor is arranged at one end, away from the coupler, of the rotating shaft; a nut is arranged in the translation stage; telescopic rods are arranged on the two sides of the nut in a symmetric manner; the outer part of each of the telescopic rods is sleeved with a spring; each of the two ends of each of the telescopic rods and the springs is fixedly connected with a fixing plate; a piece of silencer cotton is arranged at the upper end of a supporting plate; a sliding block is fixedly connected to each of the lower ends on the periphery of the translation stage. The low-noise precision electric control translation stage can not only operate stably, but also effectively reduce noise produced during operation, so that the translation stage is convenient and ingenious to use and suitable for extensive popularization.

Owner:JIANGSU HUIBO ROBOTICS TECH CO LTD

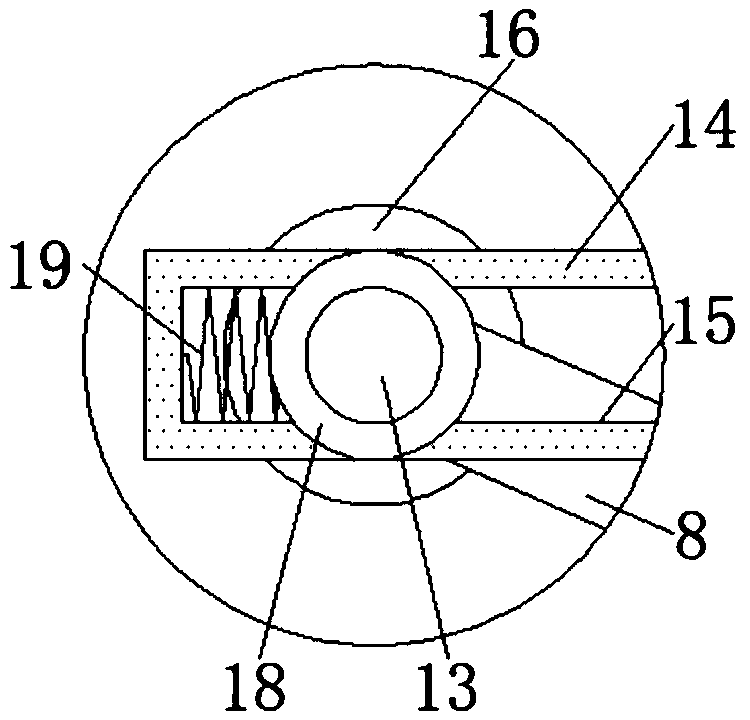

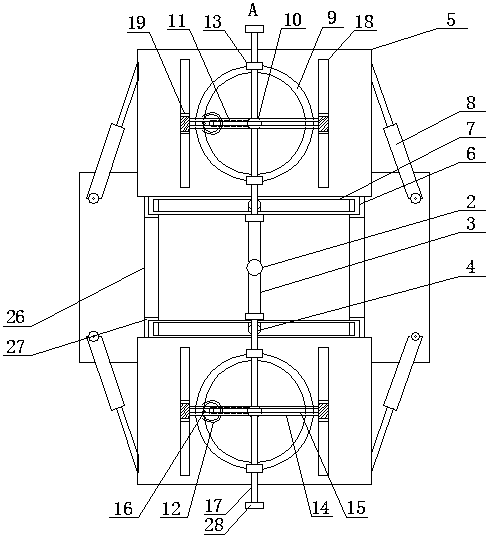

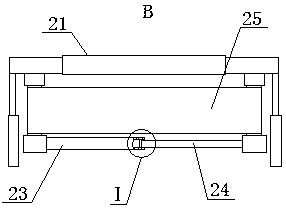

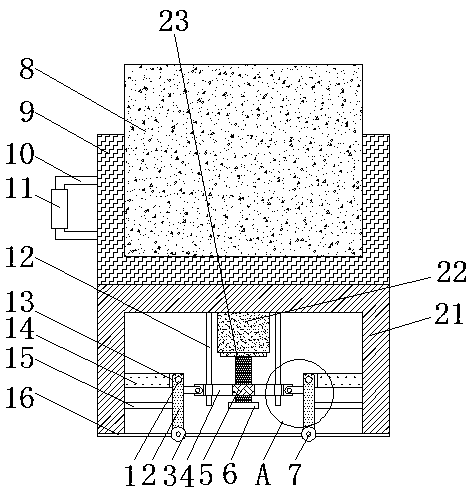

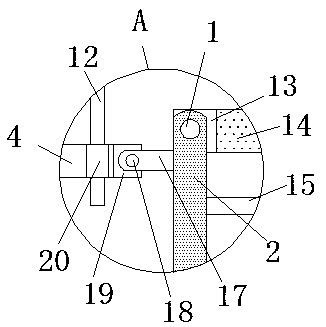

Spindle capable of being adjusted according to hole diameters of spools

The invention discloses a spindle that can be adjusted according to the size of the hole diameter of the bobbin, which includes a cylinder, a containing column is movably installed inside the cylinder, and the bottom end of the containing column passes through the cylinder and extends to the outside of the cylinder , the interior of the cylinder is movably connected with push blocks located on both sides of the accommodation column, the push block is provided with a card slot on the side close to the accommodation column, and both sides of the interior of the accommodation column are movably installed with card blocks, so The end of the clamping block close to the push block passes through the accommodating column and is clamped in the clamping slot, and the end of the clamping block away from the clamping slot is fixedly connected with a connecting plate. The present invention achieves the effect of being able to fix yarn bobbins of different sizes by setting push blocks, clamping slots, clamping blocks, connecting plates, transmission blocks, transmission sleeves, spur gears, racks, transmission rods, sleeve rods and round blocks, so that the spindles Different types of bobbins can be fixed, so as to meet the needs of the existing technology, improve the work efficiency of winding yarn, and thus be convenient for people to use.

Owner:陈礼伟

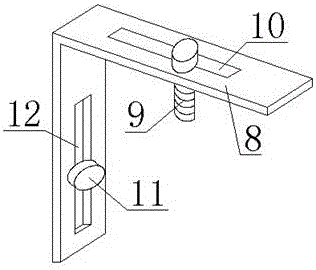

Bracket for driving multi-azimuth monitoring of camera

InactiveCN106454267AMobile stabilityEasy to operateTelevision system detailsColor television detailsDrive motorEngineering

The invention discloses a bracket for driving multi-azimuth monitoring of a camera. The bracket comprises a base and a right-angled bracket for fixing the base, wherein an adjusting groove a is formed in the base, an adjusting groove b matched with the adjusting groove a is formed in the right-angled bracket, the adjusting groove a and the adjusting groove b are connected by a bolt a, a slide bar is arranged on the base, a moving support sleeves on the slide bar, a guide plate is arranged at the bottom of the moving support, the guide plate is installed on the base, the camera is installed on the moving support, the slide bar is a lead screw, the moving support is provided with internal threads matched with the lead screw, the lead screw is connected with the moving support through threads, a drive motor is arranged on one side of the base, and an output shaft of the drive motor is connected with the lead screw. The bracket disclosed by the invention has the beneficial effects that the camera can be driven to horizontally move to realize multi-angle monitoring of the camera; remote operation of an operator is facilitated; and the structural design is reasonable, and the camera stably runs.

Owner:CHENGDU HANZHI INFORMATION TECH

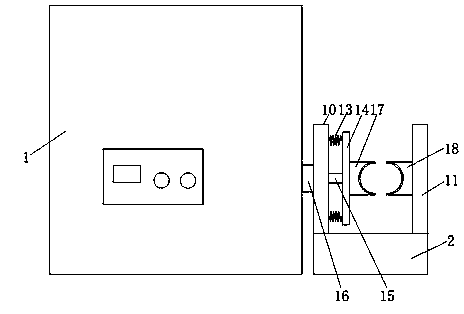

Convenient-to-use clamp holder for building steel pipe cutting

InactiveCN109396881AEasy to operateMobile stabilityPositioning apparatusMetal-working holdersMotor driveEngineering

The invention provides a convenient-to-use clamp holder for building steel pipe cutting. The control device comprises a control box and a clamping table, wherein a motor is fixedly installed on the front side of an inner cavity of the control box, a gear is fixedly installed at the output end of the motor, a control block is fixedly installed at the bottom of the inner cavity of the control box, and a sliding groove is formed in the top of the control block. The convenient-to-use clamp holder for the building steel pipe cutting is characterized in that a motor, the gear, the control block, thesliding groove, a sliding rod, the sliding block and a rack are arranged, the rotation of an output end of the motor drives the gear to rotate, the gear drives the rack to move, so that a first clampand a second clamp are enabled to clamp a steel pipe, and operation is convenient; and by cooperating with the arrangement of a limiting groove, a cross rod, a limiting block and a pulley at the sametime, the movement of the rack is prevented from shifting, so that the movement of the rack is more stable, the effect of convenient use is achieved, and the problem that an existing clamp holder forbuilding steel pipe cutting is inconvenient to use is solved.

Owner:扬州天伟新材料有限公司

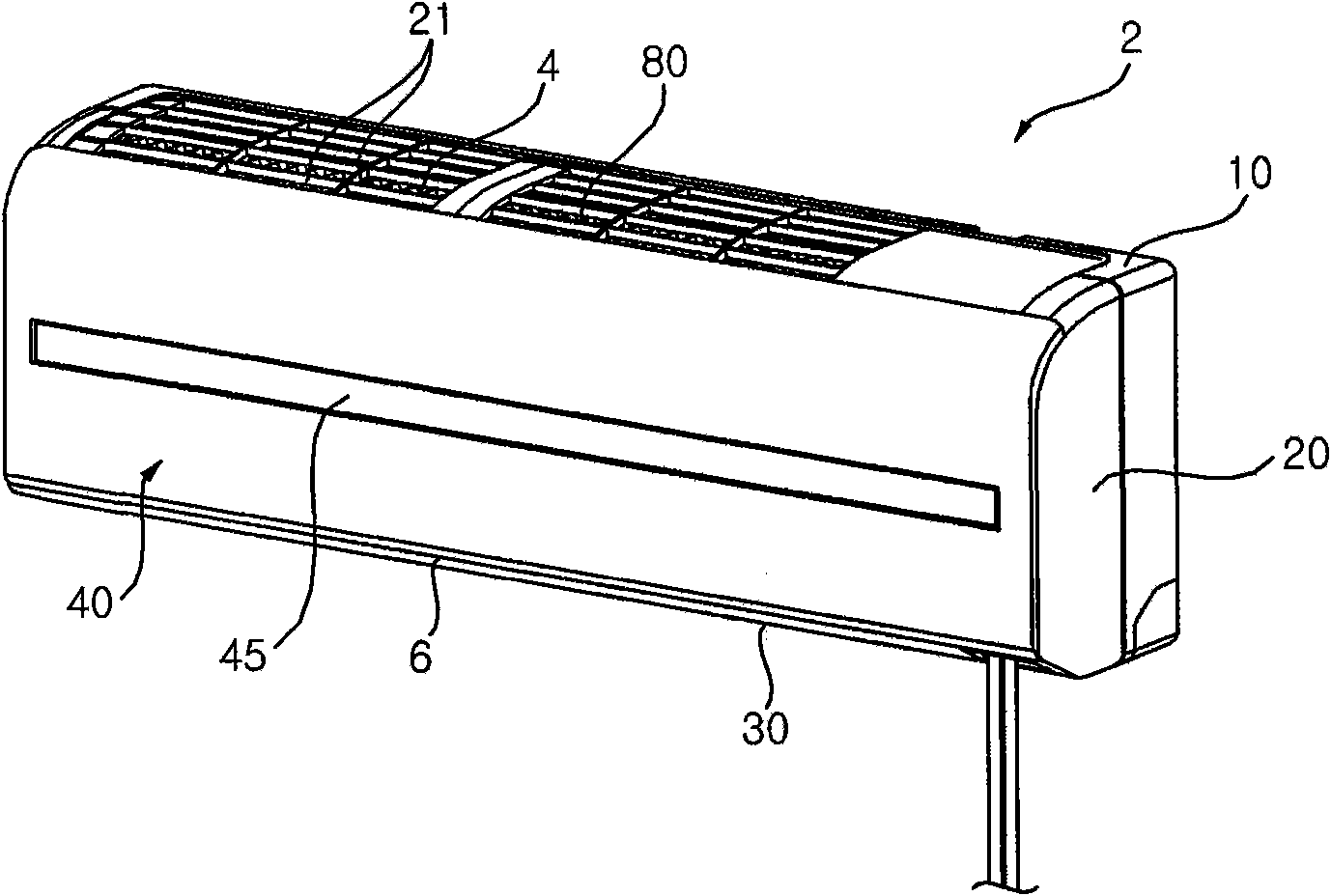

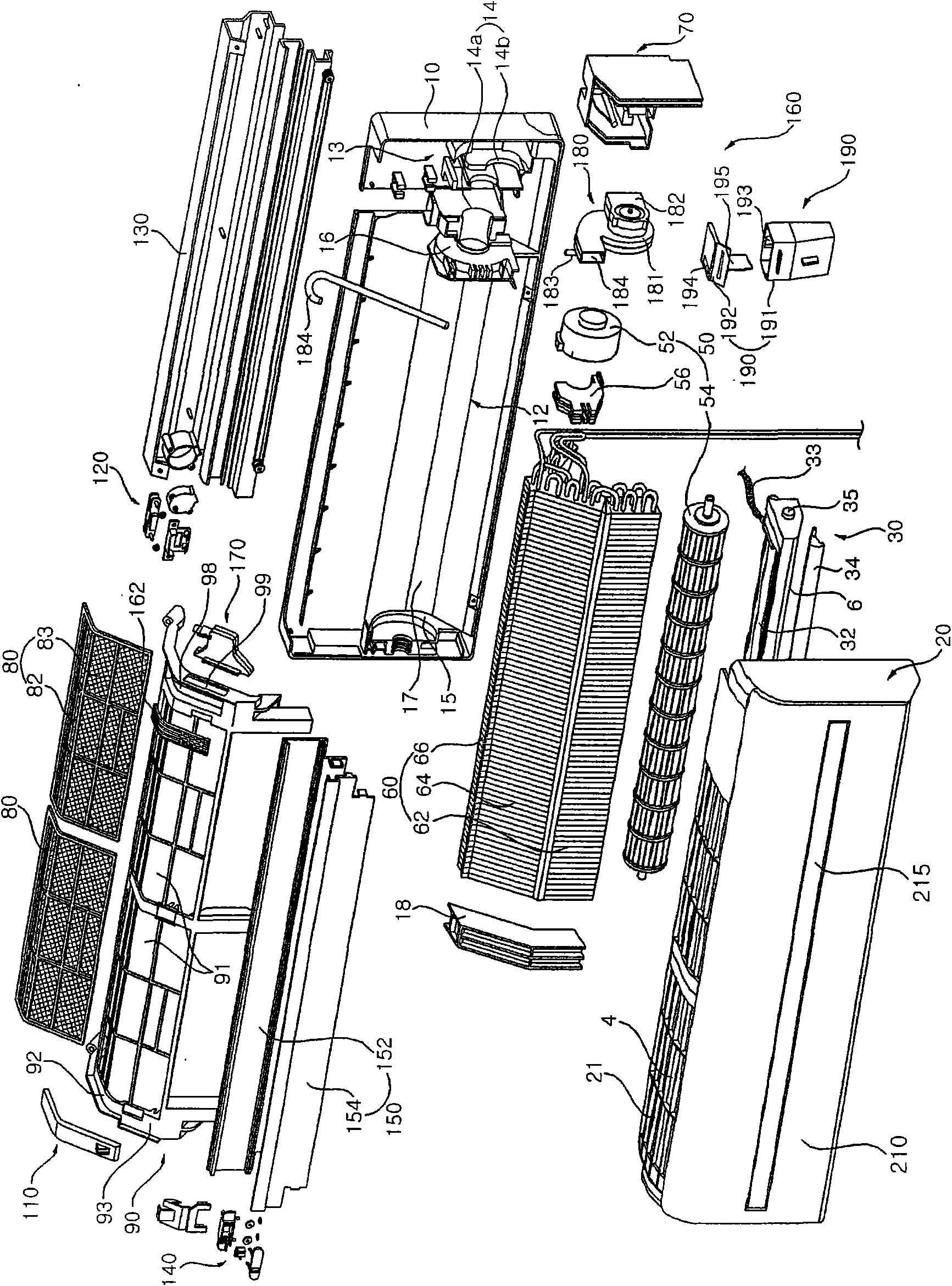

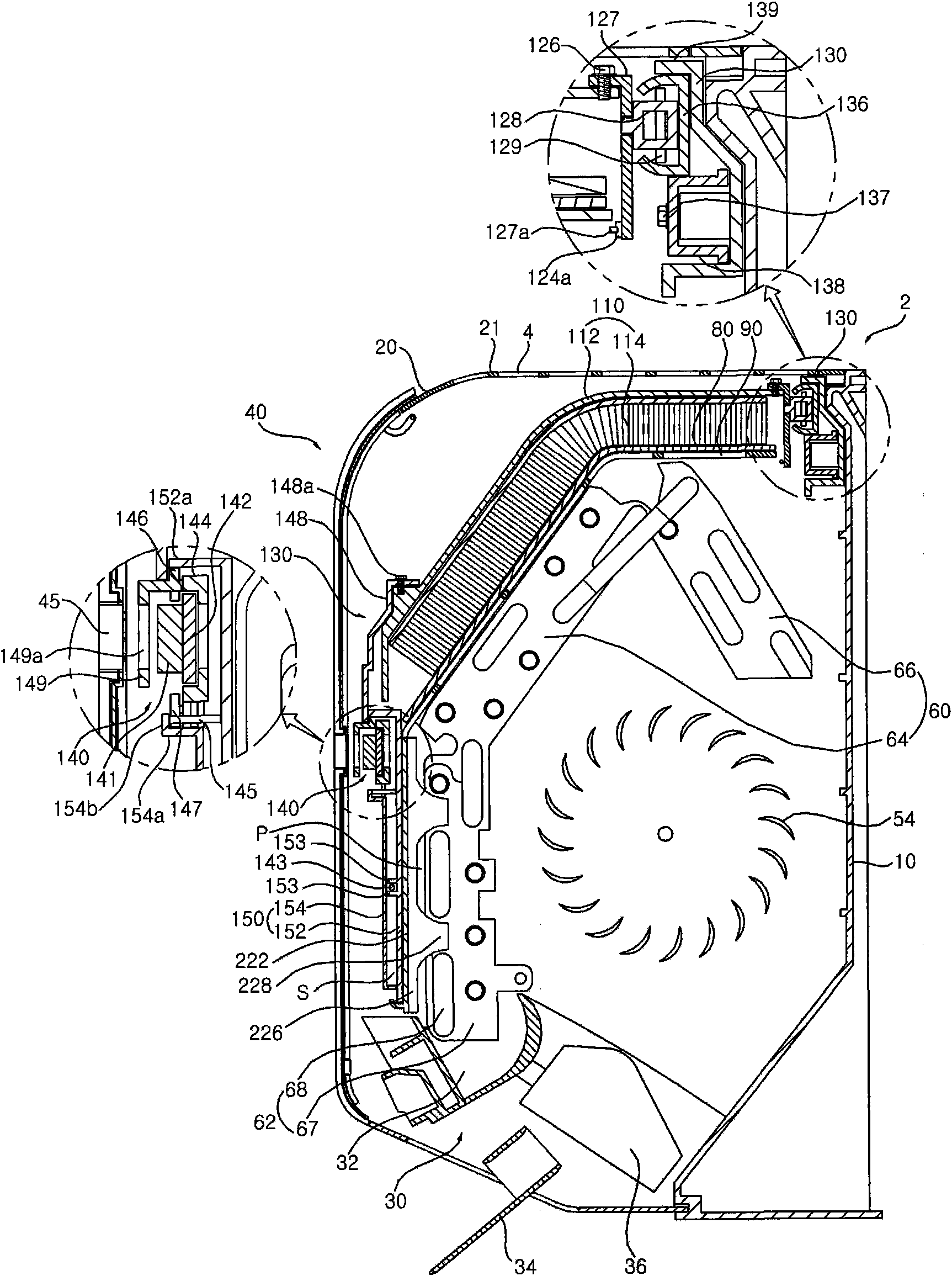

Air conditioner

ActiveCN101581471AMobile stabilityPrevents reduction in heat transfer efficiencyLighting and heating apparatusSpace heating and ventilation detailsEngineeringMetallic Lead

The invention relates to an air conditioner, comprising a body, a heat exchanger, a filter, a filter cleaning component, an electrical component, a lead and a cable guiding device, wherein the body isprovided with an air suction part and an air exhaust part; the heat exchanger is mounted inside the body; the filter is used for filtering exotic matter in air sucked towards the heat exchanger; thefilter cleaning component can move along the filter and is used for cleaning the filter; the electrical component is mounted in the filter cleaning component; the lead is connected with the electricalcomponent; and the cable guiding device is used for protecting and guiding leads. According to the invention, the lead is prevented from interference with the heat exchanger, and the like, thereby being capable of arranging / protecting safely.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Semiautomatic commodity clamping machine

InactiveCN107720254AMobile stabilityQuick and powerful reactionSortingConveyor partsEngineeringKnife blades

The invention discloses a semi-automatic product clamping machine, which comprises a box body with casters, a winding mechanism, a box clamping mechanism, an RFID identification device and a film cutting mechanism, and a packaging box placement platform and a control panel are arranged outside the box body , the working window and the switch controller, the working window is placed on the side of the packing box; the winding mechanism is located inside the box, facing the working window, which includes a motor, a rotating shaft and a working rod, one end of the rotating shaft is connected to the middle part of the working rod, and the working rod An adhesive film is placed at one end; the clamping mechanism is located in front of the working window, and it includes a motor, a synchronous belt and two parallel bars with a pressing plate of the synchronous belt; Belt, cutting part, smoothing part and positioning part, the cutting part is a synchronous belt connecting plate equipped with a blade and a brush, the smoothing part is a synchronous belt connecting plate equipped with a strip brush, and the positioning part is welded with a cylindrical metal Timing belt connecting plate. It has the characteristics of economy, durability, stability and reliability, and good packaging effect.

Owner:中天科技(清远)有限公司

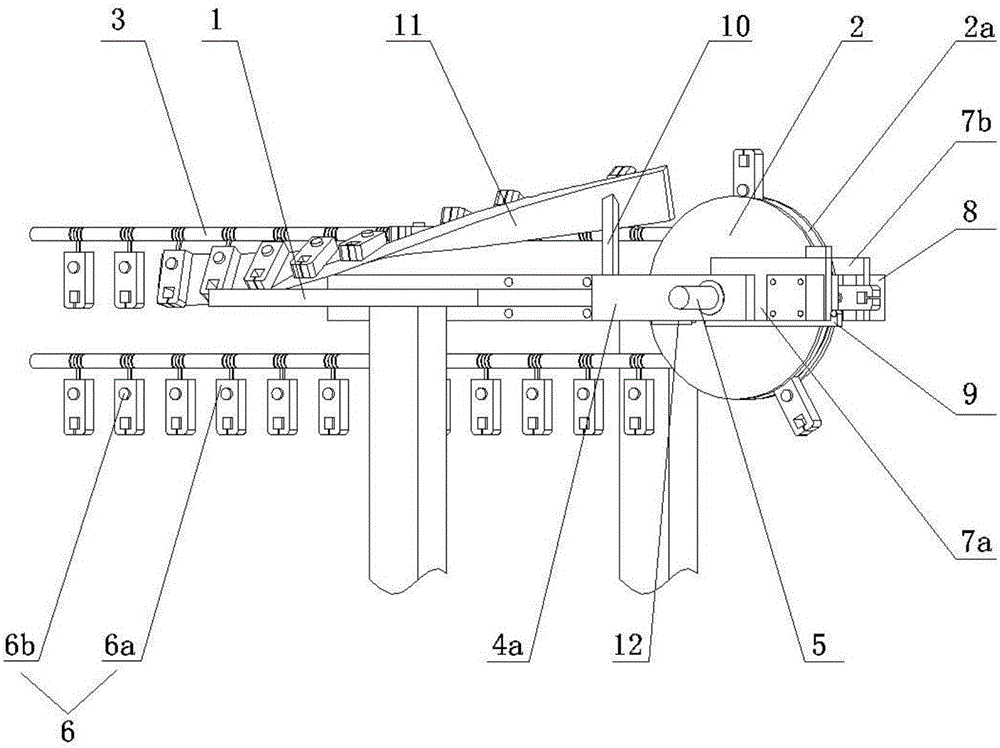

Clamping mechanism applicable to oil edge materials and method for clamping oil edge materials

ActiveCN105880116AMobile stabilityPositioning and opening precisionLiquid surface applicatorsLeather/skins/hides/pelt chemical treatment apparatusRotating disc

The invention belongs to the technical field of automatic edge oiling machines, and particular relates to a clamping mechanism applicable to oil edge materials. The clamping mechanism comprises a rack, a rotating disc and a string clamp rope, clamps are arranged on the string clamp rope at intervals, the rack comprises a rotating disc support frame, a clamp guide plate, a clamp detection device and a clamp opening device, a rotating disc shaft is arranged on the rotating disc support frame, the rotating disc is connected to the rotating disc support frame through the rotating disc shaft, an annular groove is formed in the periphery of the rotating disc, the string clamp rope is arranged in the annular groove in a sleeved mode, and a power source which drives the string clamp rope to rotate around the rotating disc is connected to the string clamp rope; each clamp comprises a clamp body and a button, the width of the bottom end of each clamp body is smaller than that of the annular groove, and the width of the annular groove is smaller than that of each button. The clamping mechanism applicable to the oil edge materials is simple in structure, convenient and safe to operate and high in work efficiency and can position the clamps accurately and achieve precise processing of small materials.

Owner:潘声君

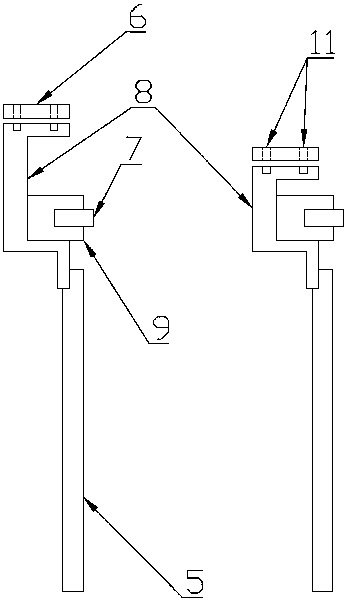

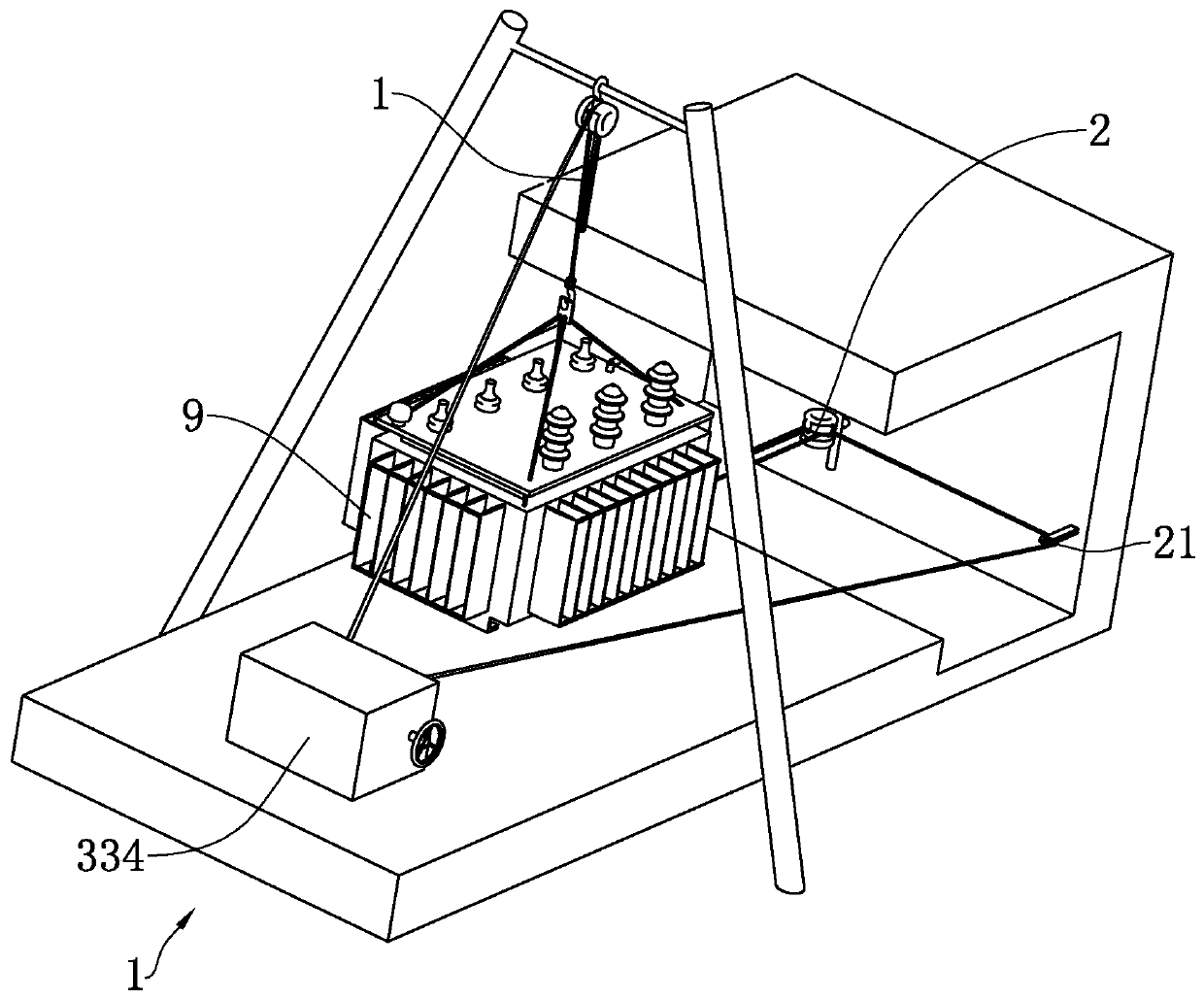

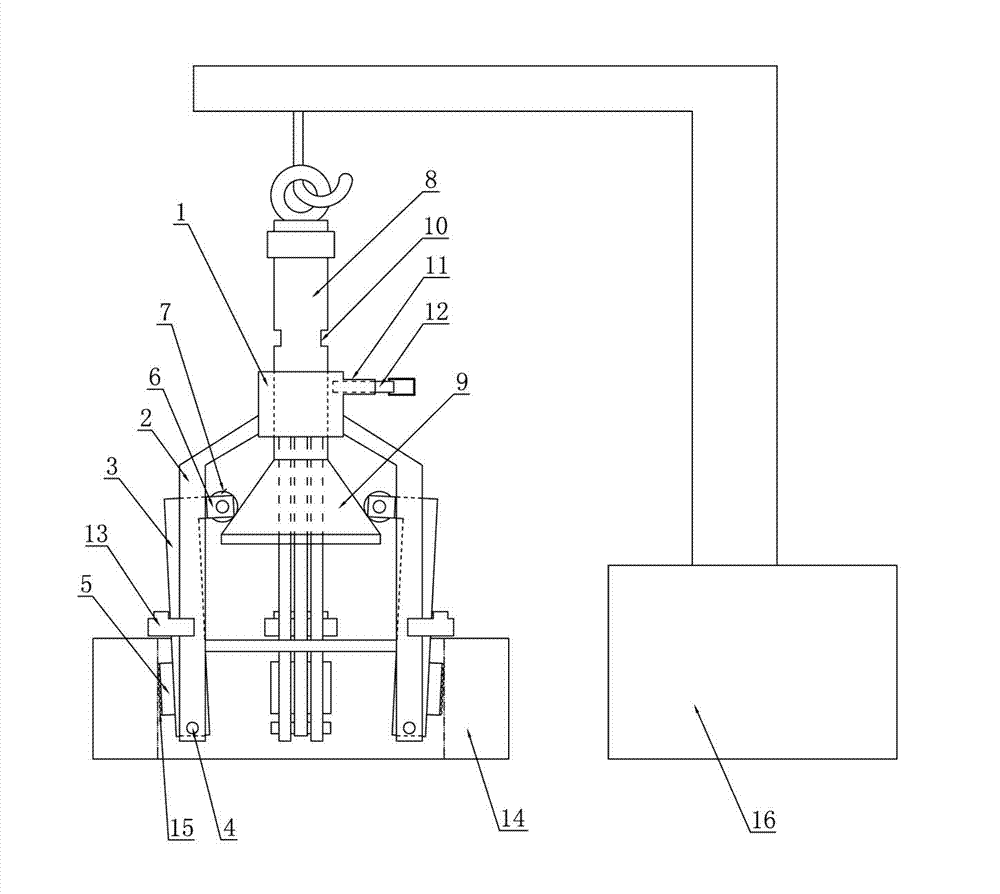

Transformer installation process and device

ActiveCN110993262AMobile stabilityEasy to operateTransformers/reacts mounting/support/suspensionInductances/transformers/magnets manufactureElectrical and Electronics engineeringMechanical engineering

The present invention discloses a transformer installation process and a transformer installation device. The device comprises a vertical chain block and a transverse chain block which are used for being connected with a transformer, the vertical chain block drives the transformer to move along a vertical direction, and the transverse chain block drives the transformer to move along a horizontal direction. An inclined mechanism is connected to the vertical chain block and the transverse chain block, comprises a vertical wheel which is detachably connected with the vertical chain block and a transverse wheel which is detachably connected with the transverse chain block and comprises the pressing mechanisms arranged on the vertical wheel and the transverse wheel respectively, and the pressing mechanisms can press and connect the vertical chain block and the vertical wheel and can press and connect the transverse chain block and the transverse wheel. The two chain blocks synchronously acton the transformer, so that the effect of stable movement of the transformer is improved.

Owner:北京中科中电电力工程管理有限公司

Cutting device used for garden greening

The invention discloses a cutting device for landscaping, which comprises an N-shaped support frame, a rotary cutting mechanism is arranged on the inner and lower sides of the N-shaped support frame, and the gap between the lower surface of the beam of the N-shaped support frame and the rotary cutting mechanism is A lifting adjustment mechanism is provided, and a moving mechanism is provided on the lower surface of the N-shaped support frame. The beneficial effect of the present invention is that it is a device that is easy to use, stable in movement, good in sapling forming effect, easy to effectively clean up weeds around the sapling, easy to adapt to cutting at different heights, reduces labor intensity, and improves work efficiency.

Owner:杨桂华

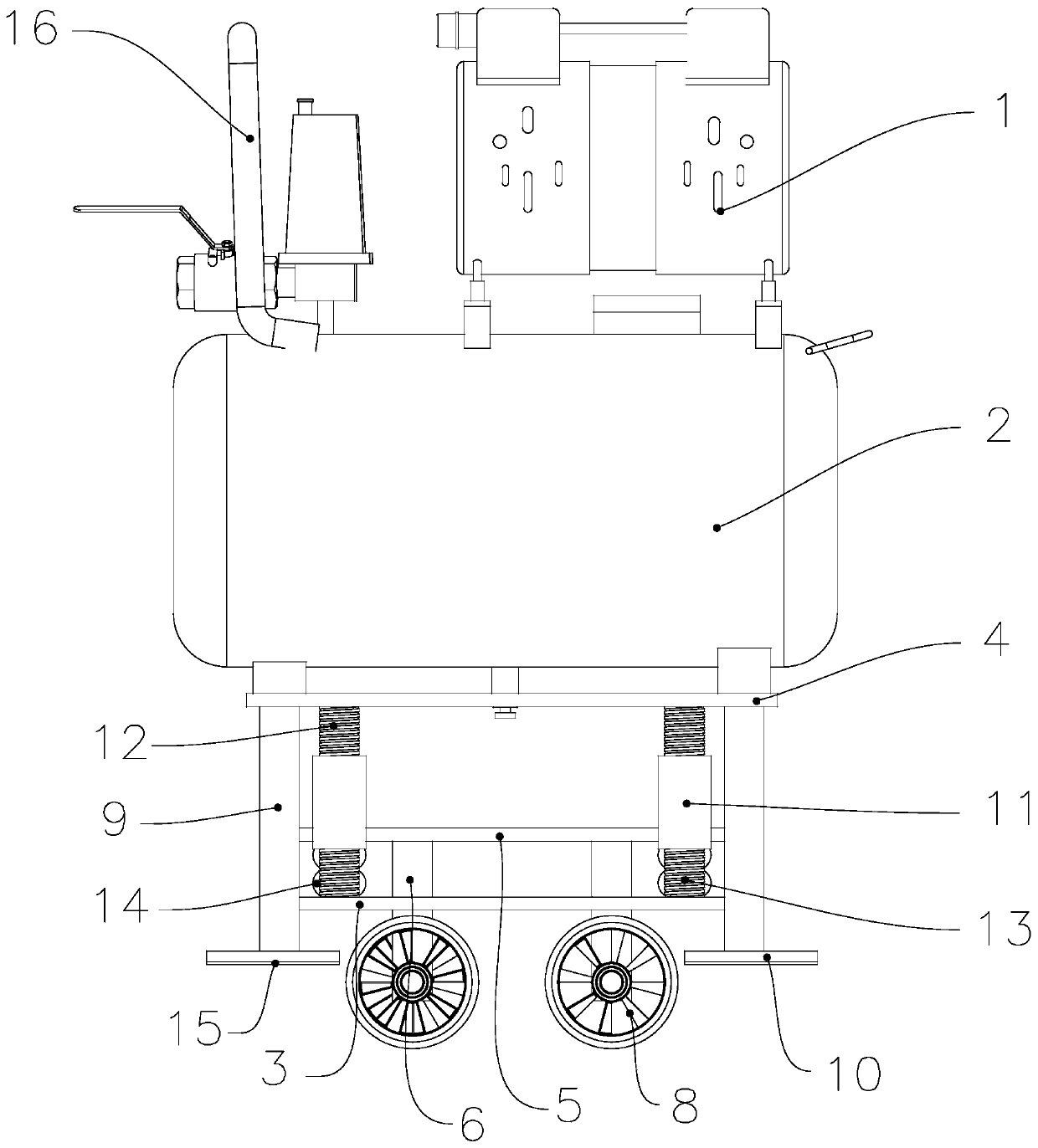

Portable air compressor

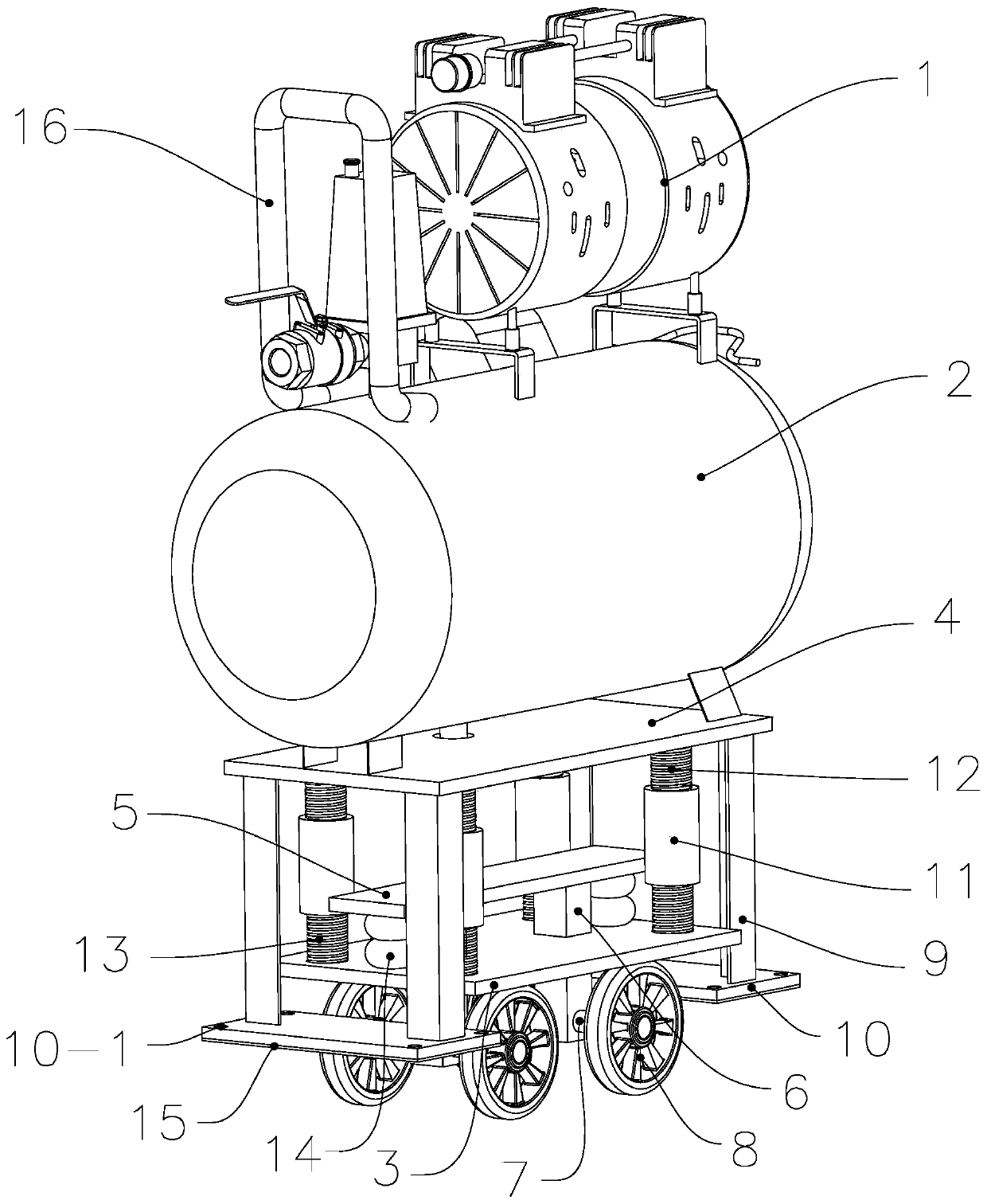

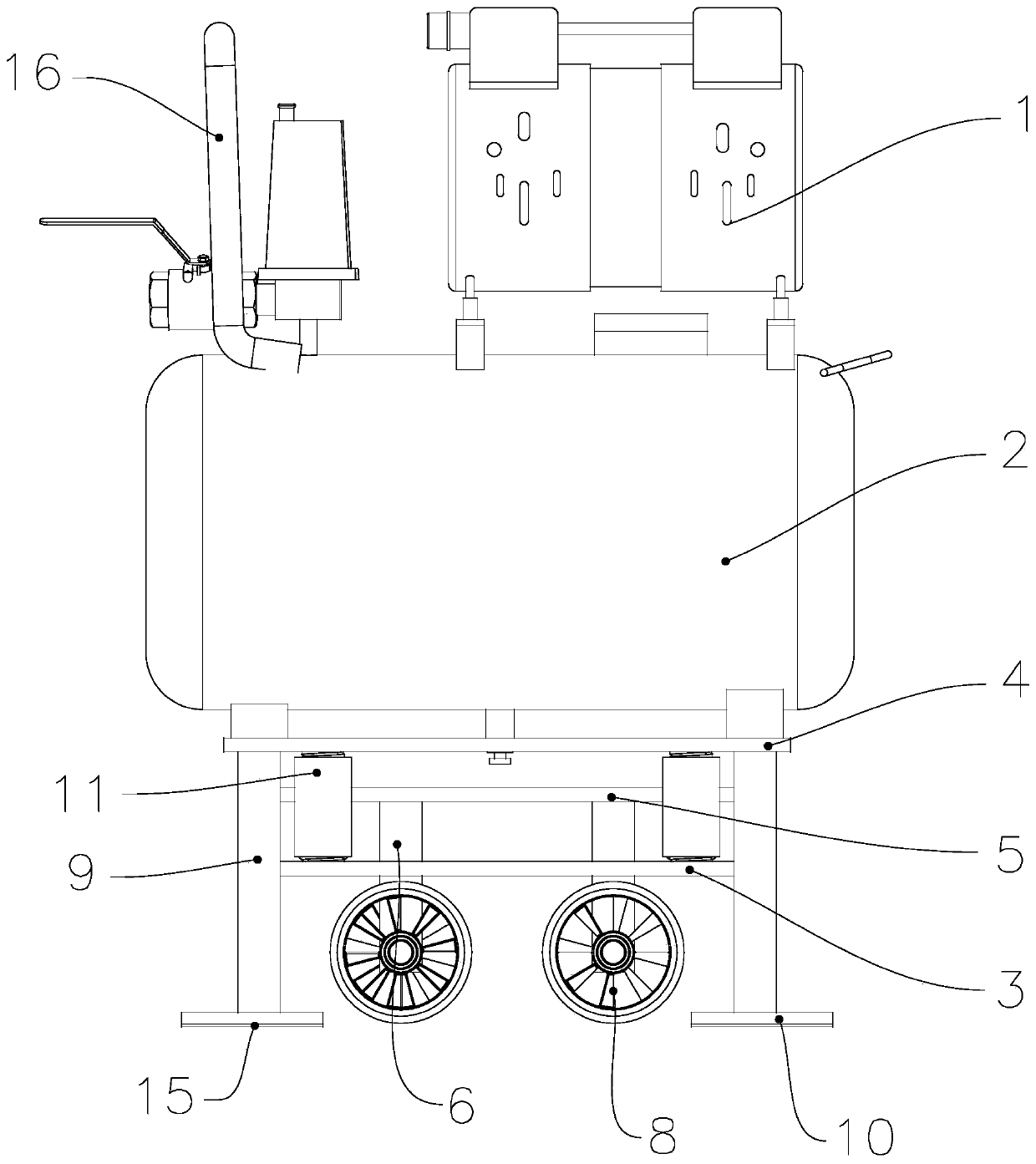

PendingCN109882376AEasy to moveMobile stabilityPositive displacement pump componentsPiston pumpsEngineeringPortable air compressor

The invention relates to a portable air compressor, and belongs to the technical field of air compressor equipment. A motor is fixedly mounted above a pump body, and a fixed plate is fixedly mounted below the pump body. A lifting assembly is fixedly mounted on the lower surface of the fixed plate, and a mounting plate is fixedly mounted on the lifting assembly. The lifting assembly drives the mounting plate to be close to or away from the fixed plate, and a damping assembly is fixedly mounted on the upper surface of the mounting plate. A damping plate is fixedly mounted on the damping assembly, and a guide column is fixedly mounted on the lower surface of the damping plate. A guide hole is formed in the mounting plate, and an axle is fixedly mounted at the end, penetrating out of the guidehole, of the guide column. Wheels are rotationally mounted at the two ends of the axle, and a supporting column is vertically and fixedly mounted on the lower surface of the fixed plate. A locating plate is fixedly mounted on the lower surface of the supporting column. The air compressor is stable in the use process. The air compressor is convenient and fast to use. When the air compressor moveson a mine, stable movement of the air compressor can be guaranteed, and the moving safety of the air compressor is guaranteed.

Owner:DANYANG CHANGSHENG MACHINERY

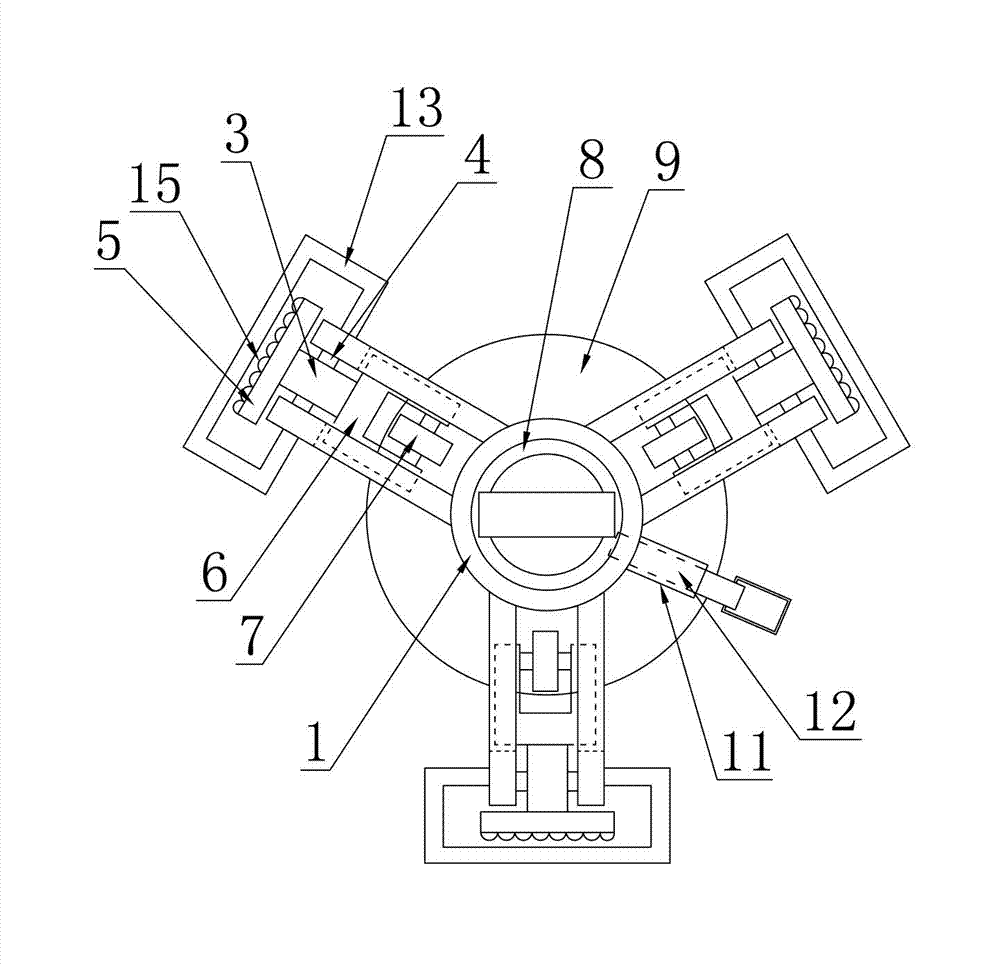

Lifting hand grab of steel wire ring

ActiveCN103496629AMobile stabilityImprove work efficiencyLoad-engaging elementsIdler-wheelLocking mechanism

The invention discloses a lifting hand grab of a steel wire ring. The lifting hand grab comprises an annular base, wherein the outer wall of the annular base is uniformly provided with at least three hand grab supports for supporting the annular base along the circumference; each hand grab support is internally provided with an articulated arm, the lower end of each articulated arm is articulated with the bottom end of the corresponding hand grab support through a connecting shaft, and supporting tightening blocks are arranged on the outer side walls of the articulated arms and are positioned above the connecting shafts; the upper end of each articulated arm is connected with a U-shaped block with an inward opening, and the U-shaped blocks are internally movably provided with idler wheels in a supporting manner; the annular base is internally movably provided with a hand grab supporting tightening guiding piece, and the hand grab supporting tightening guiding piece comprises a guiding pillar and a cone block on the bottom of the guiding pillar; when moving upward, the cone block can push each articulated arm to outward rotate through pushing the corresponding idler wheel, and thus each supporting tightening block outward expands so as to support the inner ring wall of the steel wire ring; a guiding element limiting locking mechanism is also arranged between the annular base and the hand grab supporting tightening guiding piece. The lifting hand grab provided by the invention has the advantages that the steel wire ring is stably moved, and the work efficiency is high.

Owner:张家港市中久金属制品有限公司

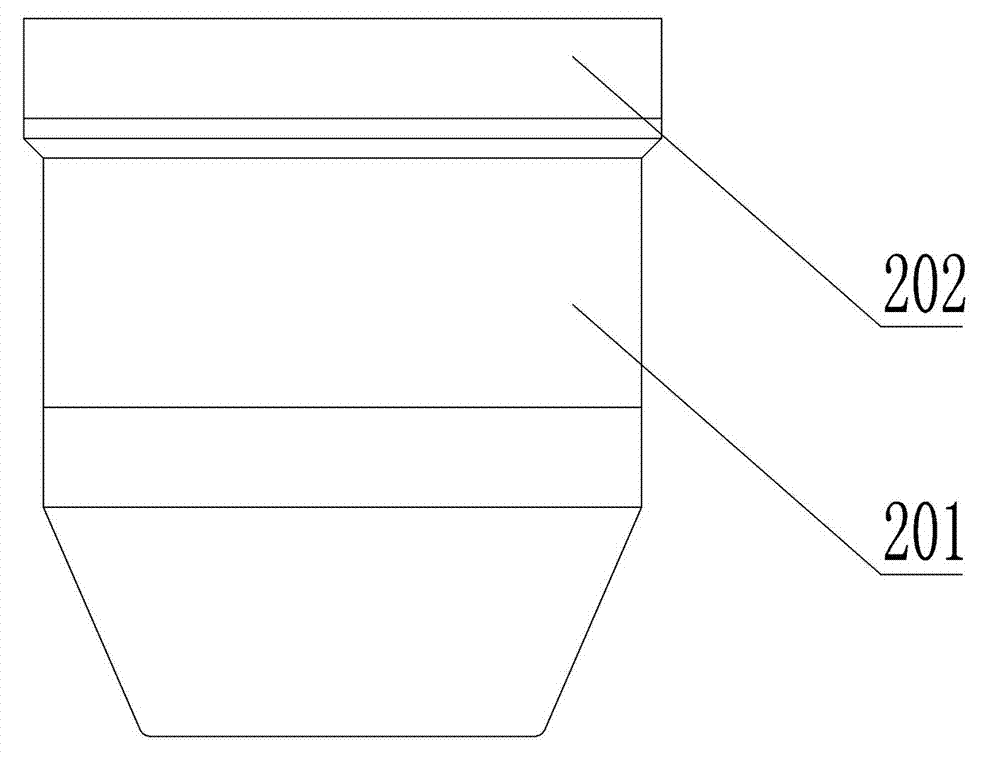

Centrifugal cover settling device

Provided is a centrifugal cover settling device. A cover settling device rotary plate comprises an upper groove plate and a lower groove plate. A guiding device is provided with an upper cover guiding plate and a lower cover guiding plate, and the two groove plates are matched with the two cover guiding plates in crossing mode. During production, bottle covers fall into cover grooves of the groove plates, and the two cover guiding plates are used for guiding and protecting cover rings and cover bodies of the bottle covers respectively so as to enable abnormal-shaped irregular bottle covers to move safely and stably. Cover blocking caused by inclining and staggering can not be caused.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

Robot chassis with anti-sliding structure

The invention discloses a robot chassis with an anti-sliding structure. A walking wheel is inserted in the chassis and comprises an abrasion-resistant wheel rim, an anti-sliding wheel rim inclined towards the center of the walking wheel is formed on the side edge of the abrasion-resistant wheel rim, a transverse supporting shaft is fixedly inserted in a hub part of the walking wheel, the outer side edge of the supporting shaft is hinged to an L-shaped outer support through a bearing block, the outer support is hinged to the chassis through a hinge, the inner side end of the supporting shaft is hinged to an L-shaped inner support through a bearing block, a driving motor is fixed to the inner support, a rotating shaft of the driving motor is fixedly connected with the supporting shaft, a plurality of grooves are formed in the chassis on the lower side of the outer support, longitudinal hinged shafts are fixedly inserted in the grooves, an overturning cylinder is fixed to the upper end face of the outer support on the upper side of the groove, a piston rod of the overturning penetrates the outer support to make a connector fixed, and the connector is inserted in and sleeves the hinged shaft. Two walking faces with different friction coefficients are set on the same walking wheel, and switching of contact surfaces of the walking wheel on the robot chassis and the ground can be achieved.

Owner:台州科金中高技术转移有限公司

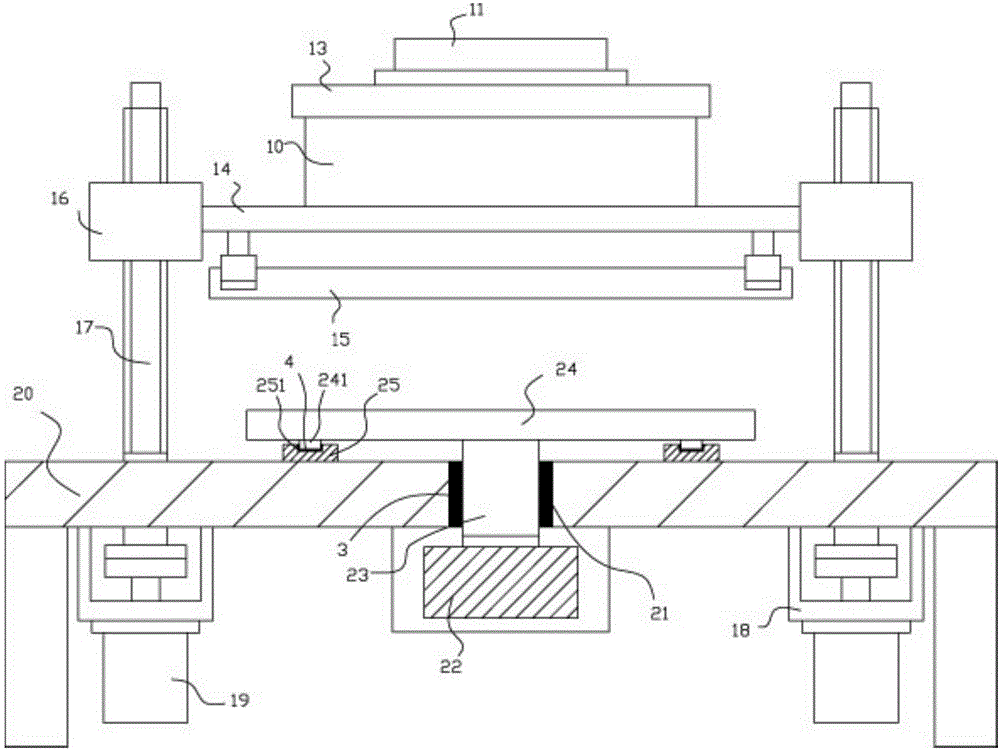

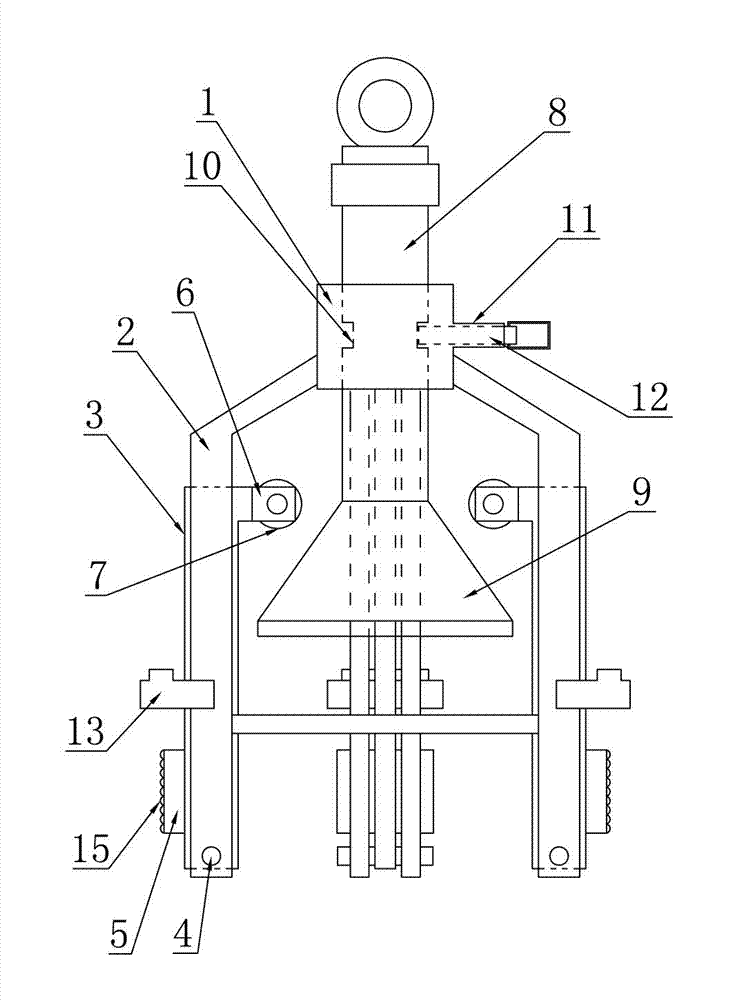

Lining press fitting device and press fitting method

PendingCN107900645AMobile stabilityImprove processing efficiencyMetal working apparatusHollow cylinderScrap

The invention discloses a lining press fitting device and relates to the technical field of damper accessories. The lining press fitting device comprises a base plate. A V-shaped block and a base arearranged on the base plate. The base is of a hollow cylinder structure. An annular groove is arranged inside the top of the base. A lining locating block matched with the base is arranged in the base.The upper end face and the lower end face of the lining locating block are provided with an upper groove and a lower groove correspondingly. A lifting ring is arranged in the annular groove. The lining press fitting device is suitable for press fitting of a subway damper lining and accurate in locating and can improve the machining efficiency, save work time, relieve the labor intensity and reduce the rejection rate.

Owner:NANYANG XIJIAN AUTOMOBILE SHOCK ABSORBER

Automatic taking mechanism for mold products

The invention discloses an automatic taking mechanism for mold products. The automatic taking mechanism includes a rack, a lower mold is fixed in the middle portion of the top surface of a top plate of the rack, and support columns are fixed to the portions, on the front and rear portions of the left and right sides of the lower mold, of the top face of the top plate of the rack; and a side connecting beam is fixed to the two support columns on the left side, and a side connecting beam is also fixed on the two support columns on the right side. Connecting plates are fixed to the positions, onthe front and rear ends of the two side connecting beams, of the inner walls of the support columns, the two ends of adjusting screws extending forwards and backwards are hinged to the two connectingplates through bearings, the rear wall face of the connecting plate on the rear is fixedly provided with a drive motor, the drive motor drives the adjusting screws to rotate, movement blocks are screwed on the adjusting screws, and the lower parts of the opposite wall surfaces of the two movement blocks are fixedly provided with horizontal connecting plates, and the horizontal connecting plates are fixedly provided with lifting mechanisms. The automatic taking mechanism can automatically grab and remove the mold products in the lower mold, and the automatic taking mechanism is convenient and safe to grab, stable in movement and good in effect.

Owner:吴明博

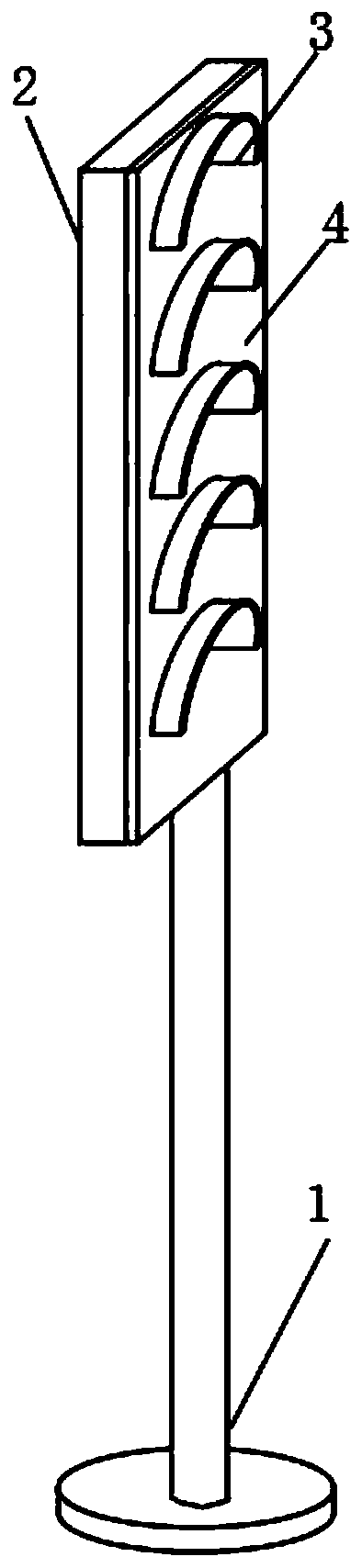

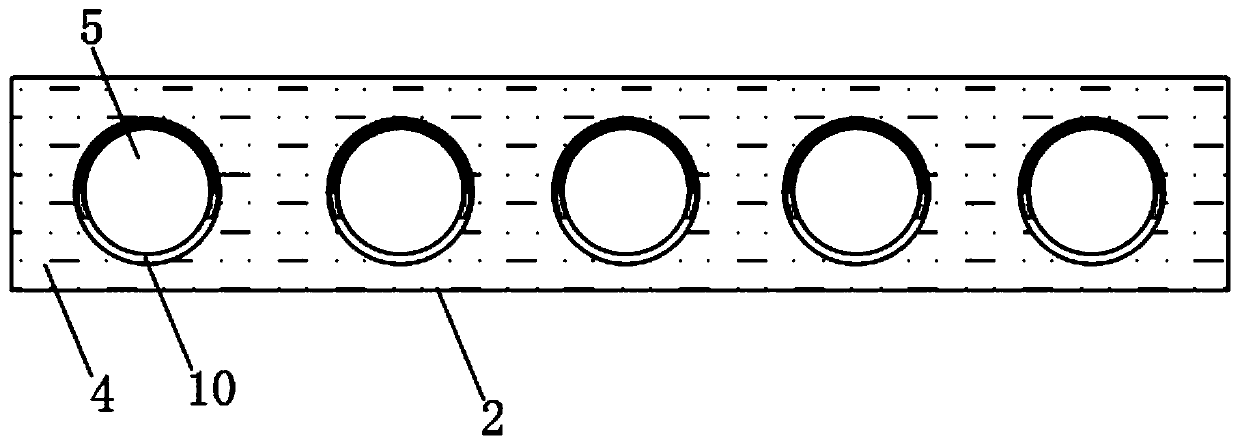

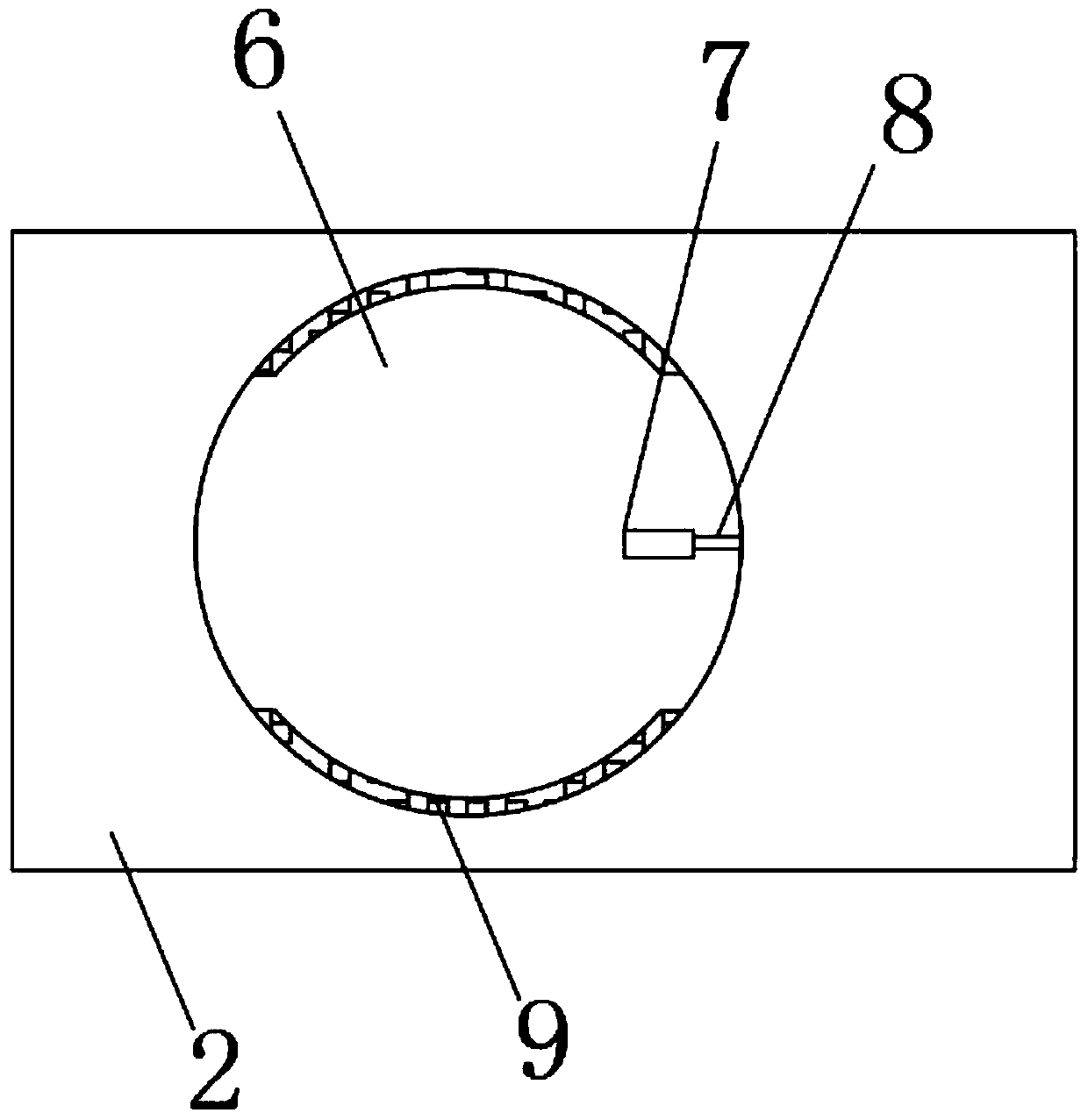

Railway signal lamp monitoring equipment and working method thereof

The invention discloses railway signal lamp monitoring equipment, which comprises a support rod, a mounting plate and a plurality of signal lamps, and is characterized in that the mounting plate is transversely mounted on one side of the top of a support rod, and the signal lamps are rotationally mounted in the mounting plate; a plurality of mounting holes is formed in the mounting plate in a penetrating mode, rotating shafts are rotatably mounted on one sides of the interiors of the mounting holes, and clamping heads are connected to one ends of the rotating shafts; the signal lamps can normally emit light for use. Rain, snow and dust are not easy to cover the exterior of the signal lamps, and light emitted by the signal lamps can keep high intensity and definition. Therefore, the signallamps can be normally used in various environments, and the application range is wider. After a water absorption pad absorbs water, the sweeping head can sweep and extrude the water absorption pad, sothat the water absorption pad can be normally recycled, and the signal lamps can be continuously subjected to water absorption sweeping.

Owner:LIUZHOU RAILWAY VOCATIONAL TECHN COLLEGE

Rotary spreader for feeding chickens and supporting feeding tray of rotary spreader

InactiveCN107624677AMobile stabilityDownstream speed and state stability specificationHollow article cleaningAvicultureEngineeringPulley

The invention provides a rotary spreader for feeding chickens and a supporting feeding tray of the rotary spreader. The rotary spreader comprises a push rod and a water storage air bag, wherein the inner side of an L-shaped rack body is provided with a motor and a feed dividing cabin from top to bottom, and the top end of the feed dividing cabin is provided with a feed inlet by utilizing a bracket; the left side of the feed inlet is provided with a spiral thruster by utilizing two bearings, and the top surface of a pushing rack is provided with a protruding rectangular protruding platform; chicken pecking cabins are divided by utilizing partition plates to be uniformly distributed in a circle in an annular groove on the periphery of a chicken feeding tray, and the water storage air bag ofan annular structure is arranged in the inner ring of the chicken feeding tray; a shield is arranged outside a conveyor belt between the motor and the spiral thruster as well as a belt pulley, and thebottom side of the feed inlet is sequentially provided with conical feed dividing plates, feed guiding channels on the conical feed dividing plates, arc plates connected between the two adjacent feedguiding channels, and feed sliding cabins of arc cavity structures which are arranged at the bottom sides of the feed guiding channels from top to bottom. The downflowing speed and state of downflowing feed are more stable and normative.

Owner:周依依

Power cable protection pipe quick cutting table

InactiveCN108500367AEasy to moveMobile stabilityShearing machinesShearing machine accessoriesEngineeringPower cable

The invention discloses a power cable protection pipe quick cutting table which comprises a cutting platen. A first sliding groove is formed inside the cutting platen, one side of the cutting platen is fixedly connected with an installing plate through a bolt, a sliding base is welded above the installing plate, a hydraulic rod is installed on one side of the cutting platen, a base plate is arranged on the side, close to the hydraulic rod, of the cutting platen, installing blocks are installed inside the first sliding groove, protection pipe containing rollers are installed above the installing blocks, and screws are installed on one sides of the installing blocks. The power cable protection pipe quick cutting table is provided with the first sliding groove and a second sliding groove, thedistance between the two installing blocks is better adjusted, and a user can conveniently place protection pipes with different diameters on the protection pipe containing rollers; and the sliding base is arranged, the protection pipes with different lengths can be better cut, the protection pipes can be conveniently machined by the user and can be conveniently moved by the user, and movement ofthe protection pipes is more stable.

Owner:浙江荣正管业有限公司

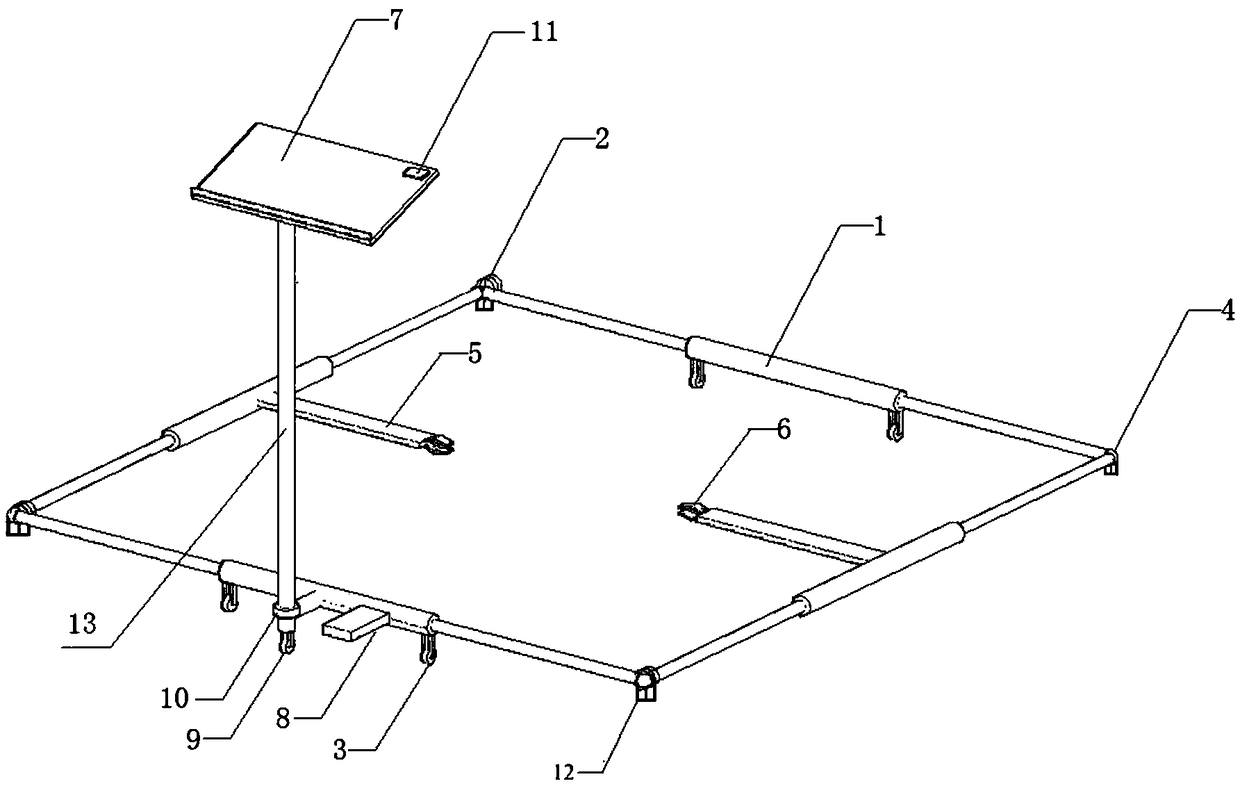

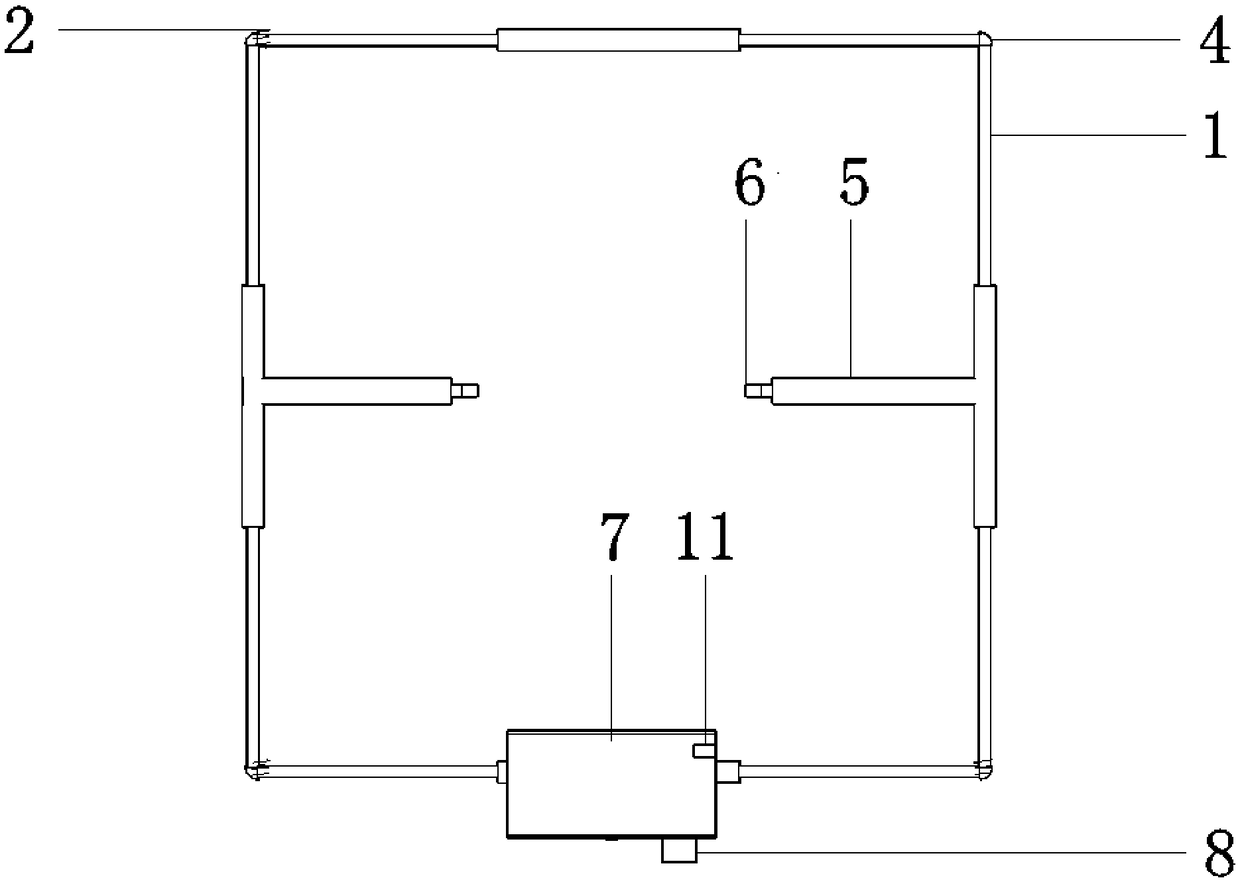

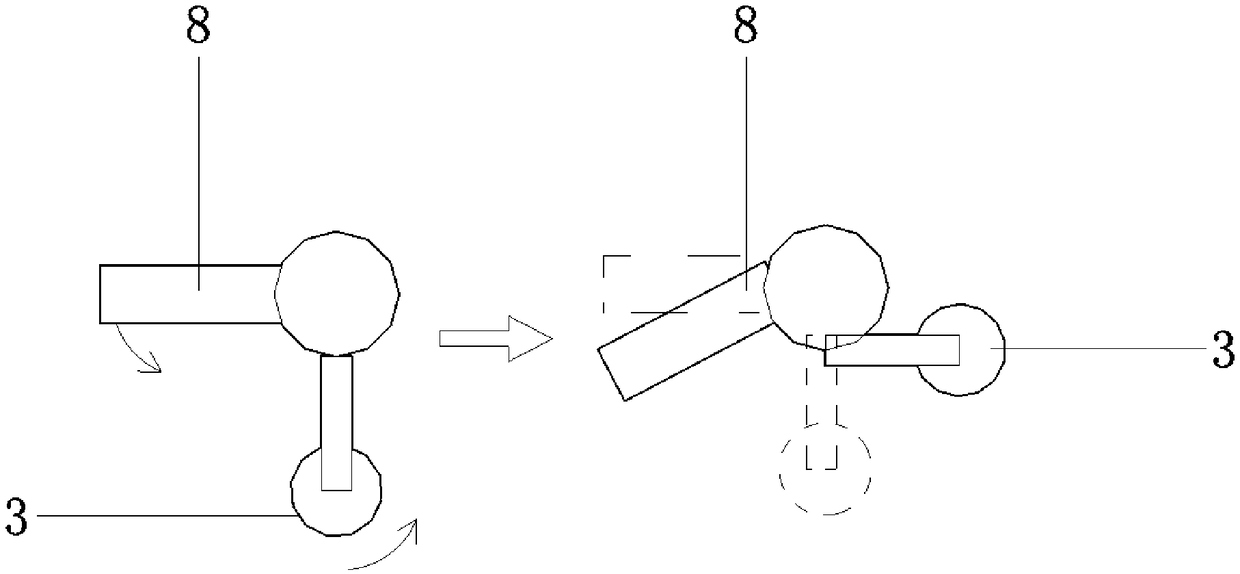

Transient electromagnetic coil leveling device for field detection and method of using the same

ActiveCN109375273AOvercome terrain effectsMobile stabilityElectric/magnetic detectionAcoustic wave reradiationTerrainElectromagnetic coil

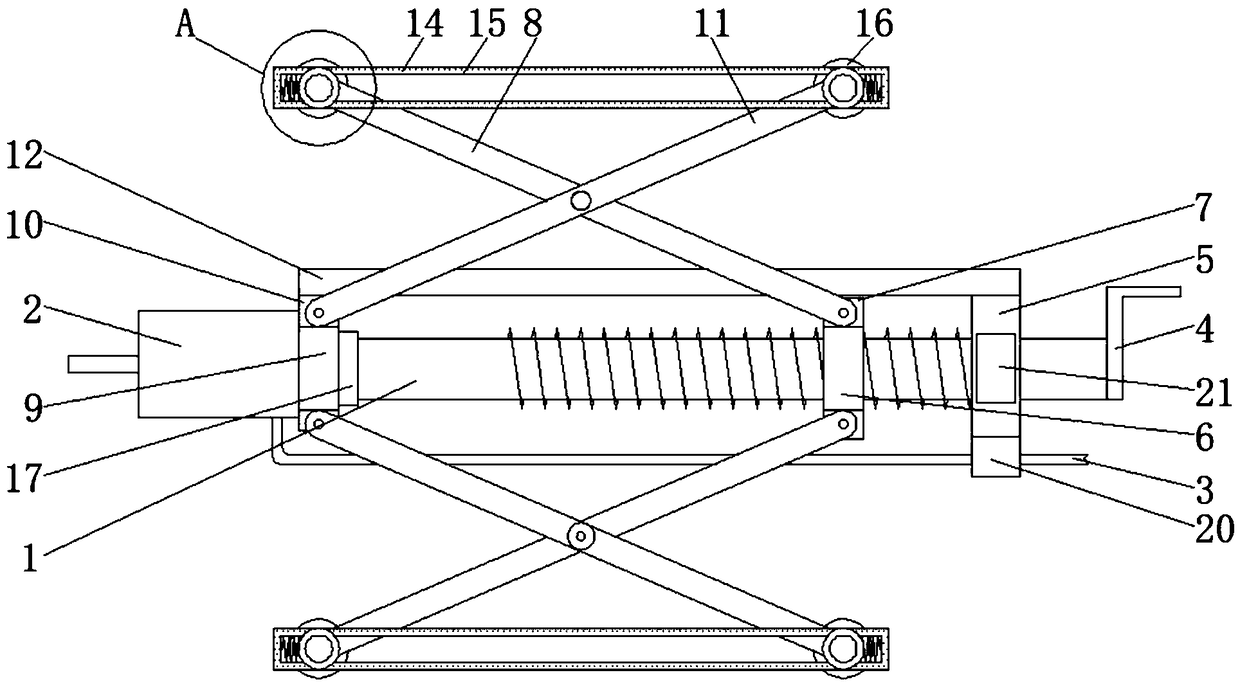

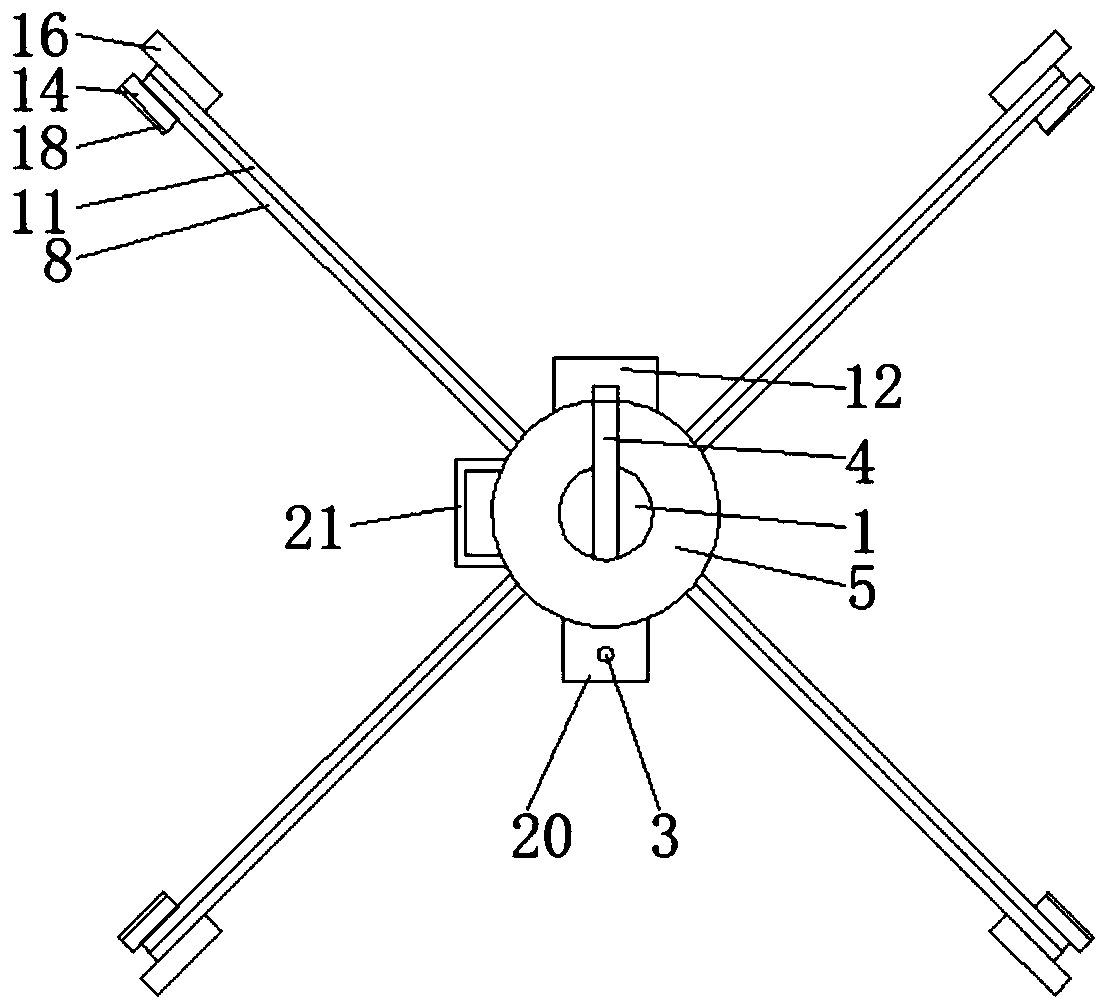

The invention relates to a transient electromagnetic coil leveling device for field detection and a method of using the same. The device mainly comprises automatic leveling mechanisms, a transmittingcoil fixation mechanism, a receiving probe fixation mechanism, a console mechanism, and a roller traveling mechanism. The automatic leveling mechanisms are arranged at four corners of the device; thereceiving probe fixation mechanism and the console mechanism are connected to the transmitting coil fixation mechanism. The transmitting coil fixation mechanism is in contact with the ground surface through four rollers, so that the device is convenient to move and data are collected conveniently. The transmitting coil fixation mechanism can be lifted by reeling or unreeling of the rollers; and the receiving probe and the transmitting coil are lifted simultaneously to ensure effectiveness of a transmitting pulse magnetic field and the receiving signal. The device is operated simply with high practicability, the influence by the terrain can be eliminated; the collection quality efficiency is improved; the labor intensity of the personnel is reduced; and the credibility of the data is enhanced.

Owner:SHANDONG UNIV

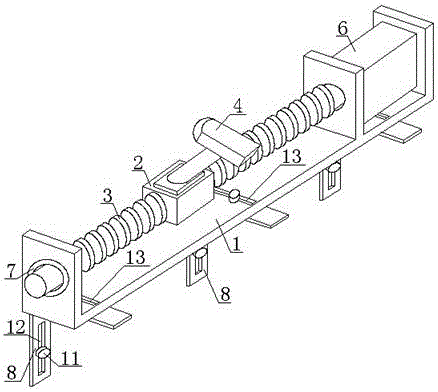

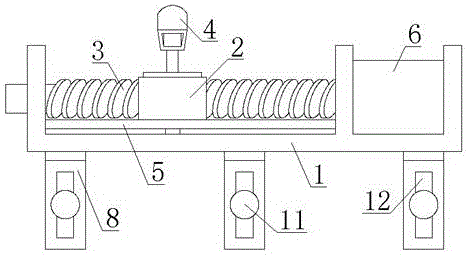

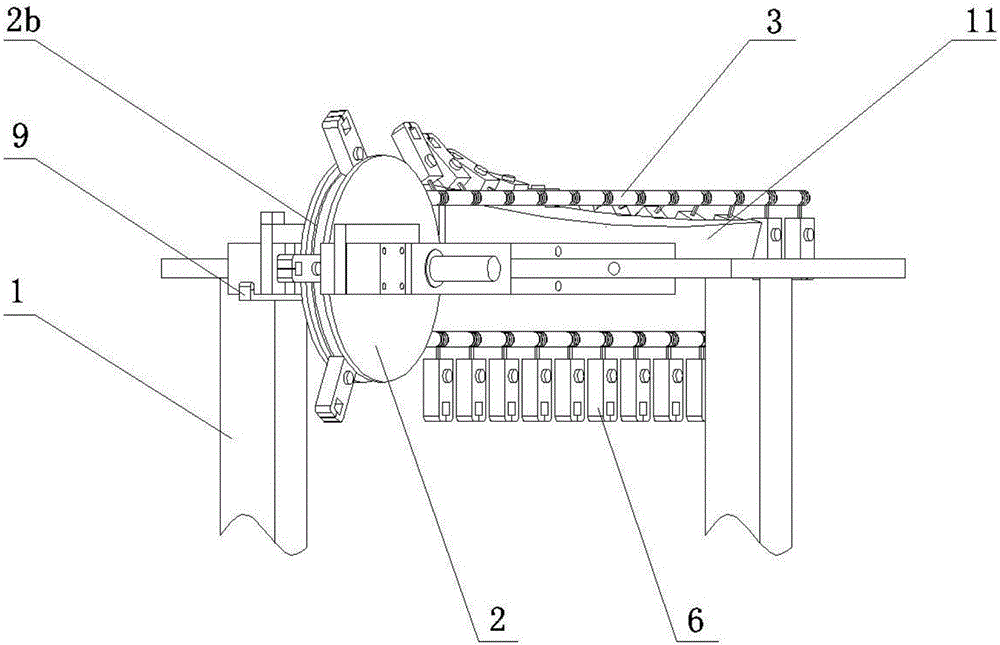

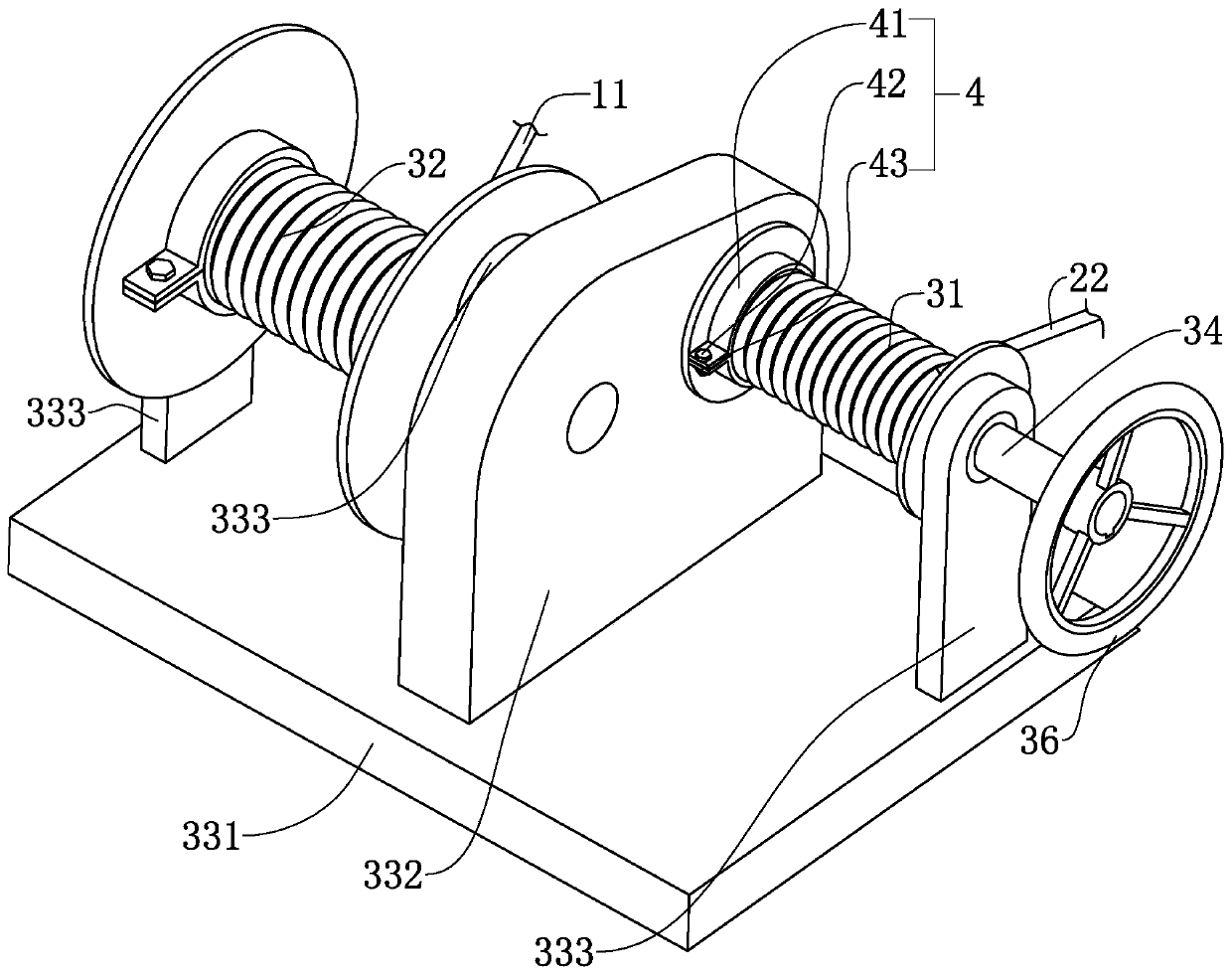

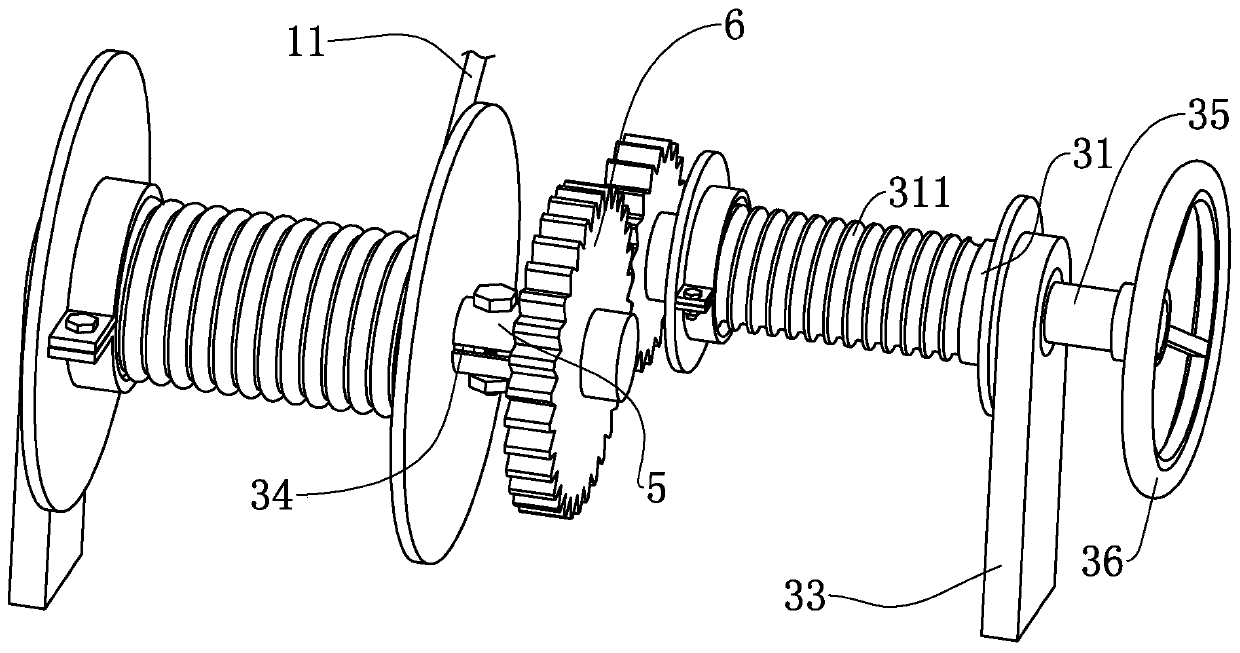

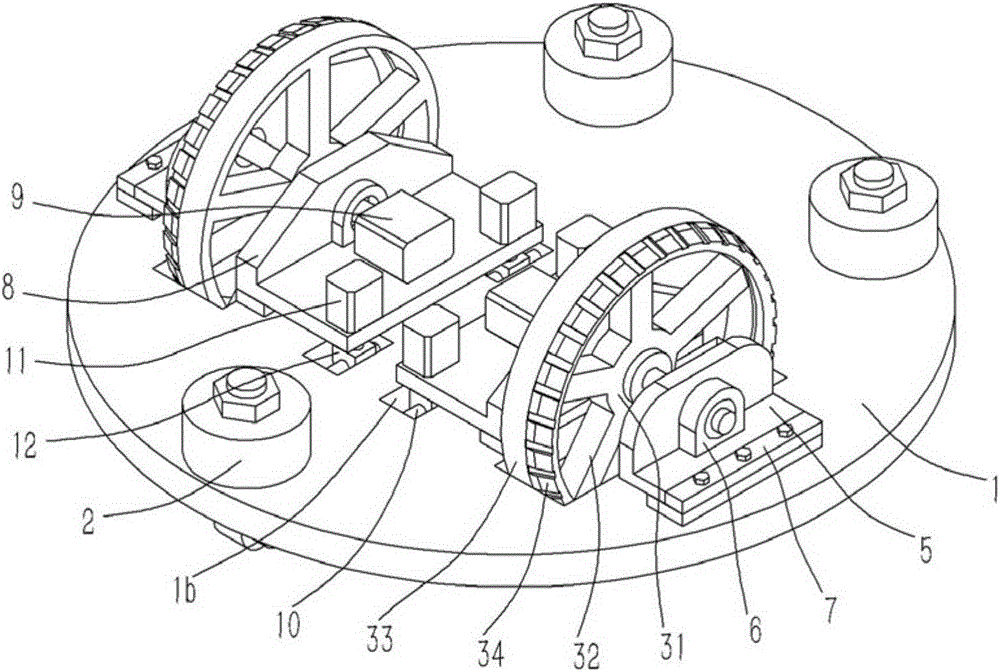

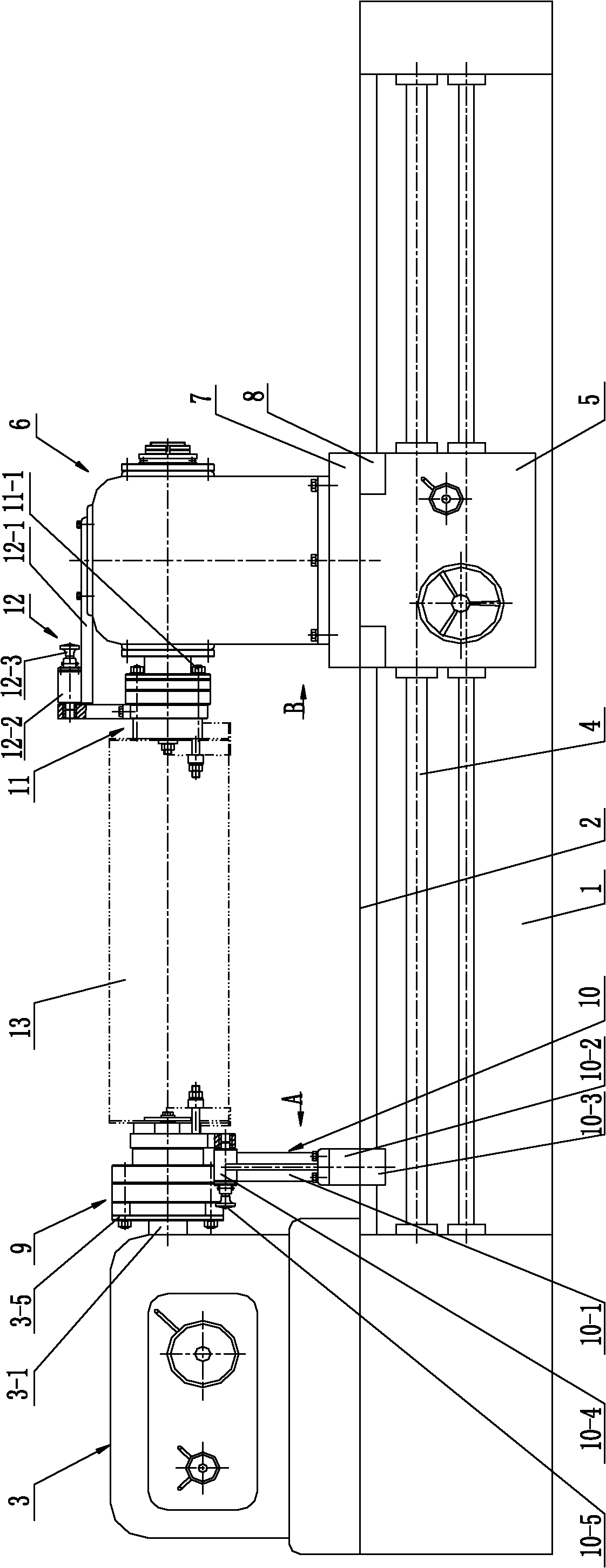

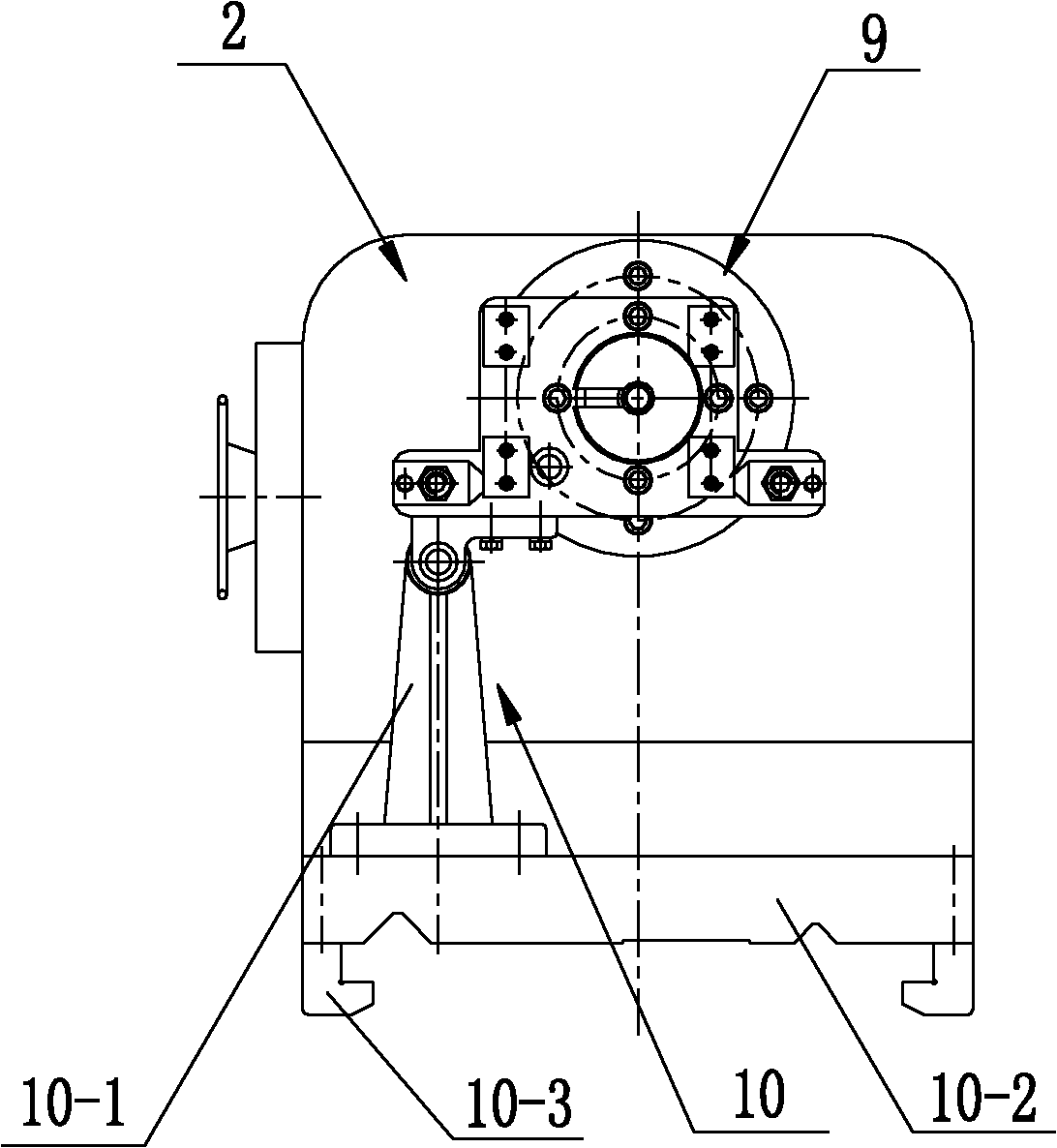

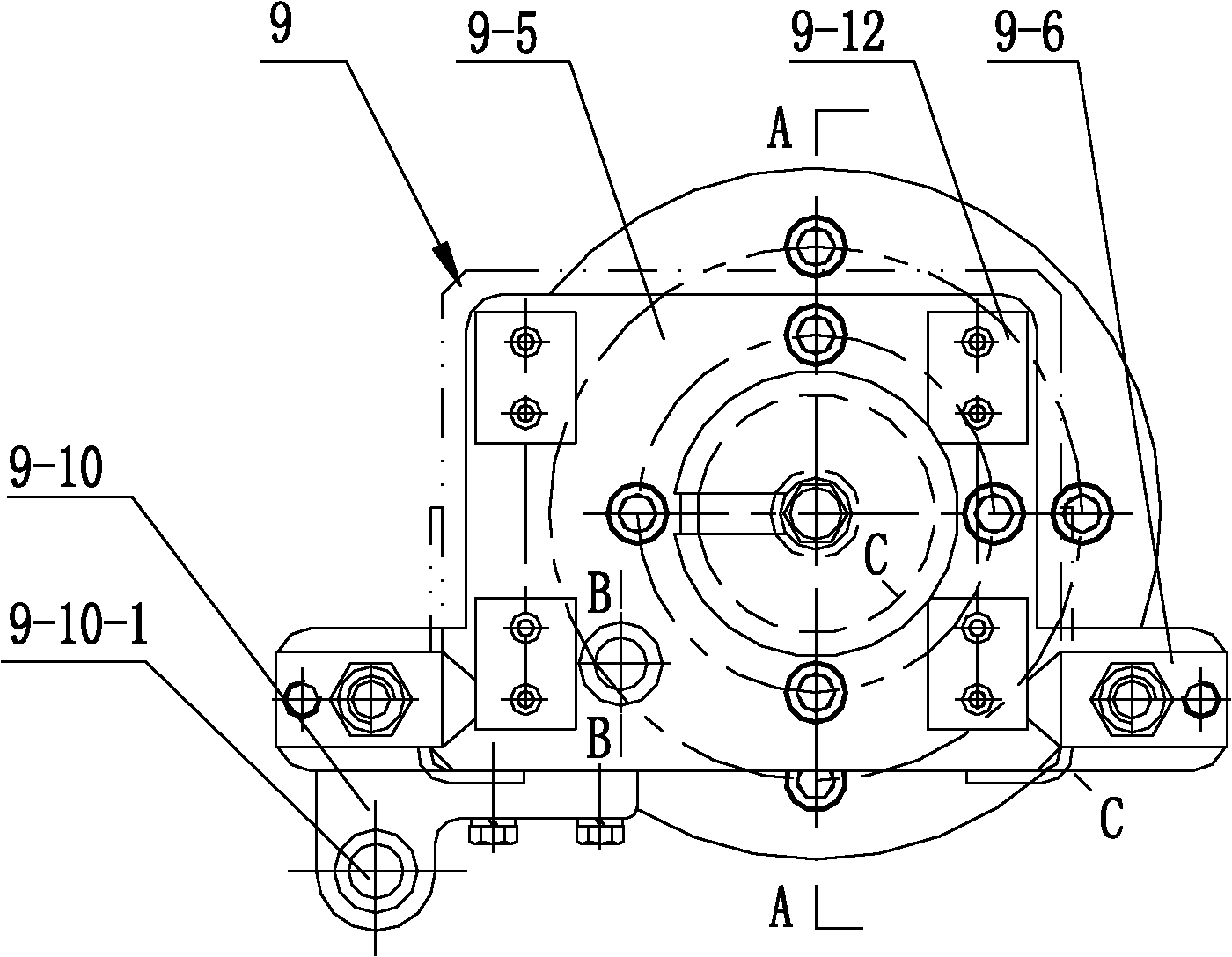

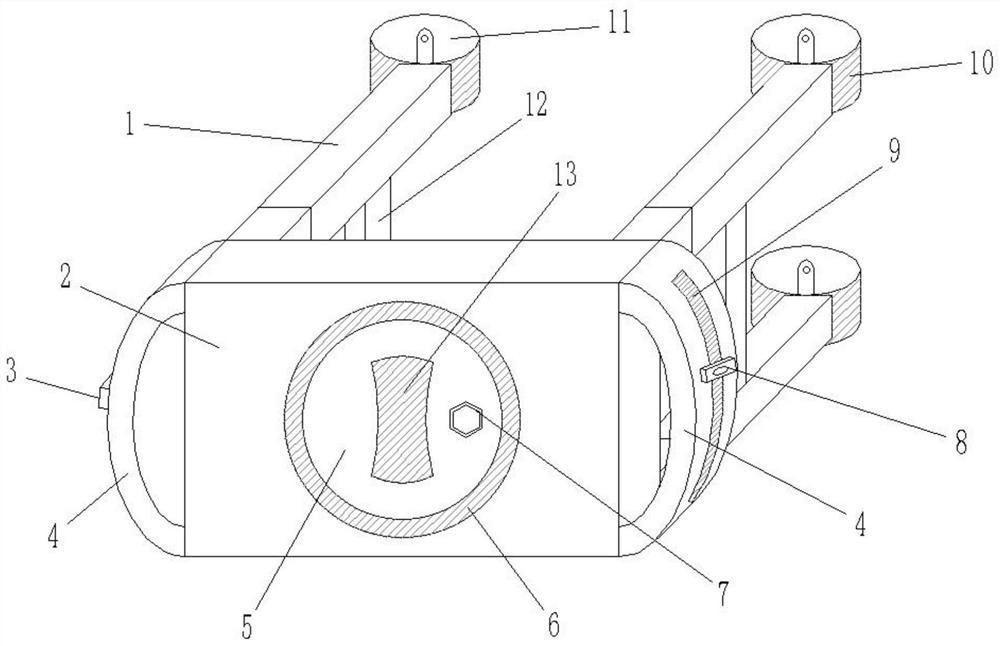

Welding tool for assembling electric hoist roller stand

InactiveCN101862932AMobile stabilityImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesLocknutEngineering

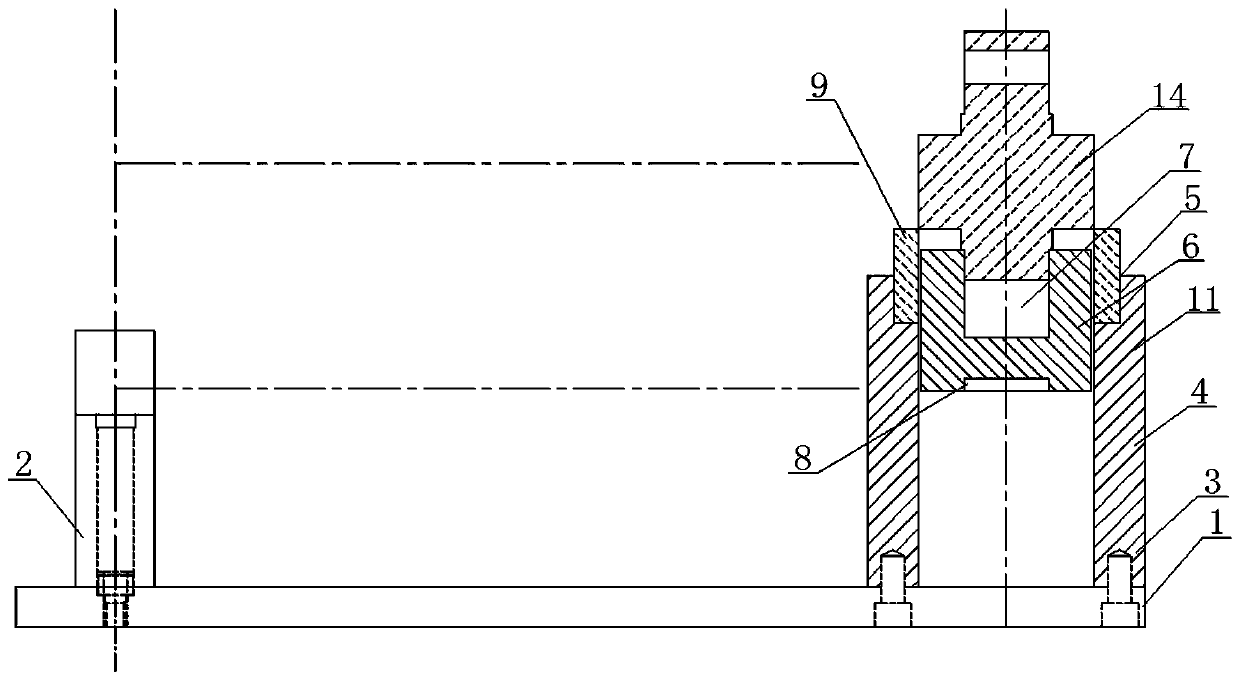

The invention relates to a welding tool for assembling an electric hoist roller stand. The welding tool is characterized by comprising a bed body, a bed body guide rail, a spindle box, a lead screw, a carriage, and a tailstock device, wherein the lead screw is connected with the spindle box; the carriage is arranged on the lead screw; the tailstock device is connected with the carriage; the tailstock device and a tailstock hook plate are arranged on the bed body guide rail through a tailstock connecting plate; a bearing side supporting mechanism is arranged on a headstock disc of the spindle box through a locking nut, a locking disc, and a connecting shaft; the bearing side supporting mechanism corresponds to a positioning device on the bed body guide rail on the lower part of the bearingside supporting mechanism; a reducer side supporting mechanism is arranged on the tailstock device through a locking nut, a locking disc, and a connecting shaft; and a positioning device is arranged on the tailstock device corresponding to the upper part of the reducer side supporting mechanism. Therefore, the spindle box can drive a workpiece to rotate during assembly, each welding surface of the workpiece is made at a downward welding position, the concentricity of a bearing side supporting plate and a reducer side supporting plate on two sides of the electric hoist roll stand is ensured, the welding quality is improved, the labor intensity of the operator is greatly reduced simultaneously, the operation safety is guaranteed, and the production cost is saved.

Owner:王丽君

Fire extinguishing device mounted in building

ActiveCN111821630AMobile stabilityCarry out firefighting operationsFire rescueStructural engineeringMechanical engineering

The invention discloses a fire extinguishing device mounted in a building. The device includes a machine body, fire source scanners, a fixing mechanism, a first switch, a roller, a first driving mechanism, and a central processor. The fire source scanners are arranged on the left and right layers of the machine body respectively; the fixing mechanism is used to fix a pipe head of a fire fighting pipeline, and is arranged in front of the machine body; the first switch is used to open and close a valve of the pipe head of the fire fighting pipeline, arranged in front of the machine body, and located on one side of the fixing mechanism; a plurality of temperature sensors are arranged on the surface of the roller densely, and the roller is connected with the rear surface of the machine body through a support leg; the first driving mechanism is used to drive the roller; and the central processor is connected with the fire source scanners, the first switch, the temperature sensors, and the first driving mechanism signally and separately. The device detects the temperature of the wall surface of a corridor continuously, and processes toward the direction of the higher temperature wall surface. When the temperature of the wall surface reaches a setting temperature, a switch in a fire hydrant is opened, so that fire extinguishing materials in the fire hydrant carry out fire extinguishing on a fire source.

Owner:JIANGSU SECURITY TECH CARRER ACADEMY

Conveniently used pipe inner wall coating device

The invention discloses a conveniently used pipe inner wall coating device. The conveniently used pipe inner wall coating device comprises a threaded rod and a support frame, wherein the support frameis arranged at the top of the threaded rod, the left end of the threaded rod is movably connected with a coating spray nozzle, the bottom of the coating spray nozzle is communicated with a coating pipe, the right end of the threaded rod is fixedly provided with a handle, and the surface of threaded rod is provided in a sleeve mode with a first moving block and threadedly connected with a threadedsleeve. By means of interaction of the threaded rod, the first moving block, a first rotating rod, a second moving block, a second fixed block, a second rotating rod, a moving rod, the support frameand wheels, the conveniently used pipe inner wall coating device solves the problem that an existing pipe inner wall coating device can only coat a single pipe during application to result in application restriction and inconvenience to users; meanwhile, the conveniently used pipe inner wall coating device has advantage of being convenient to use and capable of being applied to coating various pipes.

Owner:山东联硕木业有限公司

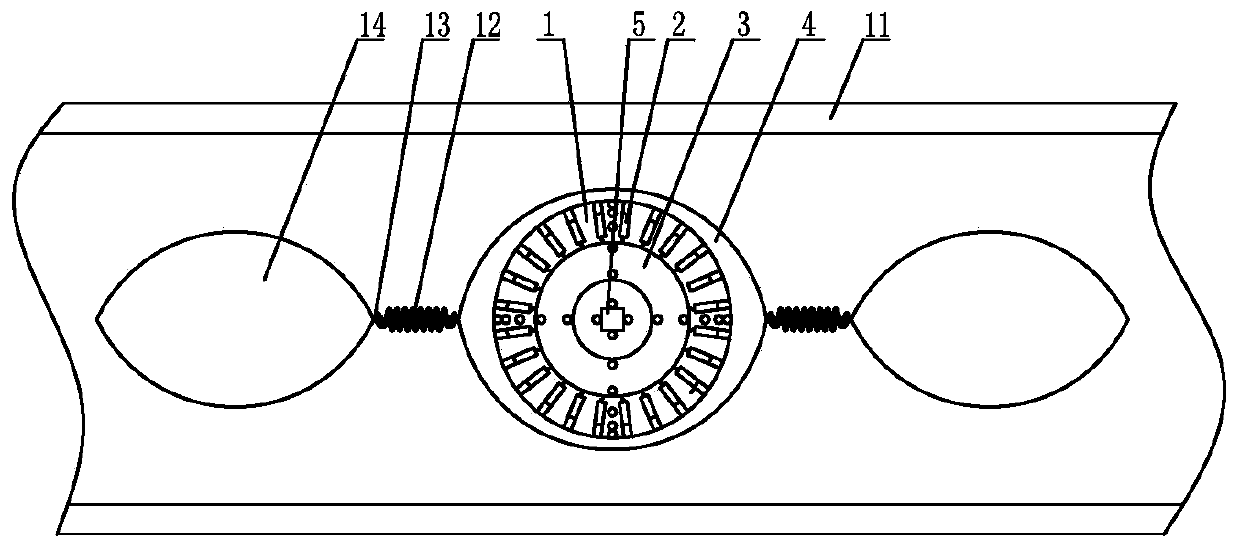

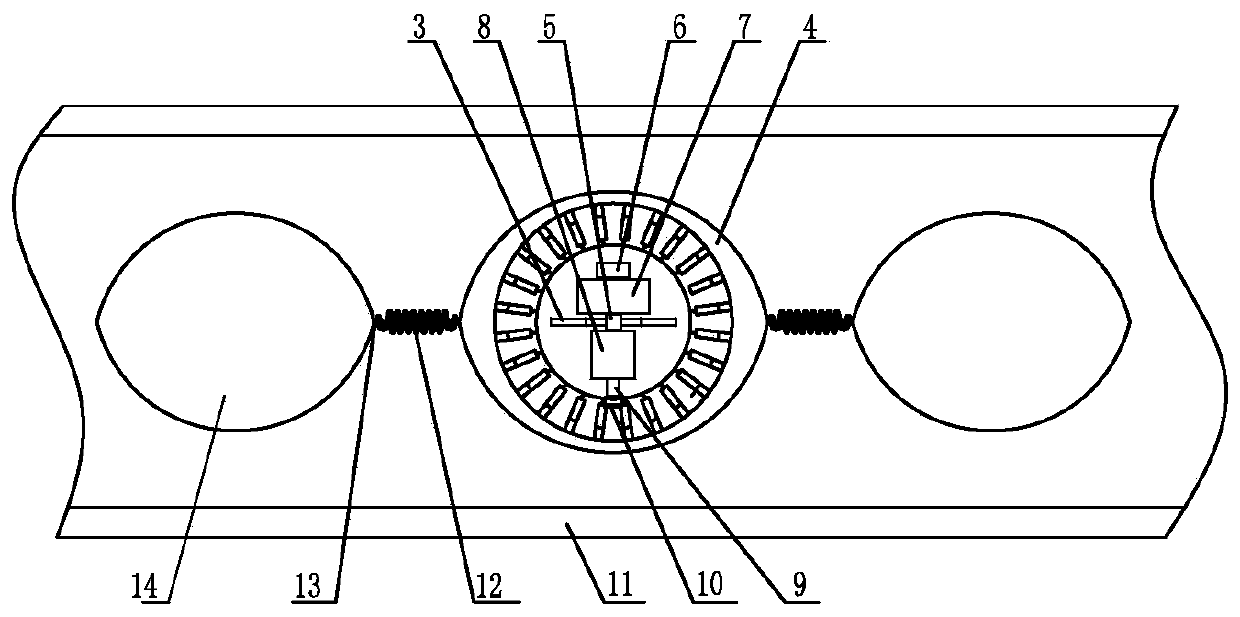

Pressure pipeline self-drifting ultrasonic inner detection intelligent ball

PendingCN110470739AEasy to operateMobile stabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesNavigation by speed/acceleration measurementsEngineeringUltrasound probe

The invention relates to the field of special equipment and aims at providing a pressure pipeline self-drifting ultrasonic inner detection intelligent ball with the characteristics of convenient operation and high detection precision. The pressure pipeline self-drifting ultrasonic inner detection intelligent ball in the technical scheme is characterized by comprising two balance balls and a detection ball connected between the two balance balls through a traction rope, wherein the detection ball includes a spherical inner shell, a signal processing unit arranged in the inner shell, a pluralityof ultrasonic probes evenly distributed on the inner shell, and an outer shell coating the inner shell; the signal processing unit includes an embedded PC platform and a multichannel ultrasonic card,an accelerometer, a magnetometer, a memory and a high-performance battery connected to an embedded PC platform respectively; and the embedded PC platform is also connected to an ultrasonic probe through a wire.

Owner:ZHEJIANG PROVINCIAL SPECIAL EQUIP INSPECTION & RES INST

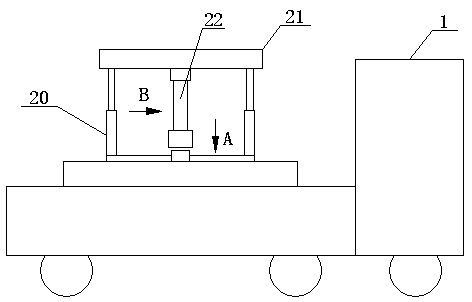

Vehicle-mounted movable studio

ActiveCN107618418AStable structureMobile stabilityWorkshop/display transportationTextileMechanical engineering

A vehicle-mounted movable studio comprises a vehicle body. A vertical first rotating shaft with a power device is fixedly installed in the middle of the top of a vehicle hopper of the vehicle body. Two horizontal connecting rods are fixedly installed at the top end of the first rotating shaft and symmetrically distributed with the first rotating shaft as the center. The opposite side ends of the two connecting rods are each movably provided with a slide rod. Two horizontal supporting plates are arranged above the vehicle hopper of the vehicle body. Fixed rods are fixedly installed on the opposite sides of the two supporting plates respectively and are parallel to each other. A first through groove is formed in the top side of each fixed rod. Each slide block can be inserted in the corresponding first through groove and slide along the first through groove. The length of a projection screen can be controlled, projections of different image sizes can all be displayed on the projection screen, light can be shielded for the projection screen through a telescopic plate, it is avoided that in the day, images projected on the projection cloth are not clear due to light and other reasons,and it is avoided that the watching effect is influenced.

Owner:临沂临港投资管理有限公司

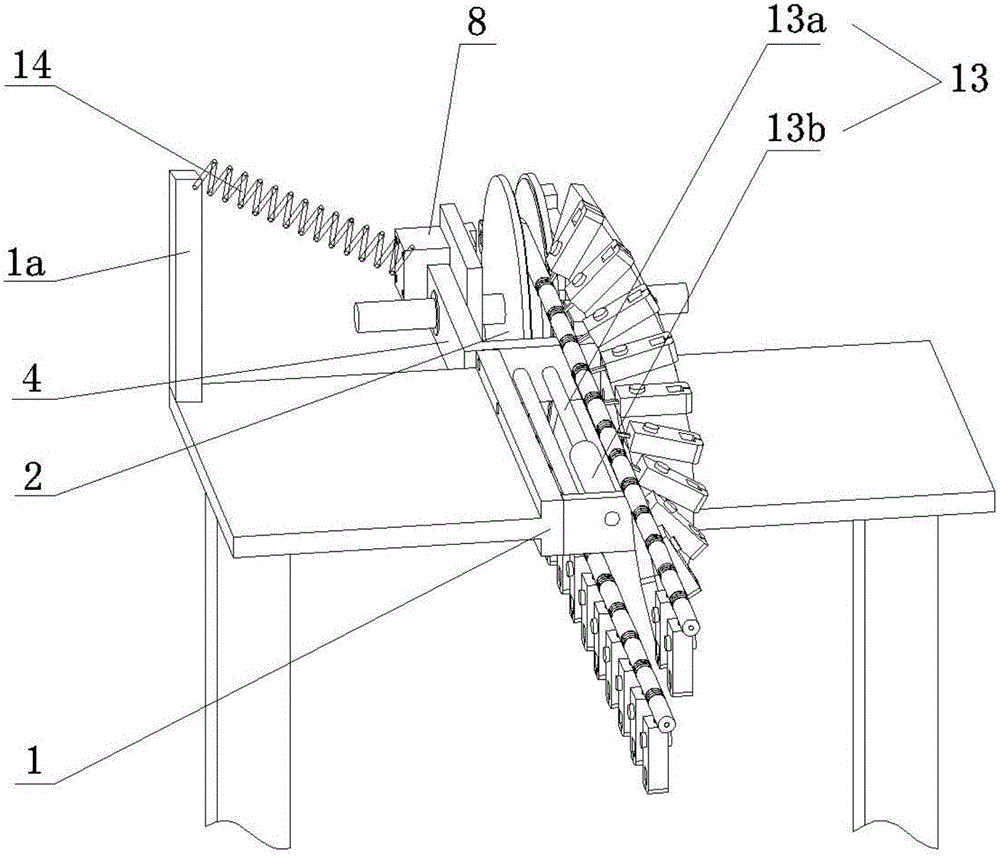

Full-automatic wire winding production line

PendingCN108792781AHigh degree of automationMobile stabilityFilament handlingConveyor partsCylinder blockConductor Coil

The invention relates to a full-automatic wire winding production line. The full-automatic wire winding production line comprises a welding wire shaft disc loading machine, a multi-shaft robot and a layer winding automatic unloading machine; the welding wire shaft disc loading machine comprises a base, an electric control cabinet, a rotating storage frame, an ejecting mechanism, an adjusting mechanism and a feeding mechanism; the adjusting mechanism comprises a substrate; a pushing cylinder is arranged on the electric control cabinet; a piston rod of the pushing cylinder is fixedly connected with a cylinder block of a pressing cylinder; a piston rod of the pressing cylinder is fixedly connected with a cylinder block of a rotating cylinder; and a spring dowel pin is arranged at the bottom of a piston rod of the rotating cylinder. In the full-automatic wire winding production line, each structure flexibly cooperates with the multi-shaft robot to realize an automatic structure of integrating such procedures as disc loading and unloading and locking of welding wire shafts, fixation of welding wires, shearing of the welding wires, bending, head end hole penetration of the welding wiresbefore wire winding, wire winding, tail end fixation of the welding wires after wire winding and unloading of the welding wire shafts, so that full-automatic production is achieved, and the purposes of saving the labor cost and improving the production efficiency and the production quality are achieved.

Owner:德州市立尊焊丝有限公司

Metallurgy and casting equipment being convenient to move

The invention discloses metallurgy and casting equipment being convenient to move. The metallurgy and casting equipment comprises an accommodating box body. A casting equipment body, matching the accommodating box body, is placed in the interior of the accommodating box body. The bottom surface of the accommodating box body is fixedly connected with a movable box body. The middle part on the innertop wall of the movable box body is fixedly connected with a motor. A movable board is arranged in the interior of the movable box body. The left side surface and the right side surface of the movable board are both equipped with second communicating grooves. The middle part on the upper surface of the movable board is fixedly embedded with a threaded pipe. The upper surface of the movable boardis fixedly embedded with two symmetrical sliding pipes. By arranging a rubber pad, the metallurgy and casting equipment is more stable in a non-moving state. By arranging a movable rod and using in conjunction with rolling wheels and third pin rolls, the equipment moves more stably. By arranging first communicating grooves, movable rods are more convenient to rotate in order to effectively ensurethat the equipment can rapidly move. Working efficiency is increased.

Owner:蔡敬东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com