Bracket for driving multi-azimuth monitoring of camera

A multi-directional, camera technology, applied in the field of camera brackets, can solve problems such as increased cost, impact on monitoring quality, degree of monitoring angle image size, unfavorable camera control, etc., and achieves stable operation, stable movement, and reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

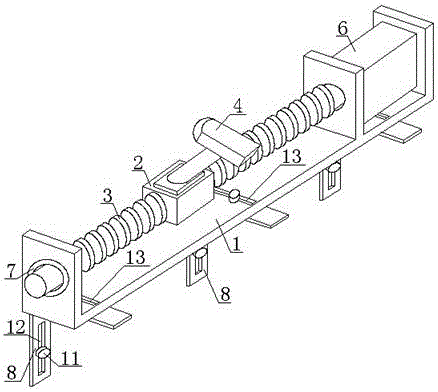

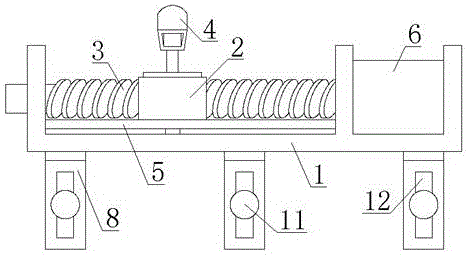

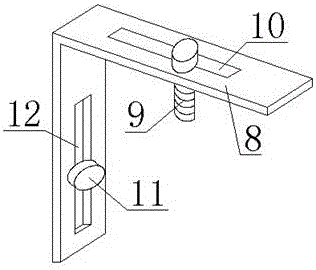

[0023] A support 1 for driving camera 4 multi-directional monitoring, such as Figure 1 to Figure 3 As shown, it includes a base 1 and a right-angle bracket 8 for fixing the base 1. The base 1 is provided with an adjustment groove 10, and the right-angle bracket 8 is provided with a b adjustment groove 13 adapted to the a adjustment groove 10, and The a adjustment groove 10 is connected with the b adjustment groove 13 through the a bolt 9, and a slide bar is provided on the base 1, and a mobile support 2 is sleeved on the slide bar, and a guide plate 5 is provided at the bottom of the mobile support 2 to guide The board 5 is installed on the base 1, and the camera 4 is installed on the mobile support 2.

[0024] During installation, first align the a adjustment groove 10 with the b adjustment groove 13, connect the base 1 with the right-angle bracket 8 through the cooperation of the a bolt 9 and the nut, and then install the right-angle bracket 8 on the wall. The base 1 is pr...

Embodiment 2

[0026] This embodiment is further optimized on the basis of the above embodiments, such as Figure 1 to Figure 3 As shown, further, the sliding rod is a screw rod 3, the moving support 2 is provided with an internal thread adapted to the screw rod 3, and the screw rod 3 and the moving support 2 are connected by threads. The sliding rod is set as the screw rod 3 and connected with the mobile support 2 through threads, so that the precise positioning of the camera 4 on the screw rod 3 can be realized.

Embodiment 3

[0028] This embodiment is further optimized on the basis of the above embodiments, such as Figure 1 to Figure 3 As shown, further, a drive motor 6 is provided on one side of the base 1 , and the output shaft of the drive motor 6 is connected to the screw rod 3 . The driving motor 6 can drive the screw to rotate, and can automatically control the movement of the camera 4 on the screw 3, thereby facilitating the operation of the operator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com