Pressure pipeline self-drifting ultrasonic inner detection intelligent ball

A technology for pressure pipelines and smart balls, which can be used in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. problems, to achieve the effect of convenient operation, safe operation, and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

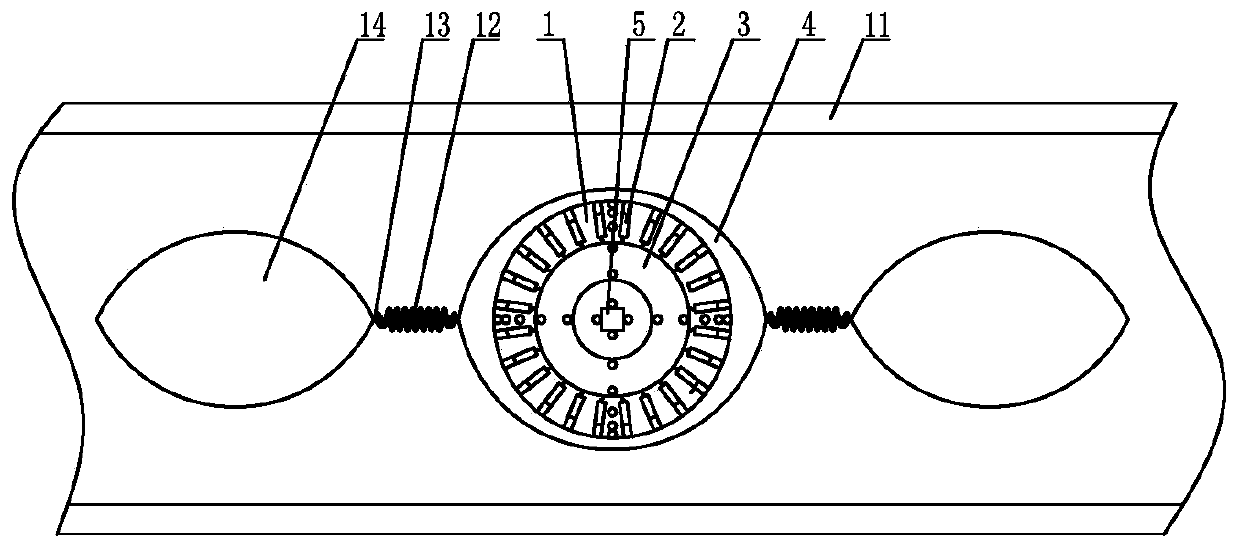

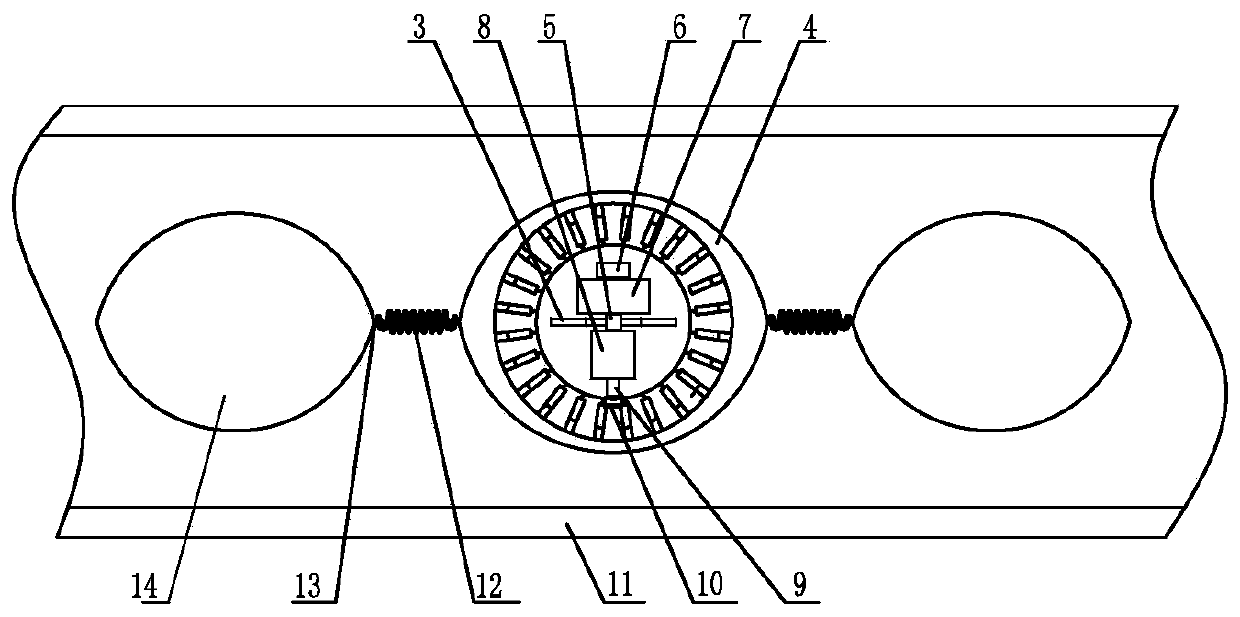

[0016] Such as figure 1 As shown, a pressure pipeline self-floating ultrasonic internal detection smart ball includes a detection ball and two balance balls 14 . Both the detection ball and the balance ball are ellipsoidal, so as to keep the drifting attitude stable. The detection ball is arranged between two balance balls, and the long axis ends of the detection ball and the balance ball are connected by a spring 12, and the detection ball and the balance ball are provided with a pull ring 13 for fixing the spring. Soft, can facilitate smart ball to pass through the elbow position of pipeline 11.

[0017] The detection ball includes a spherical inner shell 1, a signal processing unit arranged in the inner shell, several ultrasonic probes 2 arranged on the spherical inner shell, and an ellipsoidal ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com