Full-automatic wire winding production line

A production line, fully automatic technology, applied in the direction of conveying filamentous materials, conveyor objects, labels, etc., can solve the problems of not being able to adapt to industrial upgrading, difficult to reduce production costs, and unstable product quality, so as to improve production efficiency and The effect of production quality, saving labor cost, and stable movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

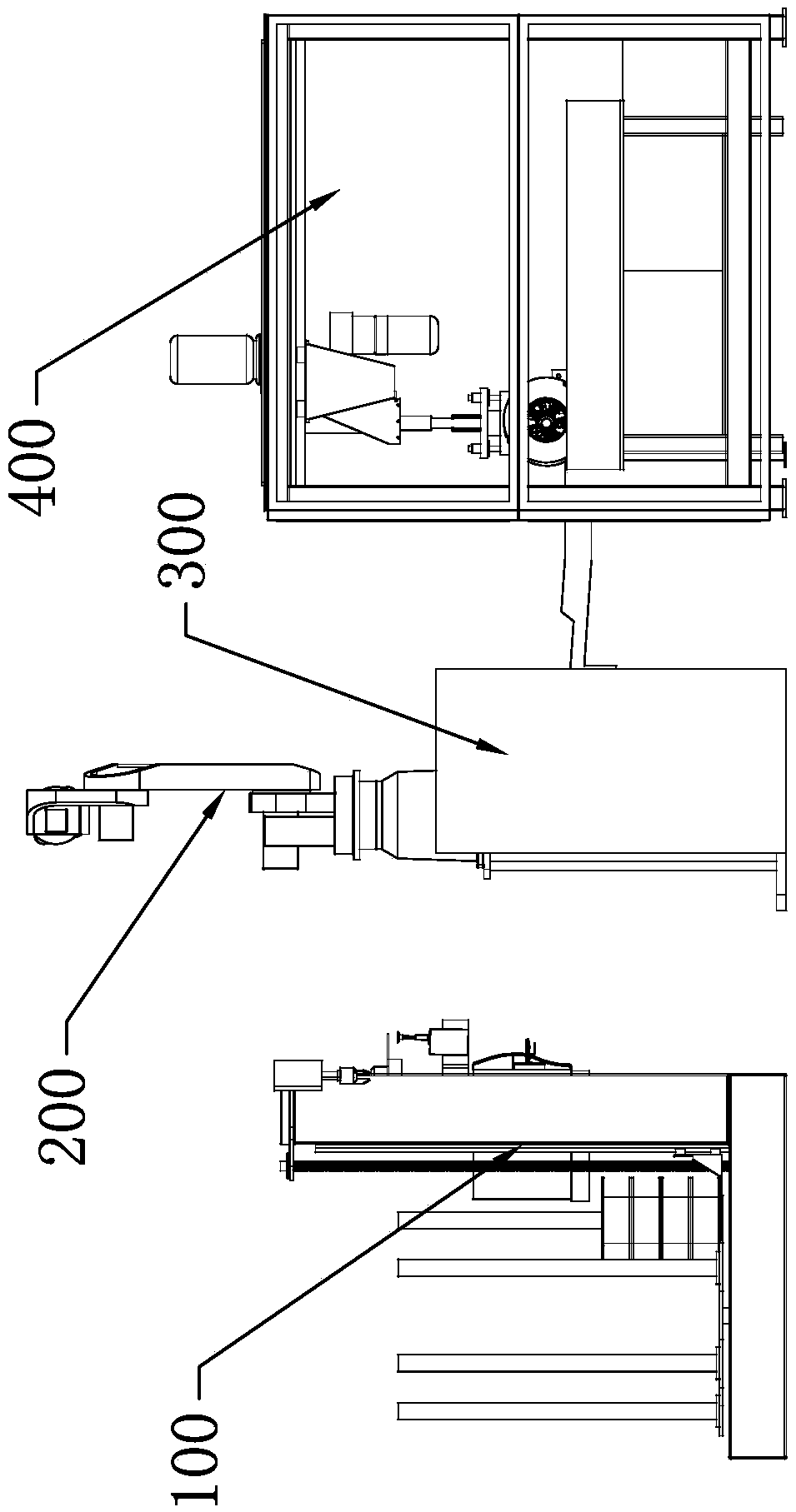

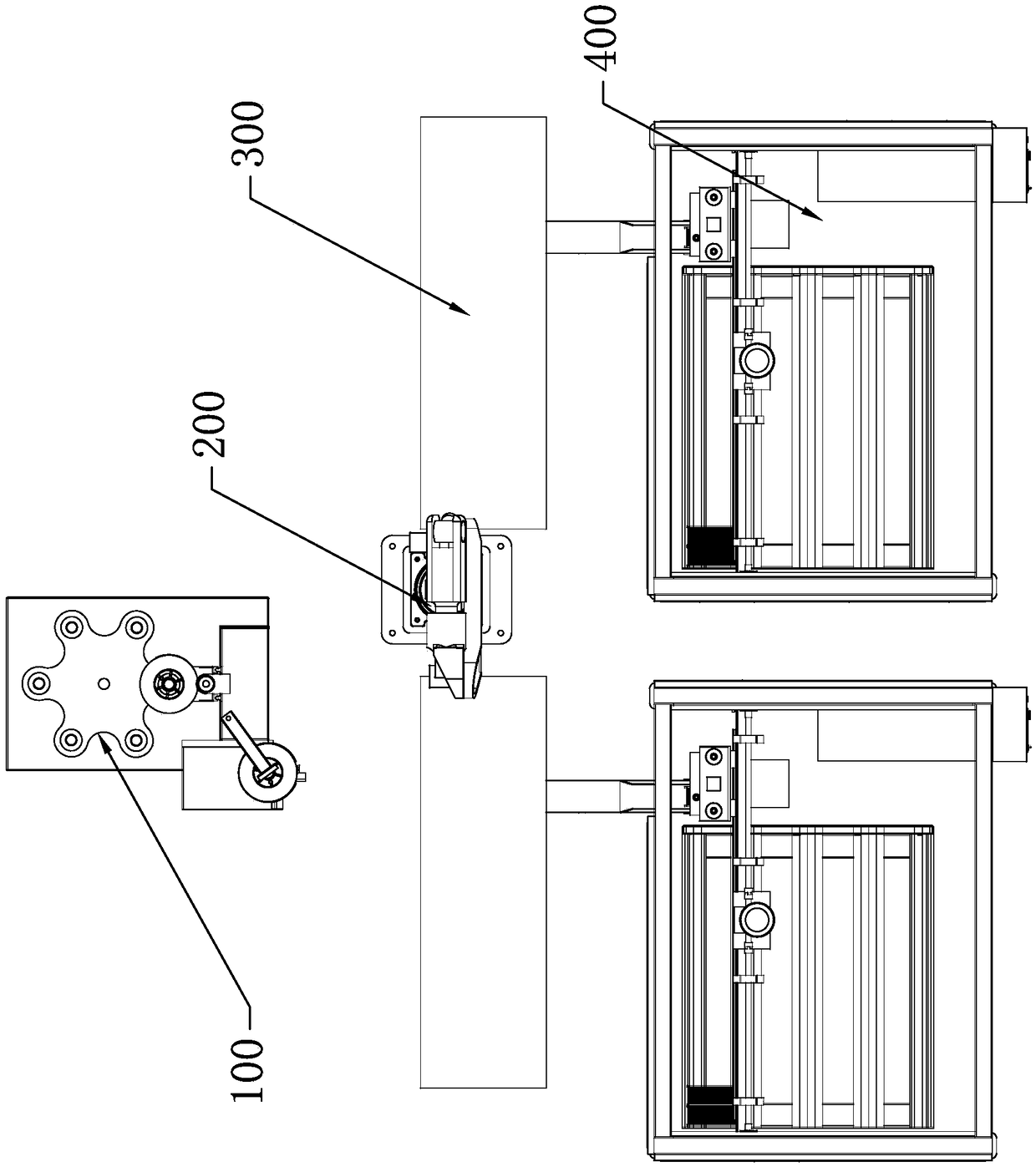

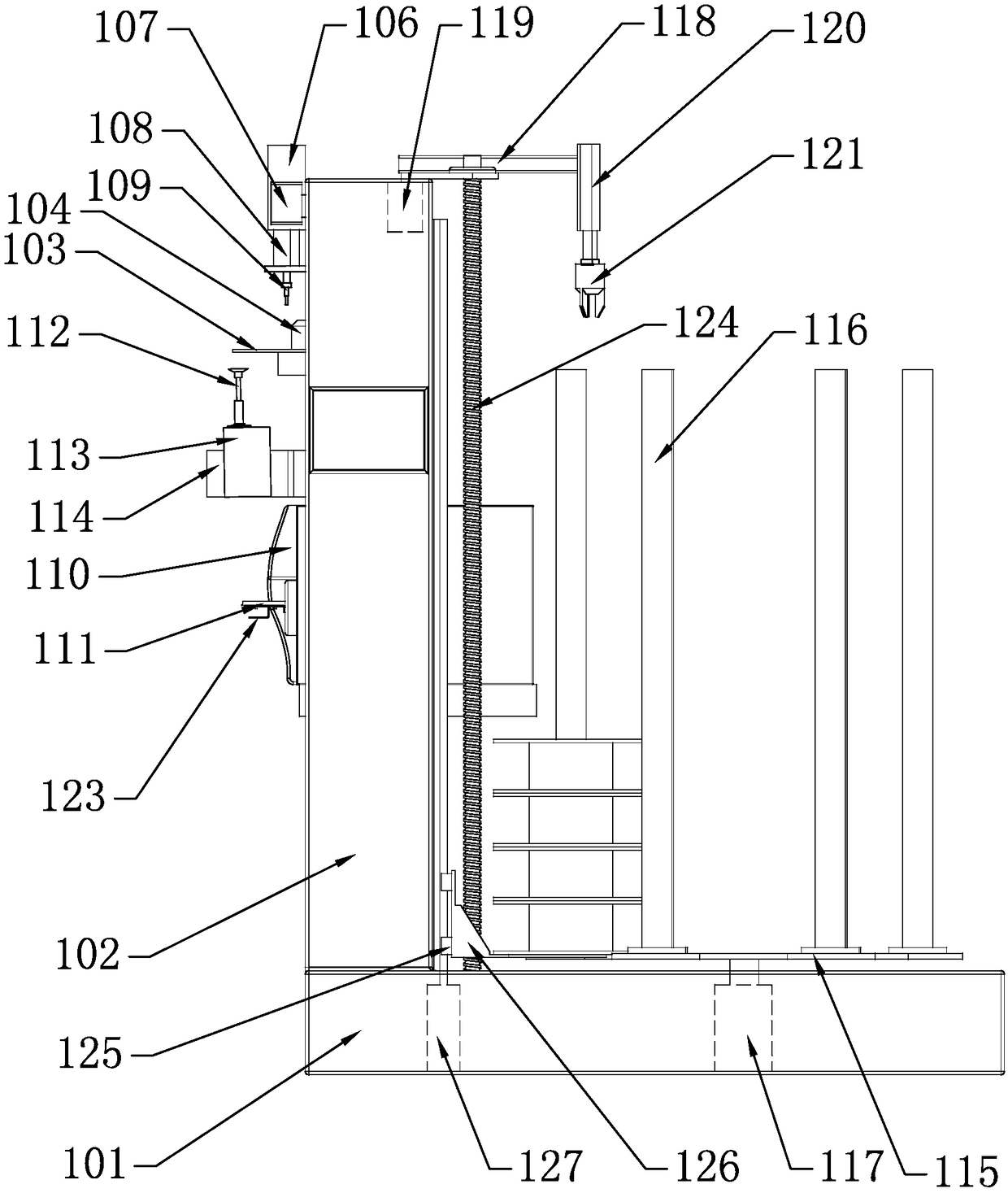

[0030] Such as Figure 1-Figure 10As shown in , the fully automatic wire winding production line in this embodiment includes a welding wire shaft loading machine 100 for storing welding wire shafts and adjusting the state of the welding wire shafts, a multi-axis robot 200, a layer winding machine 300 for winding wires on the welding wire shafts, and The layer-winding automatic unloading machine 400 for the welding wire shaft to be unloaded and transferred, the multi-axis robot 200 moves the welding wire shaft on the welding wire shaft winding machine 100 to the layer winding machine 300; the welding wire shaft winding machine 100 includes a base 101, an electric The control cabinet 102 and the rotating storage rack, the lifting mechanism that lifts the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com