Cylinder-moving conveying type packaging bag drier

A technology for moving conveying and packaging bags, applied in dryers, progressive dryers, packaging, etc., can solve problems such as troublesome installation and disassembly, limited effect, uneven heating, etc., and achieve convenient disassembly and installation, convenient replacement and maintenance, and mobile fast and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

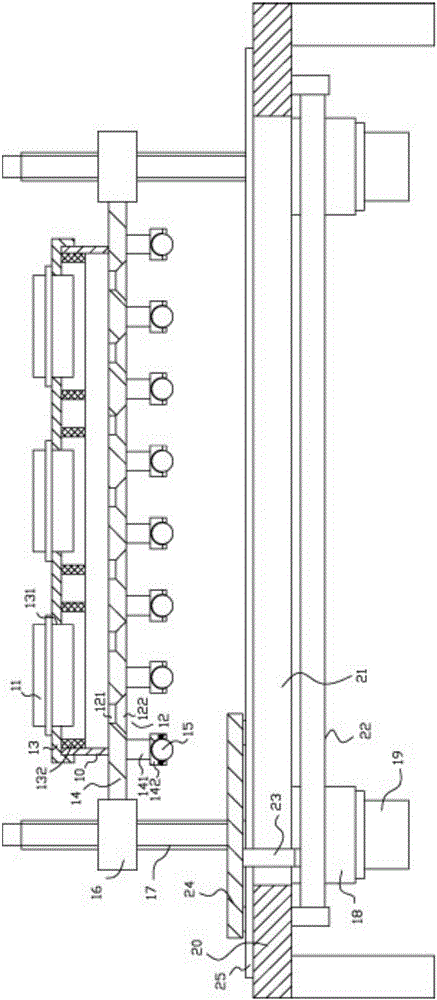

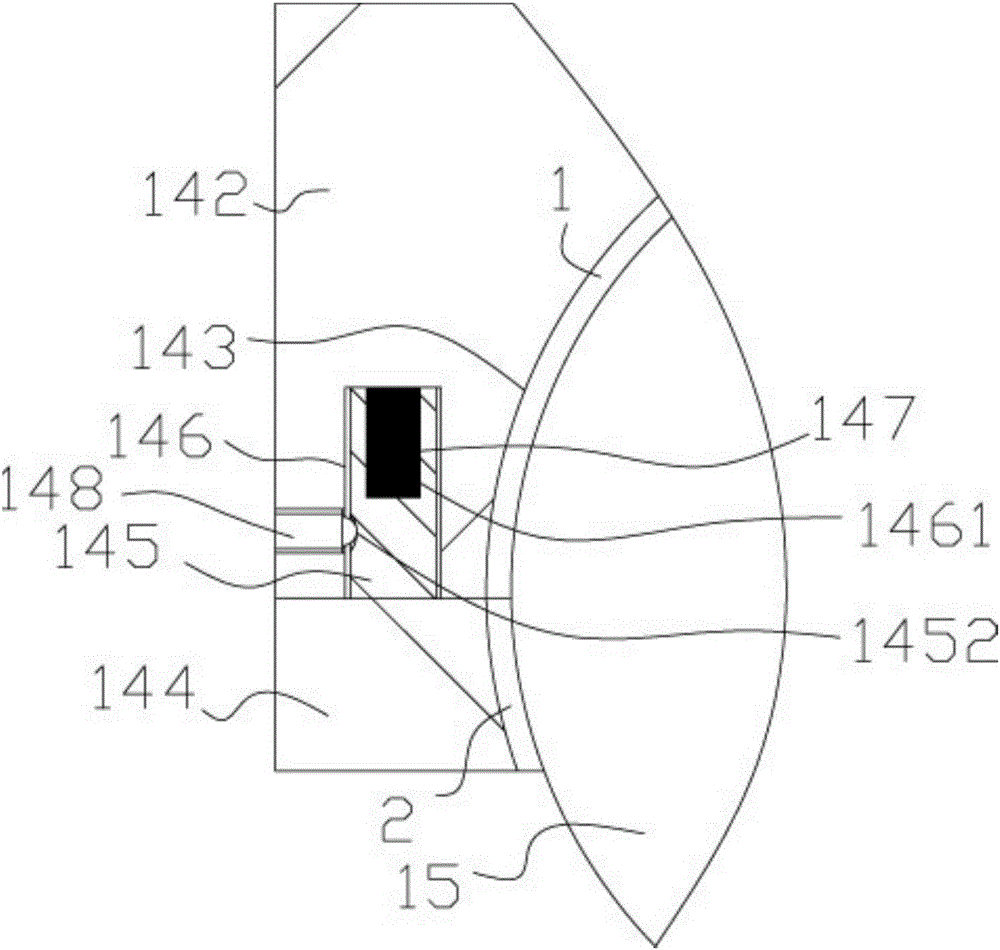

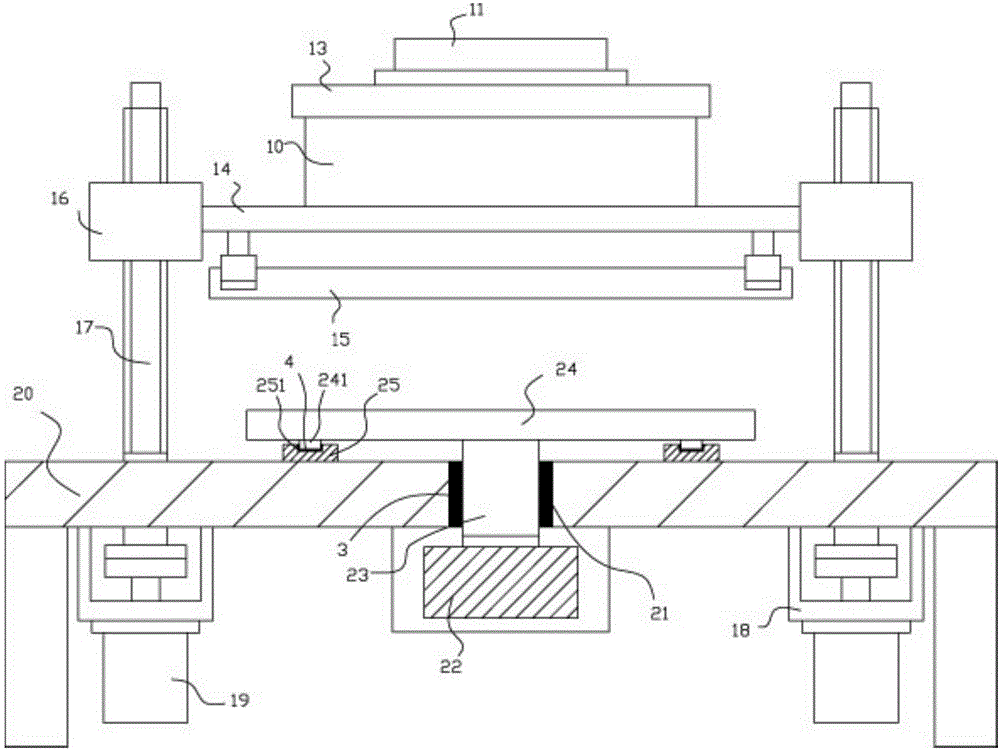

[0028] Example: see Figure 1 to Figure 3 As shown, a cylinder moving conveying type packaging bag dryer includes a frame 20 and a main board body 14. The middle part of the top plate of the frame 20 has a transverse movement channel 21, and the bottom surface of the top plate of the frame 20 is fixed with or without Rod cylinder 22, guide connecting plate 23 is fixed on the slide block of rodless cylinder 22, and guide connecting plate 23 stretches out laterally to move channel 21 upwards and is fixed with upper horizontal plate 24, and the left and right sides of the bottom surface of upper horizontal plate 24 are fixed Guide sliding block 241 is arranged, and guide track 25 is fixed on the left and right sides of the top surface of the top plate of frame 20, and the top surface of guide track 25 has slide groove 251, and guide slide block 241 is inserted and sleeved in slide groove 251;

[0029] The left and right ends of the front and rear sides of the mainboard body 14 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com