Robot chassis with anti-sliding structure

A robot and chassis technology, which is applied in the field of robots, can solve the problems of high stability requirements of food delivery robots and the inability of food delivery machines to move, and achieve the effect of smooth movement and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

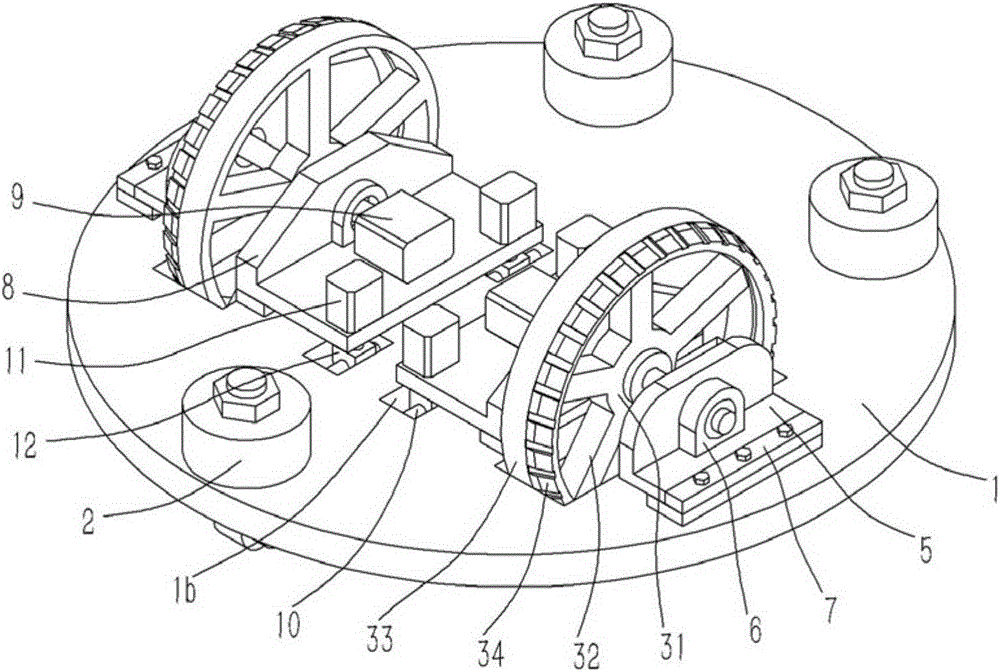

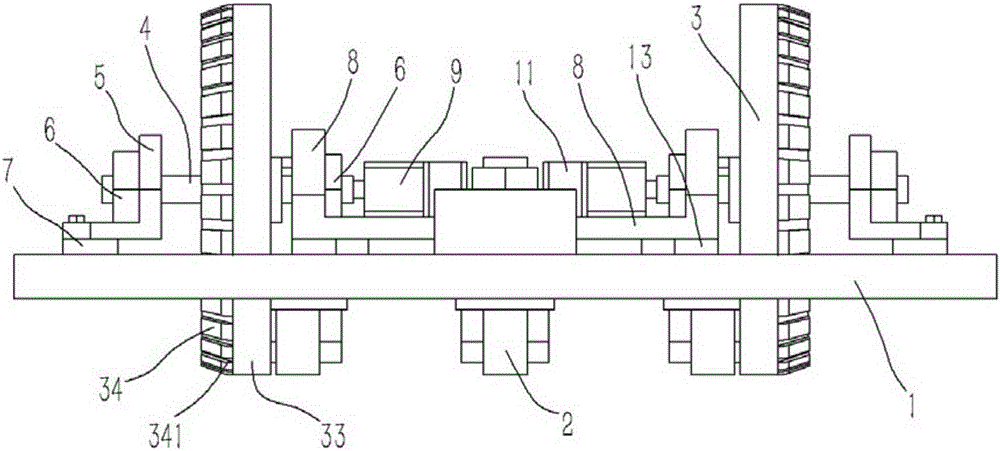

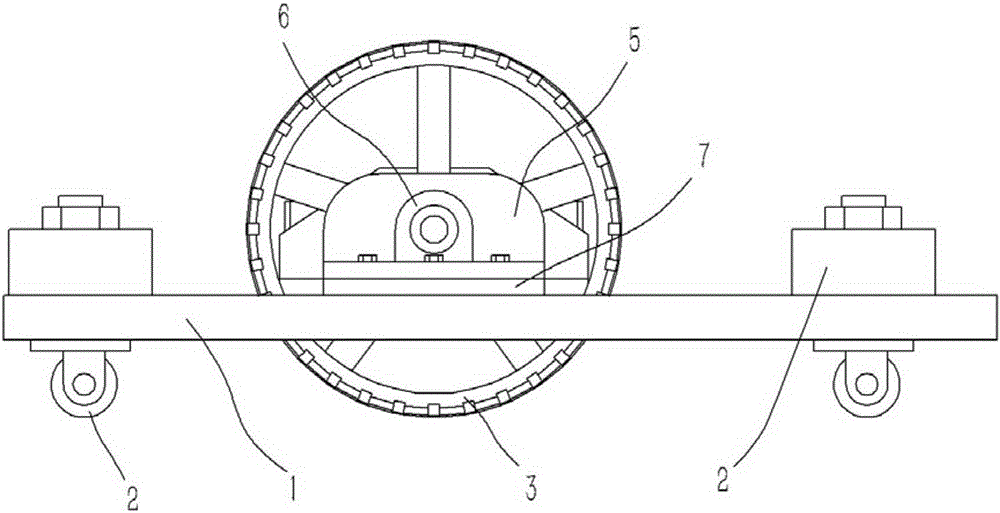

[0021] Example: see Figures 1 to 4 As shown, a robot chassis with an anti-slip structure includes a chassis 1, a plurality of universal wheels 2 are fixed on the periphery of the chassis 1, rectangular walking wheel placement grooves 1a are formed on both sides of the chassis 1, and the walking wheels of the chassis 1 are placed Groove 1a is inserted with walking wheel 3, and walking wheel 3 comprises hub portion 31, and a plurality of spokes 32 are formed on hub portion 31, and the outer end of spoke 32 is fixed on wear-resistant rim 33, and the side of wear-resistant rim 33 An anti-skid rim 34 inclined toward the center of the walking wheel 3 is formed on the top; a horizontal support shaft 4 is inserted and fixed on the hub portion 31 of the traveling wheel 3, and the outer end of the support shaft 4 is hinged to the L-shaped outer bracket 5 through the bearing seat 6. On the top, the outer bracket 5 is hinged on the chassis 1 through the hinge 7, and the inner side end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com