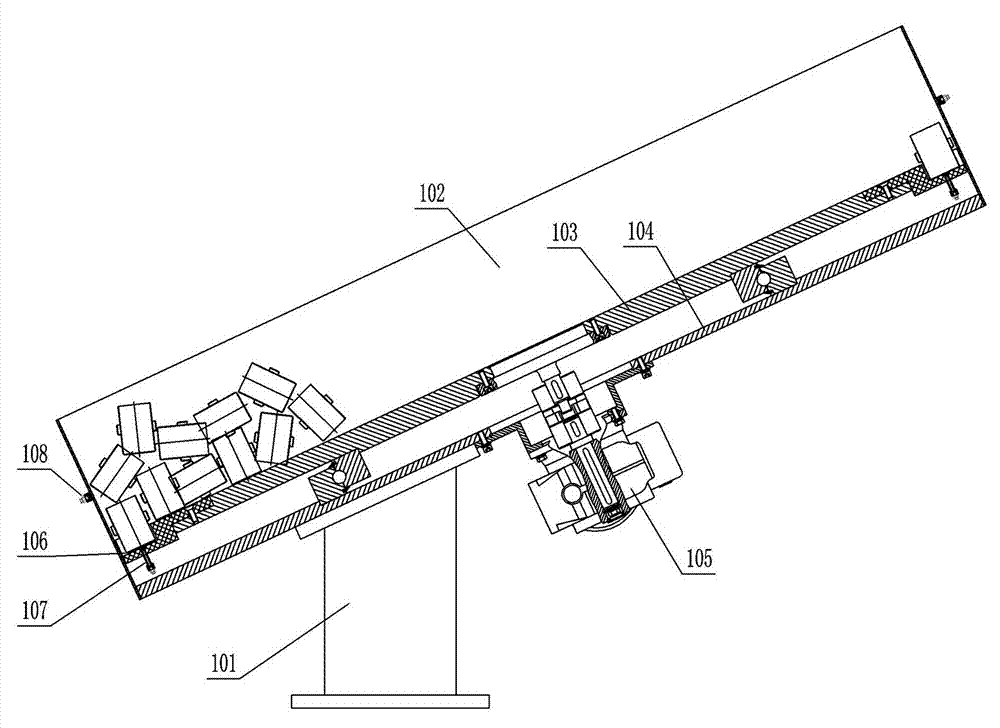

Centrifugal cover settling device

A cap unscrambler and centrifugal technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as tilt, misalignment, difficulty in ensuring the sieve cap air nozzle, and incapable of cap screening, etc., to achieve the effect of smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

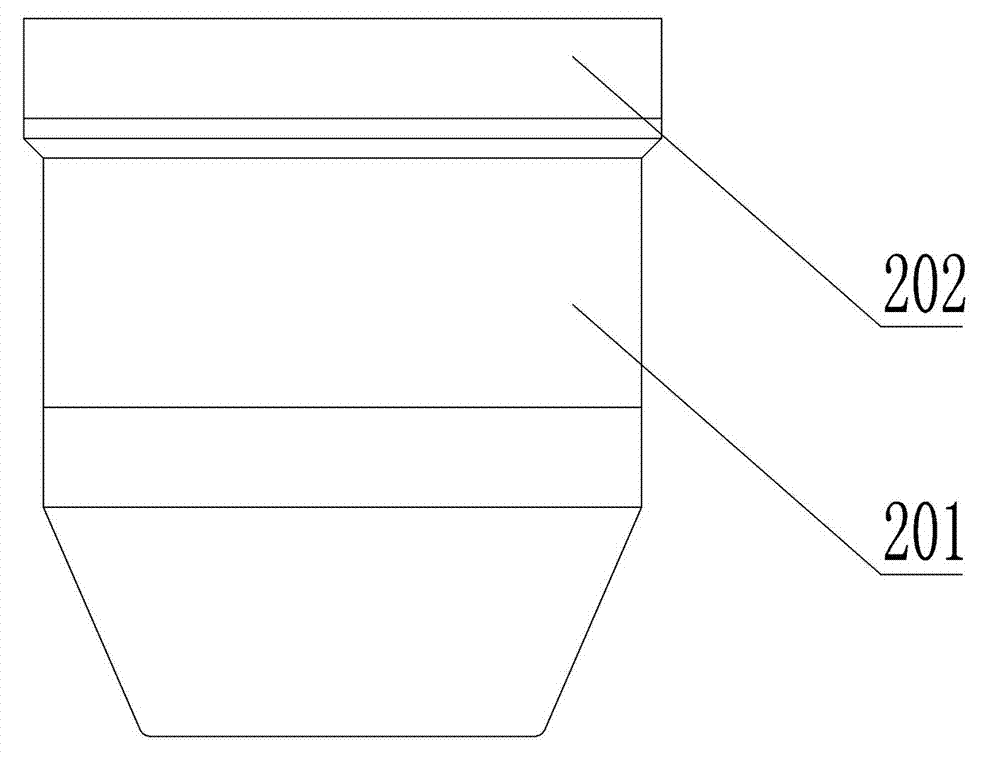

[0019] The centrifugal cap unscrambler of the present invention comprises a turntable 1 inside the cylinder body of the cap unscrambler, and cap grooves 2 matching the shape of the bottle caps are evenly distributed on the circumference of the turntable 1, and there are bottle caps in the cap groove 2. Send into the guide device 5 of the production line, the guide device 5 extends into the inside of the cap sorter cylinder and communicates with the turntable 1. The turntable 1 includes an upper slot plate 11 and a lower slot plate 12 connected together, and the upper slot plate 11 and the lower groove plate 12 have through grooves at the relative positions, and they are combined together to form a complete cover groove shape. There is a groove 13 at the junction of the two groove plates 11 and 12 close to the cover groove 2, and the groove 13 communicates with the cover groove 2 , there is at least one sieve cover air hole 3 at the bottom of the cover tank 2, the sieve cover ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com