Semiautomatic commodity clamping machine

A semi-automatic, commodity technology, applied in the field of machinery, it can solve the problems of complex structure and high cost, and achieve the effect of smooth movement and rapid and powerful response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

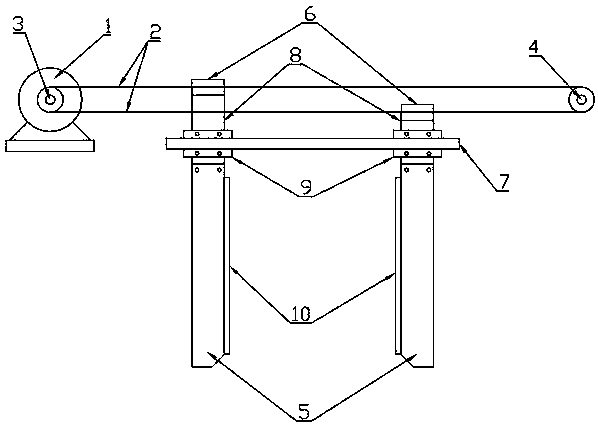

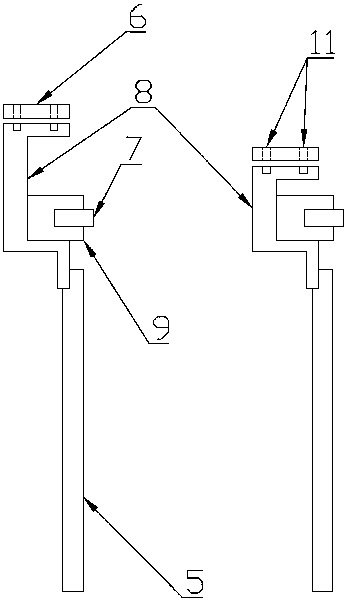

[0019] refer to figure 1 and figure 2 , a semi-automatic product clamping machine provided by the present invention, which includes the following mechanisms: a drive motor 1, a synchronous belt 2, a synchronous pulley set, a clamping component, and a linear guide rail 7; the synchronous pulley set is synchronous Belt driving wheel 3 and synchronous belt driven wheel 4; the synchronous belt driving wheel 3 is connected to the output shaft of the drive motor 1; the clamping part consists of two rigid rods 5, two transmission parts and two linear guide rails It is composed of 9 slides; the transmission parts are divided into synchronous belt pressing plate 6 and moving connecting block 8, synchronous belt pressing plate 6, synchronous belt 2 and moving connecting block 8 are in contact with each other and connected by screws 11, and moving connecting block 8 is made of screws The linear guide rail slider 9 is connected, and the bottom end of the mobile connection block 8 is con...

Embodiment 2

[0028] refer to figure 1 and figure 2 , a semi-automatic product clamping machine provided by the present invention, which includes the following mechanisms: a drive motor 1, a timing belt 2, a synchronous pulley set, a clamping component, and a linear guide rail 7; the synchronous pulley set is synchronous Belt driving wheel 3 and synchronous belt driven wheel 4; the synchronous belt driving wheel 3 is connected to the output shaft of the drive motor 1; the clamping part consists of two rigid rods 5, two transmission parts and two linear guide rails It is composed of 9 slides; the transmission parts are divided into synchronous belt pressing plate 6 and moving connecting block 8, synchronous belt pressing plate 6, synchronous belt 2 and moving connecting block 8 are in contact with each other and connected by screws 11, and moving connecting block 8 is made of screws The linear guide rail slider 9 is connected, and the bottom end of the mobile connection block 8 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com