Automatic taking mechanism for mold products

An automatic retrieving and mold manufacturing technology, which is applied in the field of automatic retrieving mechanisms for mold products, can solve problems such as danger, safety hazards, insecurity, etc., and achieve convenient and safe grasping, stable movement, and good effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

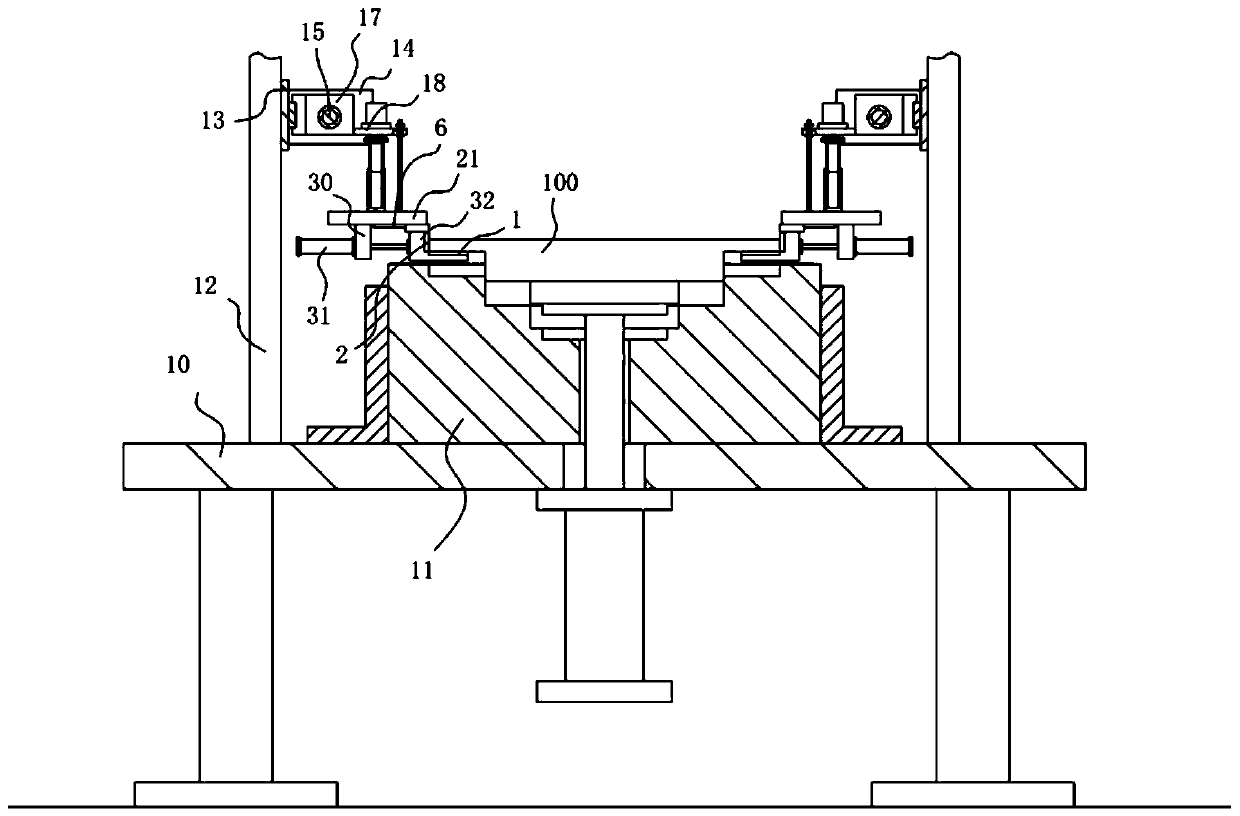

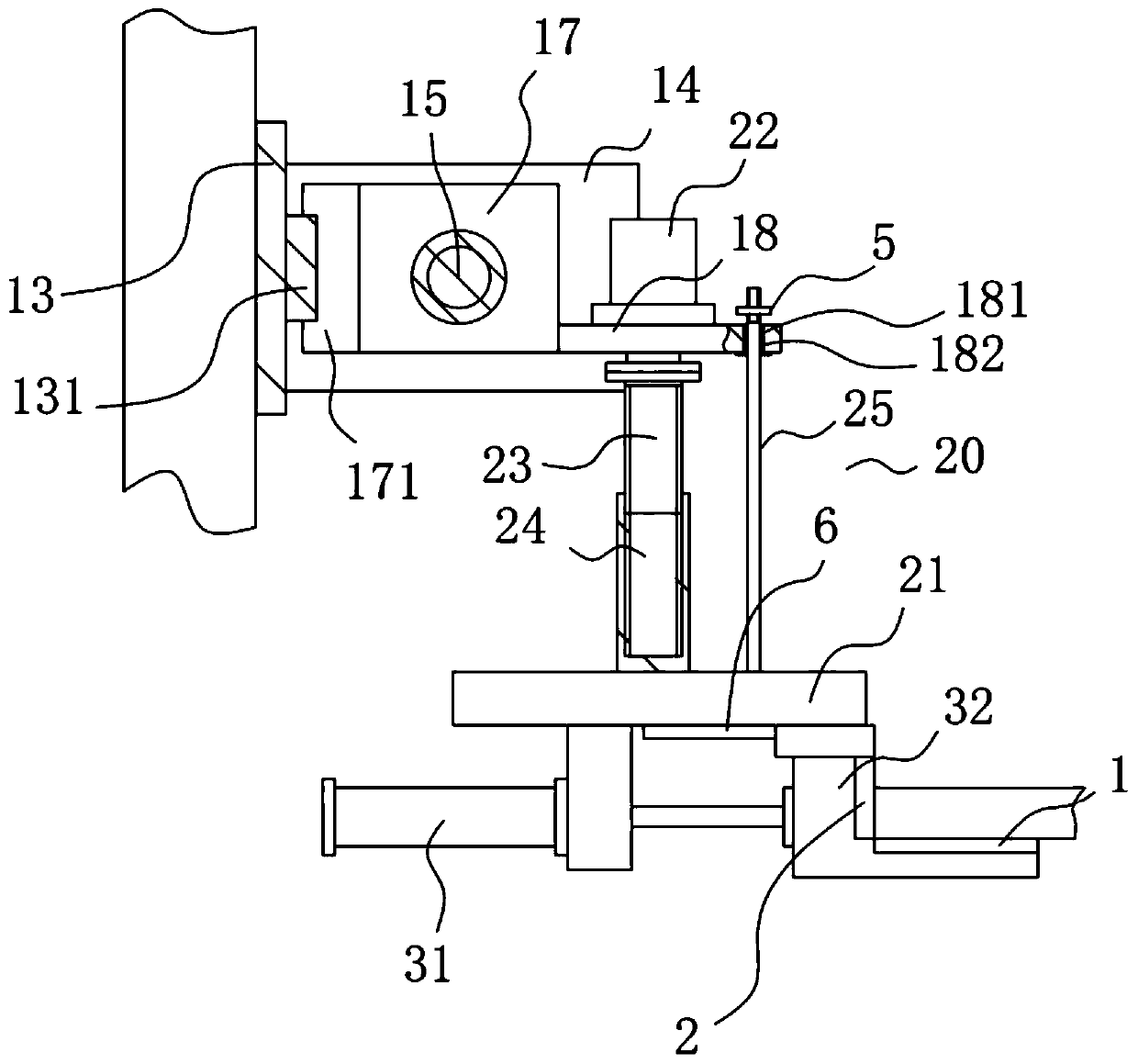

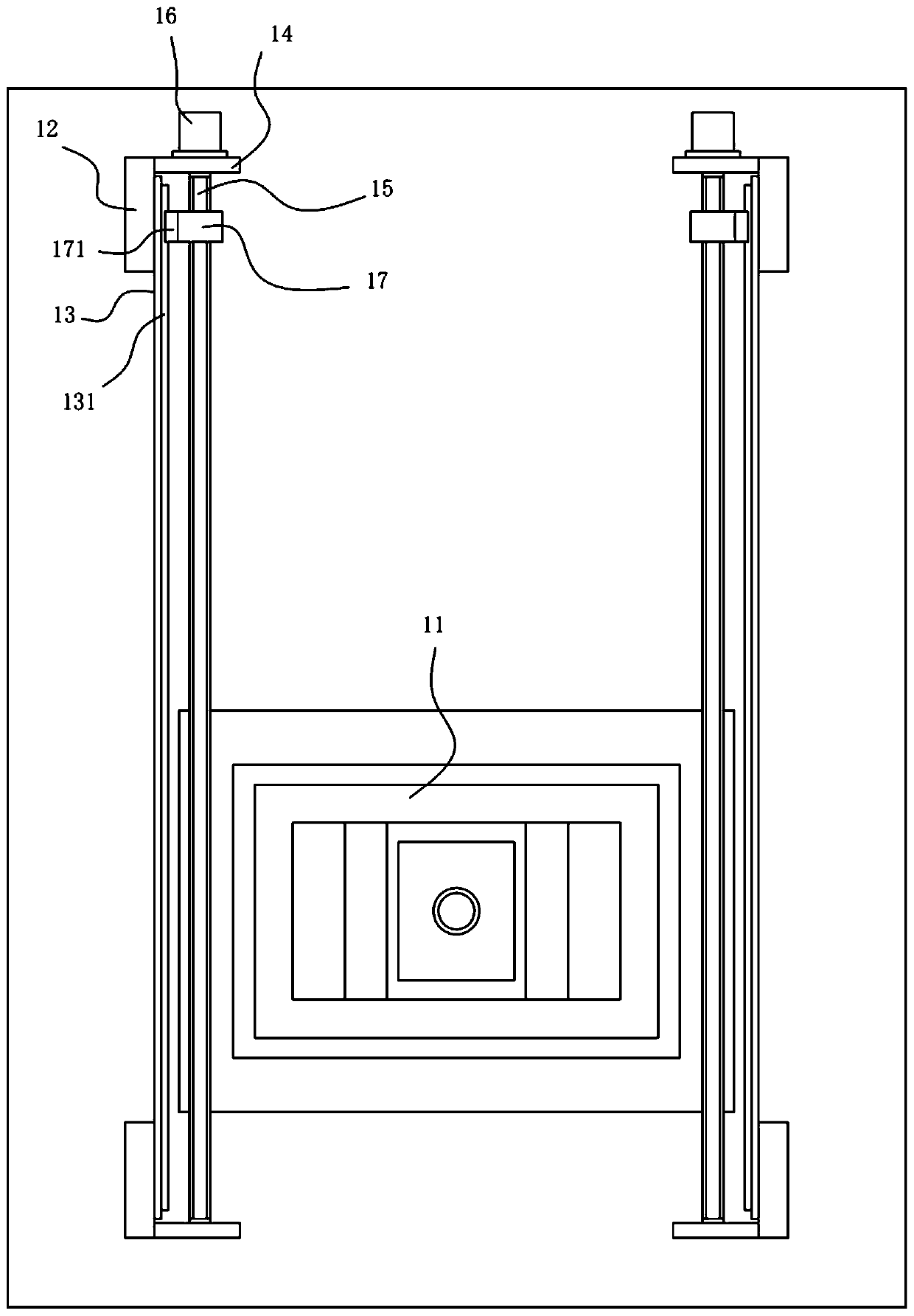

[0021] Example: see Figure 1 to Figure 3 Shown, a kind of molded product automatic feeding mechanism comprises frame 10, and the middle part of the top surface of the top plate of described frame 10 is fixed with lower mold 11, and the front and rear frame of the left and right sides of lower mold 11 A support column 12 is fixed on the top surface of the top plate of 10;

[0022] The two support columns 12 on the left side are fixed with side connecting beams 13, and the two support columns 12 on the right side are also fixed with side connecting beams 13, the front ends of the two side connecting beams 13 and the support columns 12 at the rear end. Connecting plates 14 are fixed on the inner side walls, and the two ends of the adjusting screw rod 15 extending forward and backward are hinged on the two connecting plates 14 through bearings, and a drive motor 16 is fixed on the rear wall of the connecting plate 14 at the rear, and the output of the drive motor 16 The shaft is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com