Patents

Literature

32results about How to "Safe and reliable grabbing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

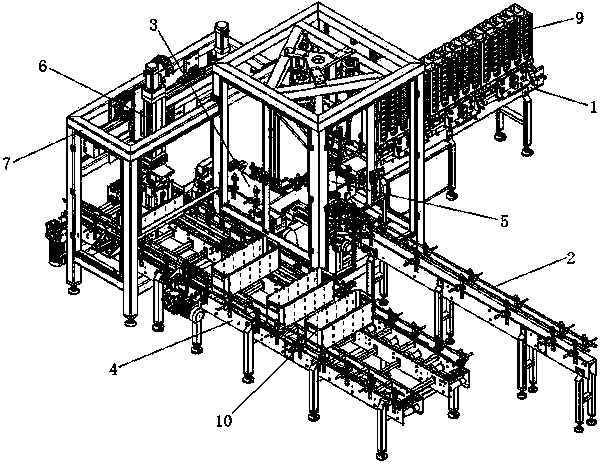

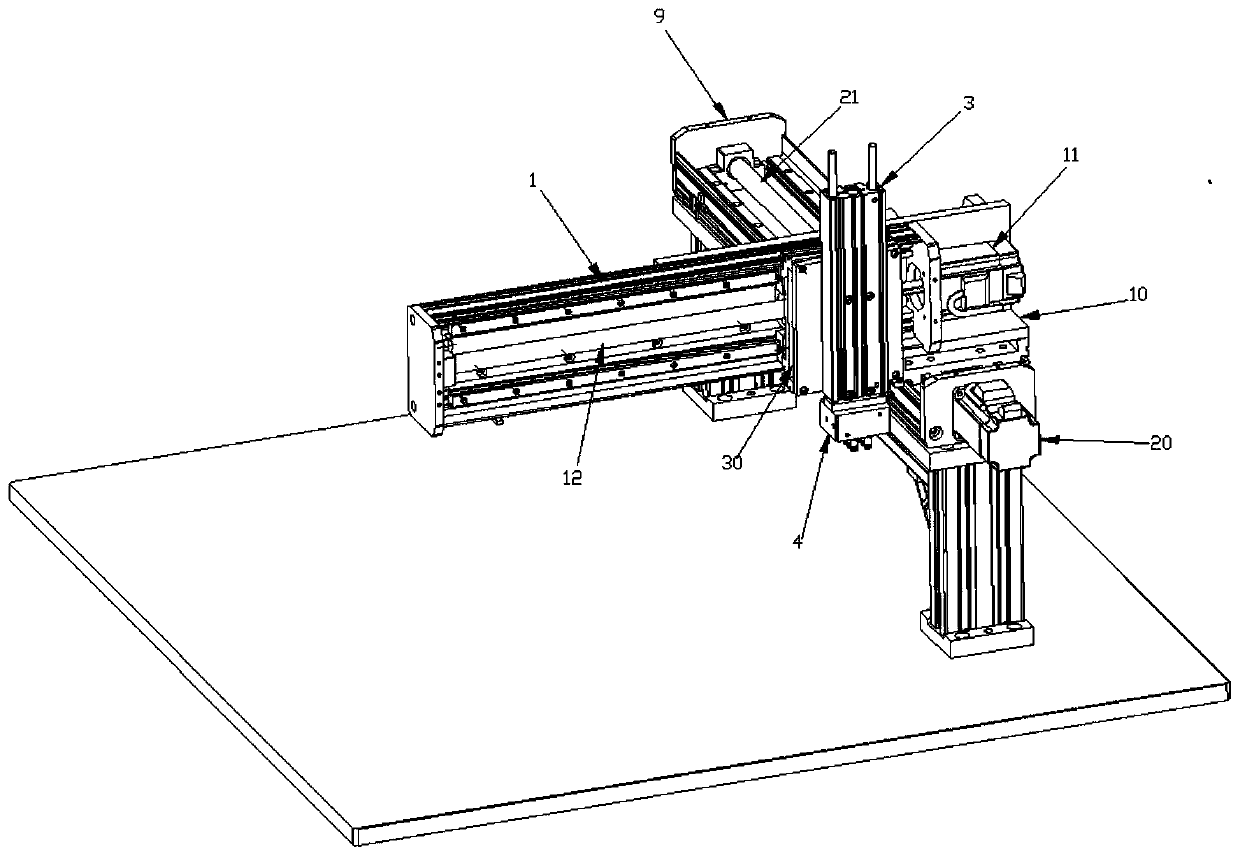

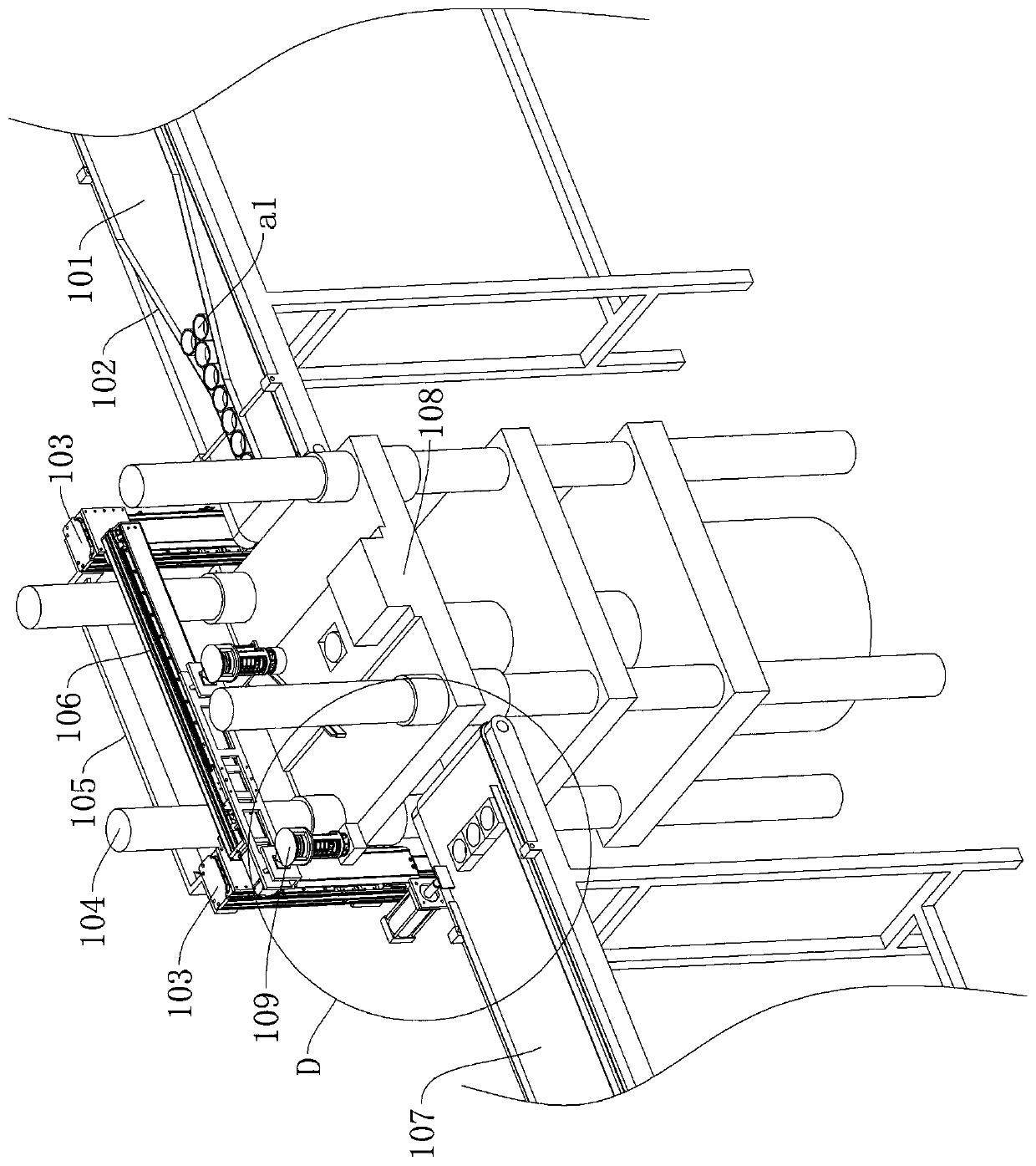

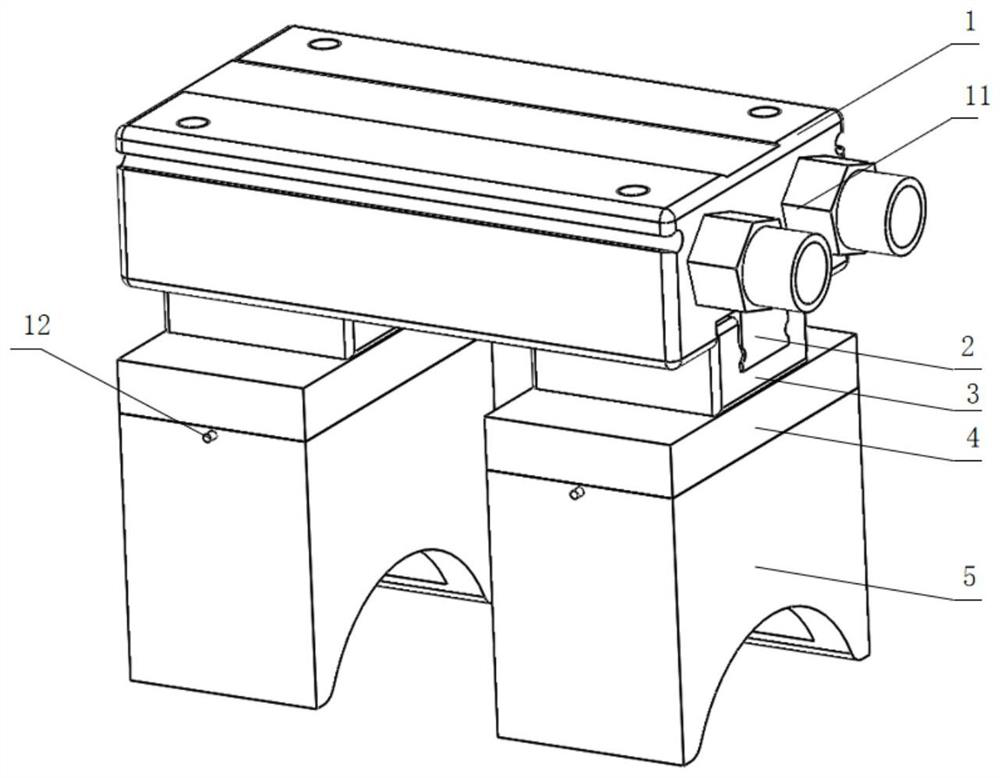

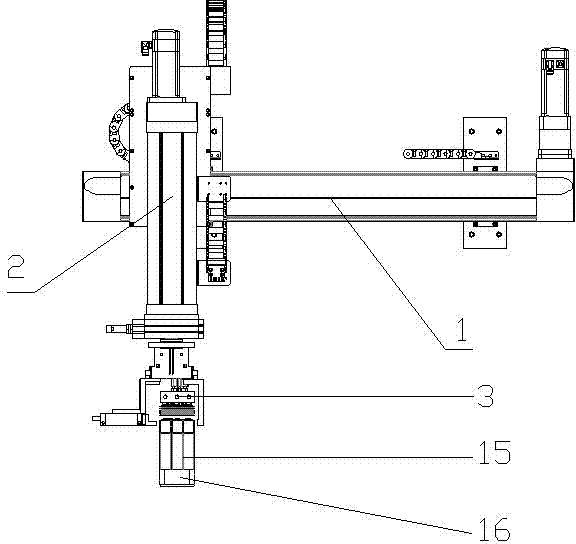

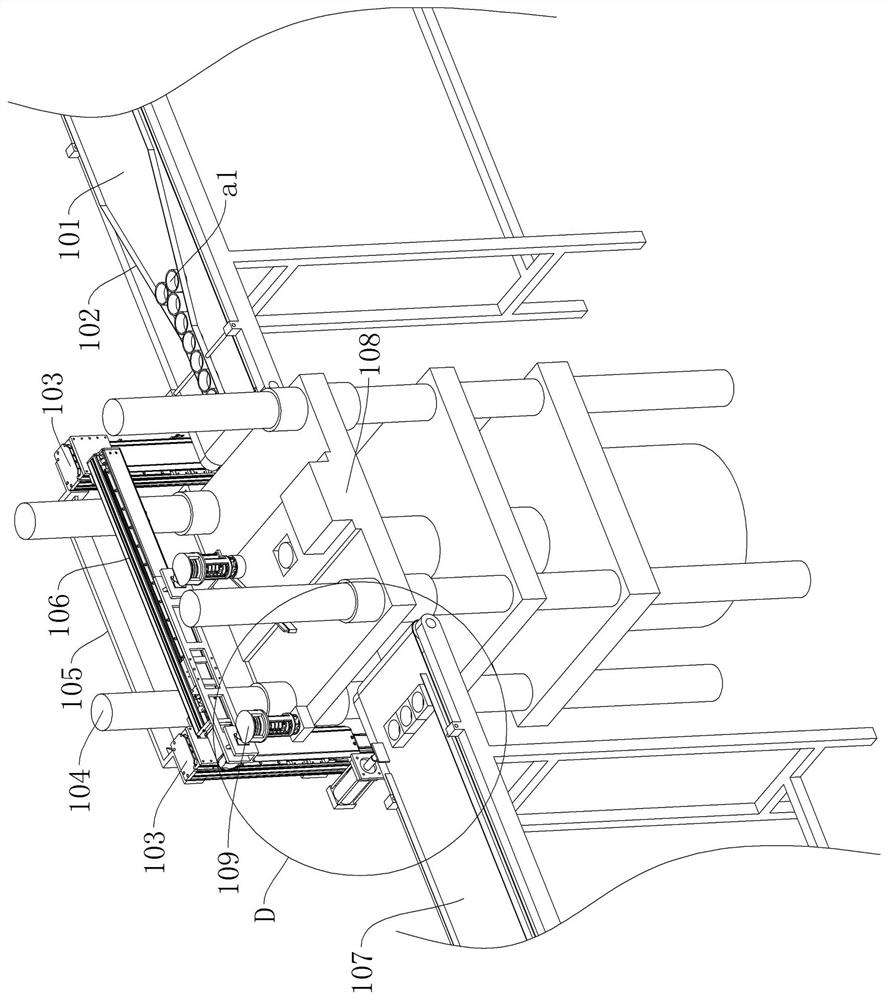

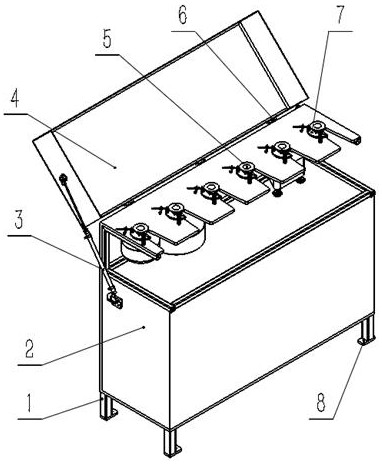

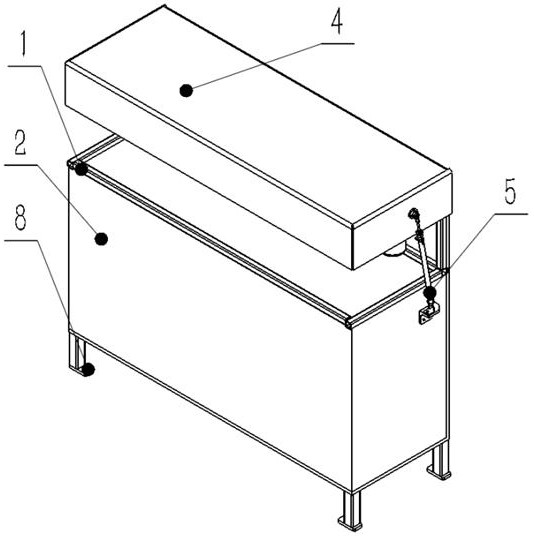

Combined box filling machine of battery assembly line

InactiveCN103419951ASafe and reliable grabbingImprove gripIndividual articlesElectricityElectrical battery

The invention discloses a combined box filling machine of a battery assembly line. The combined box filling machine comprises a controller, a cork base feeding mechanism, a battery conveying mechanism, a battery pack conveying mechanism, a battery box conveying mechanism, parallel-connection mechanical arms, an electric cylinder grasping hand and a machine frame, wherein the controller, the parallel-connection mechanical arms and the electric cylinder grasping hand are all installed on the machine frame, and the cork base feeding mechanism, the battery conveying mechanism, the battery pack conveying mechanism, the battery box conveying mechanism, the parallel-connection mechanical arms and the electric cylinder grasping hand are all electrically connected with the controller respectively. According to the combined box filling machine, batteries can be filled onto a cork base and combined into battery packs, then, the battery packs are filled into a battery box according to certain arrangement rules, automation of work for filling the batteries into the box is achieved, work efficiency is improved, and human errors are avoided.

Owner:HANGZHOU WAHAHA TECH

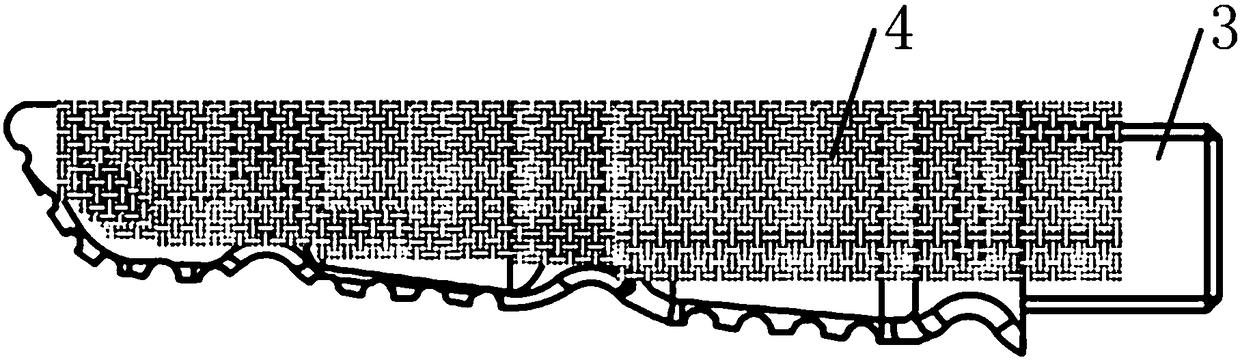

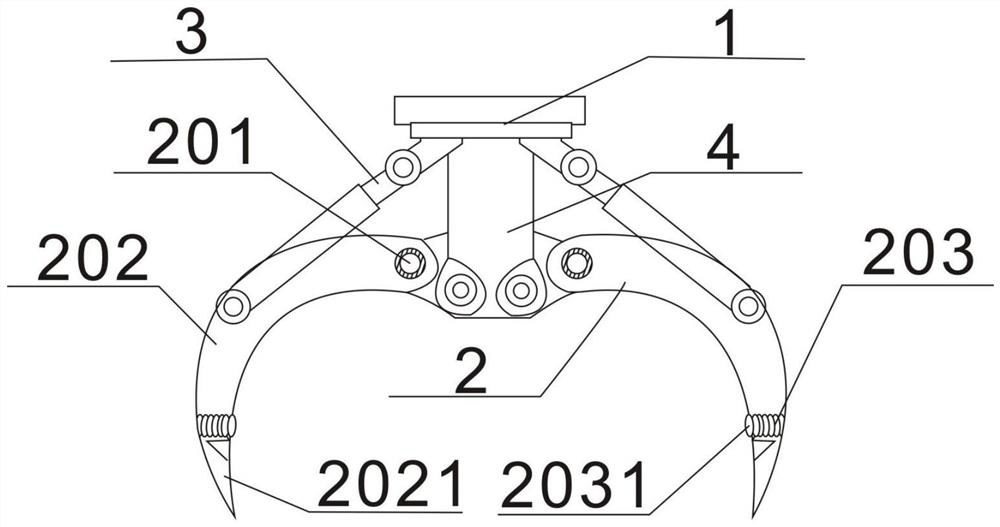

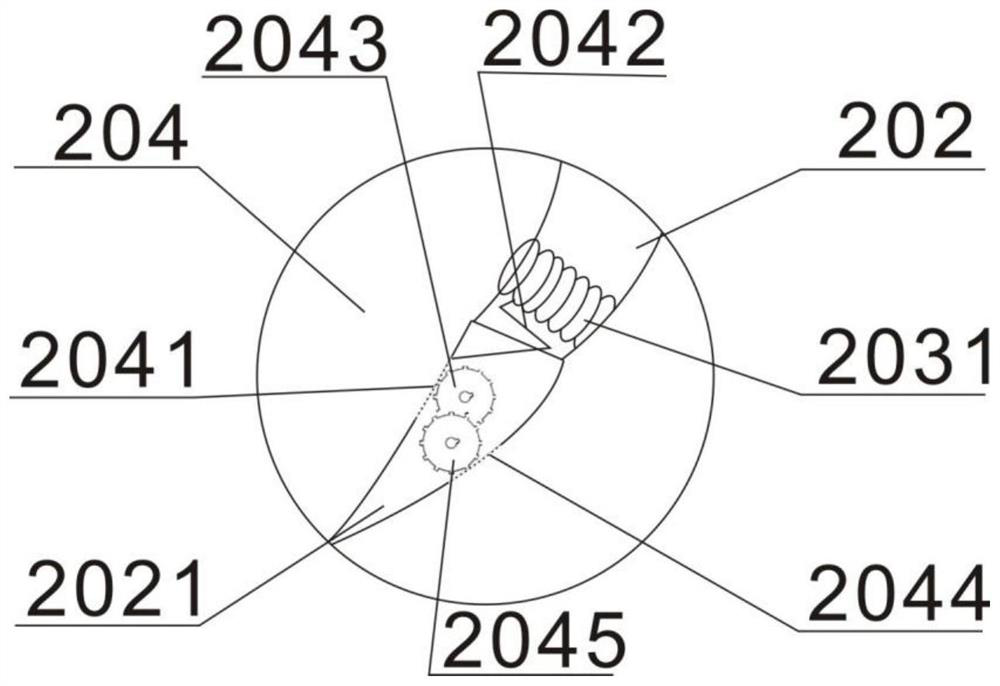

Humanoid finger inflatable soft three-finger gripper

The invention discloses a humanoid finger inflatable soft three-finger gripper, and relates to a three-finger gripper. The problem that existing soft grippers are low in load capacity is solved. Eachsoft finger module is installed on one end face of a bottom plate through a module base, a soft finger module body is internally provided with a first air cavity and a second air cavity in sequence, the first air cavity communicates with one end of a first interphalangeal joint air pipe, and the second air cavity communicates with one end of a second interphalangeal joint air pipe. The finger backof each soft finger module body is provided with at least two phalangeal joint clearance grooves through machining in the length direction of the finger back, the positions, except the finger prominence side, of the soft finger module body is wrapped with an elastic bandage, the finger prominence of the soft finger module body is provided with an elastic body, and a limiting layer is arranged between the finger prominence and the elastic body of the soft finger module body and made of a material which is easy to bend and cannot be stretched. The humanoid finger inflatable soft three-finger gripper is applied to manufacturing of a soft gripper, a robot hand, an artificial limb, a rehabilitation hand and the like.

Owner:HARBIN INST OF TECH

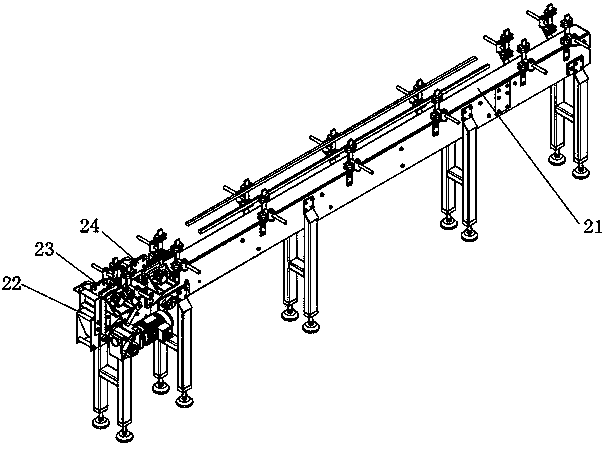

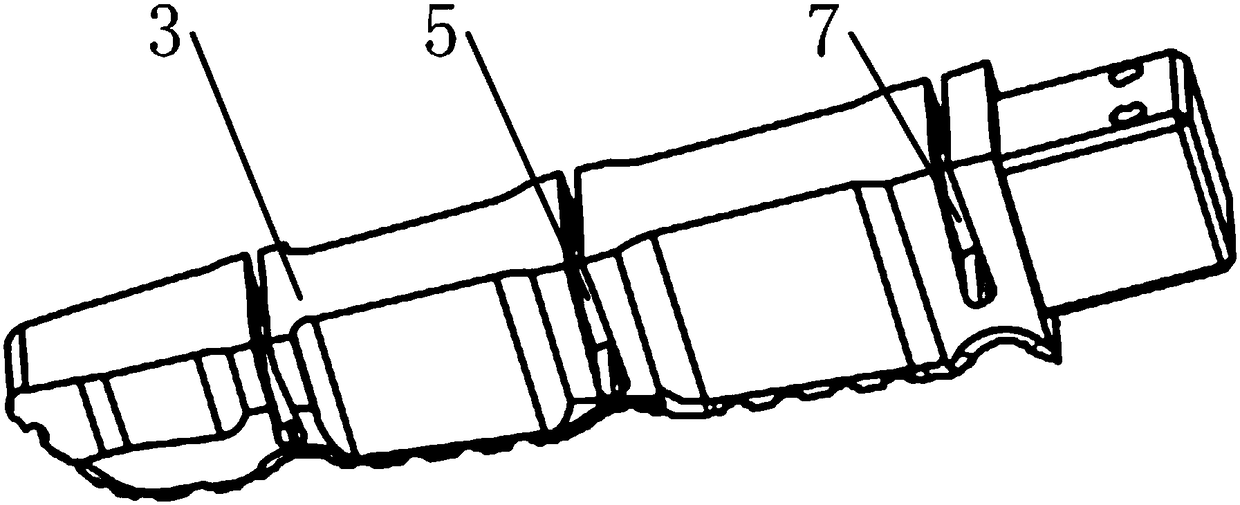

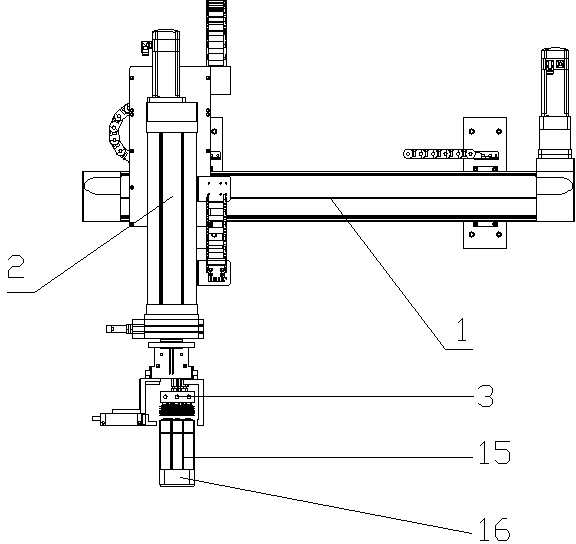

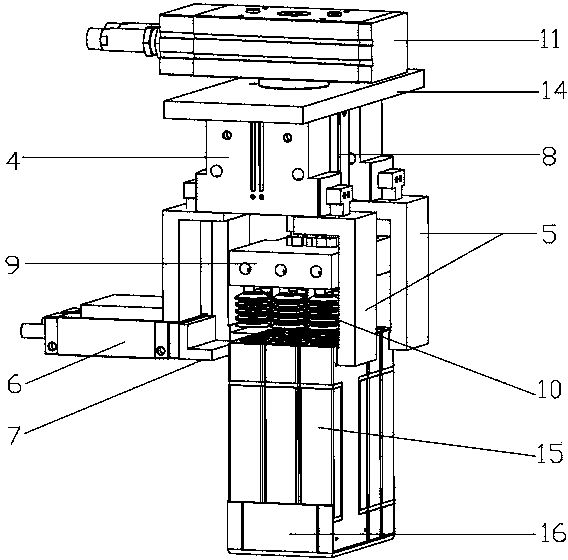

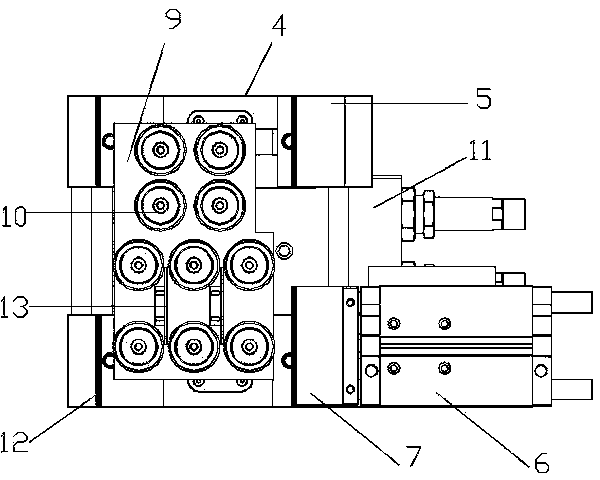

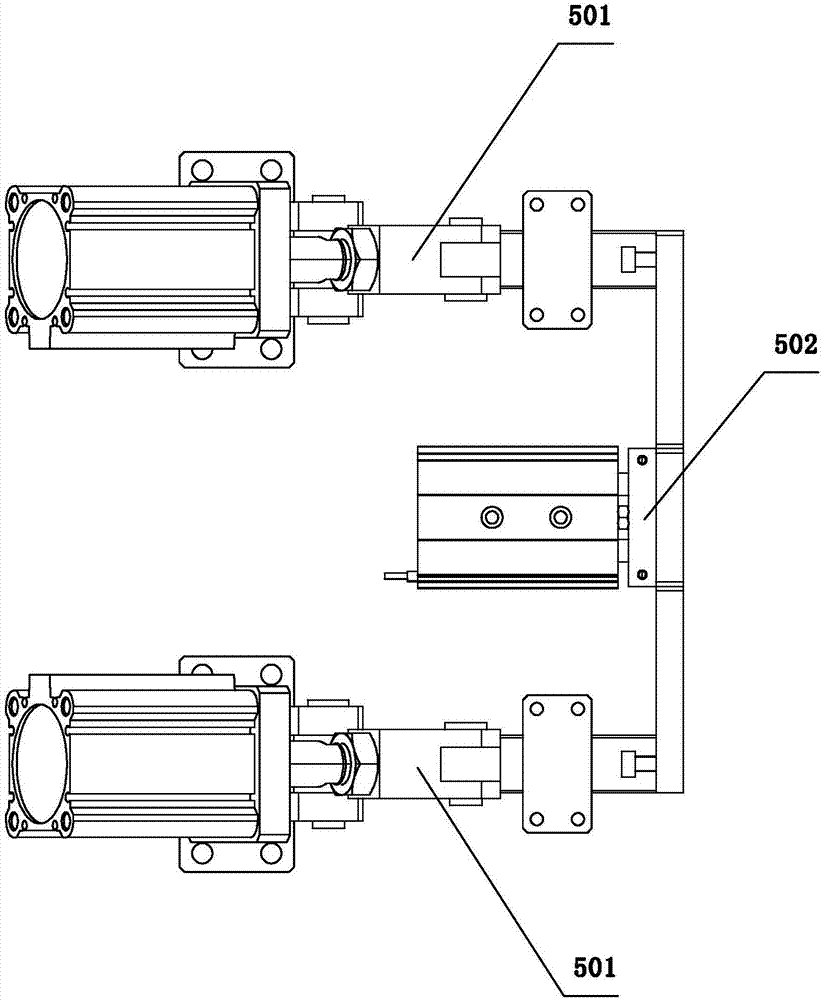

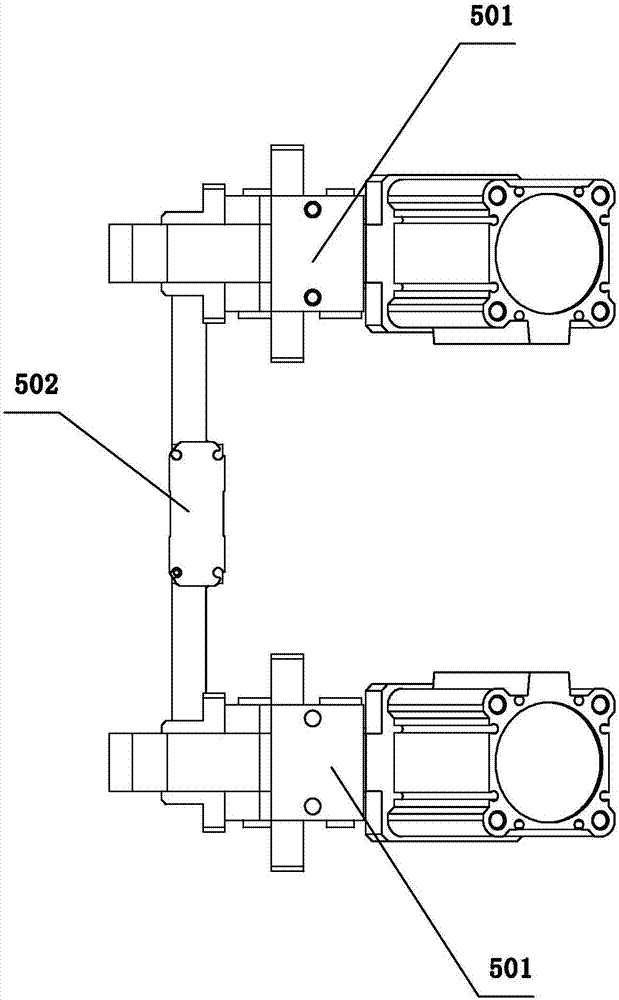

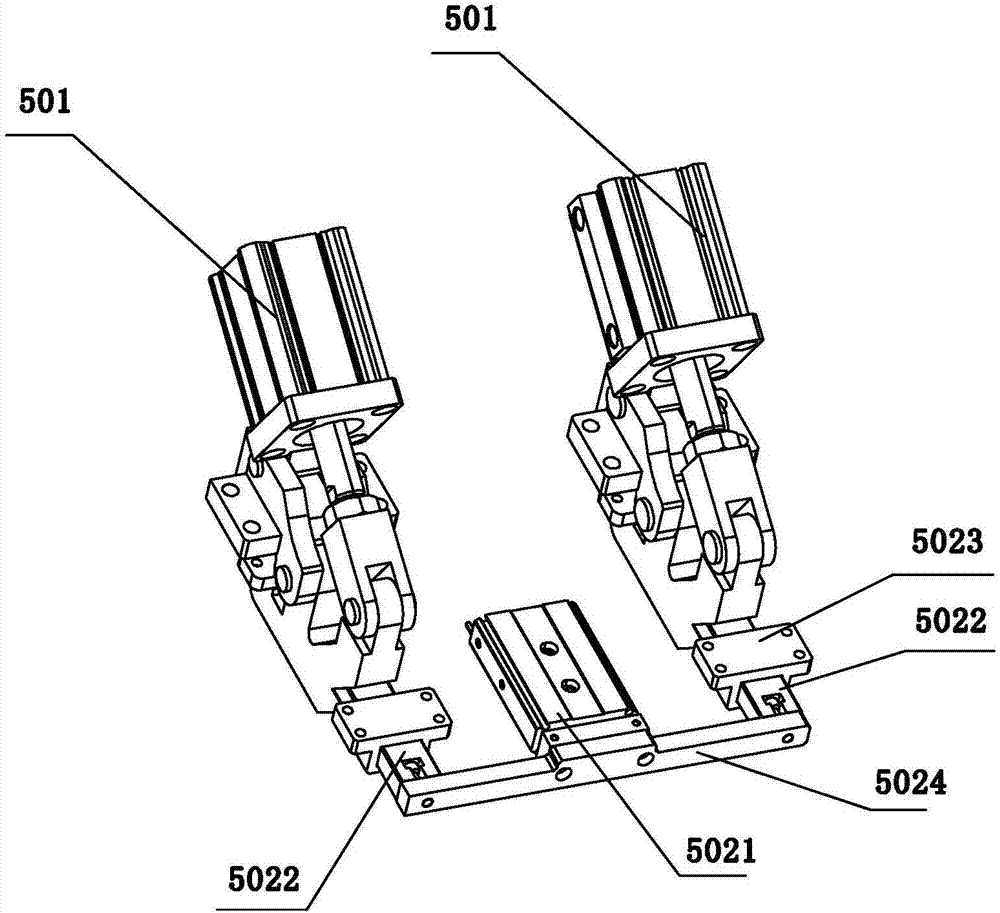

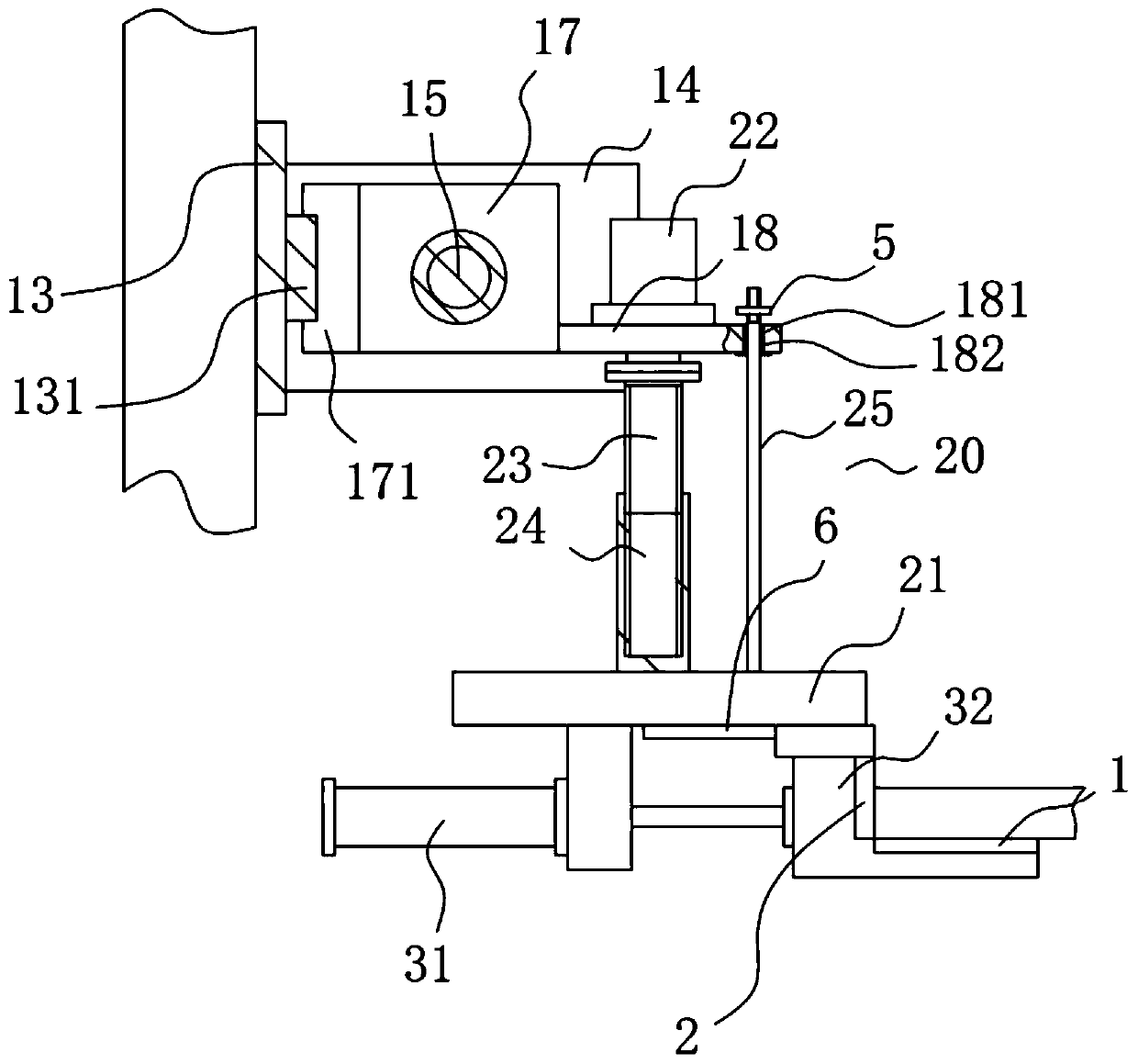

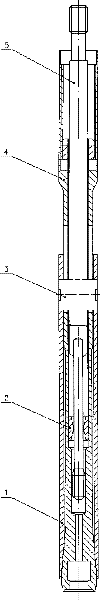

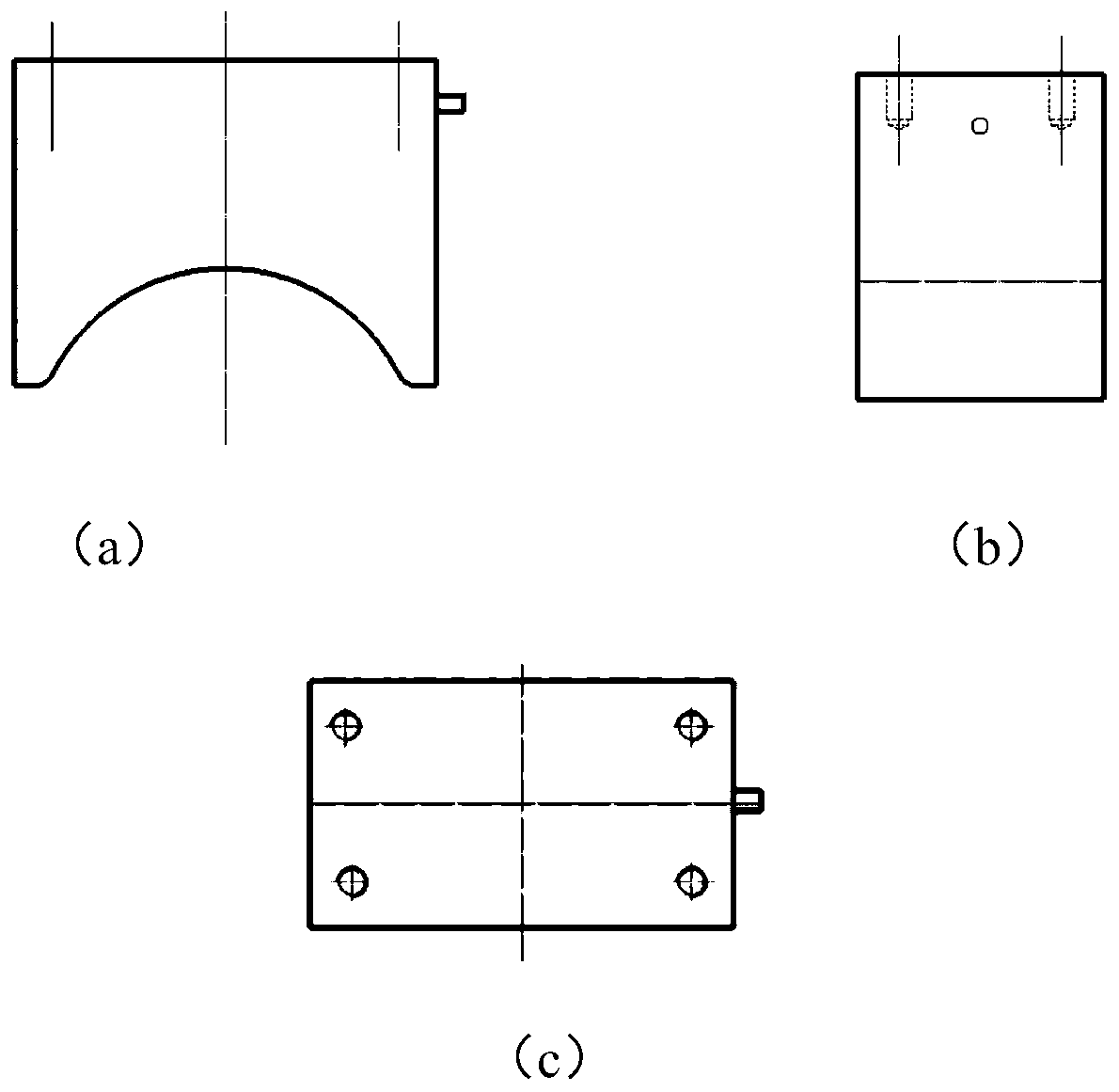

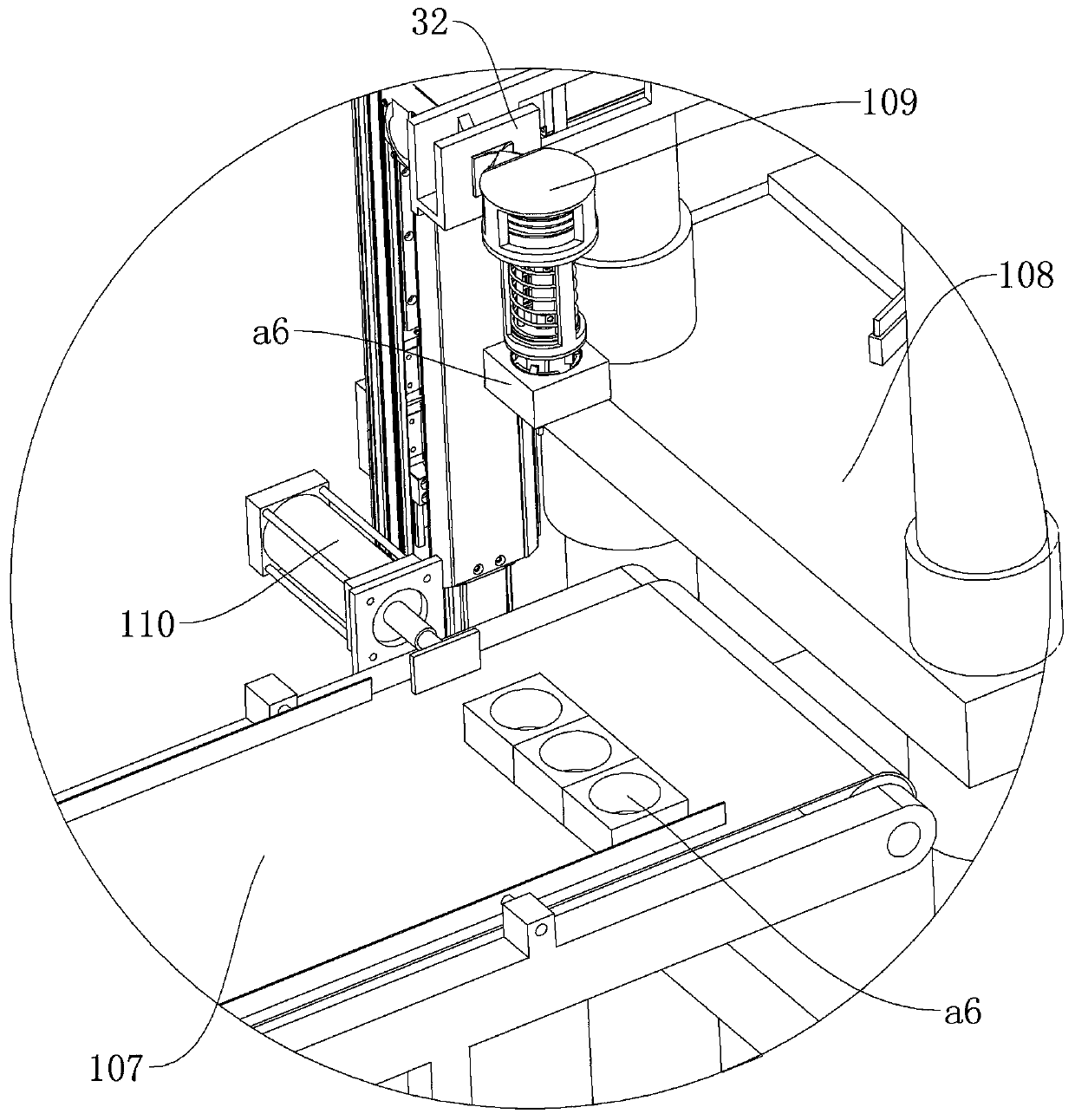

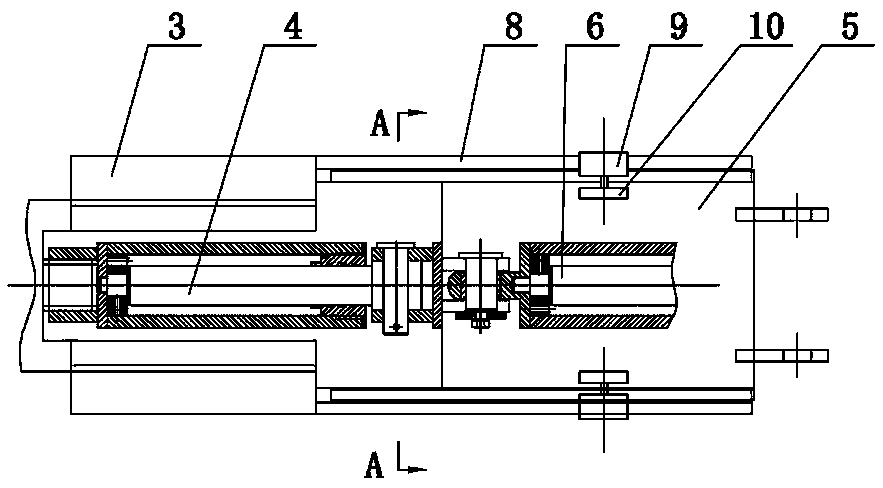

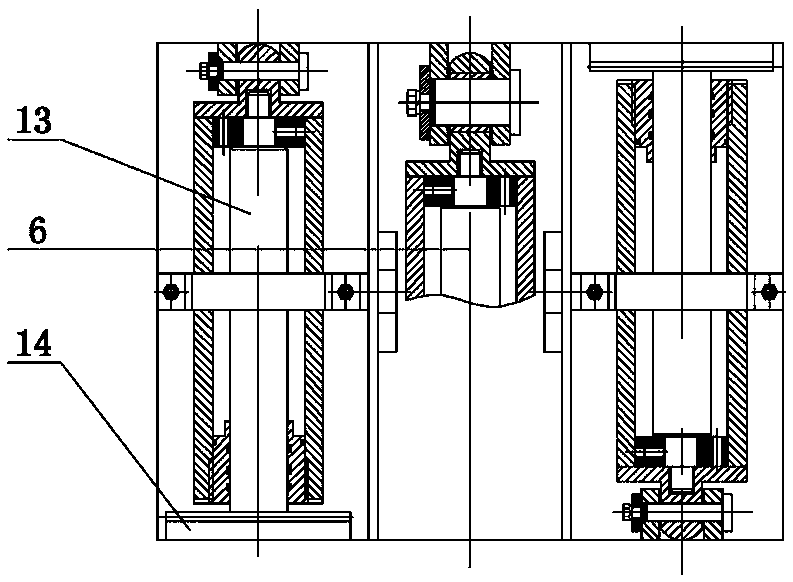

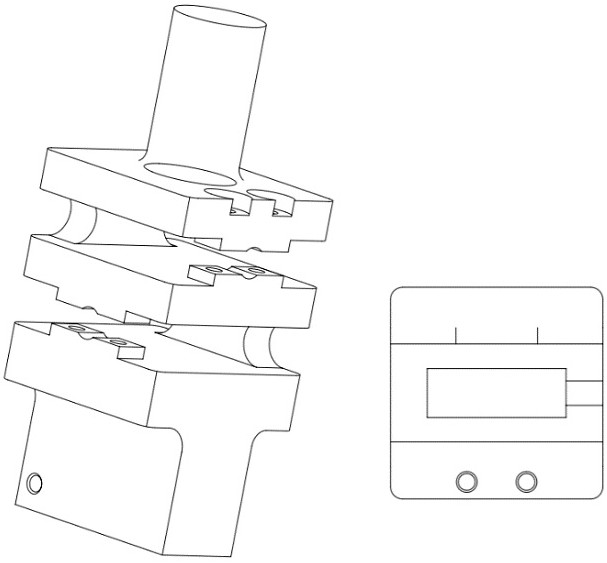

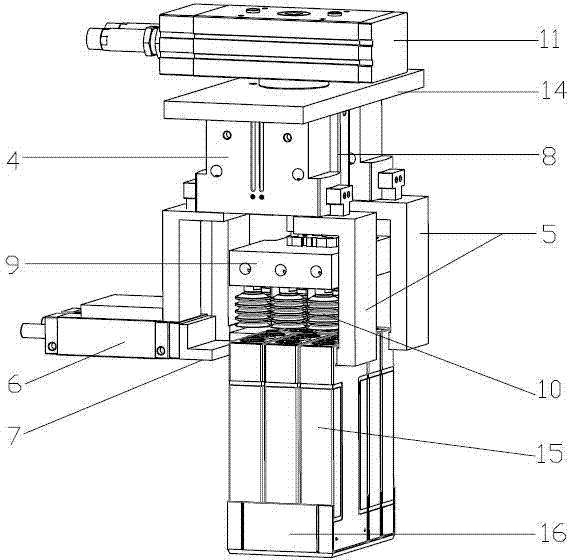

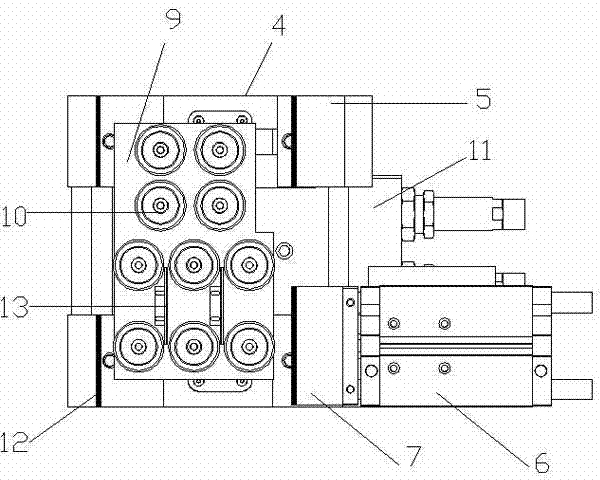

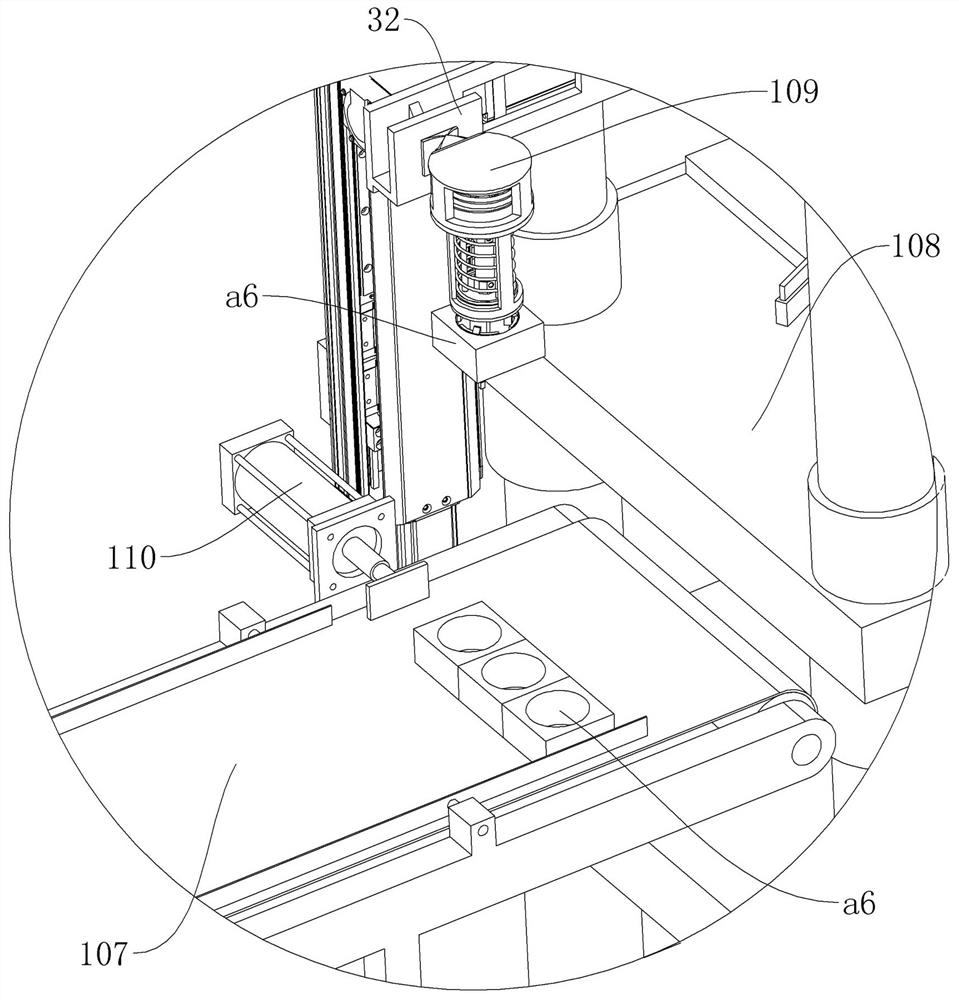

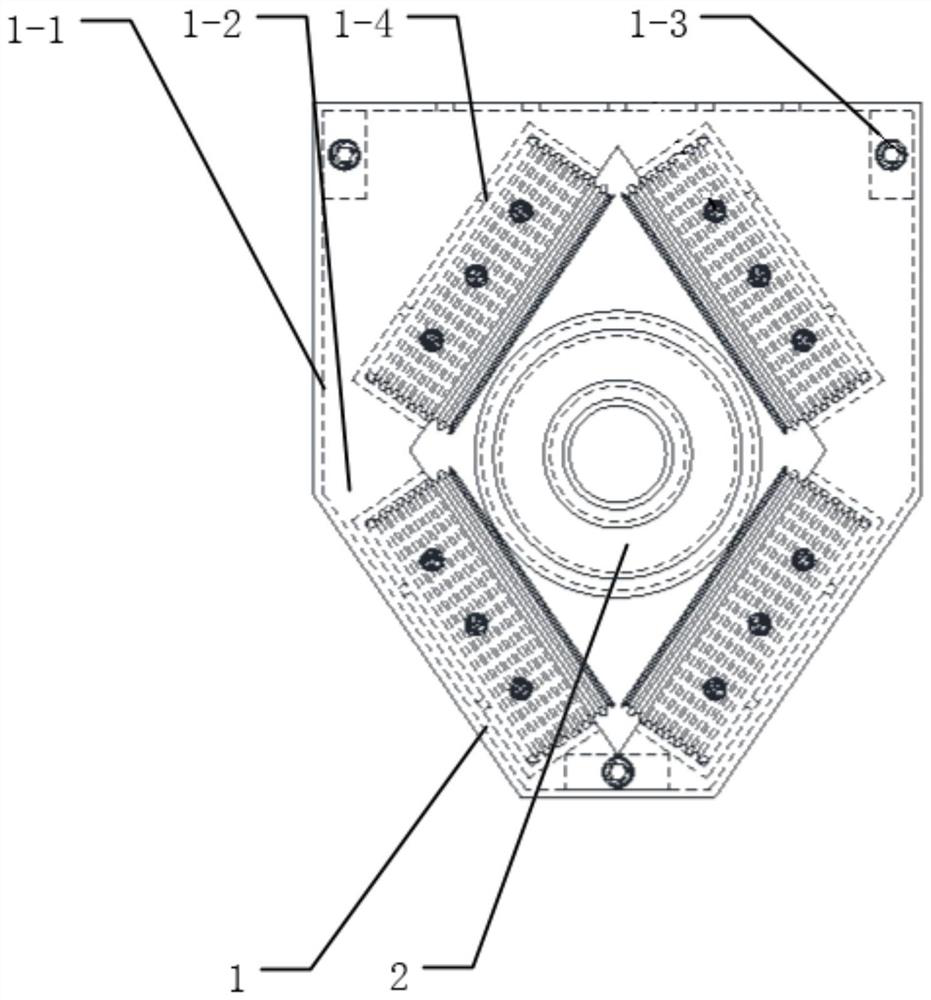

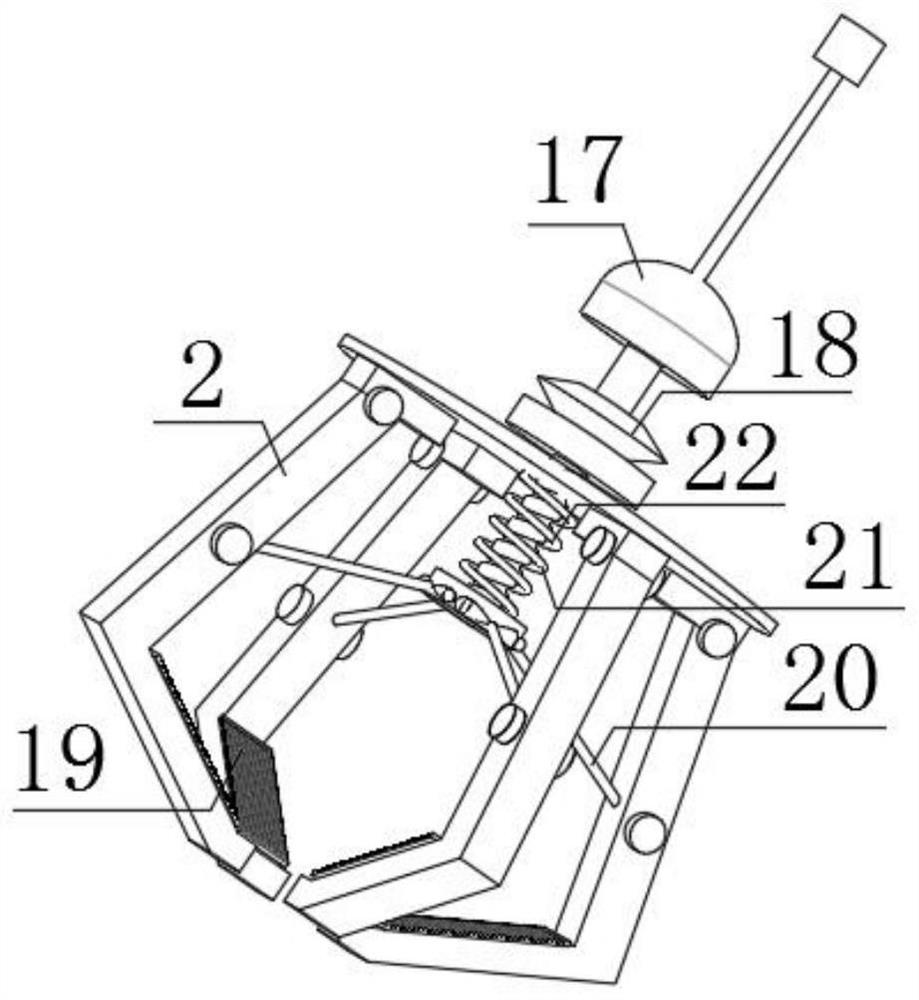

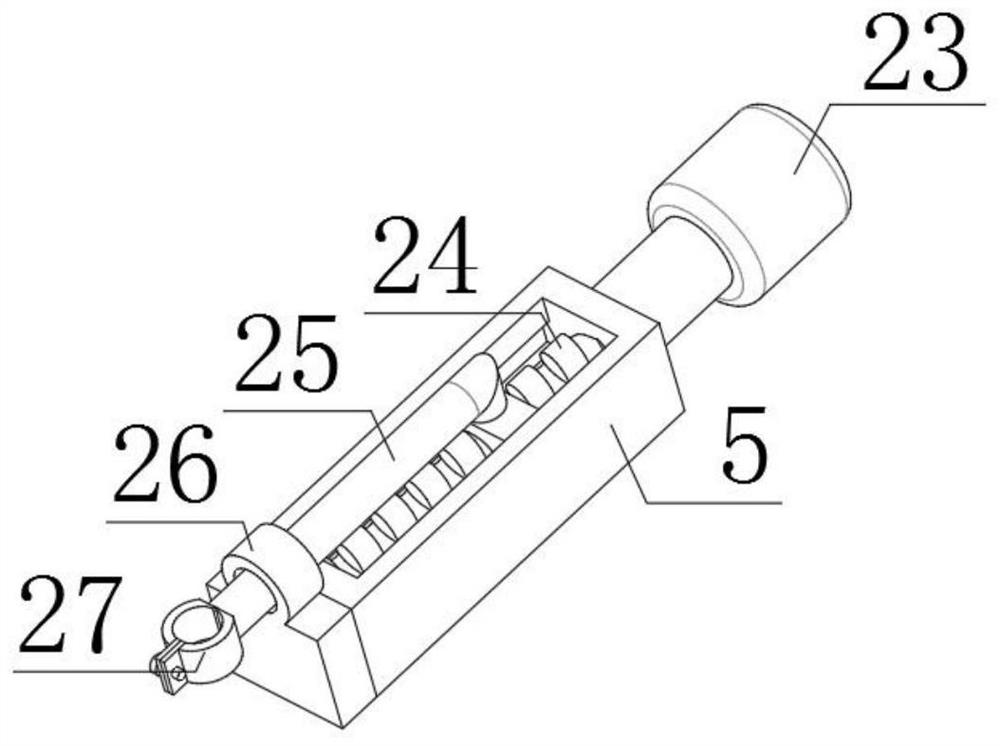

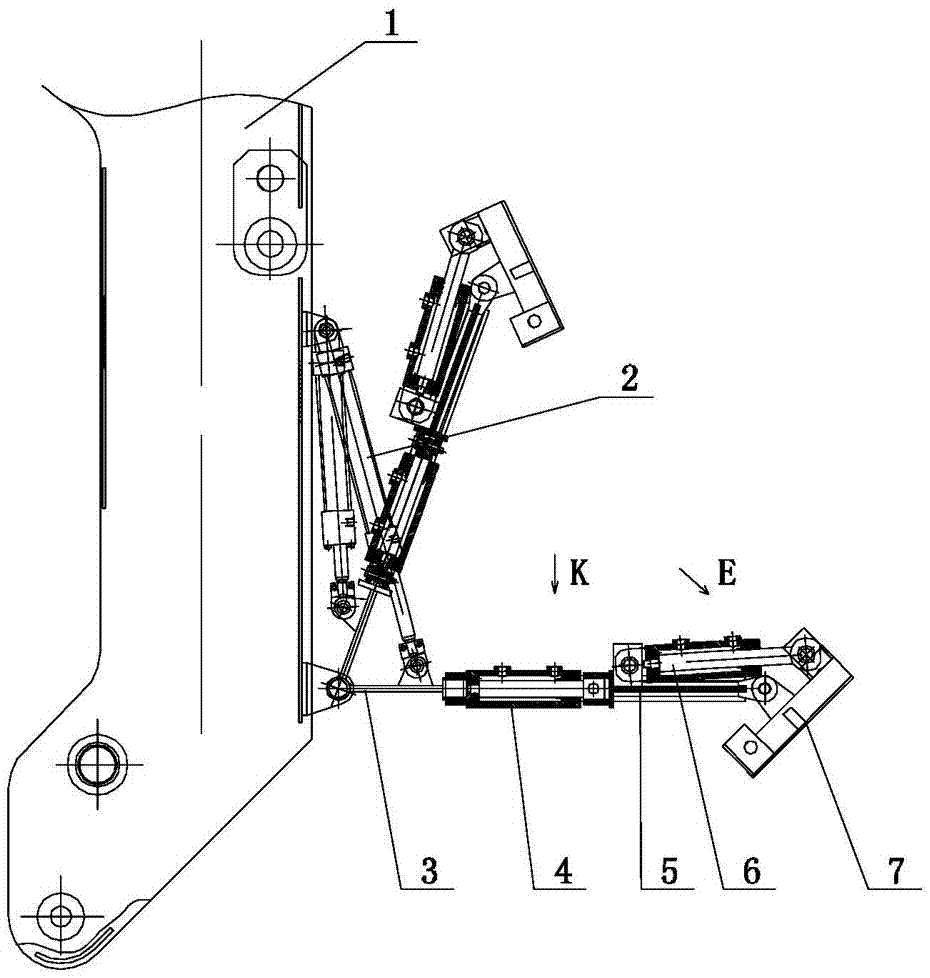

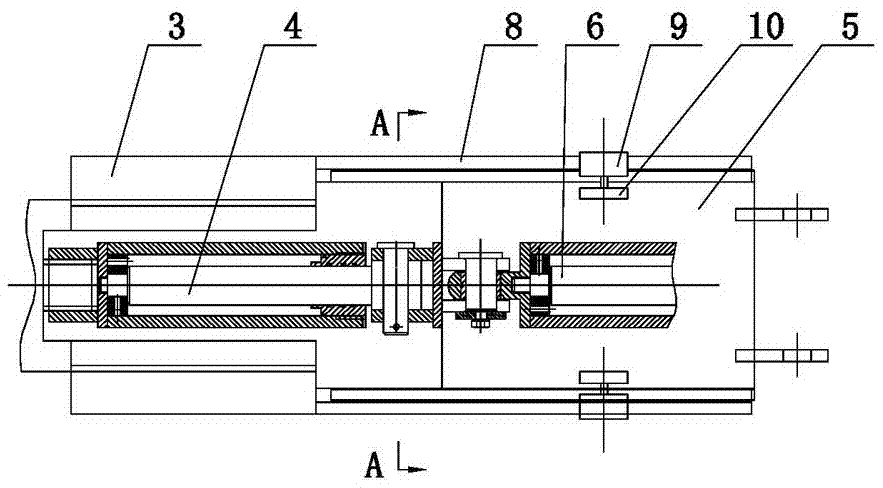

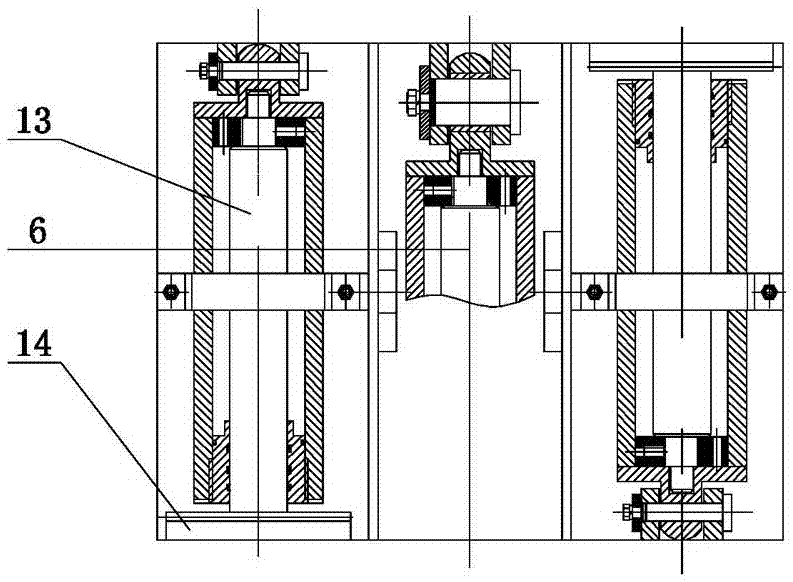

Electric cylinder hand grab used for grabbing battery pack

The invention discloses an electric cylinder hand grab used for grabbing a battery pack. The electric cylinder hand grab comprises a horizontal electric cylinder and a vertical electric cylinder connected with the horizontal electric cylinder. A hand grab body is arranged at the lower end of the vertical electric cylinder and comprises two double-end clamping air cylinders, and a clamping jaw is arranged at the stretchable end of each double-end clamping air cylinder. An auxiliary air cylinder is arranged at the head of one of the clamping jaws, and an auxiliary clamping block is arranged at the stretchable end of the auxiliary air cylinder. A vertical lifting air cylinder is arranged between the two double-end clamping air cylinders, the stretchable end of the lifting air cylinder faces downwards and is connected with a sucking disc fixing base, and a plurality of sucking discs are arranged on the lower side face of the sucking disc fixing base. The upper ends of the double-end clamping air cylinders and the upper end of the lifting air cylinder are fixedly connected through a connecting plate. A rotating air cylinder is arranged between the connecting plate and the lower end of the vertical electric cylinder. Therefore, the electric cylinder hand grab has the advantages of being capable of safely and stably grabbing the battery pack and smoothly achieving carrying and packing of the battery pack.

Owner:HANGZHOU WAHAHA TECH

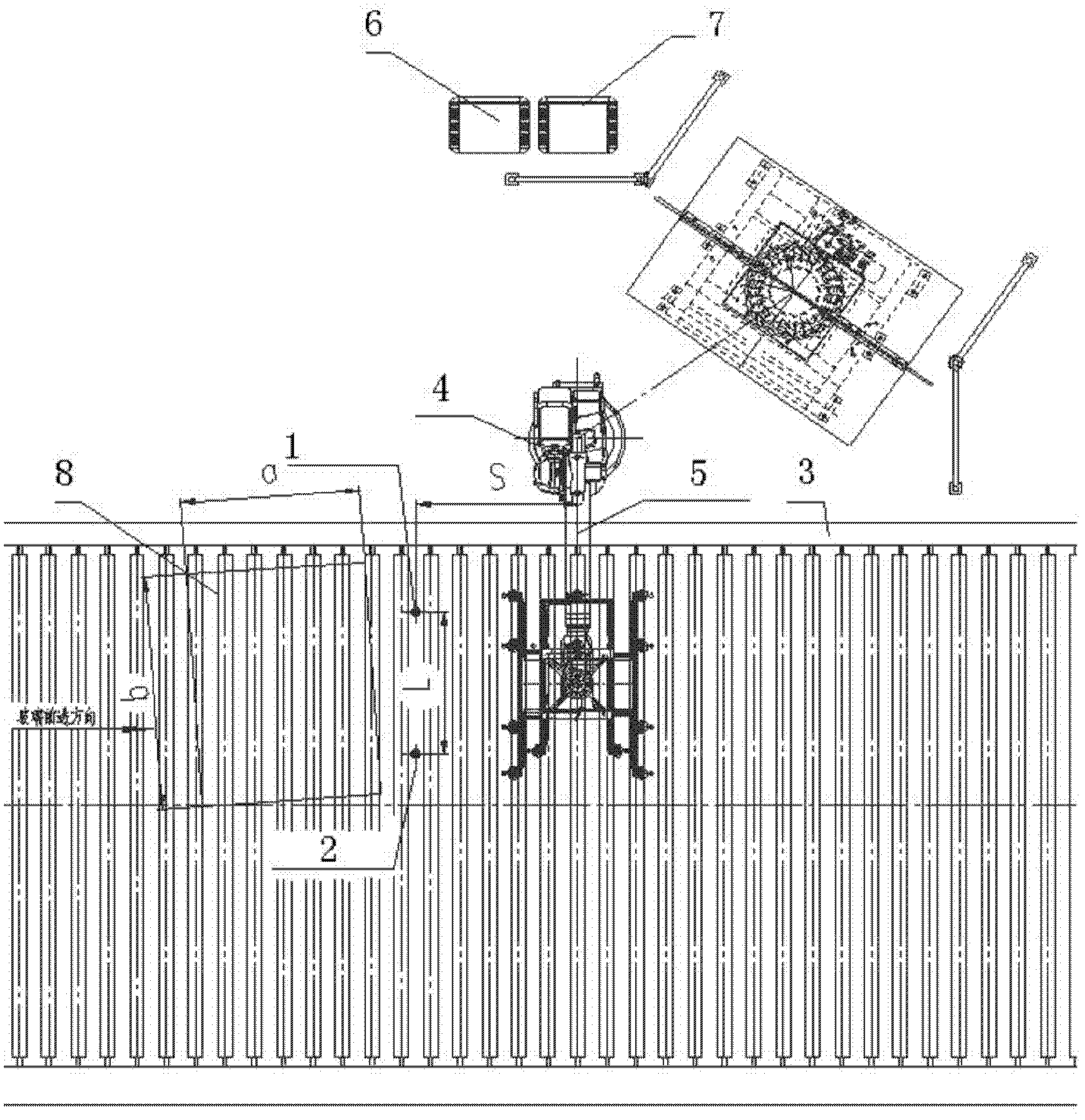

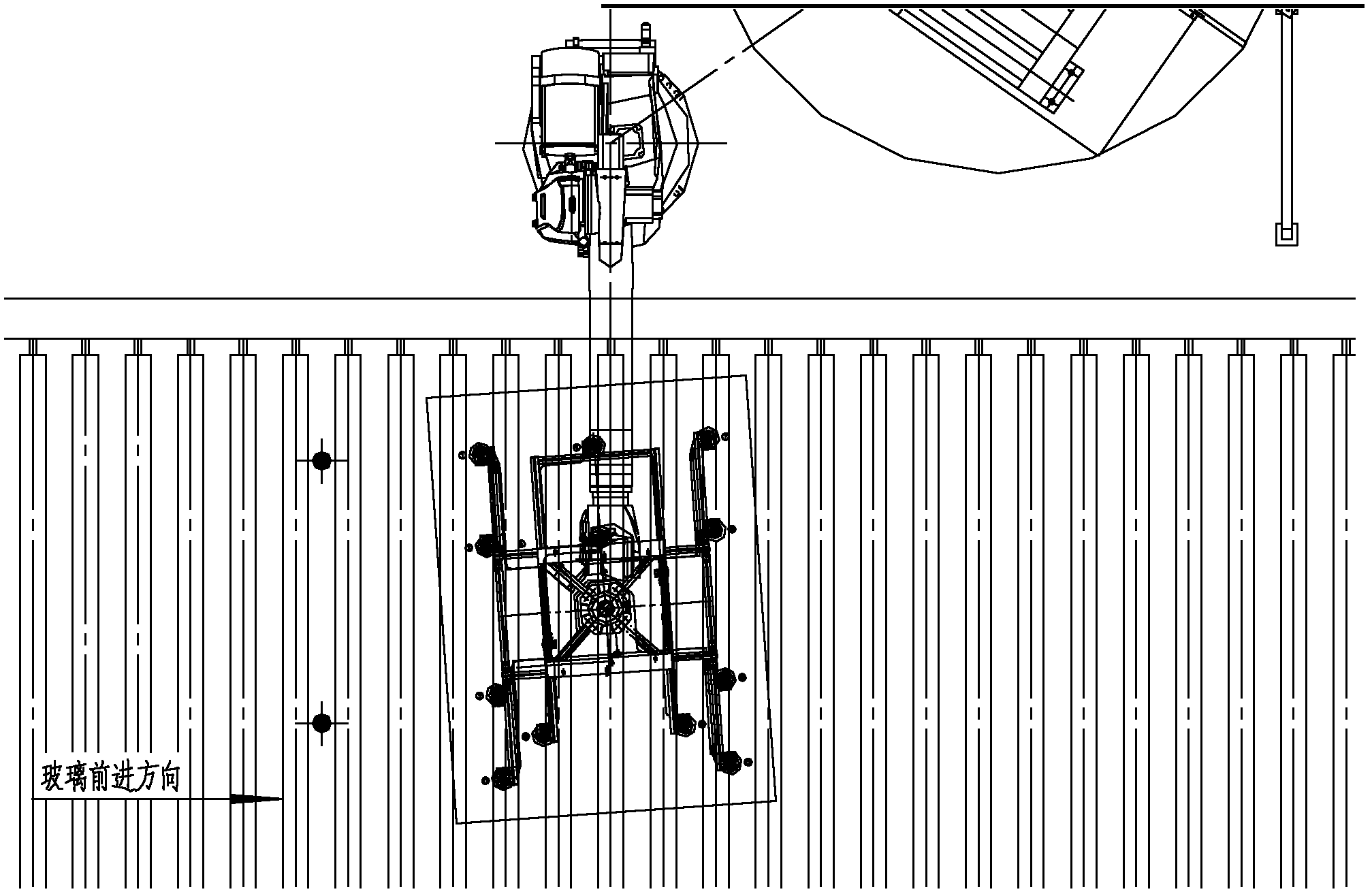

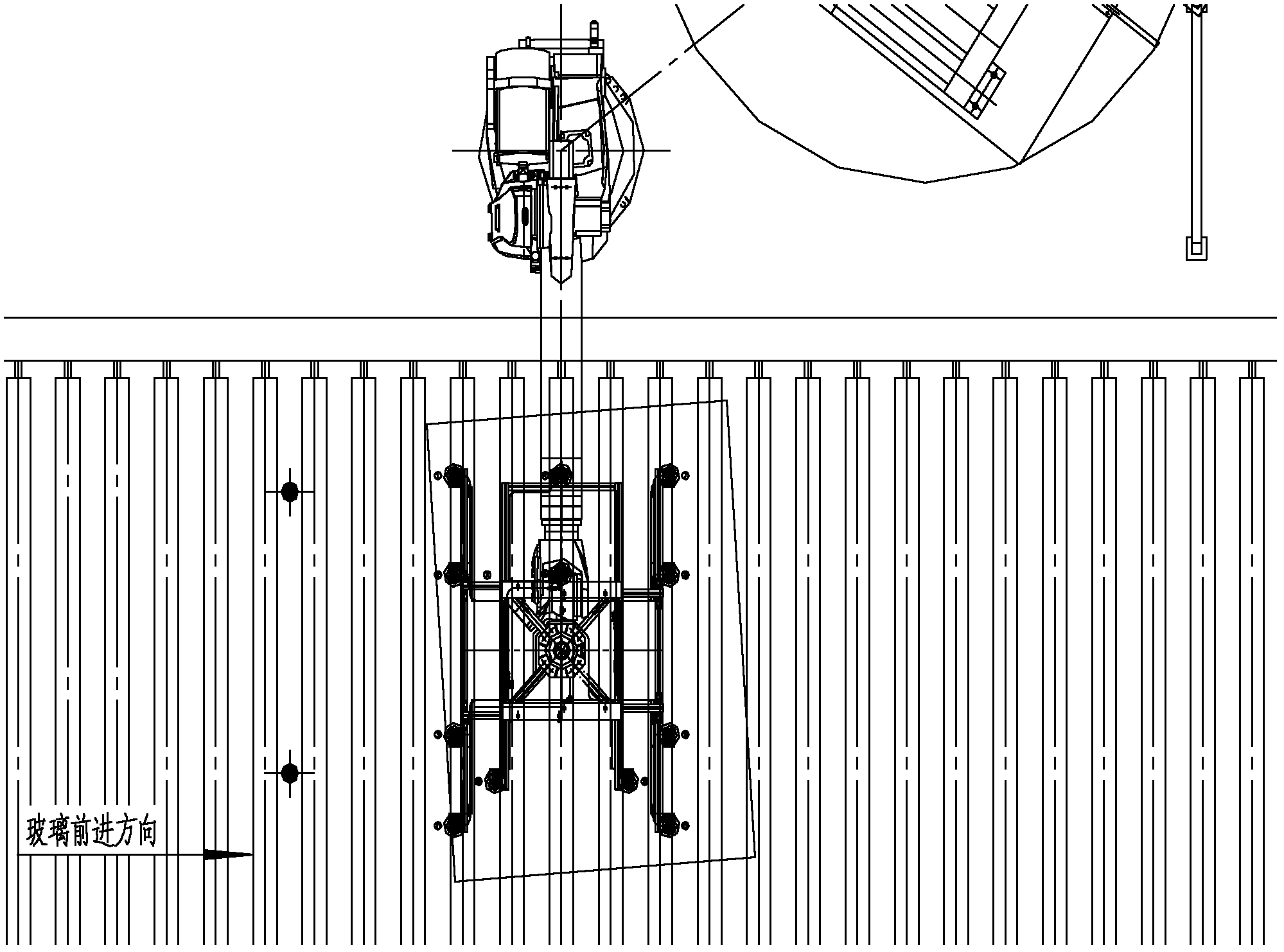

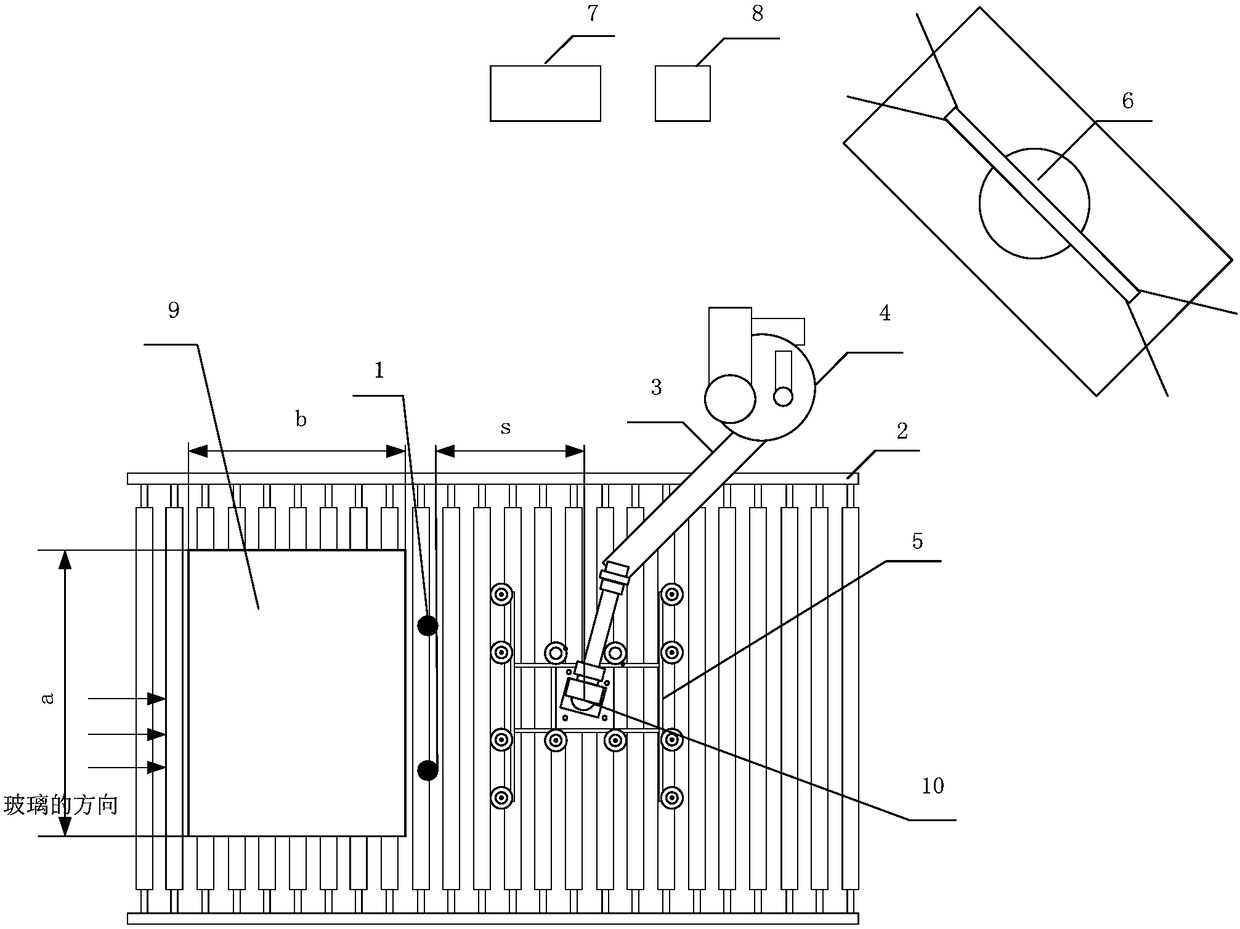

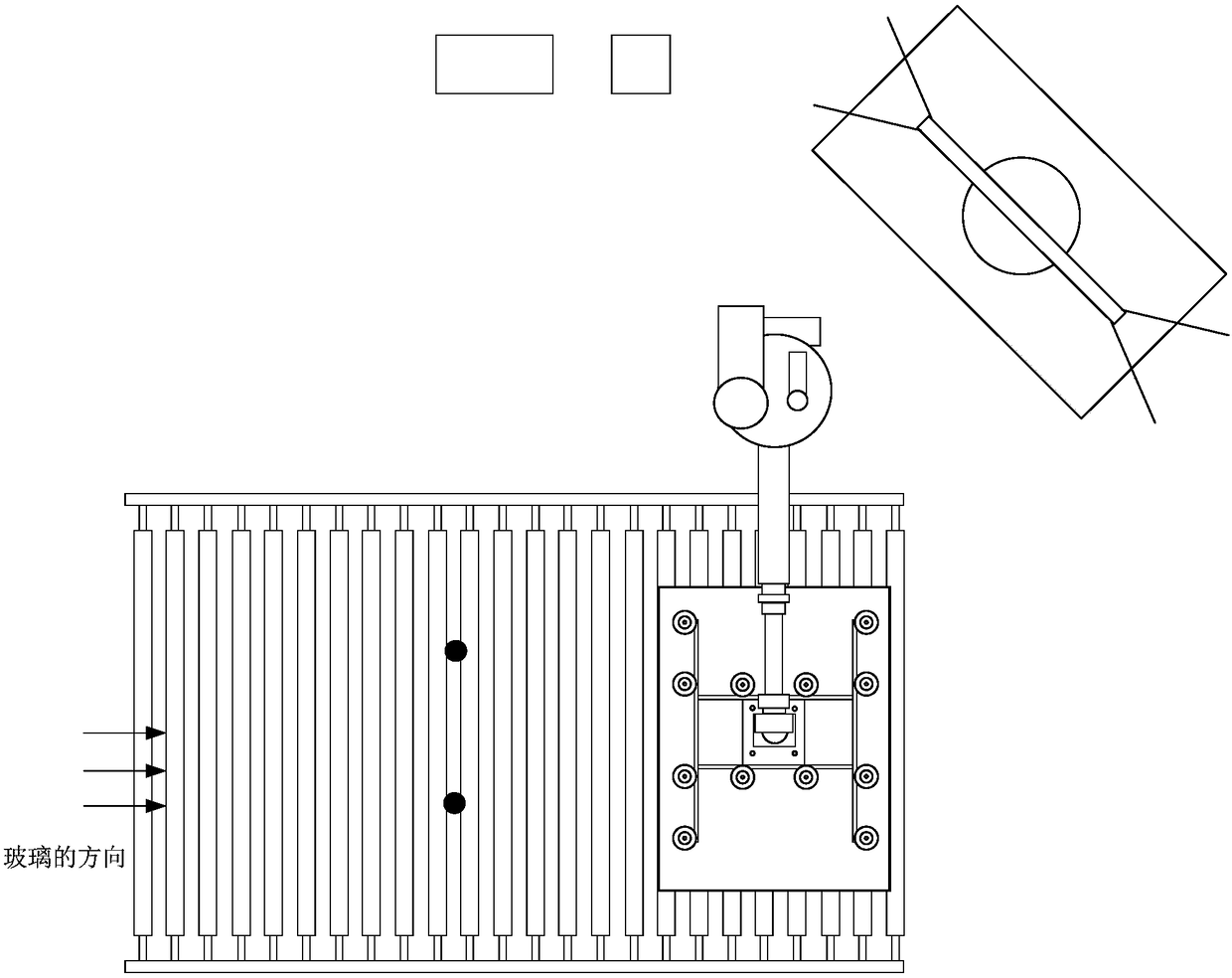

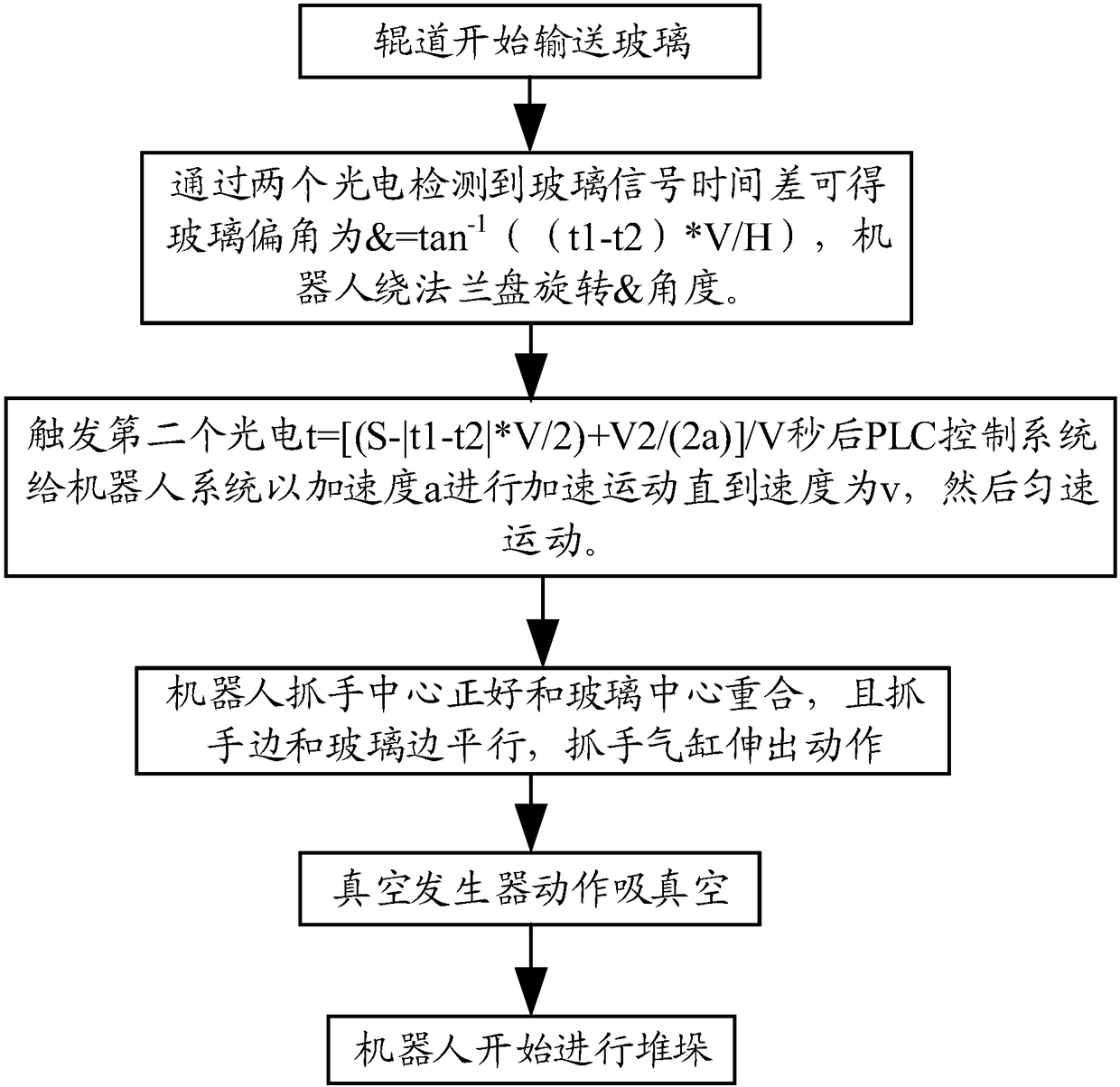

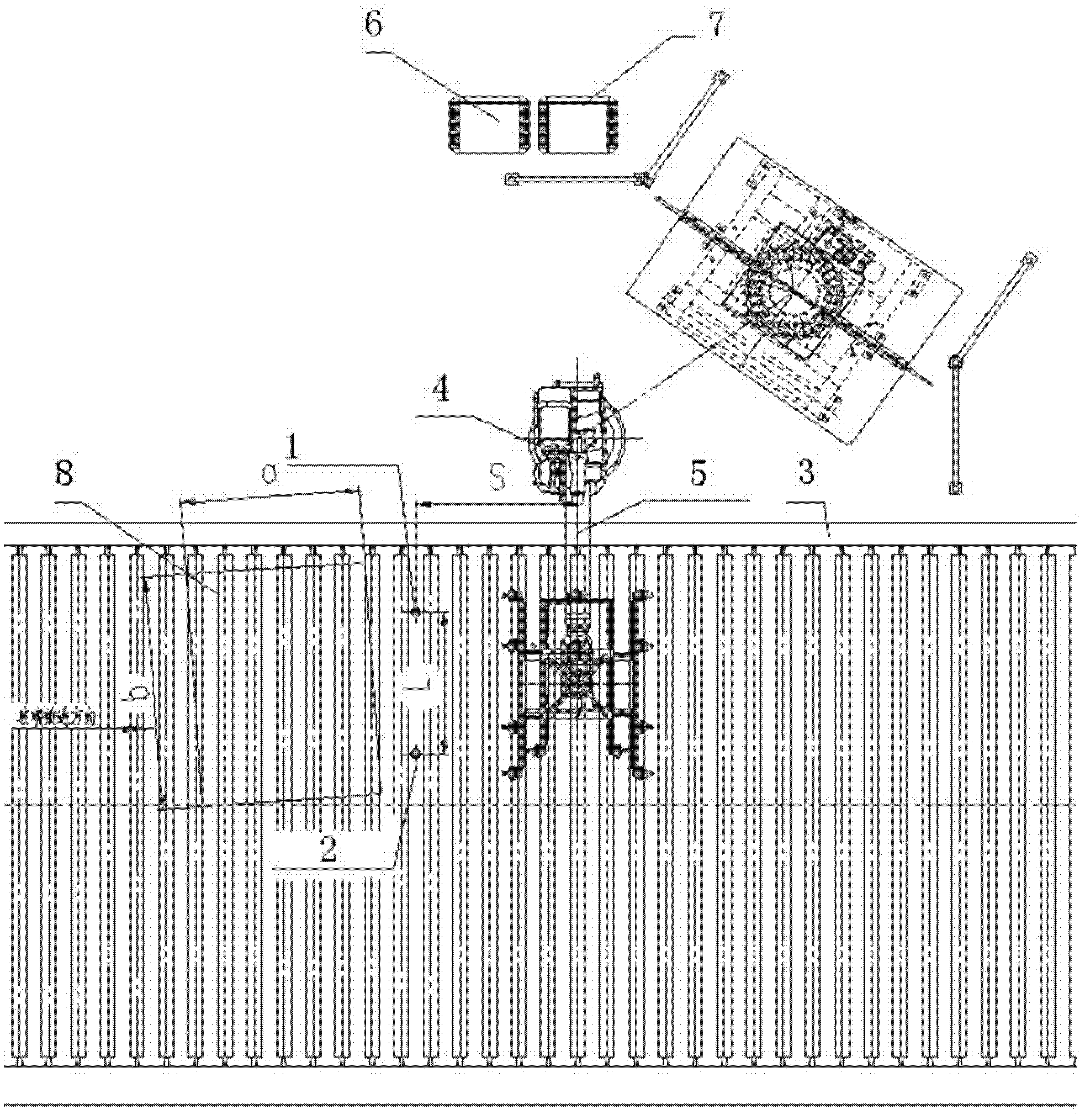

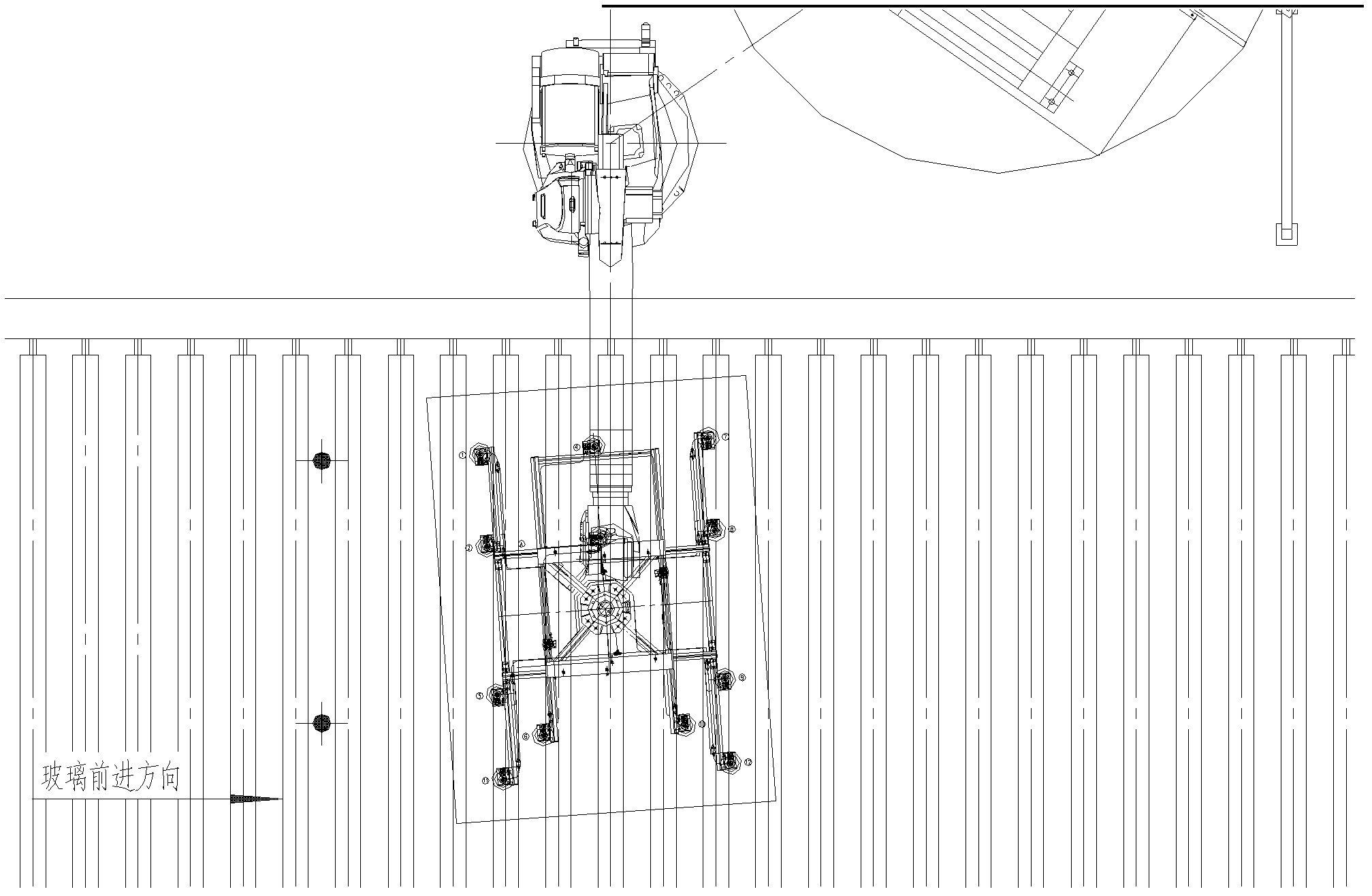

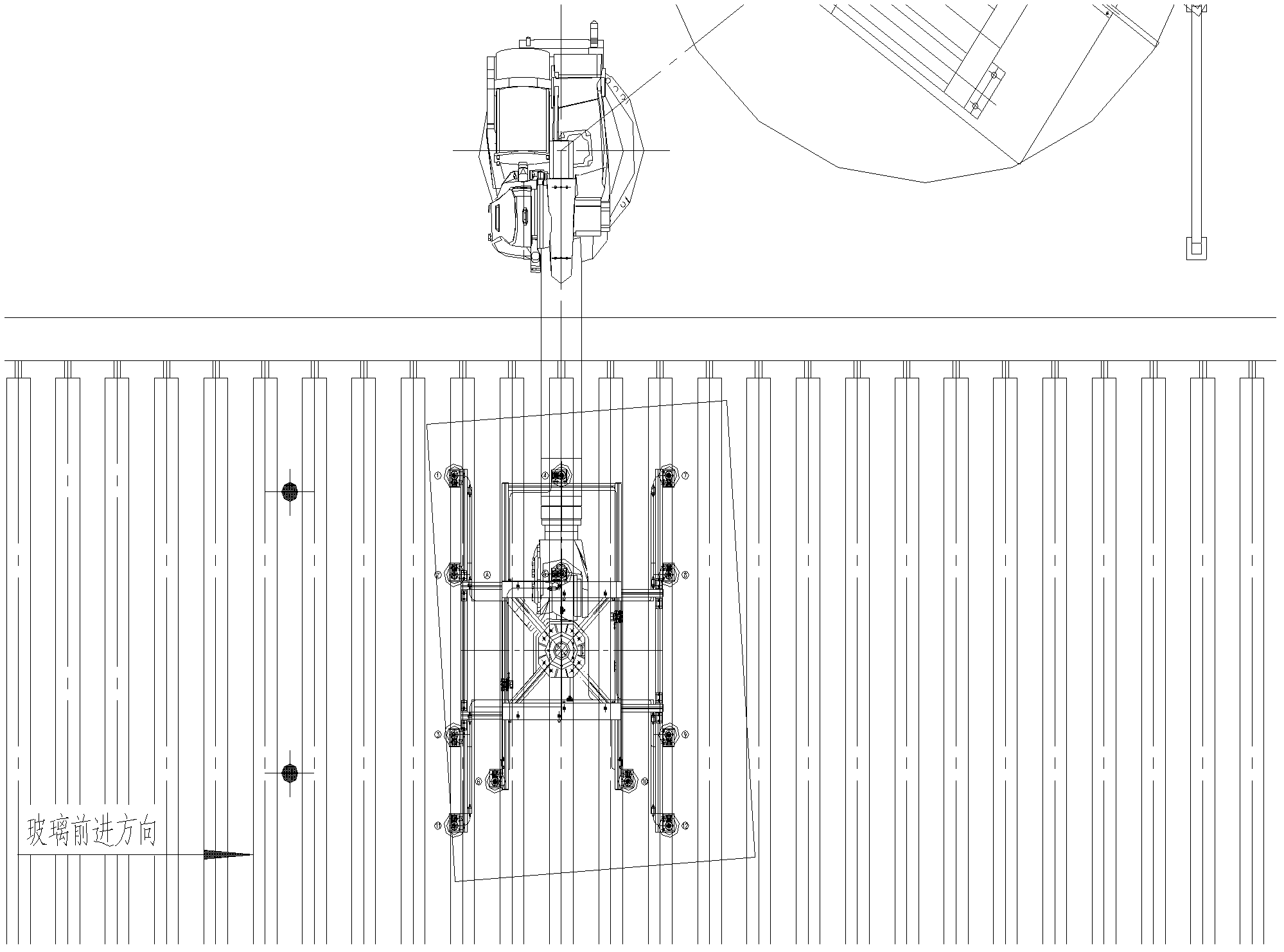

Method for correcting position during the glass grabbing process of manipulator of manipulator glass stacking system

ActiveCN102491099AAccurate captureImprove gripStacking articlesDe-stacking articlesEngineeringManipulator

The invention relates to the technical field of a manipulator glass stacking system, in particular to a method for correcting a position during the glass grabbing processing of a manipulator of the manipulator glass stacking system. A photoelectric sensor I and a photoelectric sensor II are arranged between two rollers which are arranged at the upstream of a roller bed which keeps a distance s away from the center of the manipulator, the distance between the photoelectric sensor I and the photoelectric sensor II is 1-1.5m, dimension of the glass is a*b or length*width, v is the speed of the roller bed, when the glass deflects, time t1 for the photoelectric sensor I to send a signal and the time t2 for the photoelectric sensor II to send a signal are different, is adopted: a deflection angle is acquired according to the following computational formula: deflection angle &=(t1-t2)*v / 1; and a time point of grabbing is calculated according to the formula that t=tn+(S-|t1-t2|*v / 2) / v+a / 2 / v, wherein tn is a greater time point in t1 and t2. The method provided by the invention has the advantages of convenience in installation, low cost, long service life and convenience in maintenance.

Owner:CHINA TRIUMPH INT ENG

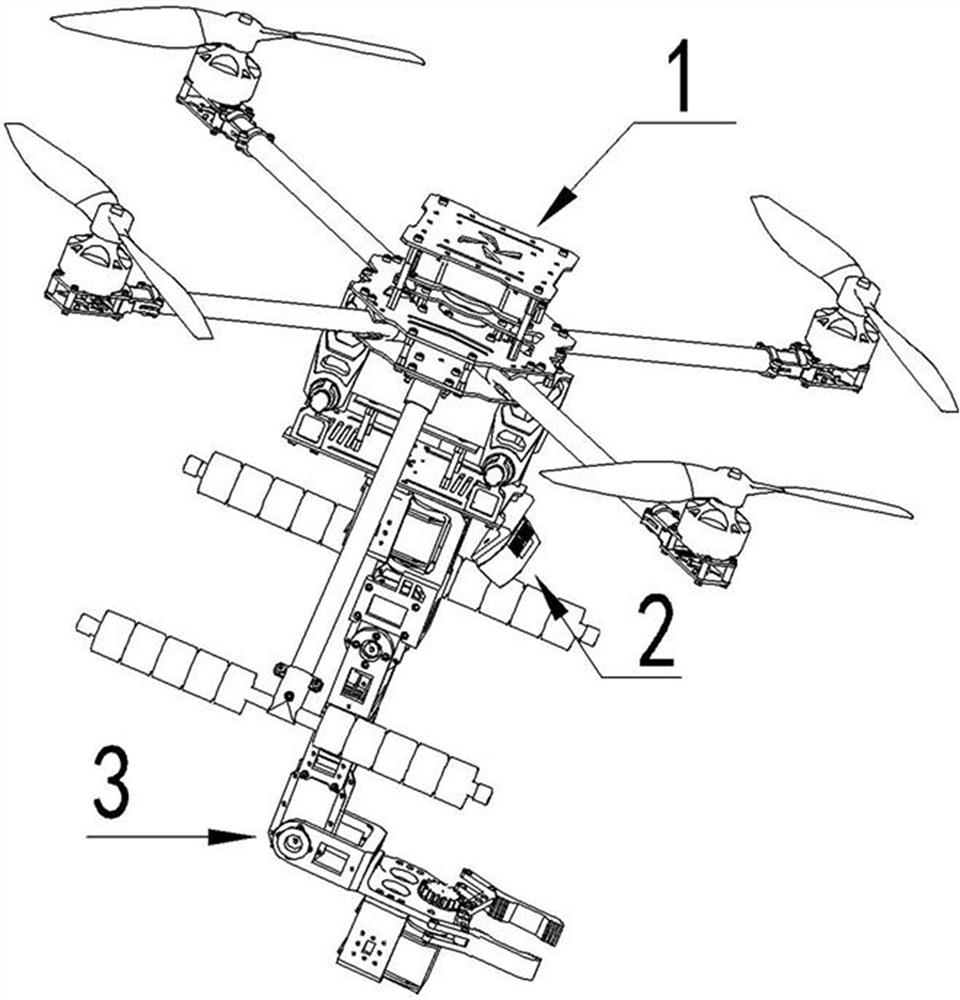

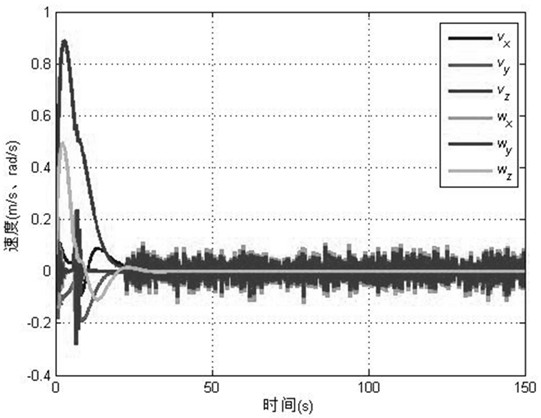

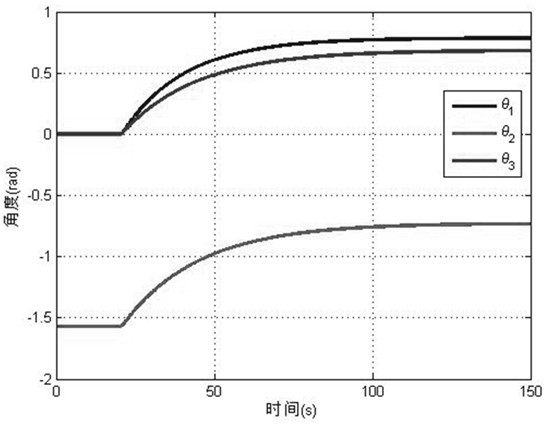

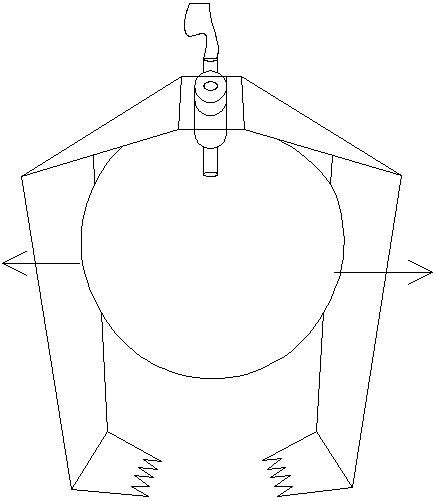

Visual servo and multi-task control method for flying mechanical arm based on spherical model

PendingCN111923049ACapable of active manipulationReduce uncertaintyProgramme-controlled manipulatorAttitude controlVisual servoingRobot hand

The invention provides a visual servo and multi-task control method for a flying mechanical arm based on a spherical model. According to the method, an adopted servo structure comprises a drone, a mechanical arm and a control module, wherein the mechanical arm is mounted on the mechanical arm mounting surface of the drone, a depth camera is further arranged on the mechanical arm mounting surface,the shooting angle of the depth camera and the mechanical arm mounting surface form an angle, the control module enables the depth camera and the mechanical arm to be combined into a robot hand-eye calibration system, an actuator is arranged at the tail end of the mechanical arm, the control module is a control module capable of controlling the flight of the drone, when the flying mechanical arm needs to operate the target, the control module evaluates the target distance through the depth camera, if the target is located outside the operation range of the mechanical arm, the control module drives the drone to fly towards the target, and if the target is located within the operation range of the mechanical arm, the control module drives the mechanical arm to operate the target. According to the method, the mechanical arm with active control capability can be mounted on the drone.

Owner:FUZHOU UNIV

Flexible arm capable of being driven to extend

InactiveCN109732640ARealize fully automatic telescopic grabbingStrong clamping forceGripping headsEngineeringAirbag deployment

The invention discloses a flexible arm capable of being driven to extend, belongs to the field of flexible arms, and aims to solve the problem of complicated control flow in a traditional pneumatic flexible clamping hand. The flexible arm capable of being driven to extend comprises a first fixed plate, a second fixed plate, a first elastic airbag, a second elastic airbag, a first air transmissionpipe, a second air transmission pipe, a connecting spring and a clamping hand module; a first through hole is formed in the first fixed plate; and a second through hole is formed in the second fixed plate. The flexible arm can effectively solve the problem of complicated control structure in a traditional flexible robot, is skillful in concept, simple in structure, low in cost, excellent in performance, reasonable in design, high in adaptability, higher in application value and better in application prospect, and deserves large-scale popularization and application. Through actual application,the flexible clamping hand can meet the clamping demands of objects with different shapes, and can realize lifting and grabbing of the objects with a higher weight than the flexible clamping hand by 10-15 times.

Owner:SOUTHWEAT UNIV OF SCI & TECH

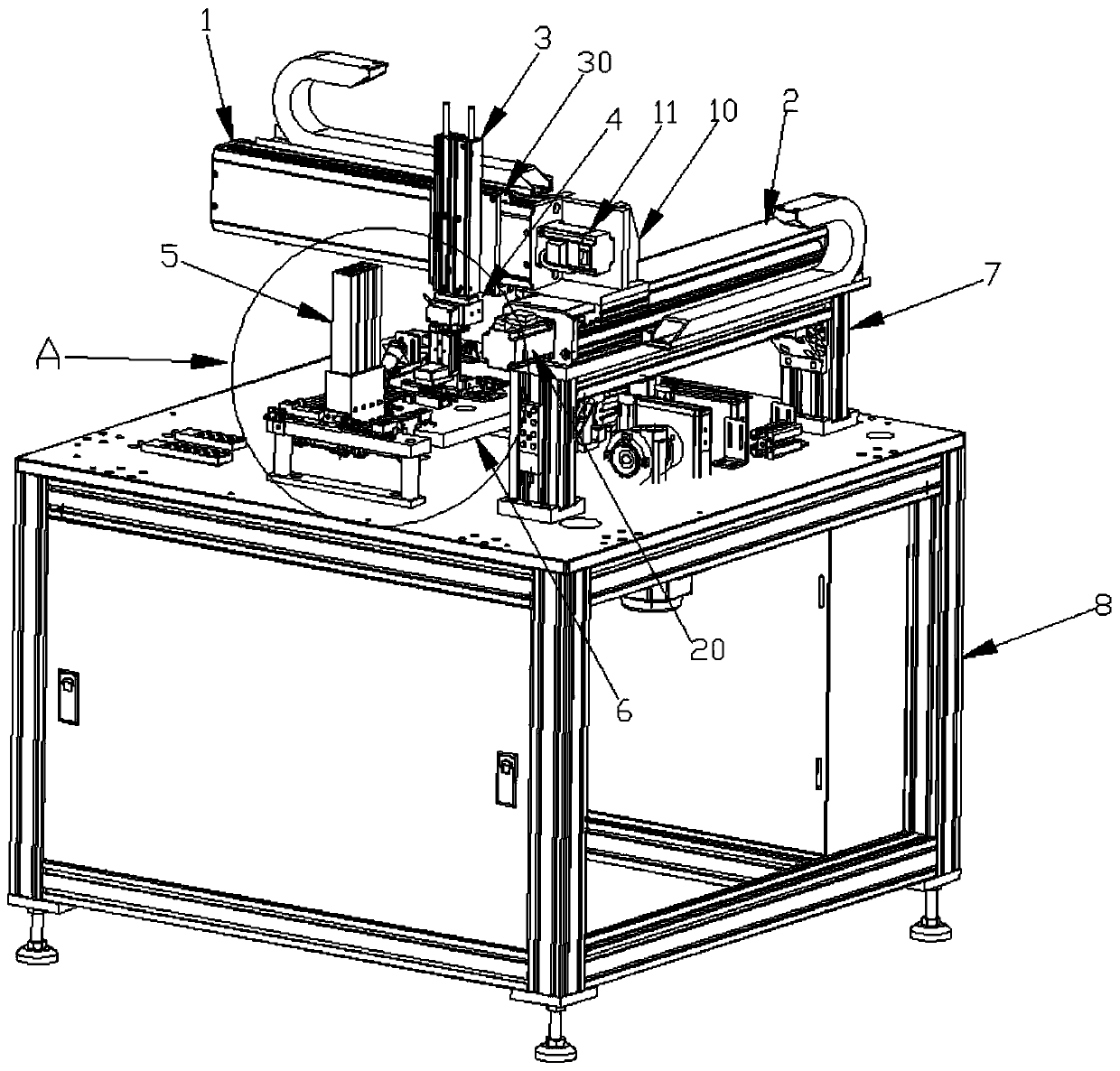

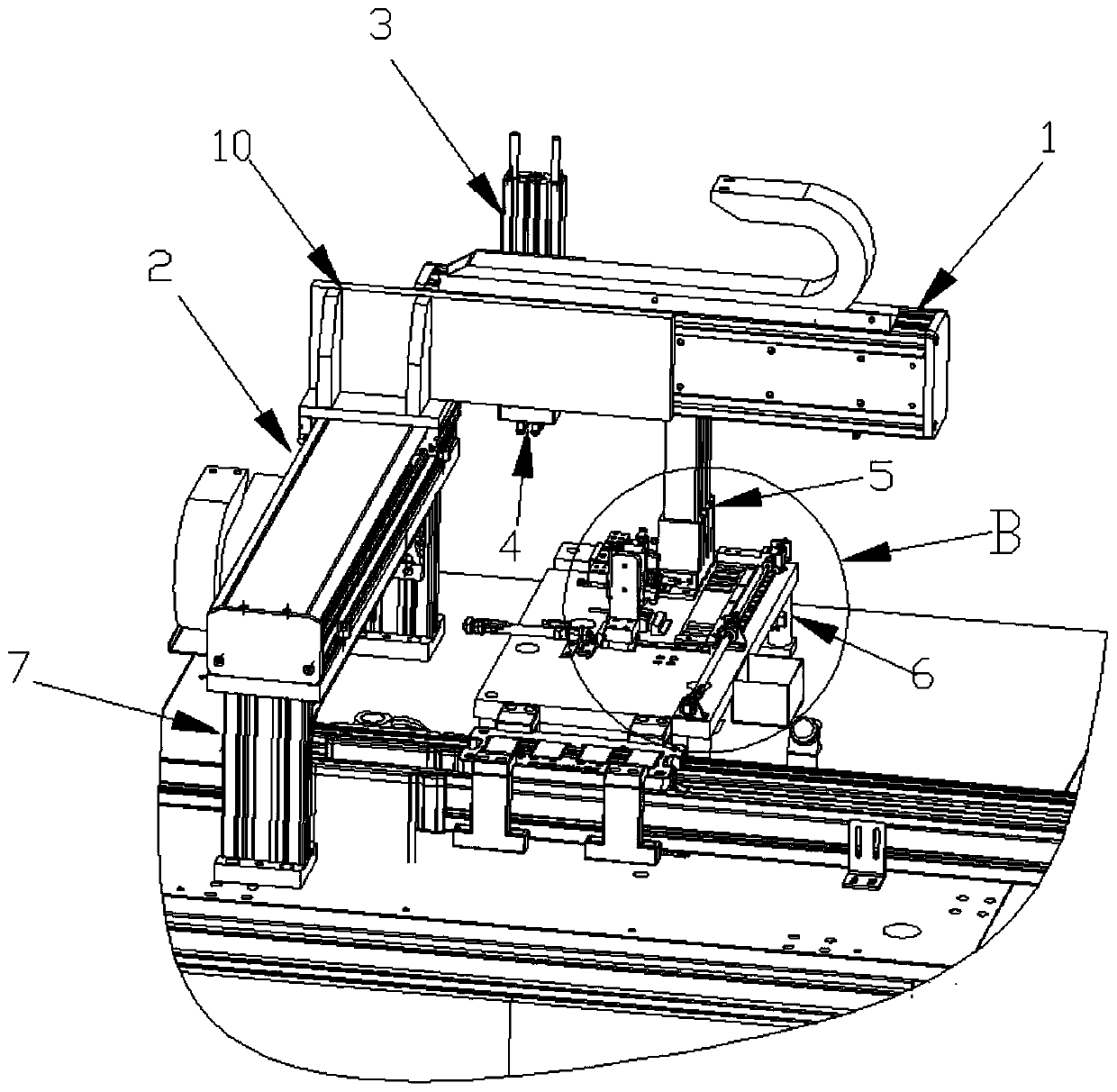

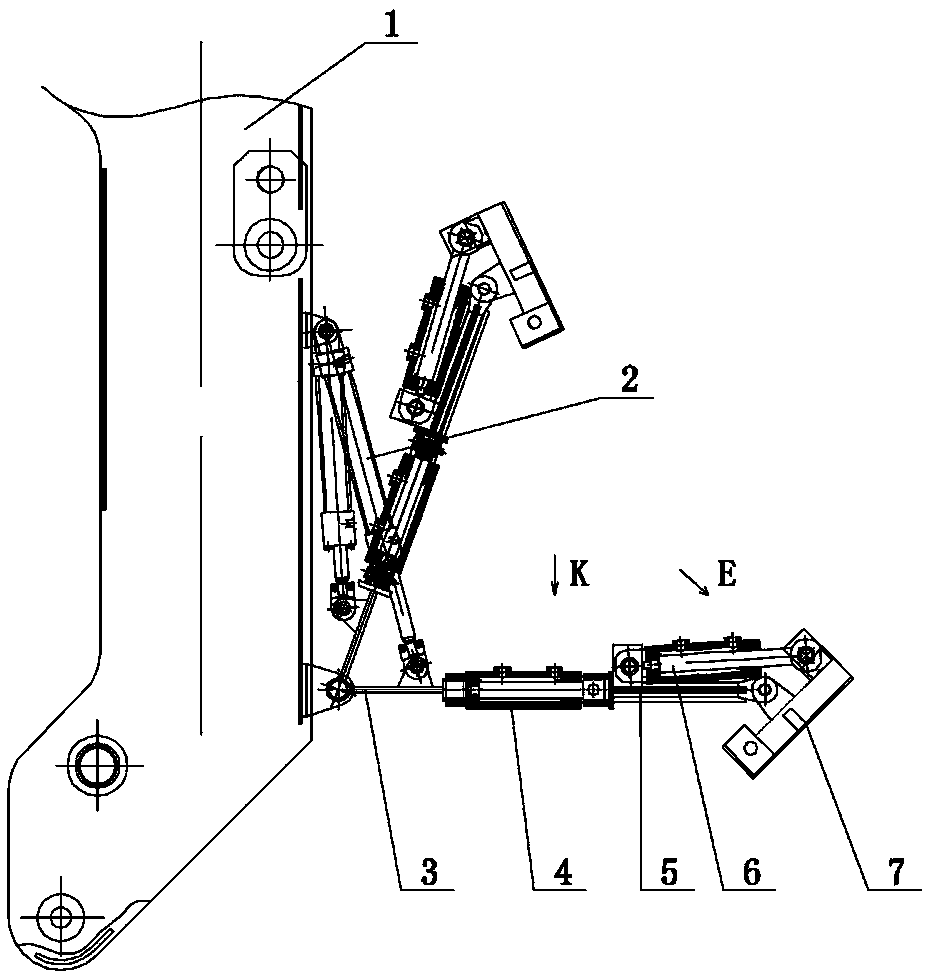

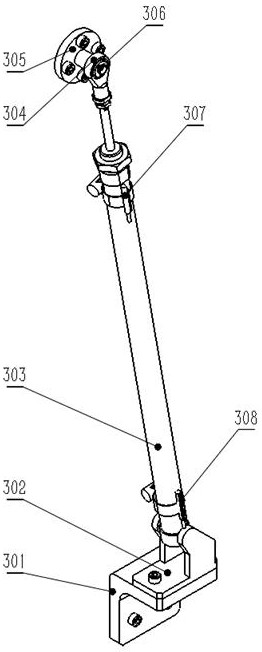

Mold servo grabbing mechanism of intelligent robot welding assembly automatic production line tool

PendingCN108000884AImprove securityWon't hurtDomestic articlesTotal factory controlProduction lineGear wheel

The invention discloses a mold servo grabbing mechanism of an intelligent robot welding assembly automatic production line tool, and belongs to the field of the intelligent robot welding matching technology. The mold servo grabbing mechanism comprises a fixed support, an operation support, a transmission device, a servo motor and a large mechanism grabbing device. The operation support and the fixed support are in transmission connection through gears and racks. The large mechanism grabbing device comprises two sets of grabbing mechanisms arranged on a base. Each set of grabbing mechanism comprises two turnover clamping structures and a locking structure. Each turnover clamping structure comprises a grabbing air cylinder, an air cylinder fixing plate, an air cylinder rod front end connecting plate, a rotary shaft connecting plate, a clamping structure fixing plate, a clamp and rotary shafts A, B and C. Each grabbing mechanism is provided with the two corresponding clamps. A protrudingportion at one end of each clamp is rotationally connected with the front end of the corresponding air cylinder rod front end connecting plate through the corresponding rotary shaft C. Each plate locking structure comprises a lock body, two lock cylinders, two lock cylinder auxiliary plates and a lock cylinder connecting plate. The mold servo grabbing mechanism has the advantages that no vibrationis generated, the product in-place precision is high, and the mold change speed is high.

Owner:宁波亿荣自动化科技有限公司

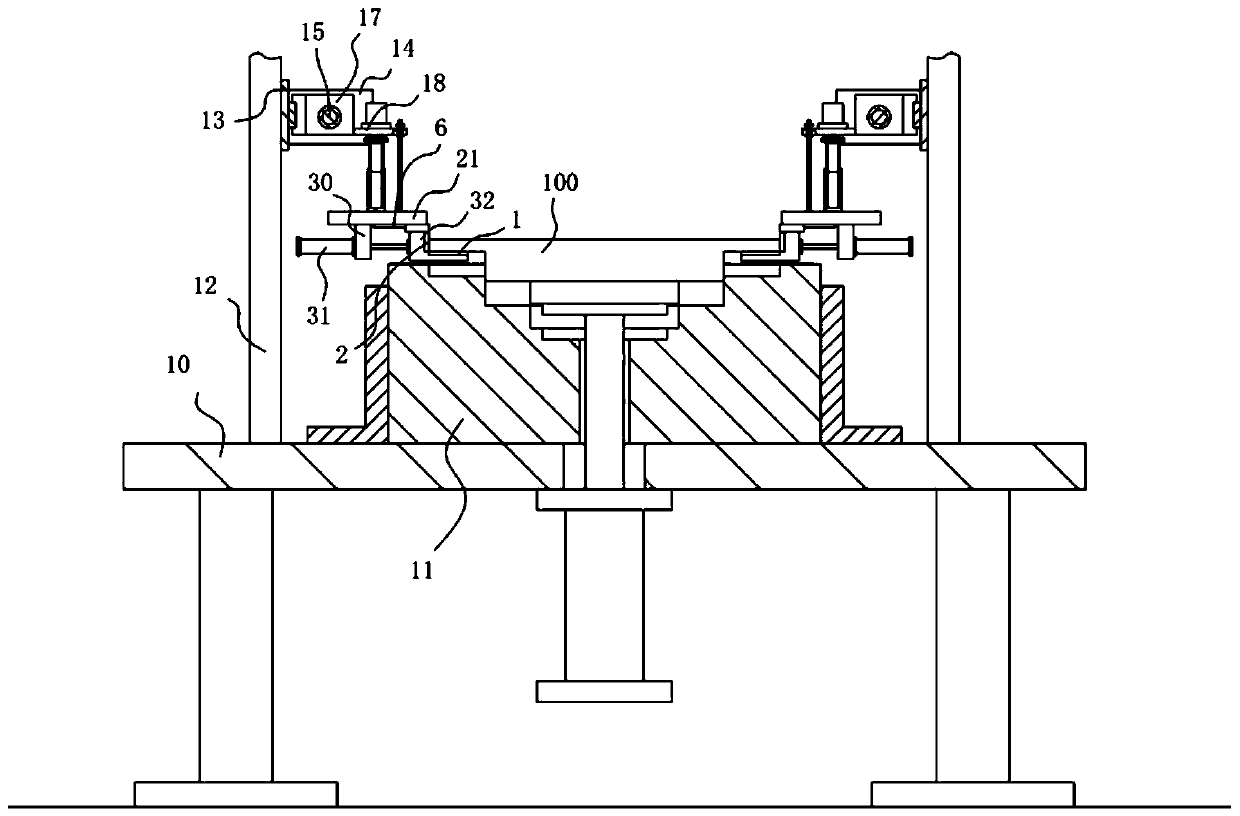

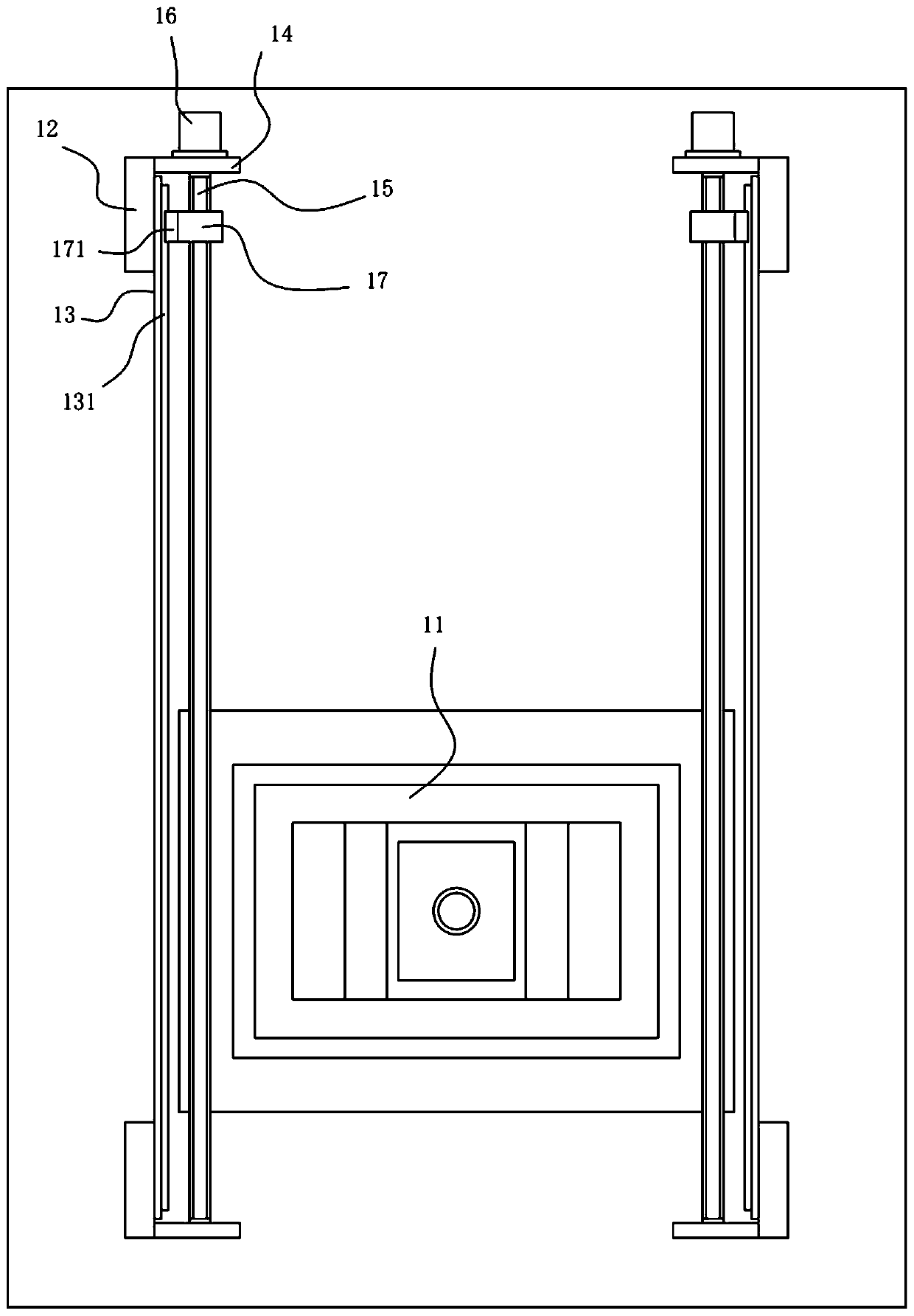

Automatic taking mechanism for mold products

The invention discloses an automatic taking mechanism for mold products. The automatic taking mechanism includes a rack, a lower mold is fixed in the middle portion of the top surface of a top plate of the rack, and support columns are fixed to the portions, on the front and rear portions of the left and right sides of the lower mold, of the top face of the top plate of the rack; and a side connecting beam is fixed to the two support columns on the left side, and a side connecting beam is also fixed on the two support columns on the right side. Connecting plates are fixed to the positions, onthe front and rear ends of the two side connecting beams, of the inner walls of the support columns, the two ends of adjusting screws extending forwards and backwards are hinged to the two connectingplates through bearings, the rear wall face of the connecting plate on the rear is fixedly provided with a drive motor, the drive motor drives the adjusting screws to rotate, movement blocks are screwed on the adjusting screws, and the lower parts of the opposite wall surfaces of the two movement blocks are fixedly provided with horizontal connecting plates, and the horizontal connecting plates are fixedly provided with lifting mechanisms. The automatic taking mechanism can automatically grab and remove the mold products in the lower mold, and the automatic taking mechanism is convenient and safe to grab, stable in movement and good in effect.

Owner:吴明博

Method for realizing manipulator rapid grabbing control in robot stacking system

The invention relates to a method for realizing manipulator rapid grabbing control in a robot stacking system. The method comprises a robot, a PLC control system, a first photoelectric sensor and a second photoelectric sensor, wherein the two photoelectric sensors are disposed on the upstream of a roller way in parallel, the intermediate points of the first photoelectric sensor and the second photoelectric sensor are located between two rollers, and the distance between the center of a manipulator and the two rollers is S; when the robot stacking system is in the process of grabbing materials,the manipulator and the materials can achieve synchronous displacement, under the situation that the manipulator and the materials remain relatively static, the materials are stacked and carried, theangle of the manipulator is adjusted according to trigger signals sent out by the two photoelectric sensors, and thus the materials after stacking are piled in order. The robot stacking system adopting the method can realize rapid grabbing of the materials and can grab the materials stably, accurately and safely; and the robot stacking system is convenient to install, low in cost and high in practicability, can greatly speed up the industrial production takt, and improves the production efficiency and the productivity.

Owner:CNBM TRIUMPH ROBOTICS SHANGHAI CO LTD

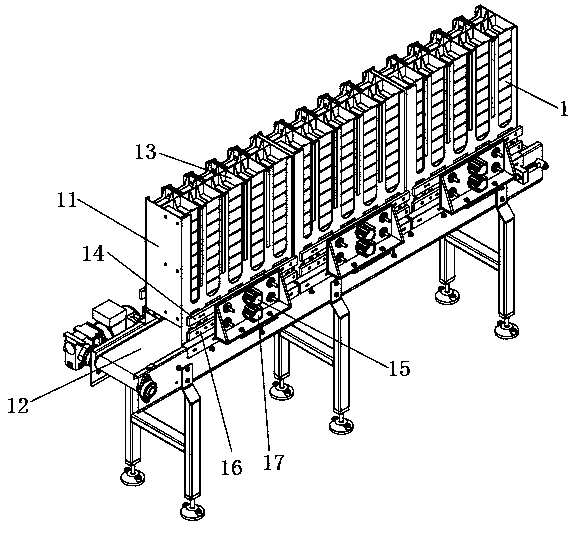

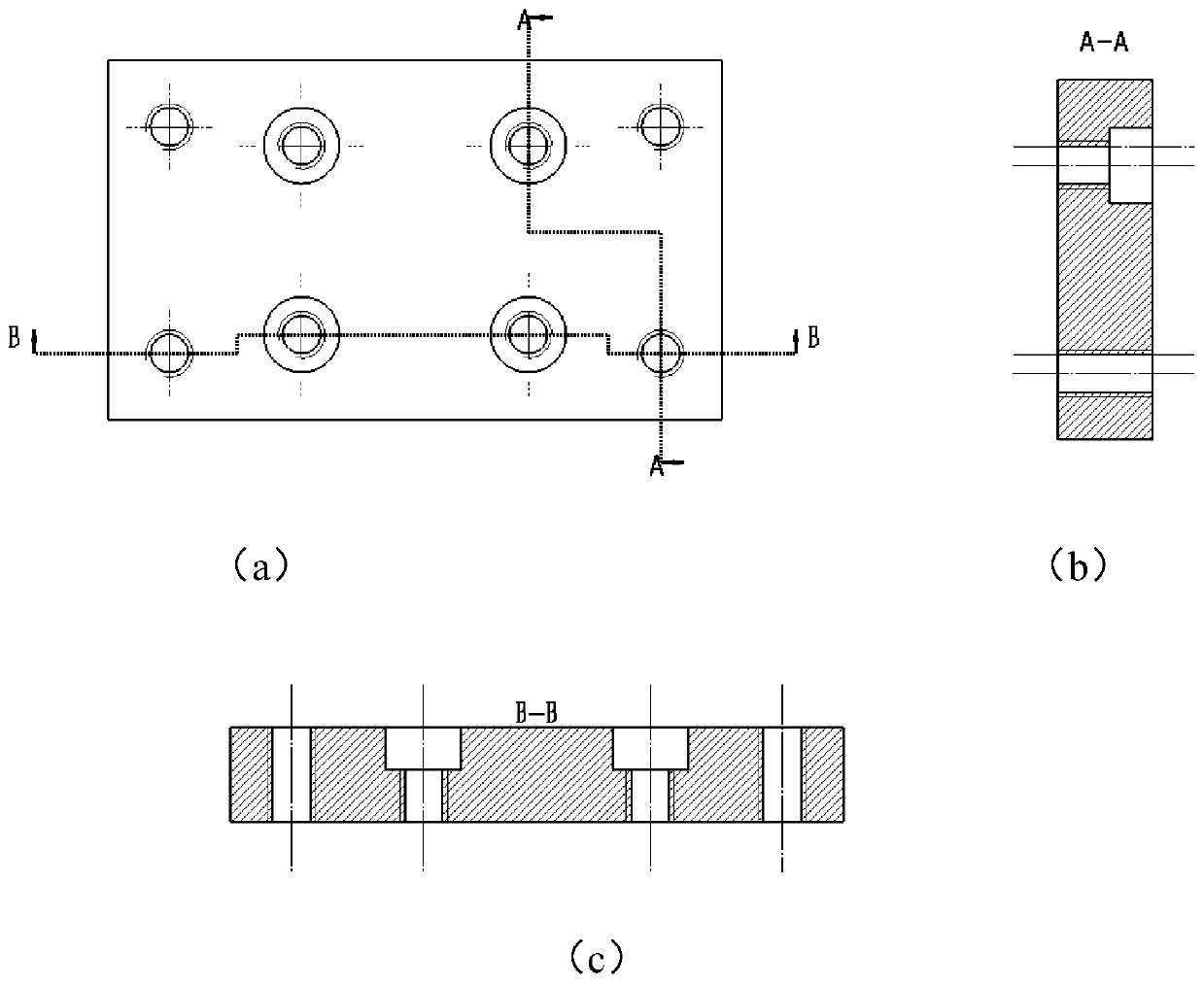

Automatic ceramic chip feeding device for PTC (Positive Temperature Coefficient) heating element preparation

PendingCN110116903ASafe and reliable grabbingOrderly rowsConveyorsDischarging arrangementVertical planeVertical cylinder

The invention discloses an automatic ceramic chip feeding device for PTC (Positive Temperature Coefficient) heating element preparation, and relates to the field of processing and preparation of PTC heating elements. The device comprises an X-axis rail, a Y-axis rail, a vertical cylinder, a vacuum chuck, a ceramic chip storing rack, a handling platform and a base platform. According to the device,the X-axis rail and the Y-axis rail are arranged to realize moving on the horizontal plane, and the vertical cylinder enables moving on a vertical plane, so that three-dimensional moving is achieved;and meanwhile, the vacuum chuck is used for picking the ceramic chip, so that the picking stability and safety are ensured; the ceramic chip storing rack is matched with a push-out cylinder to automatically push the ceramic chips, and four ceramic chips form a group; in addition, a ceramic chip groove is matched with a receiving cylinder to further take out the four pushed-out ceramic chips, andthe four ceramic chips are arranged regularly. Therefore, both time and power are saved by automatic feeding; in addition, the chuck for grabbing is safe and reliable; and moreover, the four ceramic chips can be regularly arranged.

Owner:芜湖黑特新能源汽车科技有限公司

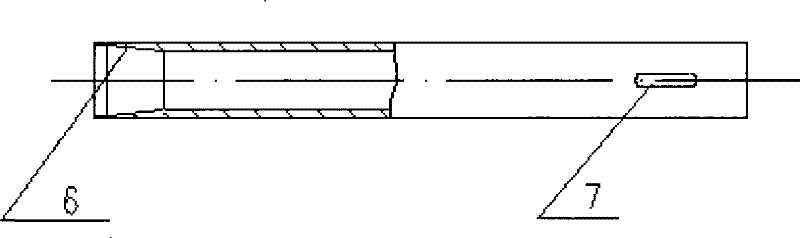

Clamping head for fuel rod replacing device

ActiveCN101271738BAchieve crawlingAchieve separationNuclear energy generationReactor fuel elementsNuclear reactorEngineering

The invention discloses a chuck used for a fuel rod replacing device, belonging to a device used for replacing nuclear fuel in a nuclear reactor. The chuck used for the fuel rod replacing device comprises a locking sleeve and an elastic chuck pipe which is arranged in the locking sleeve; the lower part of the locking sleeve is provided with a flaring conical surface; the inner side of the lower end of the elastic chuck pipe is matched with the head of the fuel rod; the pipe wall of the lower part of the elastic chuck pipe is provided with at least two longitudinal thin troughs. The chuck usedfor the fuel rod replacing device is characterized in that the elastic chuck pipe is internally provided with a flaring expansion pipe; the upper part of the flaring expansion pipe is fixedly connected with the elastic chuck pipe; the pipe wall at the lower end of the flaring expansion pipe is provided with at least two longitudinal thin troughs. The chuck used for the fuel rod replacing device has simple structure, realizes the grasping and disconnecting to the fuel rod by single motion of lifting upwards and inserting downwards of a part (core rod), commonly locks the grasping head by the clamping force of the elastic chuck pipe and the clamping force of the locking sleeve after the fuel rod is grasped, thus leading the fuel rod to be safely and reliably grasped in the detection and replacement process of the fuel rod.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD +1

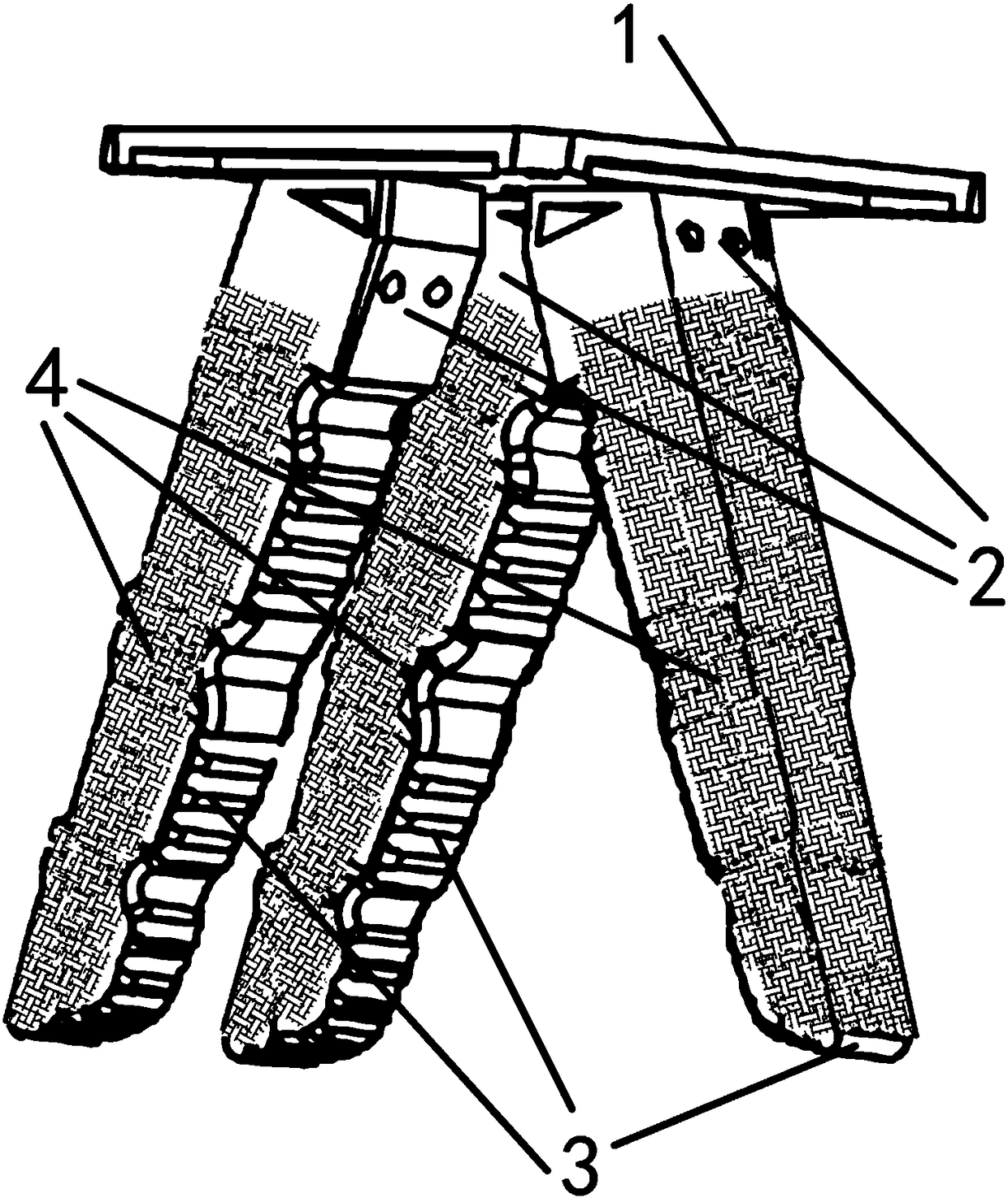

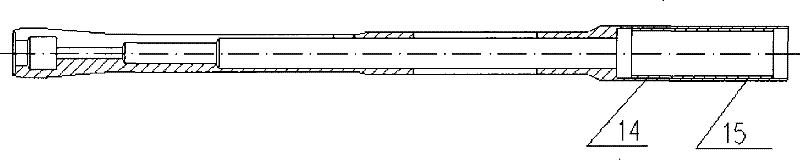

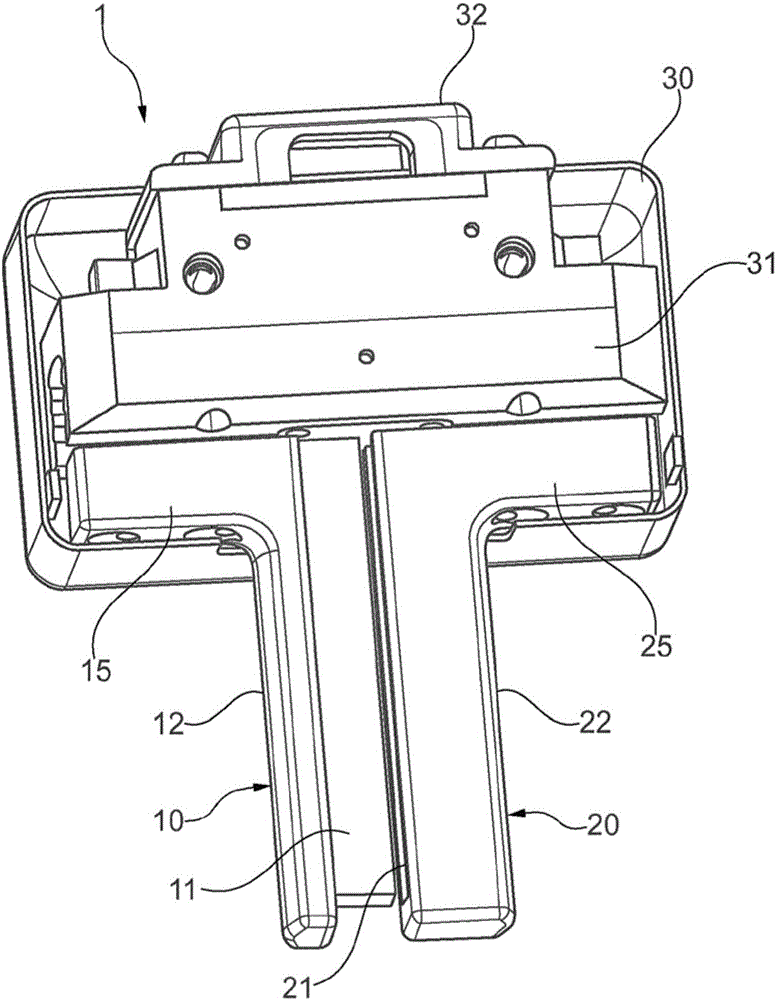

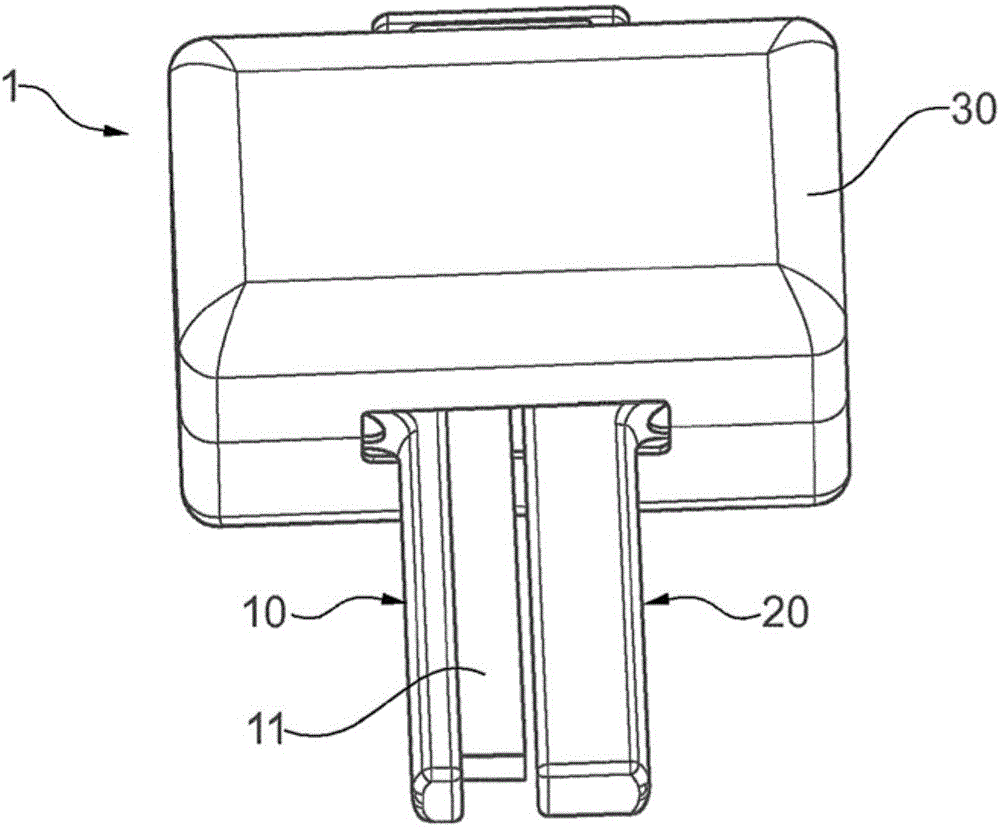

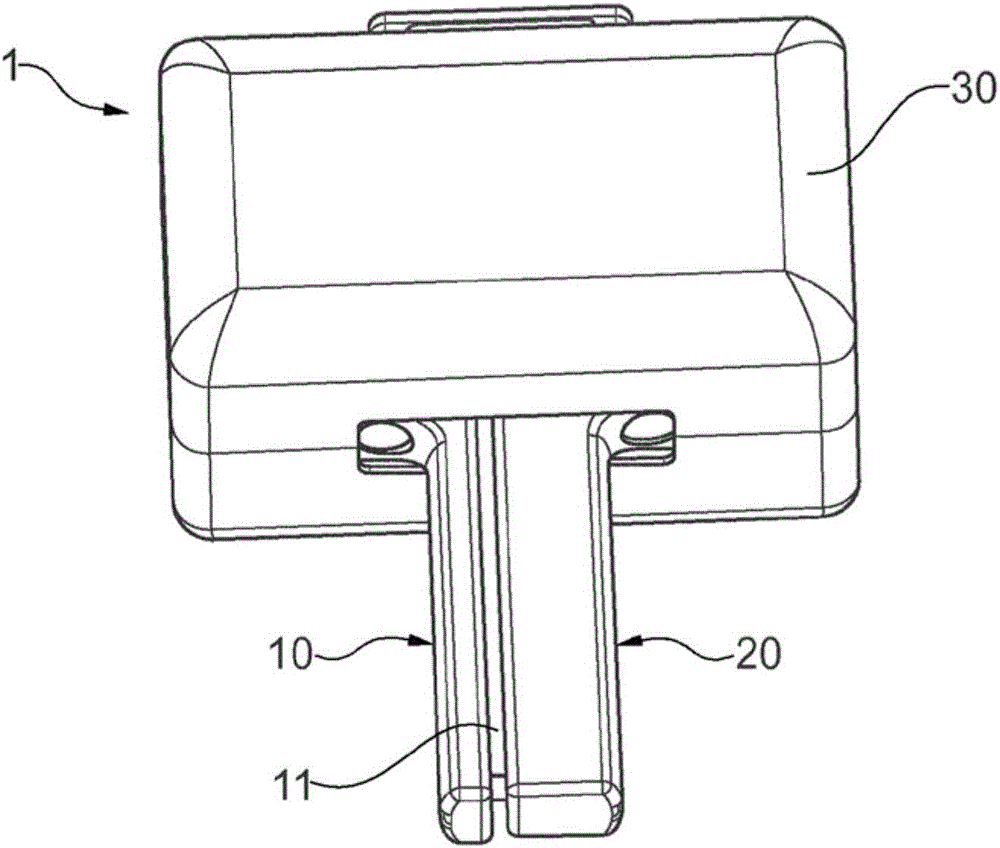

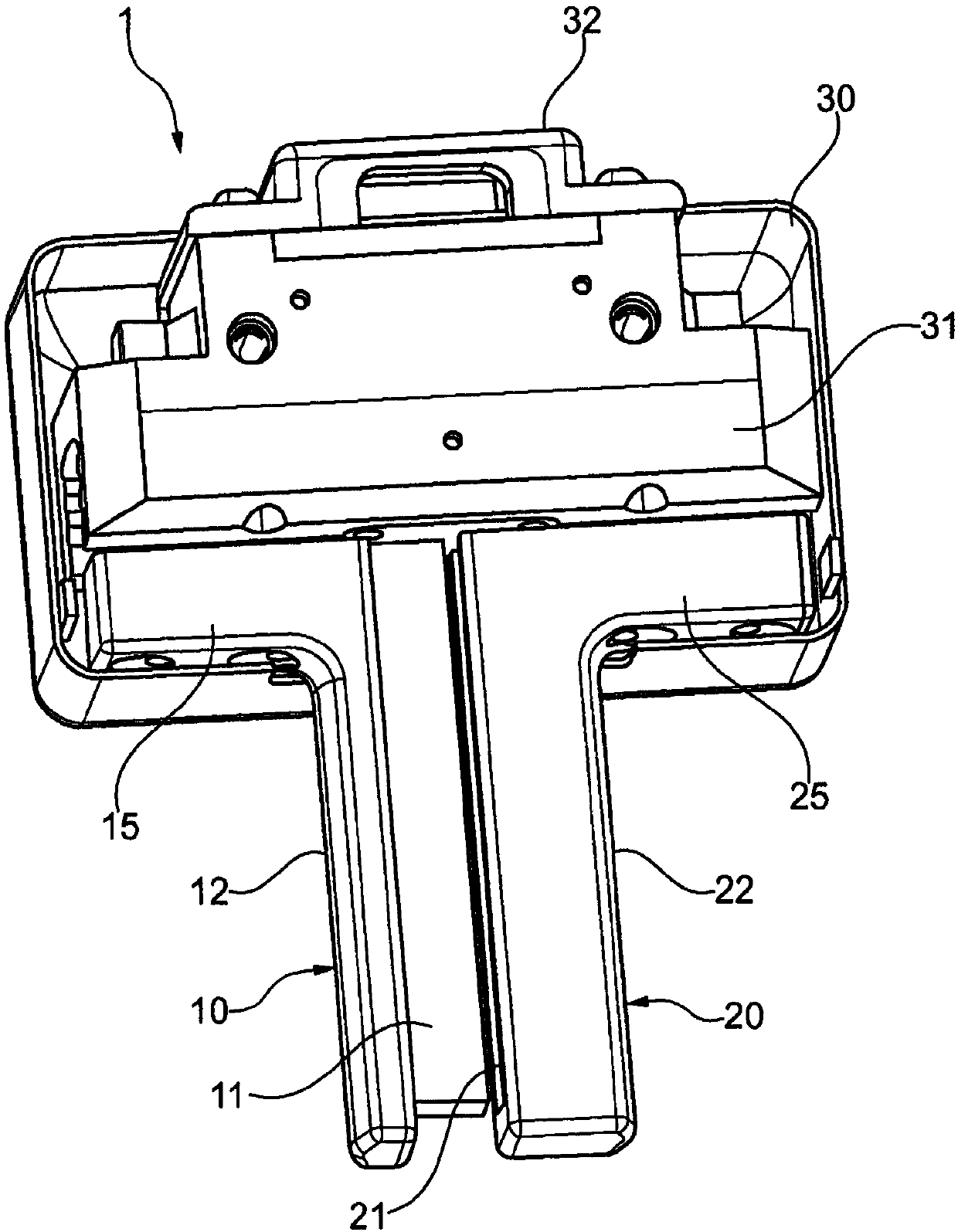

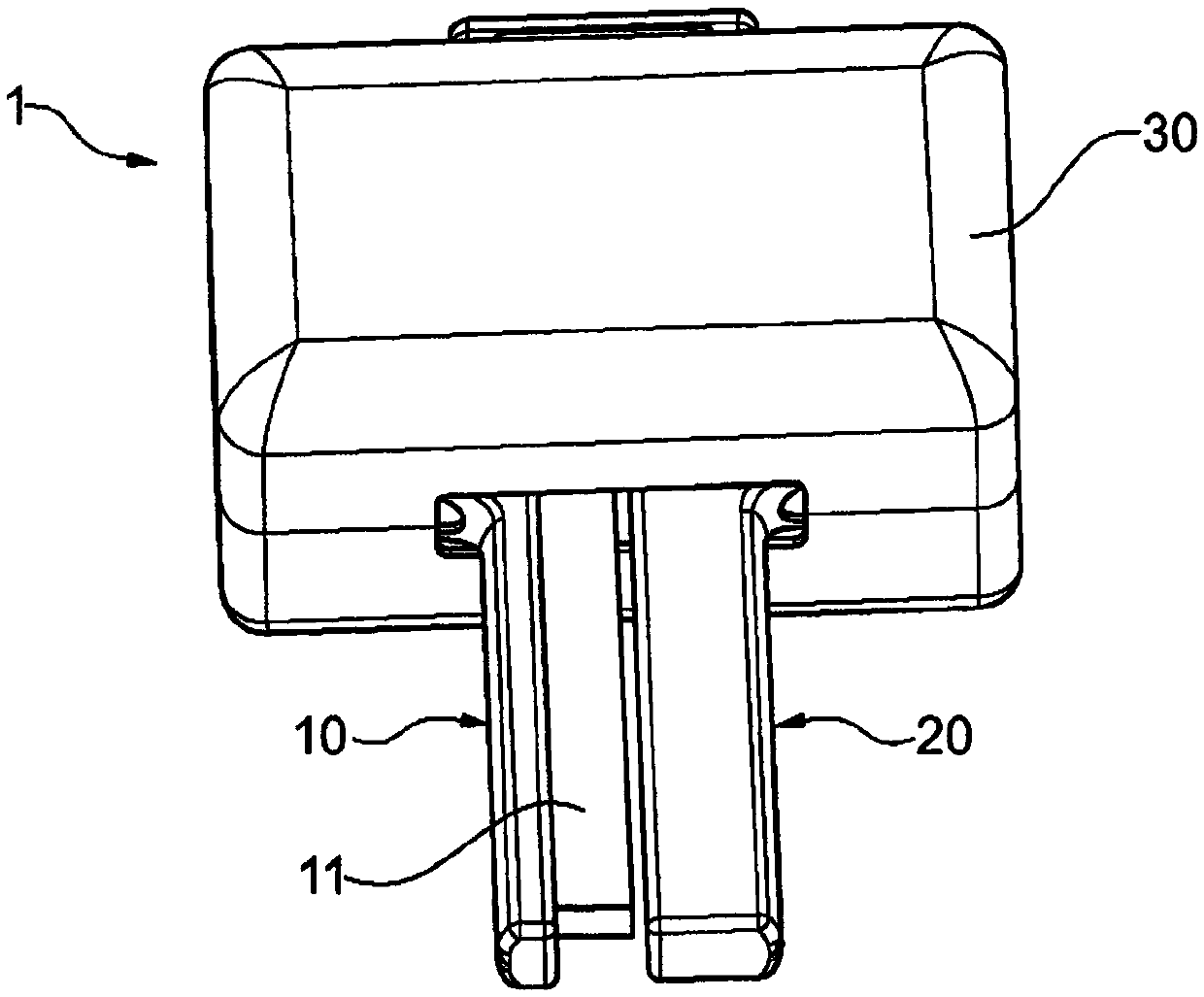

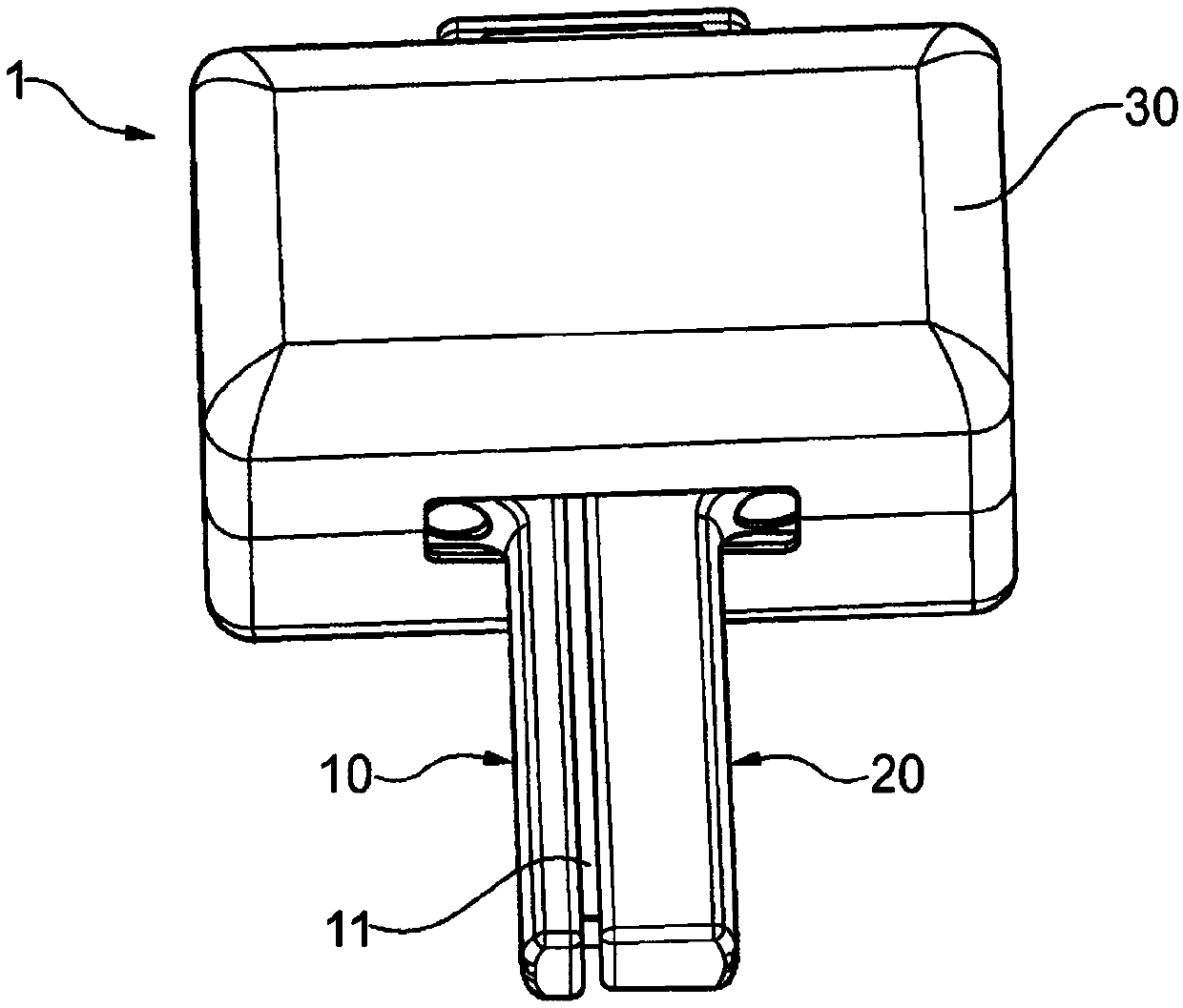

Gripping jaw safety device with tongue and groove for HRC

InactiveCN106413999AUnintentional entrySafe and reliable grabbingGripping headsEngineeringTongue and groove

The present invention relates to a gripping device (1), in particular as effector for an industrial robot, comprising first (10) and second (20) clamping jaws which are movable relative to each other to engage a workpiece. The first clamping jaw (10) has a tongue projection (11) and the second clamping jaw (20) has a corresponding groove (21) which at least partly accommodates the tongue projection (11) when the clamping jaws (10, 20) are moved towards each other in order to prevent objects or body parts from being accidentally inserted in the space between the clamping jaws.

Owner:KUKA SYSTEMS

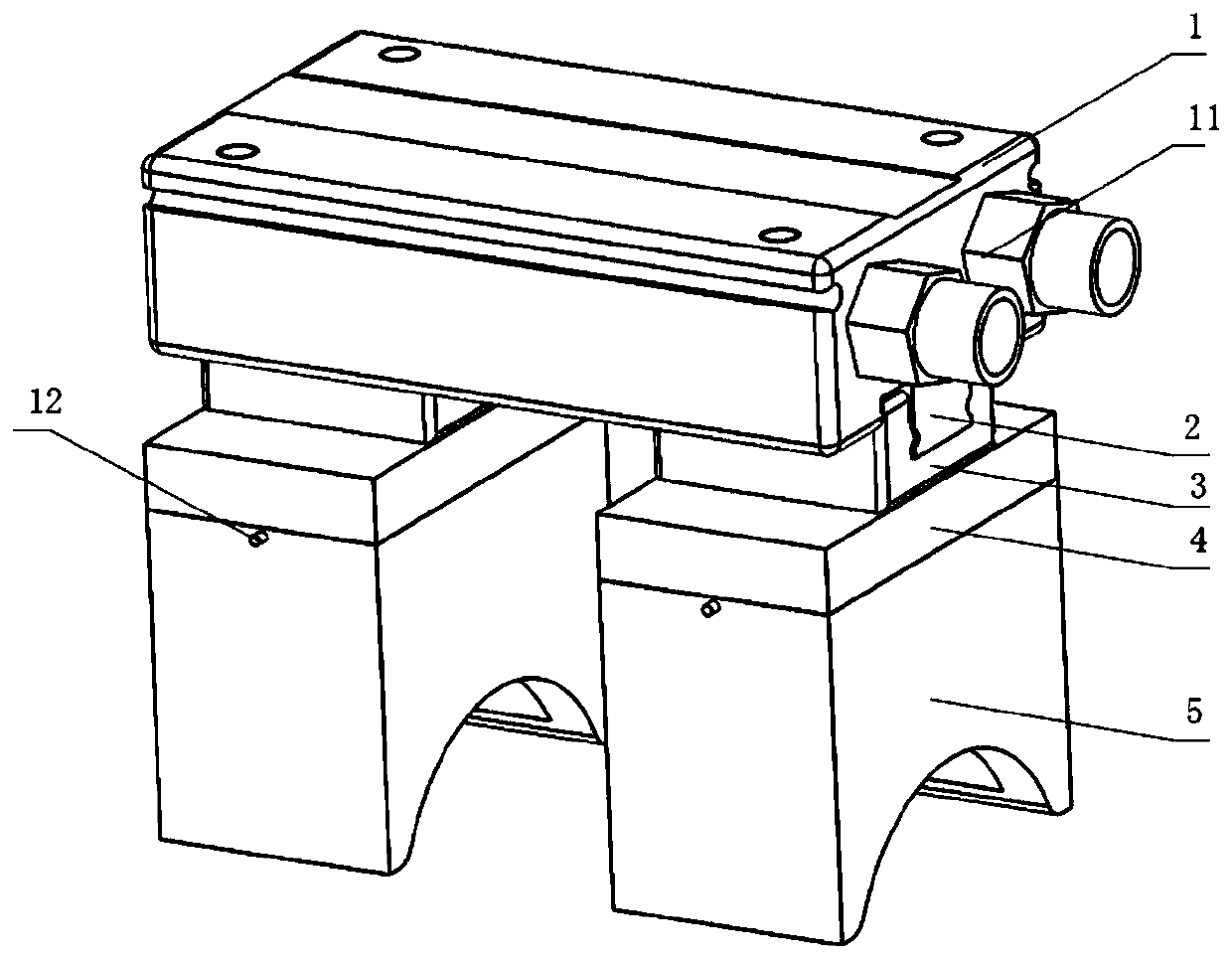

Pneumatic-electromagnetic hybrid control manipulator for grabbing cylindrical workpieces and control method of manipulator

ActiveCN111086019AIncrease load capacityExtended RadiusProgramme-controlled manipulatorGripping headsClassical mechanicsManipulator

The invention discloses a pneumatic-electromagnetic hybrid control manipulator for grabbing cylindrical workpieces and a control method of the manipulator, and belongs to the field of manipulators. According to the pneumatic-electromagnetic hybrid control manipulator for grabbing the cylindrical workpieces, a guiding rail is arranged at the bottom of a pneumatic sliding groove base, two pneumaticsliding blocks are arranged on the guiding rail, pneumatic-electromagnetic connecting plates are arranged on the pneumatic sliding blocks respectively, and electromagnets are arranged at the bottoms of the pneumatic-electromagnetic connecting plates; air openings connected with inflation and deflation devices are formed in the end surface of the pneumatic sliding groove base, and electromagnetic valves for controlling connection and disconnection of air channels are arranged on the air channels of the air openings; the guiding rail provides the motion strokes for the pneumatic sliding blocks;circular arches are formed in the bottoms of the electromagnets, the axes of the circular arches are parallel with the motion strokes for the pneumatic sliding blocks, the circle center angles of thecircular arches are 60 degrees, and the radiuses of the circular arches are equal to the radius of the largest to-be-grabbed workpiece. By the aid of the manipulator, the workpieces in the radius range of (R / 2, R] can be attracted singly.

Owner:定西高强度紧固件股份有限公司

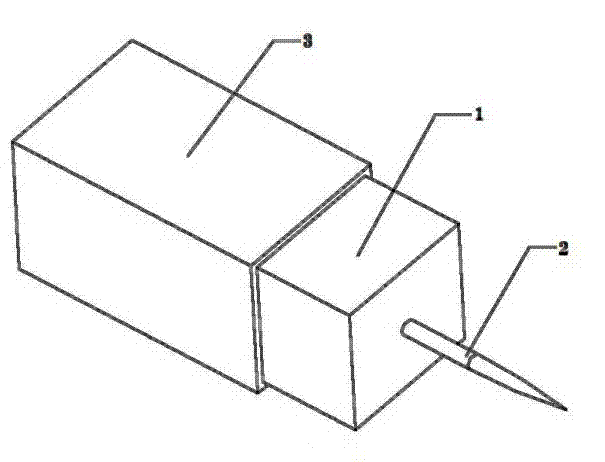

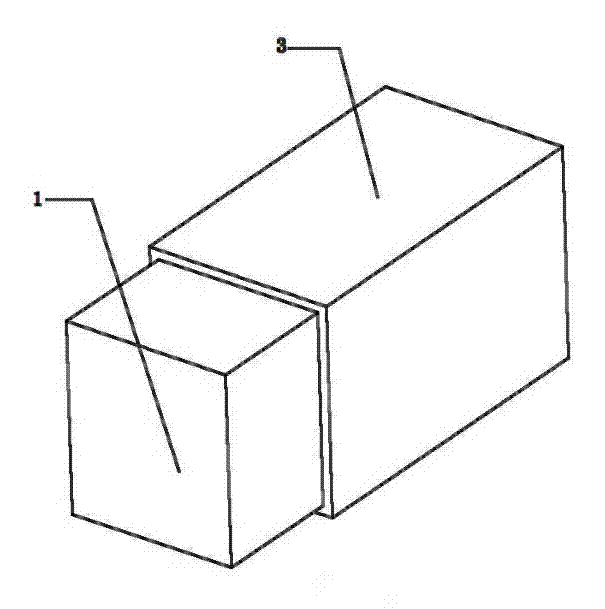

Thumbtack capable of preventing from pricking hand

The invention relates to a thumbtack capable of preventing from pricking a hand. The thumbtack comprises a nail head, a nail needle and a jacket, wherein the nail head is a columnar structure, and the nail needle is fixed at the center of the bottom of the nail head; the jacket is a sleeve-shaped structure, an inner section corresponds to the size of a section of the nail head, and the length is greater than the length of the nail needle; when the thumbtack is in an off working state, the jack is sleeved on the nail head from bottom to top, and the nail needle is located in the sleeve of the jacket; when the thumbtack is in a working state, the jacket is sleeved on the nail head from top to bottom. The thumbtack with a silica gel jacket disclosed by the invention is used for temporary fixation, and has the advantages of convenience for use, safe grasp, no harm to people, and convenience for pressing down and pulling up.

Owner:SUZHOU ORIGIN IND DESIGN

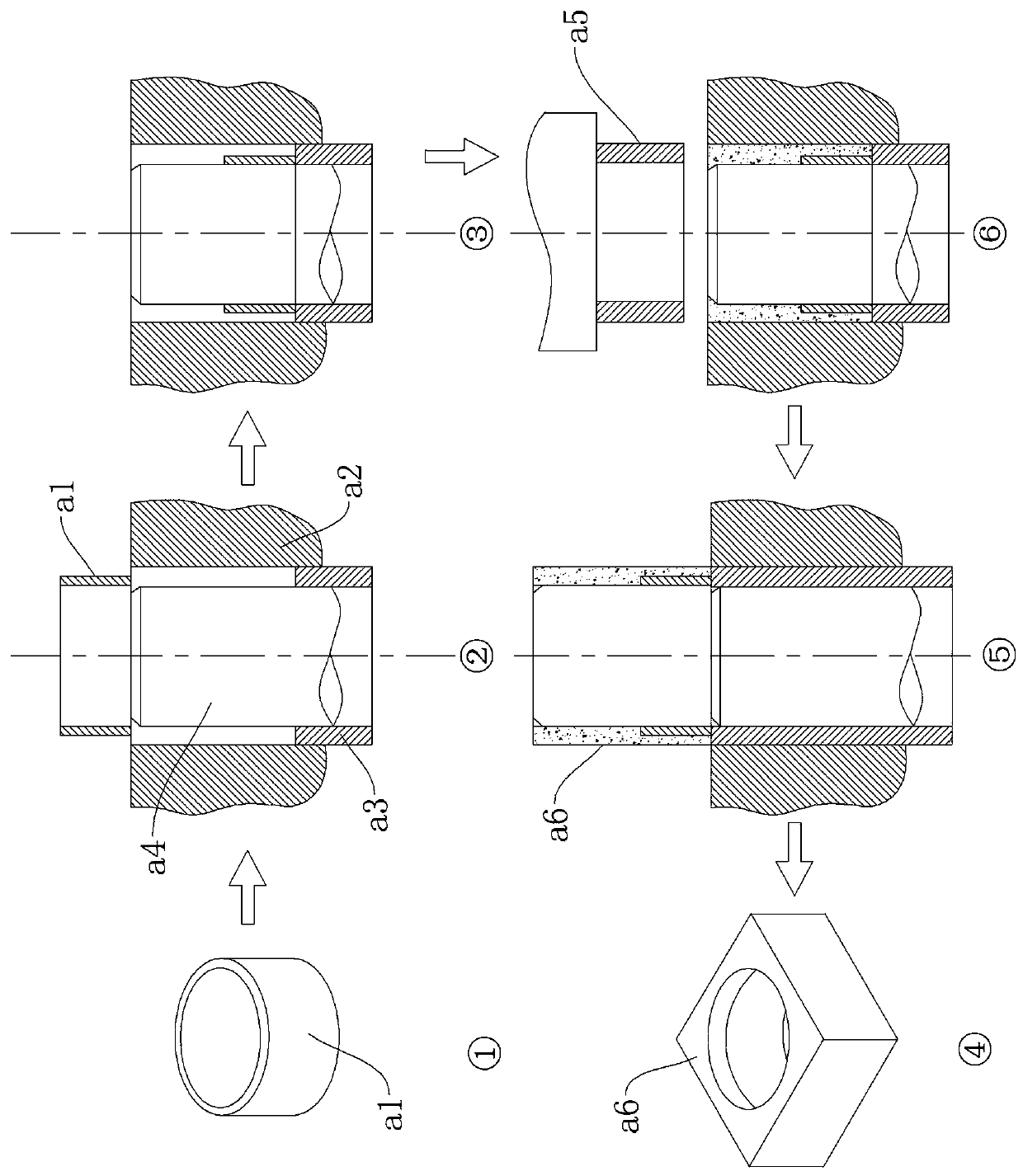

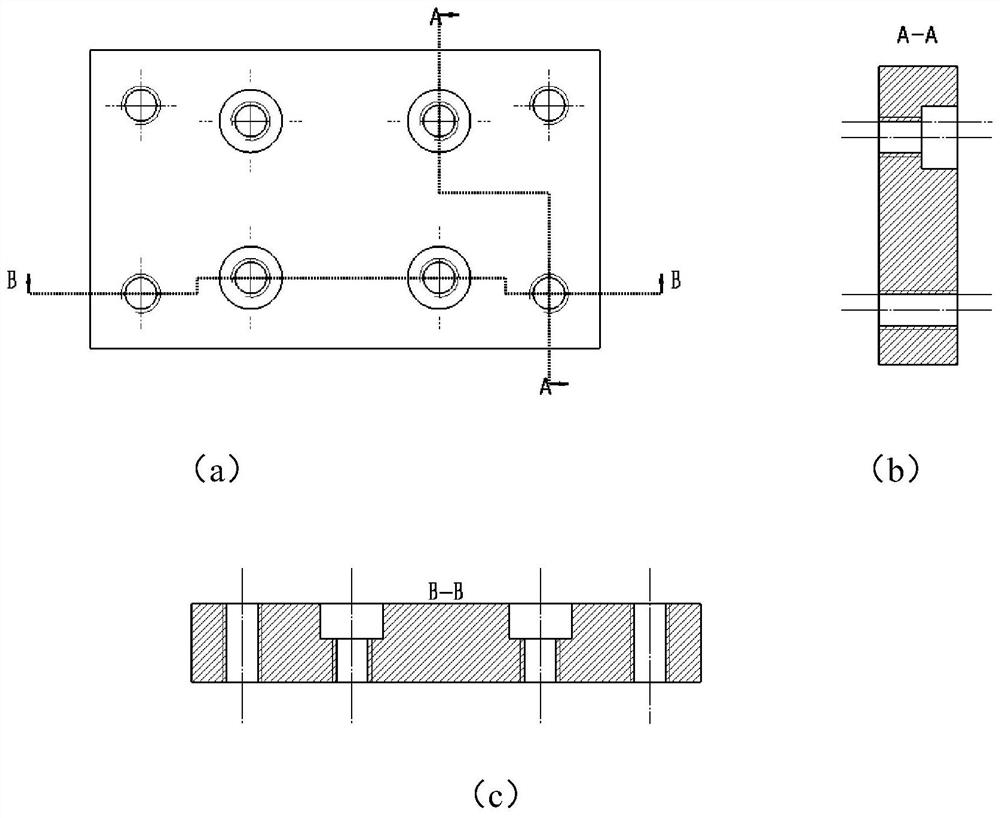

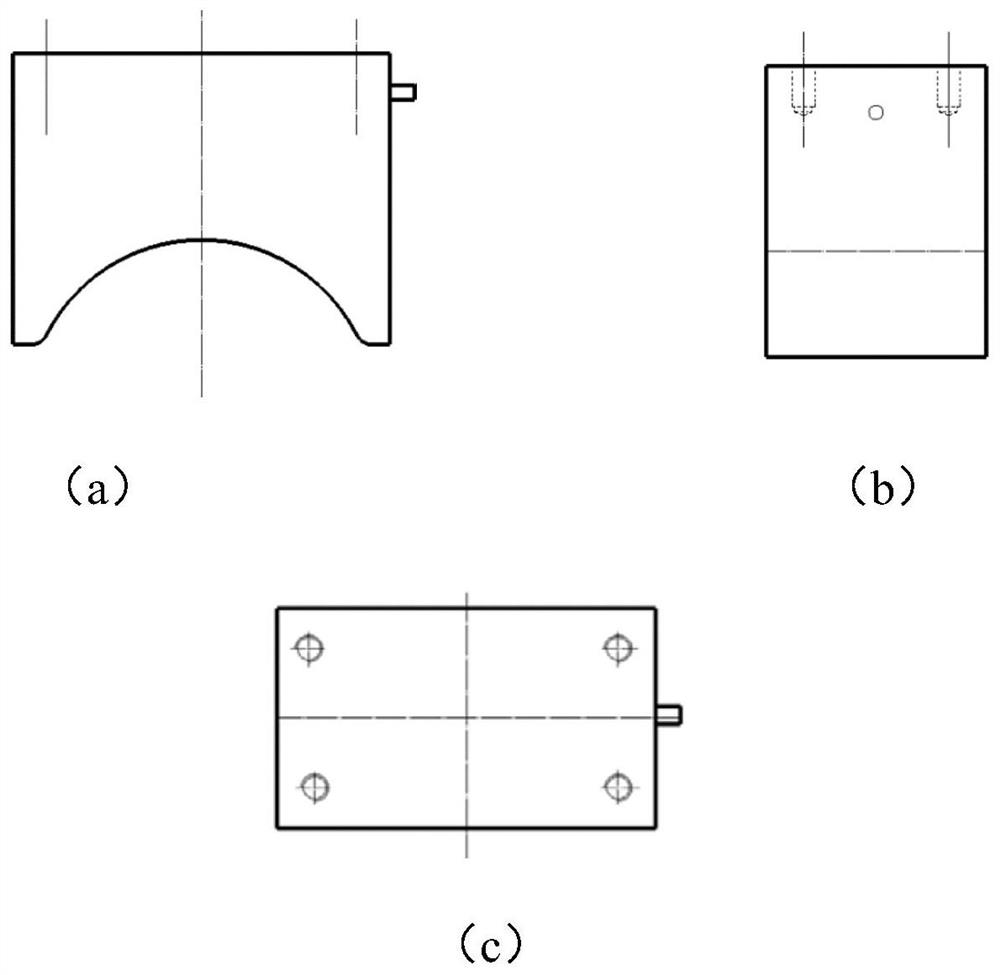

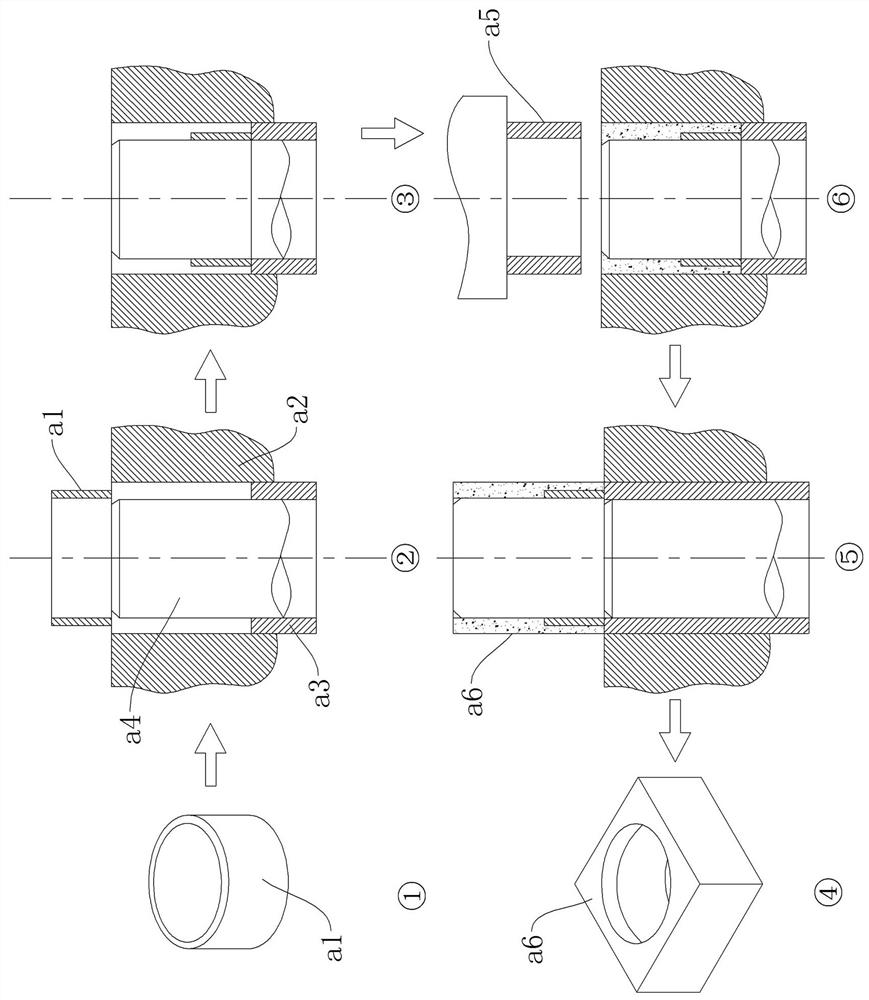

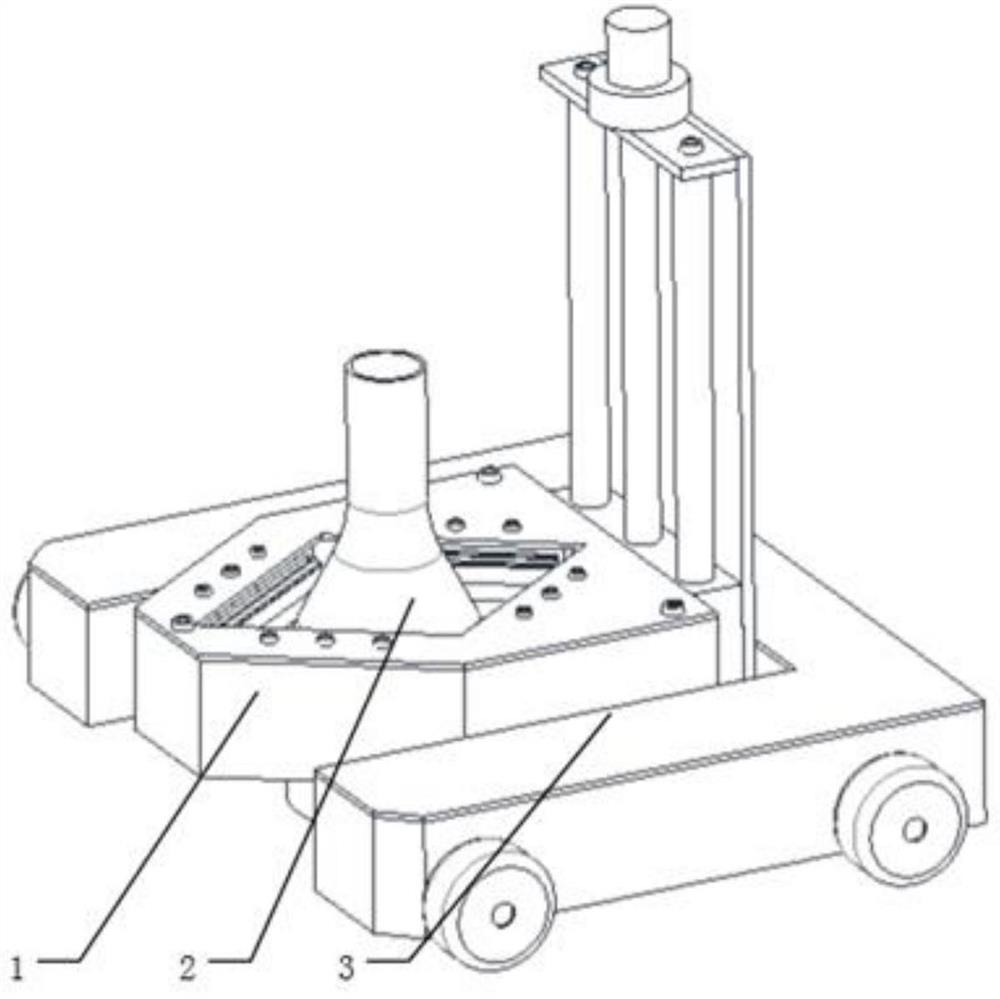

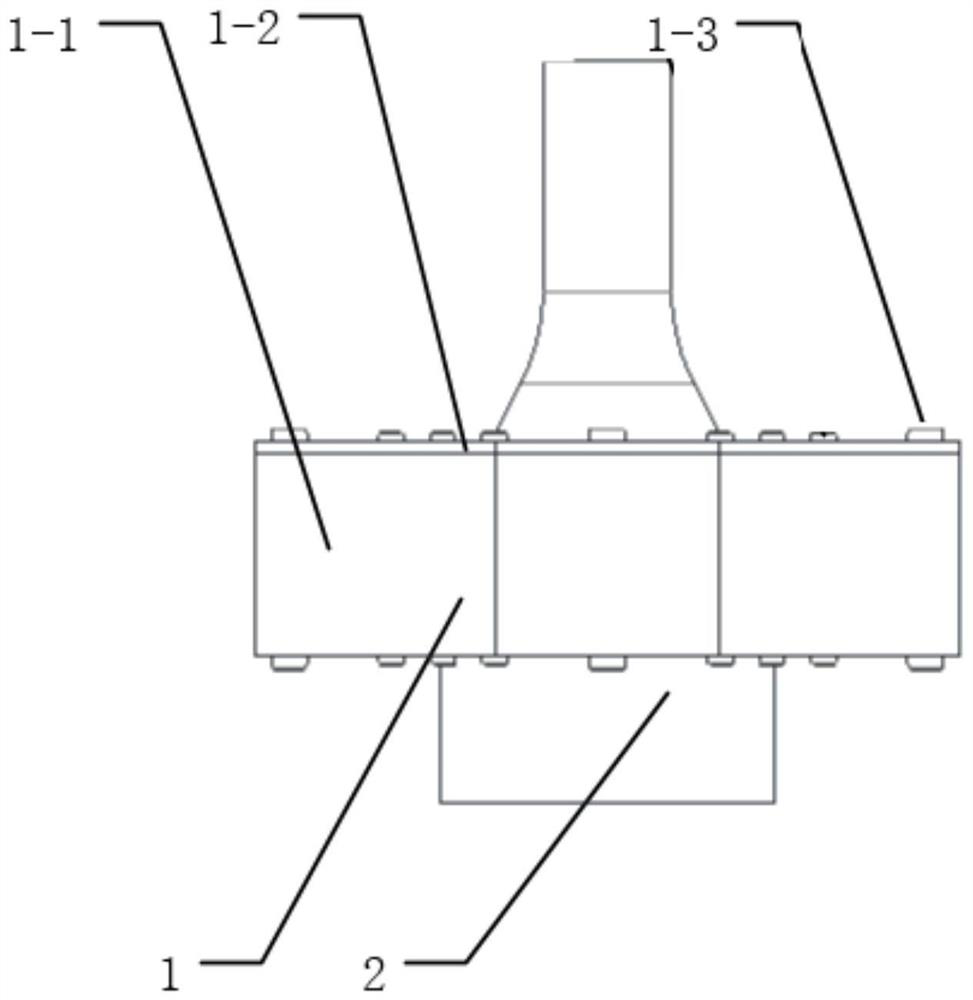

Grabbing and press-fitting complete equipment with flexible adjustment function for producing pyrophyllite blocks for diamonds

ActiveCN111376300ASolve the problem that the workpiece cannot be assembledEasy to grabGripping headsMetal working apparatusHydraulic cylinderPyrophyllite

The invention relates to grabbing and press-fitting complete equipment with a flexible adjustment function for producing pyrophyllite blocks for diamonds. The equipment comprises a feeding belt, a discharging belt and a grabbing and press-fitting machine which are arranged along a straight line, the grabbing and press-fitting machine comprises a working platform installed on stand columns, a forming die lower die assembly is installed in the middle of the working platform, a jacking hydraulic cylinder or an air cylinder is arranged below the working platform and can drive the forming die lowerdie assembly located in the middle of the working platform to ascend and descend, a workpiece moving device is installed on the side face of the working platform and comprises a vertical lifting linear module and a transverse translation linear module, and grabbing and pressing integrated mechanical arms are connected to a moving part of the transverse translation linear module. The equipment isapplied to machining of the pyrophyllite blocks in the diamond production process, grabbing and mounting automation can be achieved, the workpiece grabbing supporting force of the mechanical arms is uniform, the fragile workpiece is not prone to damage, and when the workpiece is assembled, a flexible ring has a certain pose deviation compensation function, so that the assembly is convenient.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Electrolyzer sealing cover automatic grabbing device

Owner:NFC (SHENYANG) METALLURGICAL MACHINERY CO LTD

A Pneumatic Gripper Capable of Weighing and Collision Detection

The invention relates to a weighing-capable and collision-detectable pneumatic gripper, which includes a grasping system and a sensing system. The sensing system is screwed to the gripping system. The sensing system can accurately acquire and integrate the component force information of the grasping system in the X, Y, and Z directions to ensure the accuracy of the force measurement direction and size, and realize collision detection and weighing functions through force analysis. The grasping system uses pneumatic muscles as the power source, and the claws are retracted to grasp objects by pressurizing and contracting the pneumatic muscles. The present invention can ensure the accurate acquisition of three-dimensional force information only through the synthesis of three one-dimensional force sensor mechanisms. At the same time, the gripper is designed with pneumatic muscles and the end of the gripper is enveloped, so as to avoid damage to objects and ensure safe grasping. It has advantages in the direction of object sorting and transportation. Great advantage.

Owner:SHANGHAI UNIV

A Control Method of Pneumatic-Electromagnetic Mixed Control Manipulator for Grabbing Cylindrical Workpieces

ActiveCN111086019BIncrease load capacityExtended RadiusProgramme-controlled manipulatorGripping headsElectromagnetic couplingRobotics

The invention discloses a control method of a pneumatic-electromagnetic hybrid control manipulator for grabbing a cylindrical workpiece, belonging to the field of manipulators. A pneumatic-electromagnetic hybrid control manipulator for grabbing cylindrical workpieces. The bottom of the pneumatic chute base is provided with guide rails. Two pneumatic sliders are arranged on the guide rails. The pneumatic sliders are respectively provided with pneumatic-electromagnetic connecting plates. There are electromagnets at the bottom of the pneumatic-electromagnetic connection plate; the end face of the base of the pneumatic chute is provided with an air port for connecting the charging and deflation device, and the air circuit of the air port is provided with a solenoid valve for controlling whether it is on or off; the guide rail is The pneumatic slider provides a movement stroke; the bottom of the electromagnet is provided with an arc arch, the axis of the arc arch is parallel to the movement stroke of the pneumatic slider, the central angle of the arc arch is 60°, and the arc The radius of the arch is equal to the radius of the largest workpiece to be gripped. The manipulator of the present invention can singlely absorb workpieces with a radius range of (R / 2, R].

Owner:定西高强度紧固件股份有限公司

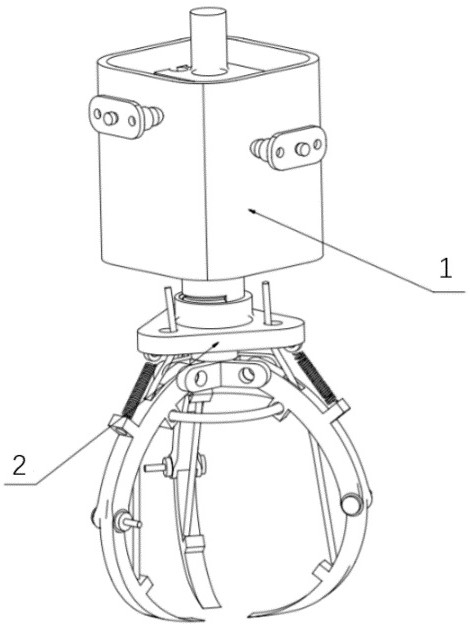

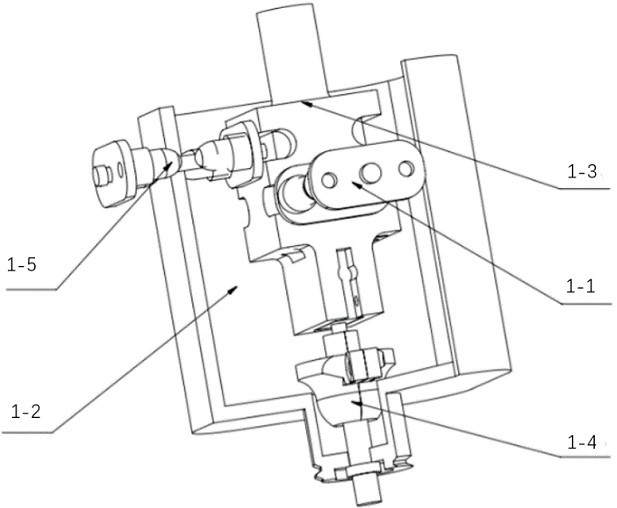

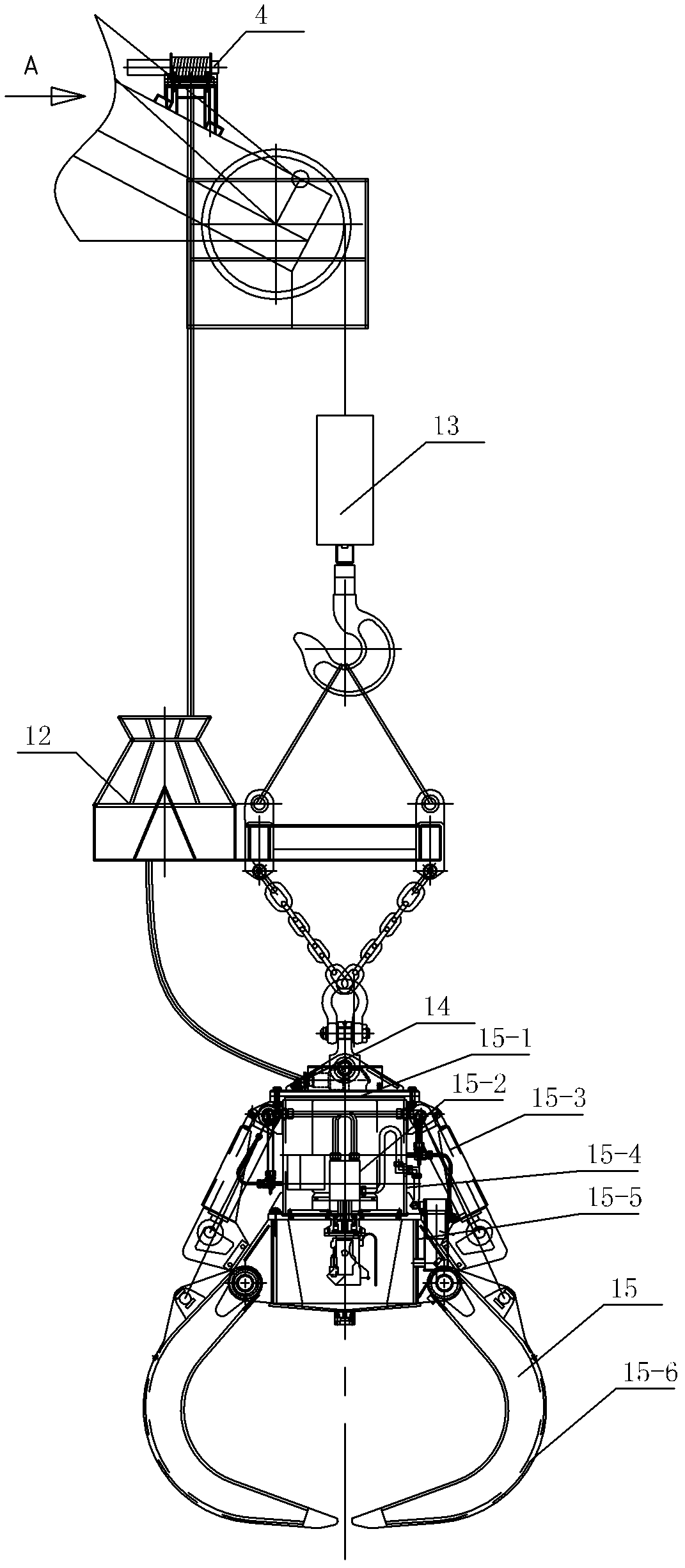

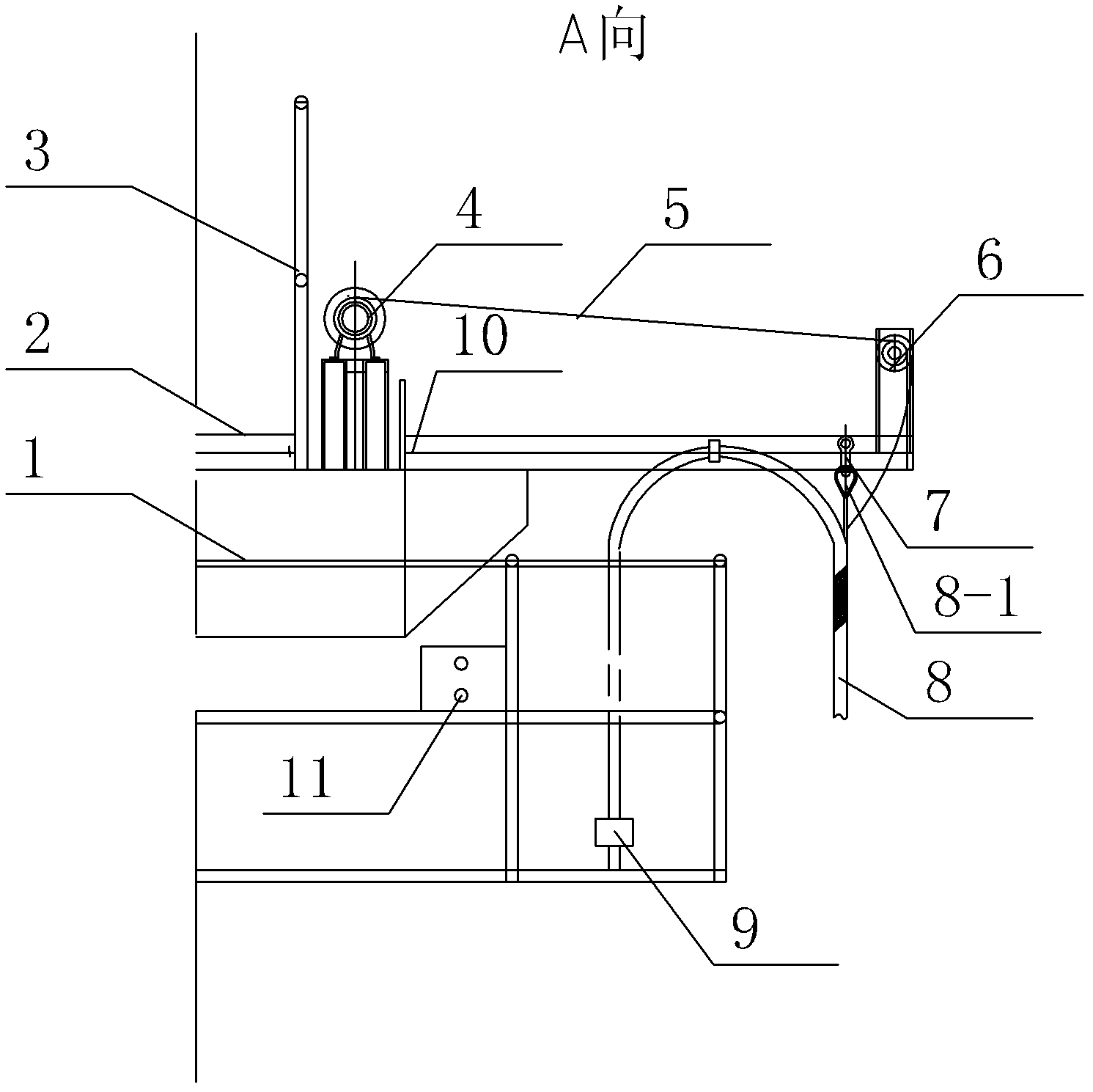

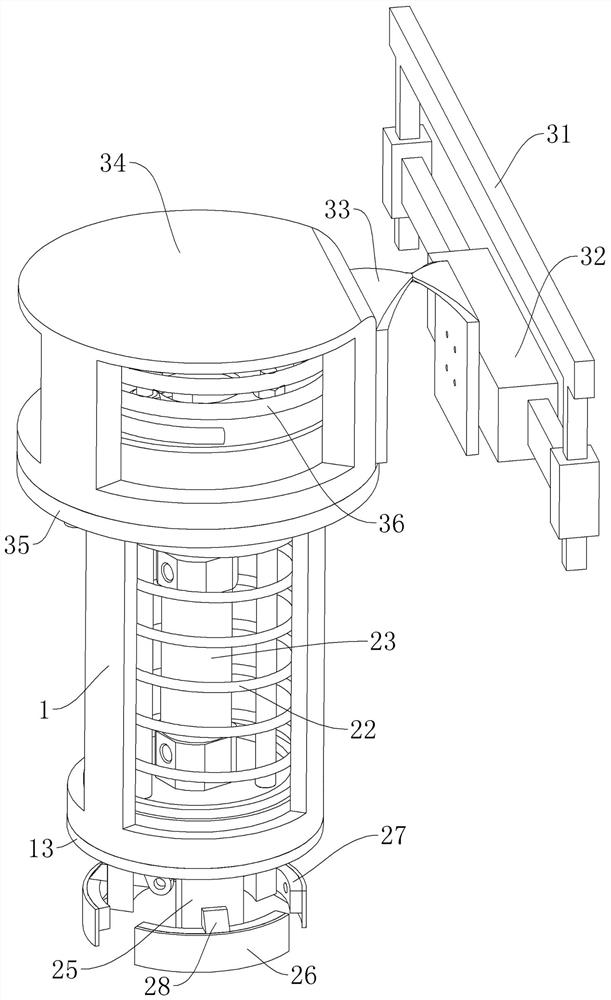

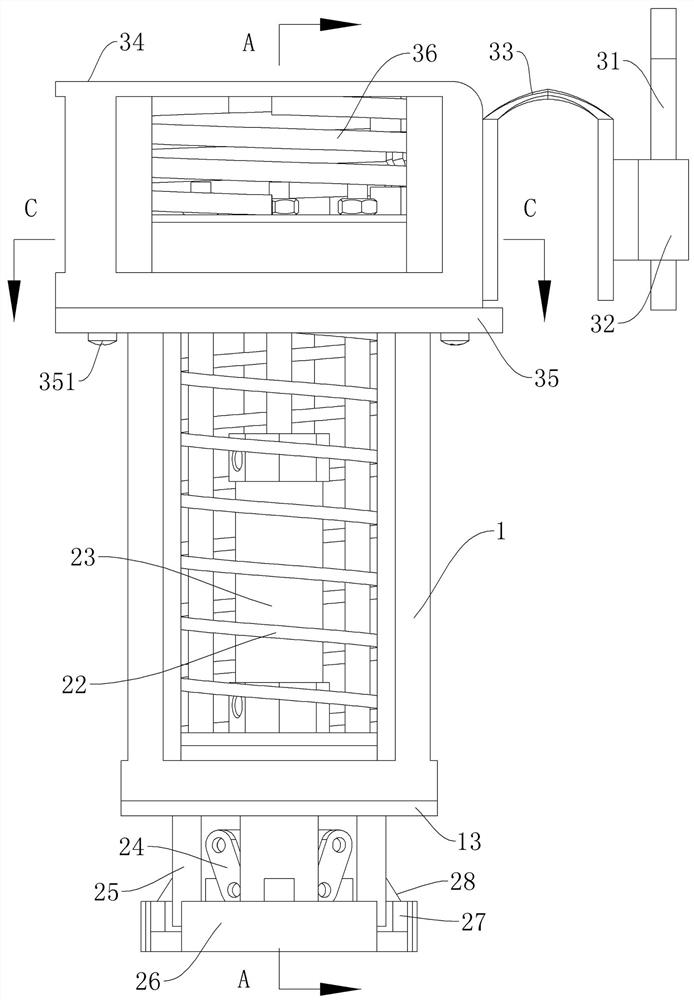

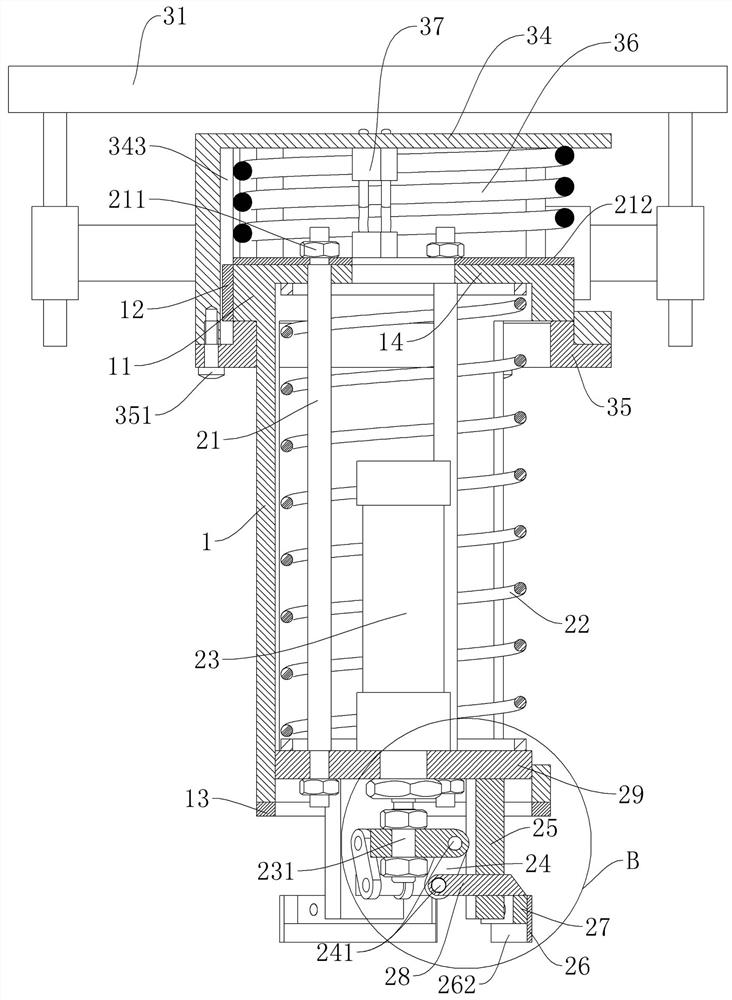

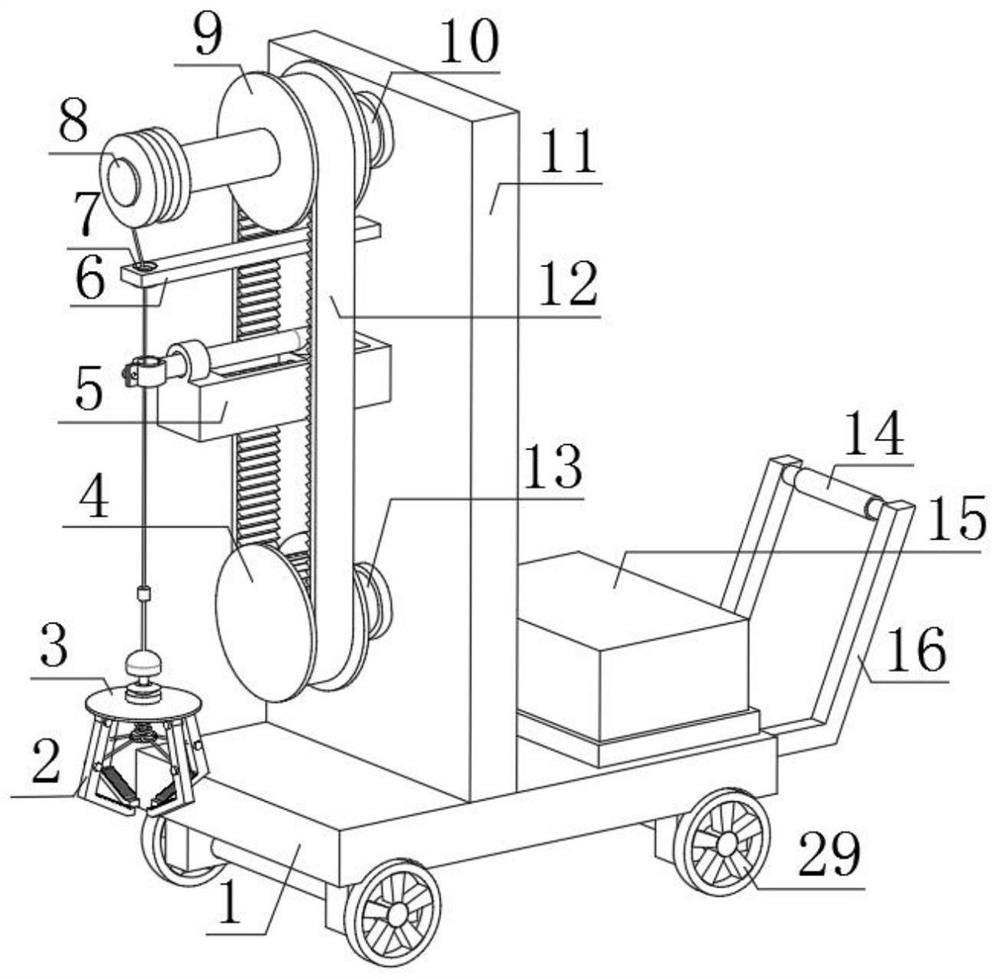

Electro-hydraulic grab bucket mechanism for portal crane

ActiveCN102442610BEfficient crawlingSafe and reliable grabbingLoad-engaging elementsElectro hydraulicEngineering

The invention relates to an electro-hydraulic grab bucket mechanism for a portal crane, in particular to a mechanism applied to a portal crane an dused for grabbing bulk cargoes such as steel scrap, garbage, medicinal materials and the like, and belongs to the technical field of hoisting and handling equipment. The electro-hydraulic grab bucket mechanism mainly comprises an operating platform, a lifting mechanism, a pulley mechanism, a cable, a base support, a cable take-up basket, a hook and a grab bucket, wherein, the base support is positioned at the top end of the portal crane; the operating platform and the lifting mechanism are positioned on the base support; the pulley mechanism is positioned on the upper surface of the head part of the base support; the hook is connected with the lower end of the pulley mechanism through a steel wire rope; the cable take-up basket is positioned on the cable; the upper end of the cable is connected in the operating platform, and the lower end of the cable is connected with the grab bucket; and the grab bucket is positioned at the lower end of the hook. The electro-hydraulic grab bucket mechanism has the advantage of simple, compact and reasonable structure, and is very easy in maintenance, overhaul and replacement; and as the electro-hydraulic grab bucket mechanism can efficiently and safely grab the special bulk cargoes such as the steel scrap, the garbage, herbal medicines and the like, the working application range of the portal crane is enlarged, the cost is lowered and the output value is increased.

Owner:无锡市新华起重工具有限公司

An electric cylinder gripper for battery pack gripping

The invention discloses an electric cylinder hand grab used for grabbing a battery pack. The electric cylinder hand grab comprises a horizontal electric cylinder and a vertical electric cylinder connected with the horizontal electric cylinder. A hand grab body is arranged at the lower end of the vertical electric cylinder and comprises two double-end clamping air cylinders, and a clamping jaw is arranged at the stretchable end of each double-end clamping air cylinder. An auxiliary air cylinder is arranged at the head of one of the clamping jaws, and an auxiliary clamping block is arranged at the stretchable end of the auxiliary air cylinder. A vertical lifting air cylinder is arranged between the two double-end clamping air cylinders, the stretchable end of the lifting air cylinder faces downwards and is connected with a sucking disc fixing base, and a plurality of sucking discs are arranged on the lower side face of the sucking disc fixing base. The upper ends of the double-end clamping air cylinders and the upper end of the lifting air cylinder are fixedly connected through a connecting plate. A rotating air cylinder is arranged between the connecting plate and the lower end of the vertical electric cylinder. Therefore, the electric cylinder hand grab has the advantages of being capable of safely and stably grabbing the battery pack and smoothly achieving carrying and packing of the battery pack.

Owner:HANGZHOU WAHAHA TECH

Self-adaptive and compliant manipulator for internal support operation of fragile thin-walled cylindrical inner wall workpiece

ActiveCN111300461BSolve the problem that the workpiece cannot be assembledEasy to grabGripping headsMetal working apparatusLinear motionRobot hand

The present invention is an inner-support type self-adaptive and compliant manipulator for fragile thin-walled cylindrical inner wall workpieces. Adapt to the connection device; the grabbing device includes a disc-shaped main body, an inner support mechanism on its lower surface, and a linear motion driver on the upper surface; the inner support mechanism includes: a support leg fixed on the lower surface of the disc-shaped main body, and a radially penetrating lower end of the support leg Sliding block; the connecting rod used to connect the sliding block and the linear motion driver, the arc-shaped inner support body fixed on the outer end of the sliding block, the adaptive connection device includes a connecting sleeve that is set outside the upper end of the sleeve, and is located inside the connecting sleeve The early warning spring and sensor, and the compliant ring used to connect the drive module and the connecting cylinder; the supporting force of the invention to grab the workpiece is relatively uniform, and it is not easy to damage the fragile workpiece, and the compliant ring has a certain position when assembling the workpiece. Attitude deviation compensation function, easy to assemble.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Grab-and-fit equipment for the production of pyrophyllite blocks for diamonds that can achieve compliance

ActiveCN111376300BSolve the problem that the workpiece cannot be assembledEasy to grabGripping headsMetal working apparatusHydraulic cylinderPyrophyllite

The present invention is a complete set of grabbing and packing equipment for diamond pyrophyllite block production that can realize compliance and adjustment, including a feeding belt, a feeding belt and a grabbing and pressing machine arranged along a straight line. The grabbing and pressing machine includes a On the working platform on the column, the lower mold assembly of the forming mold is installed in the middle of the working platform, and a jacking hydraulic cylinder or air cylinder is provided under the working platform to drive the lower mold assembly of the forming mold located in the middle of the working platform; A workpiece moving device is installed on the side of the working platform, which includes a vertical lifting linear module and a horizontal translation linear module. The moving parts of the horizontal translation linear module are connected with a gripping and pressing integrated manipulator; the invention is applied to diamond production The processing of pyrophyllite blocks in the process can realize the automation of grasping and installation, and the support force of the manipulator to grasp the workpiece is relatively uniform, and it is not easy to damage the fragile workpiece. When assembling the workpiece, the compliance ring has a certain position and posture deviation compensation function. , for easy assembly.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Gripping device, robot system and method for gripping workpieces

InactiveCN106413999BUnintentional entrySafe and reliable grabbingGripping headsRobotic systemsEngineering

A gripping device, which is provided, in particular, as an effector for an industrial robot comprises first and second clamping jaws, which are arranged so as to be moveable relative towards each other in order to grasp a workpiece. The first clamping jaw is provided with a tongue projection and the second clamping jaw with a corresponding groove, which at least partially accommodates the tongue projection in the state in which the clamping jaws are moved towards each other in order to prevent objects or body parts from being inadvertently inserted into the space between the clamping jaws.

Owner:KUKA SYSTEMS

Split type flexible grasping robot for fragile objects and working method

The invention discloses a split type flexible grasping robot for fragile objects. The split type flexible grasping robot comprises a base, a split type flexible grasping module and a lifting and lowering moving module, wherein moving wheels are arranged at the bottom of the base; the split type flexible grasping module is positioned at the upper part of the base and connected to the lifting and lowering moving module; a rhombic clamping hole is formed between the upper end surface and the lower end surface of the split type flexible grasping module; flexible telescopic modules are arranged at the four end surfaces of the rhombic clamping hole; each of the flexible telescopic modules comprises a telescopic cavity; each of the telescopic cavities is internally provided with a telescopic block; each of the telescopic blocks comprises a plurality of flexible telescopic units stacked up and down; and all of the flexible telescopic units are connected to a pressure control system. According to the split type flexible grasping robot for the fragile objects, each of the flexible telescopic units can individually extend and retract so as to adapt to the outer wall shapes of the fragile objects, so that the fragile objects with different outer wall shapes can be grasped. Meanwhile, through the arrangement of servo overflow valves, the clamping force requirement of the fragile objects can be met, and safe and efficient grasping of the fragile objects is achieved.

Owner:青岛中德智能技术研究院

Robot quick-change tool magazine

ActiveCN114454215AReliable grabbingImprove gripWork tools storageManipulatorMechanical engineeringRobot

The robot quick-change tool magazine comprises a box body, and a plurality of tool placing positions are arranged on the upper portion of the box body; tools are placed in the tool placing positions; the tool placing position is a U-shaped notch with a large opening and a small bottom, a crescent plate is arranged on the edge of one side of the U-shaped notch, the edge of one side of the crescent plate is a concave surface, the concave surface faces the tool placing position, and the crescent plate is provided with a rotating shaft; when the tool slides into or out of the tool placing position, the edge of the upper end of the tool slides from outside to inside by attaching to the concave surface of the crescent plate, the crescent plate is forced to rotate, and the tool placing position or the crescent plate is provided with a detection assembly used for sensing the position change of the crescent plate so as to judge whether the tool is in a warehousing state or not; according to the quick-change tool library for the robot, the robot can reliably, stably and safely grab tools by optimally designing the tool taking and placing position, process detection, information interaction and action interlocking, and assistance is provided for simple and quick deployment of the robot.

Owner:南通新蓝机器人科技有限公司

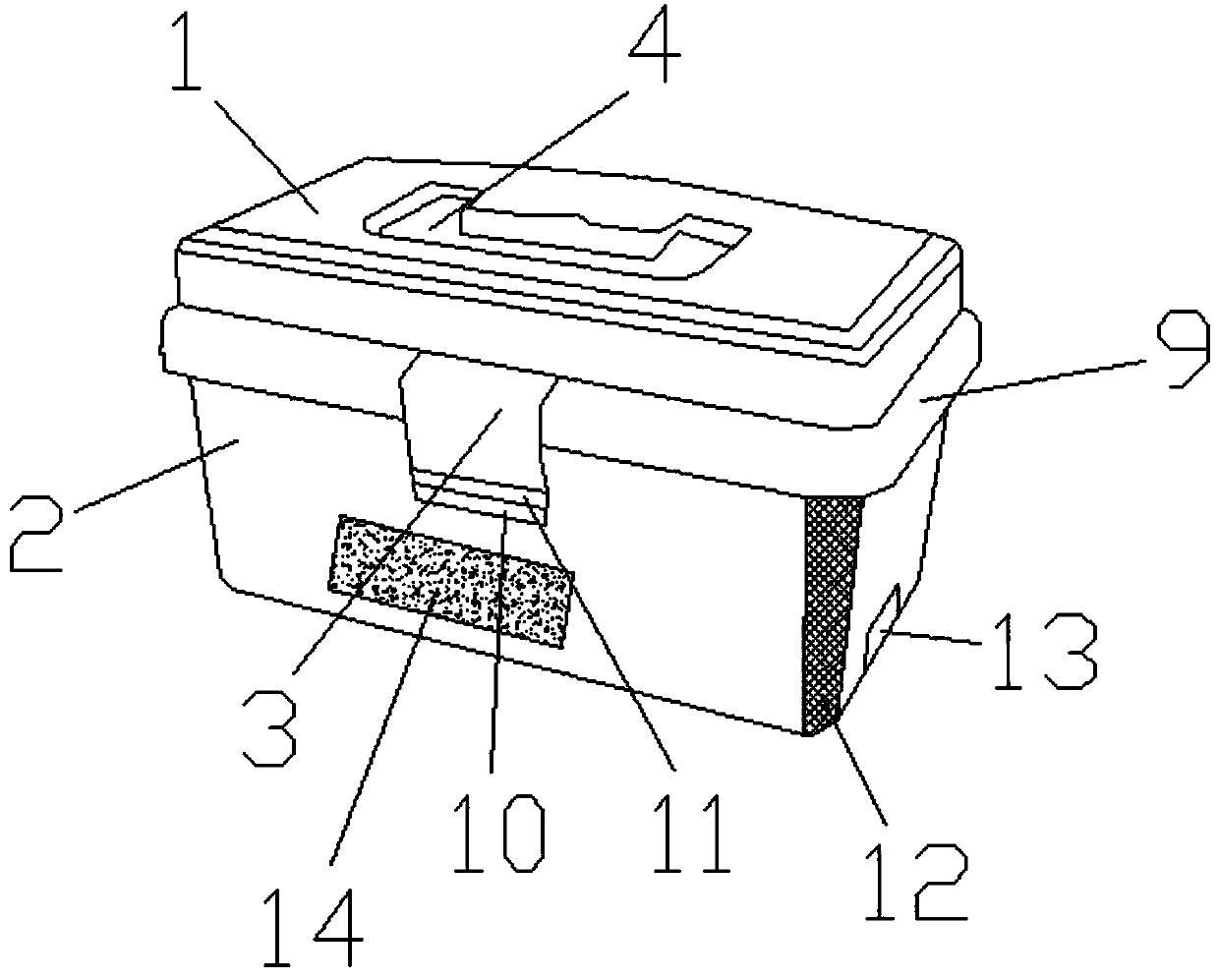

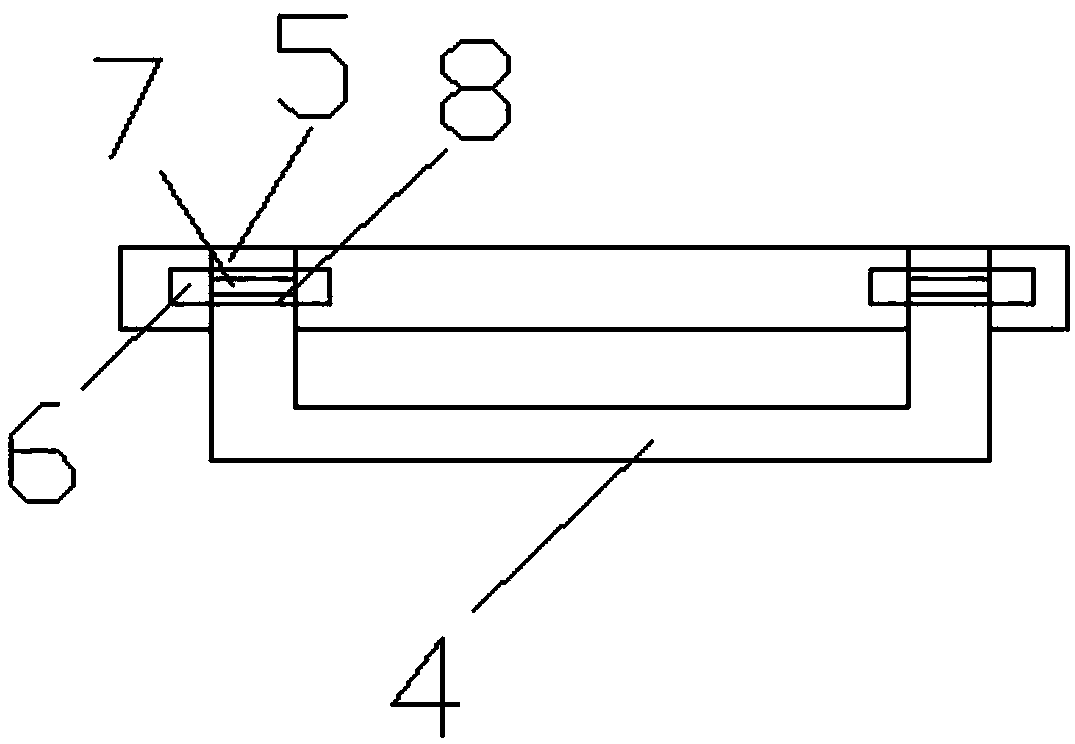

Convenient and rapid plastic EU box

InactiveCN107814062AEfficient crawlingSafe and reliable grabbingClosures with lifting/suspending meansClosure with auxillary devicesRotational axisEngineering

The invention discloses a convenient and rapid plastic EU box comprising a box cover, a box body and a pull clasp. A carrying handle is arranged in the middle of the box cover in an embedded mode andconnected to the box cover through a rotary shaft, and the rotary shaft comprises a fixing shaft, a shaft core and a rotating shaft. The fixing shaft is connected to the box cover in a welded mode, the shaft core is connected to the fixing shaft in a welded mode, and the rotating shaft is movably connected to the outer side of the shaft core. The rotating shaft is connected to the carrying handlein a welded mode, integrated barrier-free handles are evenly arranged on the periphery of the box body, and the pull clasp is connected to the box cover. A fixing clasp is arranged on the lower side of the pull clasp, and the fixing clasp is movably connected to a clamp strip. According to the convenient and rapid plastic EU box, through the additionally-arranged integrated barrier-free handles, the situation that operators more effectively and more safely grab the box body can be facilitated to a certain extent, thus carrying can be more convenient and rapider, and the convenient and rapid plastic EU box accords with human engineering principles.

Owner:TIANJIN AOXIBO PLASTIC PROD

Mine rock clamping and lifting device

The invention discloses a mine rock clamping and lifting device, and provides the following scheme aiming at the problems that an existing device is prone to being affected by the ground environment and the lifting manner is difficult to adjust due to the fact that a mechanical claw is made to get close to lifted goods by moving a device main body. The mine rock clamping and lifting device comprises a bottom plate; and a vertical plate is fixedly connected to the center of the outer wall of the top of the bottom plate, a driven rotating rod is connected to the outer wall of one side of the vertical plate through a bearing, a driven fluted disc is fixedly connected to one end of the driven rotating rod, a winch is fixedly connected to the outer wall of one side of the driven fluted disc, and a traction rope is wound around the outer wall of the winch. The bottom end of the traction rope is fixedly connected with a connecting buckle, and a grabbing mechanism is arranged at the bottom end of the connecting buckle. The drooping traction rope is buckled in a buckle plate, the grabbing mechanism connected to the lower portion of the traction rope is moved through pushing of a supporting rod, the adjusting effect of the grabbing mechanism is simply and flexibly achieved, and practicability is higher.

Owner:邓腊平

Excavator claw for building construction

InactiveCN112127410AOptimize product structureProtection materialSoil-shifting machines/dredgersExcavatorArchitectural engineering

The invention discloses an excavator claw for building construction, and relates to the technical field of excavator claws. The excavator claw comprises an excavator claw body and a grabbing device, wherein the grabbing device is movably connected with the excavator claw body through a rotary button, the grabbing device comprises a clamping jaw, a limiting block is arranged on the inner wall of the clamping jaw, one end of the limiting block extends into the clamping jaw, and spring clamping teeth are arranged in the limiting block; and the clamping jaw is provided with a transmission mechanism, the transmission mechanism comprises a first rack and a V-shaped spring, the first rack is arranged on the inner wall of one side of a front arm of the clamping jaw, a second rack is arranged on the other side of the front arm of the clamping jaw, the V-shaped spring is arranged in the clamping jaw, and one side of the V-shaped spring is connected with the spring clamping teeth. According to the excavator claw, the excavator grabbing device can be optimized, the stability and firmness of material grabbing are improved, the working efficiency is improved to a certain extent, and meanwhile, the excavator claw is safer under the condition that a large number of objects or heavy objects are used.

Owner:江苏圣达建设集团有限公司

Method for correcting position during the glass grabbing process of manipulator of manipulator glass stacking system

ActiveCN102491099BAccurate captureImprove gripStacking articlesDe-stacking articlesEngineeringLife time

The invention relates to the technical field of a manipulator glass stacking system, in particular to a method for correcting a position during the glass grabbing processing of a manipulator of the manipulator glass stacking system. A photoelectric sensor I and a photoelectric sensor II are arranged between two rollers which are arranged at the upstream of a roller bed which keeps a distance s away from the center of the manipulator, the distance between the photoelectric sensor I and the photoelectric sensor II is 1-1.5m, dimension of the glass is a*b or length*width, v is the speed of the roller bed, when the glass deflects, time t1 for the photoelectric sensor I to send a signal and the time t2 for the photoelectric sensor II to send a signal are different, is adopted: a deflection angle is acquired according to the following computational formula: deflection angle &=(t1-t2)*v / 1; and a time point of grabbing is calculated according to the formula that t=tn+(S-|t1-t2|*v / 2) / v+a / 2 / v, wherein tn is a greater time point in t1 and t2. The method provided by the invention has the advantages of convenience in installation, low cost, long service life and convenience in maintenance.

Owner:CHINA TRIUMPH INT ENG

Automatic electrolytic cell sealing cover grabbing device

The invention belongs to the technical field of metallurgy machines, and relates to an automatic electrolytic cell sealing cover grabbing device, in particular to an automatic electrolytic cell sealing cover grabbing device in the electrolytic aluminum production and operation process. The automatic electrolytic cell sealing cover grabbing device high in automation degree, free of worker near-distance operation, and capable of lowering the labor intensity of workers and eradicating potential safety hazards is provided. The automatic electrolytic cell sealing cover grabbing device comprises a lifting oil cylinder hinged to a shell beating mechanism, and is characterized in that a piston rod of the lifting oil cylinder is hinged to a rotation plate; the rotation plate is provided with a thrust oil cylinder, and a piston rod of the thrust oil cylinder is connected with a horizontal moving plate; the end portion of the horizontal moving plate is hinged to the middle portion of an approaching plate; the horizontal moving plate is provided with a rotation oil cylinder, and a piston rod of the rotation oil cylinder is hinged to the upper portion of the approaching plate; and two clamping oil cylinders are reversely arranged on the two sides of the approaching plate, and each of piston rods of the two clamping oil cylinders is provided with a clamping plate.

Owner:NFC (SHENYANG) METALLURGICAL MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com