Automatic ceramic chip feeding device for PTC (Positive Temperature Coefficient) heating element preparation

An automatic feeding and ceramic chip technology, applied in unloading devices, ceramic molding machines, manufacturing tools, etc., can solve the problems of time-consuming and labor-intensive quality, unguaranteed quality, and neat placement of four ceramic chips, etc., to achieve grasping Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

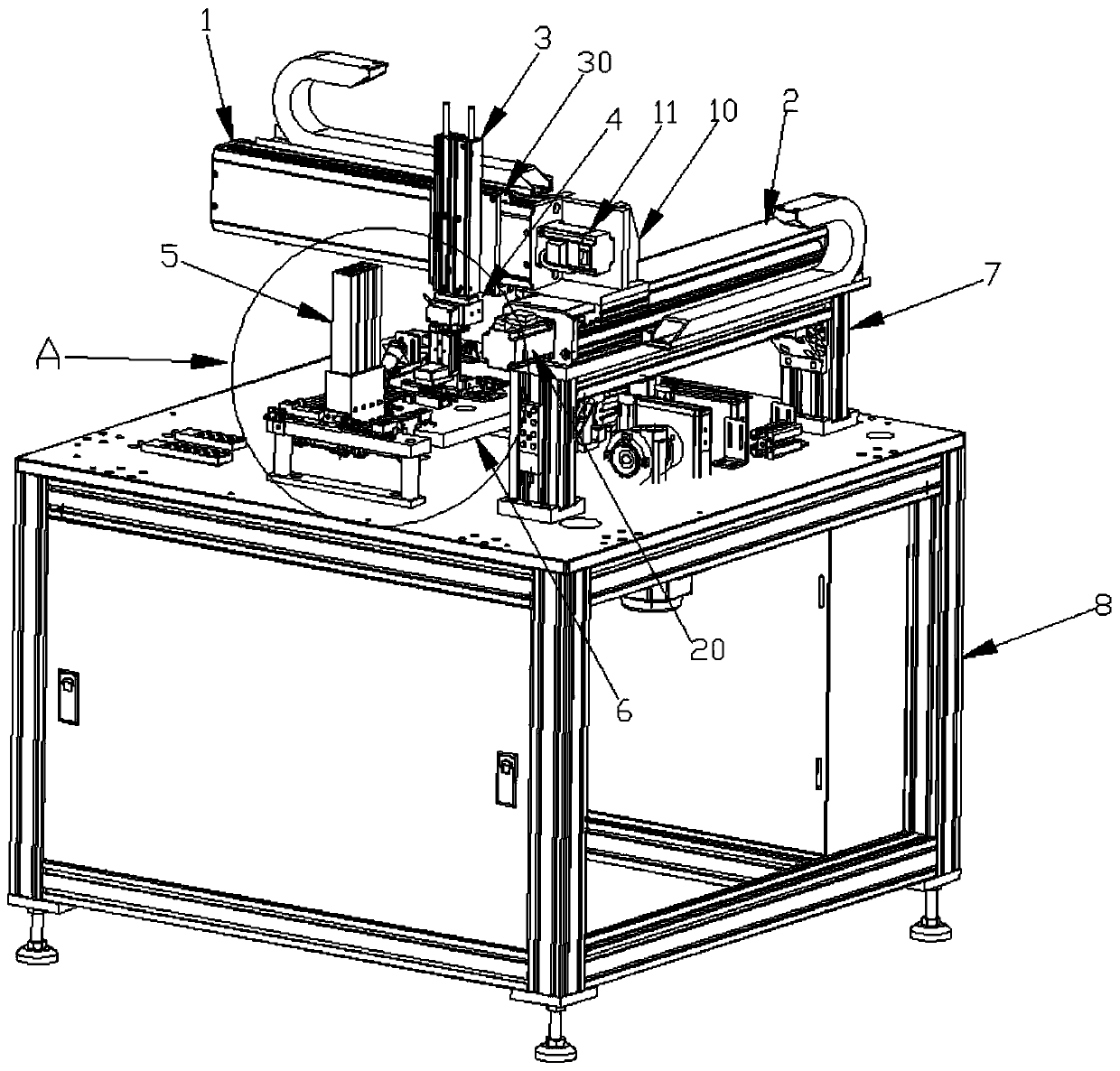

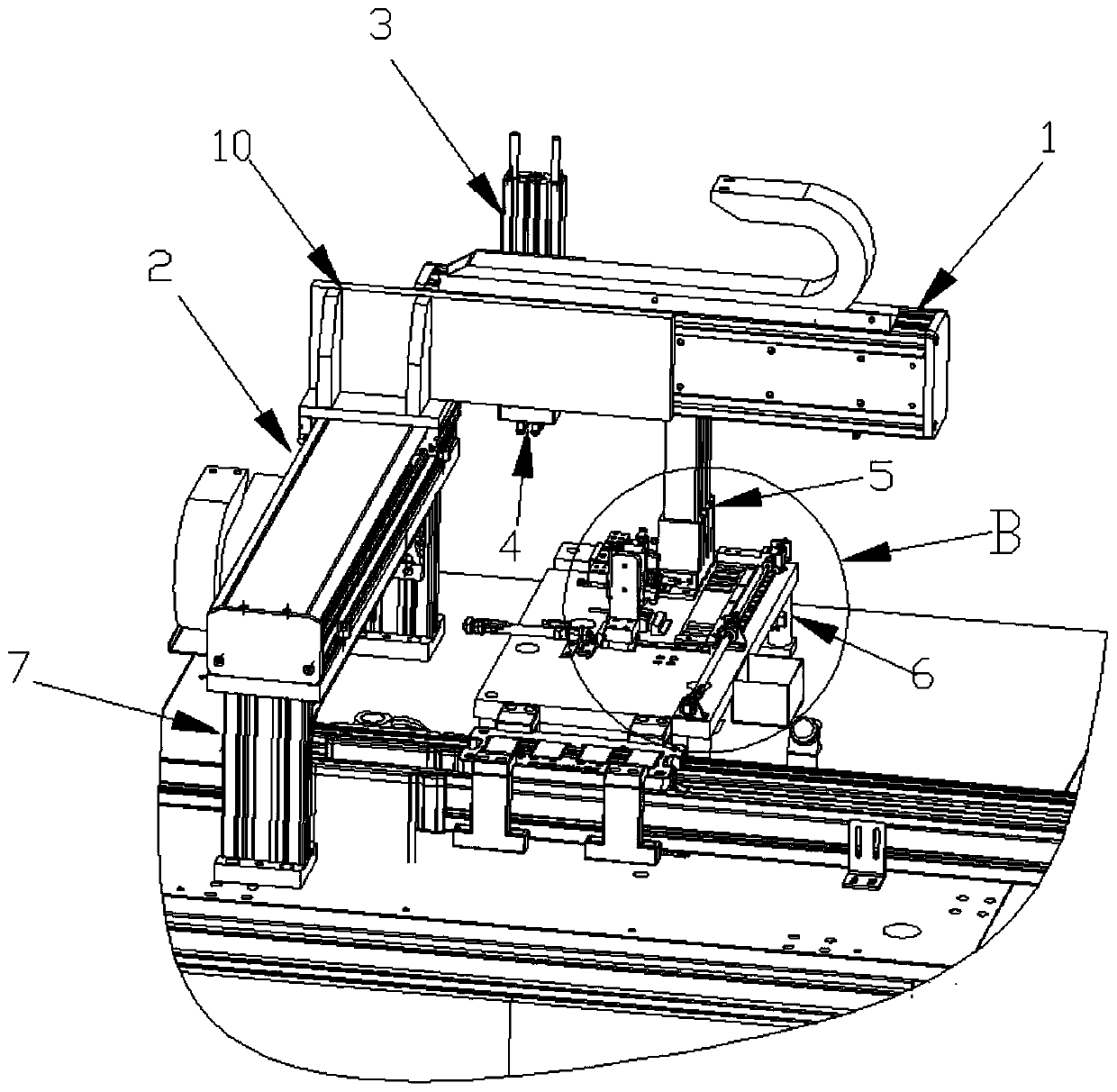

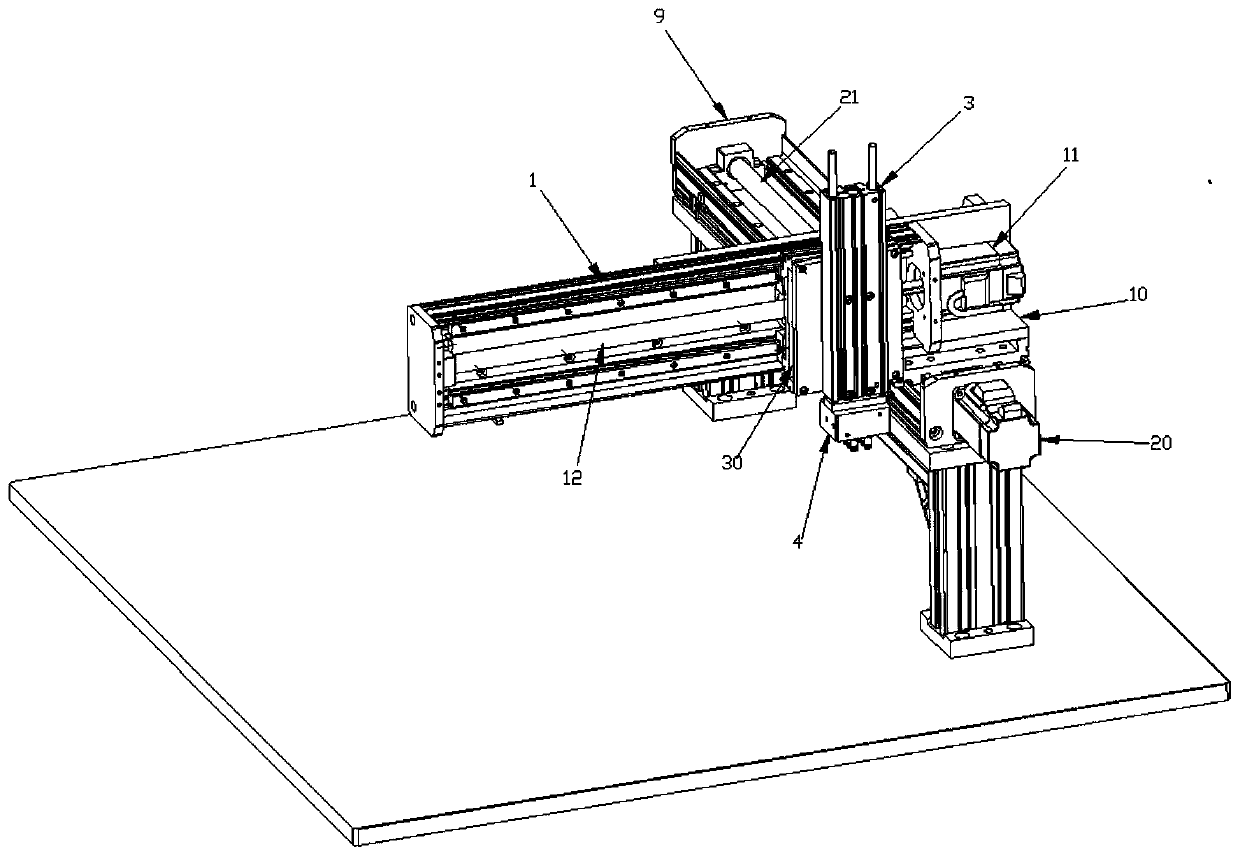

[0026] Such as Figure 1 to Figure 7 As shown, an automatic ceramic sheet feeding device for making PTC heating sheets, including X-axis track 1, Y-axis track 2, vertical cylinder 3, vacuum suction cup 4, ceramic sheet placement frame 5, processing platform 6 and abutment 8; Set X-axis track 1 and Y-axis track 2 to realize horizontal movement, set vertical cylinder 3 to realize vertical movement, and then realize three-dimensional movement.

[0027] The Y-axis track 2 is fixedly connected to the abutment 8 through the feet 7 (a foot 7 is provided at the bottom of both ends of the Y-axis track 2 to play a load-bearing and stable role), and the X-axis track 1 is installed through the X-axis The seat 10 is slidingly connected with the Y-axis track 2, the vertical cylinder 3 is slidably connected with the X-axis track 1 through the cylinder mounting seat 30, and the vacuum chuck 4 is connected with the output shaft of the vertical cylinder 3; one end of the X-axis track 1 passes t...

Embodiment 2

[0031] Such as Figure 1 to Figure 7 As shown, an automatic ceramic chip feeding device for making PTC heating chips, including X-axis track 1, Y-axis track 2, vertical cylinder 3, vacuum chuck 4, ceramic chip placement frame 5, processing platform 6 and abutment 8;

[0032] The Y-axis track 2 is fixedly connected to the base 8 through the feet 7, the X-axis track 1 is slidably connected to the Y-axis track 2 through the X-axis mount 10, and the vertical cylinder 3 is connected to the X-axis through the cylinder mount 30. The track 1 is slidingly connected, and the vacuum chuck 4 is connected with the output shaft of the vertical cylinder 3;

[0033] The processing platform 6 is fixedly connected to the base platform 8, and the ceramic chip placement frame 5 is fixedly connected to the upper end of the processing platform 6. The processing platform 6 is also provided with a push-out cylinder 50, a ceramic chip groove 60 and a material receiving cylinder. 61, the ejection cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com