Mine rock clamping and lifting device

A technology for lifting devices and rocks, applied in cranes, safety devices, transportation and packaging, etc., can solve the problems of heavy mine rocks, difficulty in adjusting lifting methods, and impact on the ground environment, etc., and achieve high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

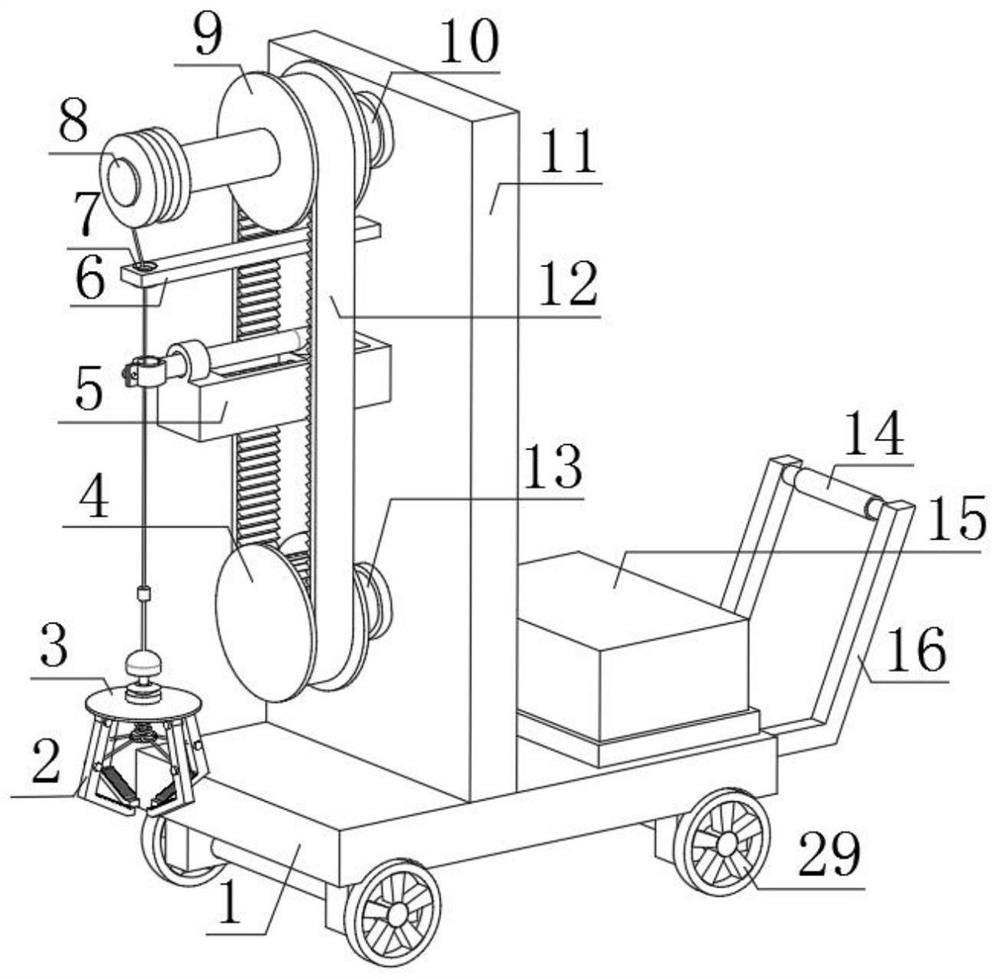

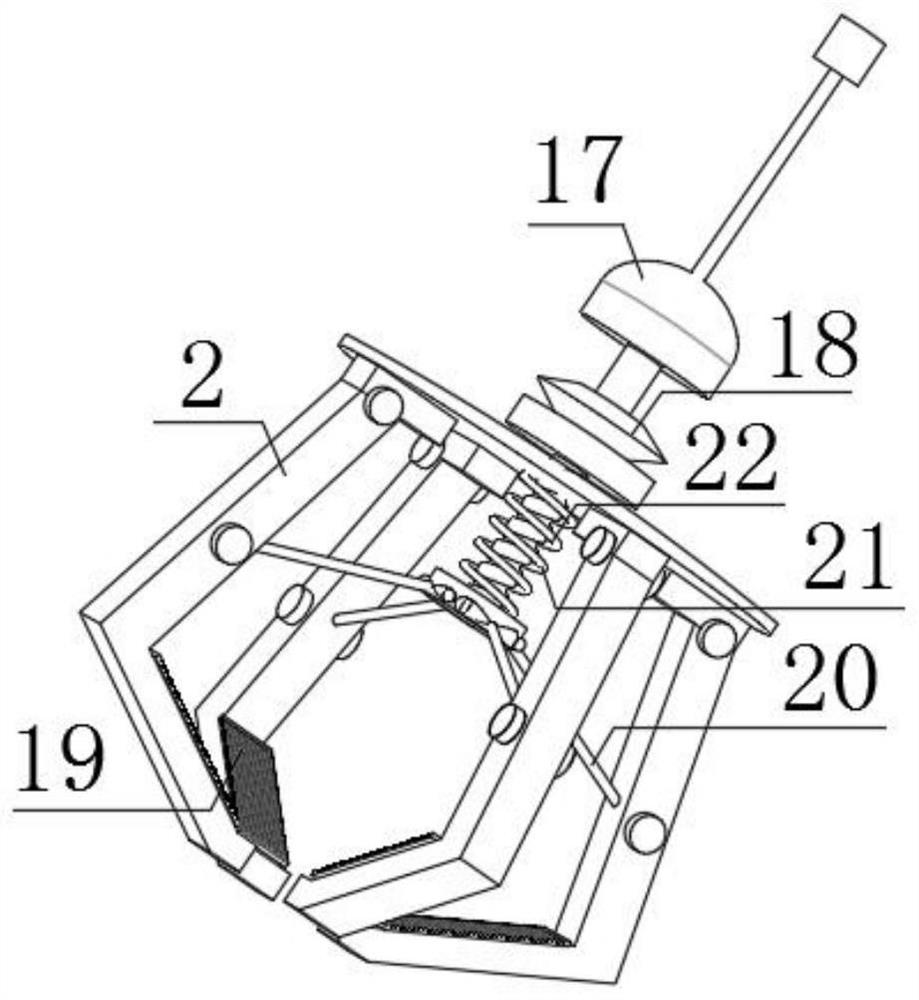

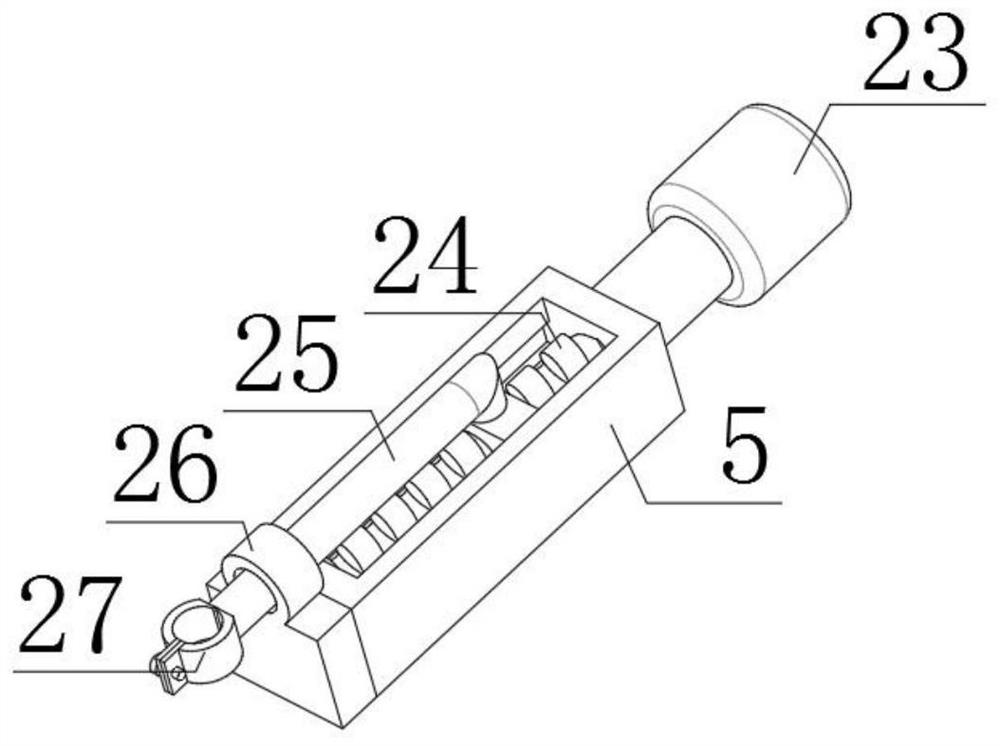

[0028] refer to Figure 1-4 , a mine rock clamping lifting device, comprising a base plate 1, a riser 11 is fixedly connected to the central position of the outer wall of the top of the base plate 1, and a driven rotating rod 10 is connected to the outer wall of one side of the riser 11 through a bearing. One end of the rod 10 is fixedly connected with the driven chainring 9, and the outer wall of one side of the driven toothed plate 9 is fixedly connected with the winch 8, and the outer wall of the winch 8 is wound with a traction rope, and the bottom end of the traction rope is fixedly connected with a connecting buckle 17. The bottom end of the connecting buckle 17 is provided with a grasping mechanism, and the outer wall of one side of the riser 11 is fixedly connected with the adjustment frame 5, and the inner wall of the adjustment frame 5 is connected with the second threaded rod 24 through a bearing, and the other side of the riser 11 One side outer wall is fixedly con...

Embodiment 2

[0039] refer to Figure 5 , a lifting device for clamping mine rocks. Compared with Embodiment 1, this embodiment further includes that a storage box 30 is fixedly connected to one side of the outer wall of the bottom plate 1 .

[0040] When in use, some tools needed in the mining process are placed in the storage box 30 arranged on one side of the bottom plate 1. During the lifting operation, when human assistance is needed, it is safer and more convenient to wear protective tools.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com