Automatic electrolytic cell sealing cover grabbing device

A technology of grabbing device and sealing cover, which is applied in the field of automatic grabbing device for electrolyzer sealing cover, can solve problems such as low production efficiency, potential safety hazards, and high labor intensity of workers, so as to improve production efficiency, improve safety, and reduce labor costs. The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

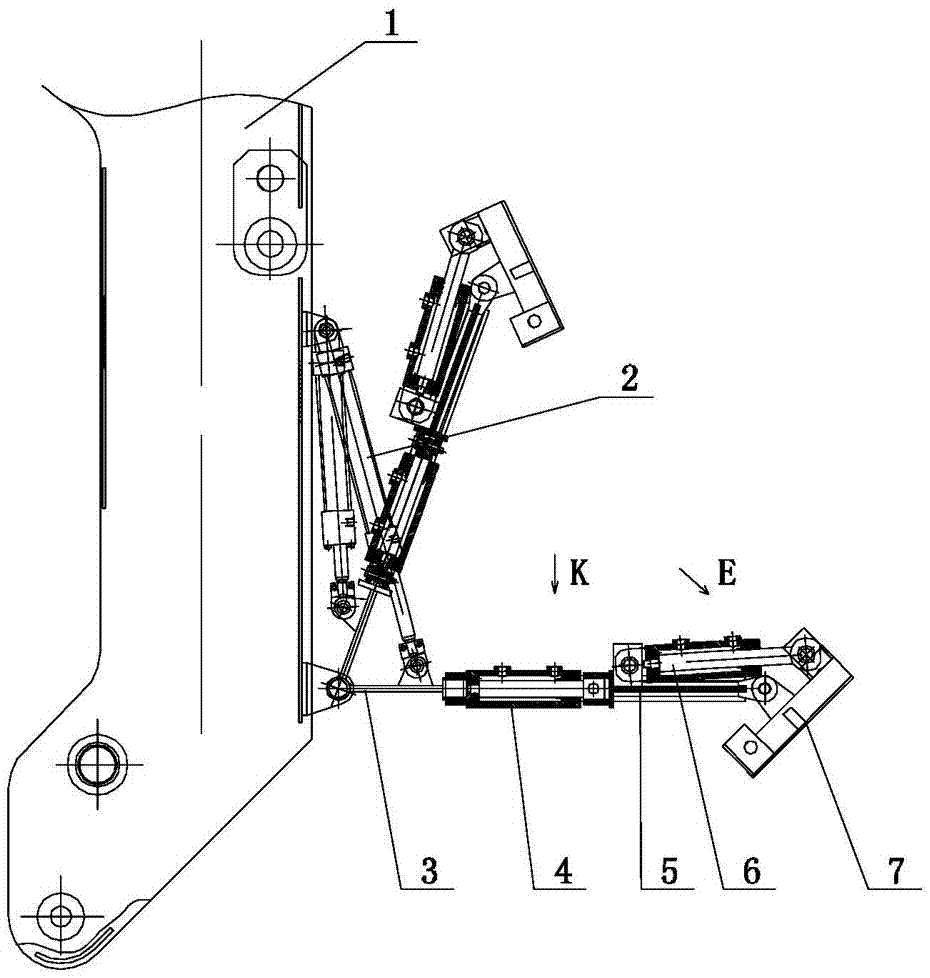

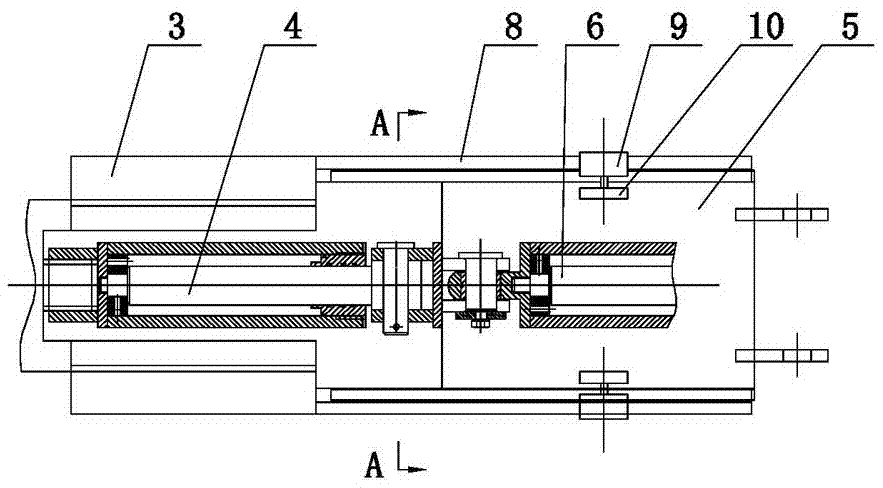

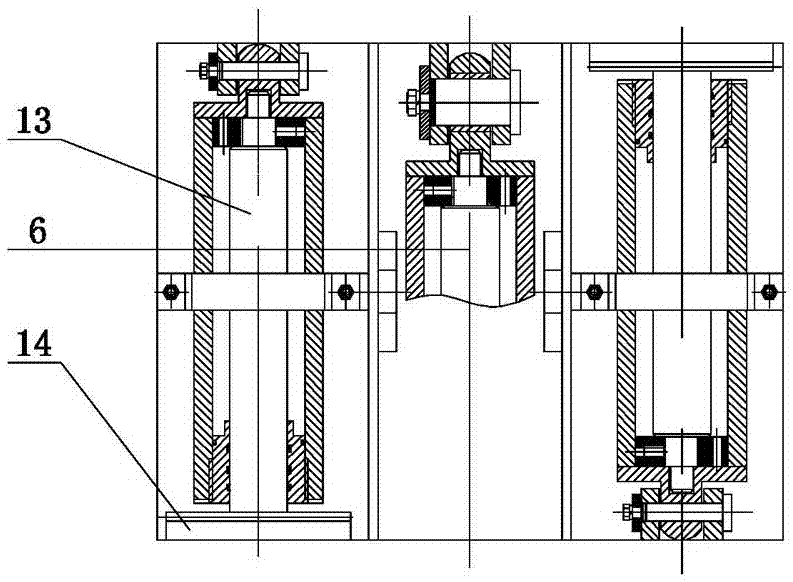

[0019] The present invention comprises the lifting oil cylinder 2 that is hinged with shelling mechanism 1, is characterized in that: the piston rod of lifting oil cylinder 2 is hinged with a rotary plate 3, is provided with thrust oil cylinder 4 on the rotary plate 3, and the piston rod of thrust oil cylinder 4 is connected with a horizontal Moving plate 5 links to each other, and the end of horizontal moving plate 5 is hinged with the middle part of approaching plate 7, and horizontal moving plate 5 is provided with rotary oil cylinder 6, and the piston rod of rotating oil cylinder 6 is hinged with the top of described approaching plate 7; Two clamping oil cylinders 13 are arranged on opposite sides of the plate 7 , and a splint 14 is arranged on the piston rods of the two clamping oil cylinders 13 .

[0020] As a preferred solution of the present invention, two guide arms 8 are extended on both sides of the end of the rotating plate 3, and T-shaped slots 11 are arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com