Patents

Literature

140results about "Drawing pins" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

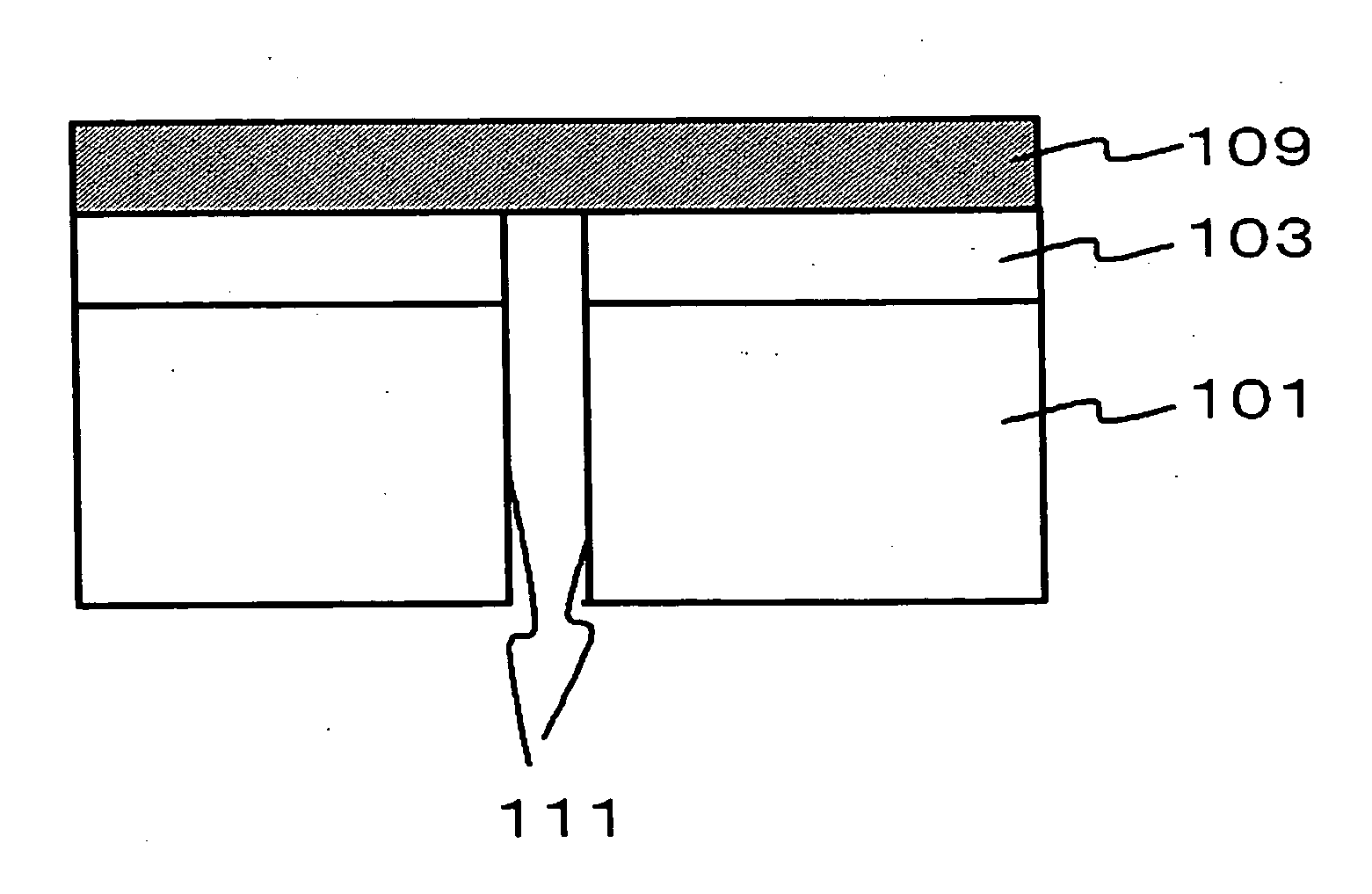

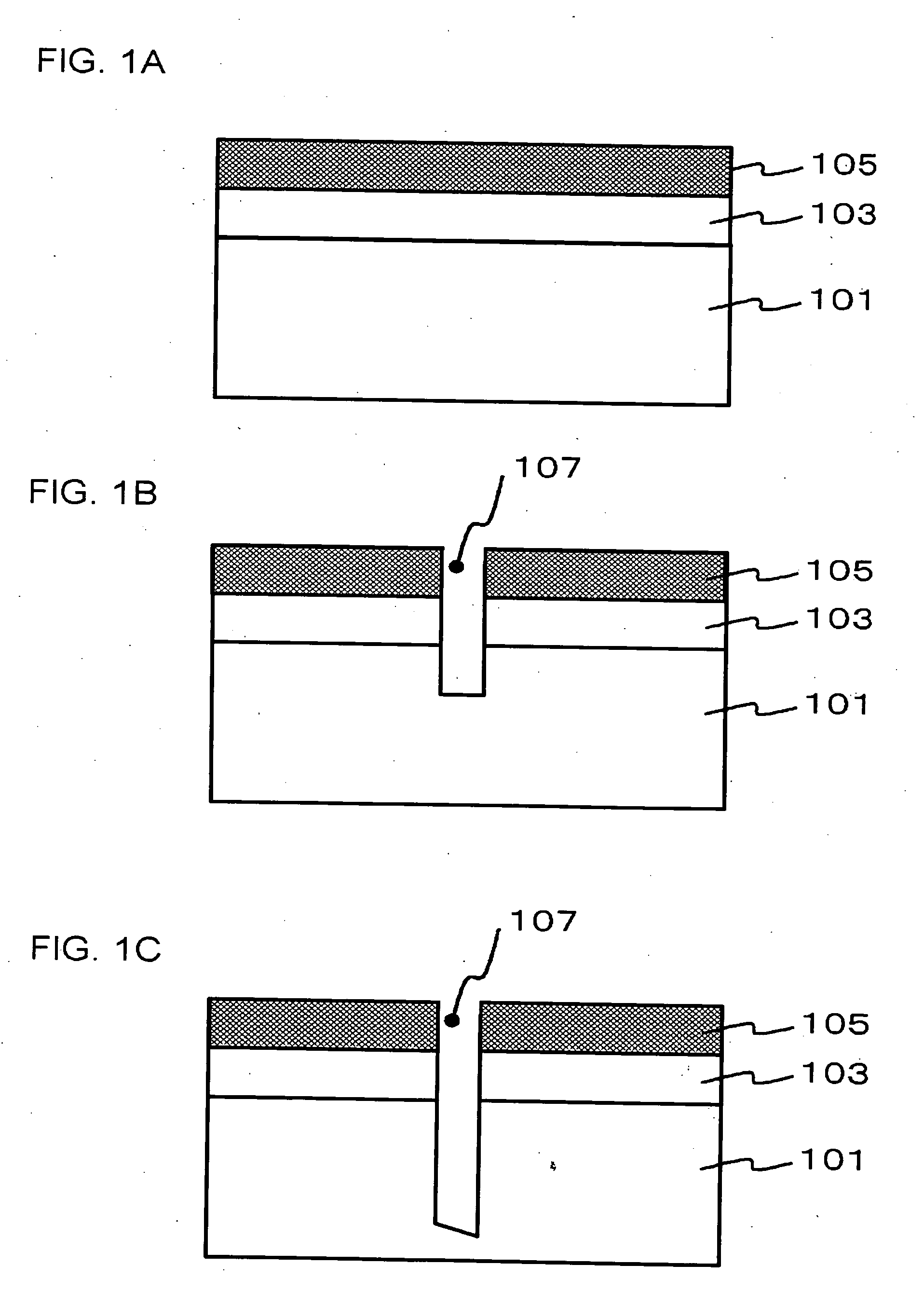

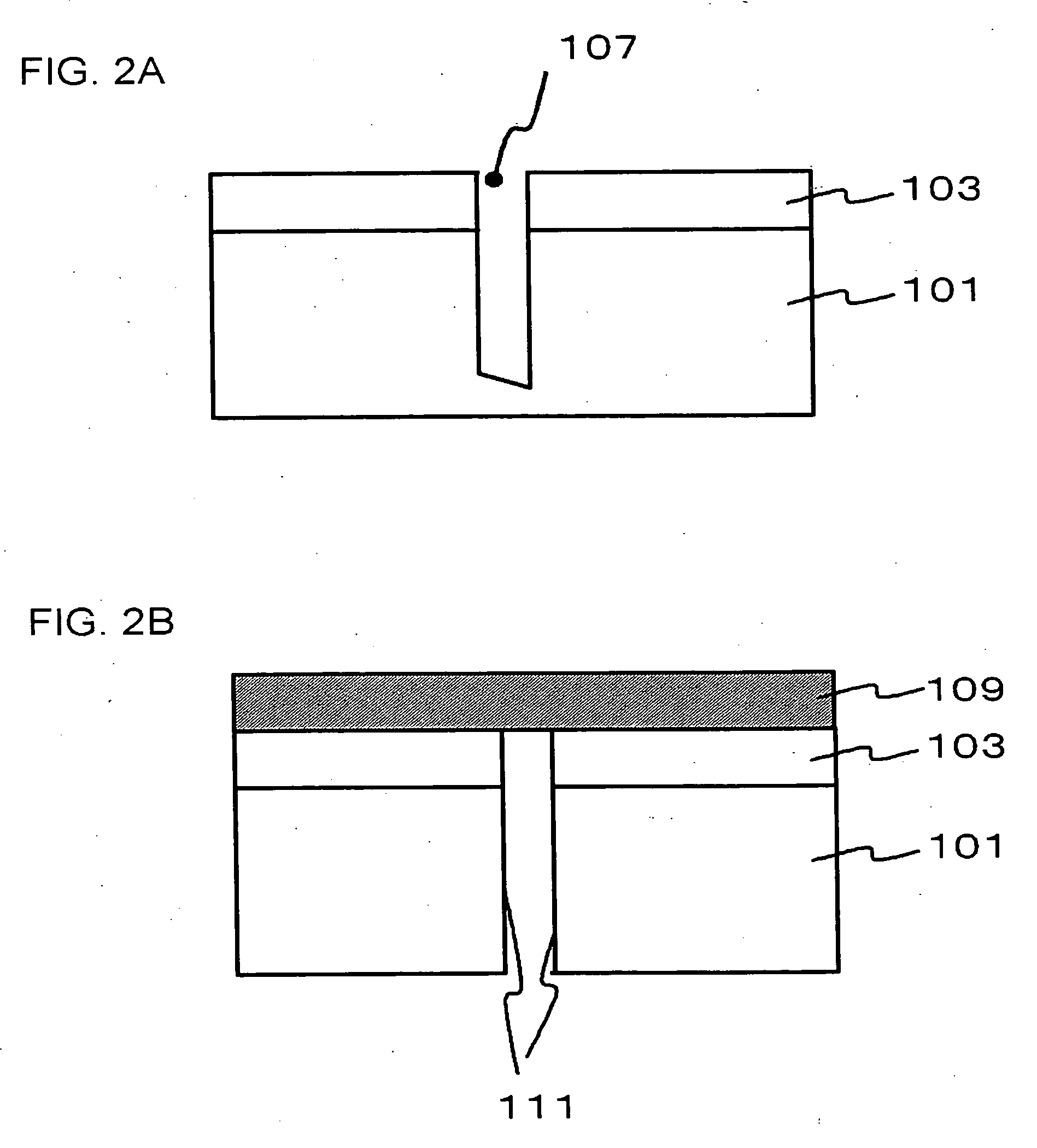

Method for manufacturing semiconductor device

InactiveUS20060205182A1Reduce widthRate of the processing for providing the trenched portion can beSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialDevice form

A method of dicing a semiconductor wafer includes providing an interconnect layer providing a protective film on the interconnect layer on the side of a device-forming surface of a silicon wafer, irradiating the protective film with a laser beam to provide a trenched portion that extends through the interconnect layer from the protective film and reaches to an inside of the silicon wafer, removing a portion of the silicon wafer selectively in a depth direction from a bottom of the trenched portion, after irradiating with the laser beam to provide the trenched portion and dividing the silicon wafer along the portion where the trenched portion is provided into respective pieces of the silicon wafer, after removing a portion of the silicon wafer 101 selectively in the depth direction.

Owner:NEC ELECTRONICS CORP

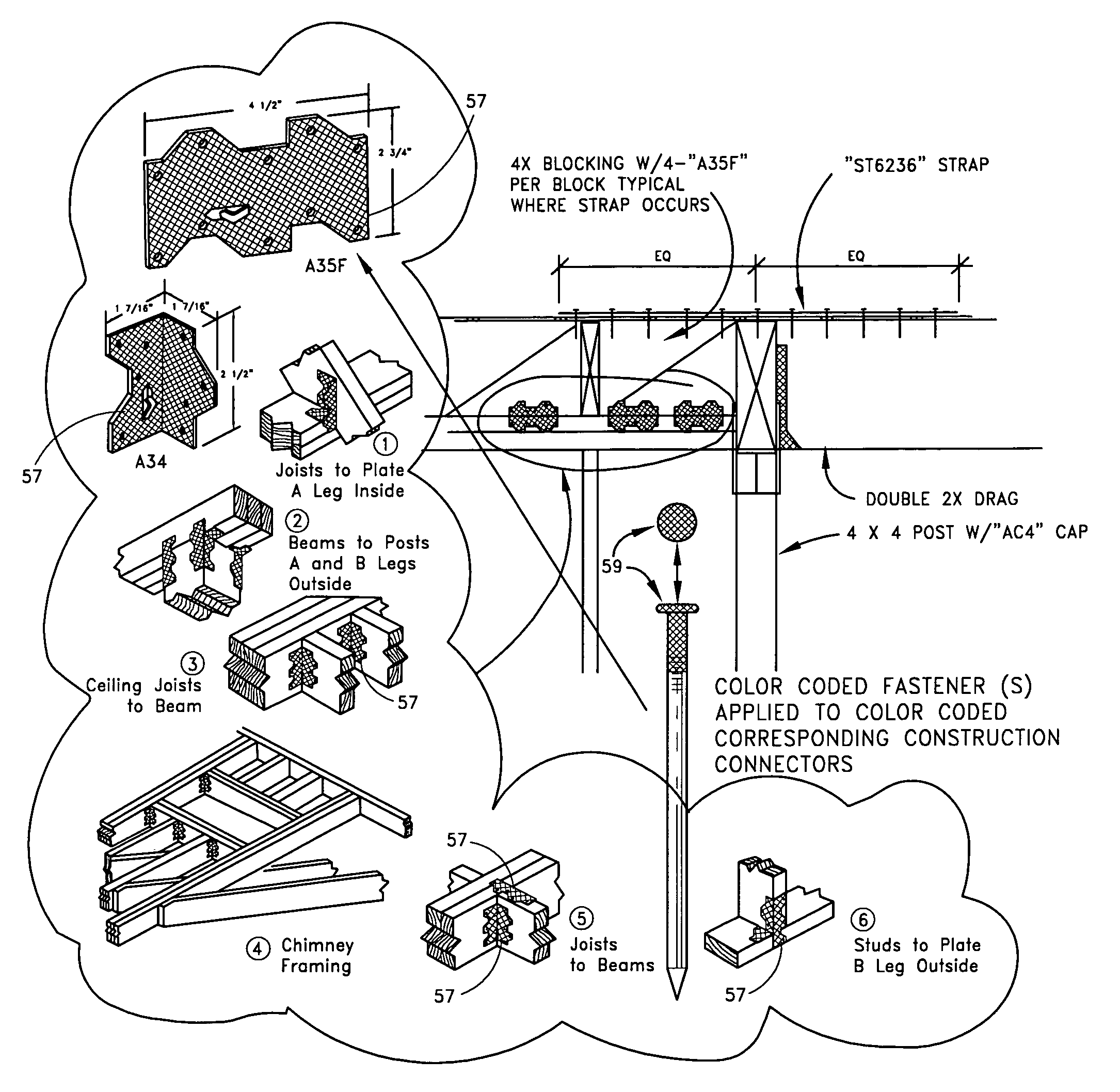

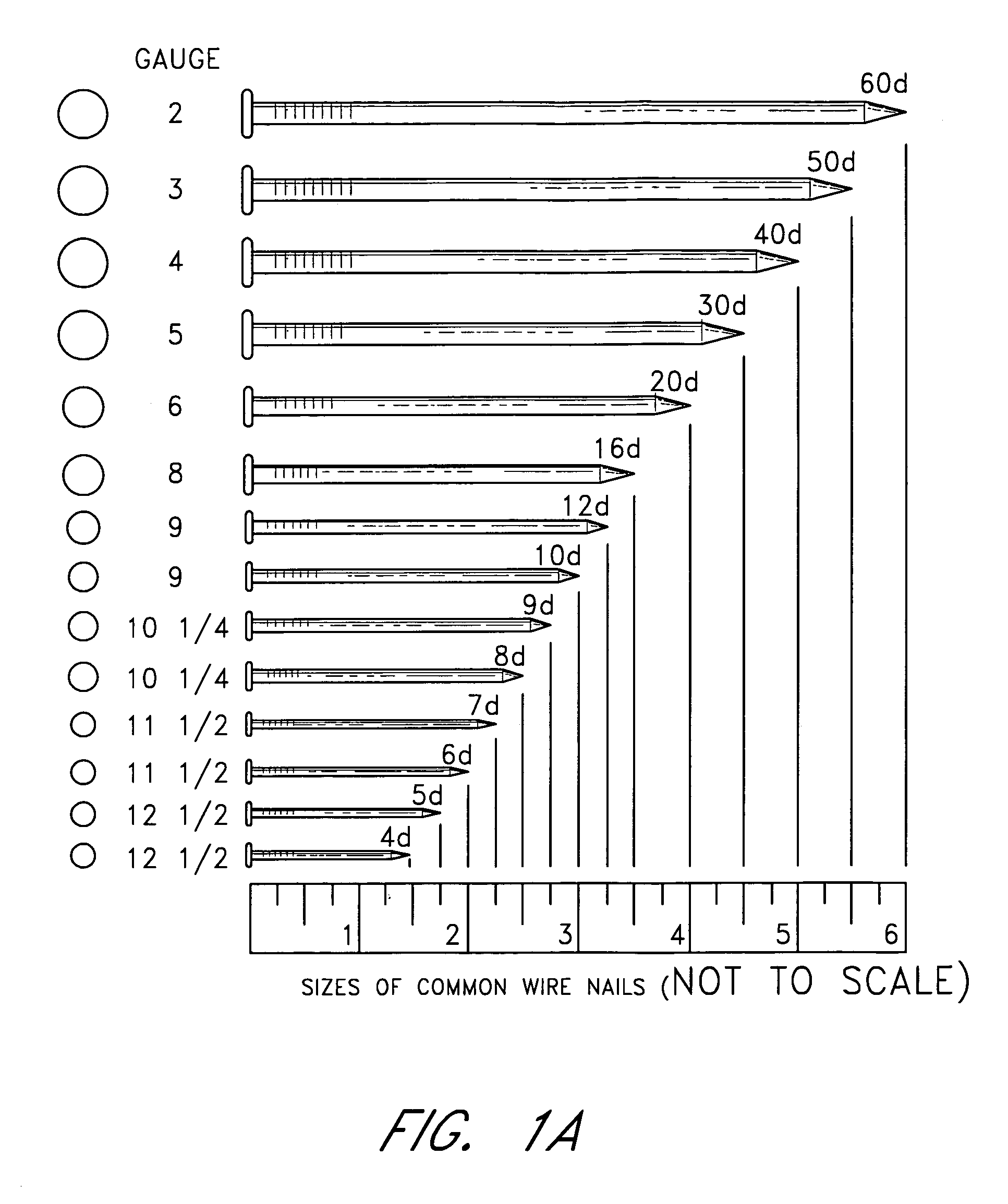

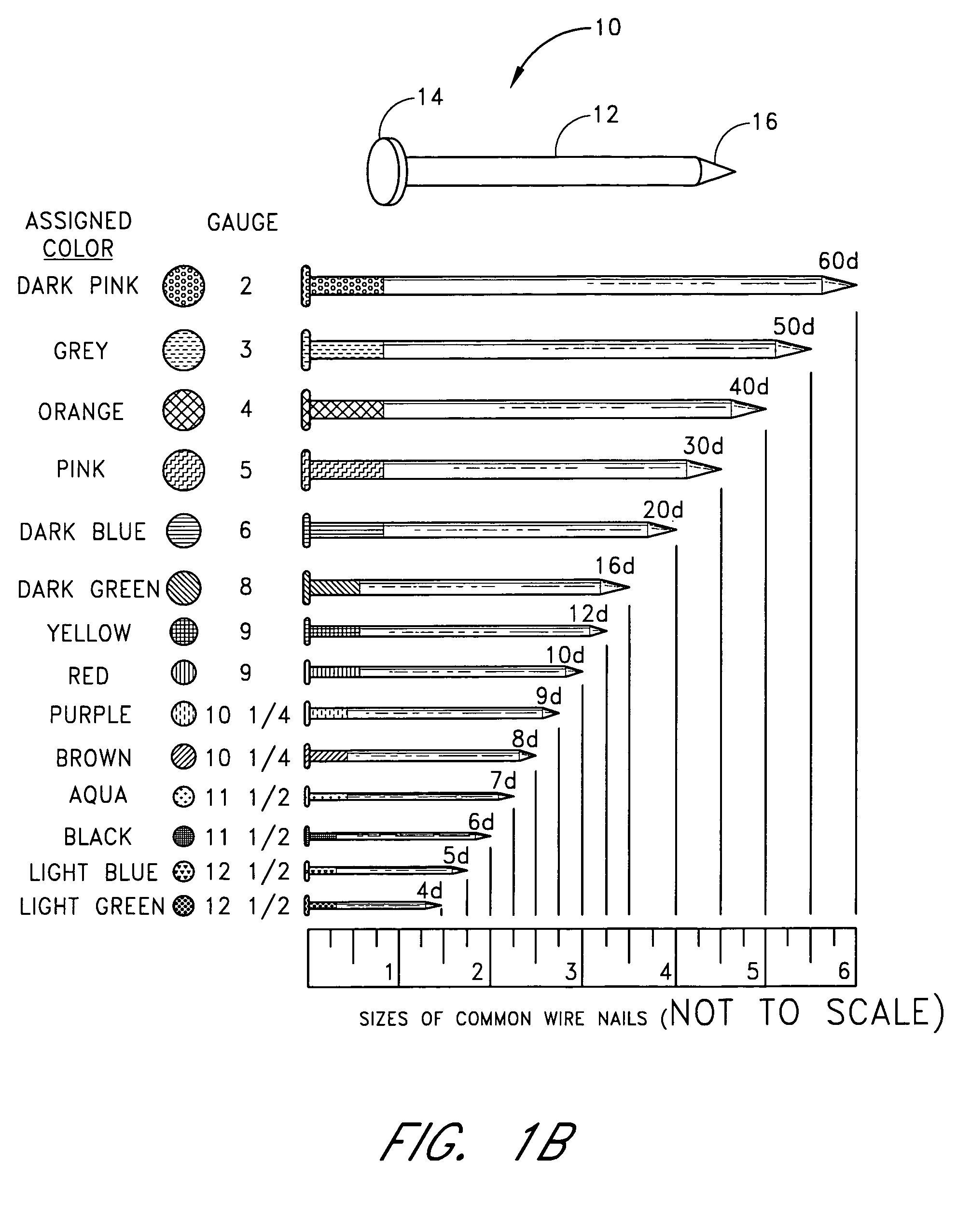

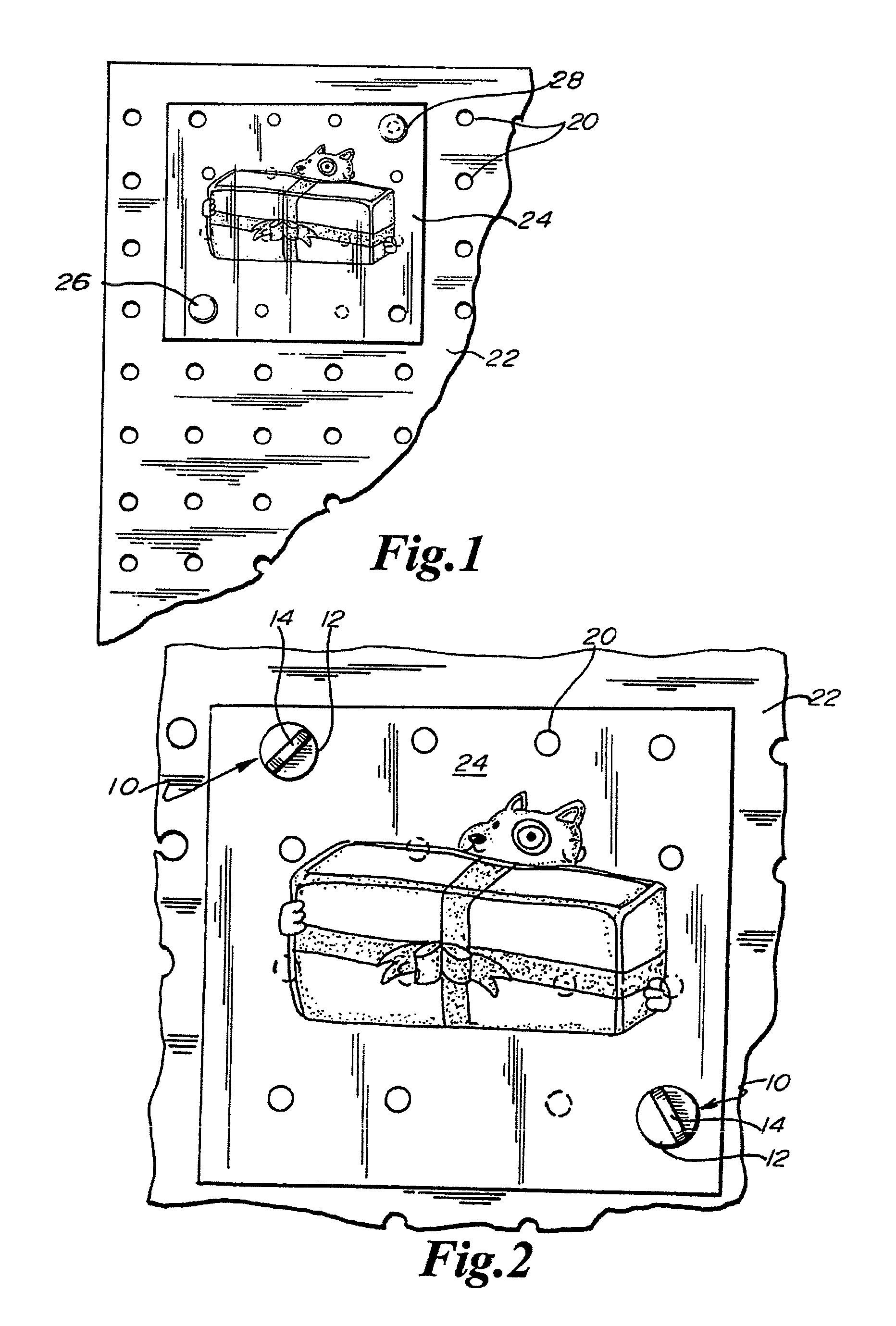

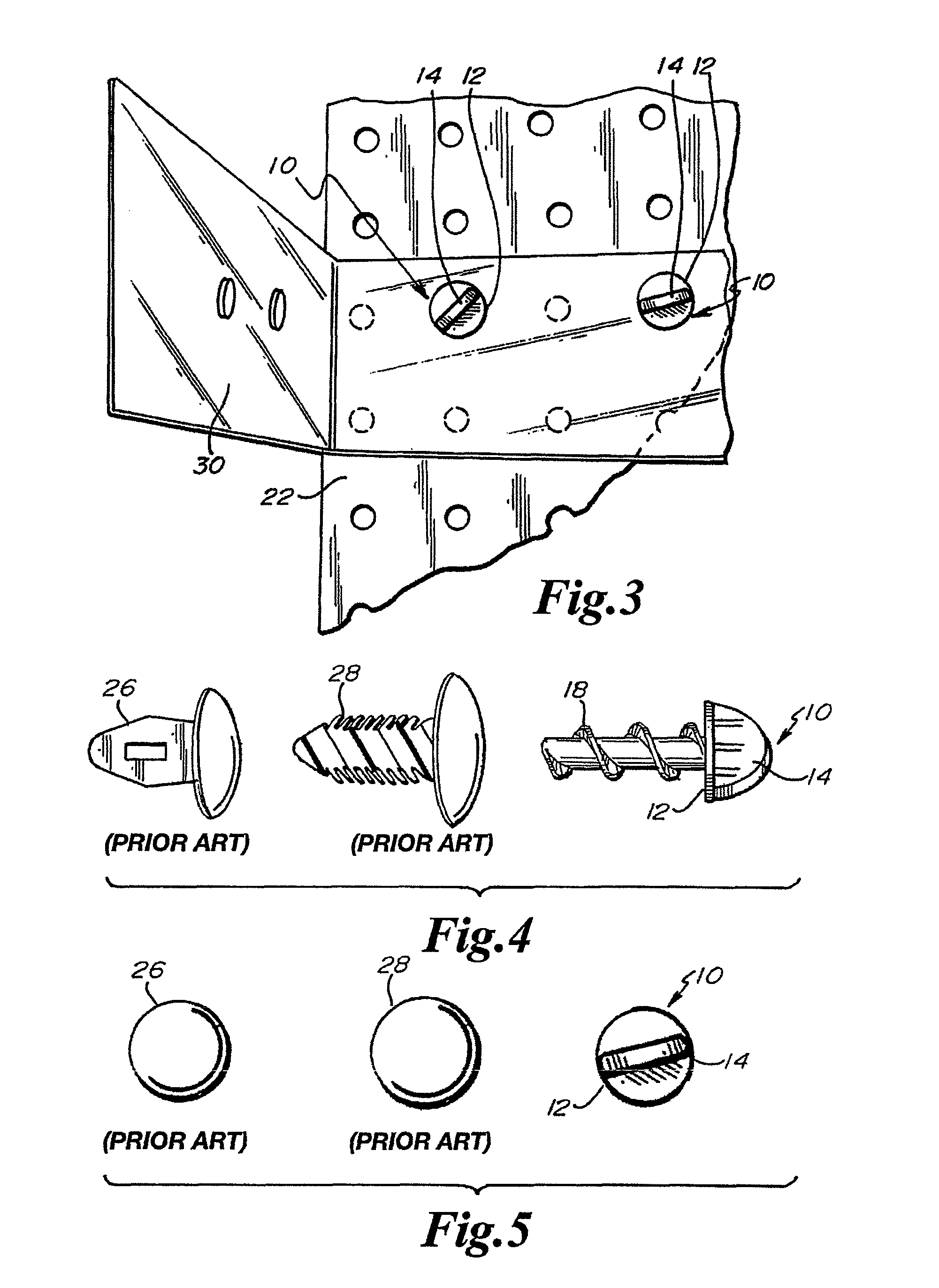

Categorizing fasteners and construction connectors using visual identifiers

InactiveUS7021878B1Improve accuracyShorten the timeStapling toolsRemovable ornamentalEngineeringColor-coding

A method of categorizing fasteners and construction connectors by size and type using a color coding system. Each fastener receives a designated and distinct color contained on the surface that is exposed before and after installation. The colors are preselected to define one or more physical properties of the fasteners. A color key is provided to determine the physical properties of the fasteners based on the coloring of exposed portions of the inserted fasteners. Similarly, construction connectors receive a designated and distinct color contained on the surface that is exposed before and after installation. The color represented on the surface of the construction connector is such that the corresponding fastener is the same color.

Owner:TRACKERS

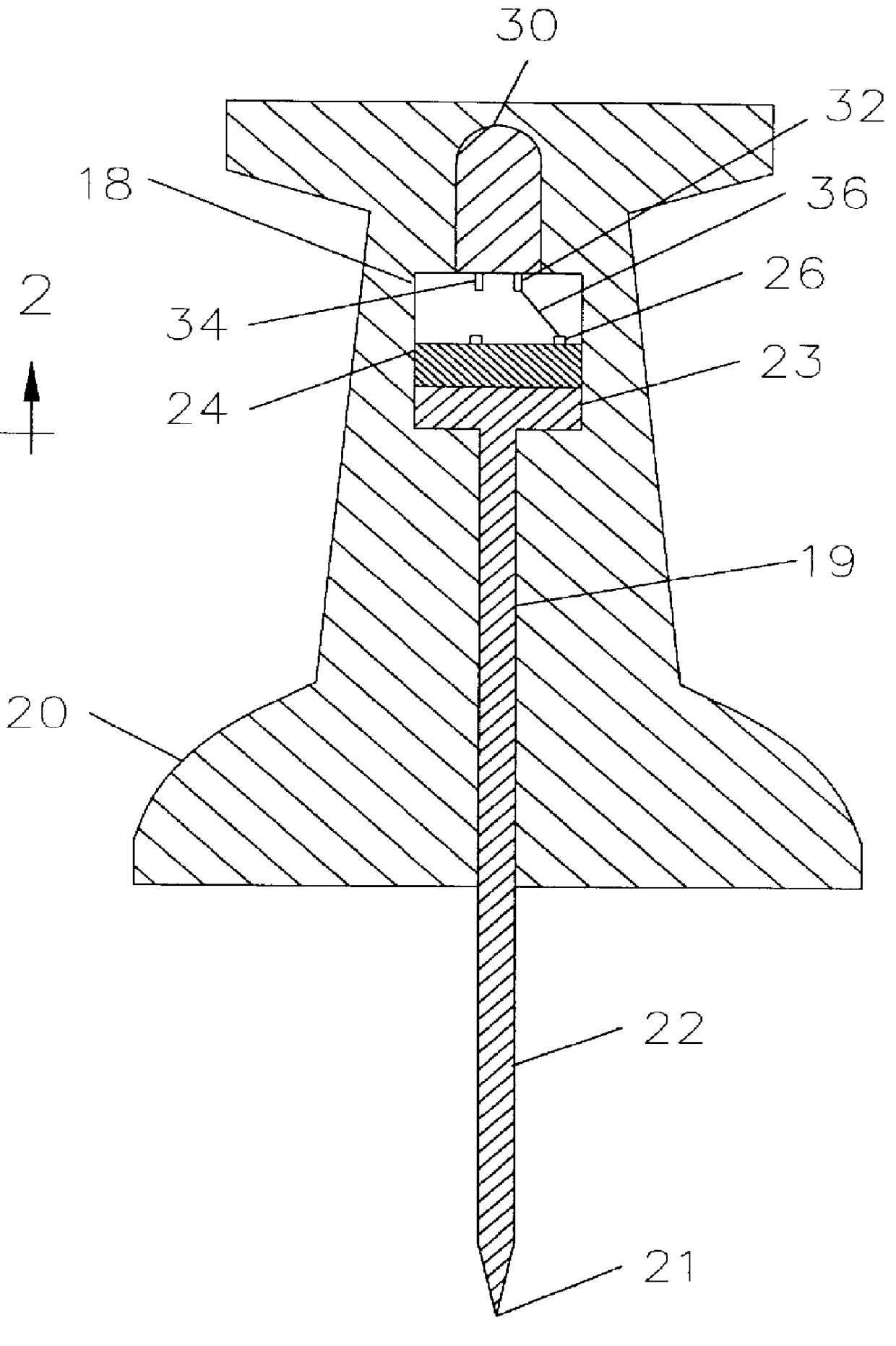

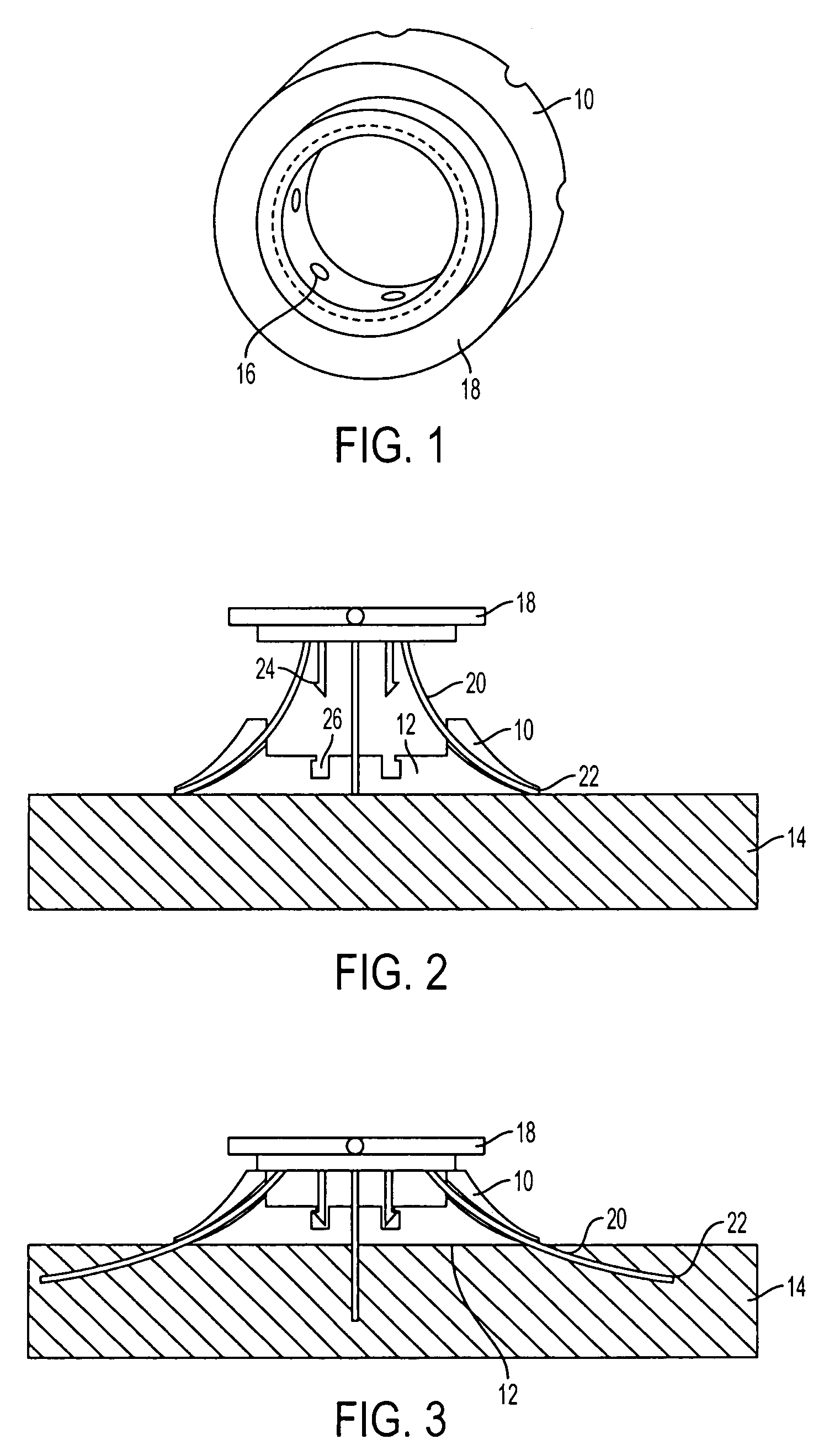

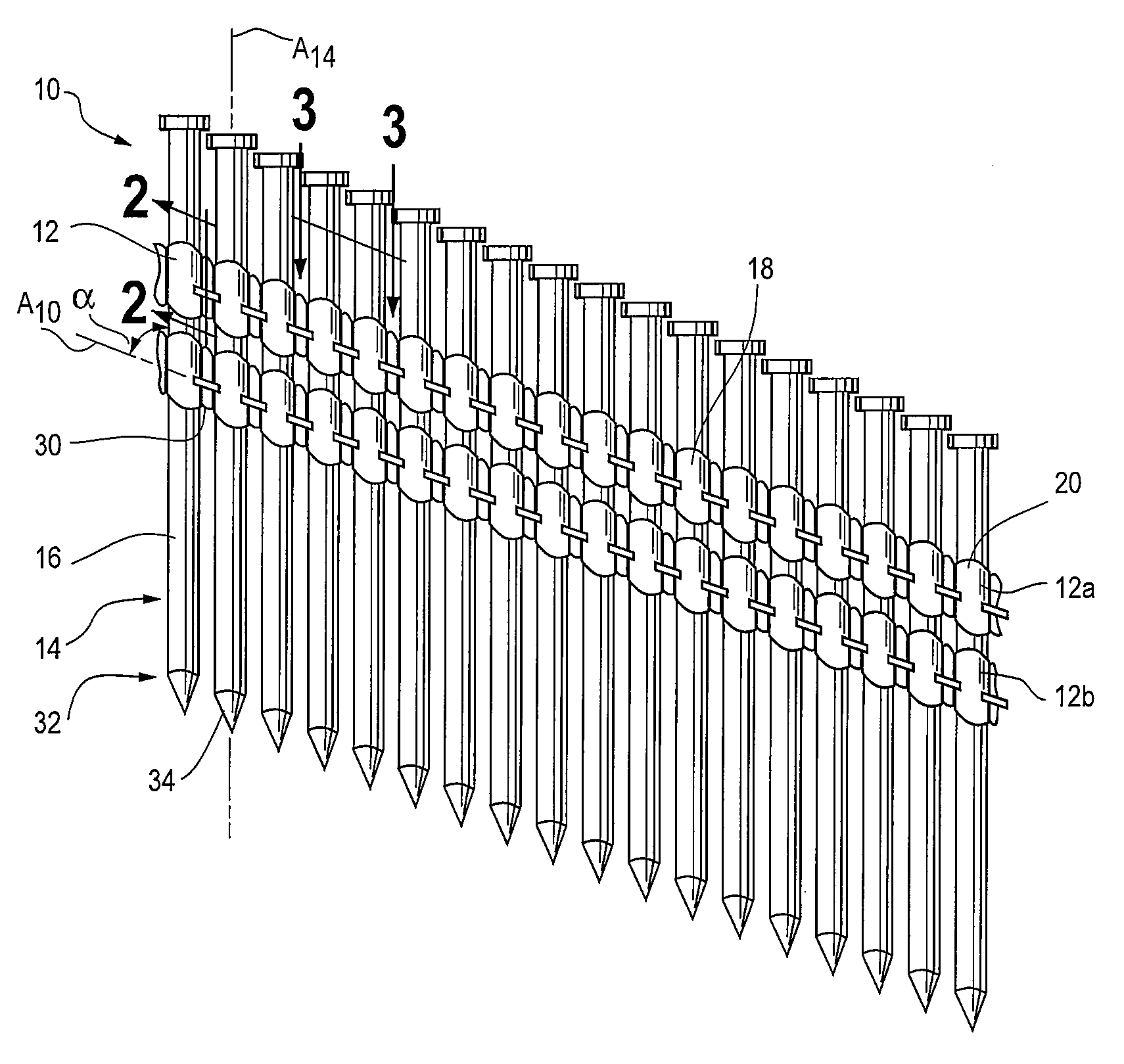

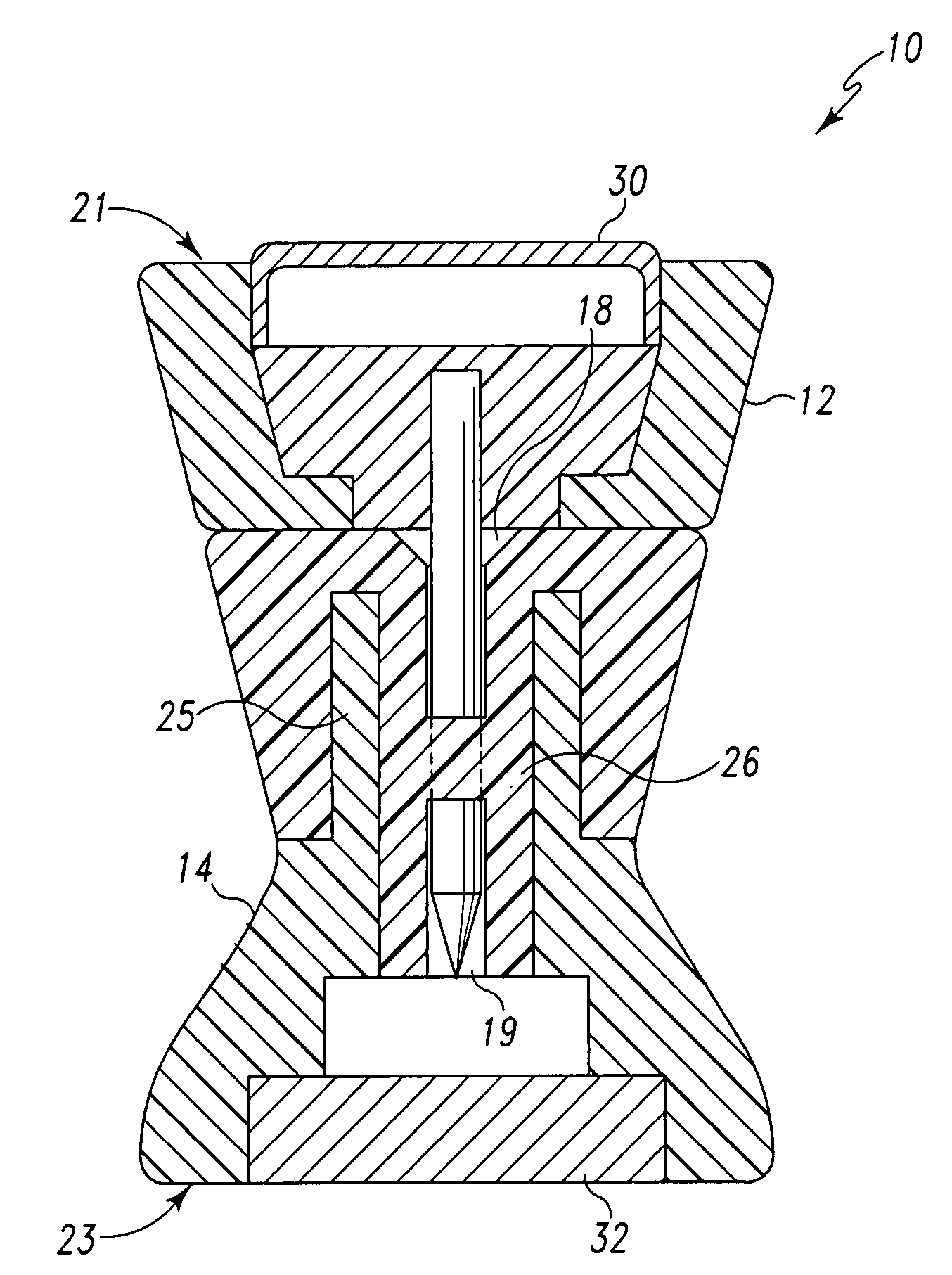

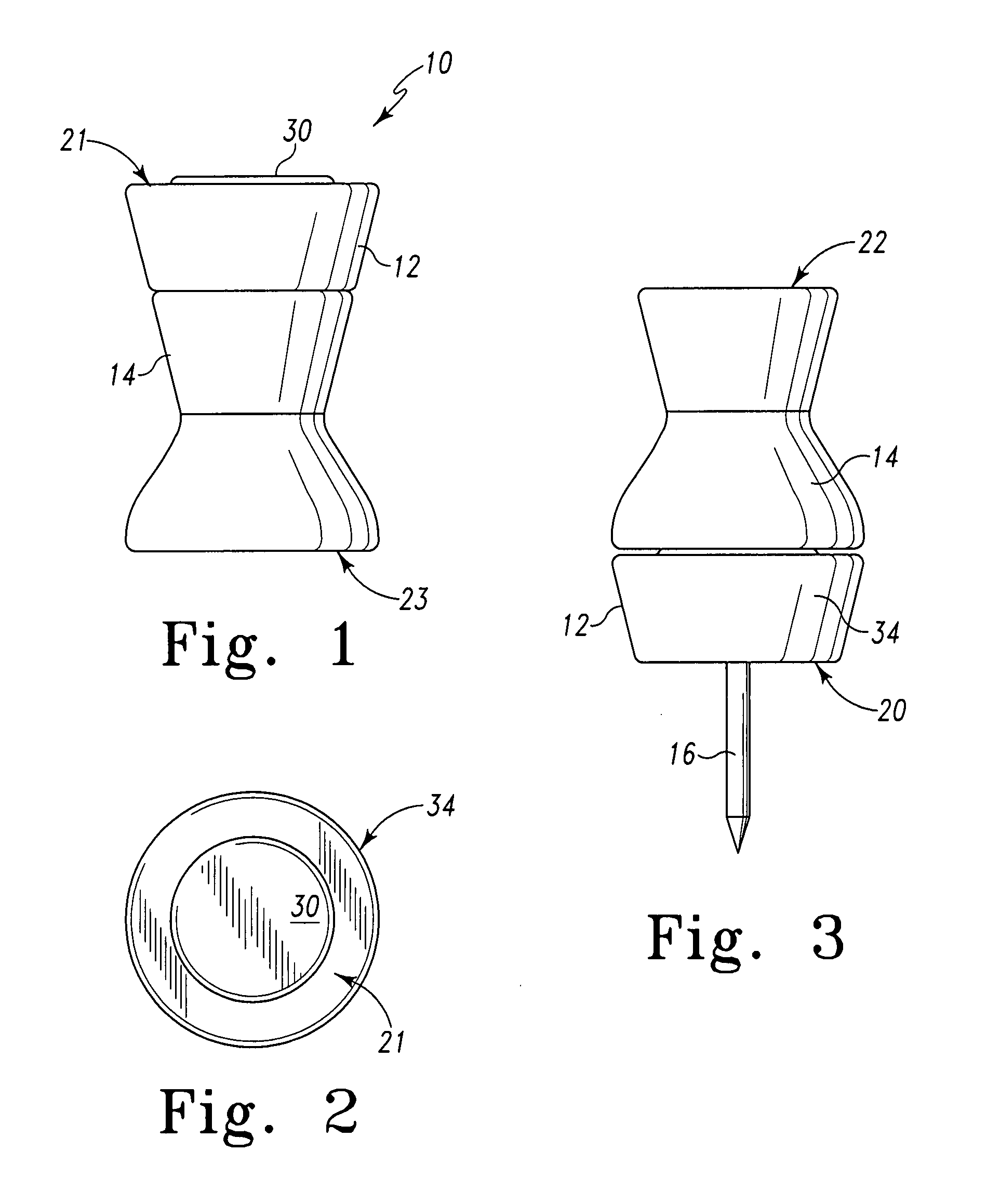

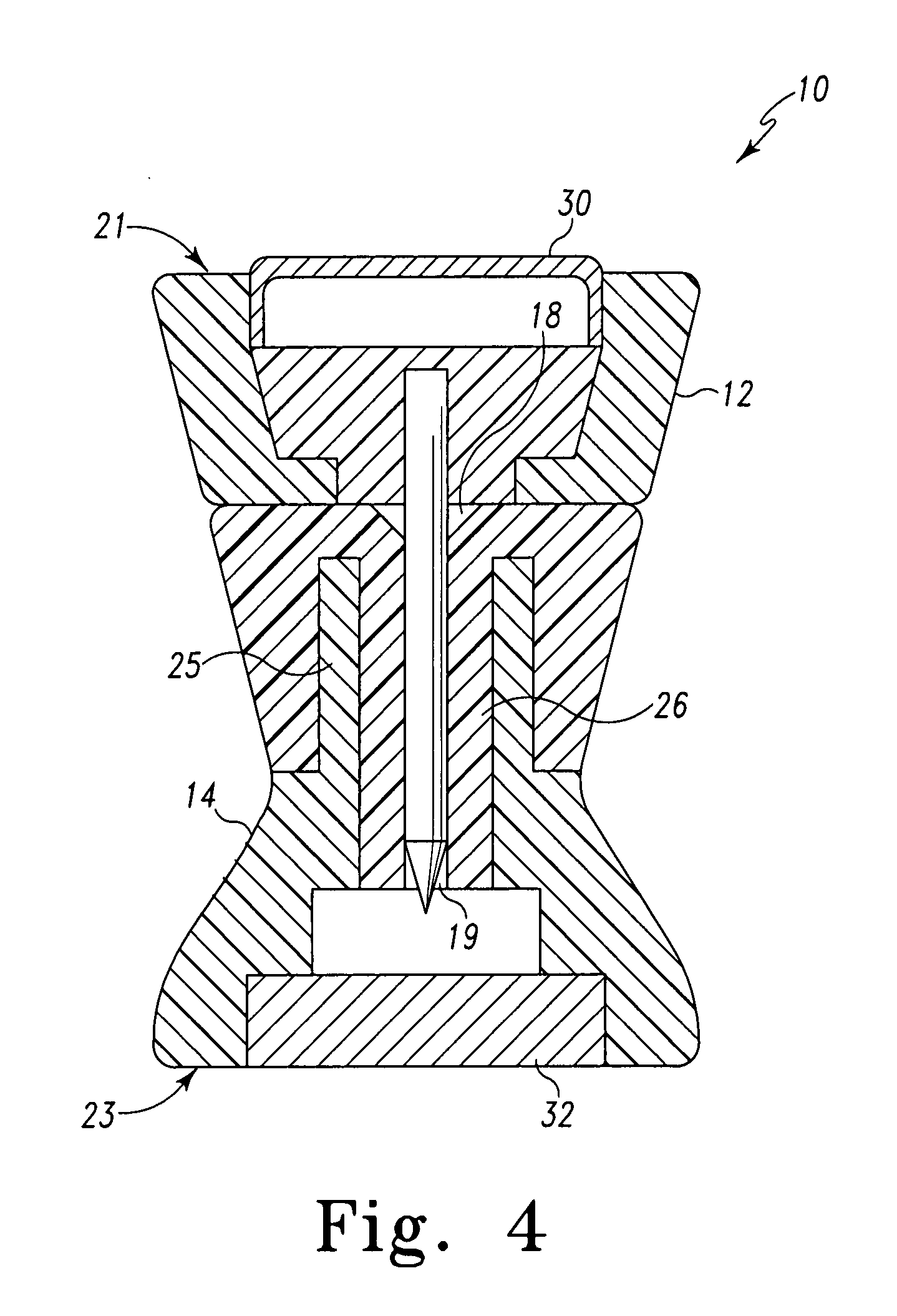

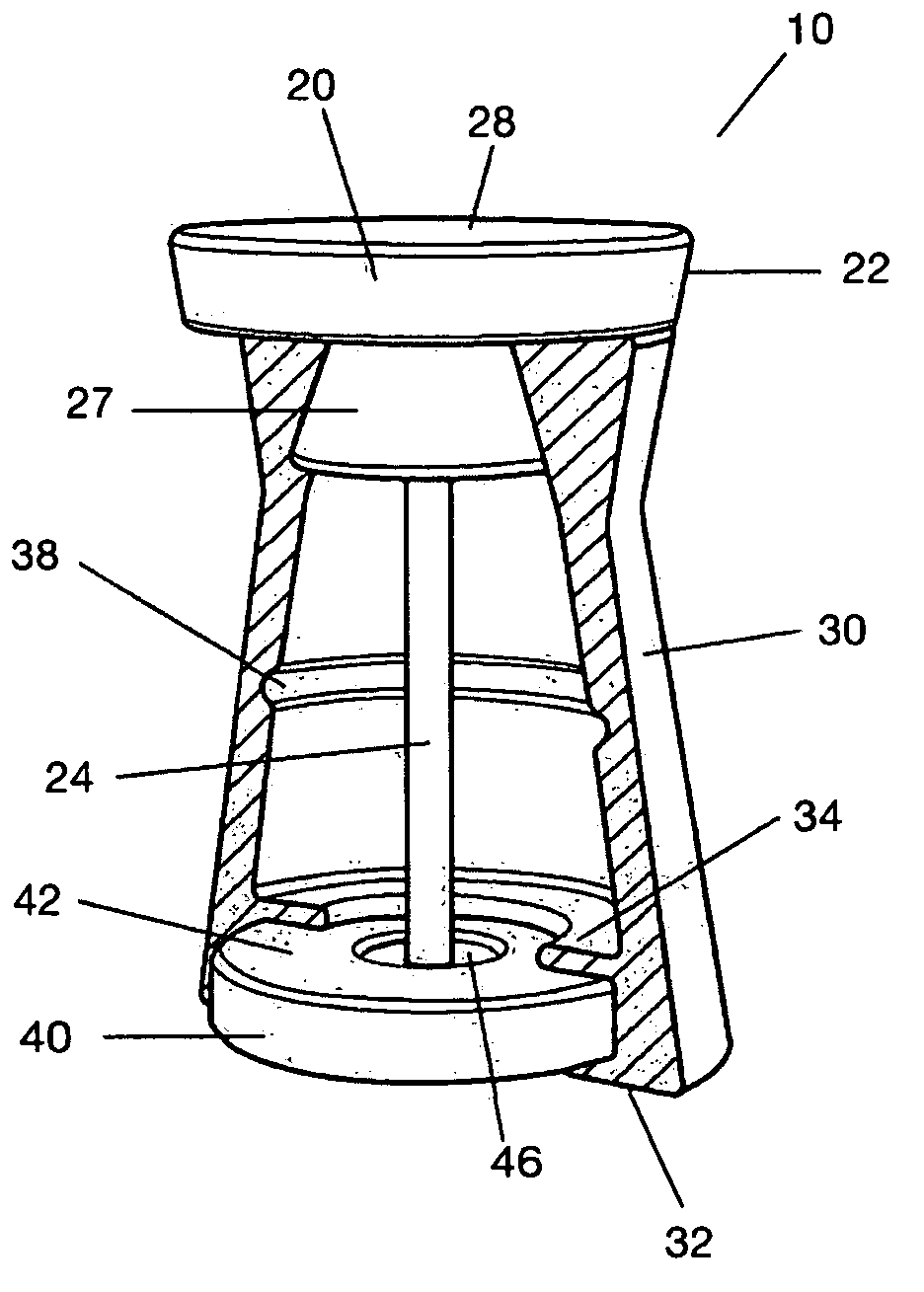

Illuminating push pin

A lighted push pin is provided that is a relatively low cost device which will perform all of the traditional functions of push pins while providing a superior capability to draw attention to specific items or highlight specific information through the use of illumination. Illumination is provided by an on-board battery that powers a light generating device such as a light bulb or light emitting diode. Another embodiment of the invention utilizes a chemical light source. Thus, the invention has eliminated any need for electrified boards or external sources of power.

Owner:GALLO ANTHONY RICHARD

Peg board display fastener and connector

Owner:PROCESS DISPLAY LLC

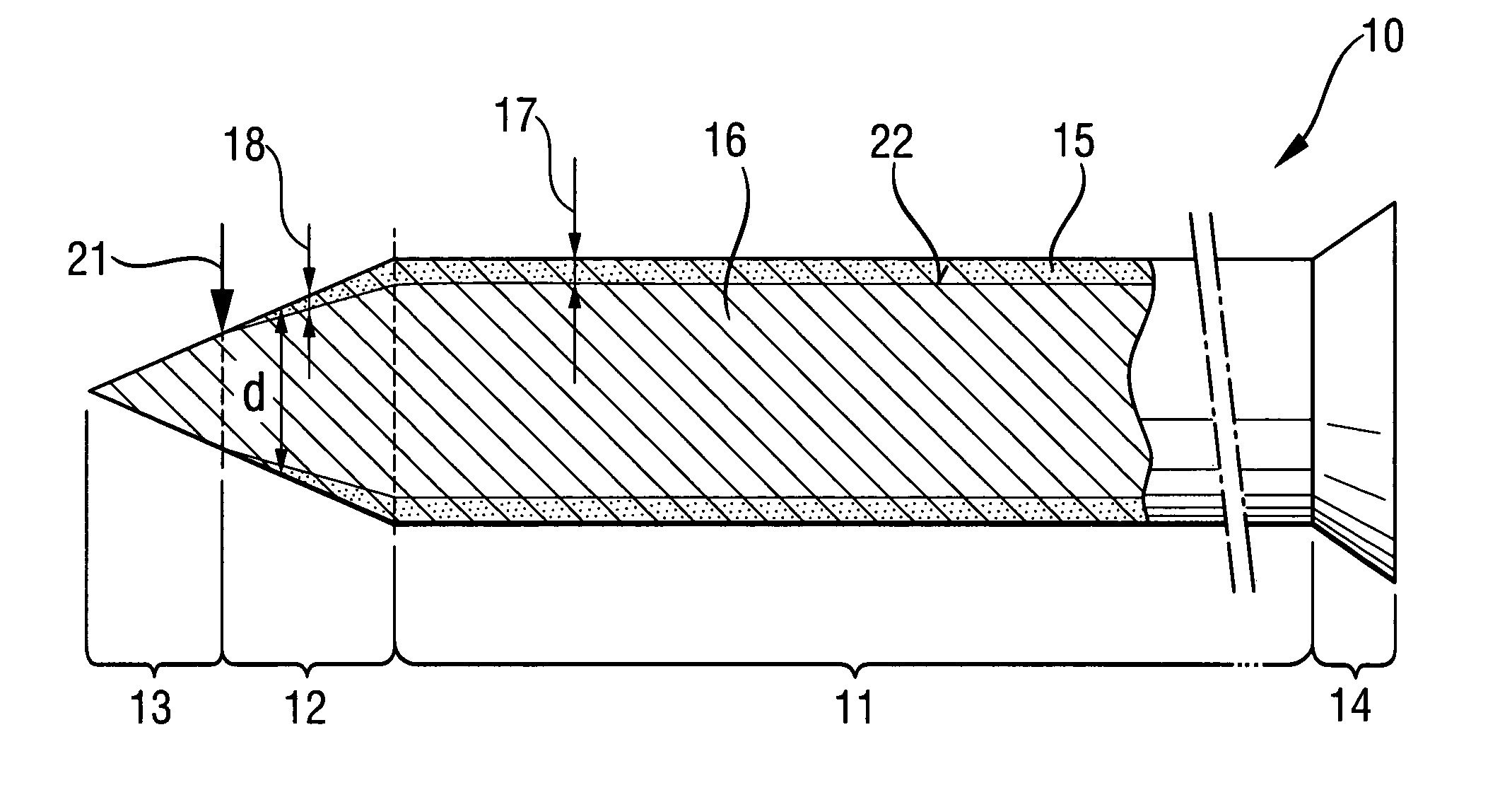

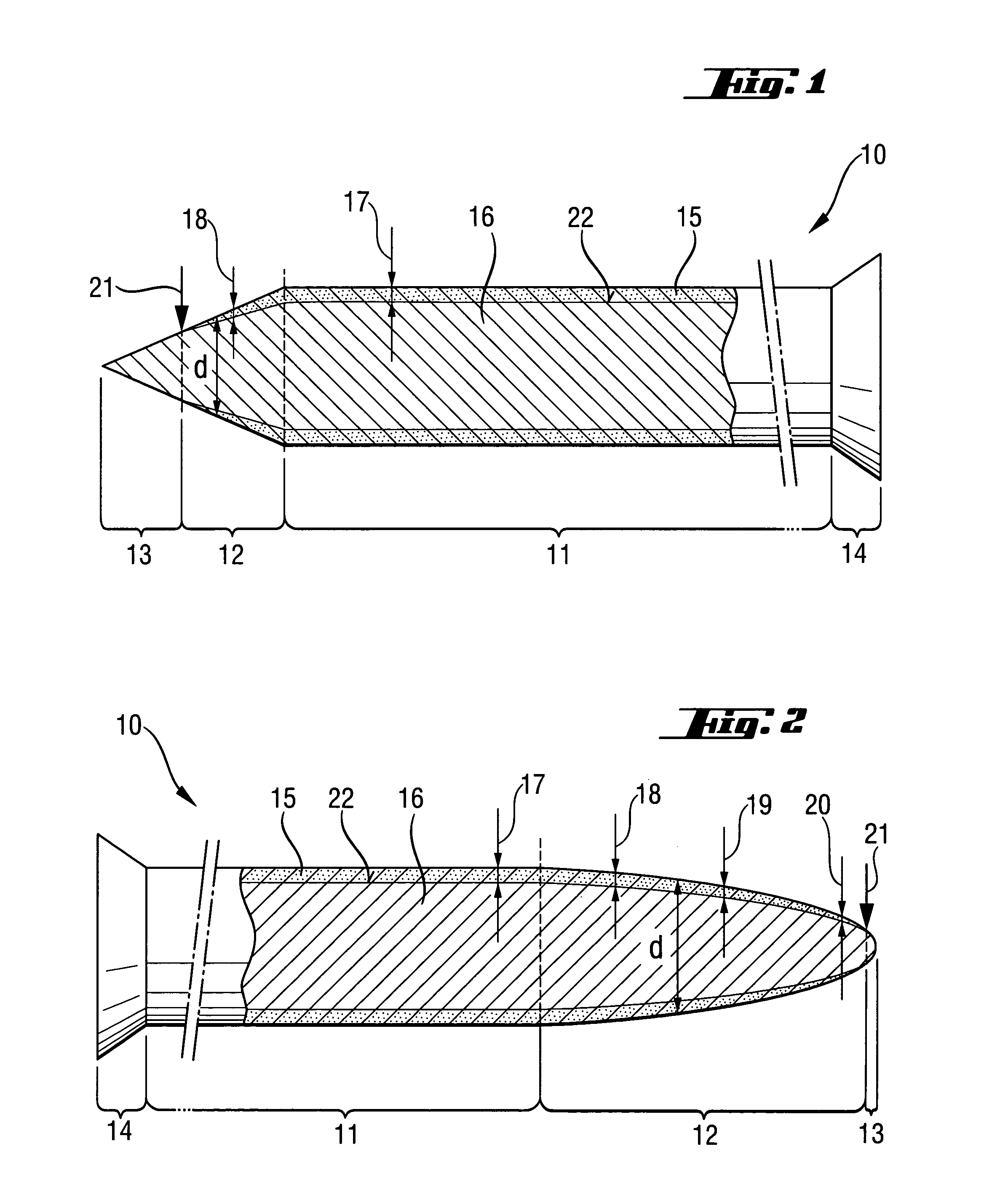

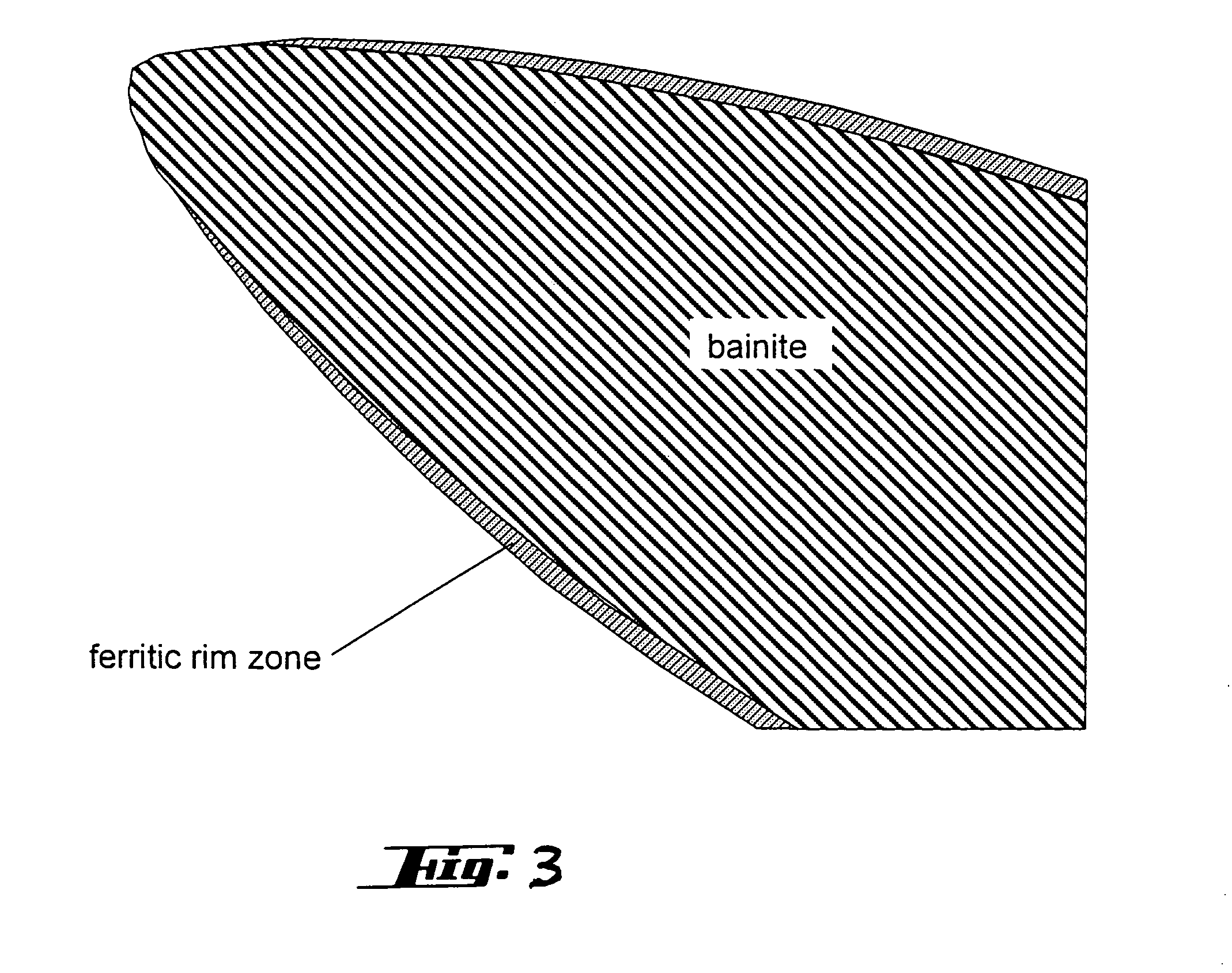

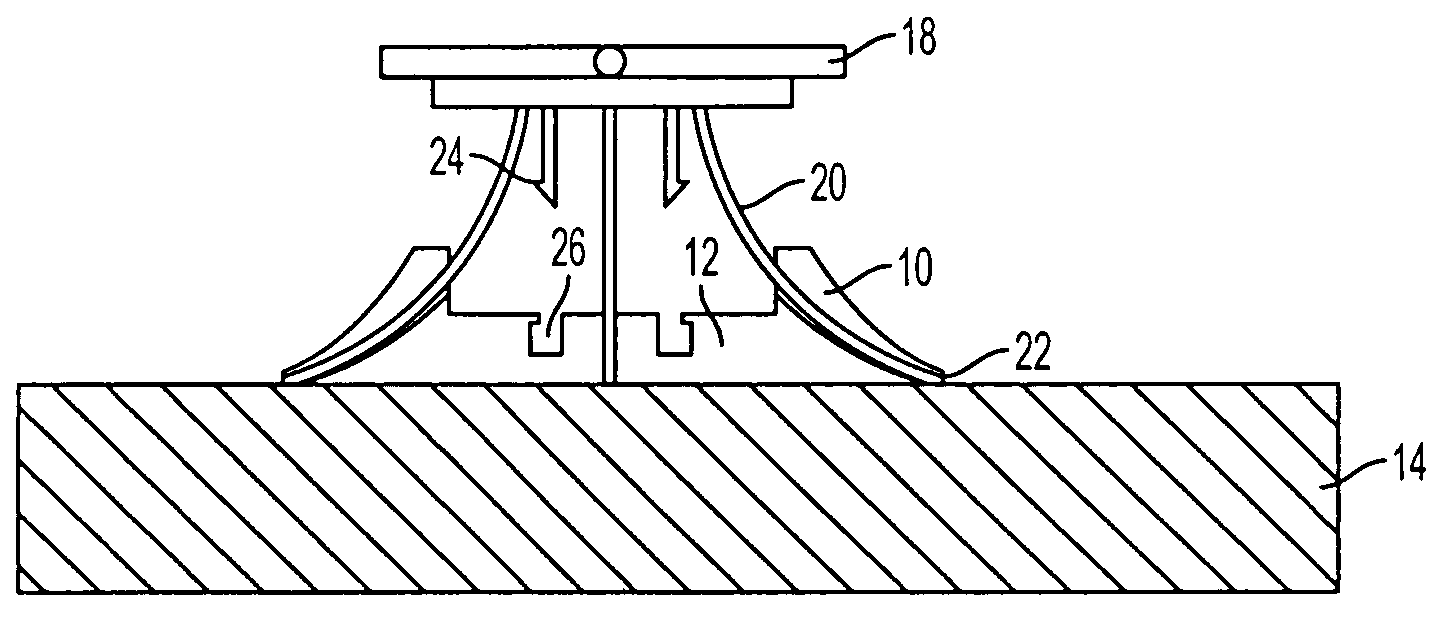

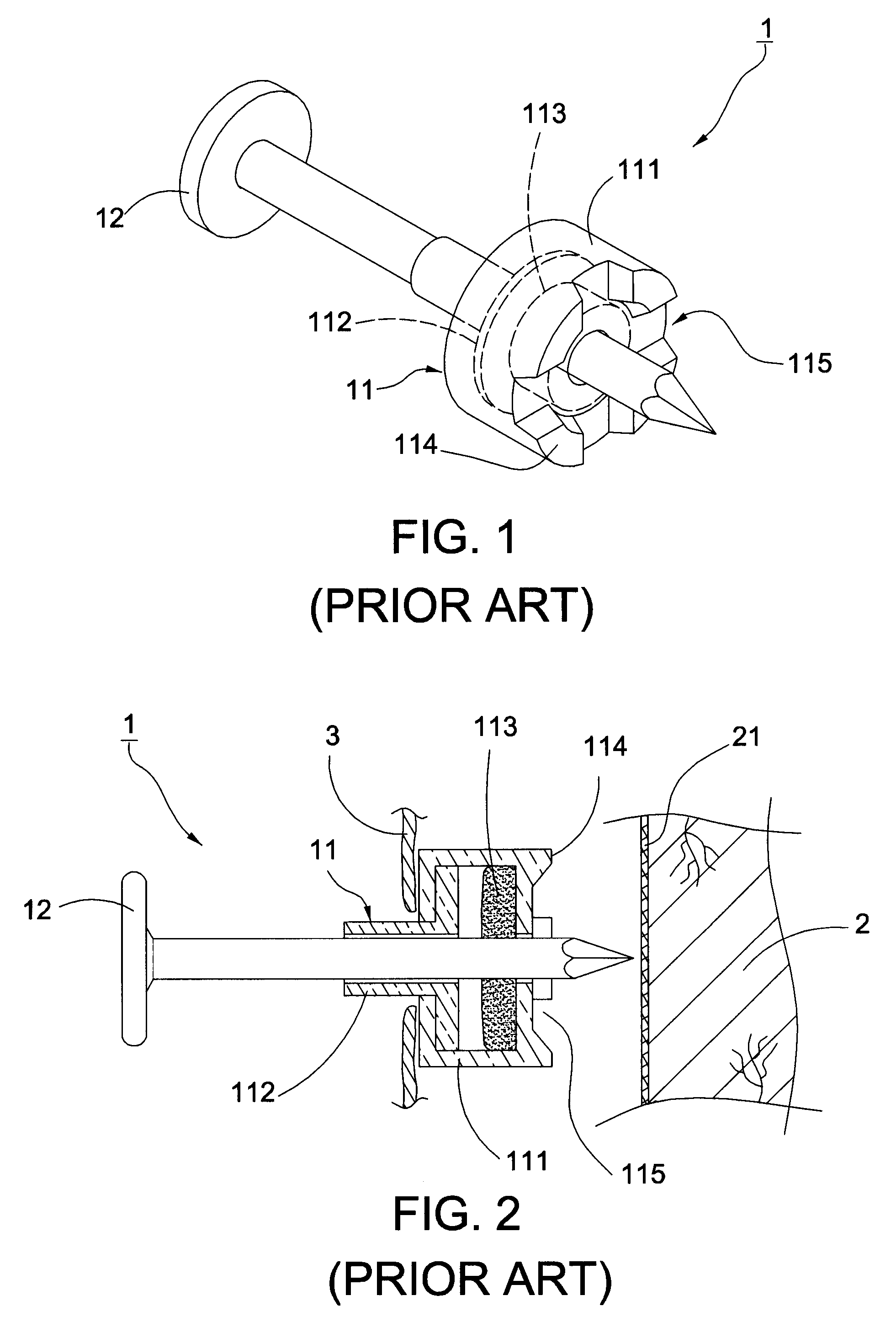

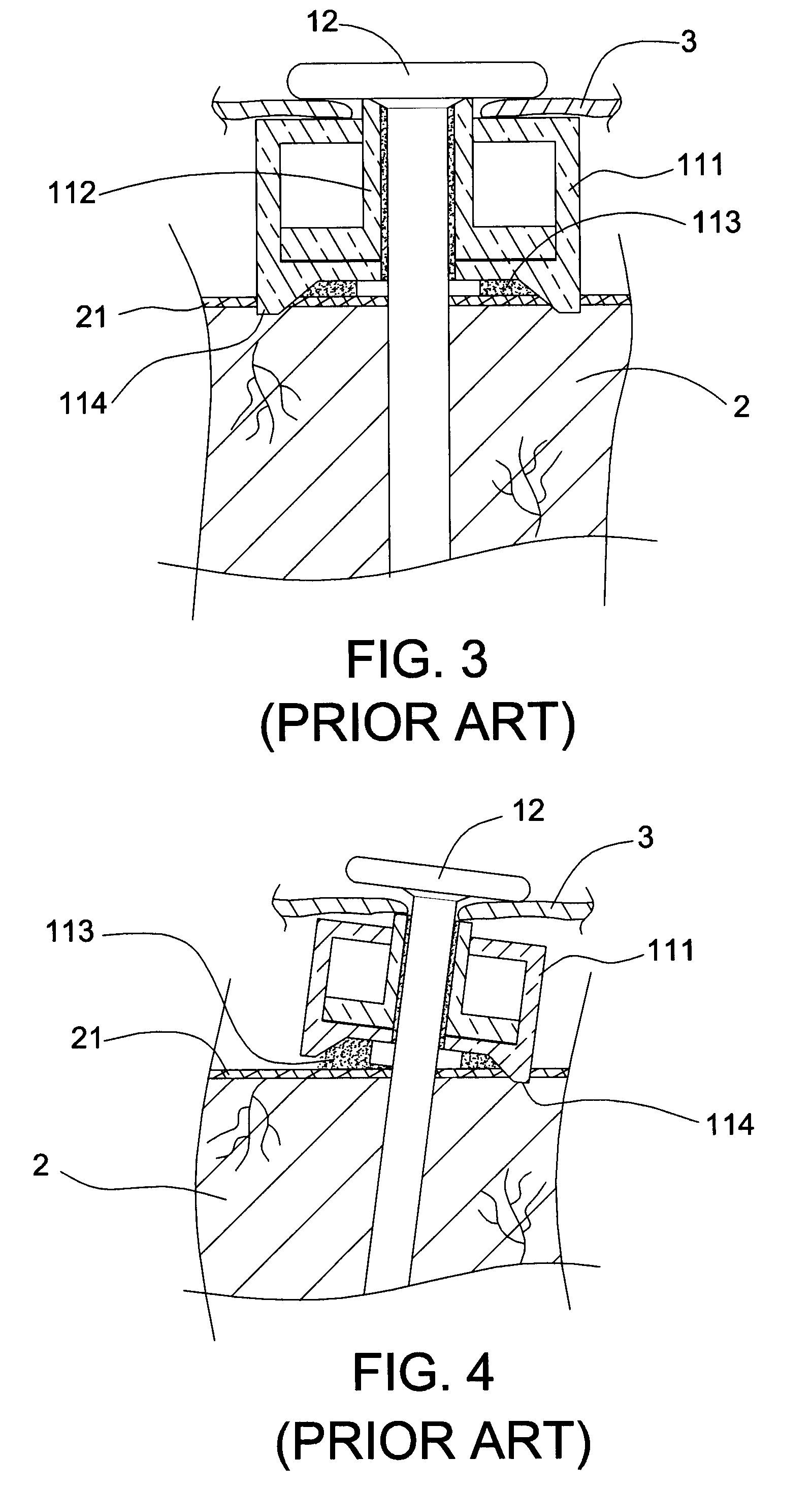

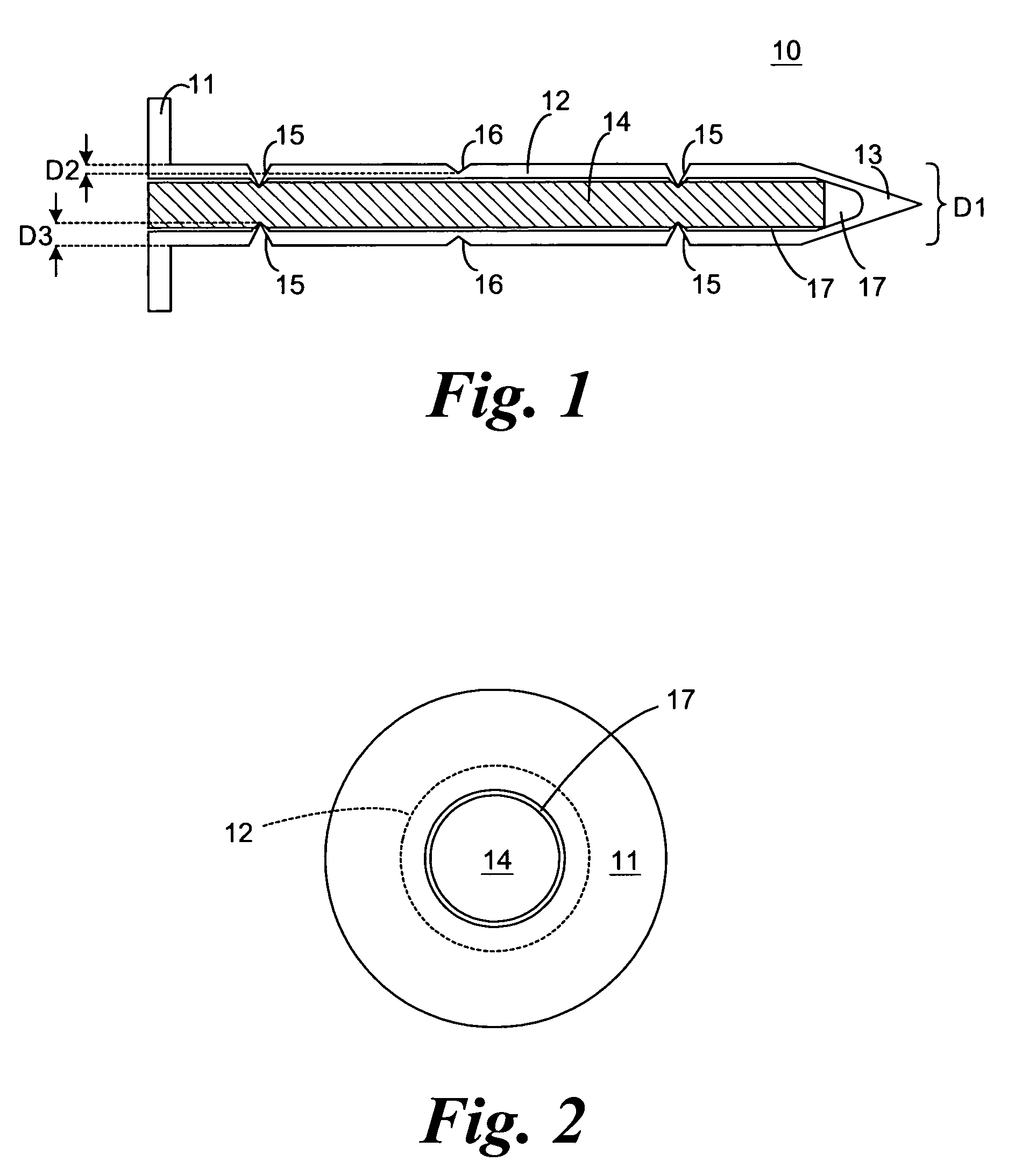

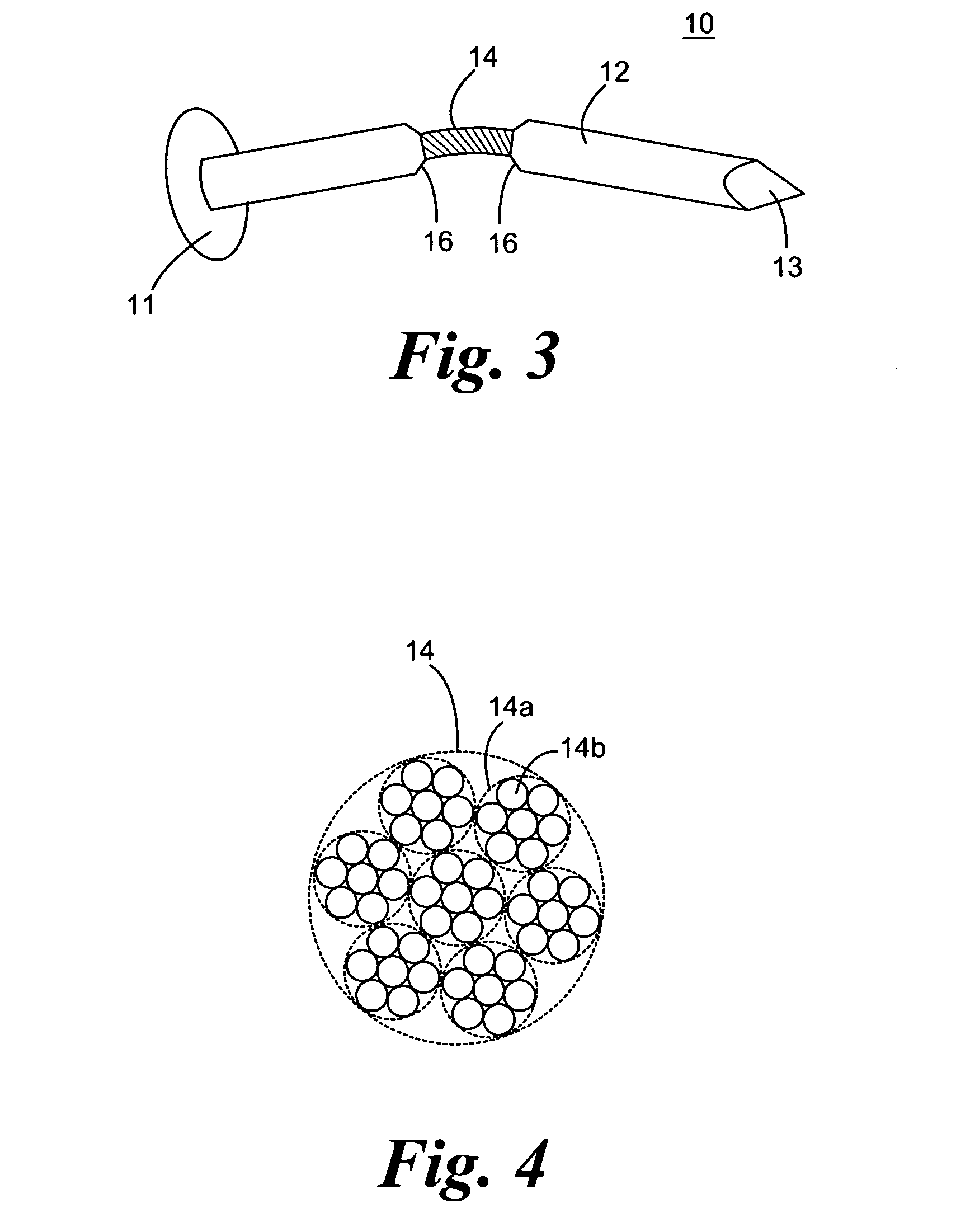

Fastening element

A fastening element which has a core (16) of a relatively hard, carburized steel and a ferritic rim zone (15) of a less hard, low-carbon steel, includes a stem (11), a head (14) provided at one end of the stem (11), a tip (13) provided at an opposite end of the stem (11), and a transition region (12) extending between the stem (11) and the tip (13) and in which a thickness (18, 19, 20) of the ferritic rim zone (15) gradually diminishes from the stem (11) in a direction toward the tip (13) to a nill value (21), so that the tip (13) is free from the ferritic rim zone (15).

Owner:HILTI AG

Device that attaches to a surface

Owner:ALVA IP I +2

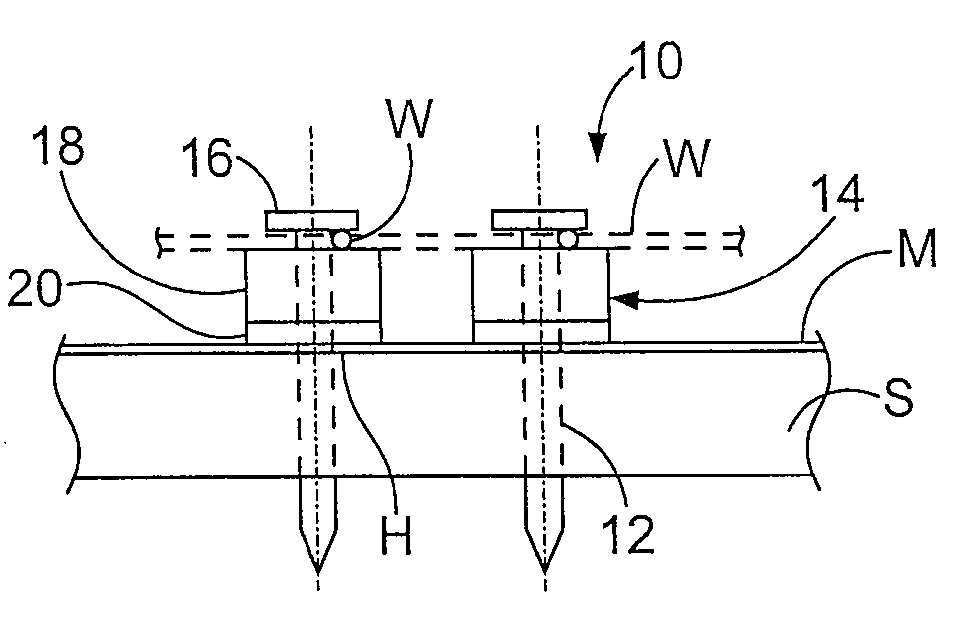

Debris-free plastic collating strip for nails

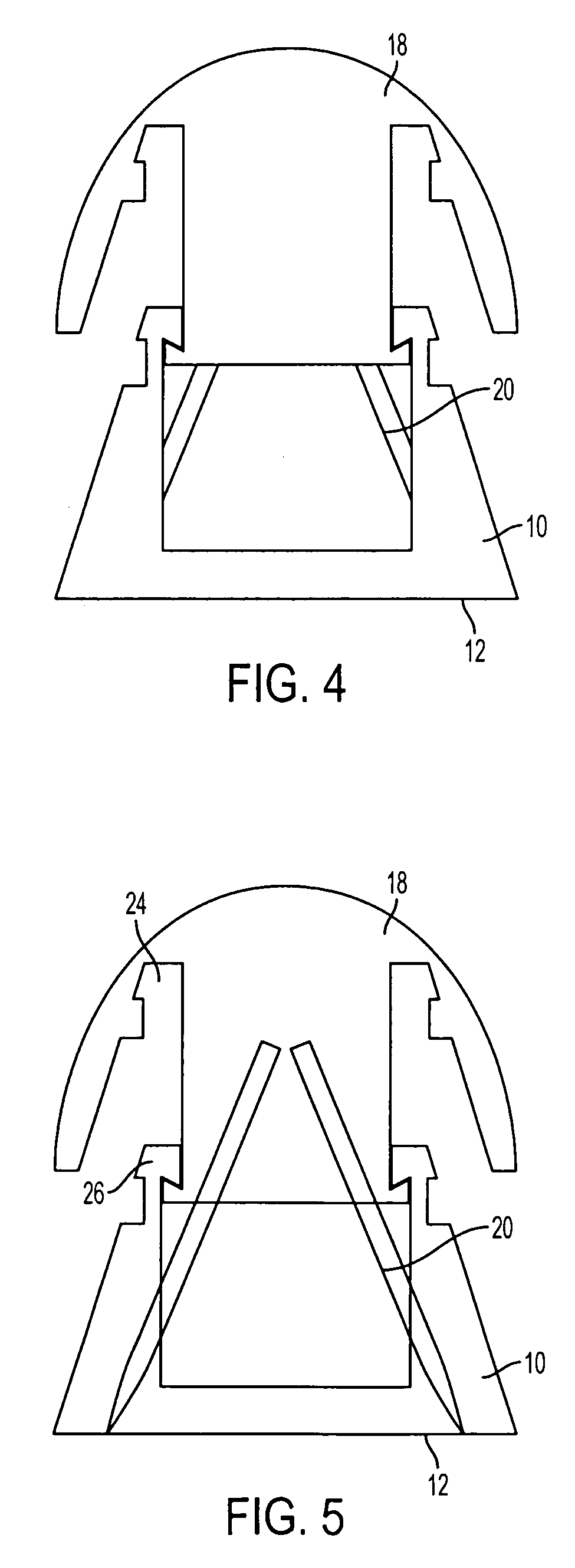

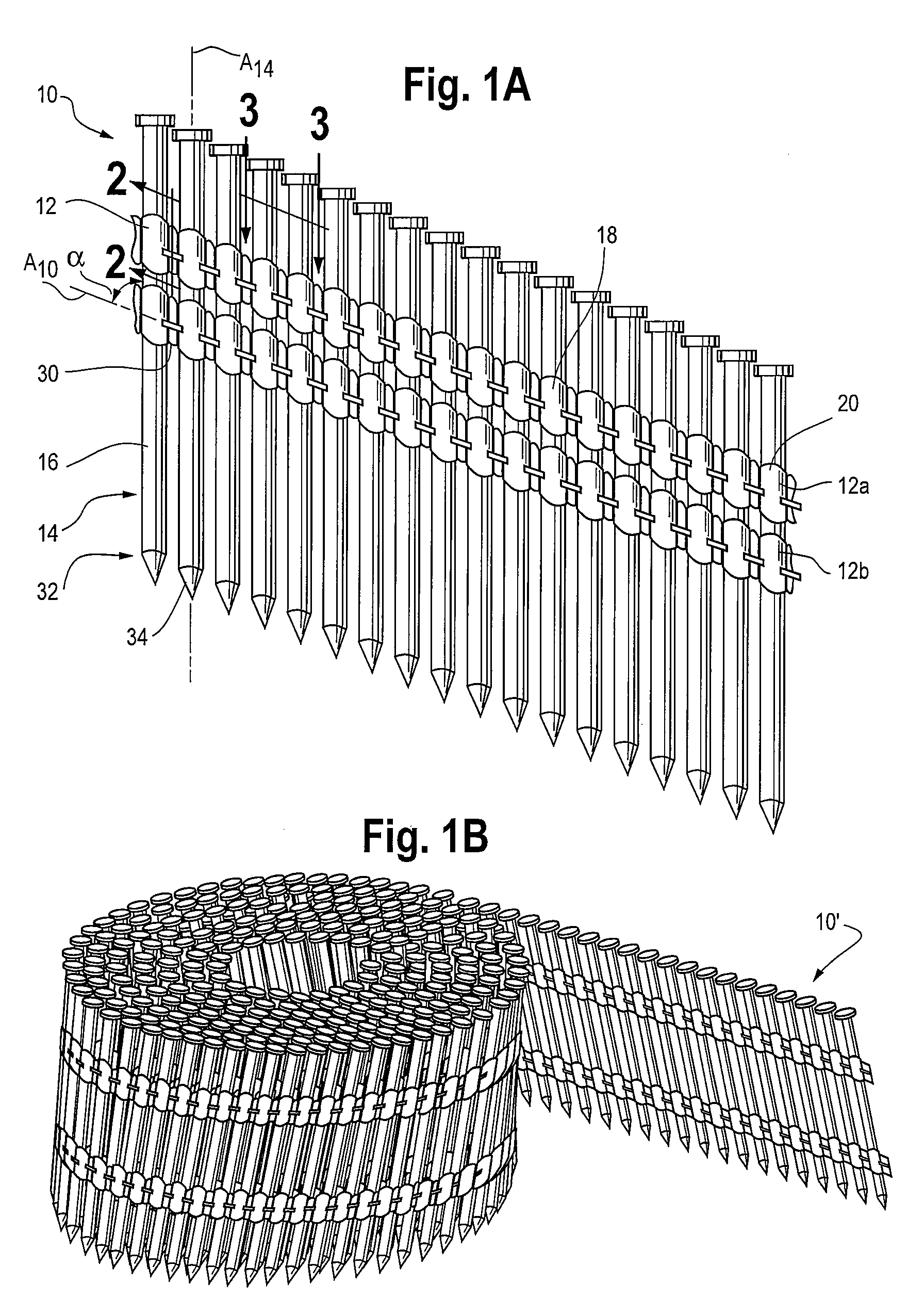

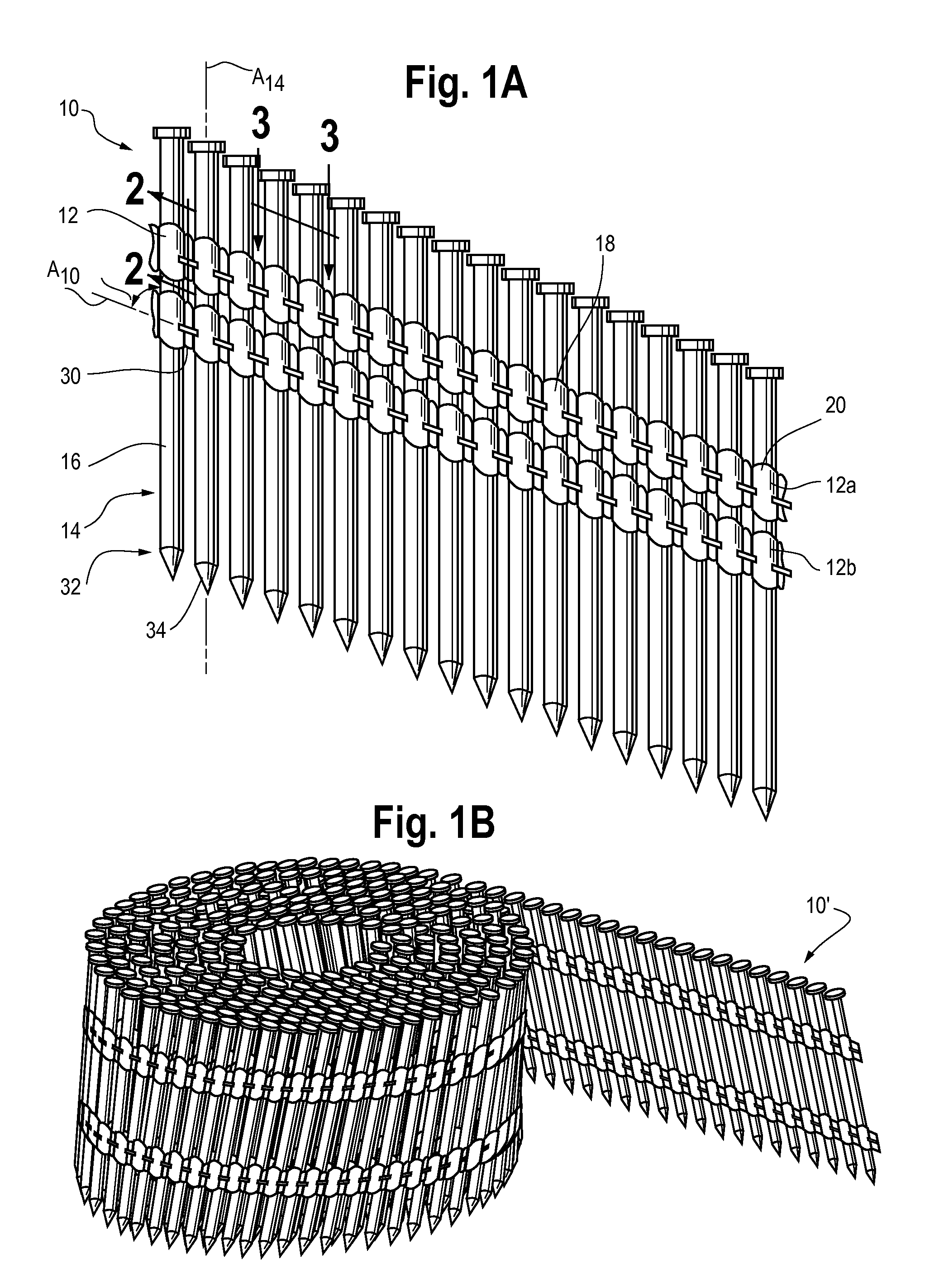

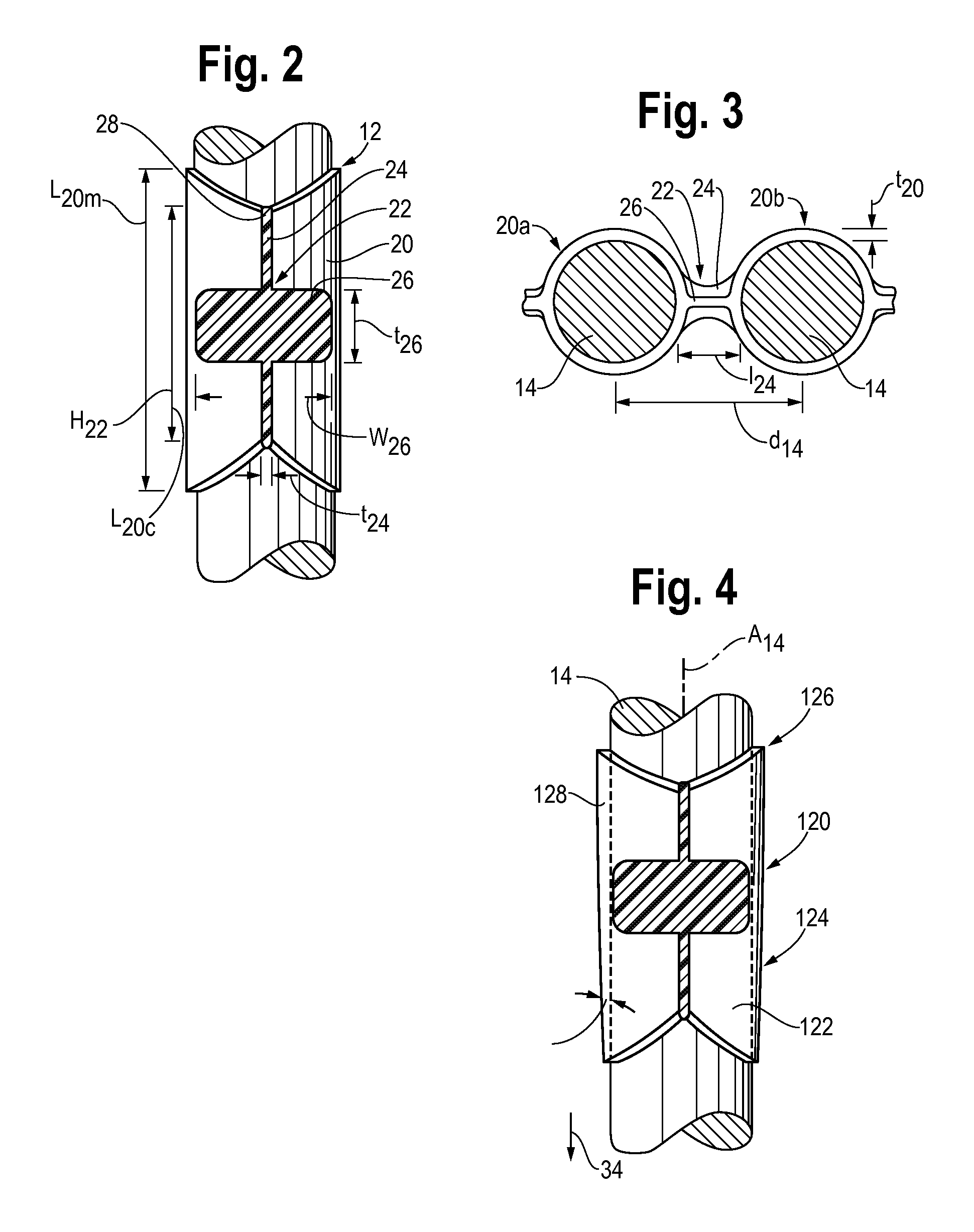

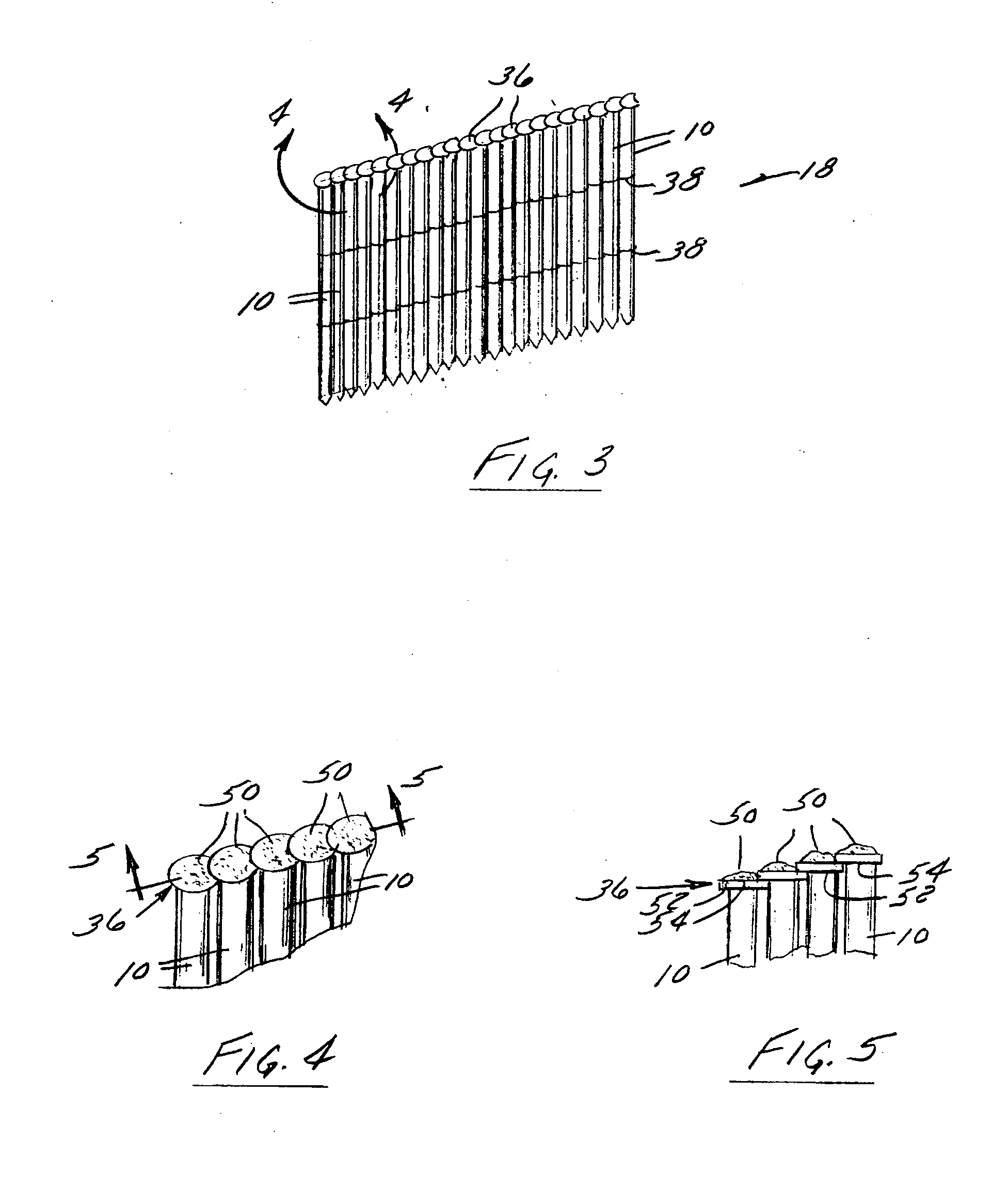

ActiveUS20070264103A1Reduce fragmentationReduce connectionsStaplesRail fastenersPlastic materialsEngineering

A fastener assembly for use in an associated fastener driving tool for driving a fastener from the assembly, in sequential order, into an associated substrate, includes a row of fasteners arranged substantially parallel to each other, each fastener having a shank and defining an axis and a collation system formed from a plastic material that is molded onto and adhered to the fasteners. The plastic material defines a collar portion at least substantially encircling the fastener shank and a connecting portion extending between and connecting adjacent collar portions. When the fastener is driven from the driving tool, the collar portion remains adhered to the fastener such that the collar portion penetrates the substrate with the fastener, and the connecting portion includes a preferentially weakened region to influence separation of the connecting portion from the collar at a desired location.

Owner:ILLINOIS TOOL WORKS INC

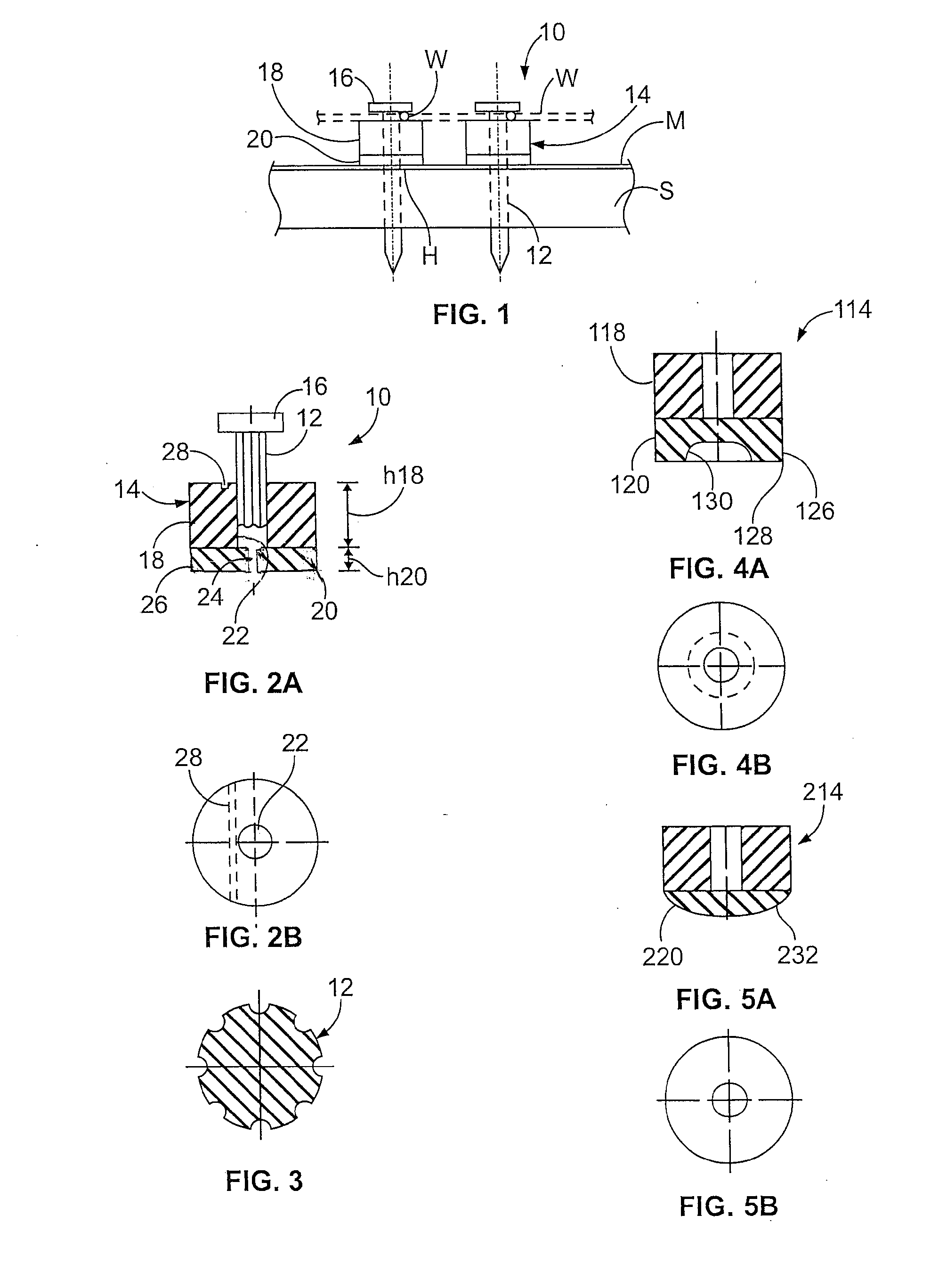

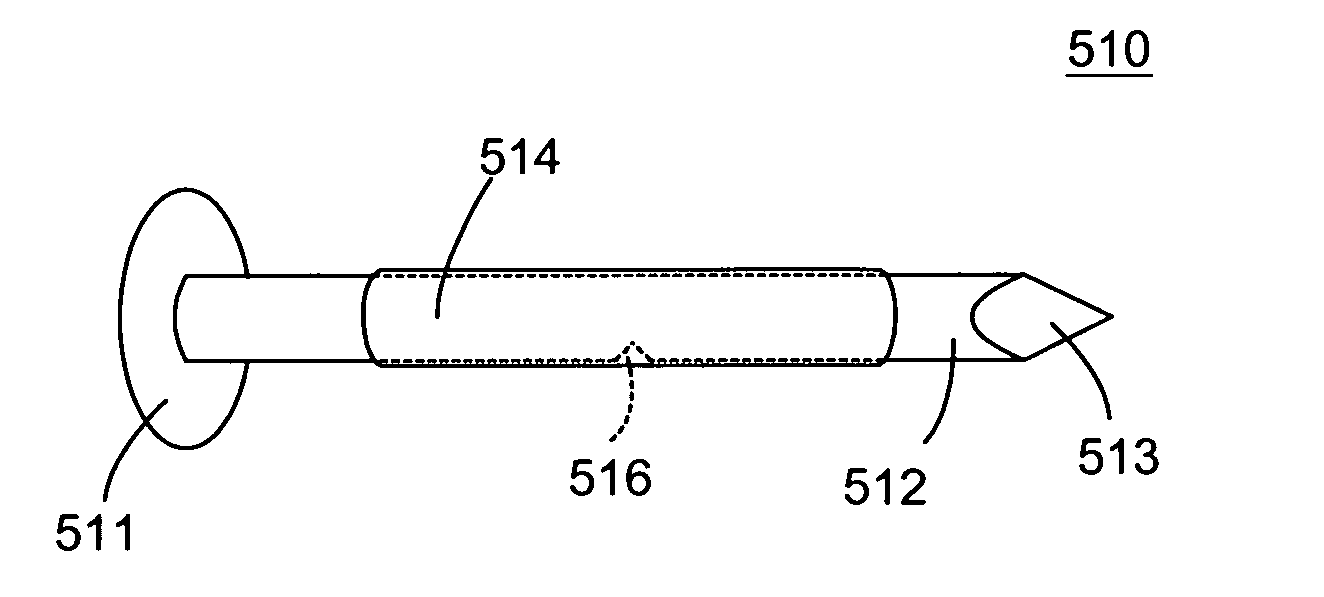

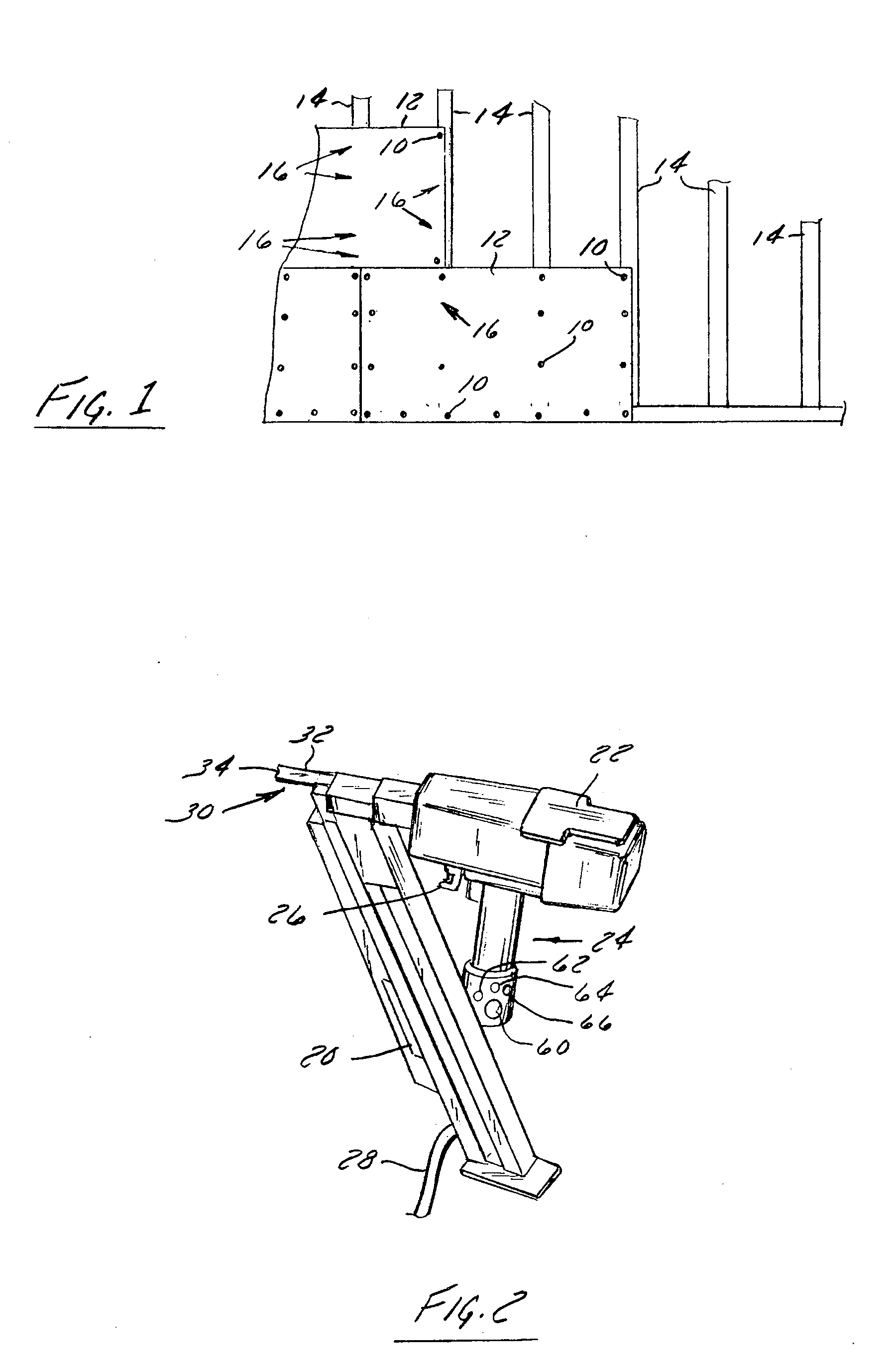

Stucco fastener

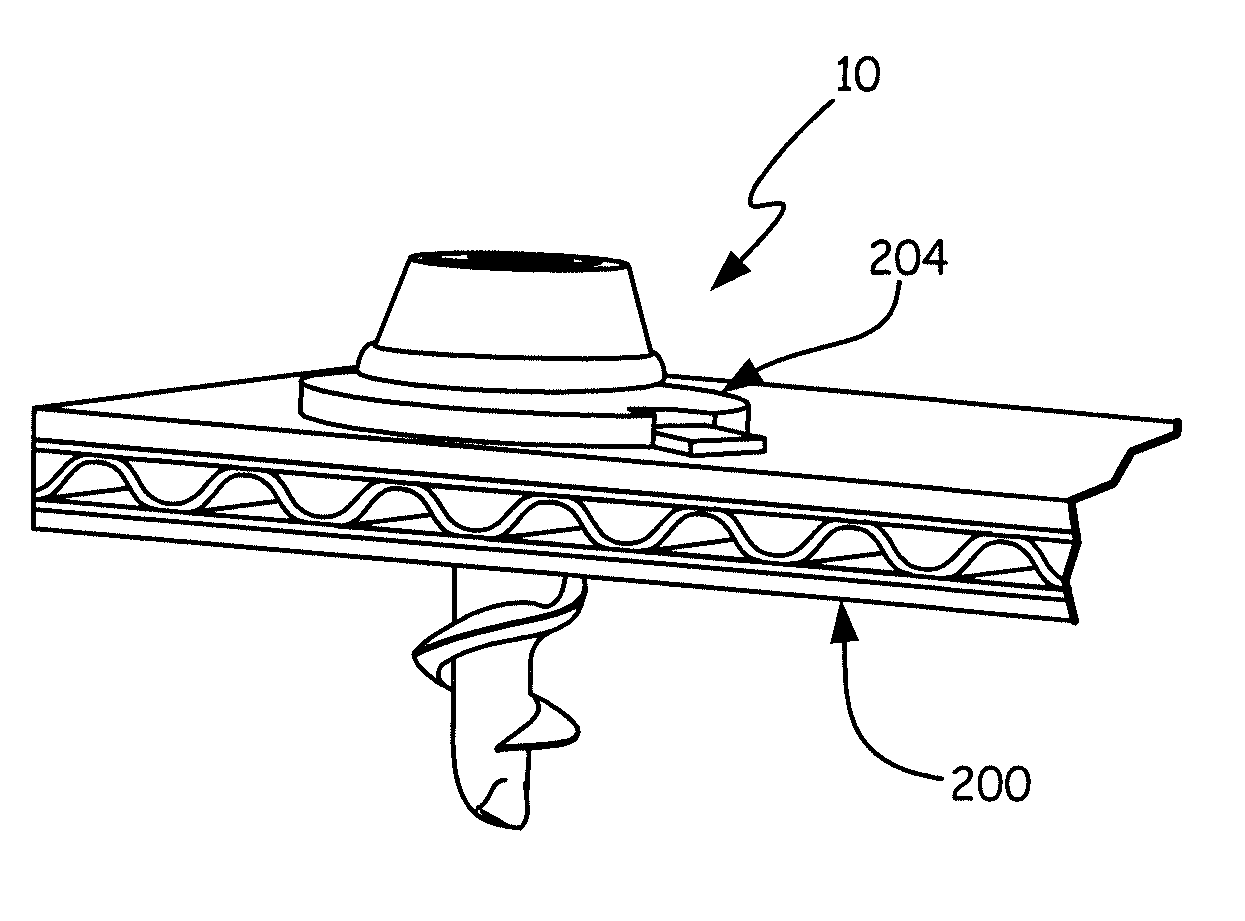

A fastener is configured for securing a lath to a surface for, for example, the application of stucco to the surface. The fastener includes a fastener having a head, a shank and a penetrating tip. The head has a diameter and the shank has a diameter less than the head diameter. The stucco fastener has a sealing / spacer assembly having spacer element and a sealing element. The spacer element is formed from a relatively incompressible material and has a diameter greater than the shank diameter. The spacer element has a bore therein having a diameter about equal to the shank diameter. The sealing element is formed from a resilient, water-resistant material and is positioned adjacent to and in contact with the spacer element. When the fastener is driven into the surface, the fastener penetrates the surface to secure the fastener to the surface and a portion of the lath is captured between the head of the fastener and the spacer element to space the lath from the surface. The sealing element contacts the surface to form a seal at the fastener penetration to prevent the incursion of liquid into the surface around the fastener penetration, and the sealing element, as least in part, conforms to the surface between the surface and the spacer element.

Owner:ILLINOIS TOOL WORKS INC

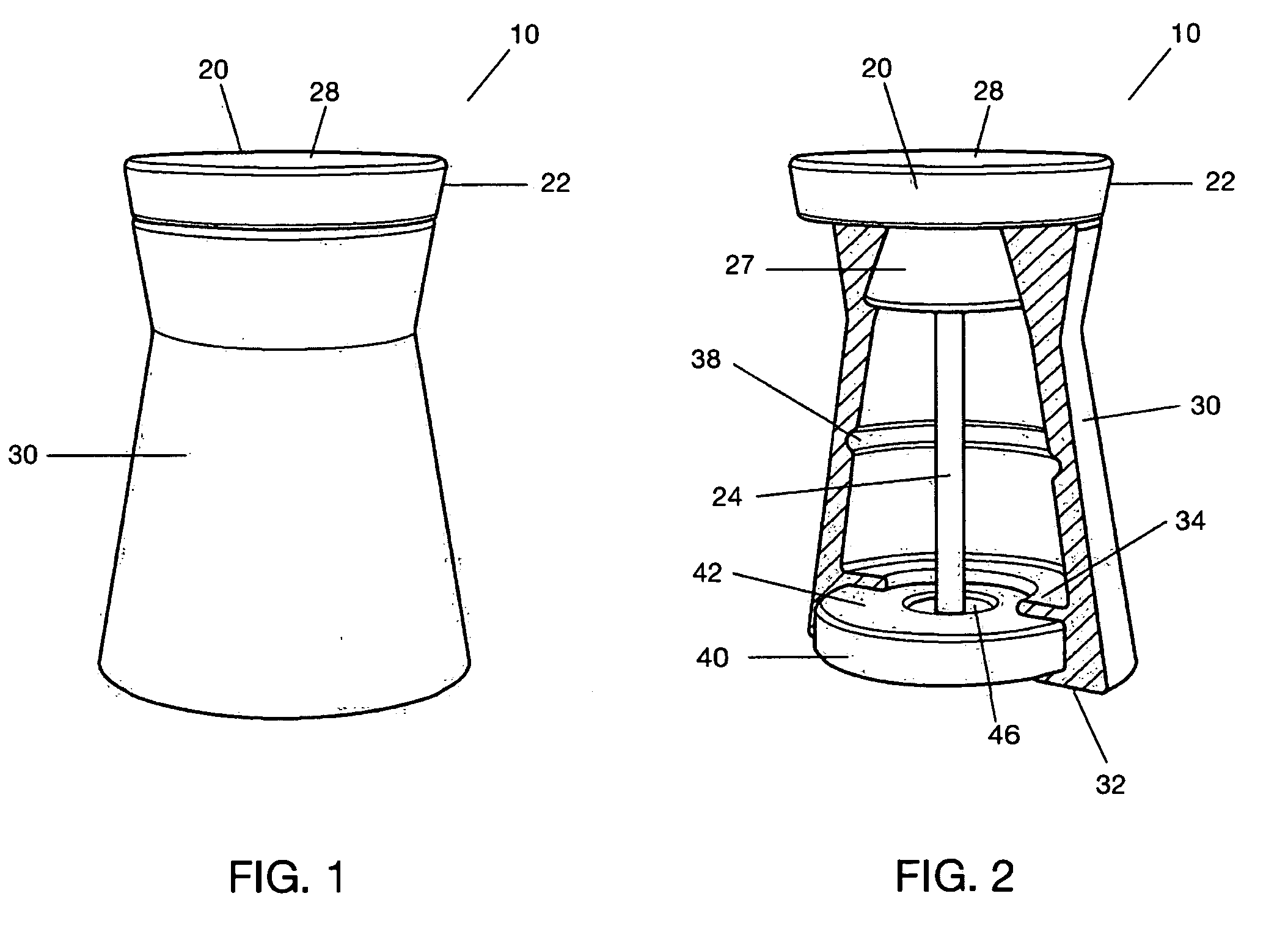

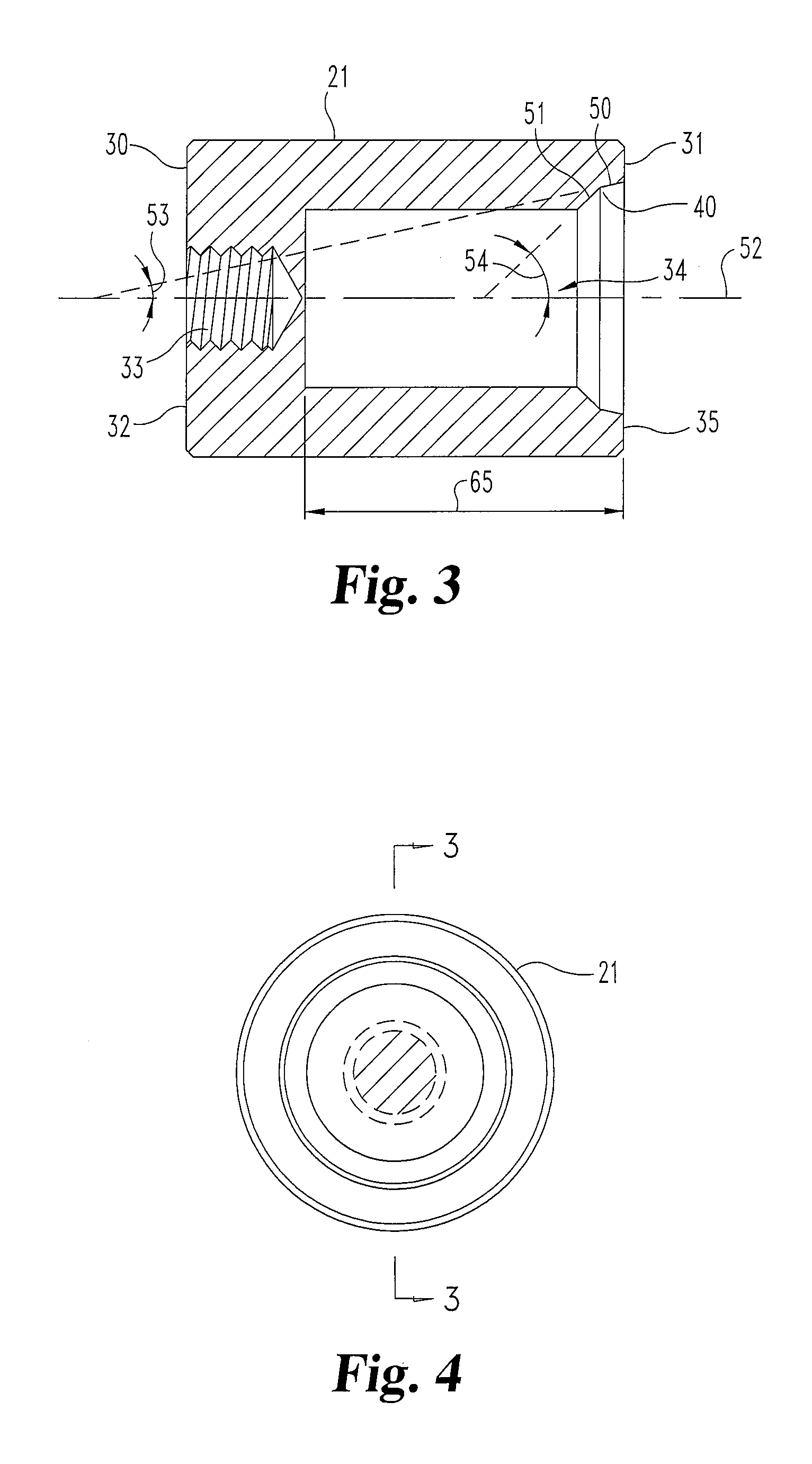

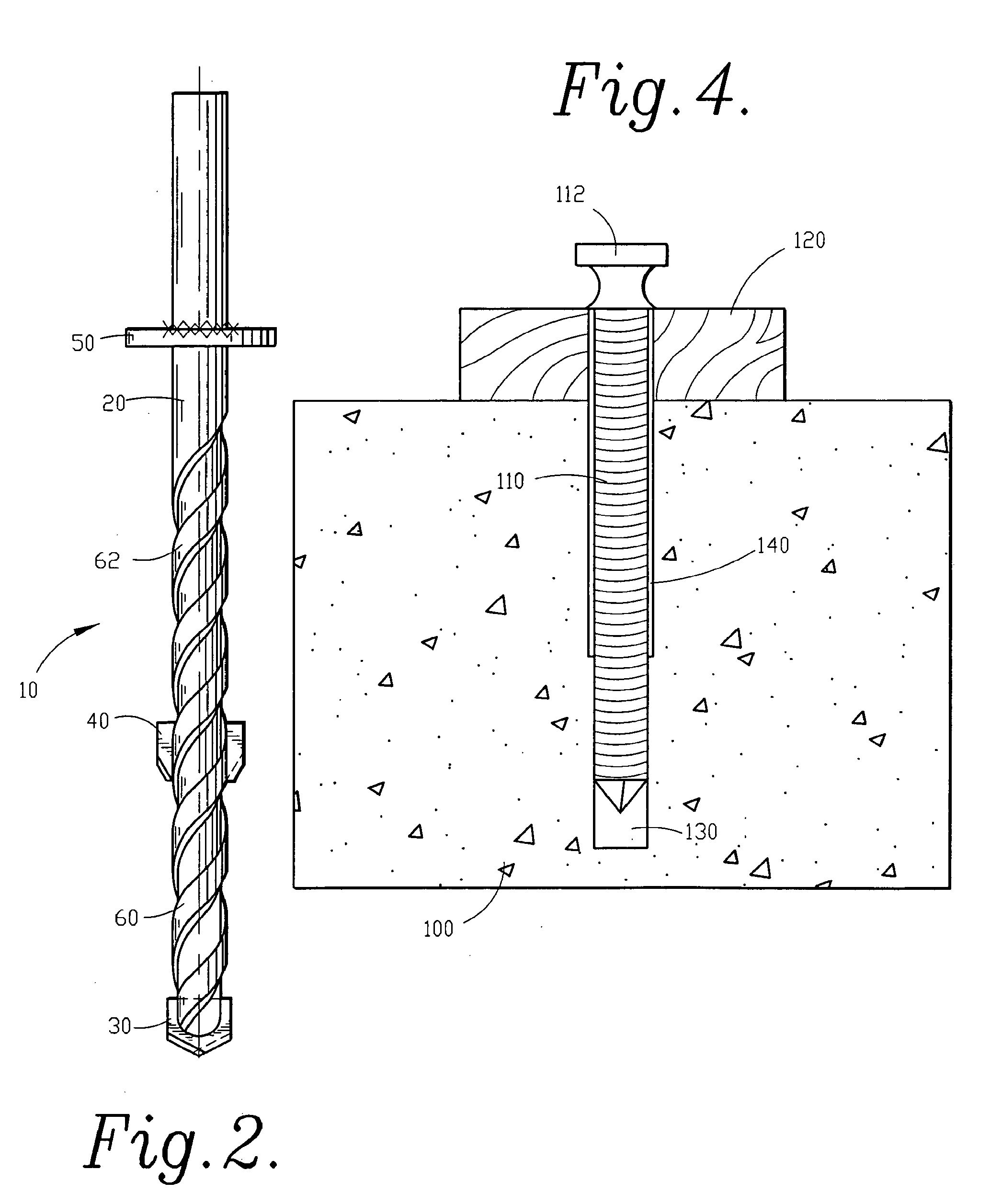

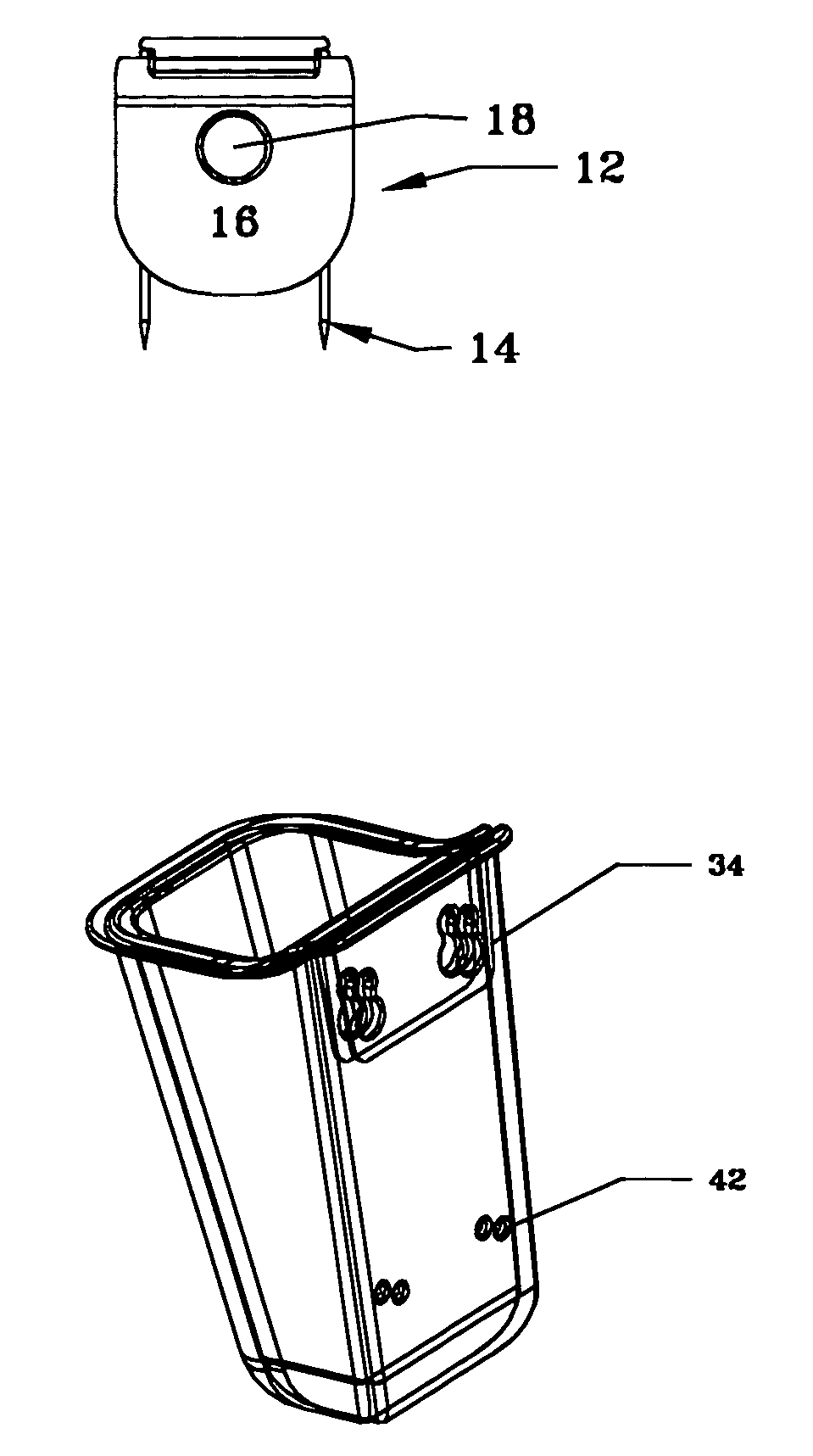

Magnetic pushpin

InactiveUS20080005873A1Simple structureAdditional operating advantageSnap fastenersClothes buttonsCavity wallFriction force

A pushpin which is readily adaptable for use as a pushpin or a magnet is disclosed. The pushpin includes a first body having opposing surfaces, a pin member extending from the body, and a magnetically susceptible component positioned opposite the pin member on the body. The pushpin also includes a second body having opposing surfaces, an opening, a cavity beginning at the opening and extending into the second body, and a magnetically susceptible component positioned on the second body. The particular pushpin cavity is configured to conceal the pin and at least one of either the magnetically susceptible component on the first body and the magnetically susceptible component on the second body is magnetic. Retention means for retaining the pin when it is inserted into the cavity are also provided within the cavity and include friction applied to the pin by a cavity wall. Lining at least a portion of the cavity with a thermoplastic rubber (TPR) material, or providing a plug of such or similar material within the cavity for piercing by the pin, provides such friction.

Owner:HELEN OF TROY LIMITED

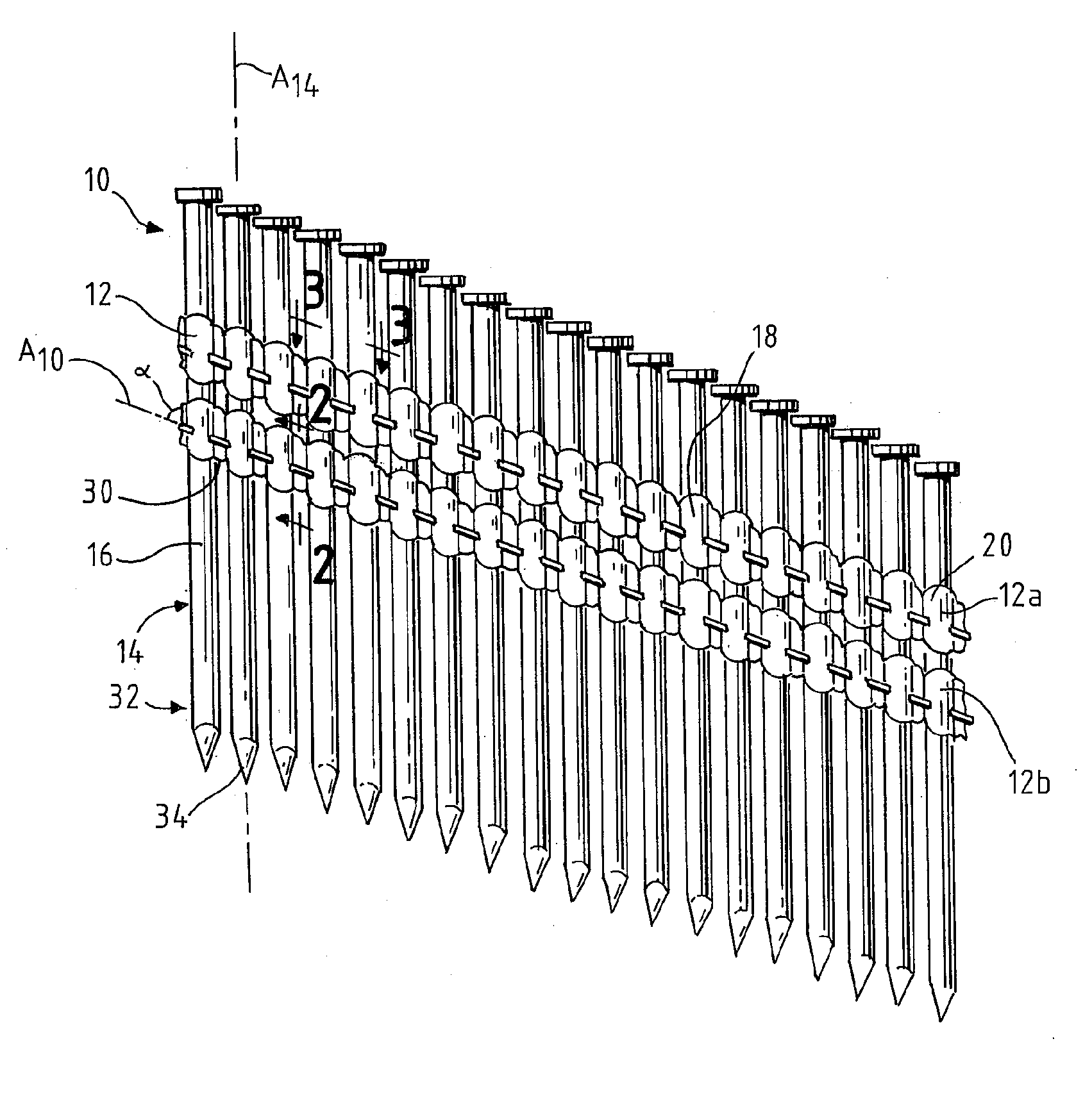

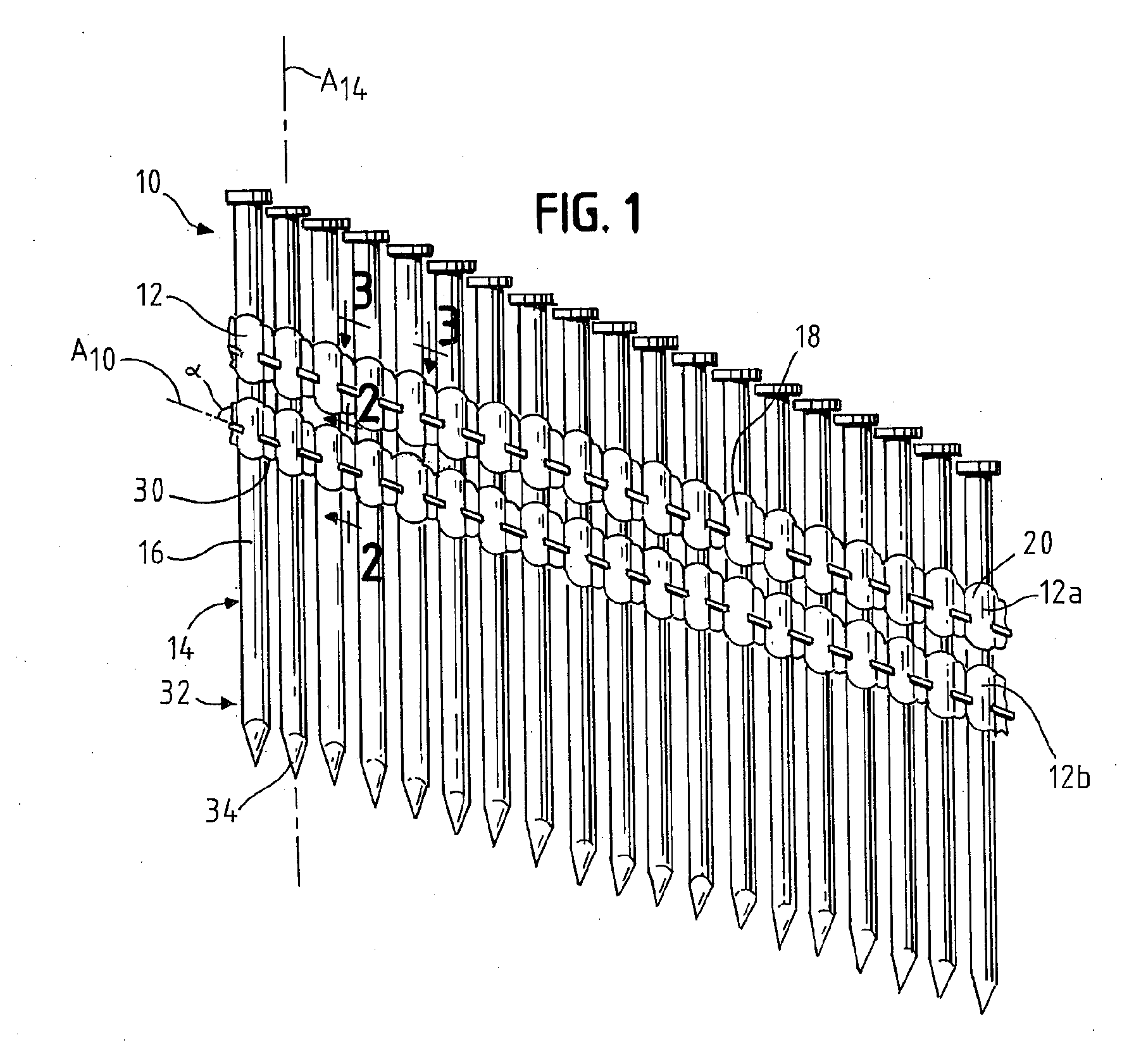

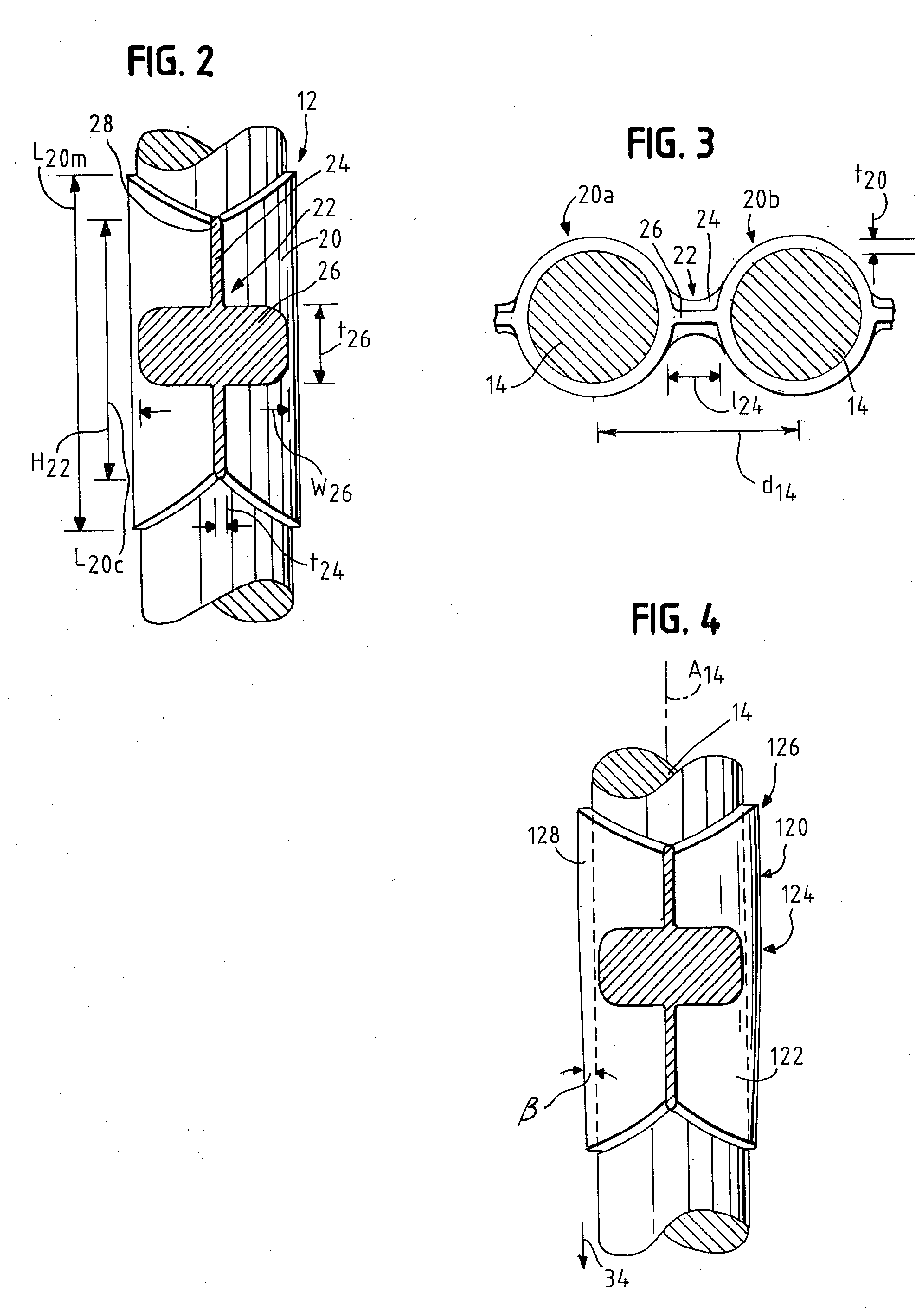

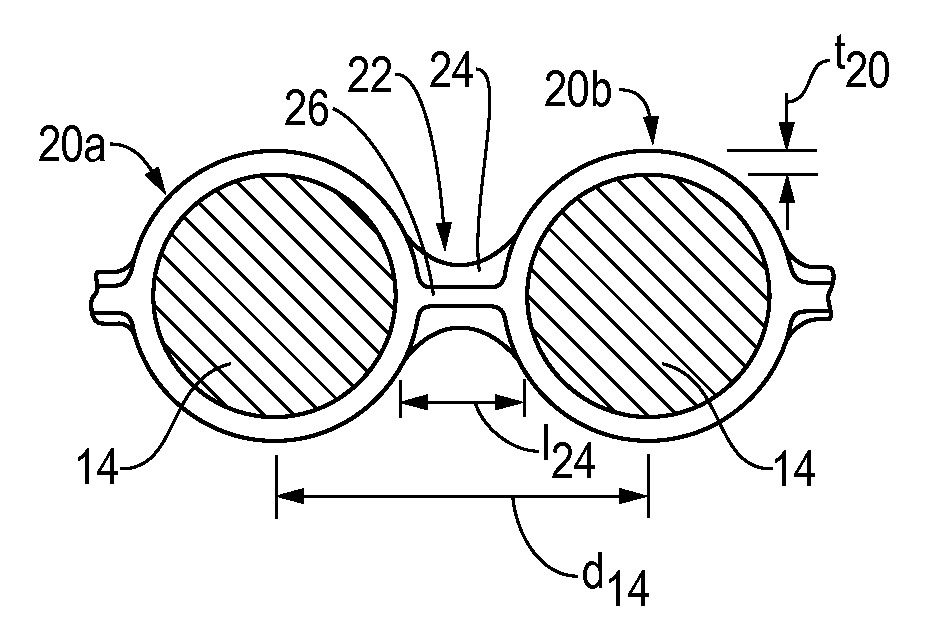

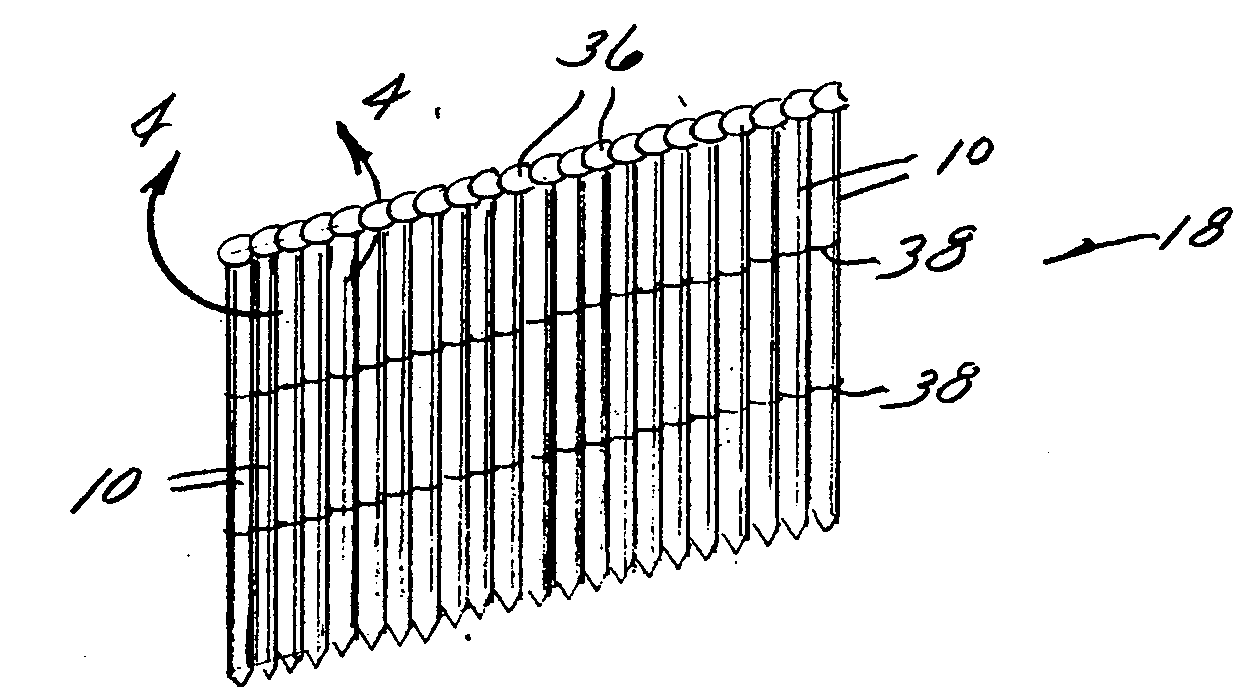

Debris-free plastic collating strip for nails

ActiveUS20070264102A1Increase surface areaImprove featuresStaplesRail fastenersPlastic materialsEngineering

A fastener assembly is configured for use in an associated fastener driving tool for driving a fastener from the assembly into an associated substrate. The assembly includes a row of fasteners, each having a shank, arranged substantially parallel to each other. A collation system is formed from a plastic material that is molded onto and adhered to the fasteners. The plastic material is molded to define a collar portion substantially encircling the fastener shank and a connecting portion extending between and connecting adjacent collar potions. The plastic material is formulated from an adhesive polymer. When the fastener is driven from the driving tool, the collar portion remains adhered to the fastener such that the collar portion penetrates the substrate with the fastener.

Owner:ILLINOIS TOOL WORKS INC

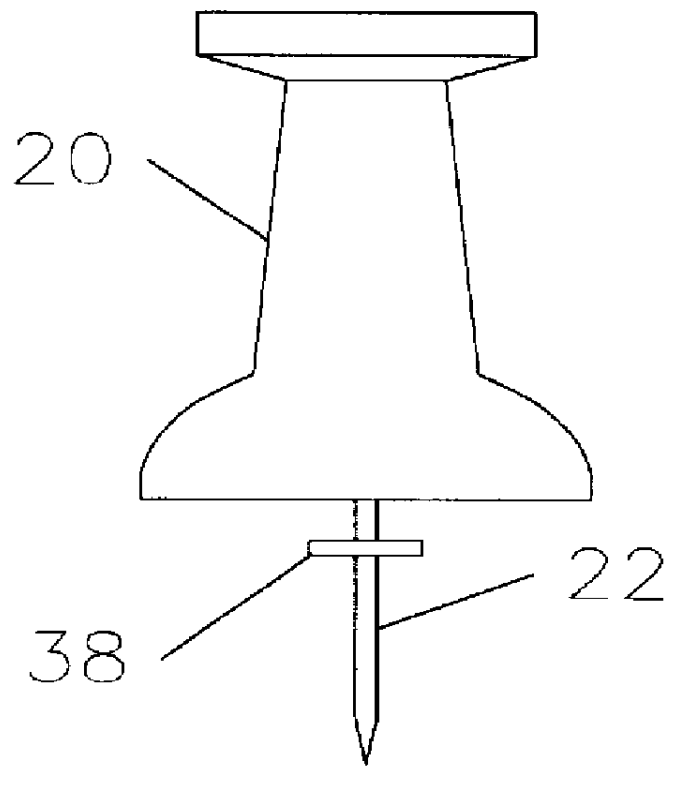

Push pin device

Owner:MANIFOLD PRODS

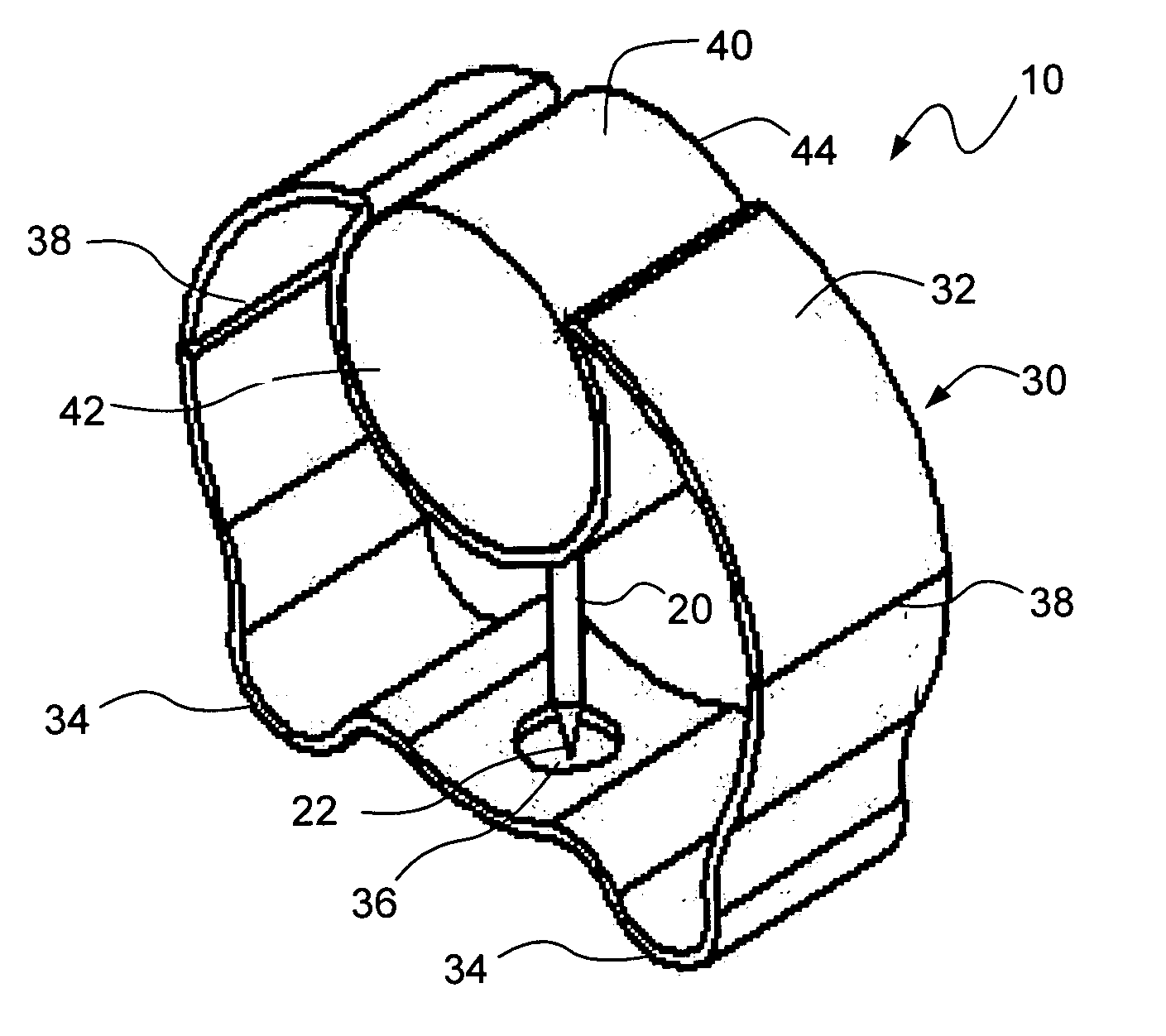

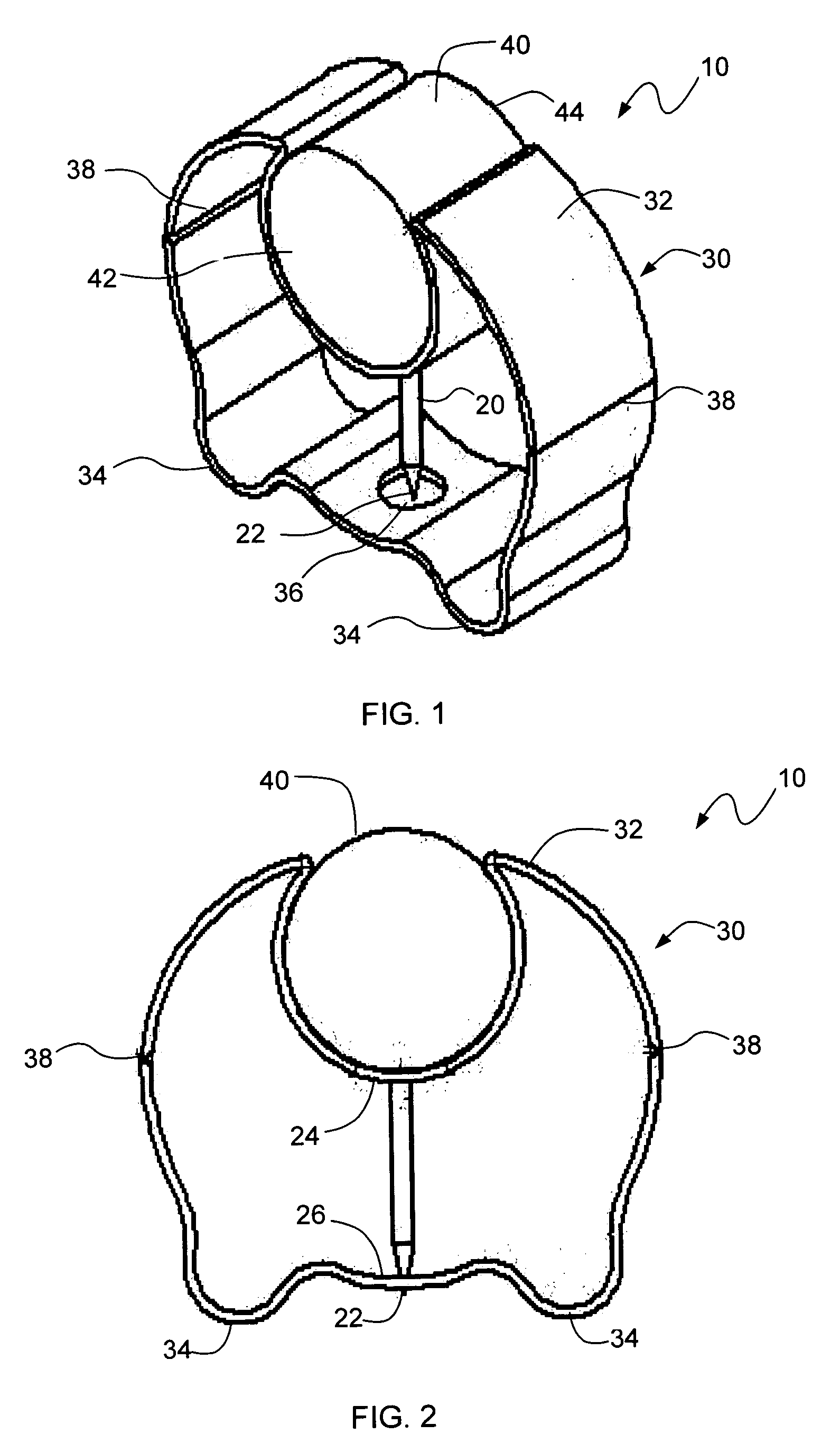

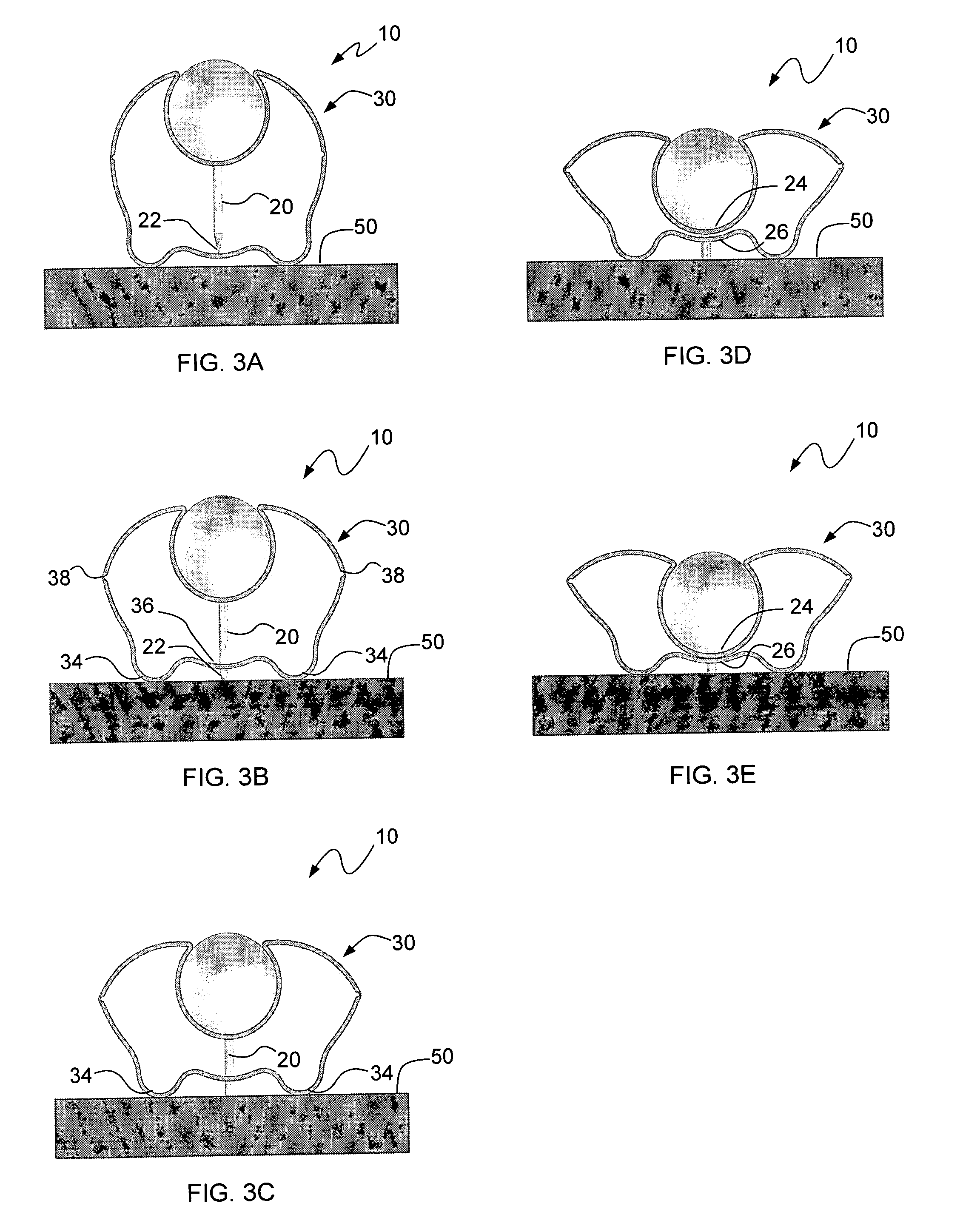

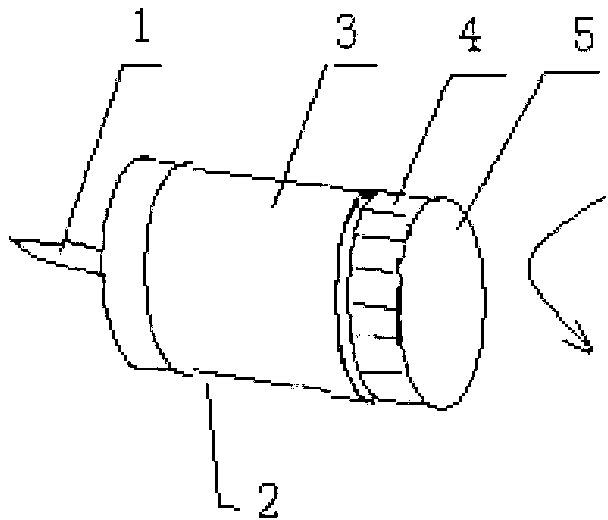

Assemblage of sealing nail

InactiveUS20100212244A1Improve sealing efficiencySmooth hammering operationCeilingsCovering/liningsPropellerEngineering

The present invention pertains to an assemblage of sealing nail essentially containing a nail, a propeller, and a blocker that is partially extended beyond the propeller. Wherein, the nail would sequentially penetrate the propeller, the blocker, and then a plank. By means of the nail entering the plank, the propeller and the blocker would be simultaneously urged to densely cover up where the nail inserted. Therefore, a preferred sealing efficiency between the nail and the plank is achieved to guarantee a favorable grouting on the plank.

Owner:YU BO ZHANG

Debris-free plastic collating strip for nails

ActiveUS20080131232A1Reduce fragmentationReduce connectionsStaplesRail fastenersPlastic materialsEngineering

A fastener assembly is for use in an associated fastener driving tool. The assembly includes a row of fasteners arranged substantially parallel to each other. Each fastener has a shank and defines an axis. A collation system is formed from a plastic material that is molded onto and adhered to the fasteners. The plastic material defines a collar portion at least substantially encircling the fastener shank and a connecting portion extending between and connecting adjacent collar portions. The connecting portion includes a bridge and a rib. The bridge is a relatively thin, elongate element spanning adjacent collar portions and the rib is a relatively thick, short element that is disposed at about an upper portion of the bridge. When the fastener is driven from the driving tool, the collar portion remains adhered to the fastener such that the collar portion penetrates the substrate with the fastener. The connecting portion can include a weakened region for separating the connecting portion from the collar.

Owner:ILLINOIS TOOL WORKS INC

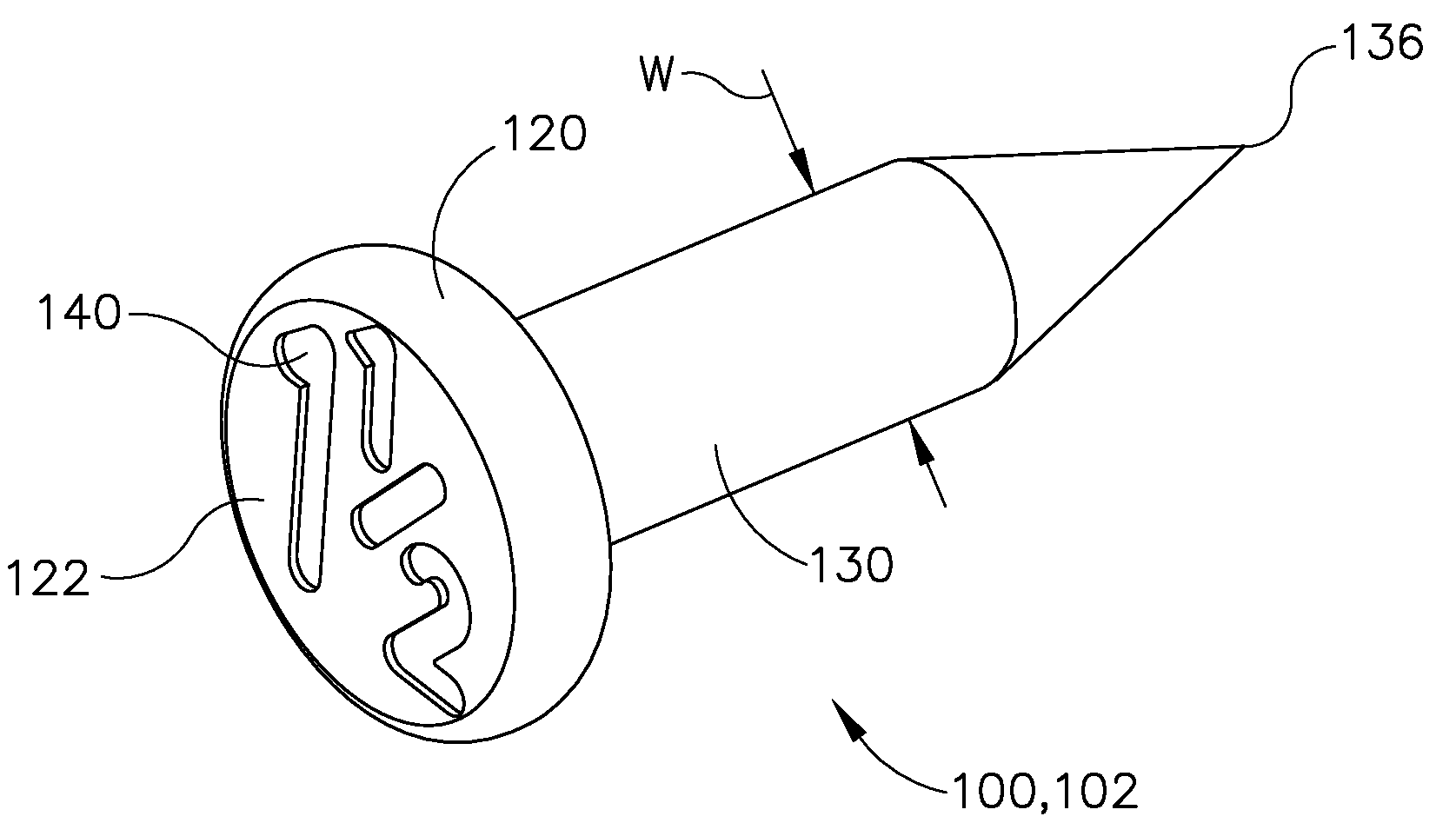

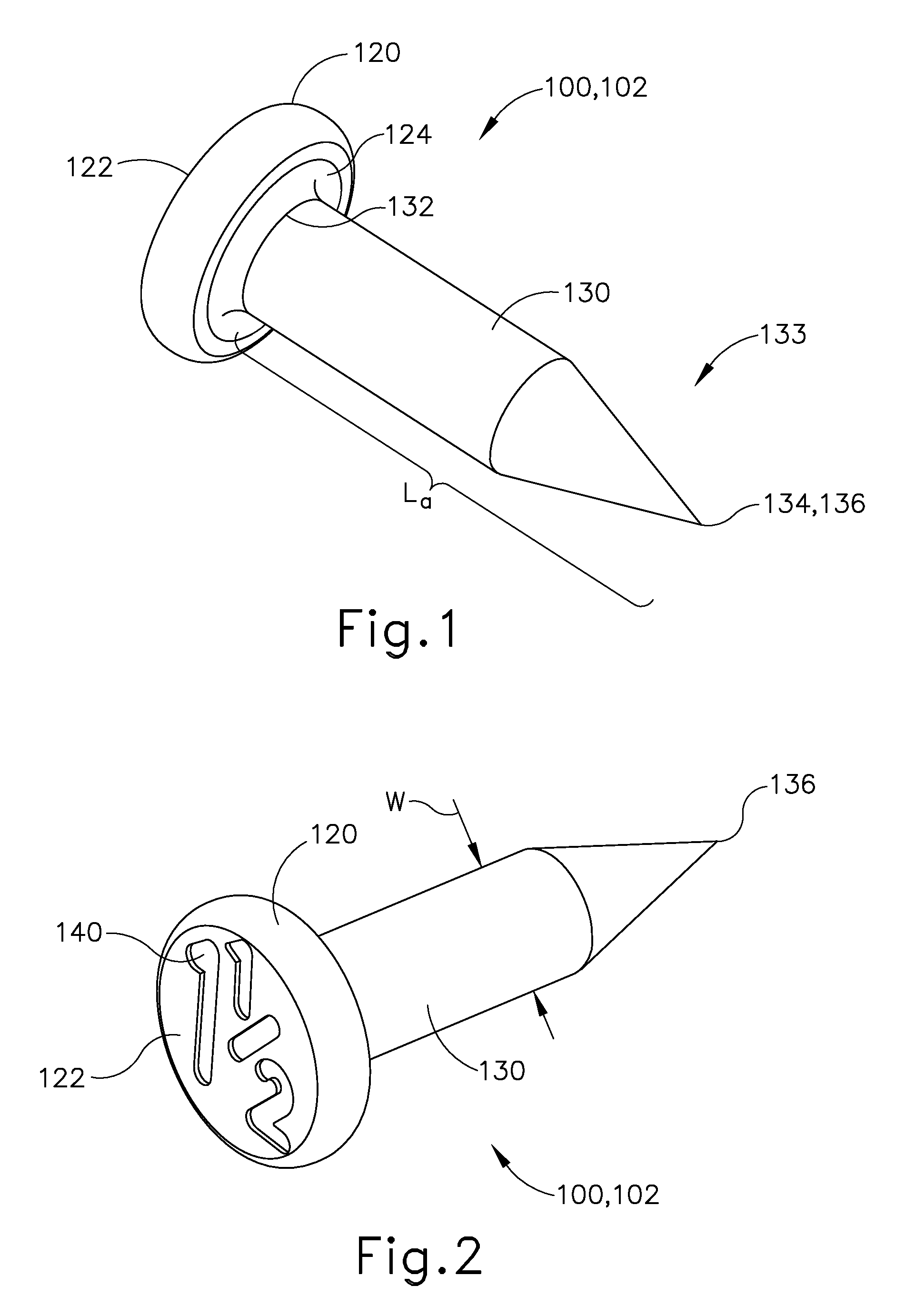

Fastener having supplemental support and retention capabilities

Owner:NELSON CHARLES +2

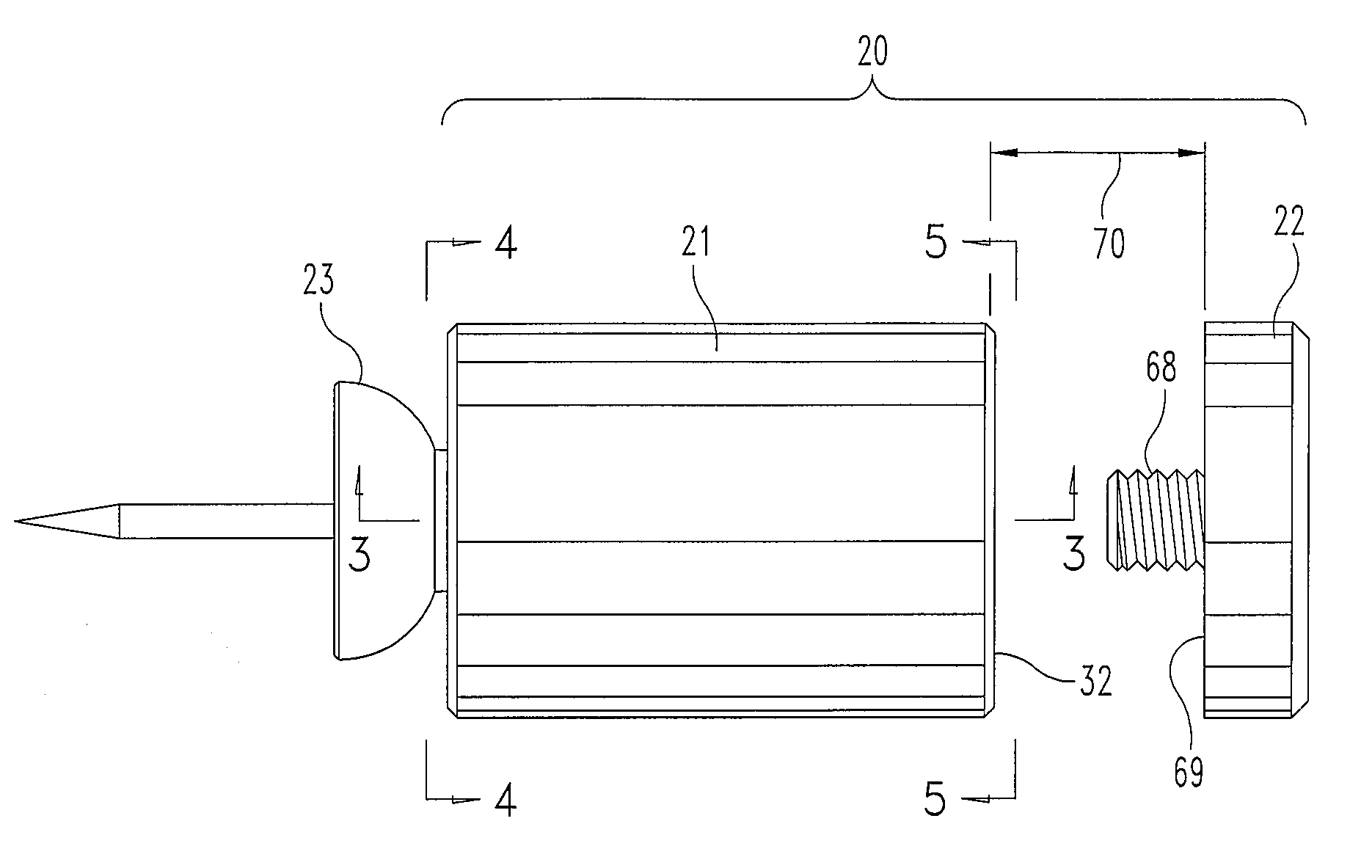

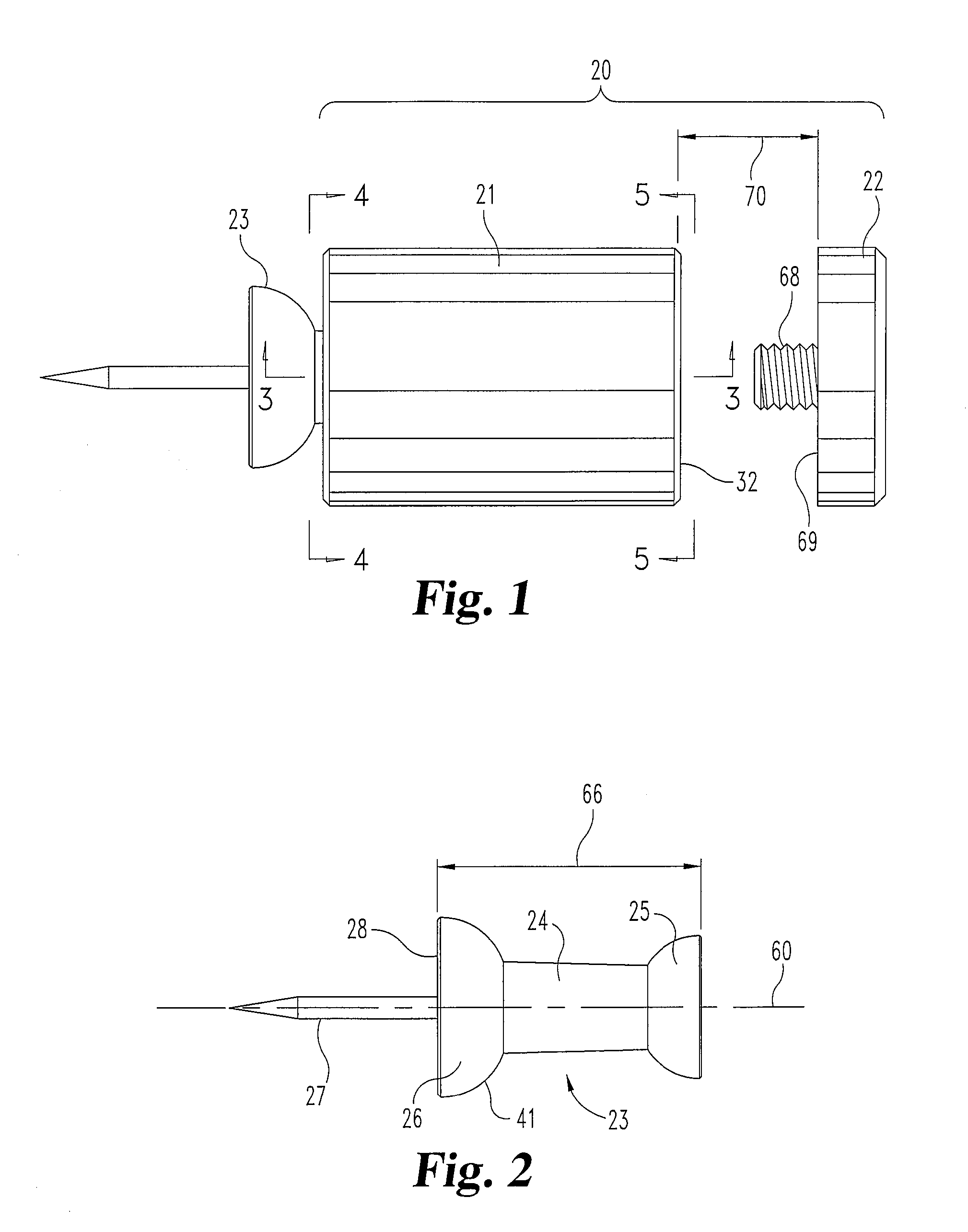

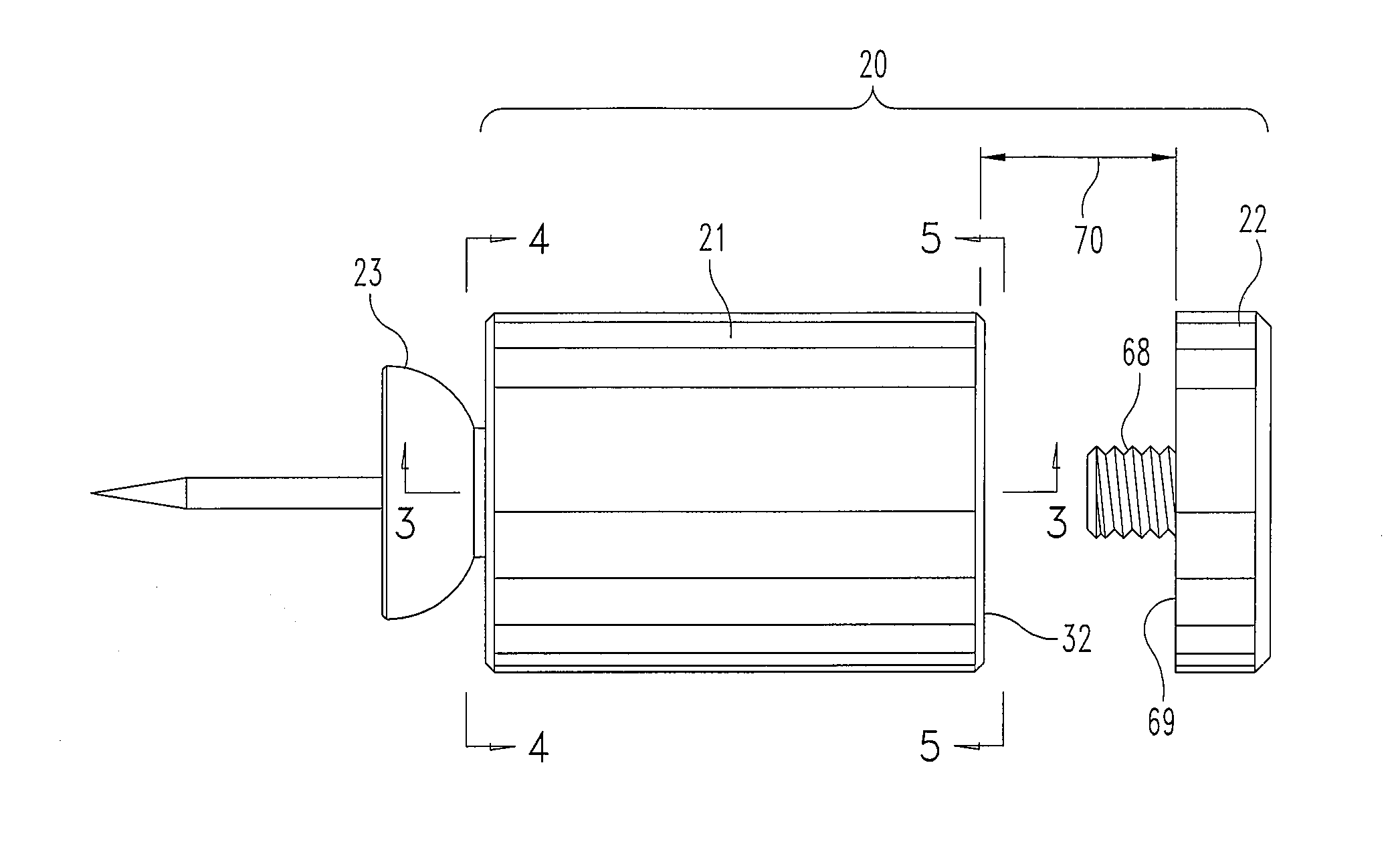

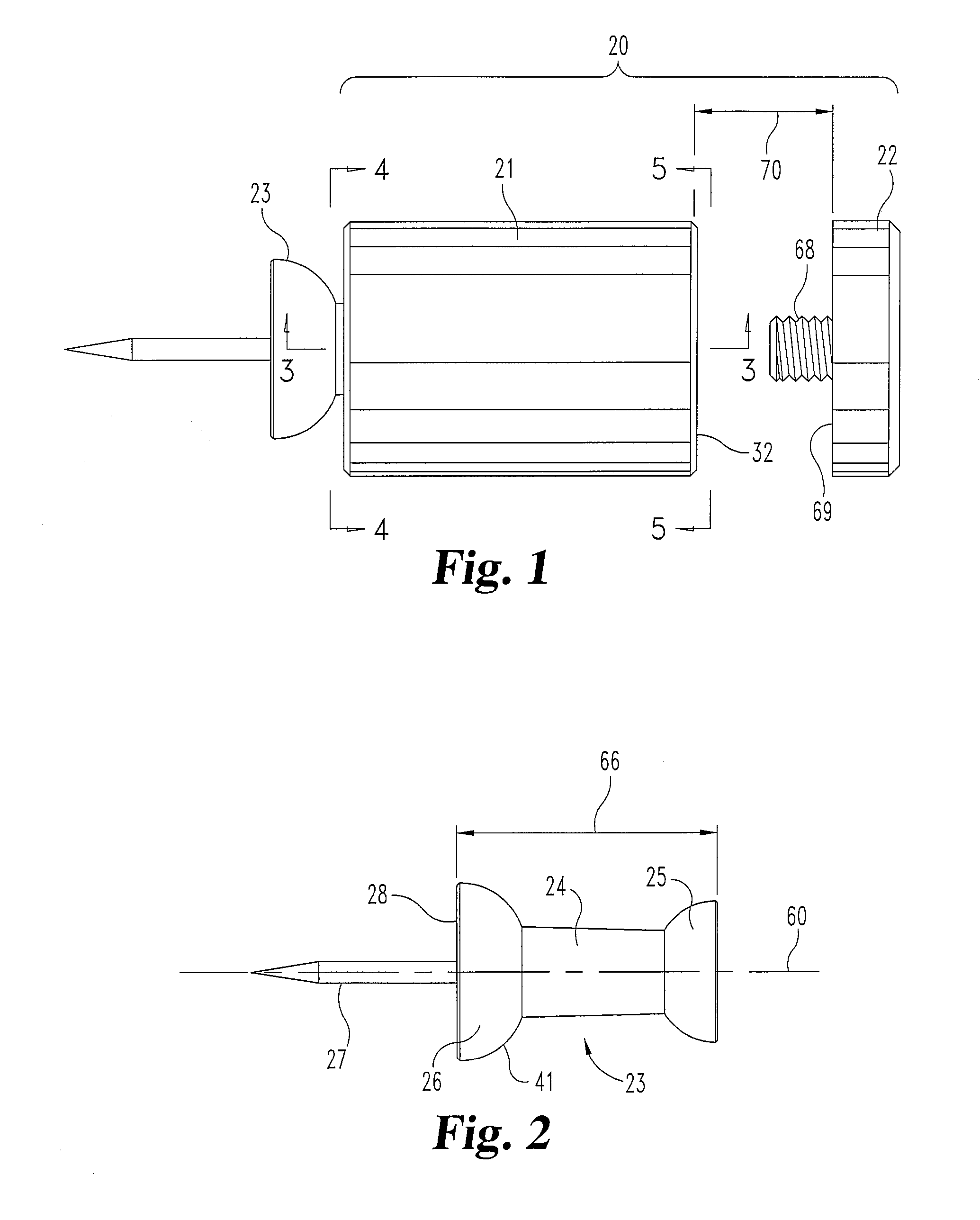

Fastener identification marking

A fastener for being inserted a first depth d1 through a first object and a second depth d2 into or through a second object, is provided. The fastener includes, but is not limited to, a head having an outer surface opposed to an inner surface, a shank connected with the inner surface of the head at a first end and forming a tip at a second end opposed to the first end, and an identification marking formed on the outer surface. The outer surface remains exposed upon the fastener being inserted into an object. The shank has an actual length La from the first end to the second end, and wherein the actual length La is equal to or greater than the sum of the first depth d1 and the second depth d2. The identification marking indicates an embedment depth de of the fastener.

Owner:ILLINOIS TOOL WORKS INC

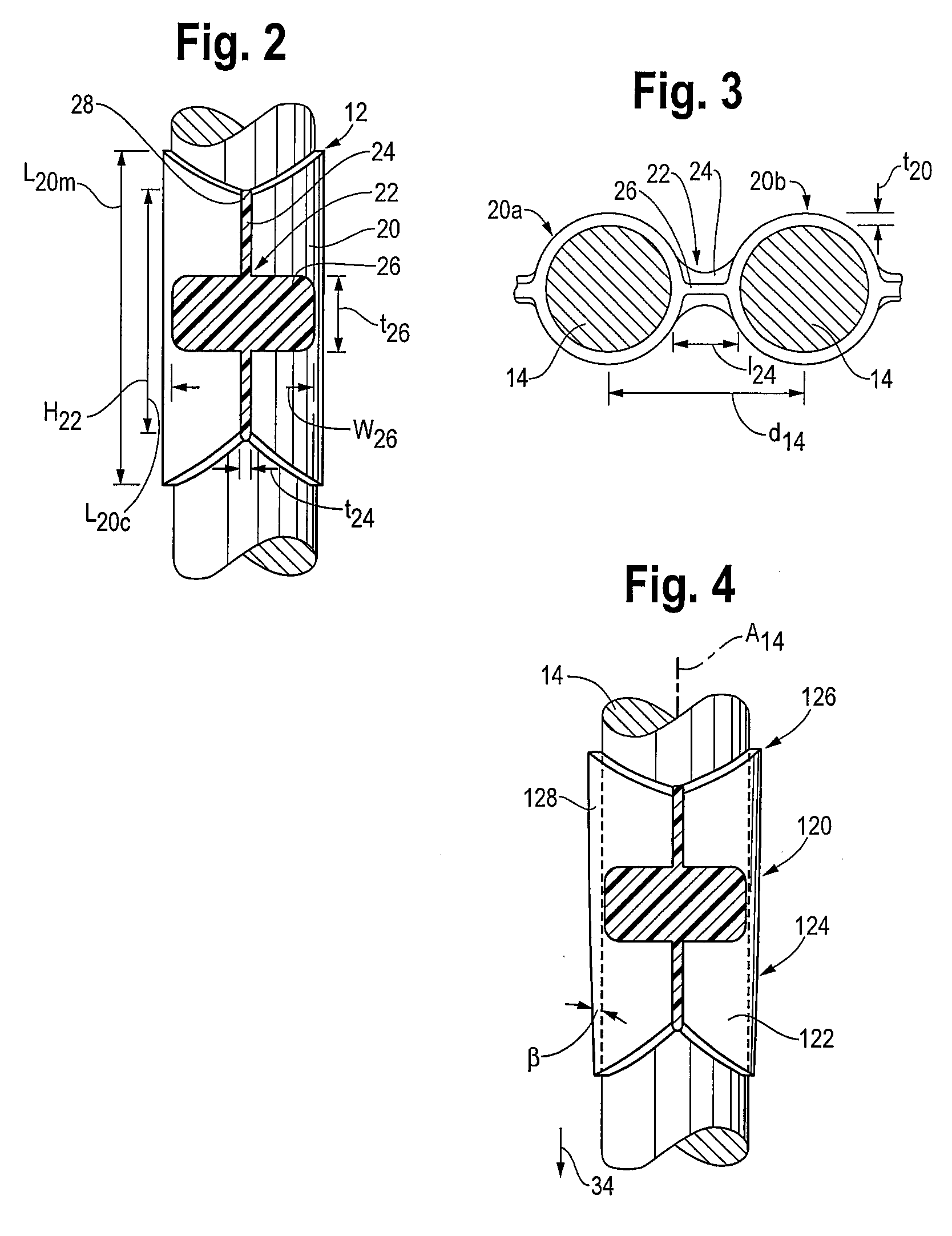

Apparatus and method of making an offset nail

A nail having an offset head is configured with a multi-step support gusset formed integrally between an undersurface of the offset head and a superior portion of a shank. The head of the nail is relatively thin, and the shank is positioned radially off center of the head. A first portion of the gusset defines an angle relative to the shank axis and the second portion of the gusset defines an angle relative to the shank axis different from that of the first portion. The support gusset reinforces the junction of the shank with the head, supports the toe of the head, and distributes the force of a load on the head through a longitudinal axis of the shank, preventing the toe from bending or yielding and prevents the shank from yielding to the stresses of the load applied.

Owner:ILLINOIS TOOL WORKS INC

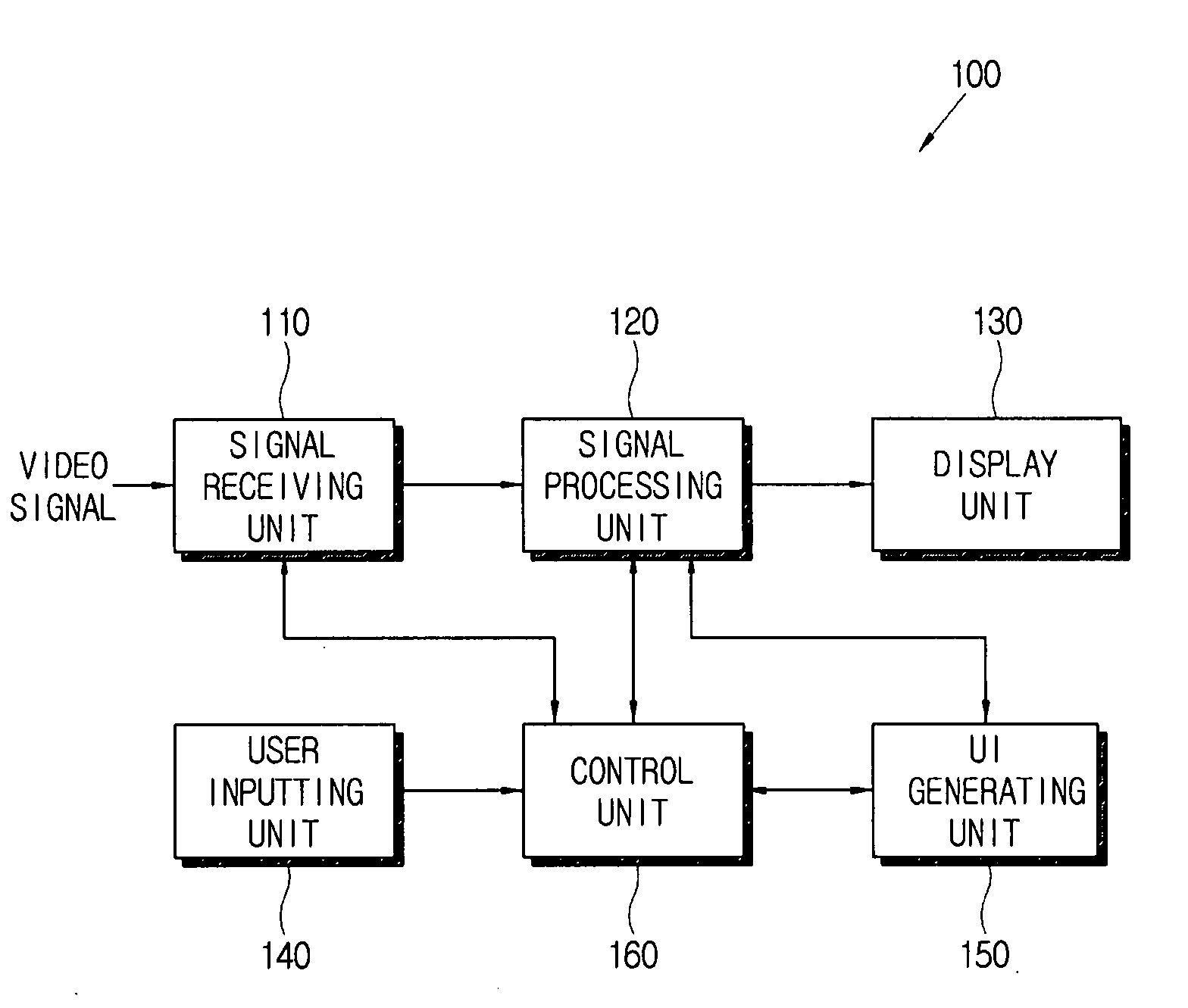

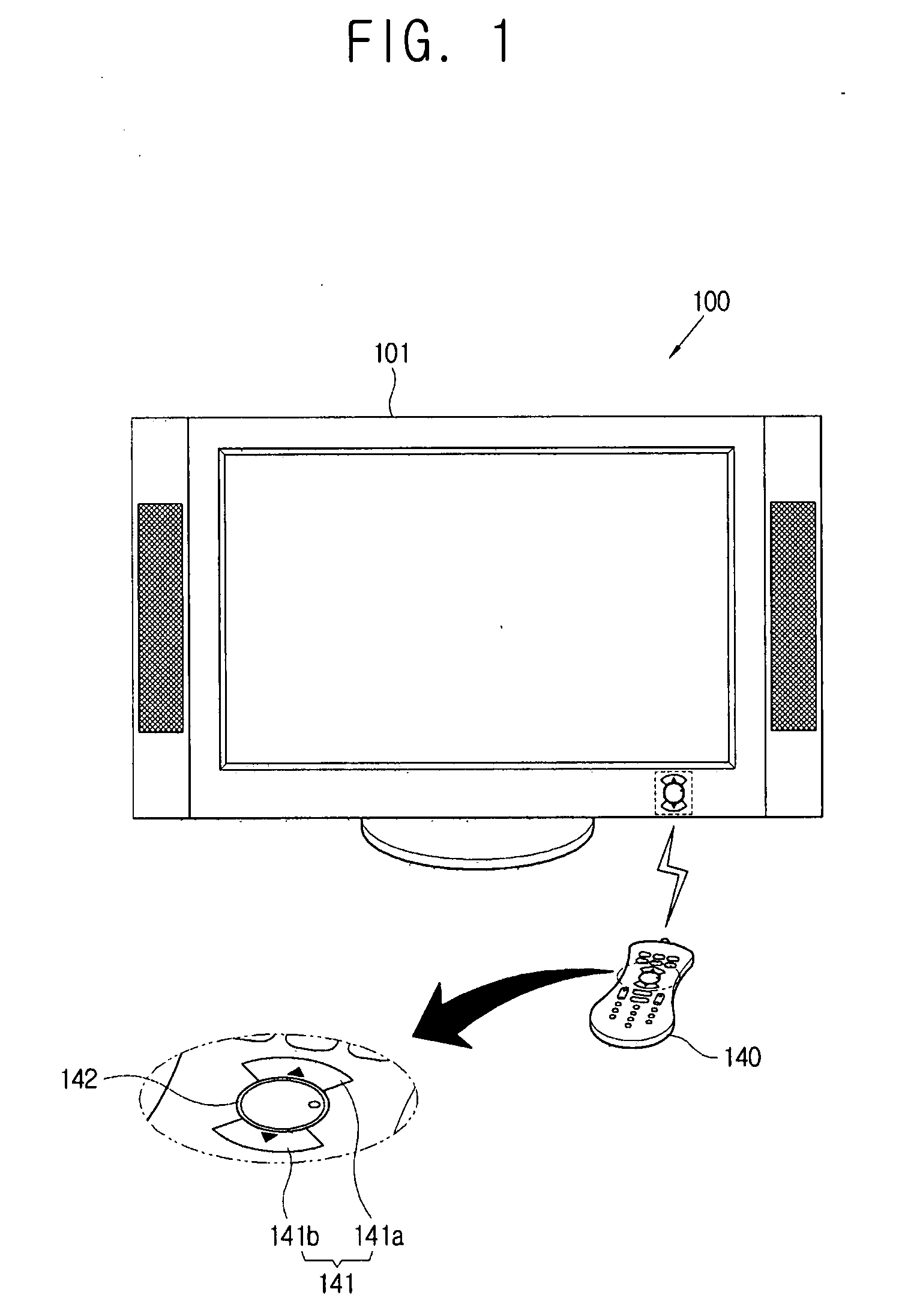

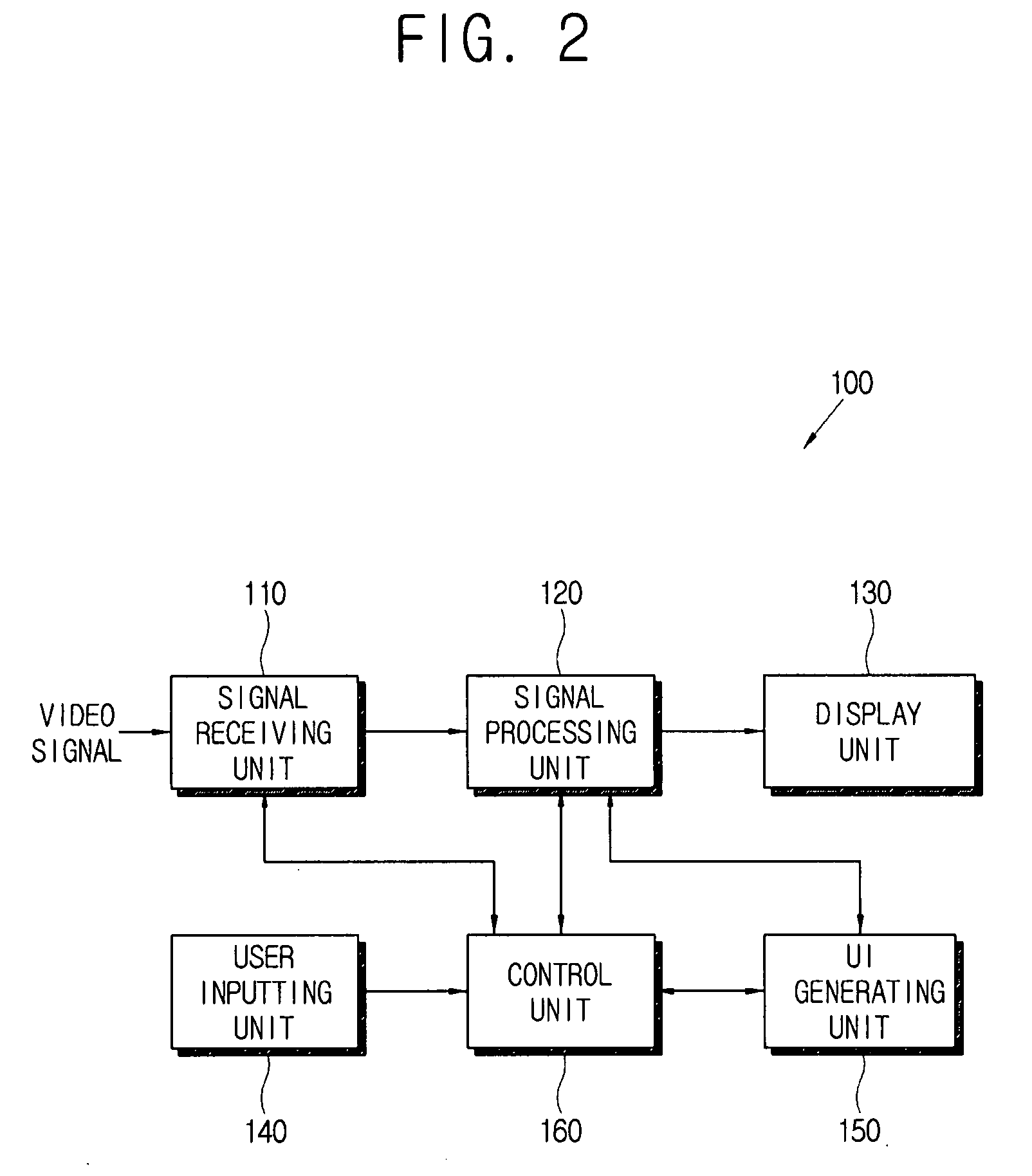

Video signal processing apparatus and control method thereof

InactiveUS20070226622A1Rapidly and conveniently search channel informationTelevision system detailsColor television detailsUser inputVideo recording

A. video. signal processing apparatus, comprises: a display unit; an user interface (UI) generating unit that generates a UI including a channel information array in which a plurality of channel informations are arranged to be displayed to the display unit; a user inputting unit that receives a first moving instruction and a second moving instruction for moving the channel information array, the second moving instruction including a position information about moving of the channel information array; and a control unit that controls the UI generating unit so that the channel informations arranged in the channel information array can move one by one if the first moving instruction is received, and the channel informations arranged in the channel information array can move in an manner that corresponds to the position information if the second moving instruction is received.

Owner:SAMSUNG ELECTRONICS CO LTD

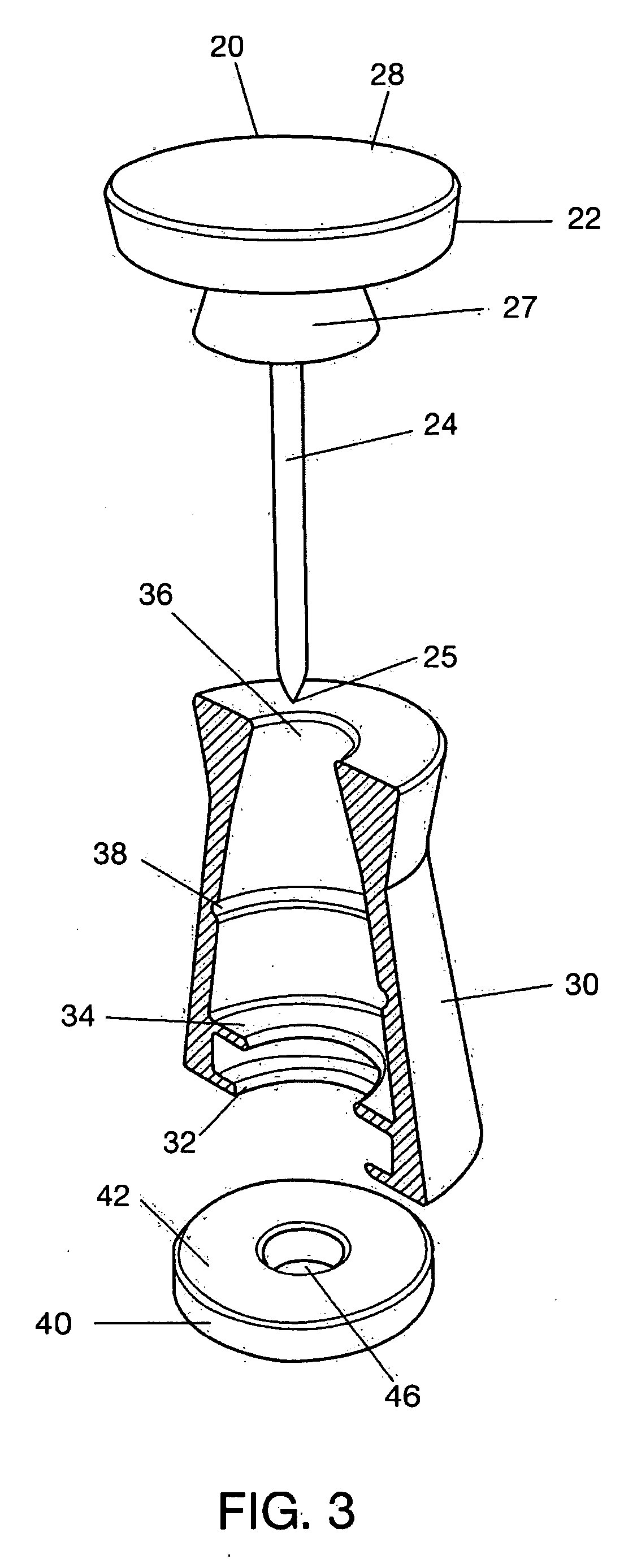

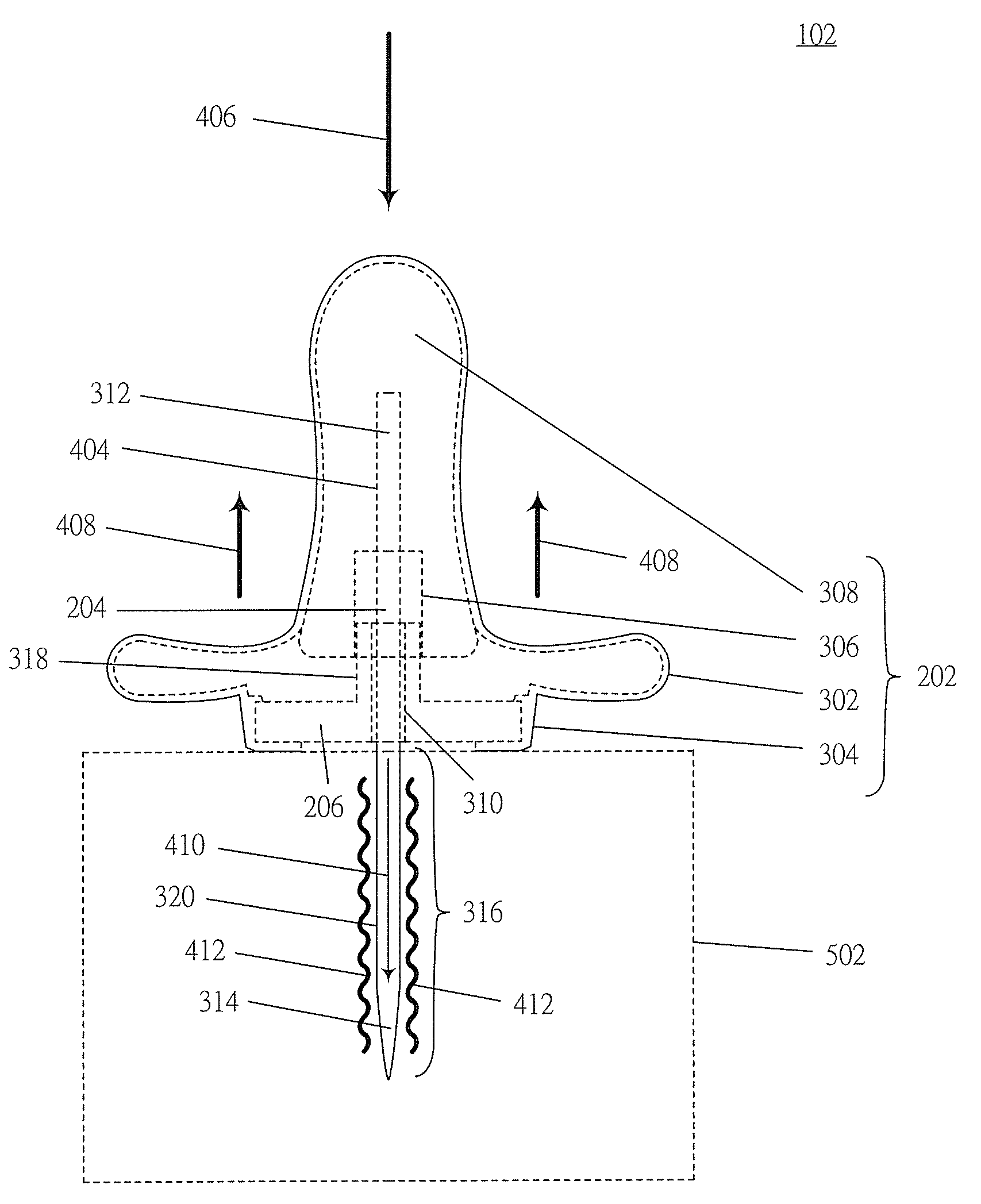

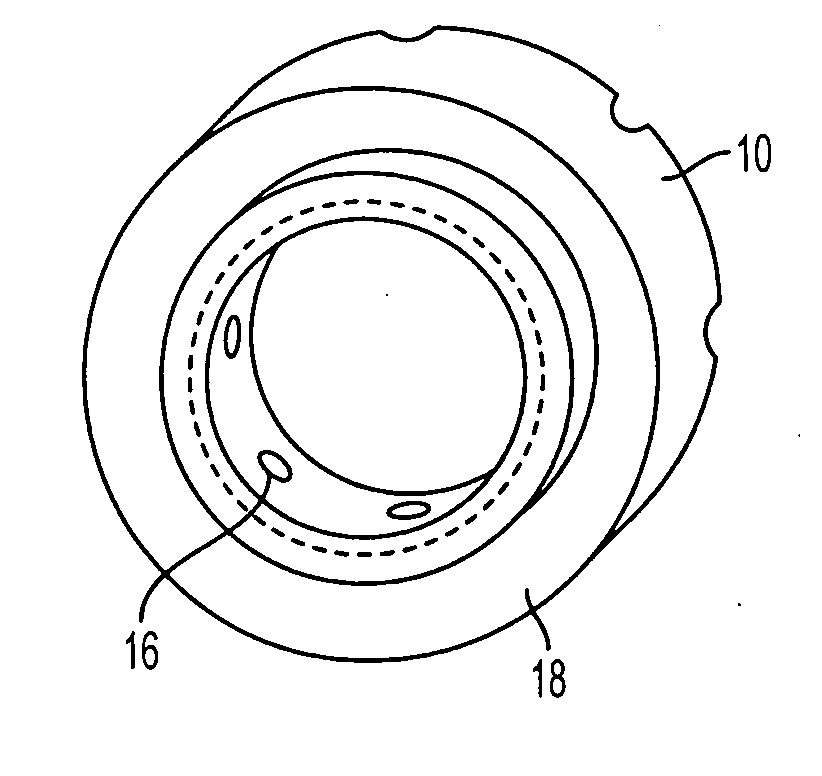

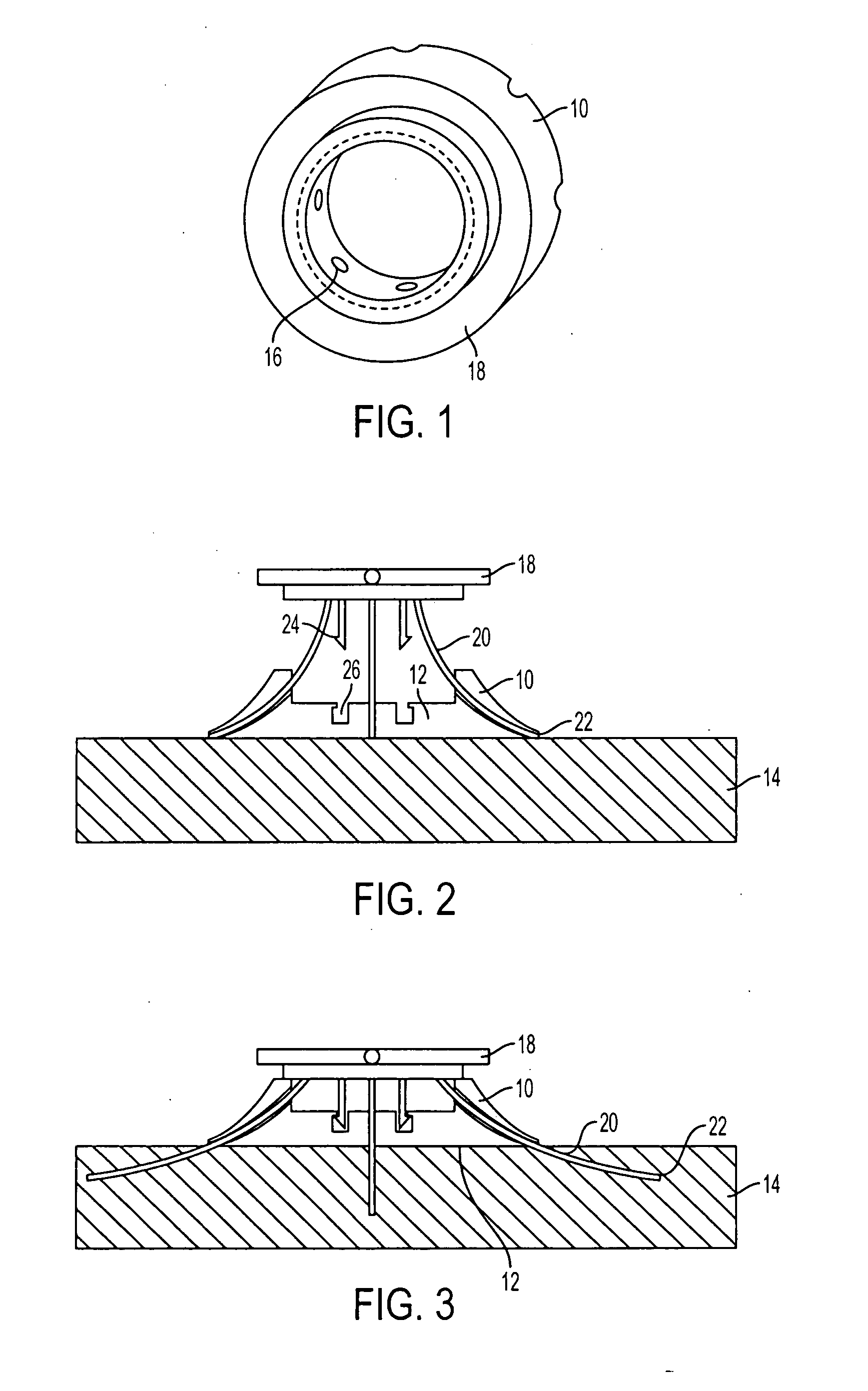

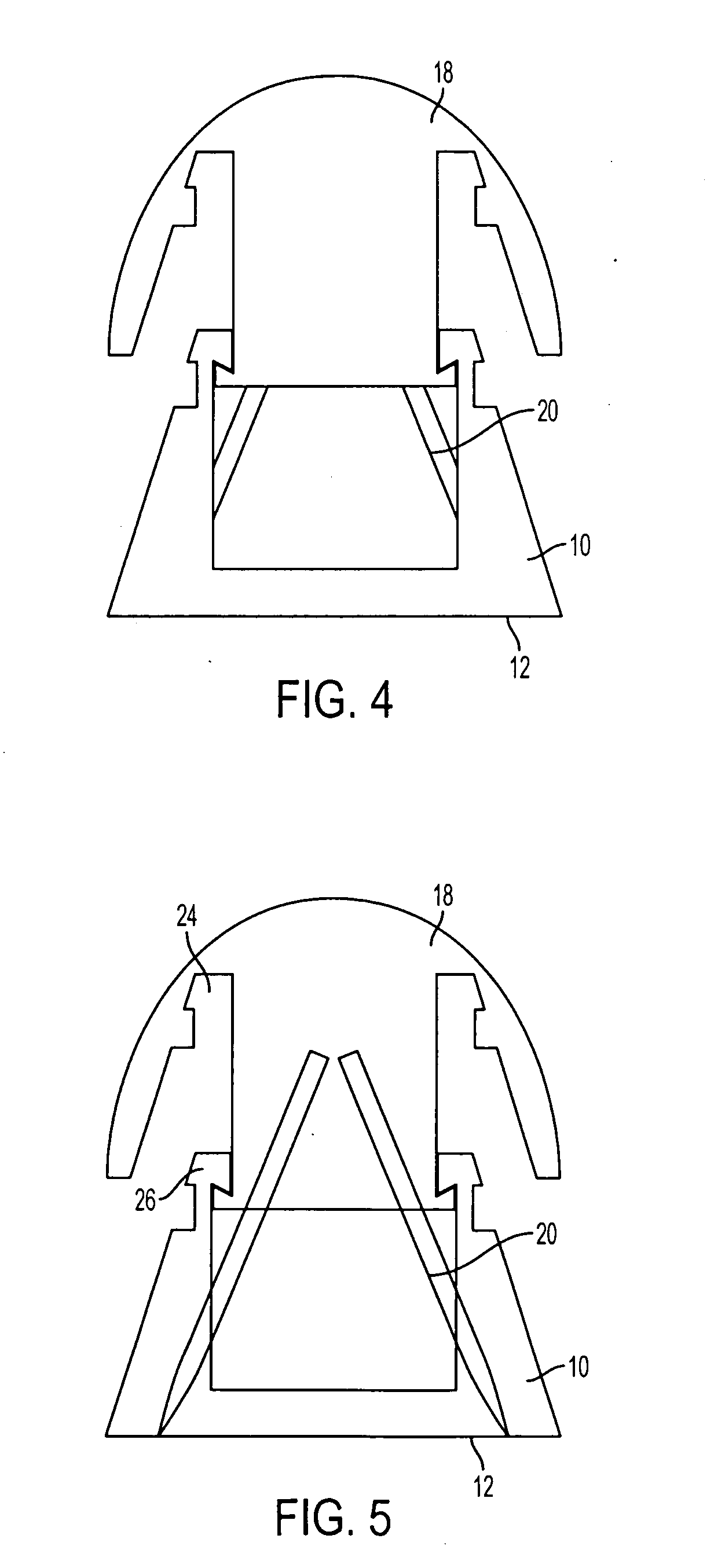

Magnetic safety pushpin

InactiveUS20100263174A1Easy to adaptSo as not to damageSnap fastenersSewing needlesEngineeringHead moving

A pushpin device of one embodiment preferably comprises a head adapted to allow a user to apply pressure to the head without discomfort. A longitudinally extending fastening member comprises a point at a distal end and is coupled to the head at a proximal end. A base comprises an aperture. The aperture is configured to allow the fastening member to pass through the base as the head moves proximate to the base. An outer member is coupled to the head and the base. The outer member comprises a first position in which the head is spaced from the base and the outer member encloses a longitudinal segment of the fastening member. In a second position the head is proximate to the base and the outer member is deformed, thereby allowing the fastening member to extend through the aperture. The outer member exerts a countering force on the base and the head. One of the head and the base comprises magnetically susceptible material and the other comprises magnetic material. A magnetic force between the head and the base maintains the outer member in the second position in opposition to the countering force.

Owner:ENLISTED DESIGN

Standoff adaptor for push pin

Owner:ACCURATE MFGD PRODS GROUP

Fastener With Visual Indicator

A fastener that includes a head portion and a body and is configured to be driven into material. The body is configured for engaging the material and the head portion is constructed to be engaged by a driver of a power nailer. A color coating is applied to a face of the head portion for visually locating fasteners engaged with the material

Owner:PARMANN JASON B

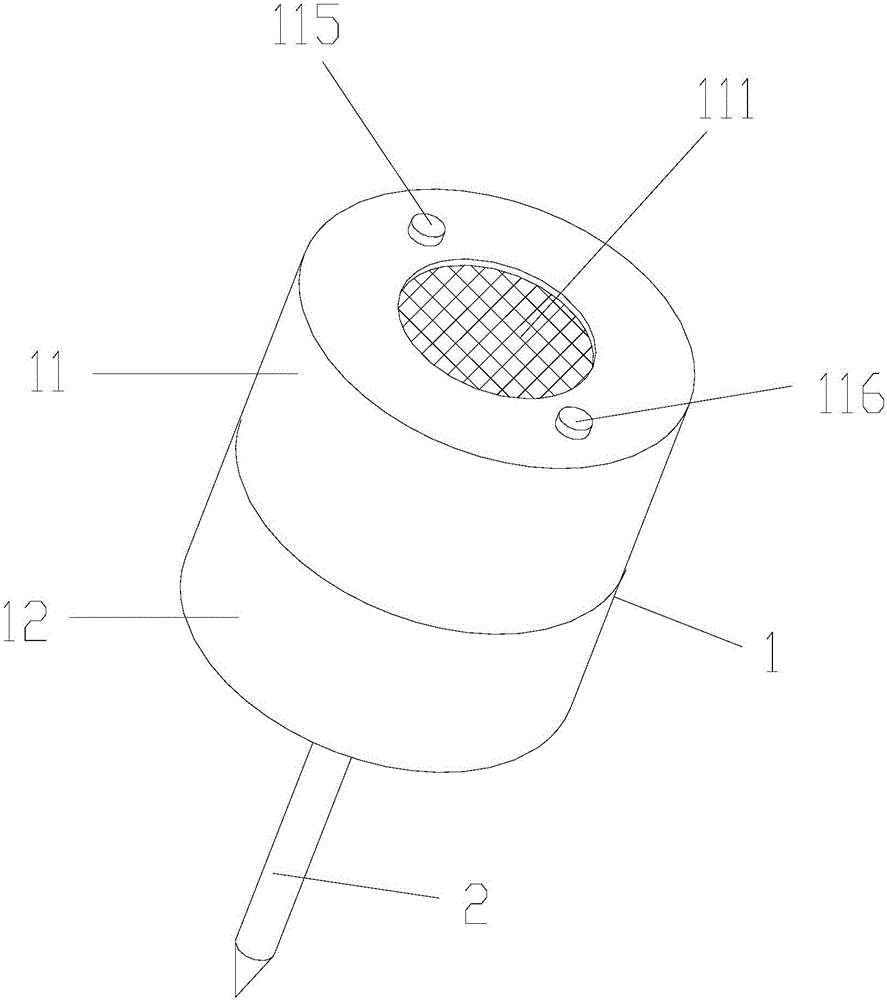

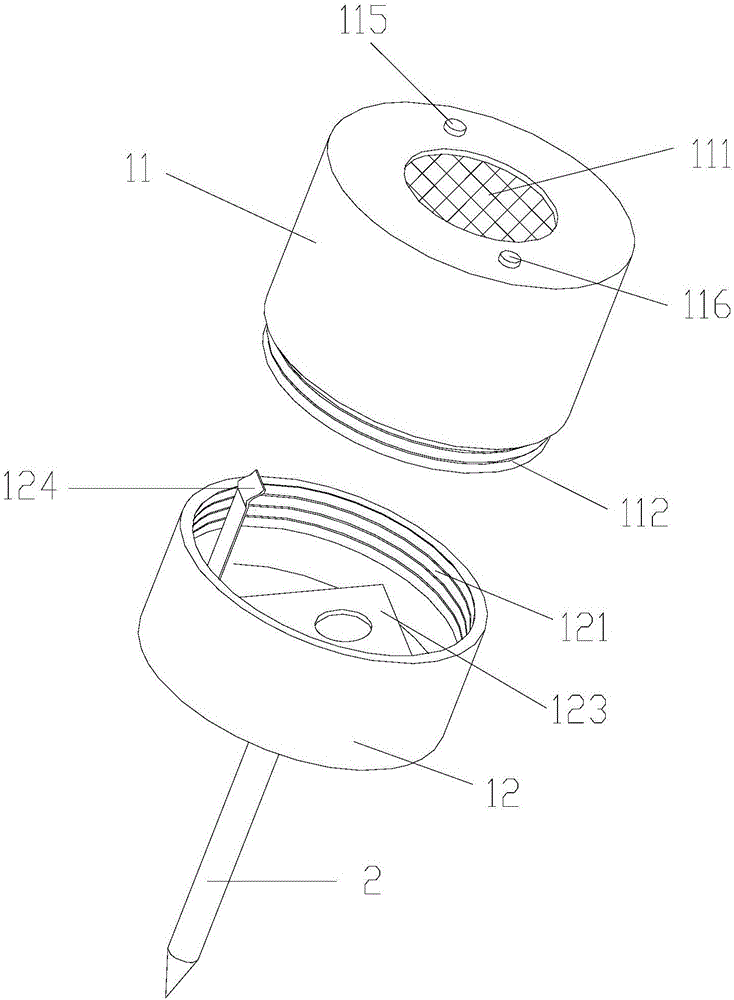

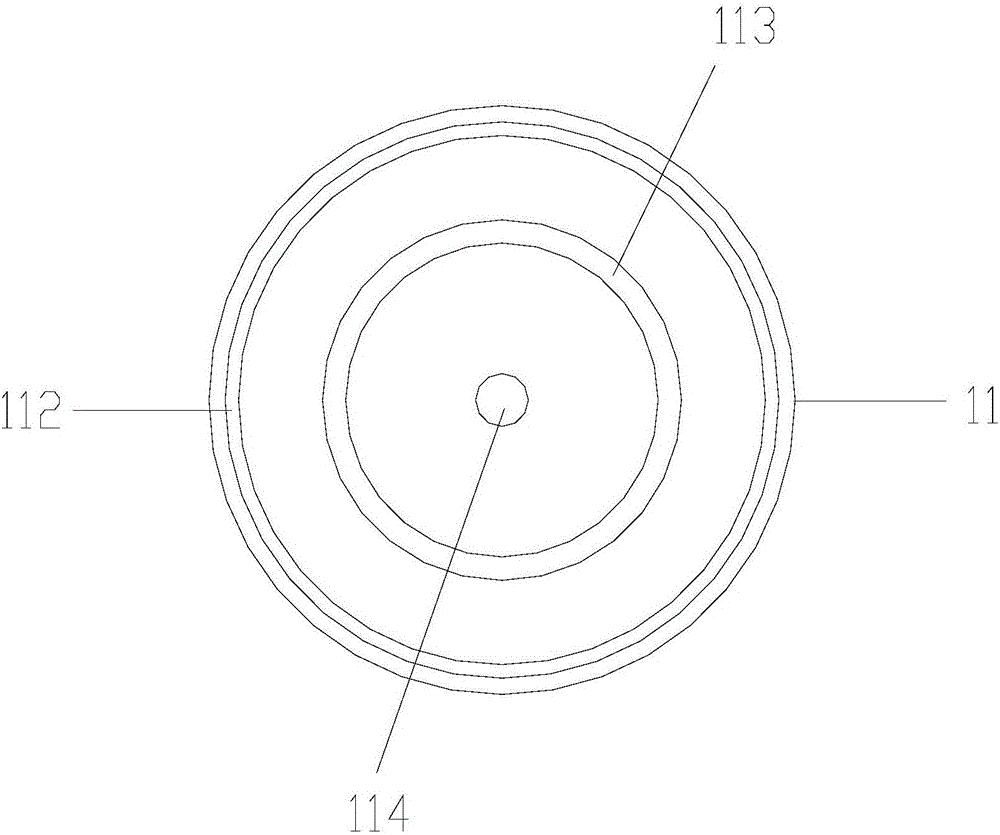

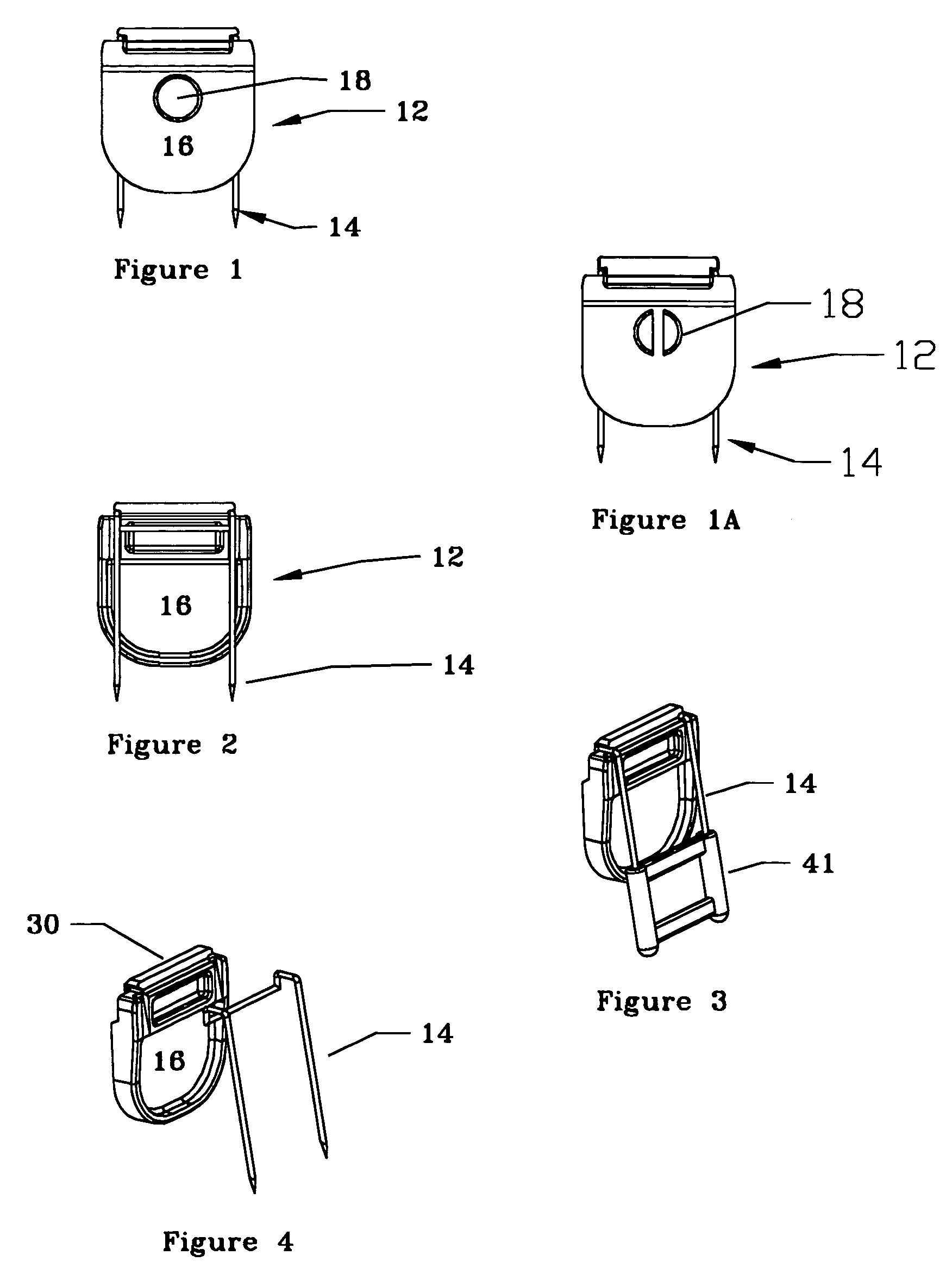

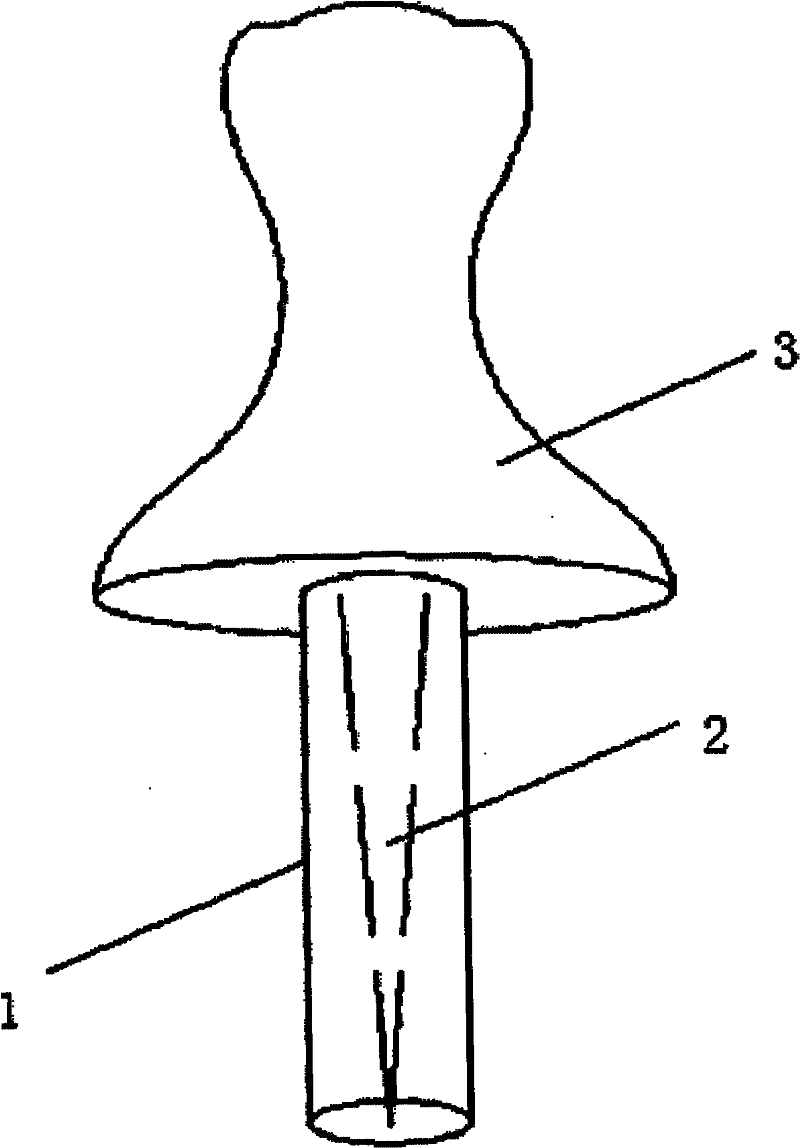

Timing reminding drawing pin

The invention relates to drawing pin design and especially relates to a timing reminding drawing pin. According to the technical scheme provided by the invention, the timing reminding drawing pin comprises a pin cap and a pin head, wherein the pin cap is divided into a first pin cap and a second pin cap; the first pin cap is in threaded connection with the second pin cap; an MCU, a buzzer and a sound outlet are arranged in the first pin cap; a battery jar is arranged in the second pin cap. The timing reminding drawing pin has the advantages that the timing buzzer is utilized to attract the user, so that the user can observe a notepaper nailed by the drawing pin.

Owner:GUANGDONG TANJIN ELECTRONICS TECH CO LTD

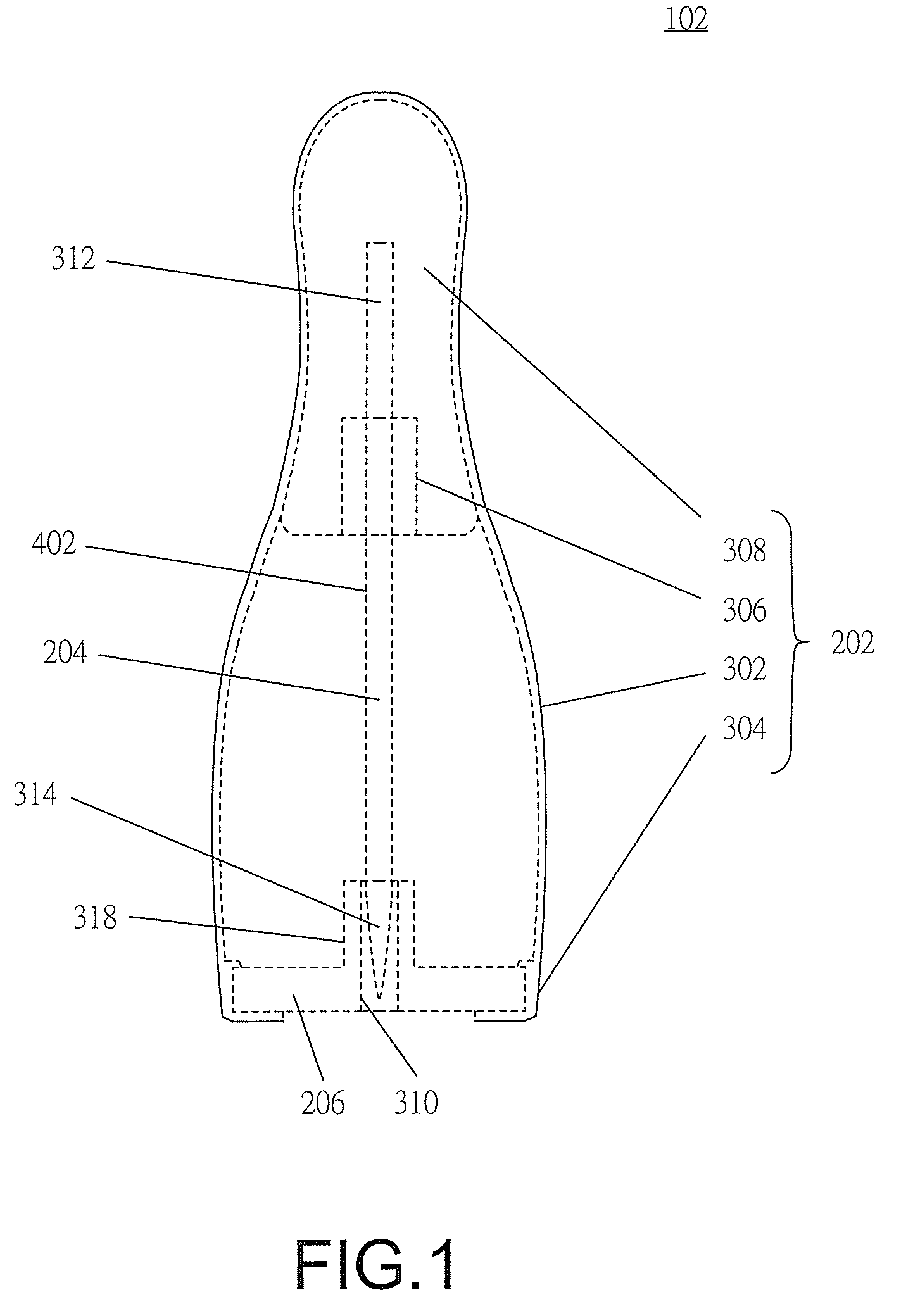

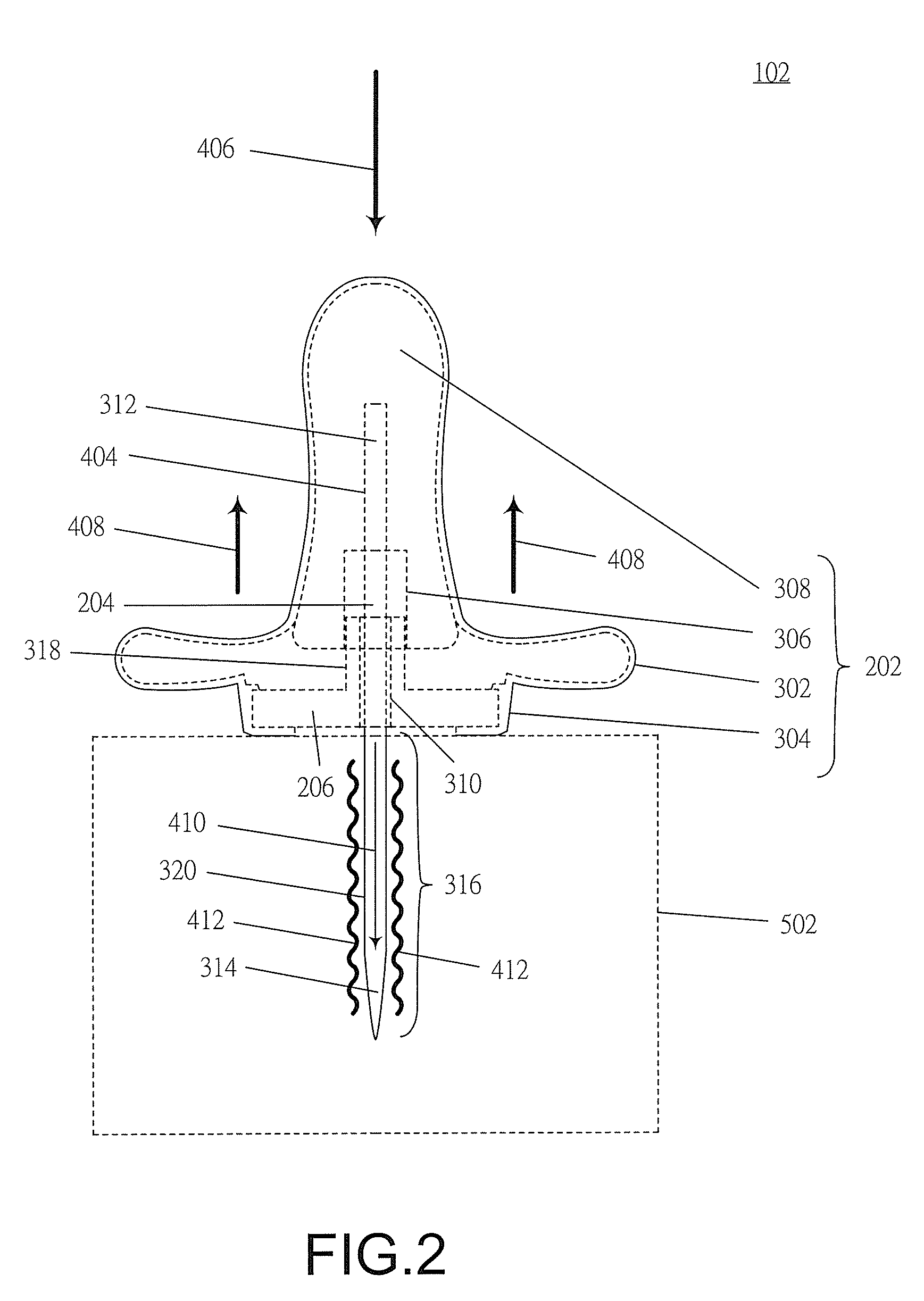

Drawing pin having functionality of drawing back automatically

Owner:NAT TAIWAN UNIV OF SCI & TECH

Device that attaches to a surface

Owner:ALVA IP I +2

Standoff adaptor for push pin

Owner:ACCURATE MFGD PRODS GROUP

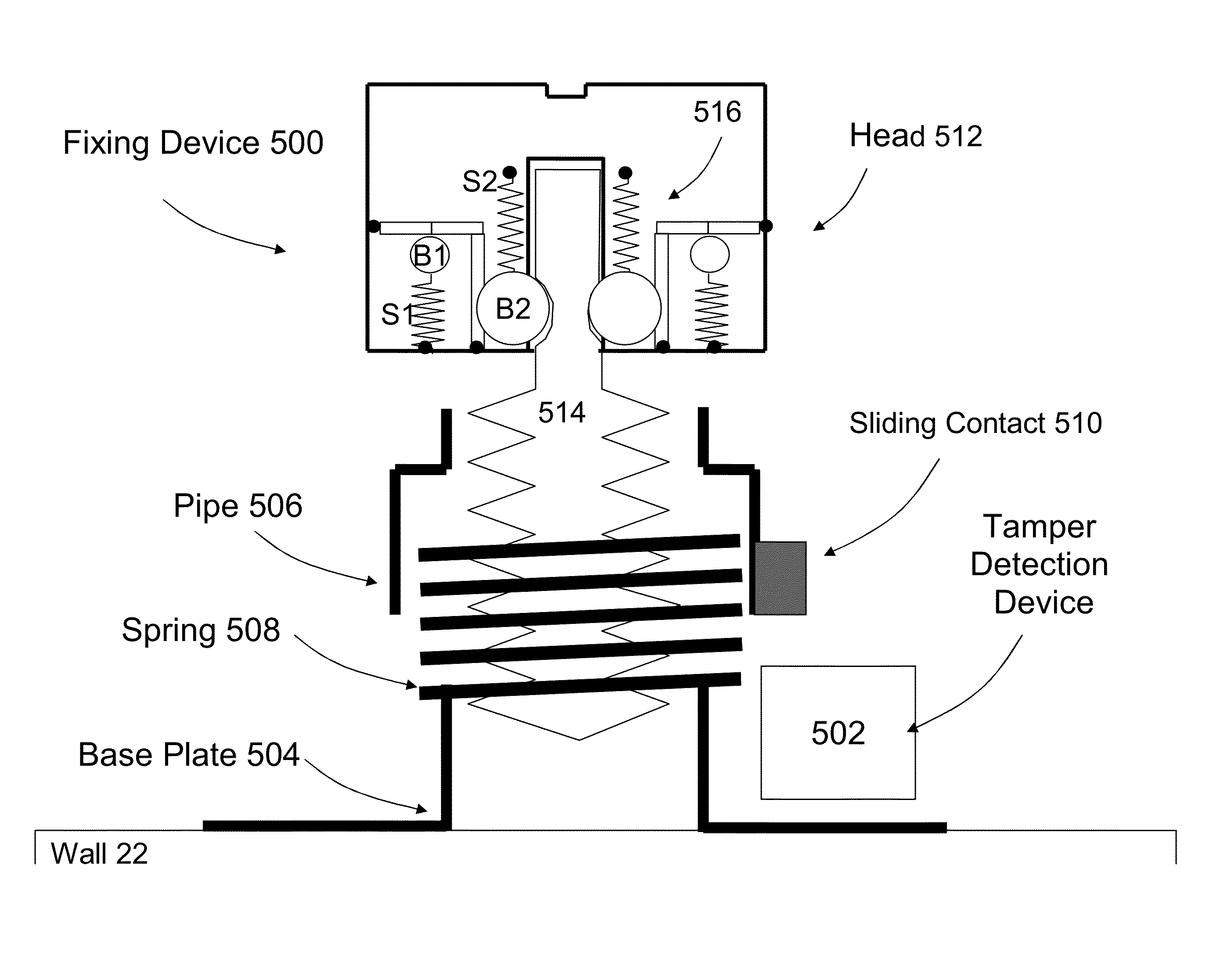

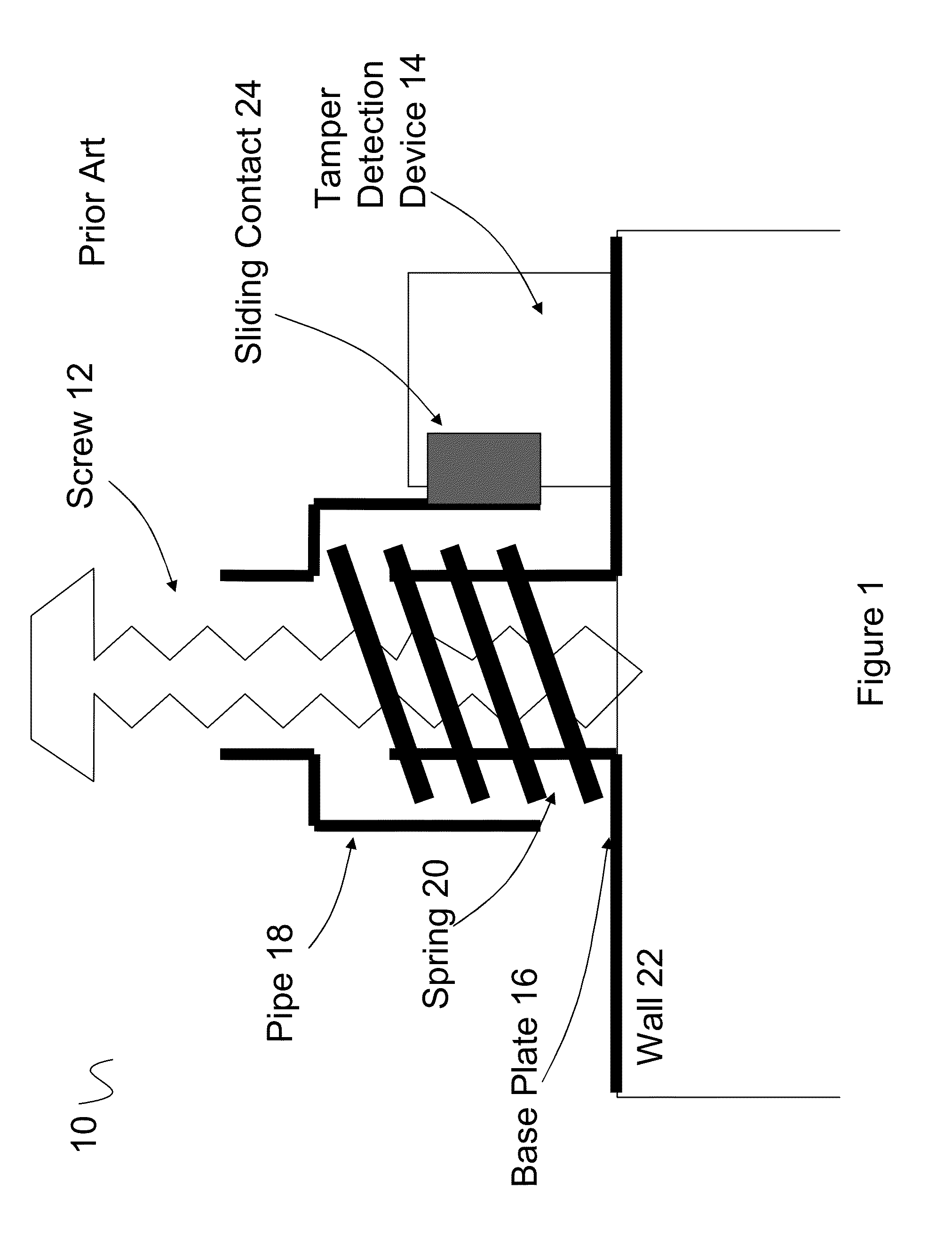

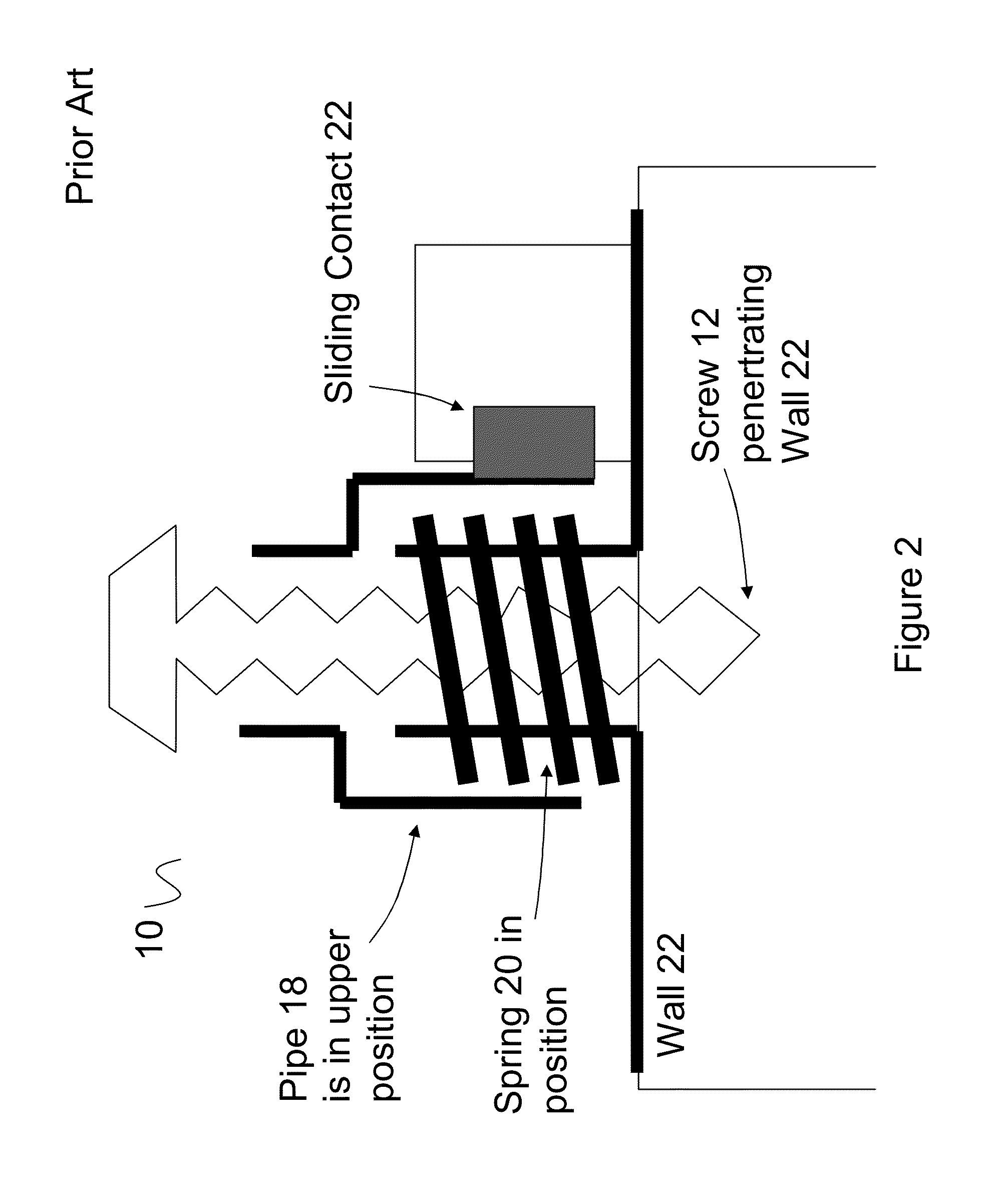

Anti-tamper system

ActiveUS20130322984A1Minimize timeEasy to usePinsRivetsEngineeringElectrical and Electronics engineering

An anti-tamper system including: a fixing device and an anti-tamper detection device; the fixing device comprising a body and a head whereby the head having a larger cross section then the body for enabling a tool to engage and drive the body into a first material layer thereby makes a firm connection with the anti-tamper detection device between the head and the first material layer; the fixing device further comprising a lock wherein the head is locked to the body by the lock where there is no external magnetic field and wherein the head becomes disengaged from the body when the lock is unlocked by an external magnetic field; and whereby the anti-tamper detection device detects and records a change the connection when the head becomes disengaged.

Owner:IBM CORP

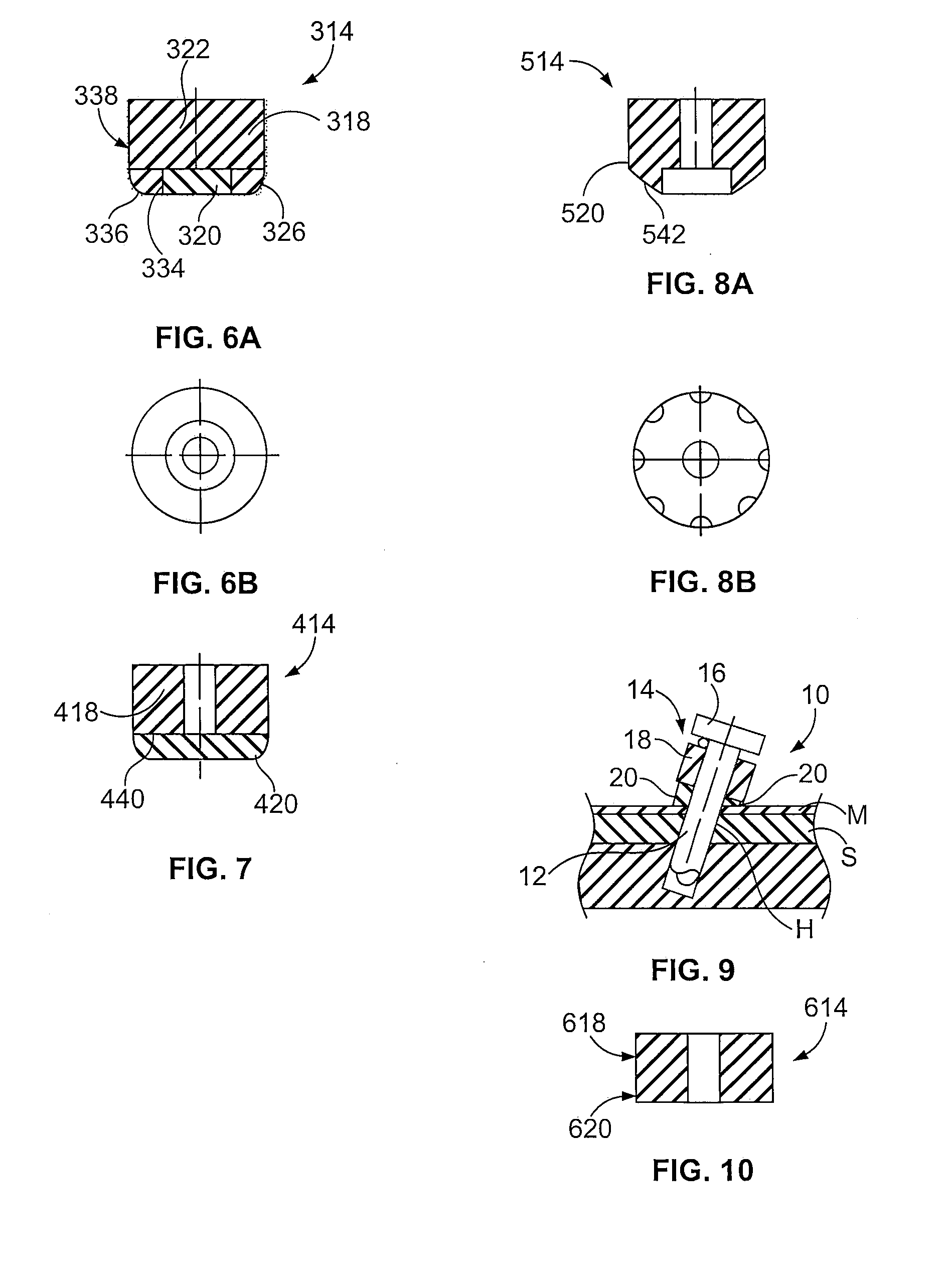

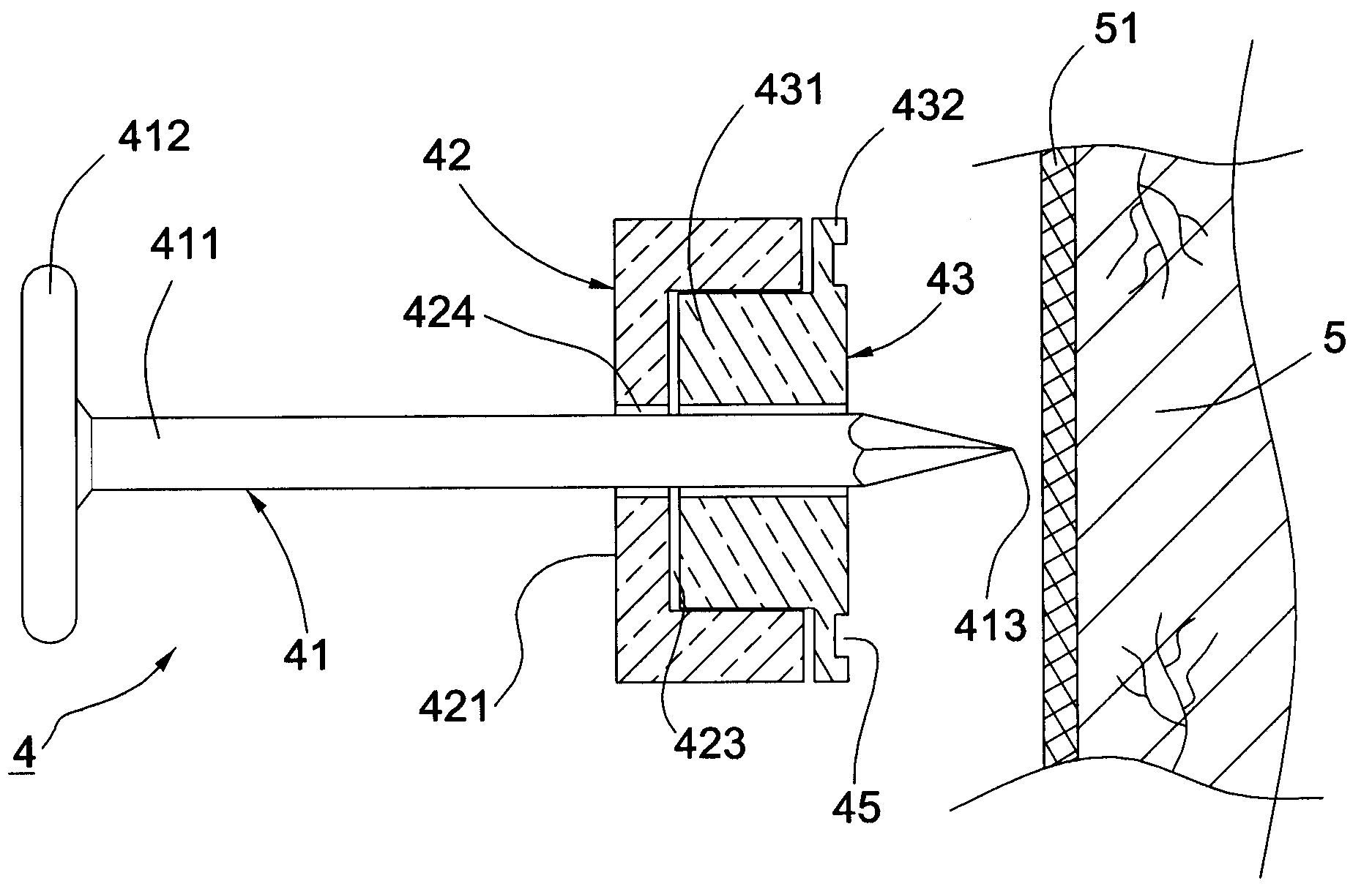

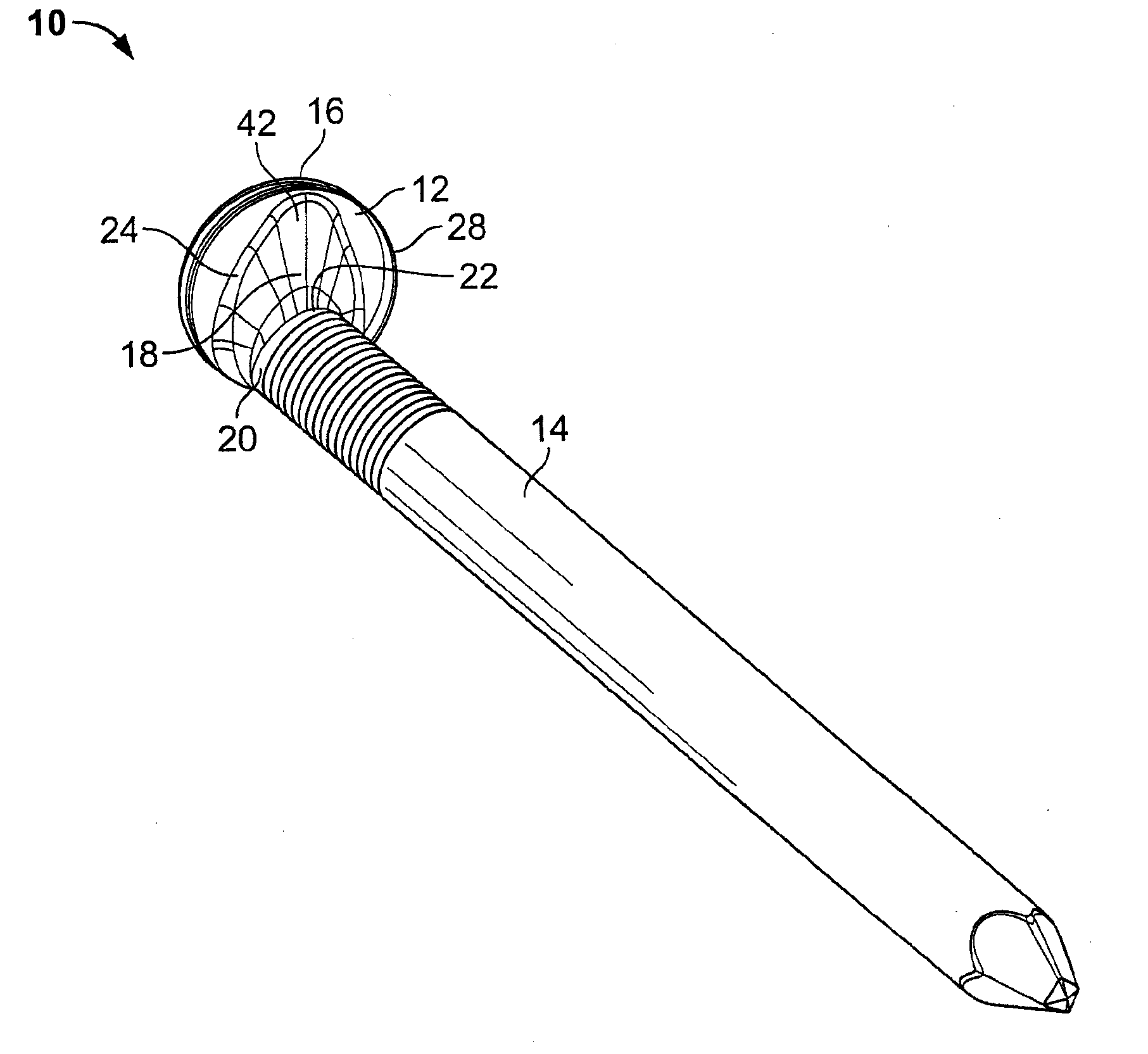

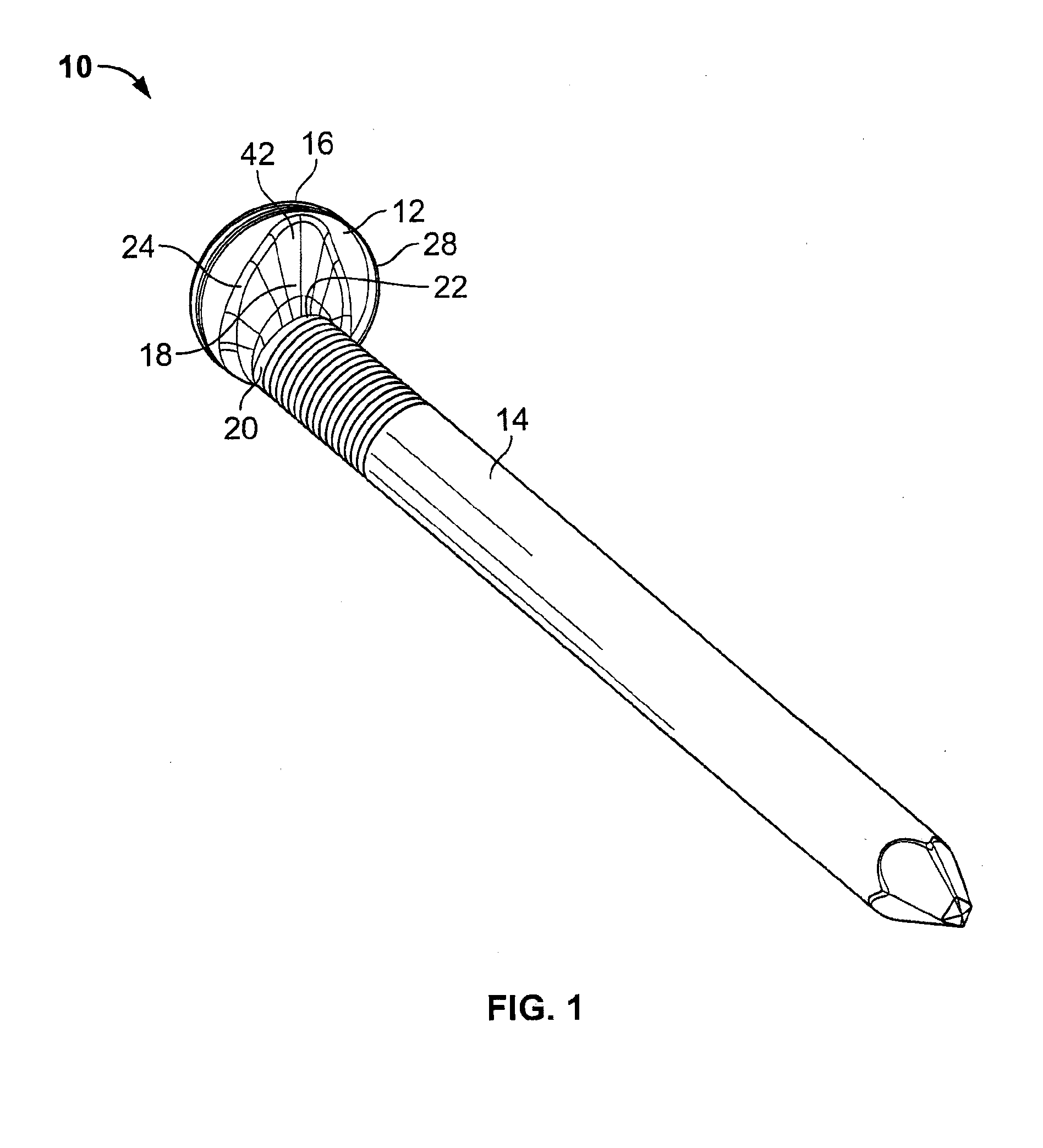

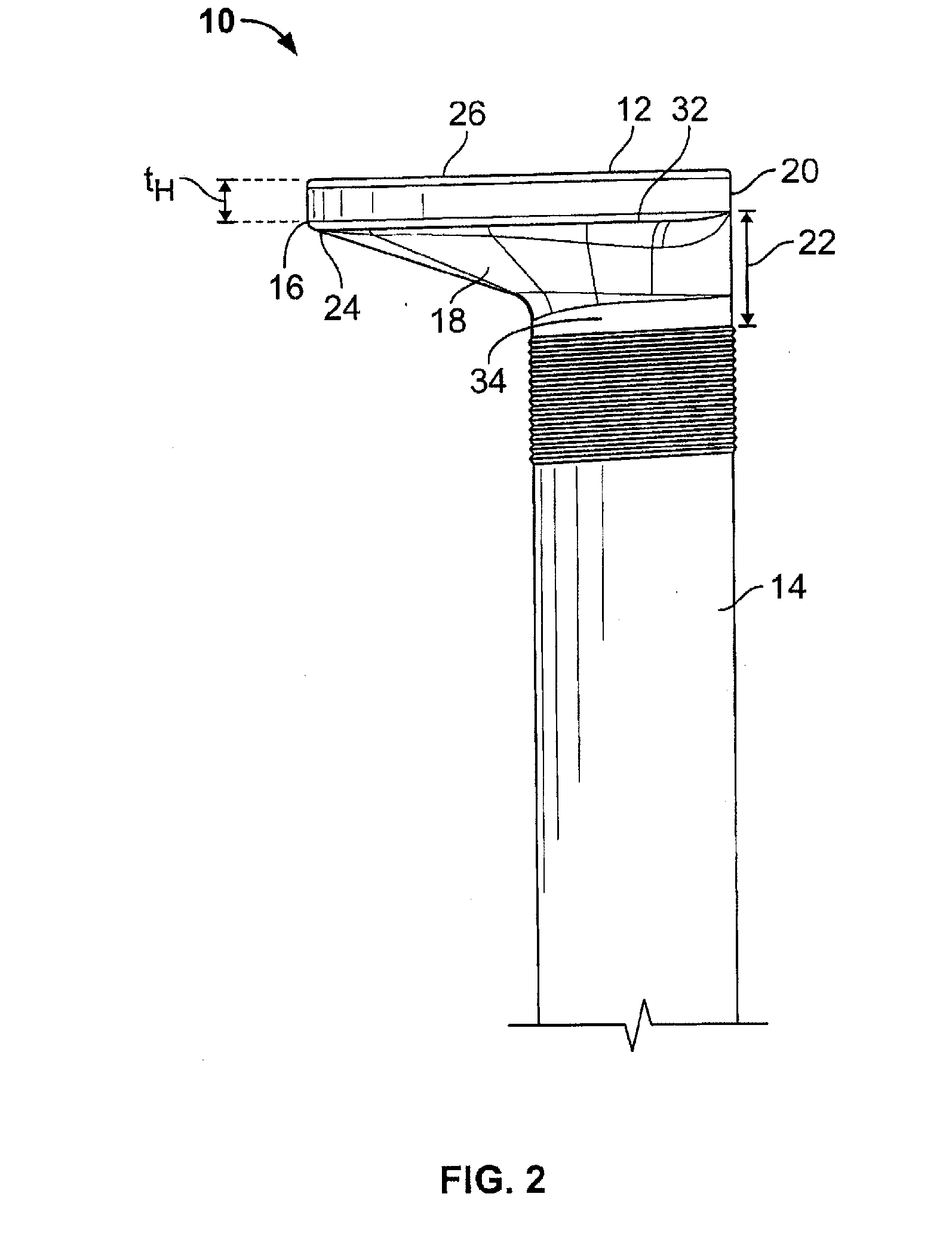

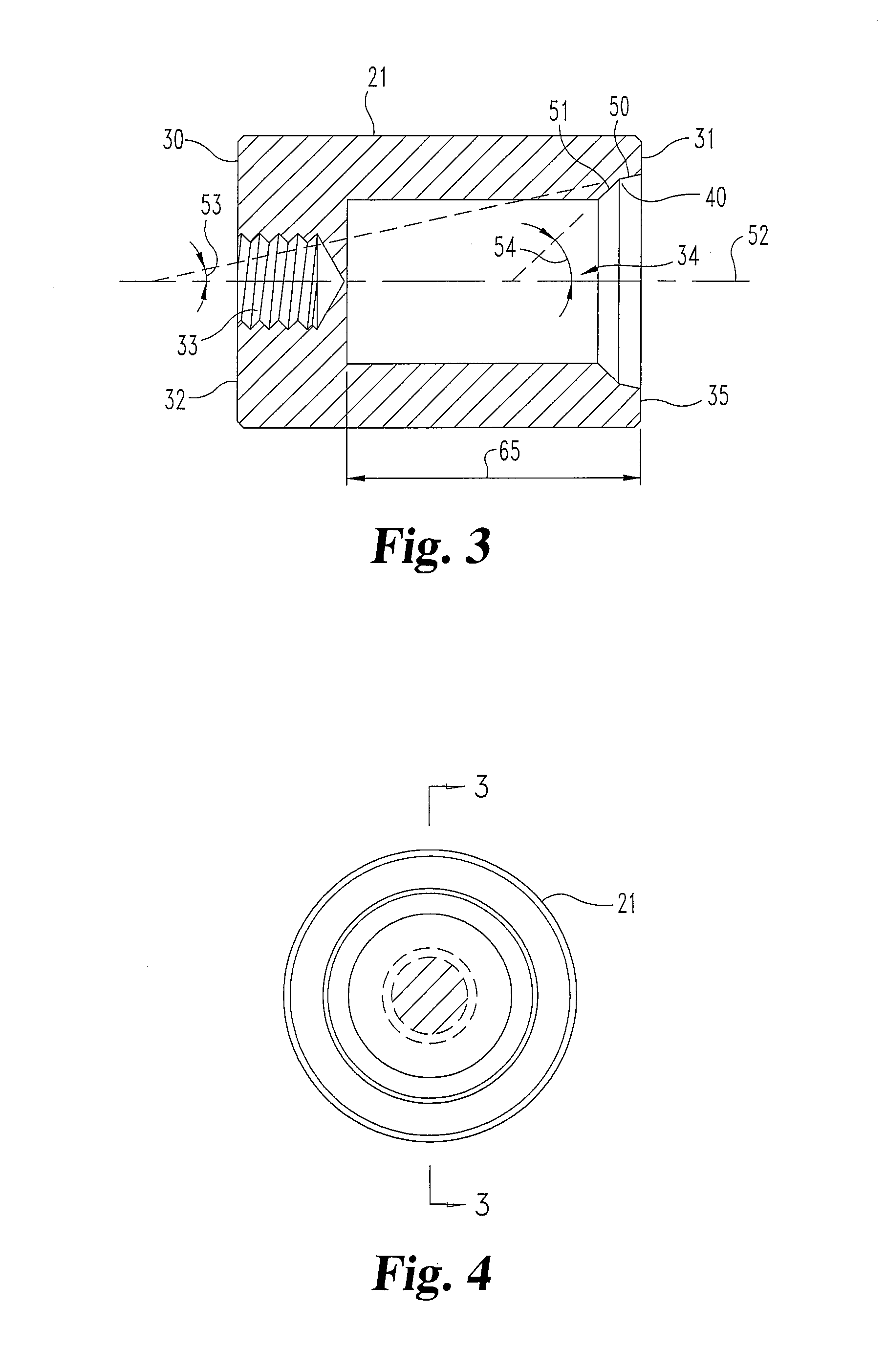

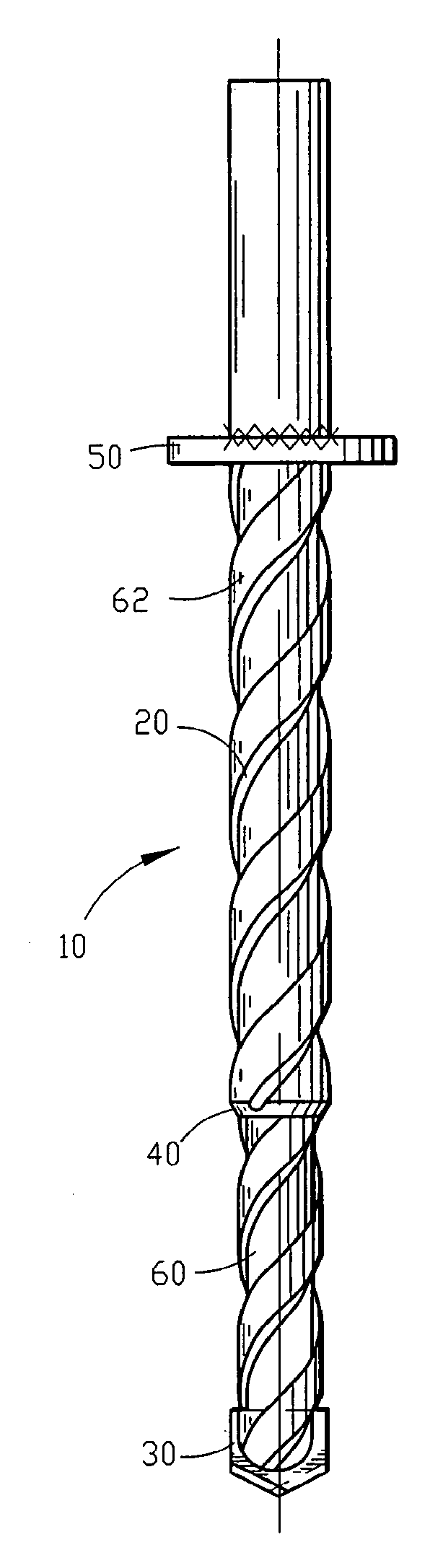

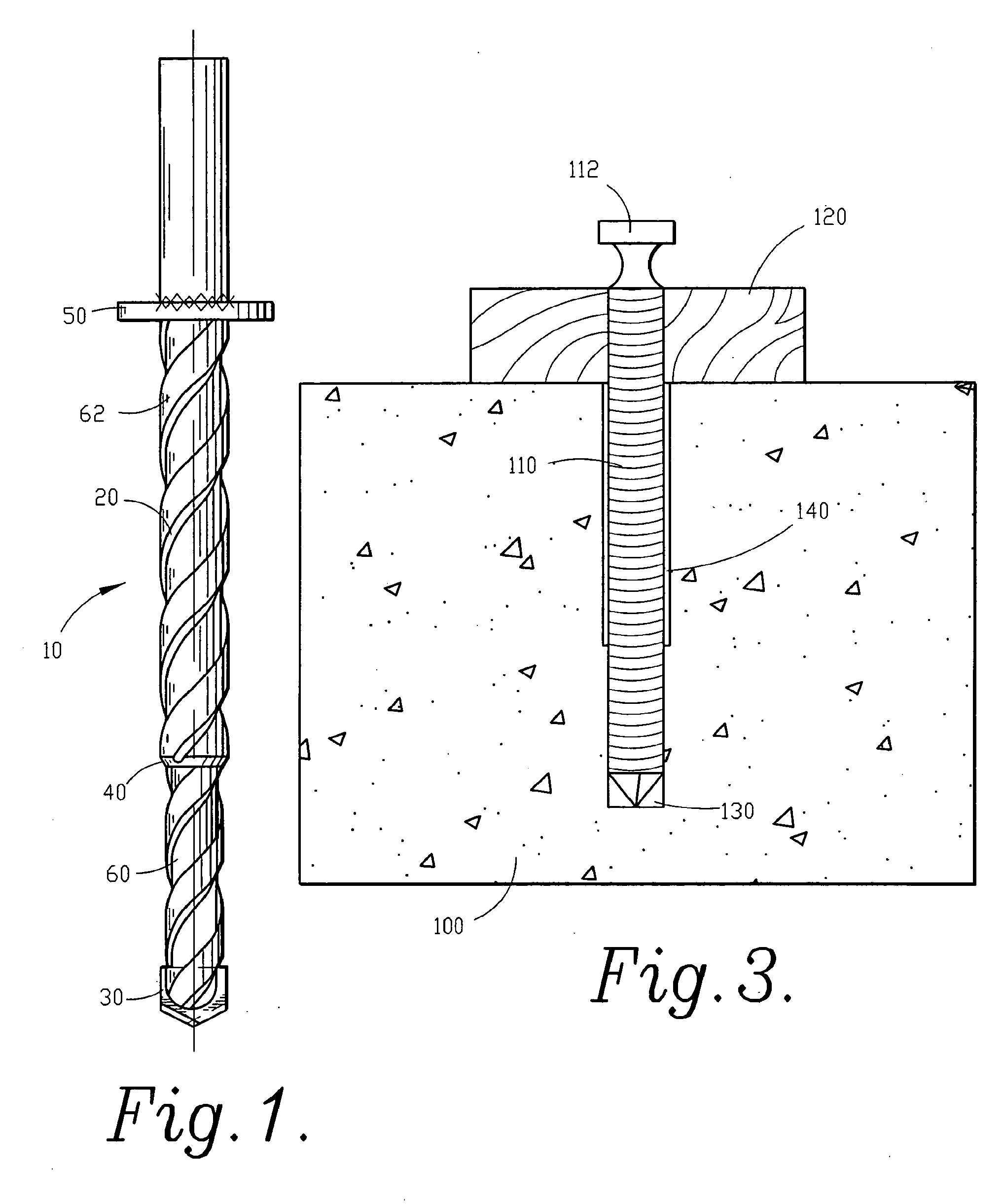

Anchoring drill bit, system and method of anchoring

InactiveUS20080014048A1Low costReduce frictionDrilling/boring measurement devicesDrill bitsPilot holeEngineering

A system, apparatuses and methods for anchoring are provided. The system includes two-stage drill bit and a method of anchoring into a two-stage hole drilled by the drill bit. The apparatus of the instant invention includes a two-stage drill bit for drilling a pilot hole for a common nail into a material such as concrete, stone, masonry or cementuous or other materials. The method of the instant invention includes the steps of drilling a first hole within a material to which an object is to be anchored, drilling a second hole concentric with the first hole, and placing an anchor within the holes.

Owner:NADLER DONALD S

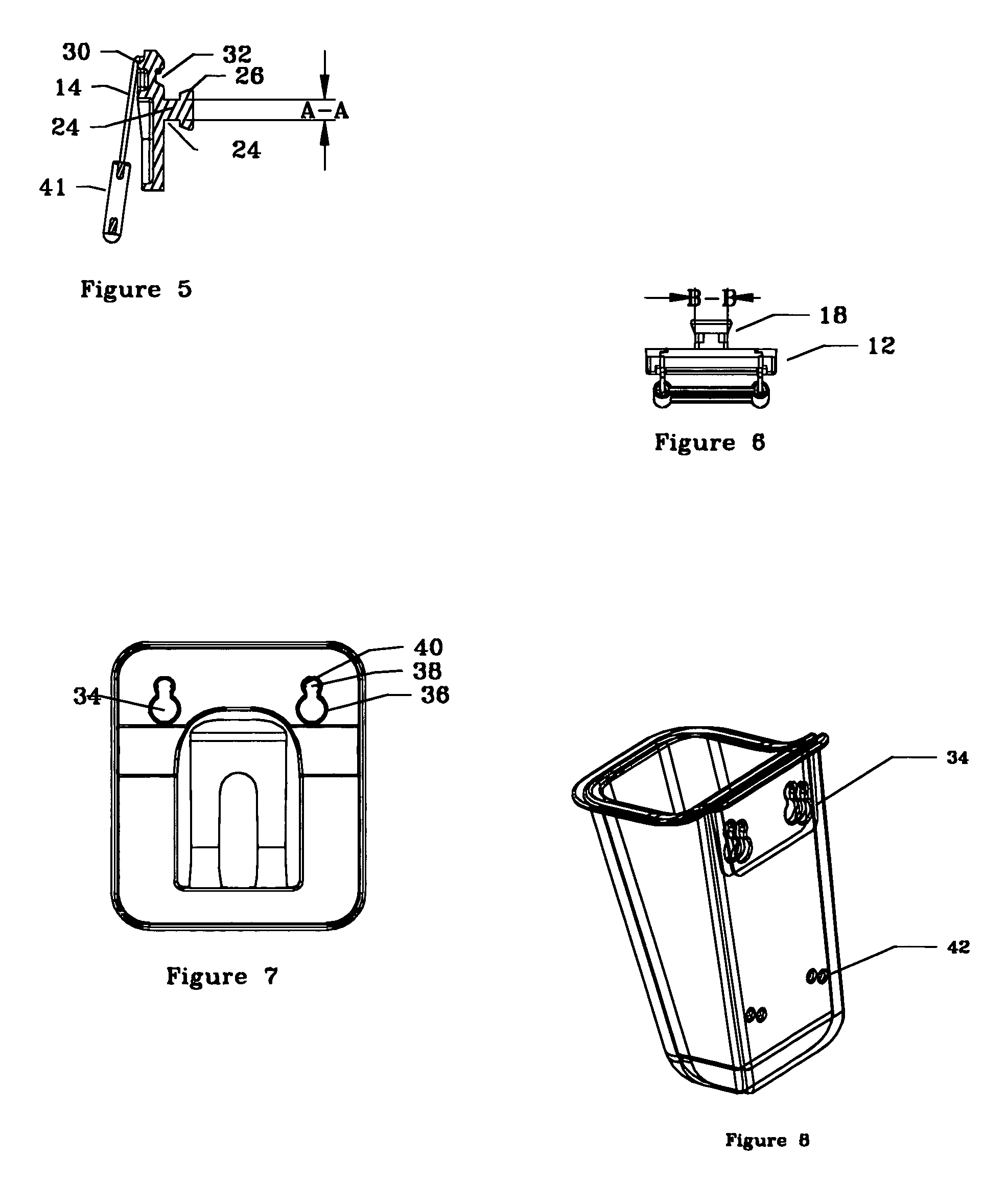

Attachment device for panel walls

Owner:OFFICEMATE LLC

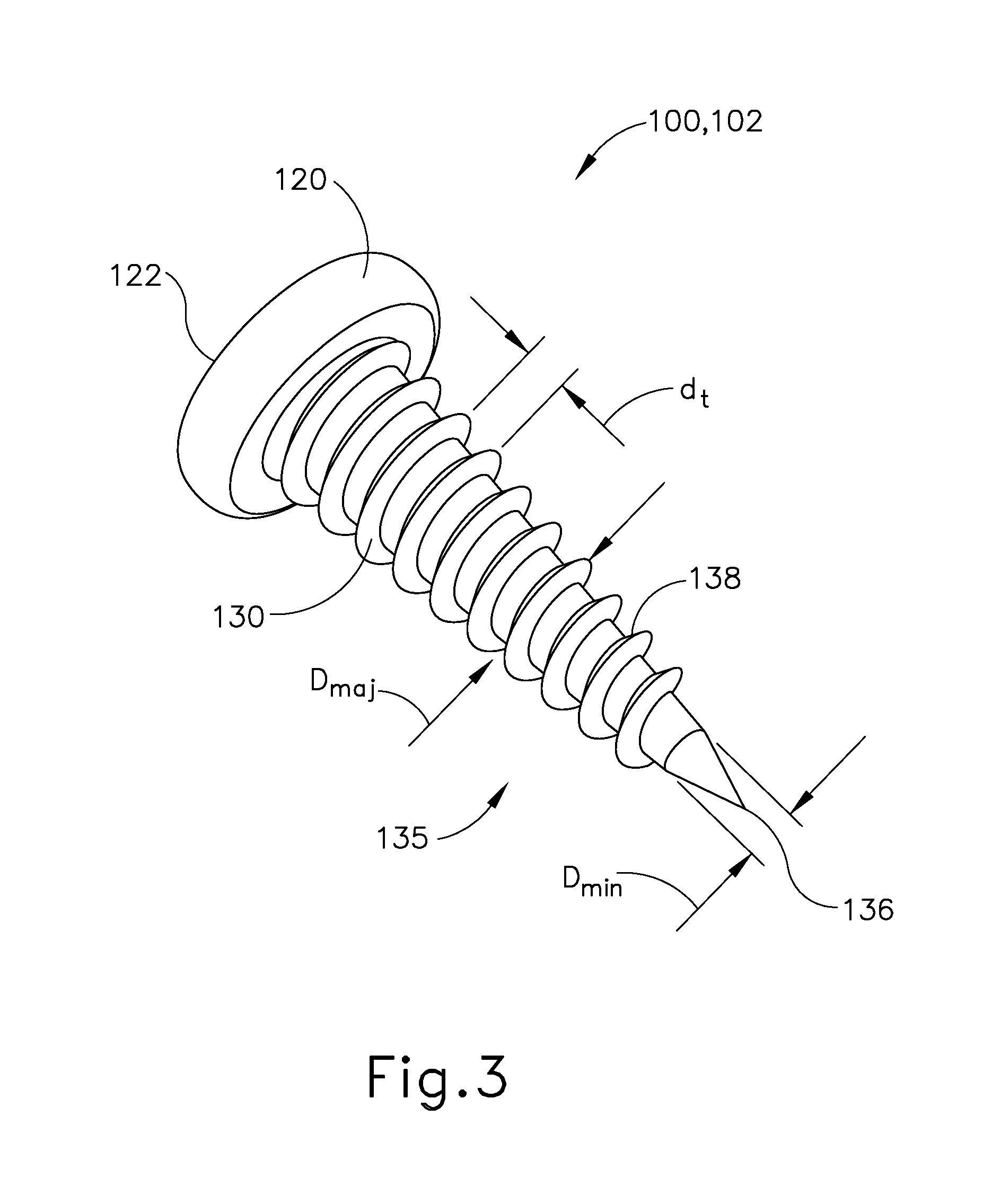

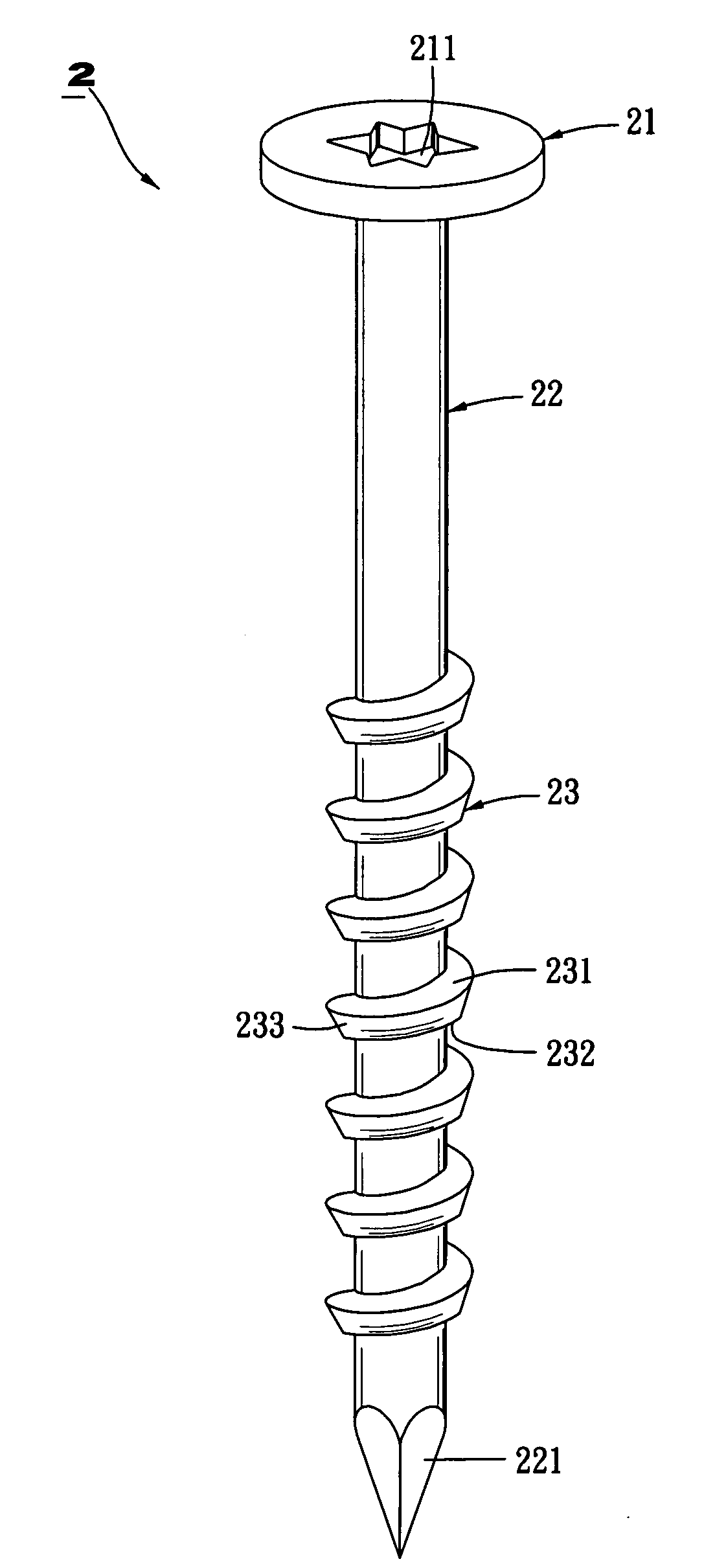

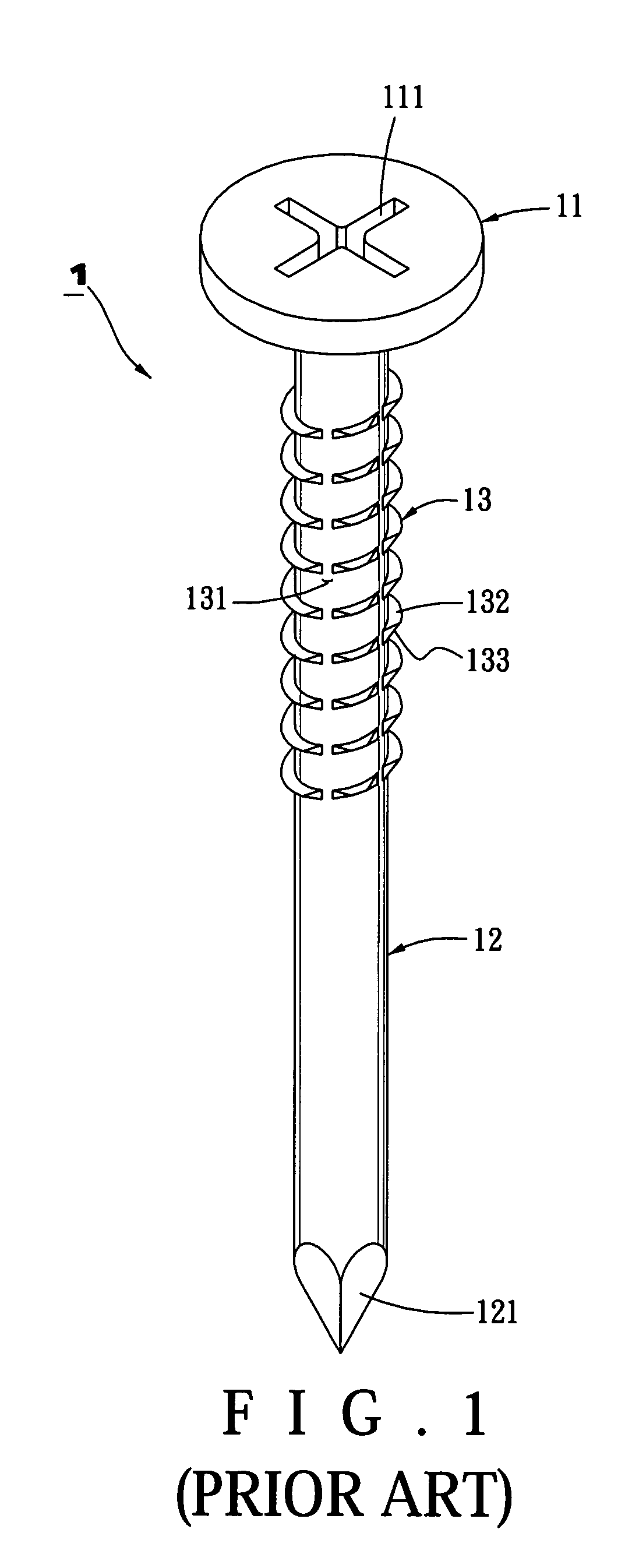

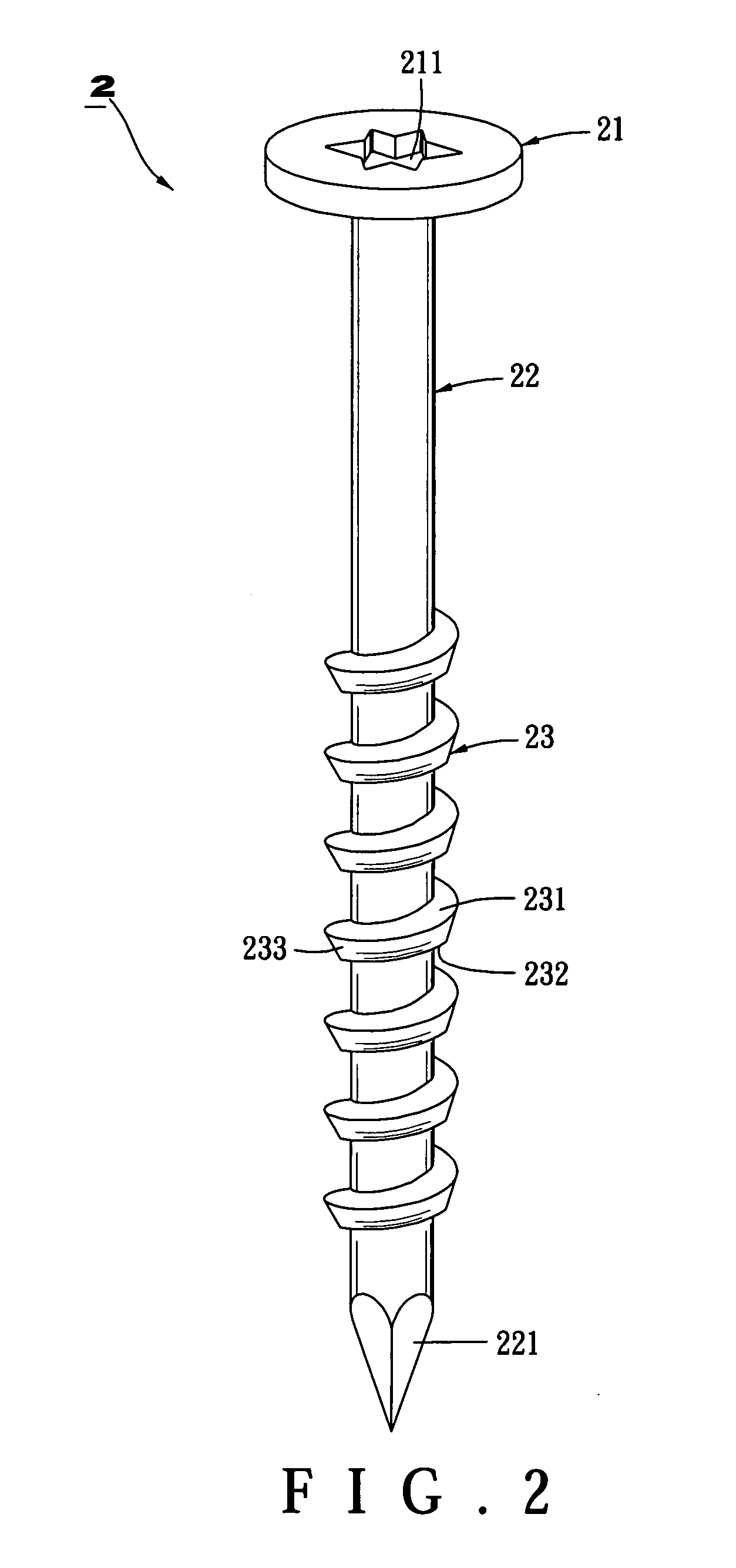

Nail

InactiveUS20080240885A1Prevent from damaging surface of plankingShorten the timeStaplesRail fastenersEngineeringScrew thread

A nail comprises a plurality of umbrella-shaped threads spirally formed on the shank and extended from the nail end to the head, wherein the umbrella-shaped thread includes a top face and an end edge face, in which the outer diameter of the top face is greater than the outer diameter of the end edge face, such that the nail can be nailed into a planking easily and successfully without the obstacle of the umbrella-shaped threads. While pulling out the nail, an actuating tool is used directly to rotate back the nail, so as to prevent from damaging the surface of the planking and efficiently save the time and labor.

Owner:CHANNG CHIN IND CORP

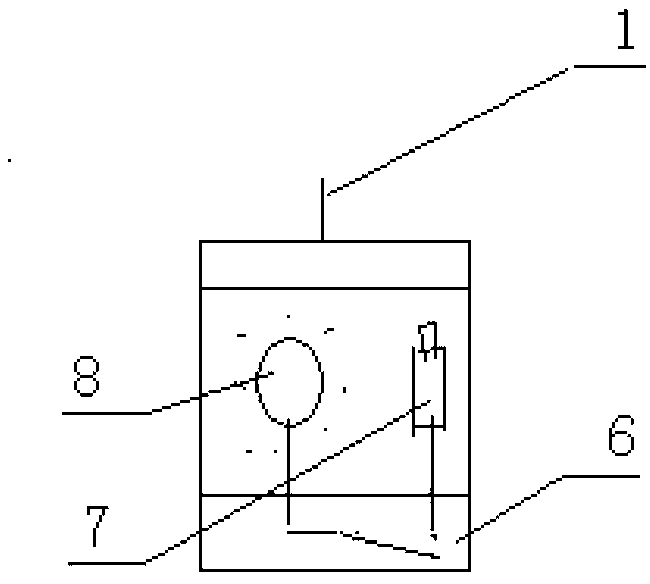

Pin with regular reminding function

InactiveCN103223806ASimple structureReminder is practicalDrawing pinsElectricityBiochemical engineering

The invention provides a pin with a regular reminding function, which comprises a pinpoint part and a pin body part, wherein the pinpoint part is fixedly arranged on one end surface of the pin body part; a light source and a power source are arranged in a cavity in the pin body part; a timer is arranged on the other end surface of the pin body part; and a switch for the timer is arranged between the light source and an electric connection passage of the power source. The pin provided by the invention has the benefit of simple structure, has functions of reminding according to the priority and time setting, and is strong in applicability.

Owner:天津市亚鼎科技有限公司

safety pin

Owner:SHANGHAI ZHABEI DISTRICT HETIANLU PRIMARY SCHOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com