Patents

Literature

40 results about "Incompressible material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Answer Wiki. The molecules in an incompressible material is held to its length by a sufficient amount of force to resist change in distances between them.

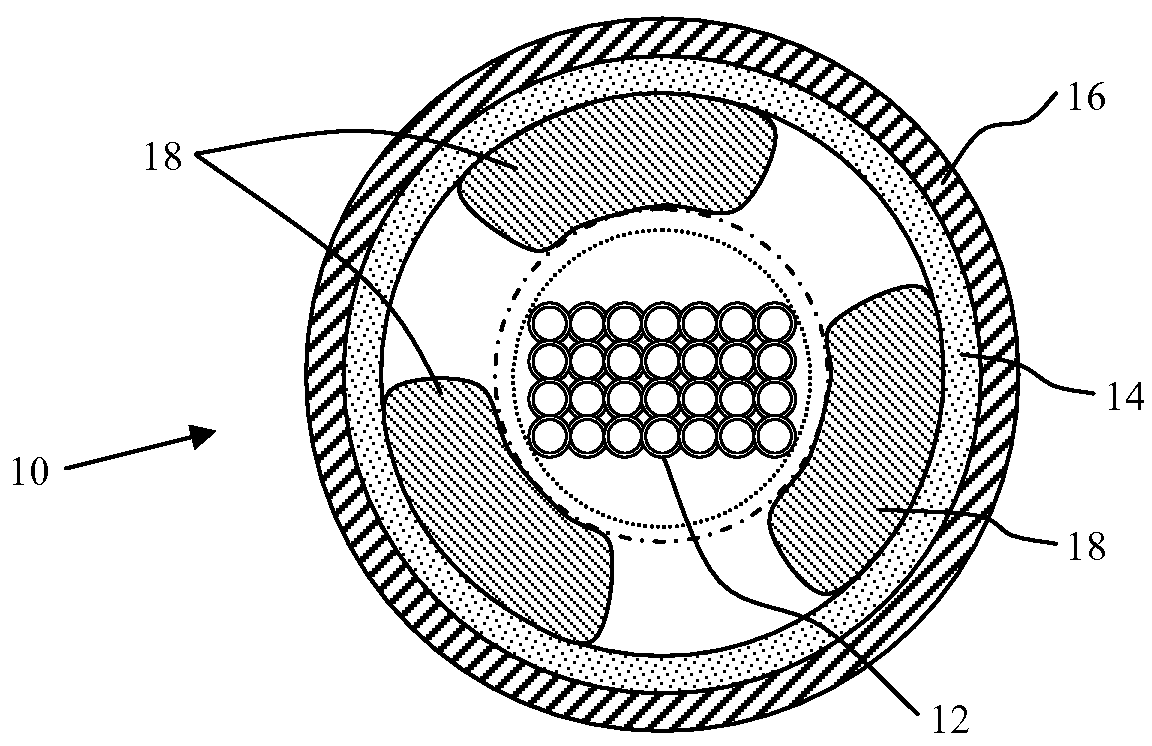

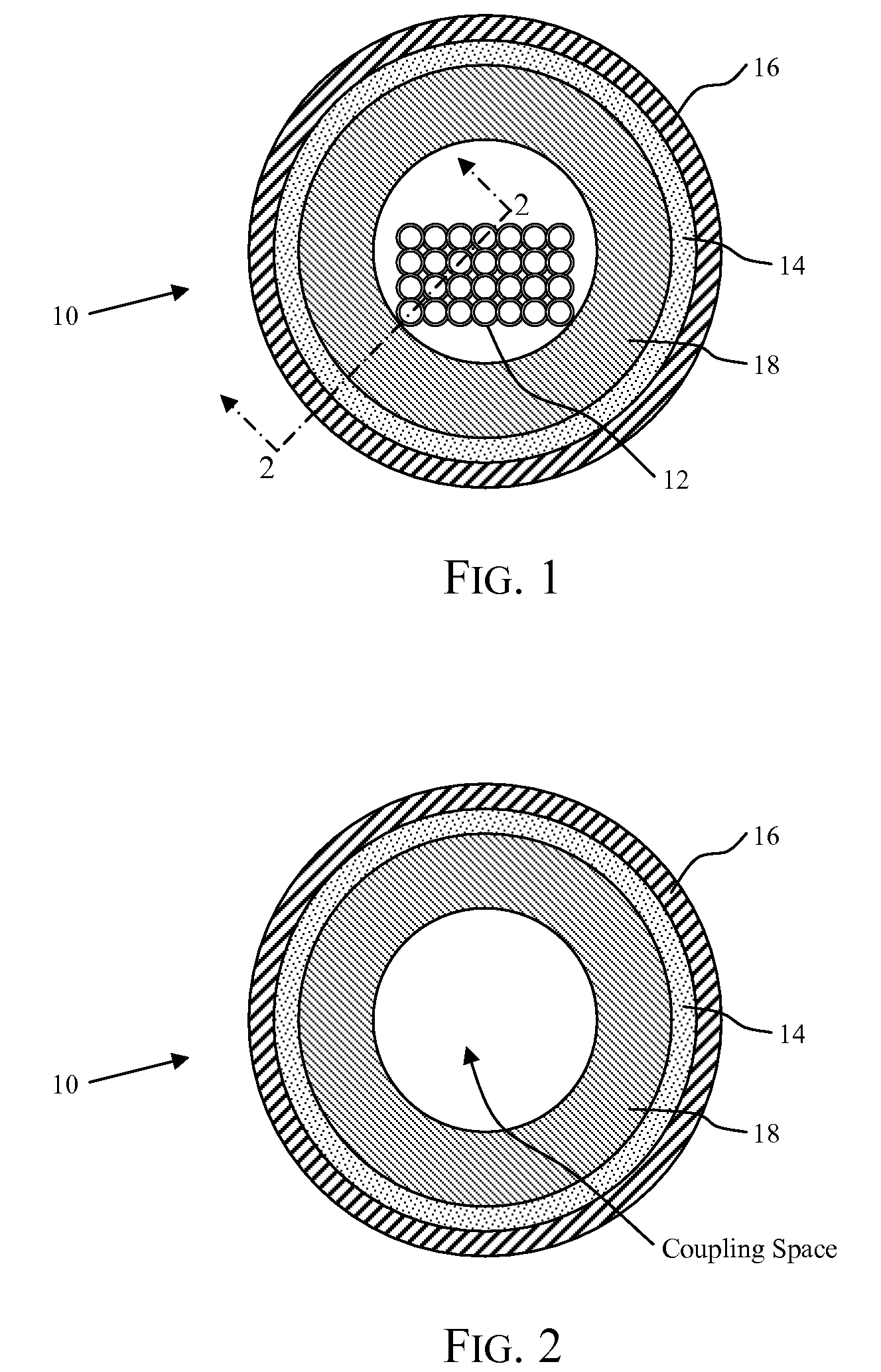

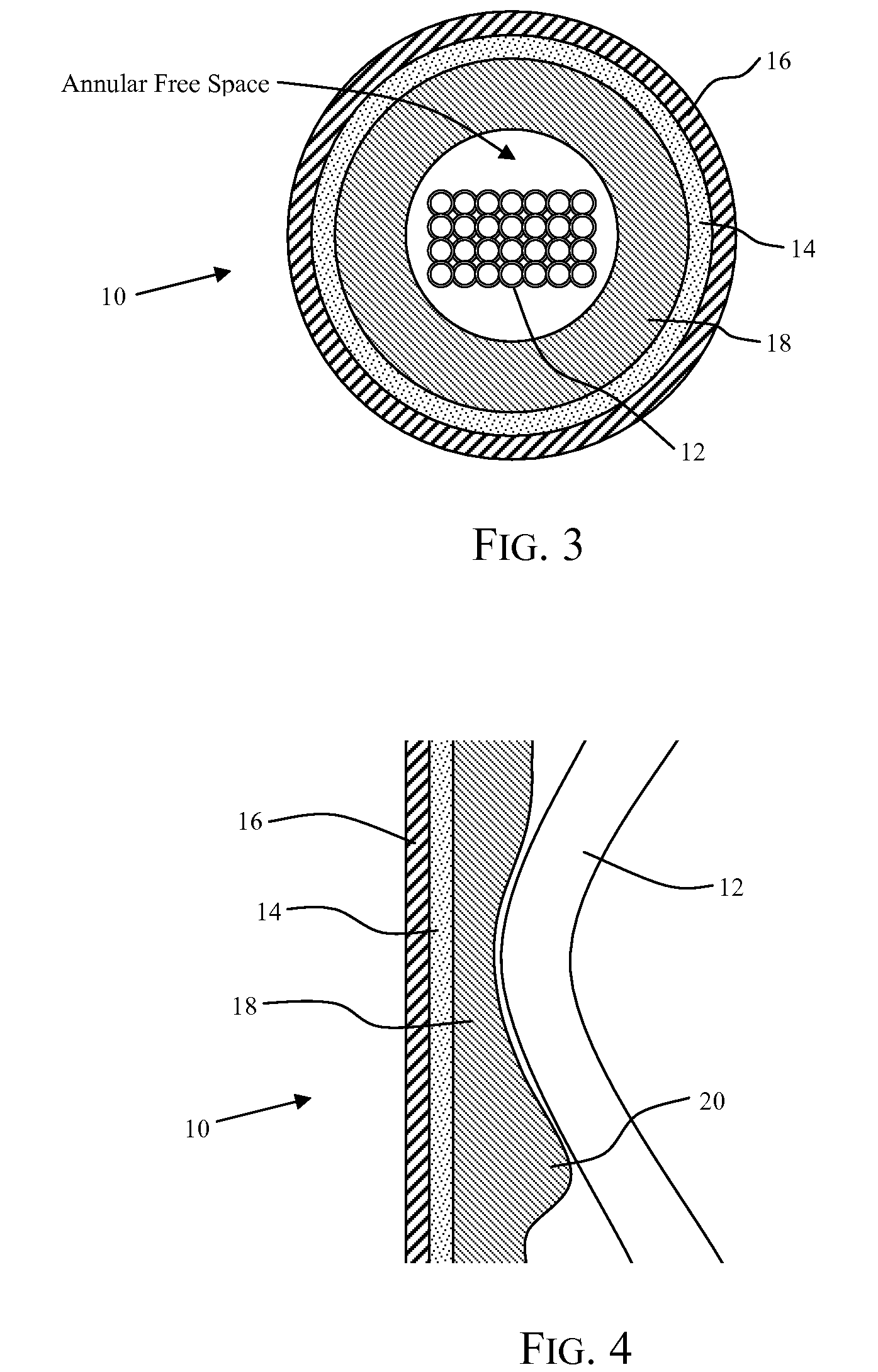

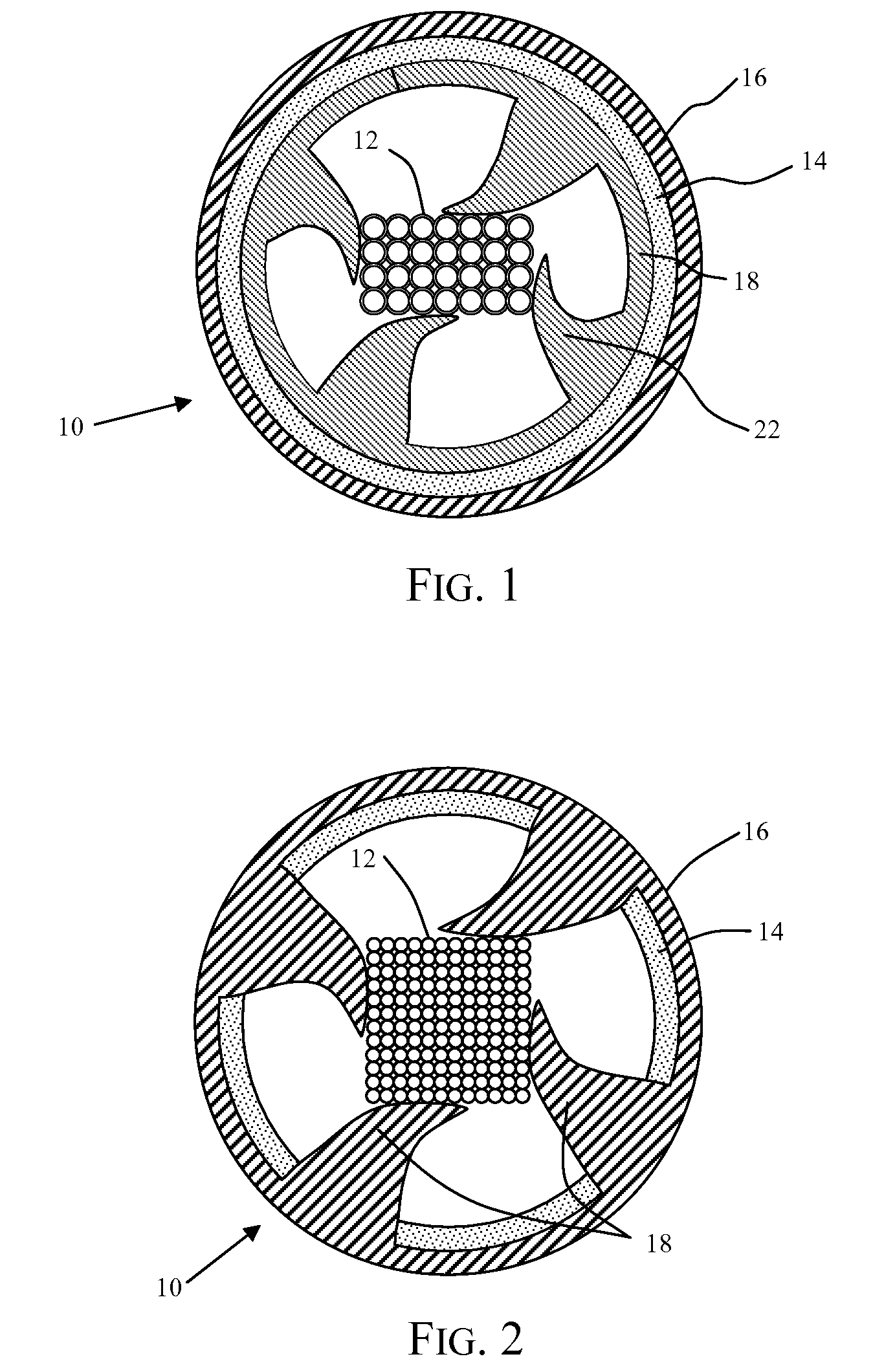

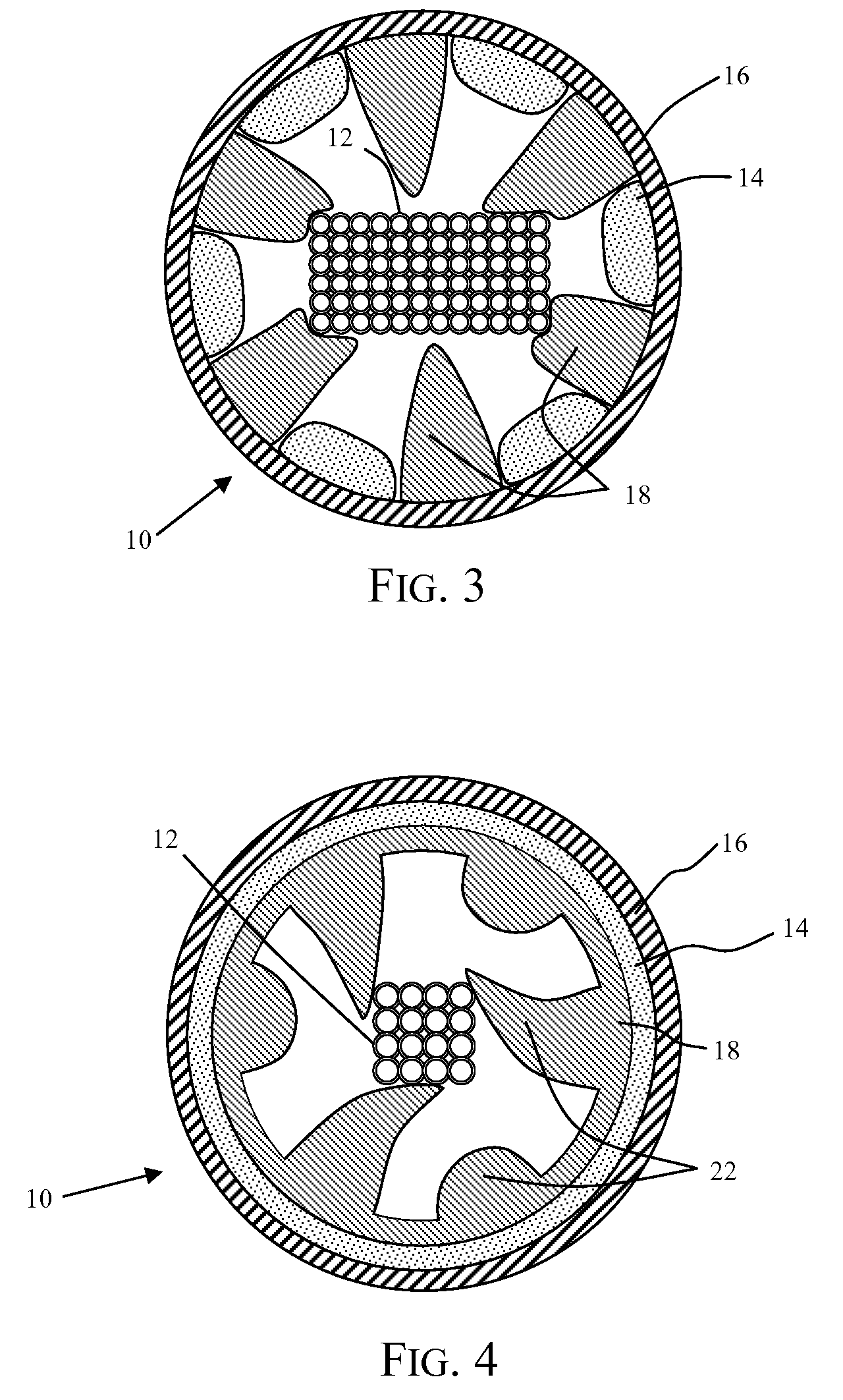

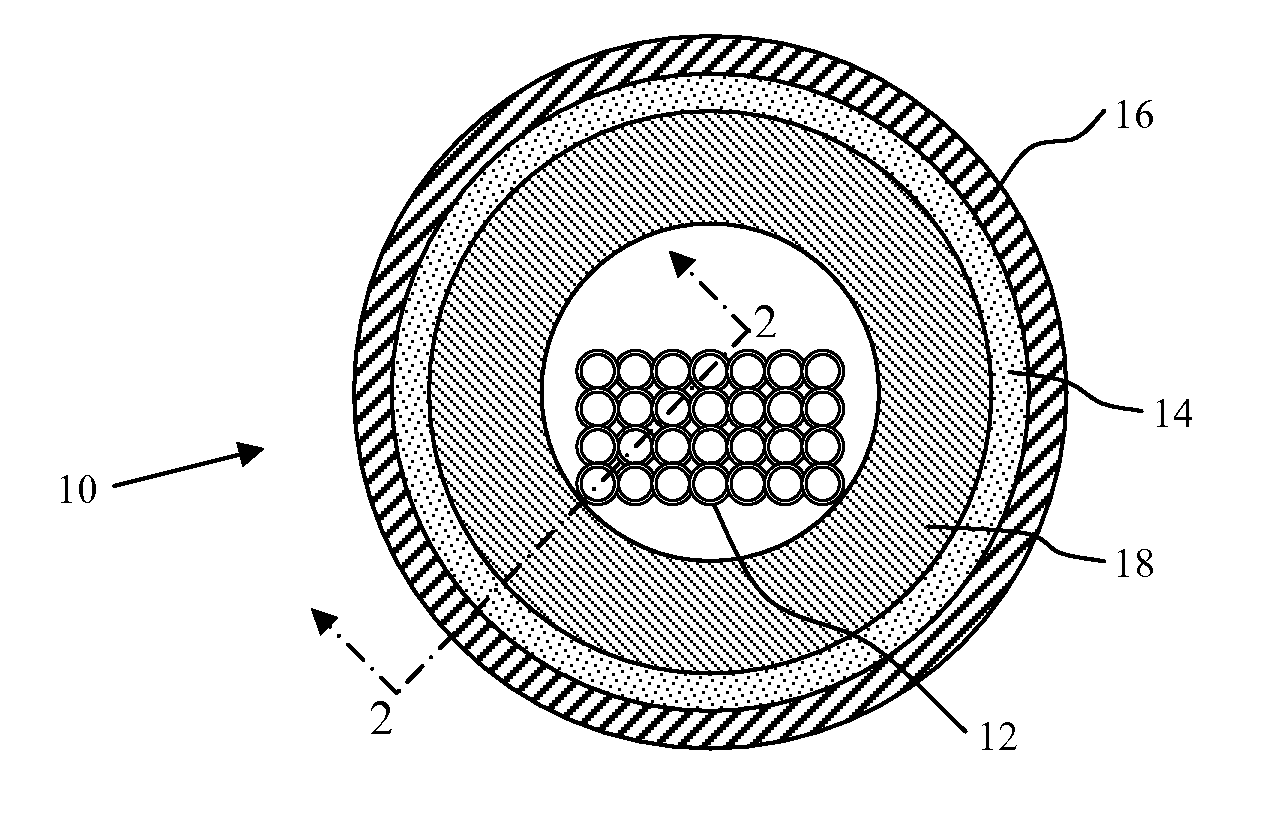

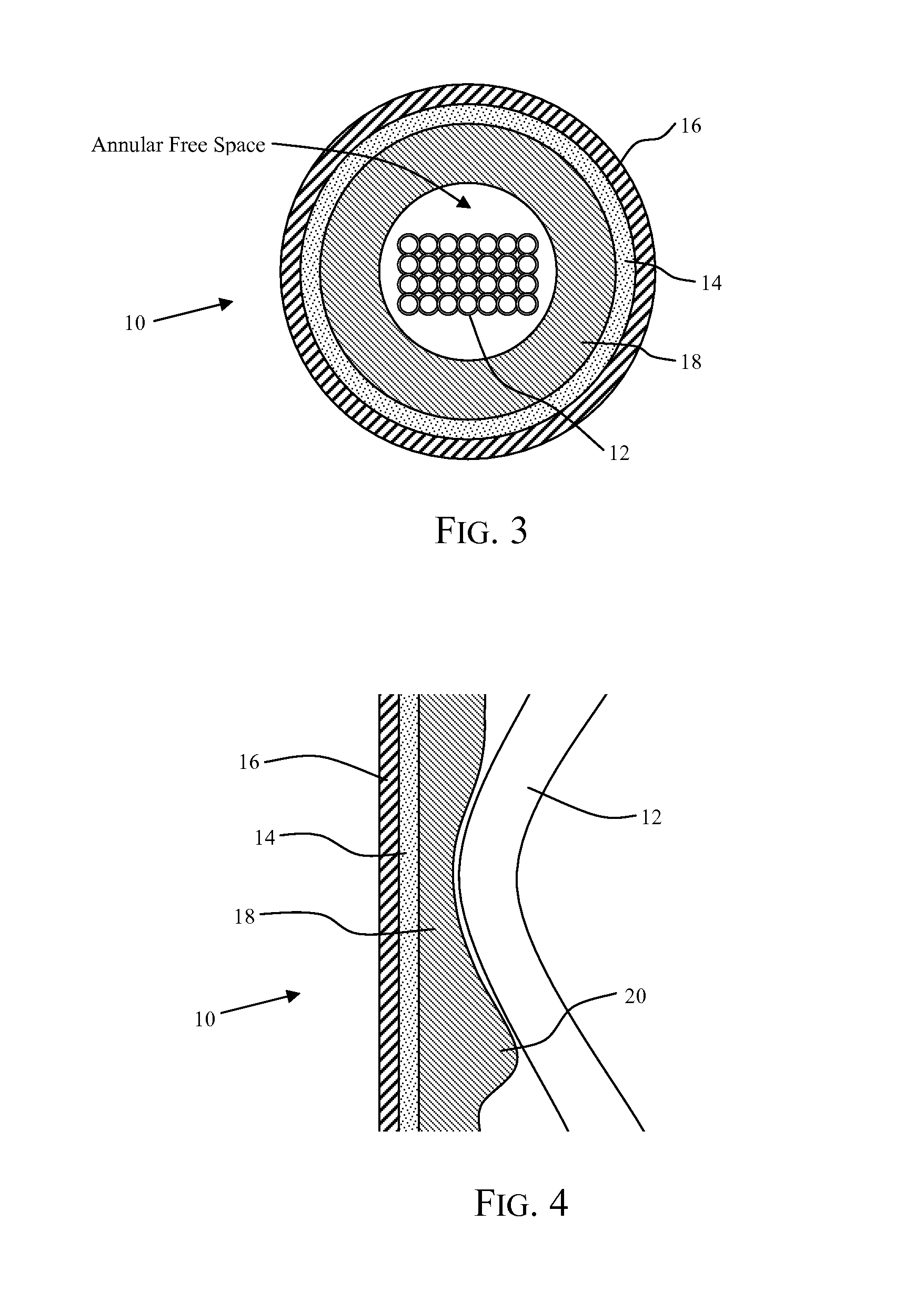

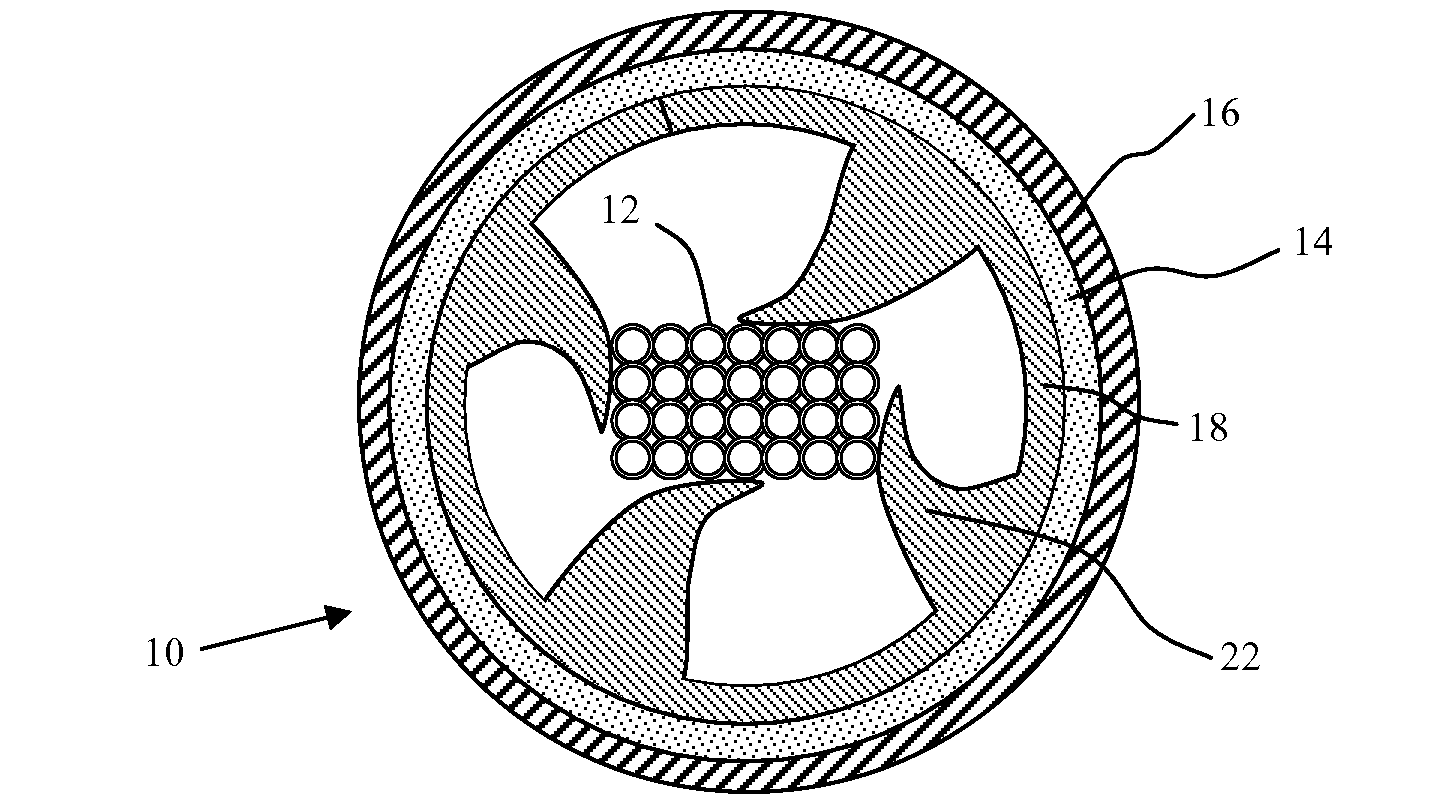

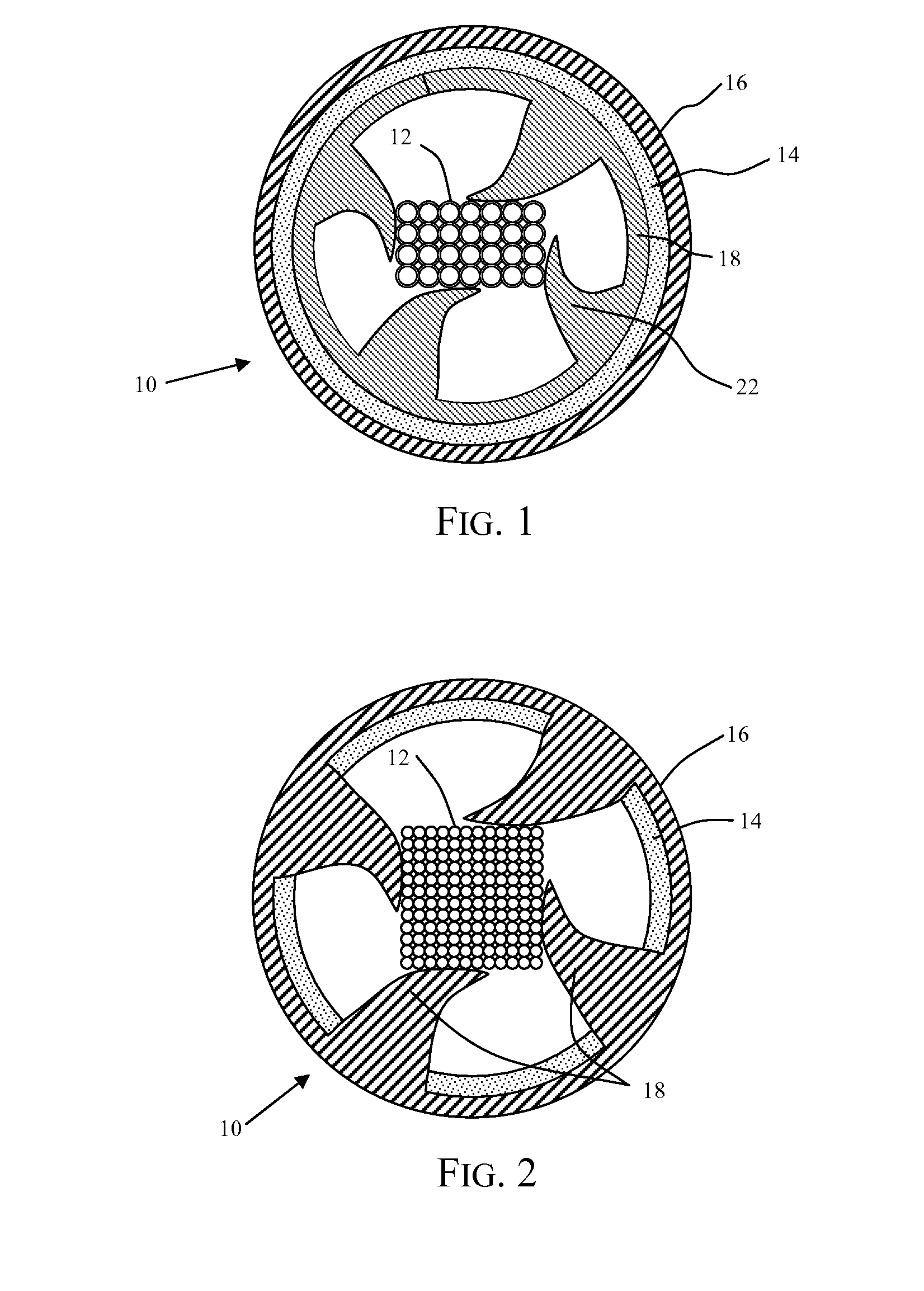

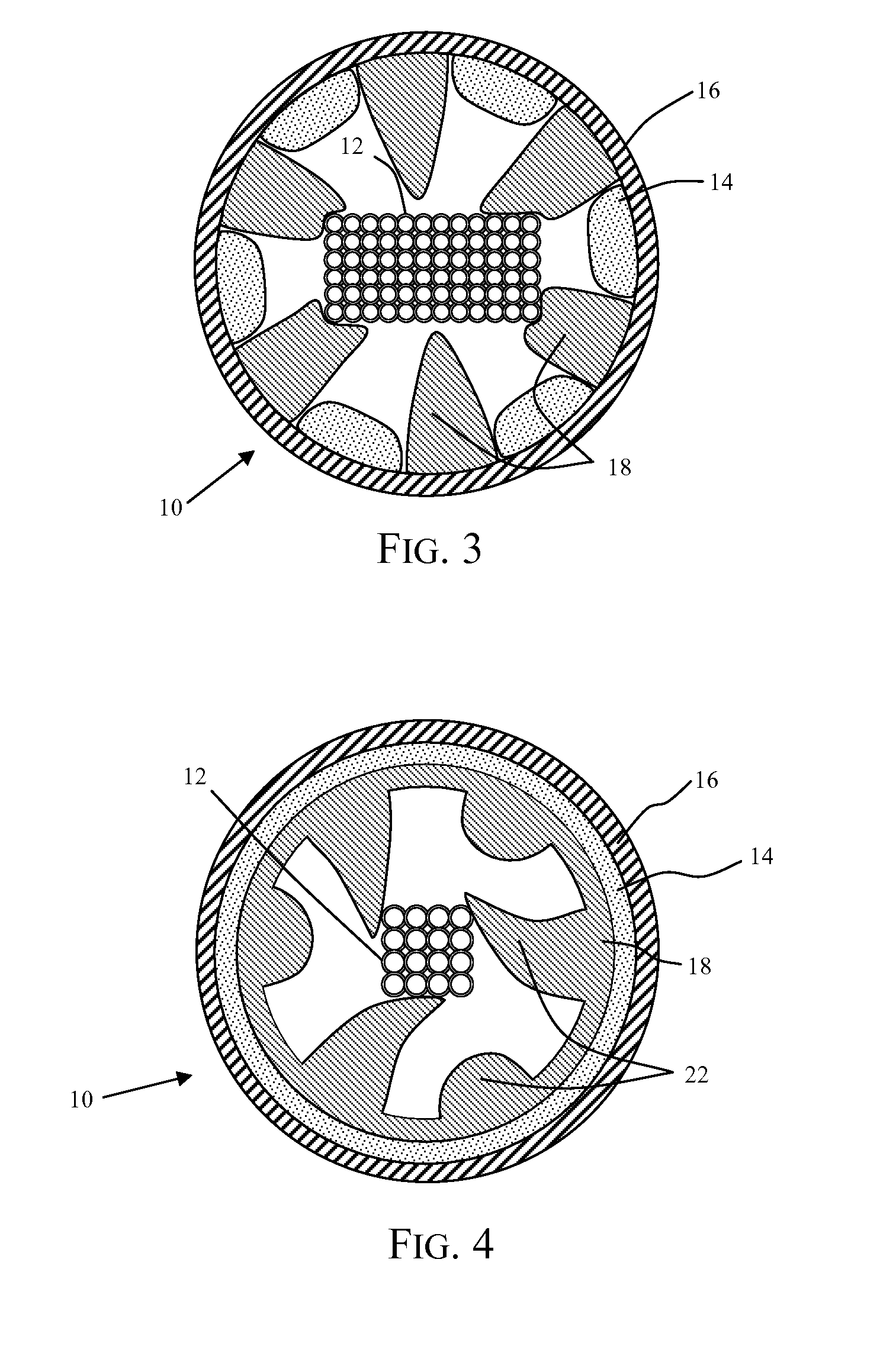

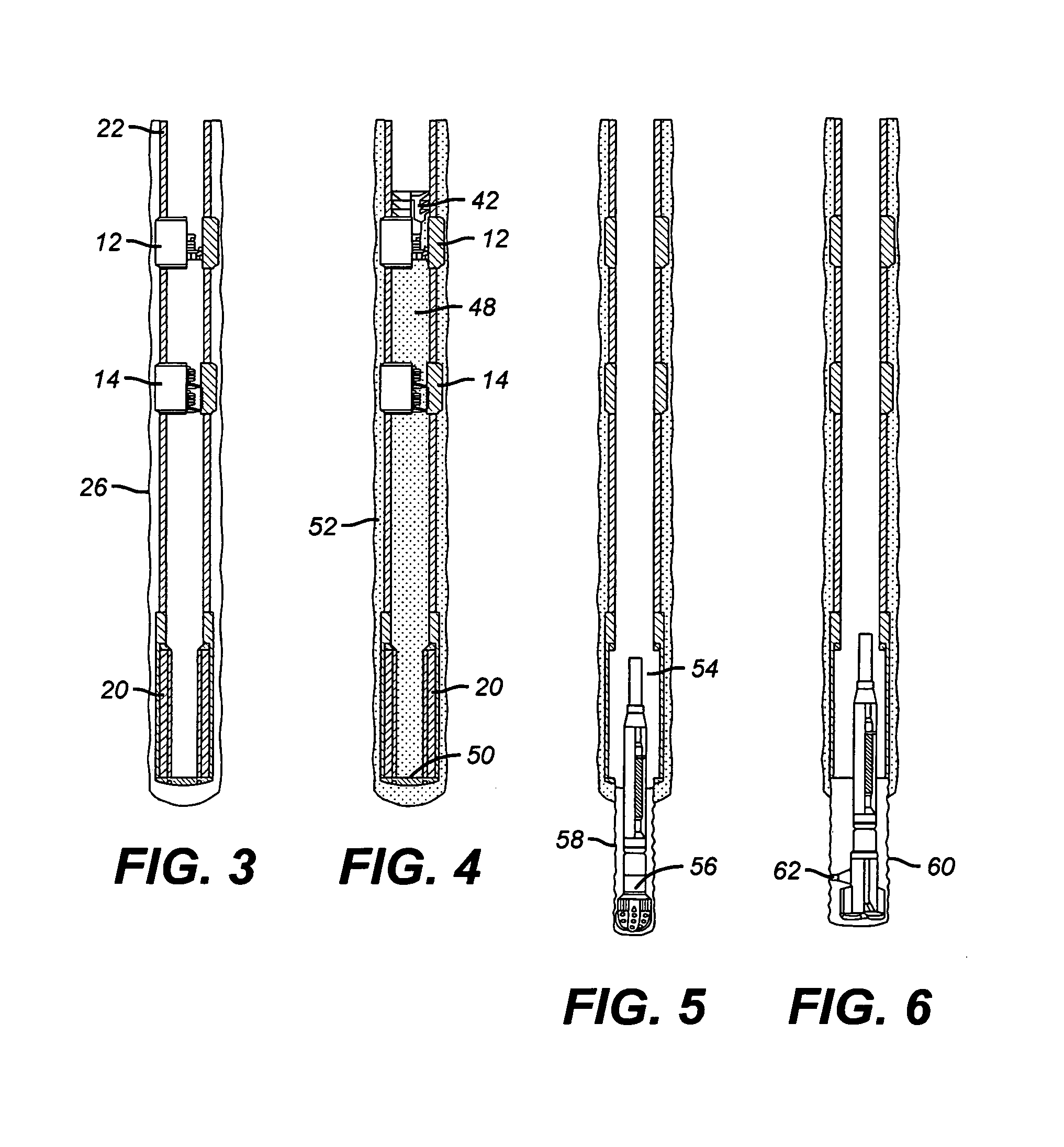

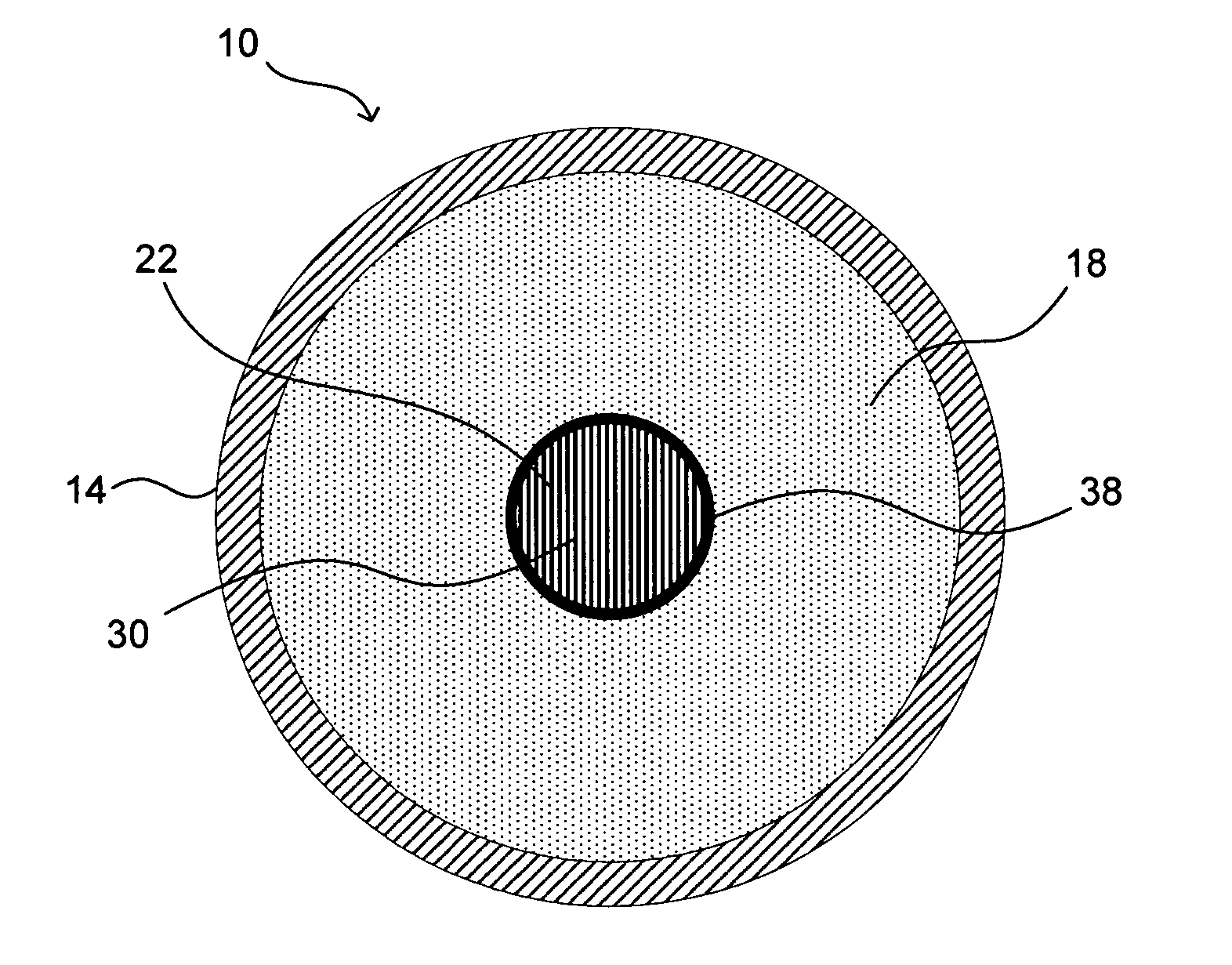

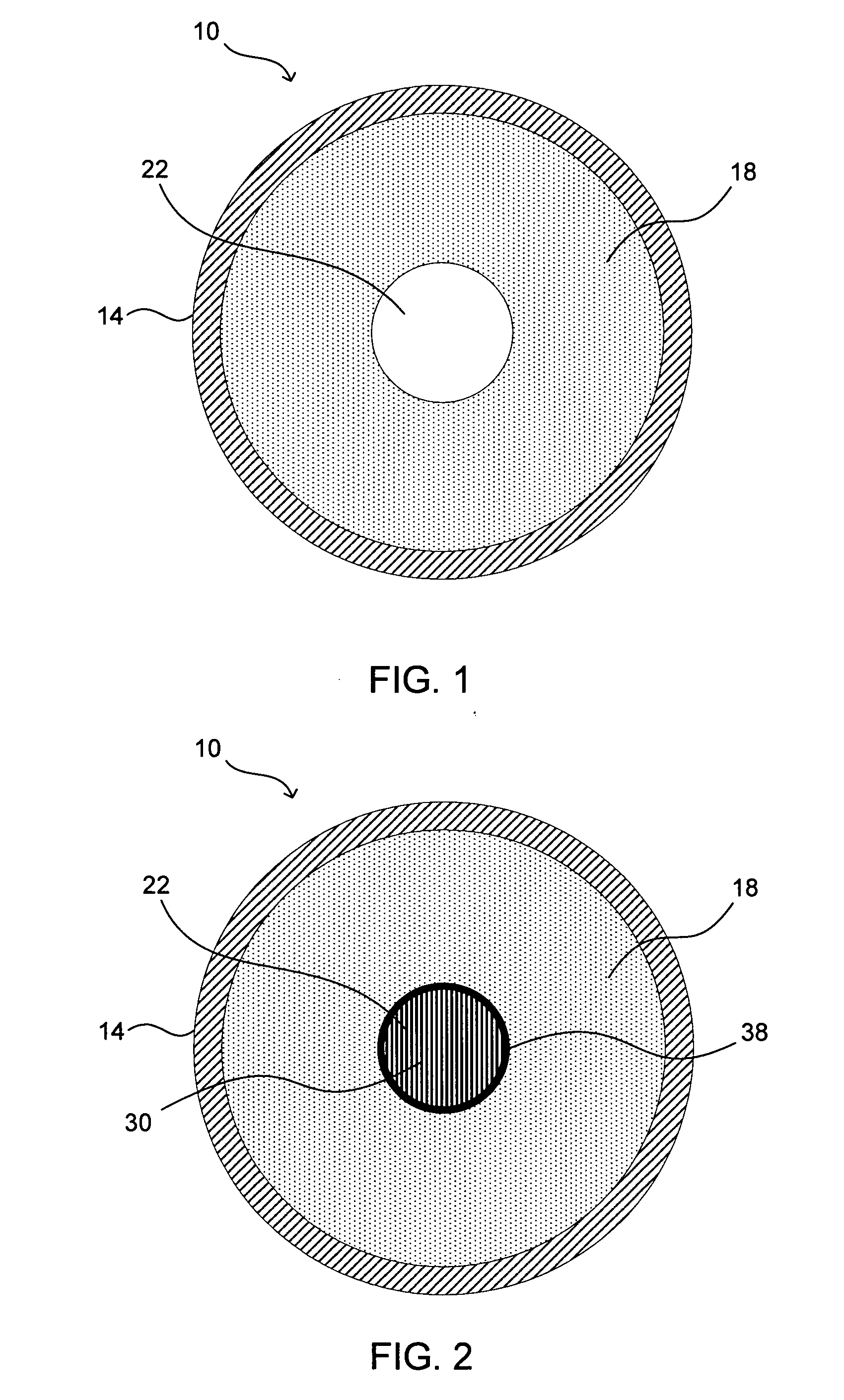

Optical fiber cable having a deformable coupling element

InactiveUS7639915B2Reduce collectionInhibitionGlass making apparatusFibre mechanical structuresThermal dilatationEngineering

Disclosed is an optical fiber cable that includes optical fibers and a deformable coupling element enclosed within a buffer tube. The coupling element is formed from a deformable yet substantially incompressible material that is capable of releasably and intermittently coupling the optical fibers to the buffer tube in various orientations. The design of the coupling element layer permits coupling of the optical fibers to the buffer tube without the use of a compressive cushioning layer and yet permits localized movement the optical fibers relative to the buffer tube to account for disparate thermal expansion and to accommodate optical fiber placement.

Owner:DRAKA COMTEQ BV

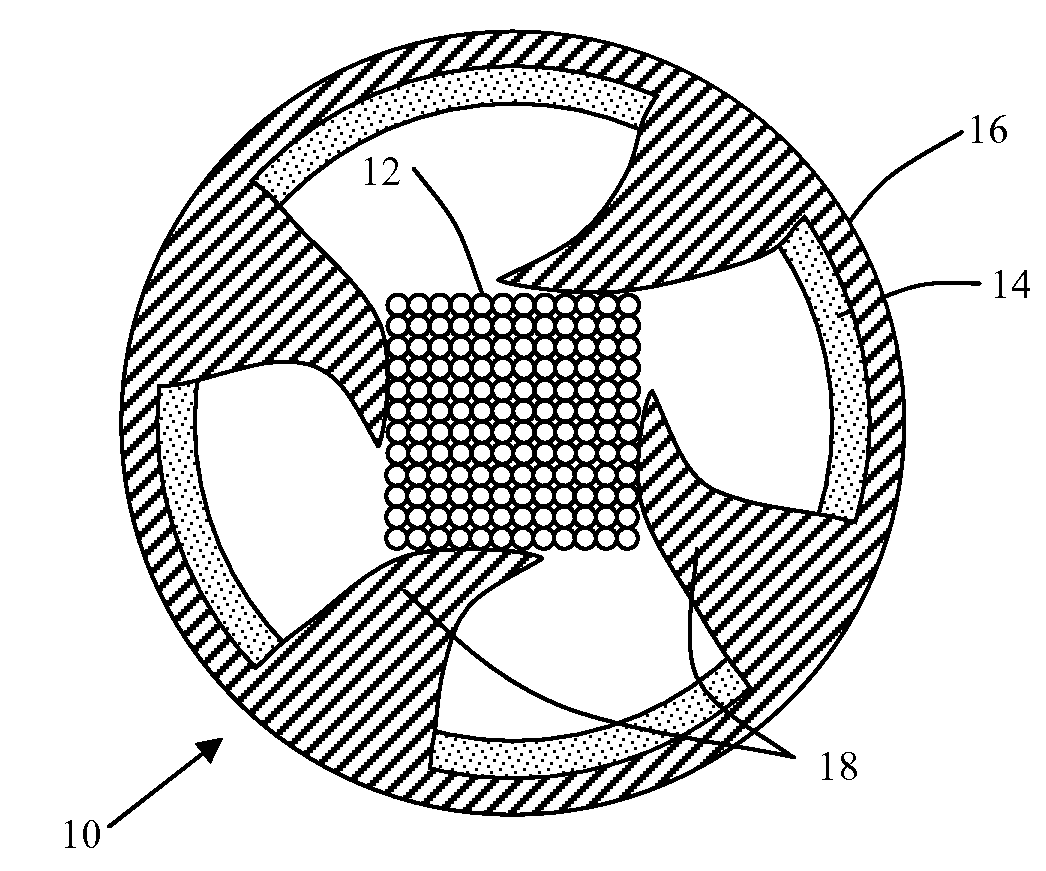

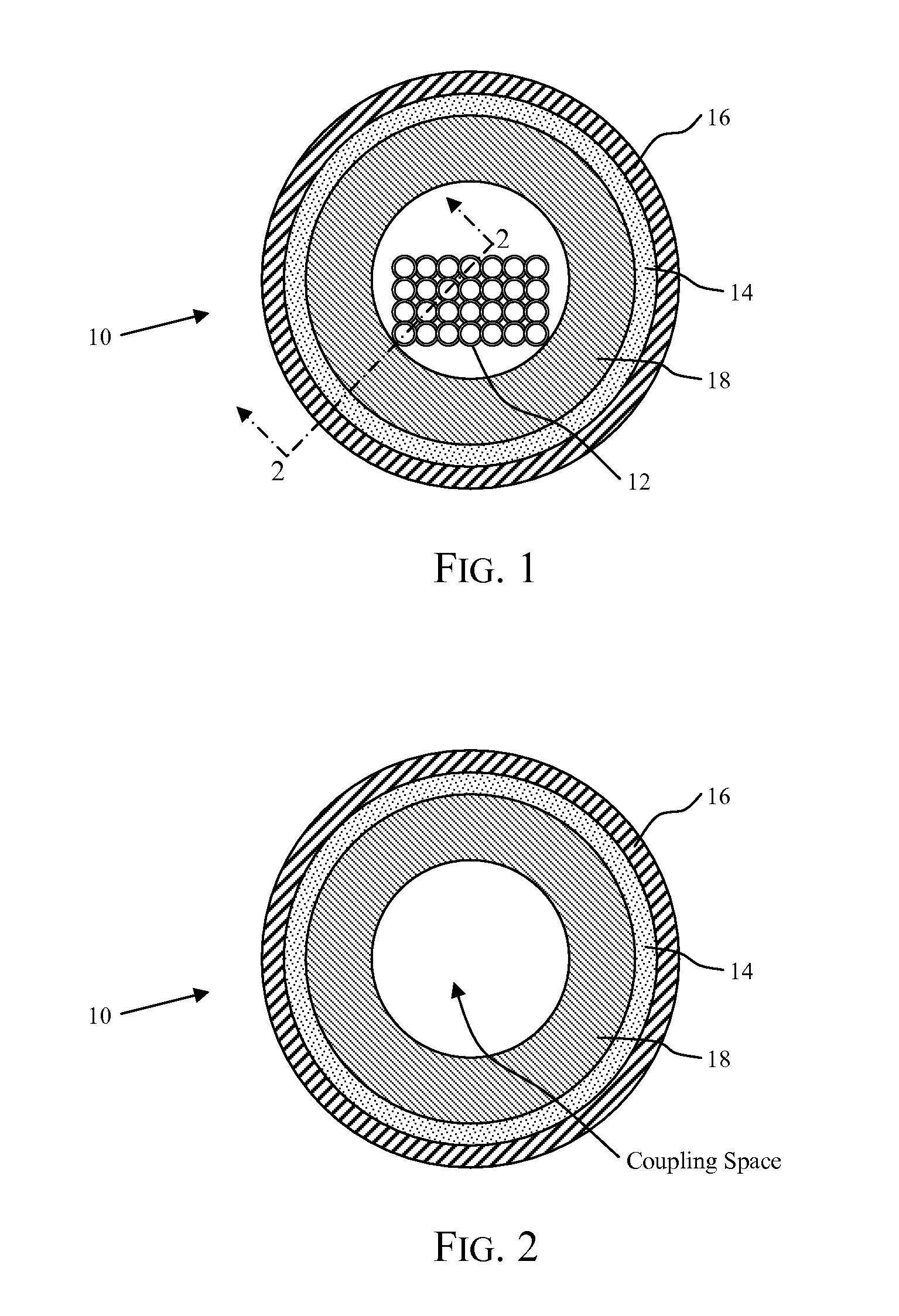

Optical fiber cable having raised coupling supports

InactiveUS7646952B2Limited amountInhibitionGlass making apparatusFibre mechanical structuresCouplingEngineering

Disclosed is an optical fiber cable that includes optical fibers and a deformable coupling element enclosed within a buffer tube. The coupling element is formed from a deformable yet substantially incompressible material and features a number of raised members projecting toward the optical fibers. The design of the coupling element layer permits coupling of the optical fibers to the buffer tube without the use of a compressive cushioning layer. This arrangement distributes the compressive force applied to discrete points along the outer perimeter of the optical fiber element.

Owner:DRAKA COMTEQ BV

Optical Fiber Cable Having A Deformable Coupling Element

InactiveUS20090003781A1Reduce collectionInhibitionGlass making apparatusFibre mechanical structuresThermal dilatationEngineering

Disclosed is an optical fiber cable that includes optical fibers and a deformable coupling element enclosed within a buffer tube. The coupling element is formed from a deformable yet substantially incompressible material that is capable of releasably and intermittently coupling the optical fibers to the buffer tube in various orientations. The design of the coupling element layer permits coupling of the optical fibers to the buffer tube without the use of a compressive cushioning layer and yet permits localized movement the optical fibers relative to the buffer tube to account for disparate thermal expansion and to accommodate optical fiber placement.

Owner:DRAKA COMTEQ BV

Optical Fiber Cable Having Raised Coupling Supports

InactiveUS20090003779A1Limited amountInhibitionGlass making apparatusFibre mechanical structuresCouplingEngineering

Disclosed is an optical fiber cable that includes optical fibers and a deformable coupling element enclosed within a buffer tube. The coupling element is formed from a deformable yet substantially incompressible material and features a number of raised members projecting toward the optical fibers. The design of the coupling element layer permits coupling of the optical fibers to the buffer tube without the use of a compressive cushioning layer. This arrangement distributes the compressive force applied to discrete points along the outer perimeter of the optical fiber element.

Owner:DRAKA COMTEQ BV

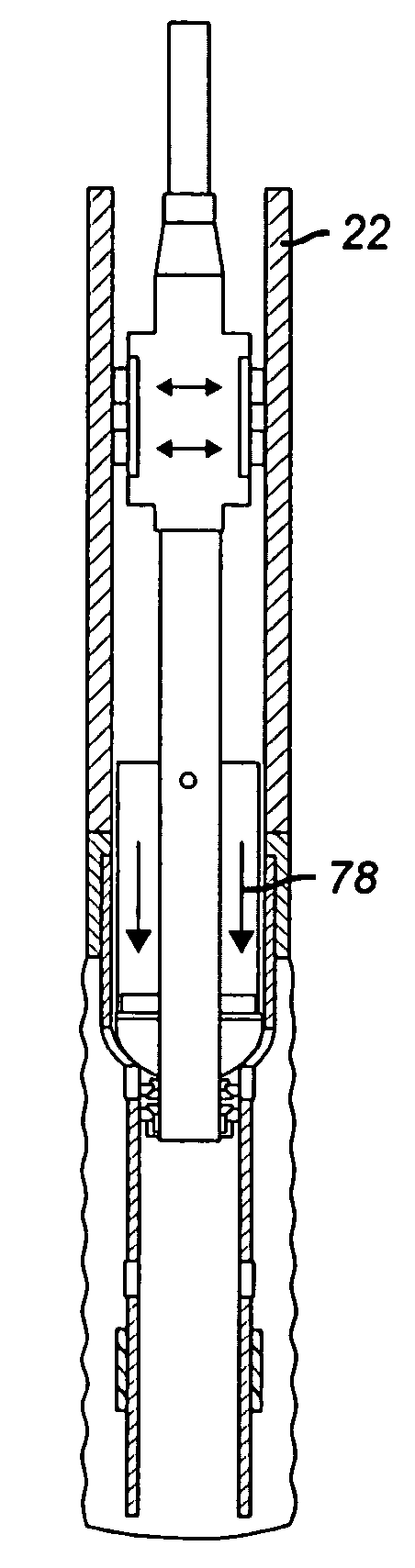

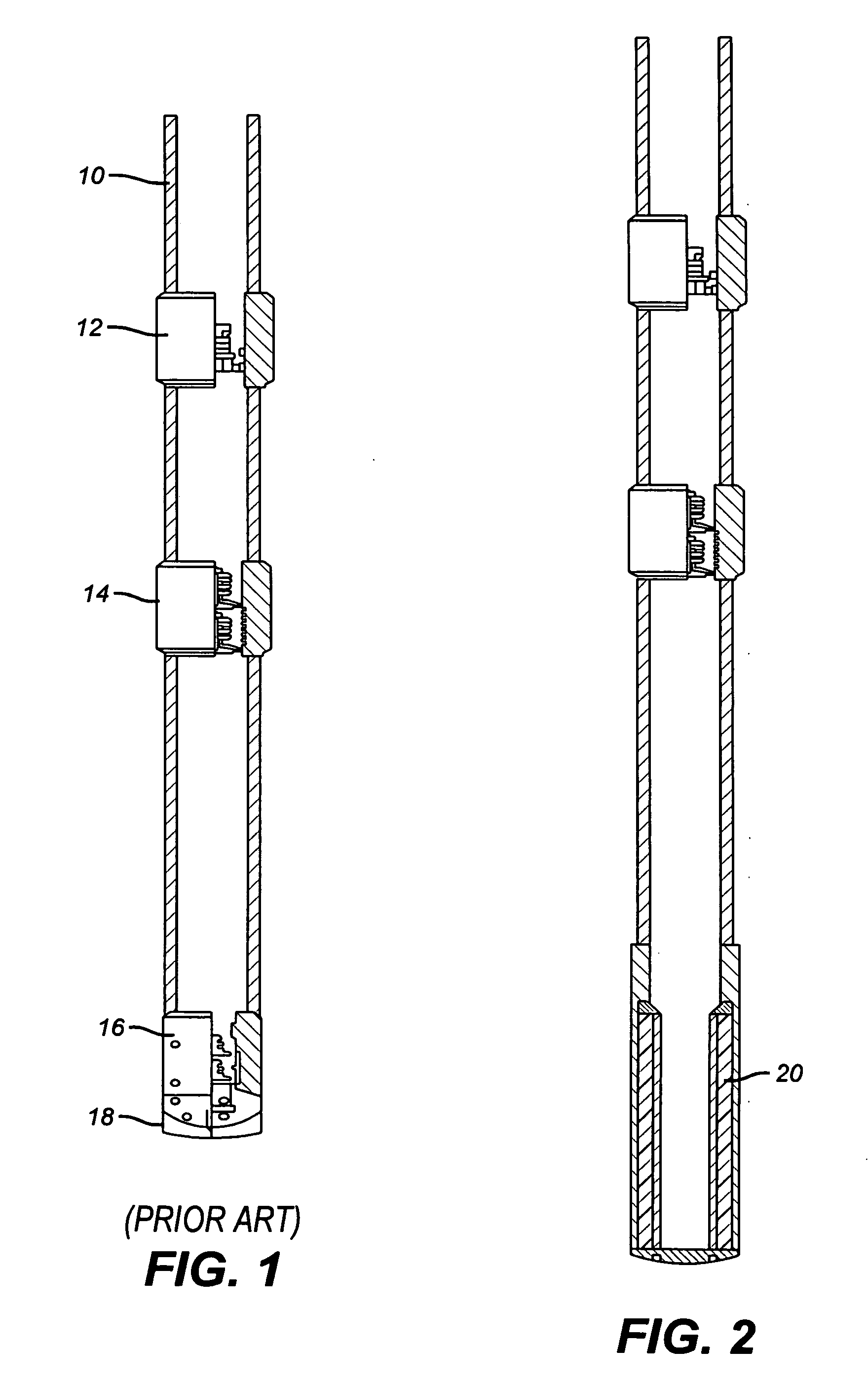

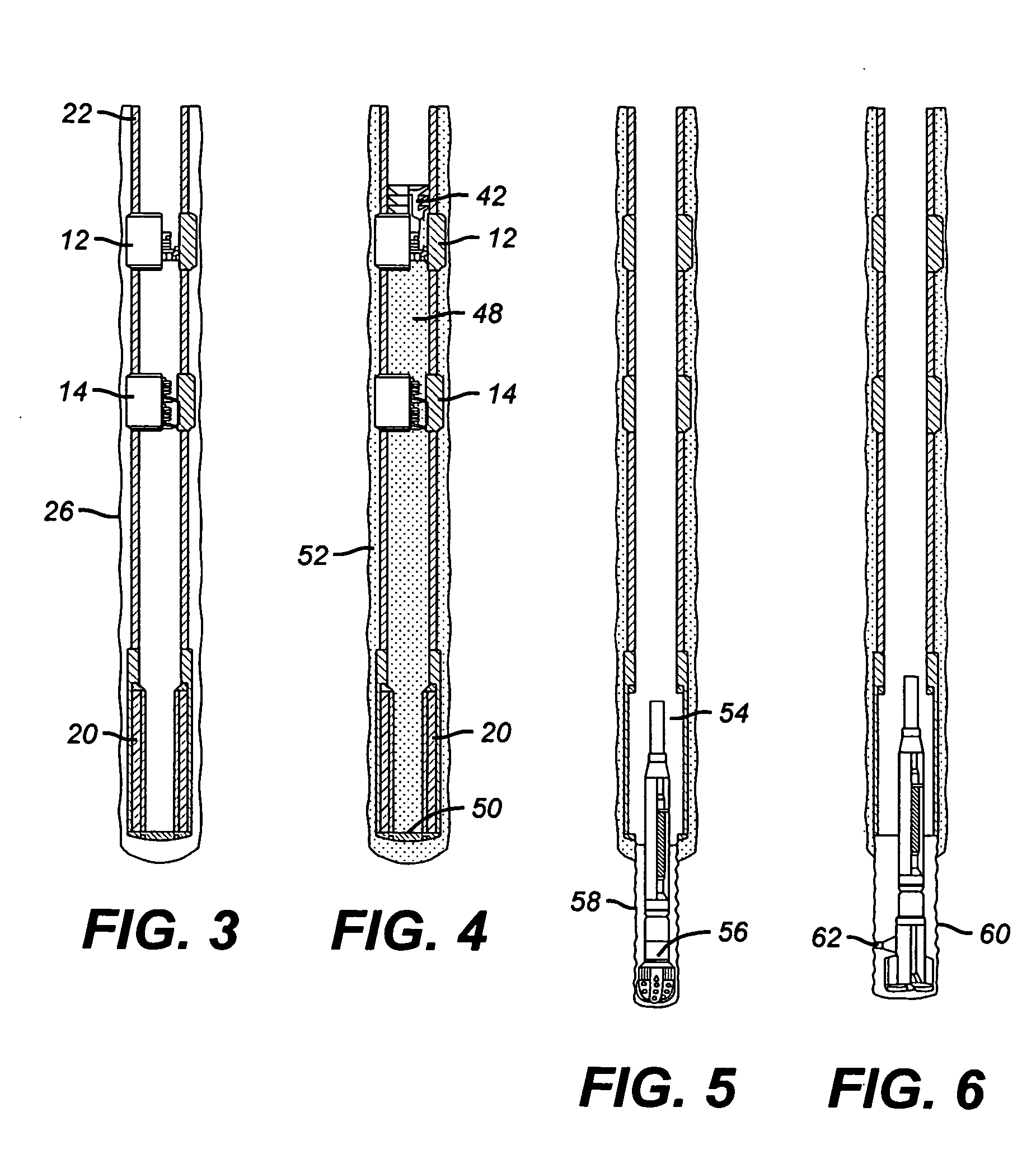

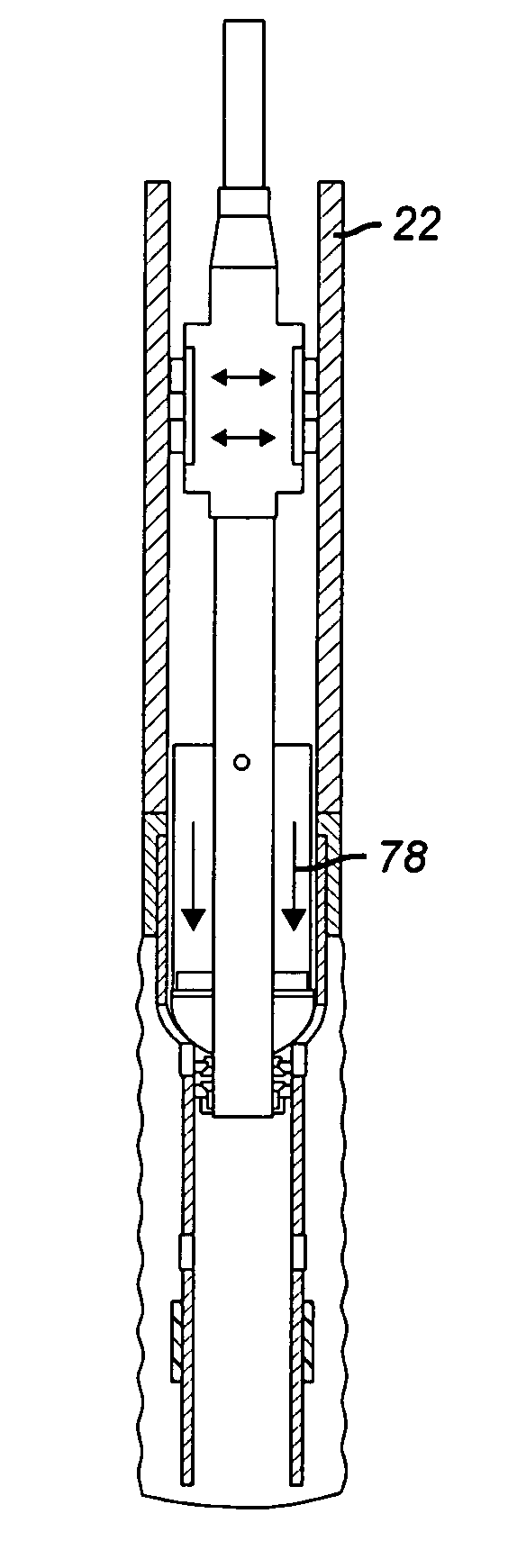

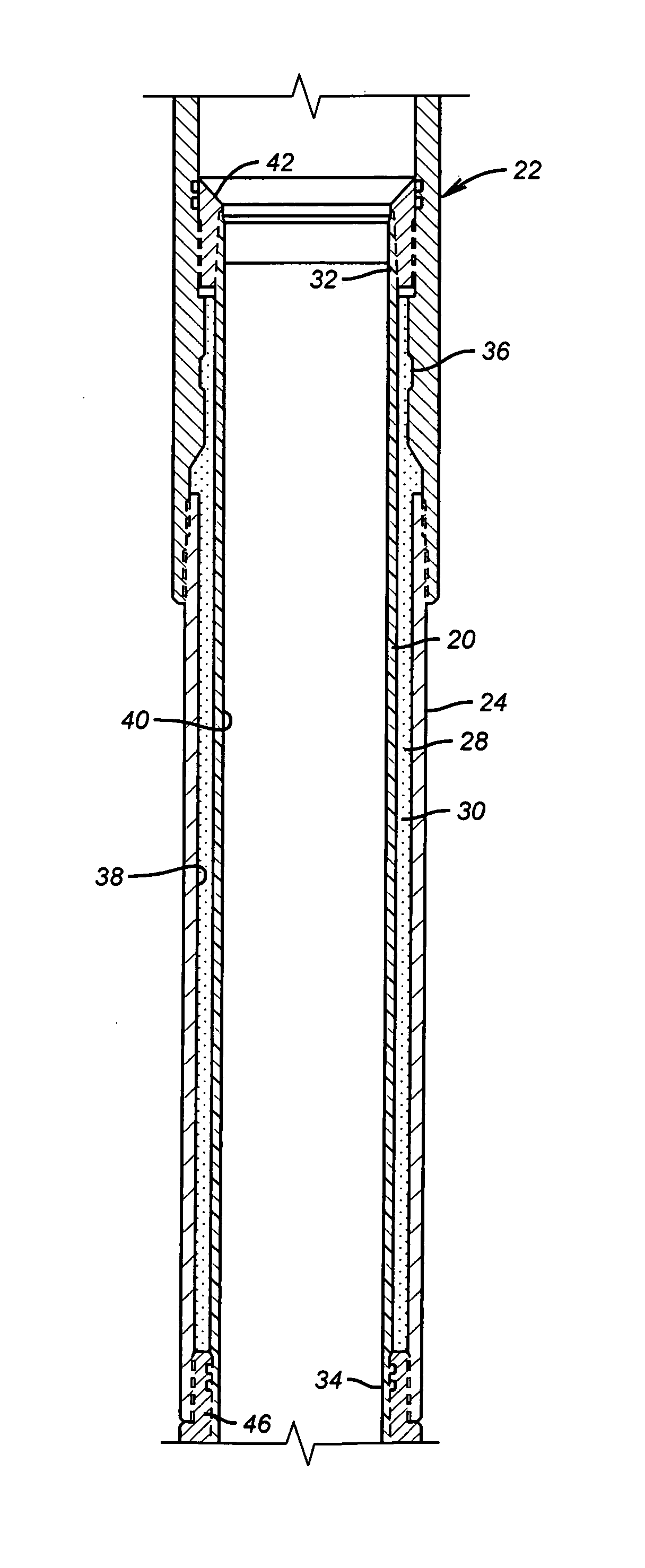

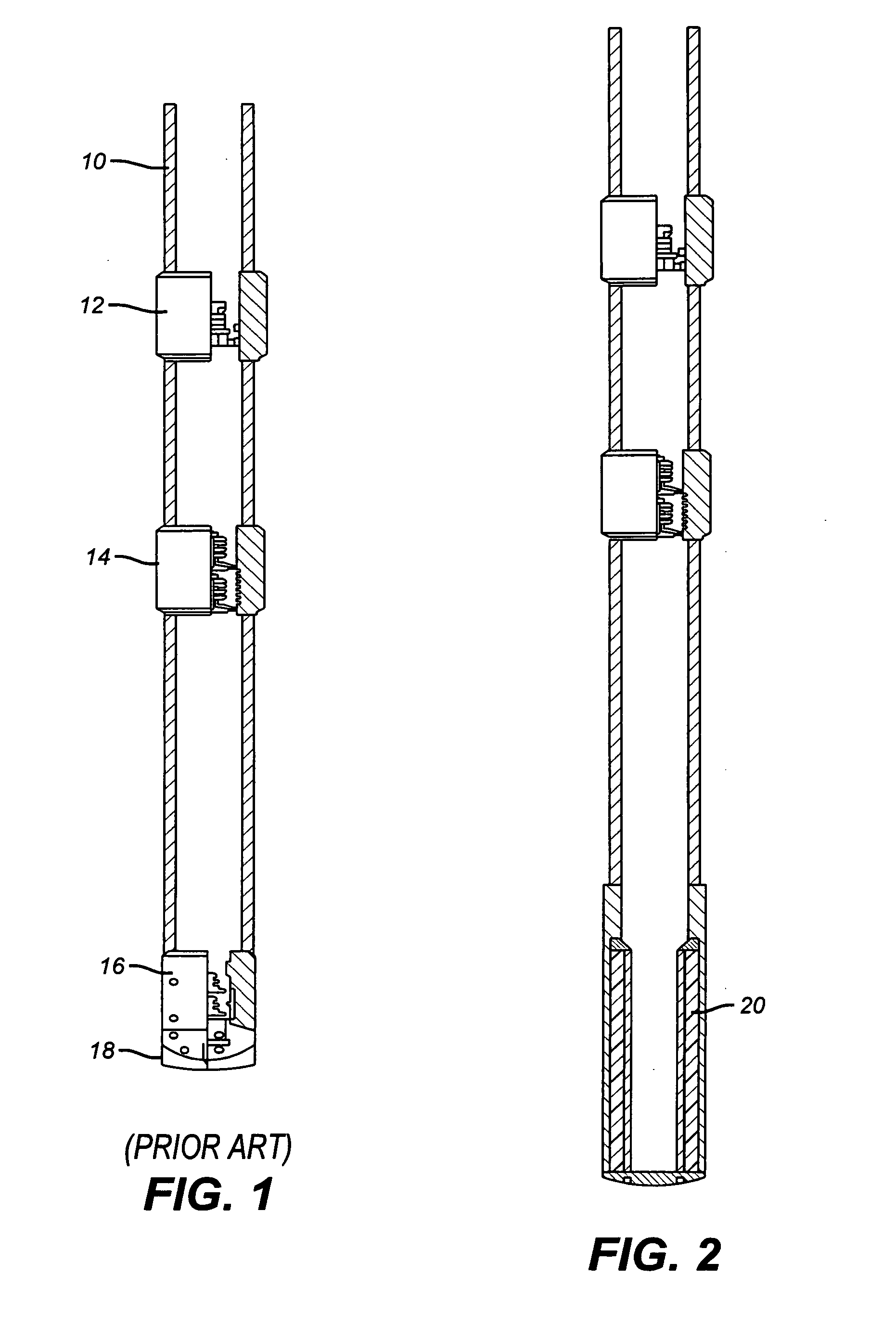

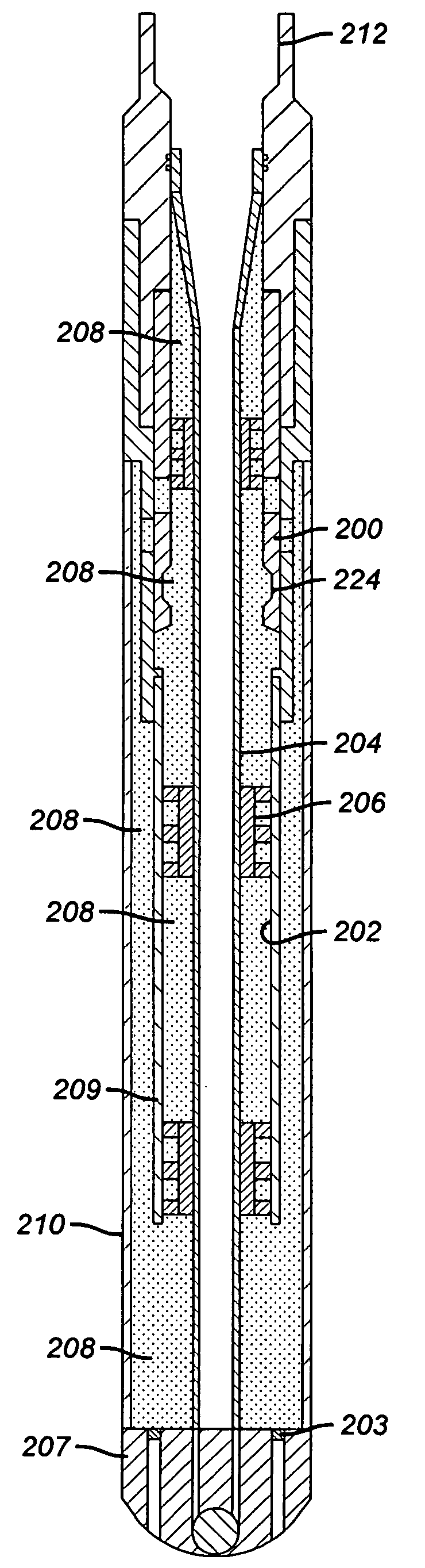

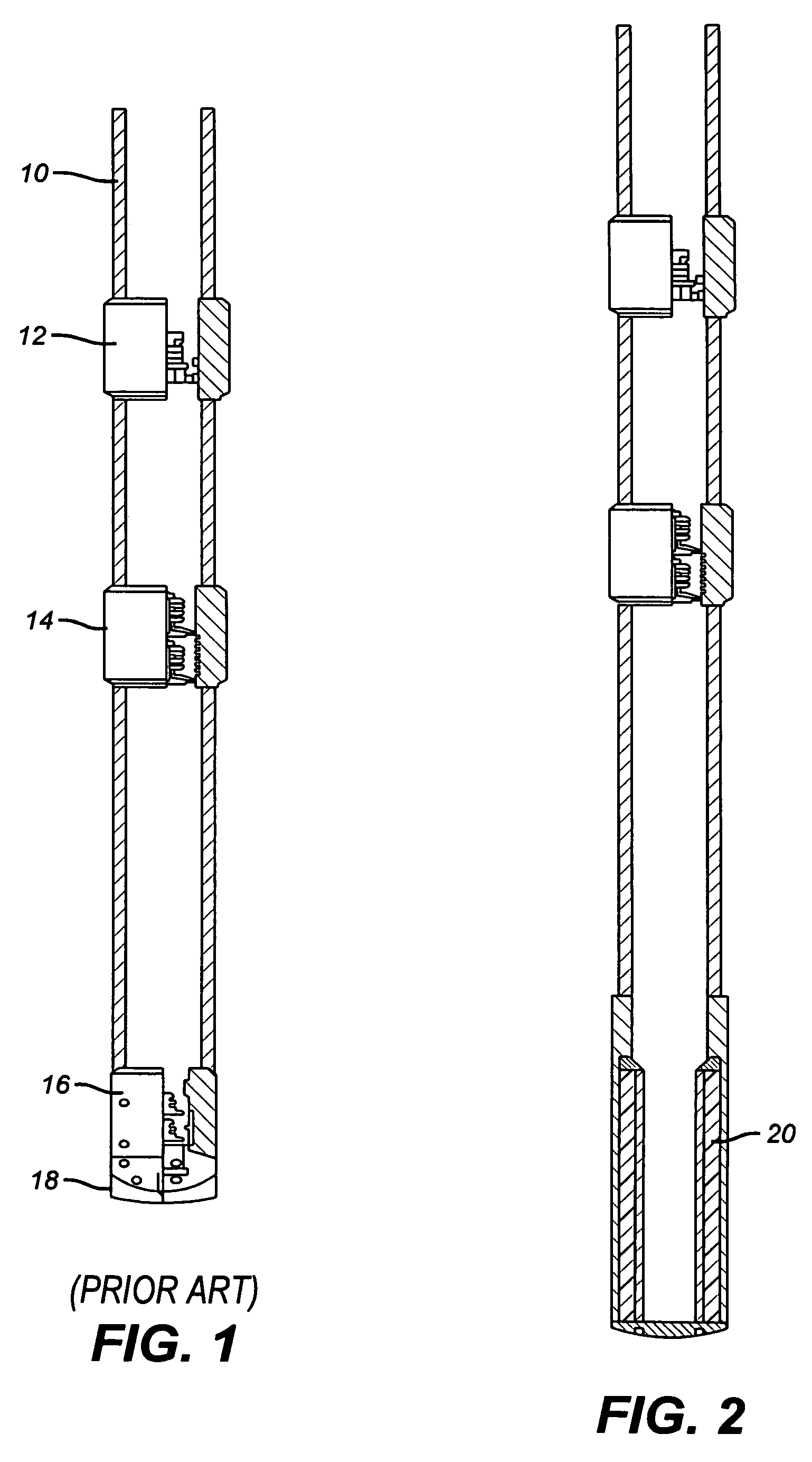

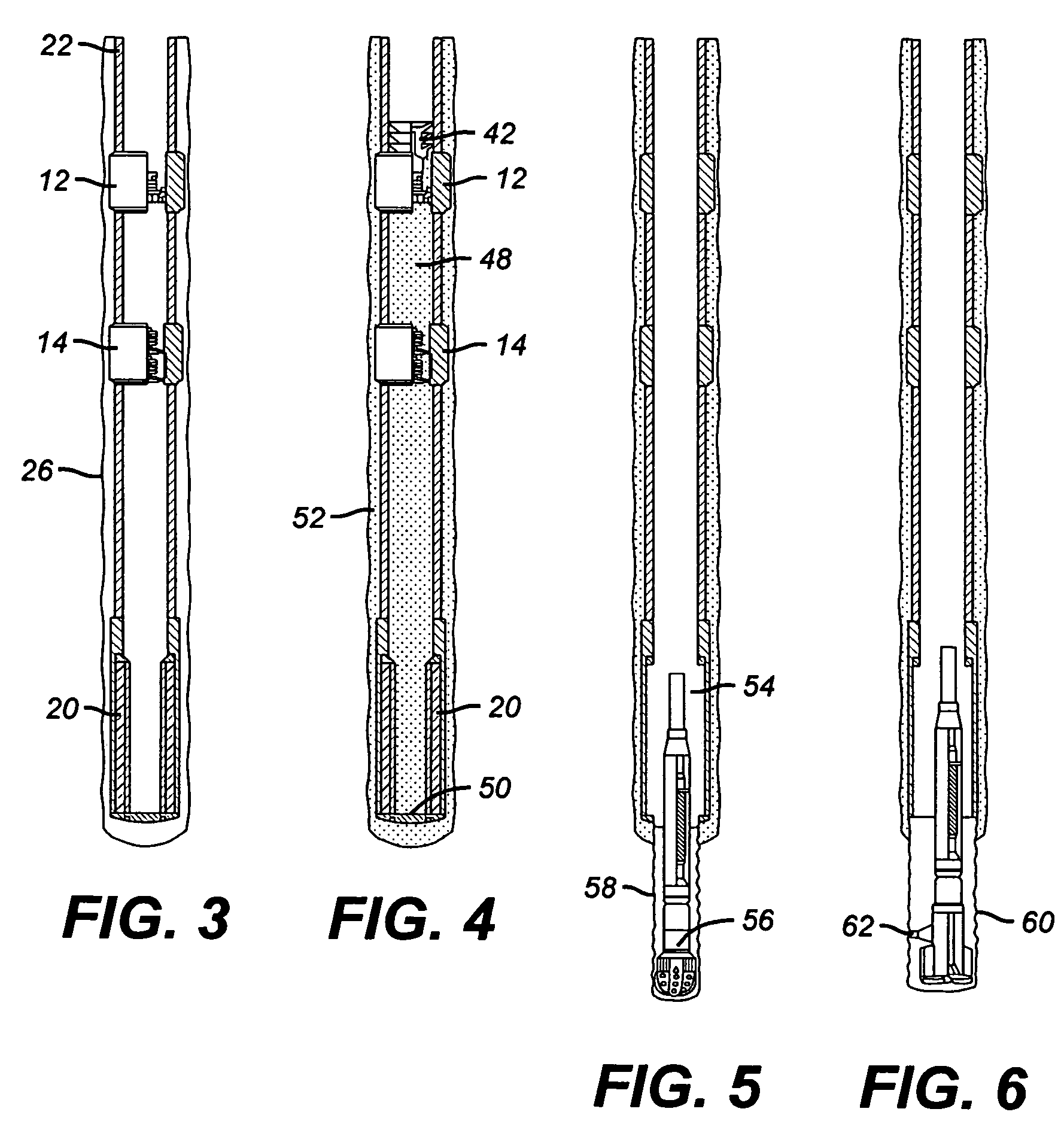

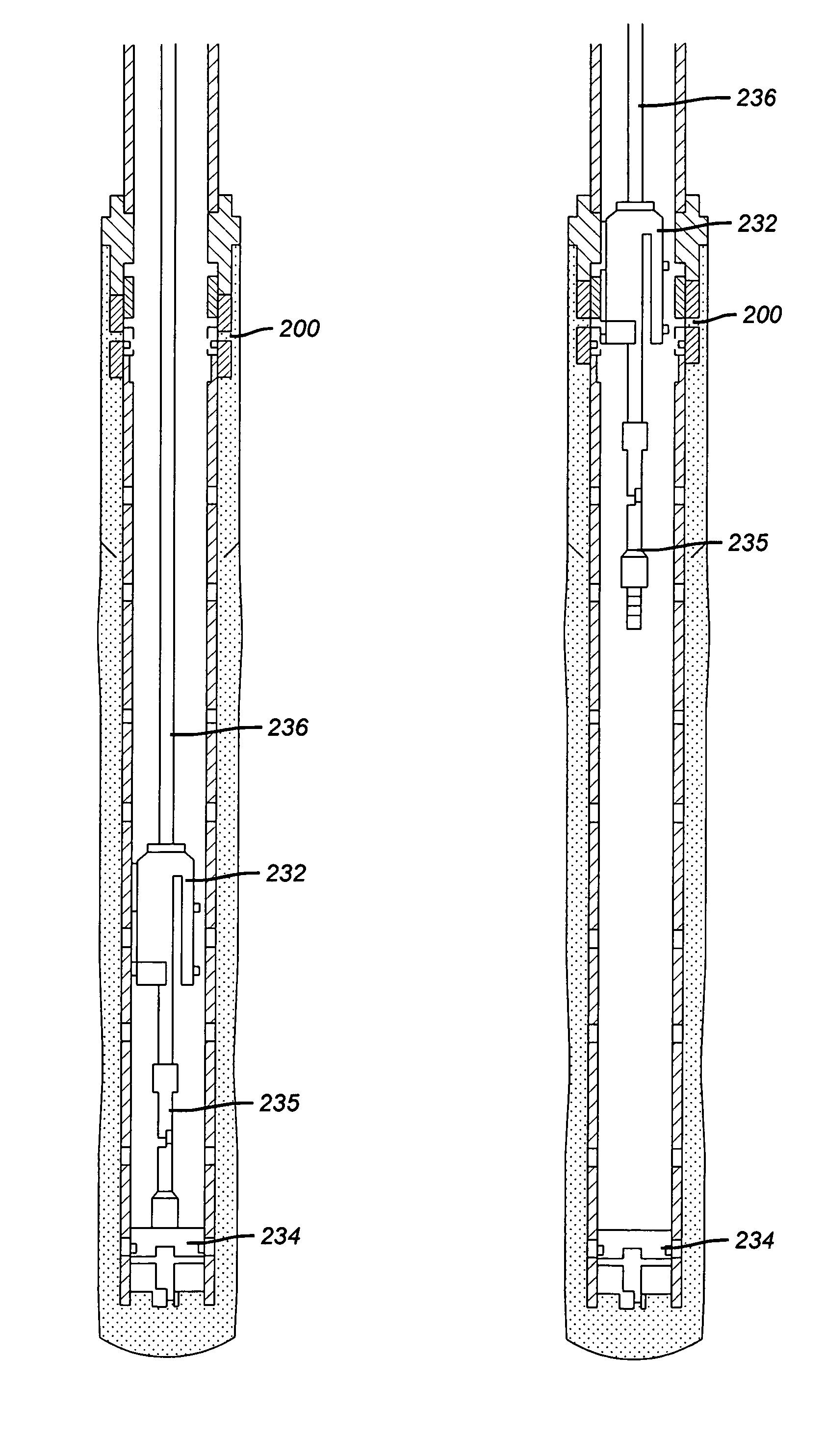

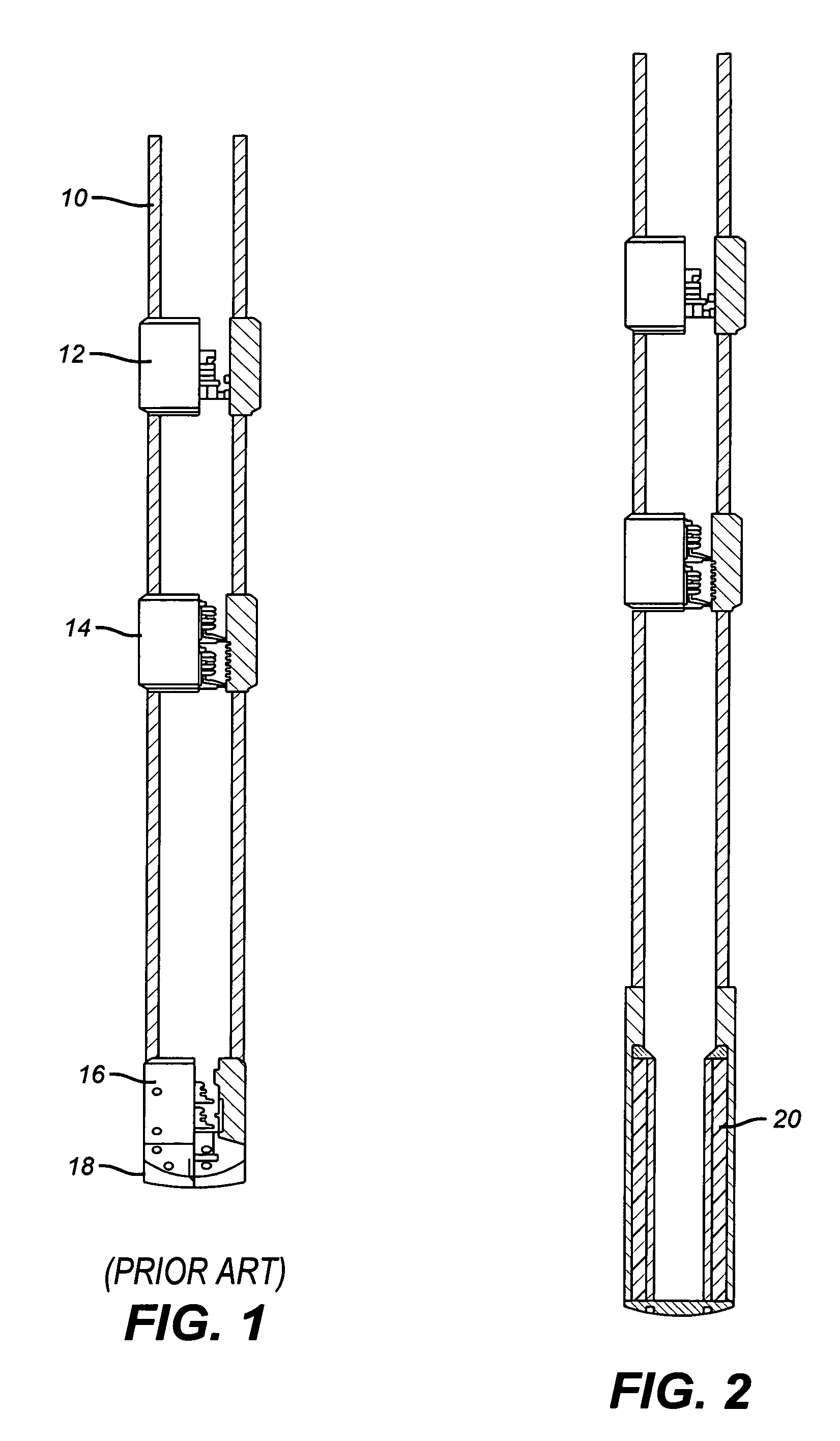

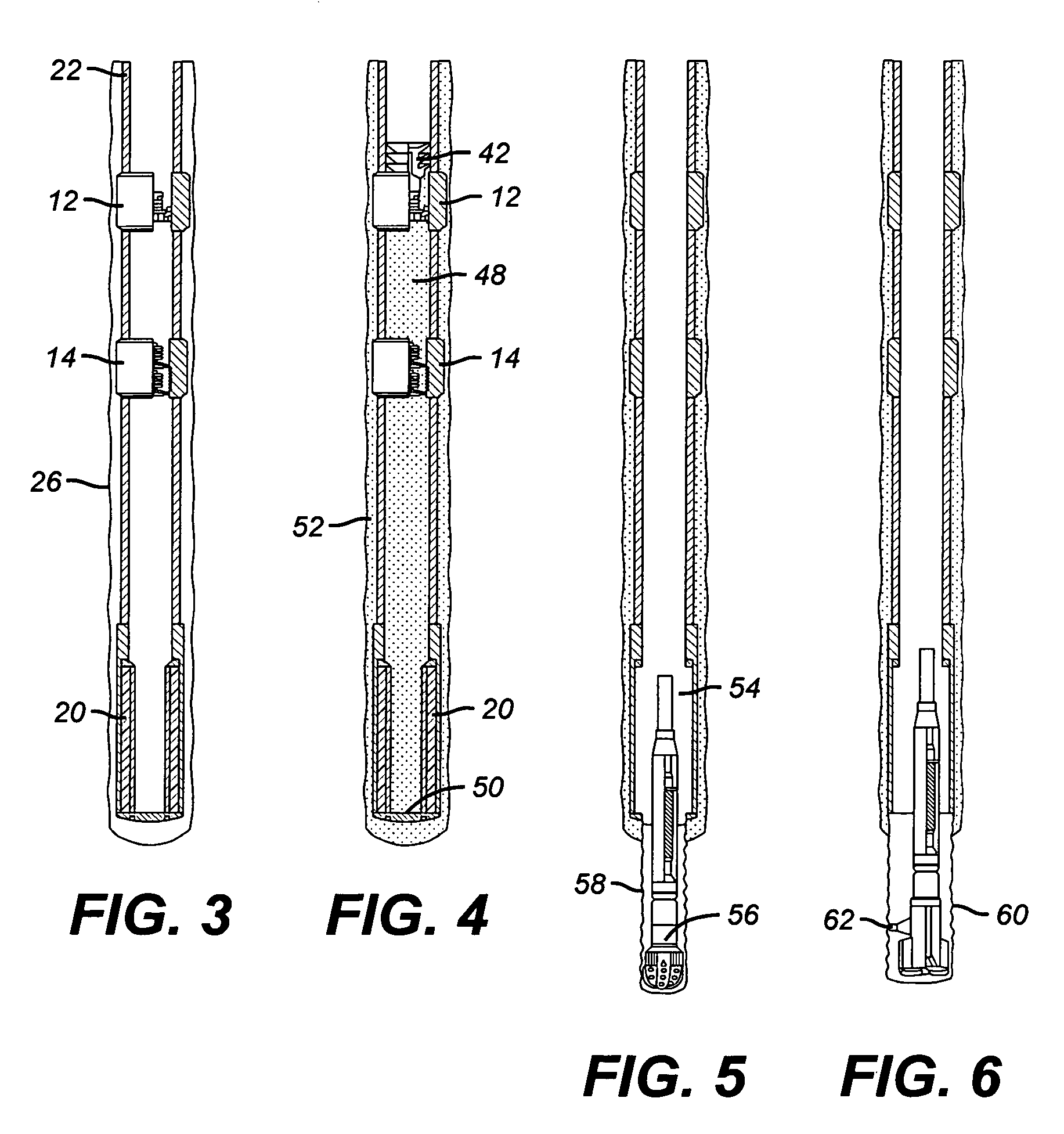

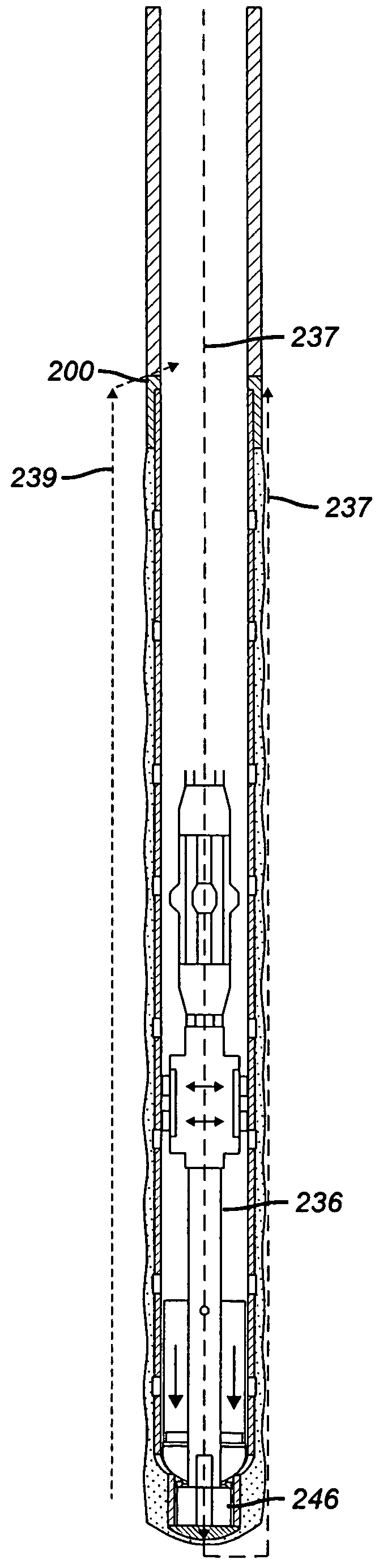

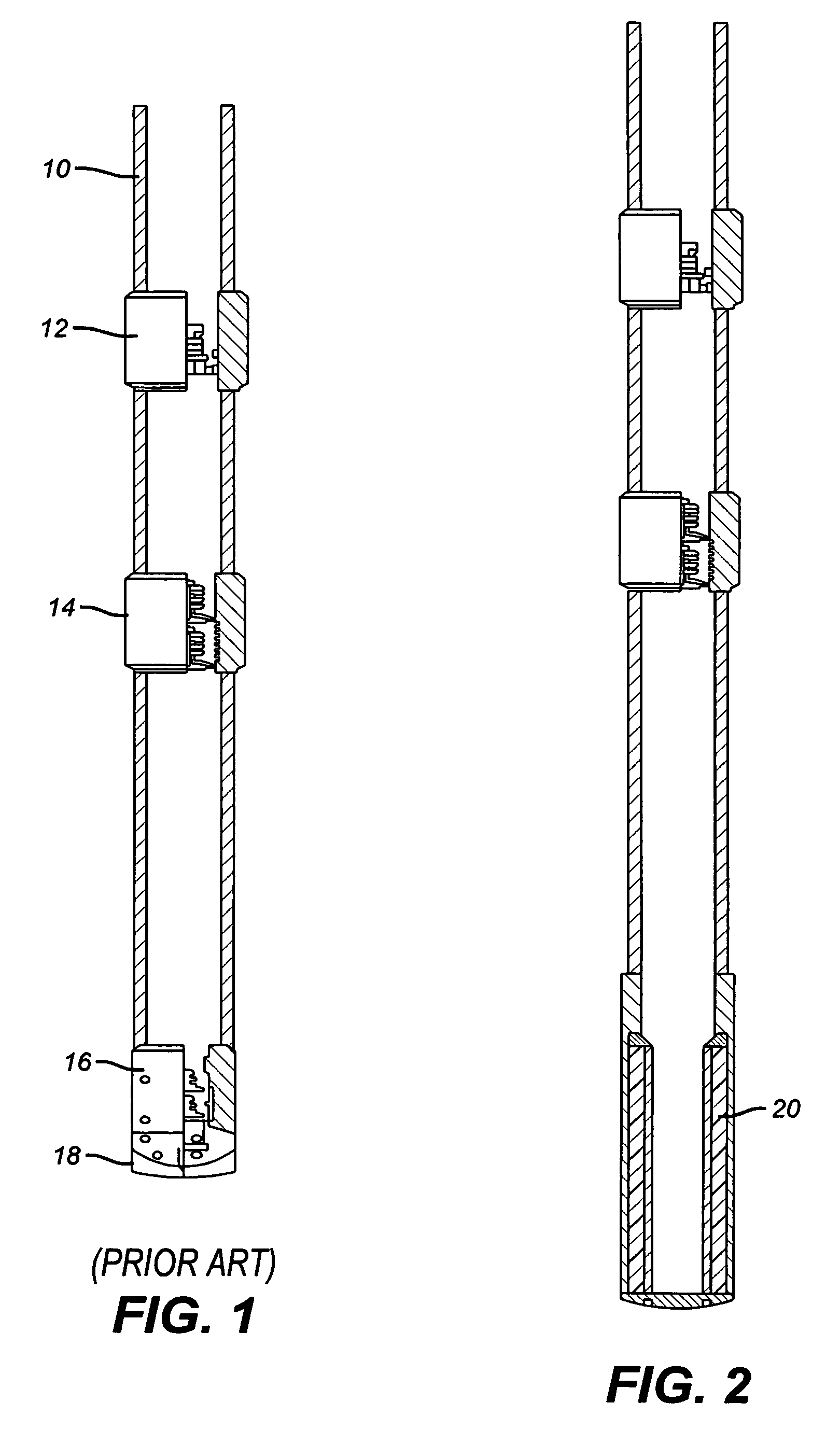

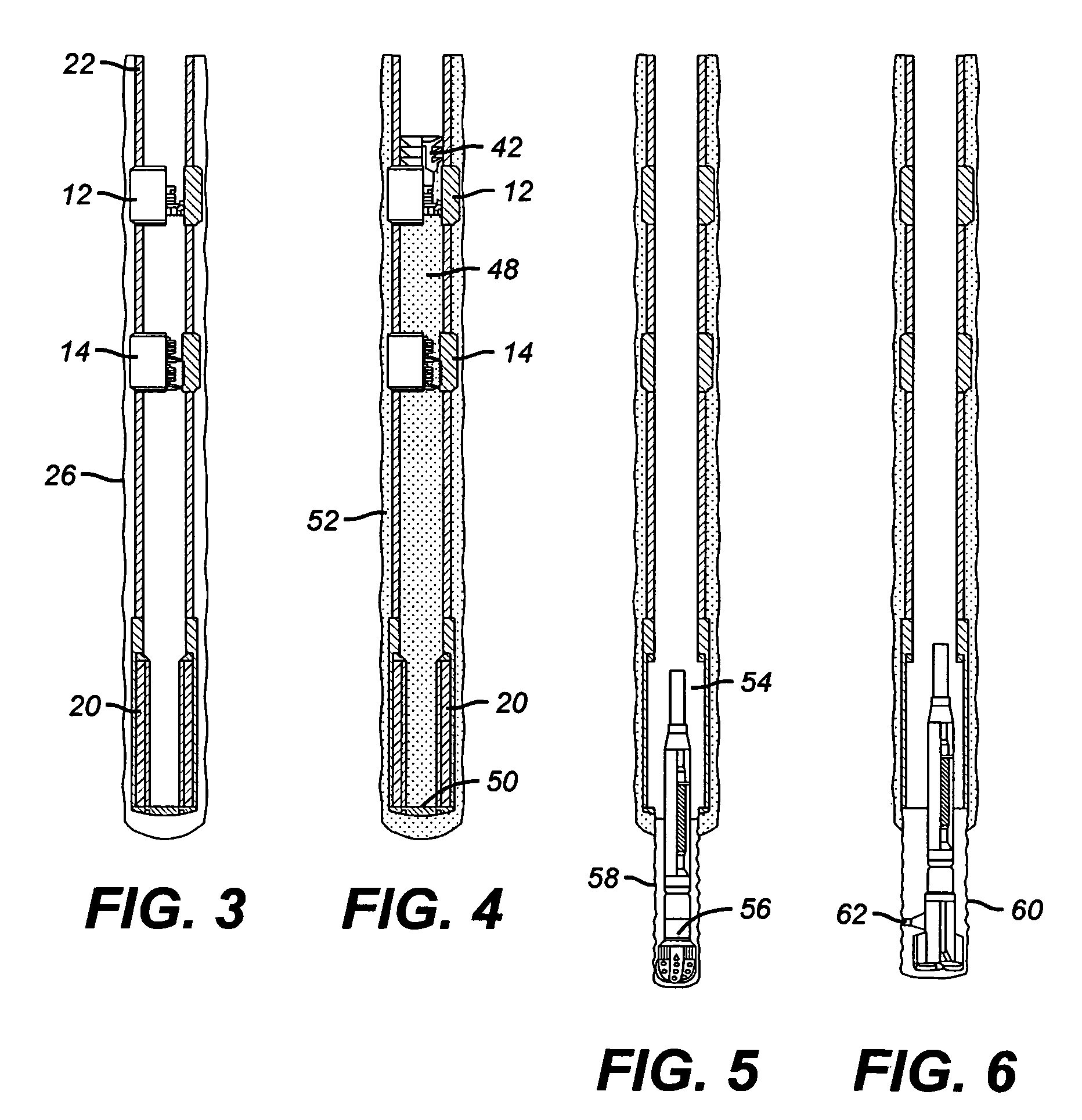

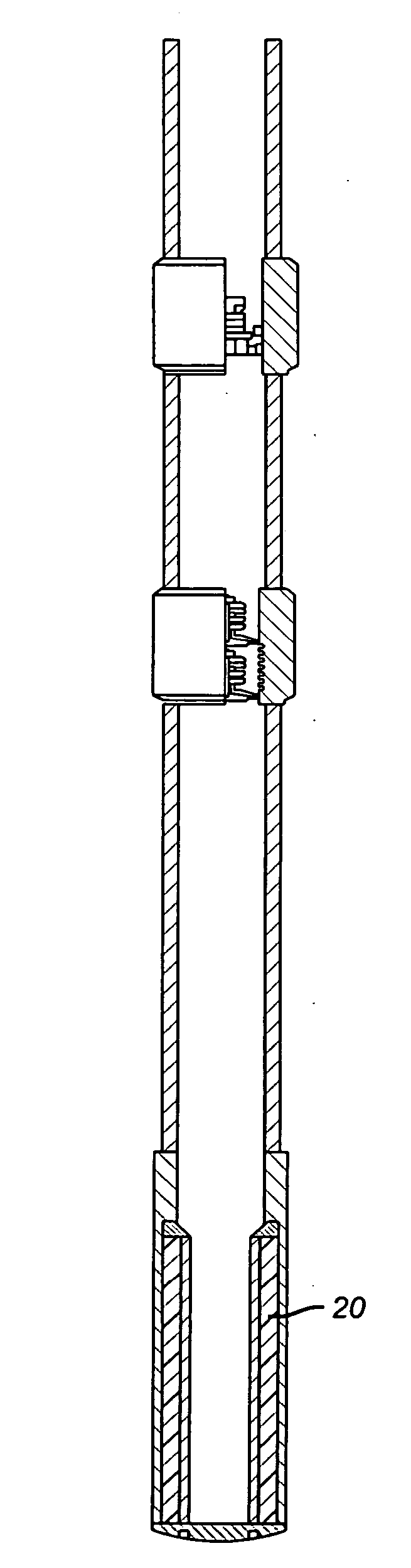

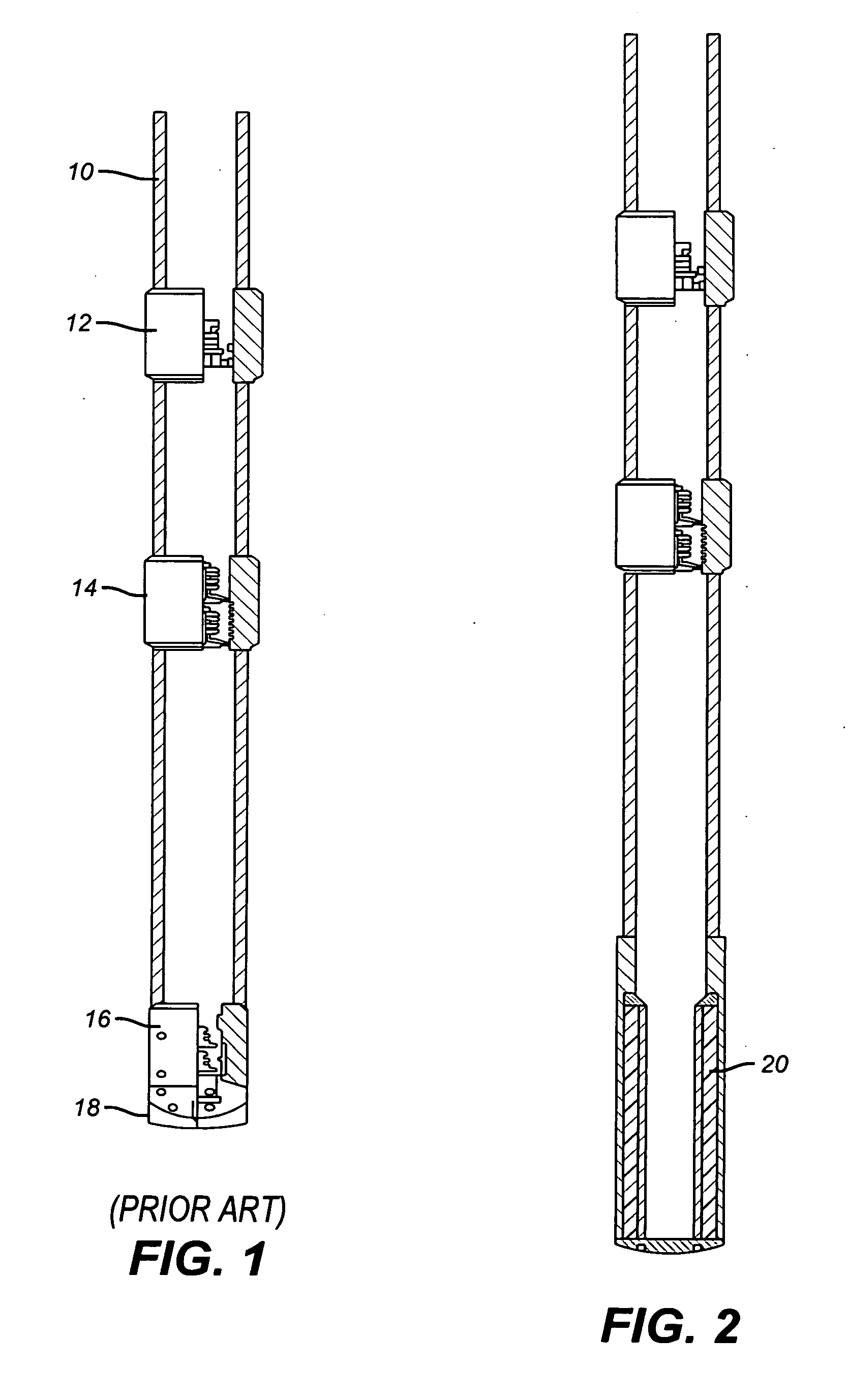

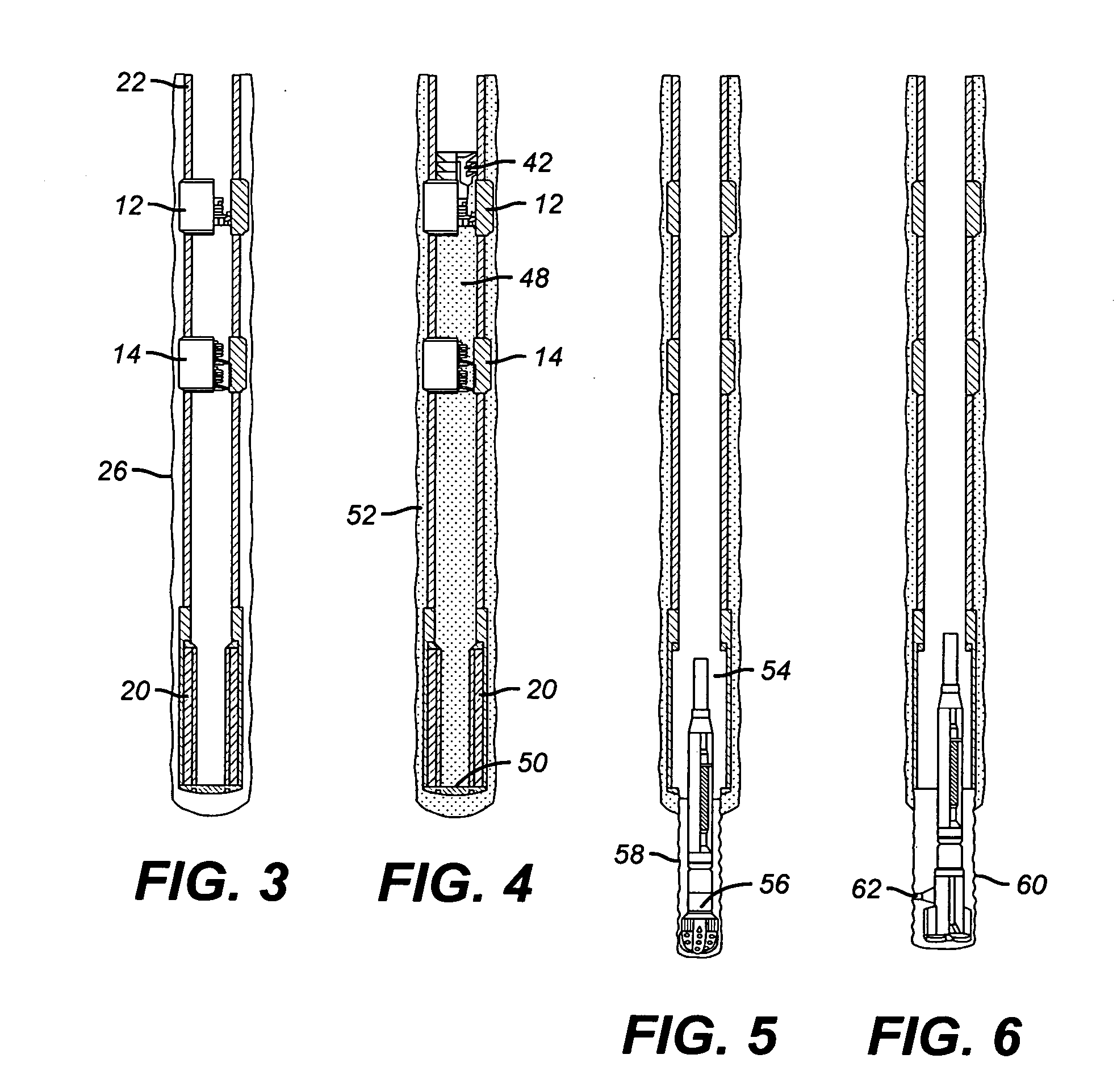

One trip cemented expandable monobore liner system and method

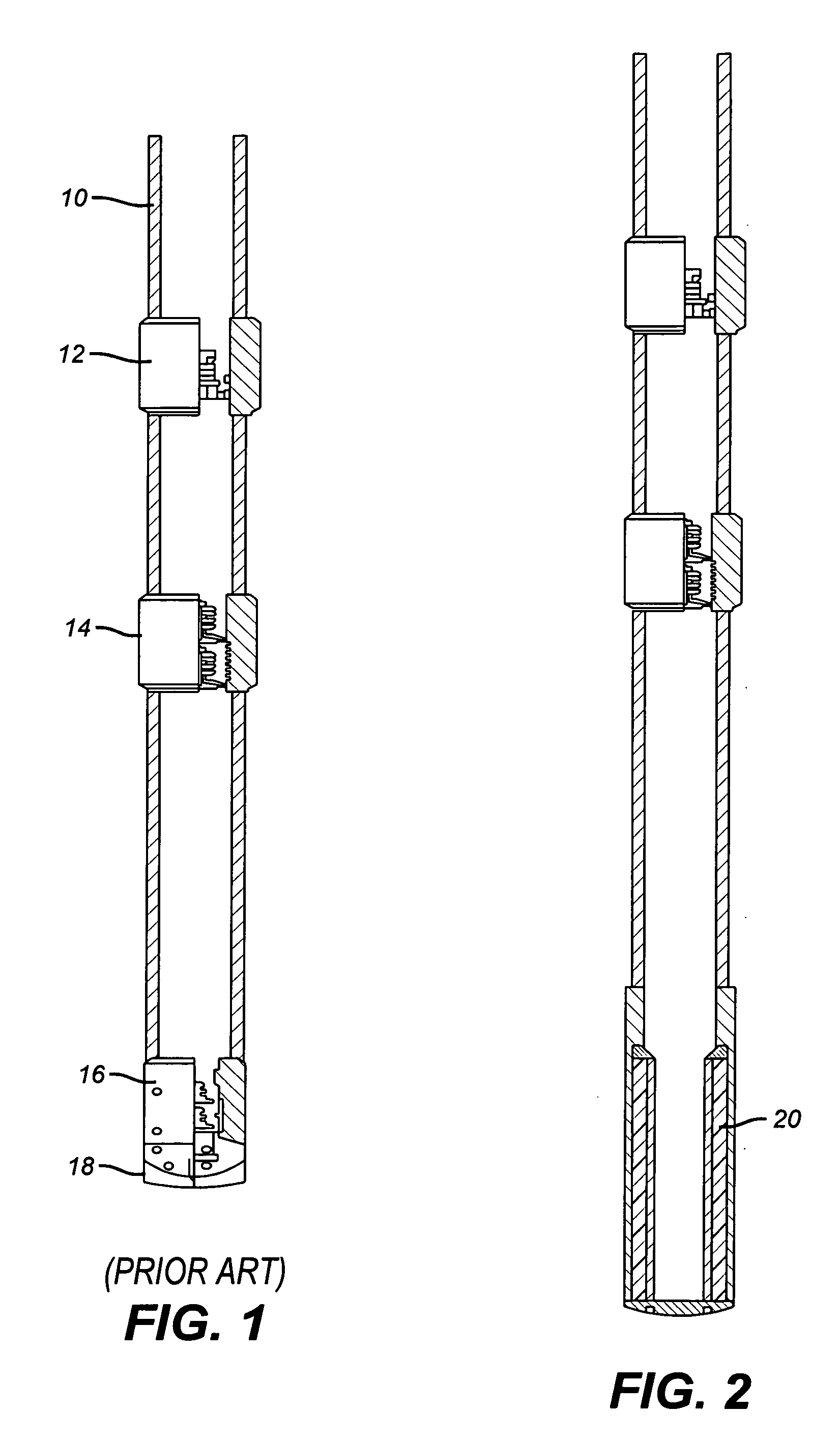

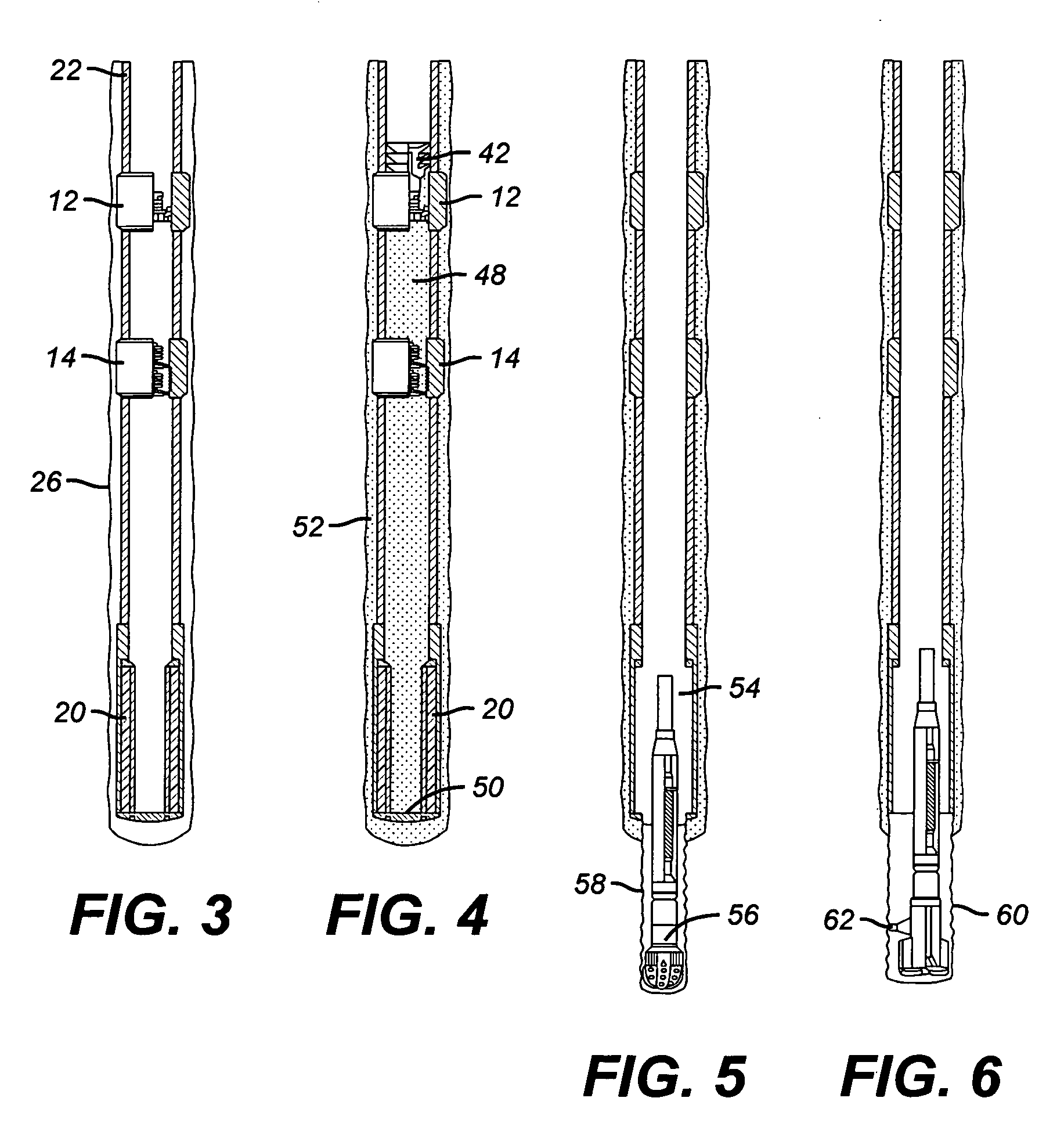

An apparatus to protect the mounting area of casing and a locating profile and optionally a sliding sleeve valve and a flow path from the outside of the valve to the annulus when subsequent attachment of an expanded liner is intended and the expanded liner is to be cemented in place. A barrier sleeve, nose, and outer sleeve define a sealed cavity having a loose incompressible material inside that covers the mounting location on the casing. A locating profile and an optional sliding sleeve valve and a flow path from the outside of the valve to the annulus can be provided. The cementing of the casing takes place through the barrier sleeve. After the cementing, the sleeve and nose are drilled out and the incompressible material is removed to the surface with the drill cuttings. A liner is inserted in the casing and is preferably expanded into sealing contact with the mounting location on the casing. After expansion a cement retainer positioned at the bottom of the expanded liner and the sliding sleeve located either above the mounting location of the liner in the casing shoe or in the liner below the mounted top section allow cement to be delivered outside the expanded liner and the displaced wellbore fluid to return into the casing through so that the liner can be cemented. The cement retainer can be delivered with either the liner or the expansion tools to allow expansion and cementing in a single trip. A shifting tool can be run on the expansion string to actuate the sliding sleeve and if necessary to allow for cement to be pumped from the drill string into the annulus through the sliding sleeve. The cement retainer can be milled out in a separate trip.

Owner:BAKER HUGHES INC

One trip cemented expandable monobore liner system and method

An apparatus to protect the mounting area of casing and a locating profile and optionally a sliding sleeve valve and a flow path from the outside of the valve to the annulus when subsequent attachment of an expanded liner is intended and the expanded liner is to be cemented in place. A barrier sleeve, nose, and outer sleeve define a sealed cavity having a loose incompressible material inside that covers the mounting location on the casing. A locating profile and an optional sliding sleeve valve and a flow path from the outside of the valve to the annulus can be provided. The cementing of the casing takes place through the barrier sleeve. After the cementing, the sleeve and nose are drilled out and the incompressible material is removed to the surface with the drill cuttings. A liner is inserted in the casing and is preferably expanded into sealing contact with the mounting location on the casing. After expansion a cement retainer positioned at the bottom of the expanded liner and the sliding sleeve located either above the mounting location of the liner in the casing shoe or in the liner below the mounted top section allow cement to be delivered outside the expanded liner and the displaced wellbore fluid to return into the casing through so that the liner can be cemented. The cement retainer can be delivered with either the liner or the expansion tools to allow expansion and cementing in a single trip. A shifting tool can be run on the expansion string to actuate the sliding sleeve and if necessary to allow for cement to be pumped from the drill string into the annulus through the sliding sleeve. The cement retainer can be milled out in a separate trip.

Owner:BAKER HUGHES INC

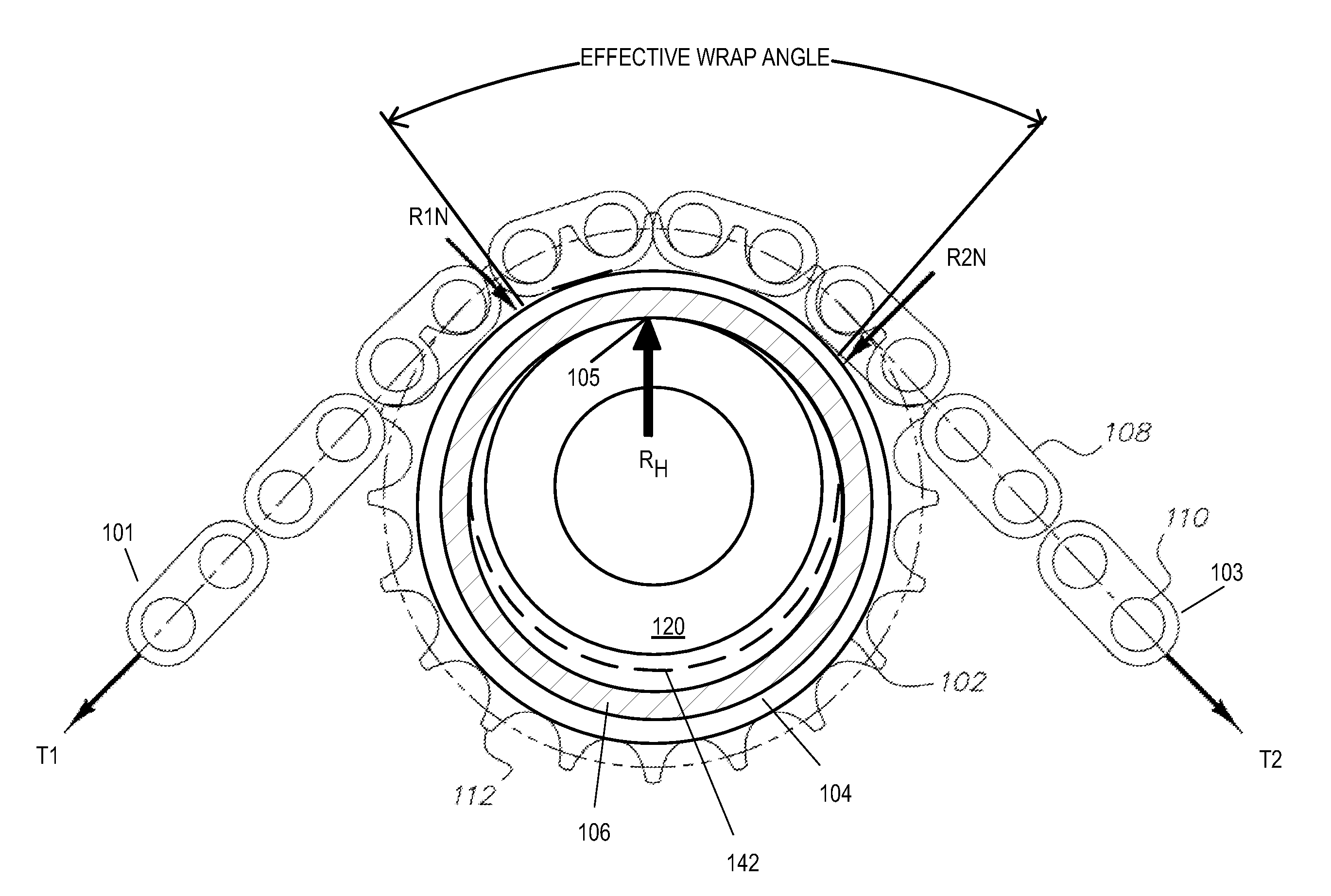

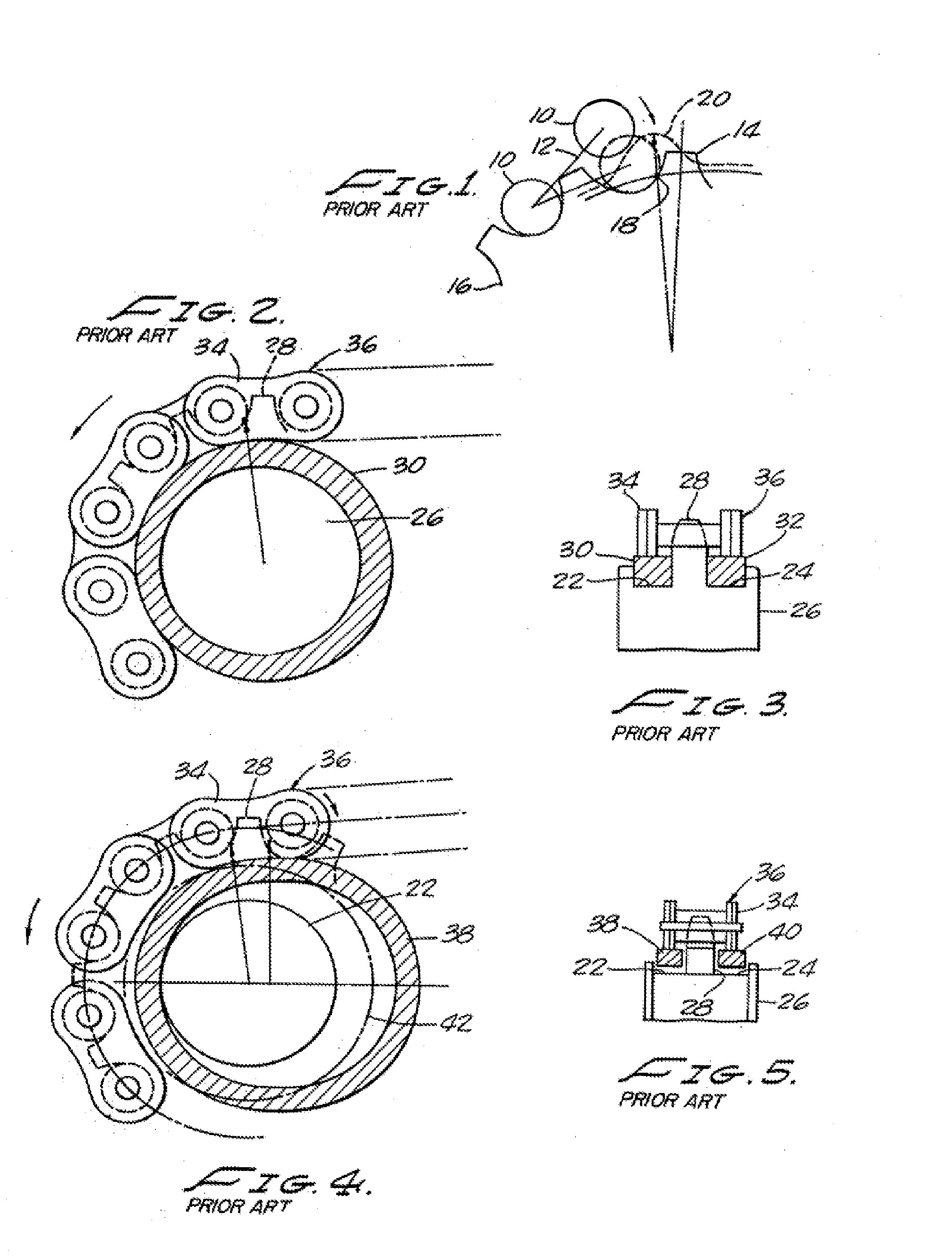

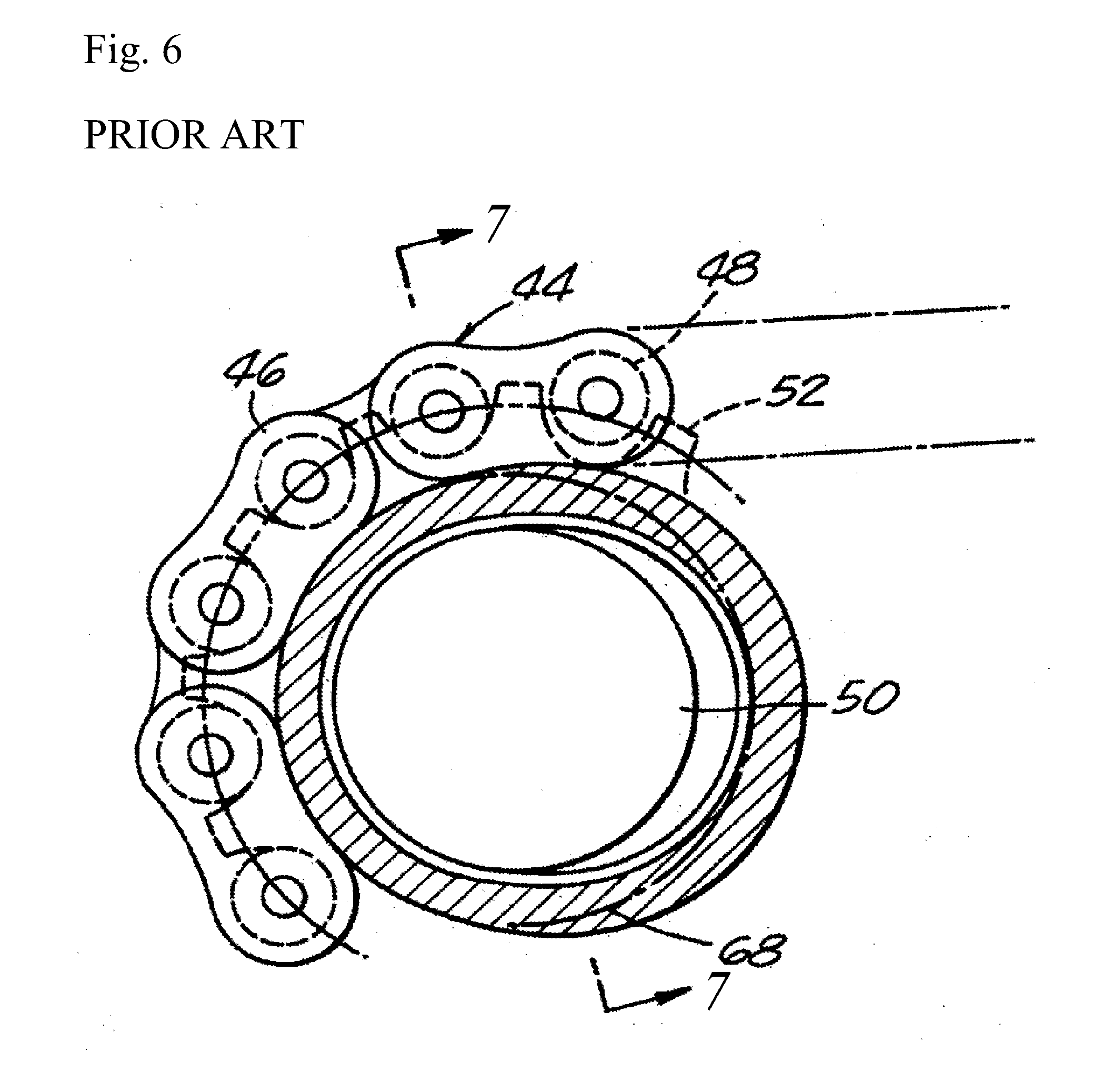

Chain noise reduction device

A cushion ring (102) is received in a concentric groove in a sprocket (112) with teeth and a hub. More specifically, the groove is defined between an annular portion of the hub and the teeth. The cushion ring has an inner ring (106) and an outer ring (104). The outer ring is made of an incompressible material that has a load bearing area for receiving load from the links of the chain. The load and engagement noise energy of the chain links are combined and distributed over a large area of the outer ring. The inner ring receives this distributed load and noise energy from the outer ring and absorbs most of such energy. This improved distribution decreases wear and increases life of the resilient material while also providing for a reduced level of chain engagement noise.

Owner:BORGWARNER INC

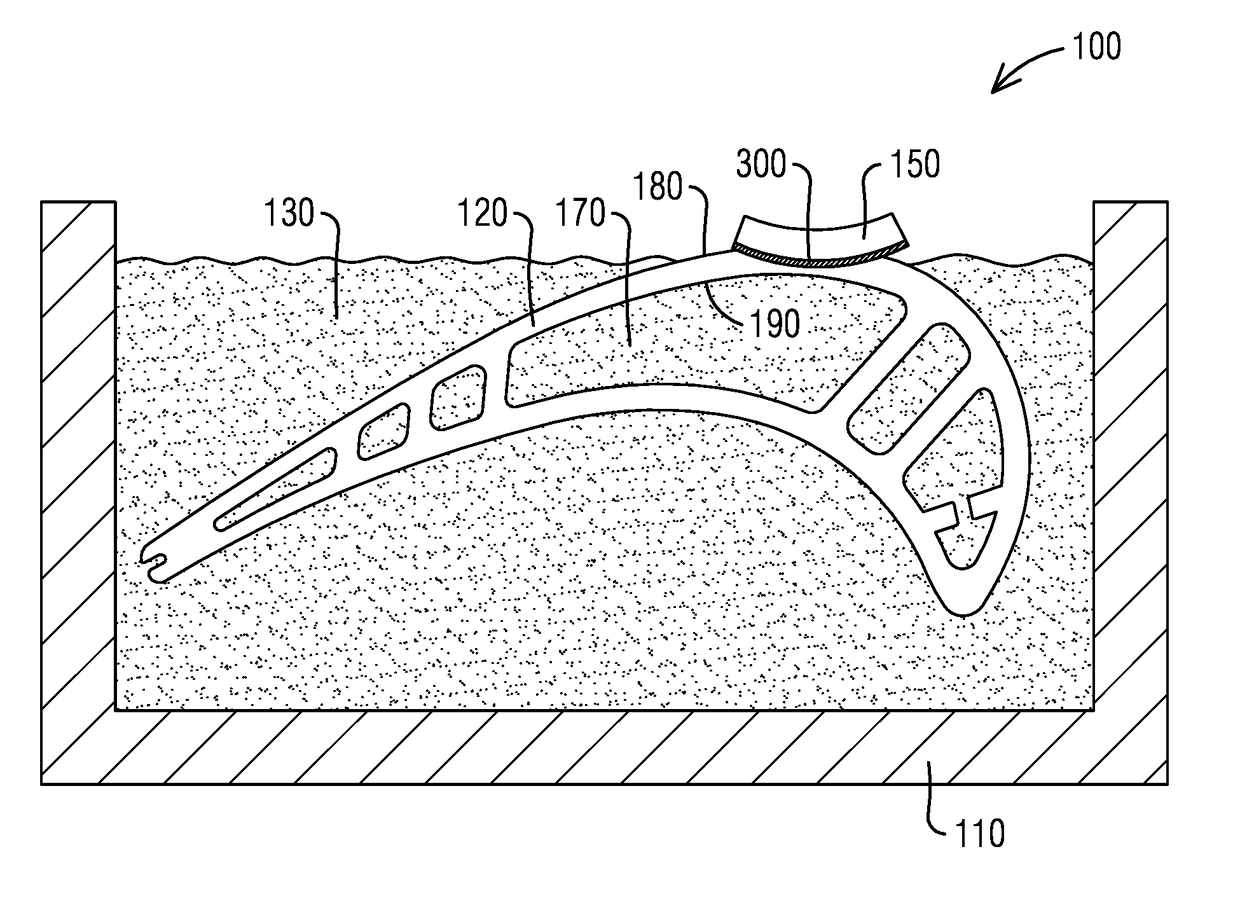

Shoe for expandable liner system and method

An apparatus to protect the mounting area of casing when subsequently attaching a tubular is disclosed. A sleeve that defines a sealed cavity having a loose incompressible material inside covers the mounting location on the casing. The cementing of the casing takes place through the sleeve. After the cementing, the sleeve is drilled out and the incompressible material is removed to the surface with the drill cuttings. A tubular is inserted in the casing and is preferably expanded into sealing contact with the mounting location on the casing. At the end of expansion, the run in shoe on the tubular is retrieved.

Owner:BAKER HUGHES INC

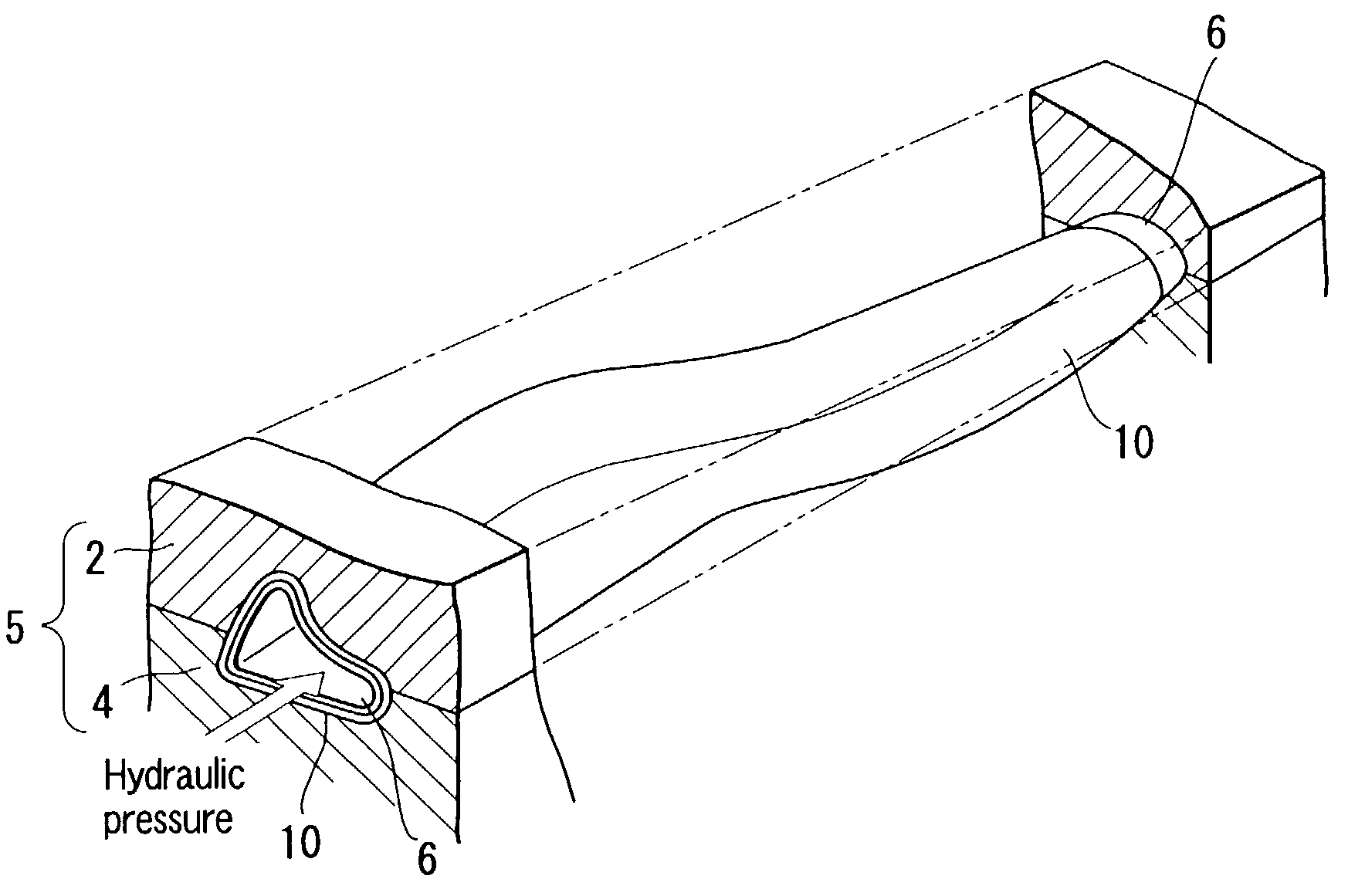

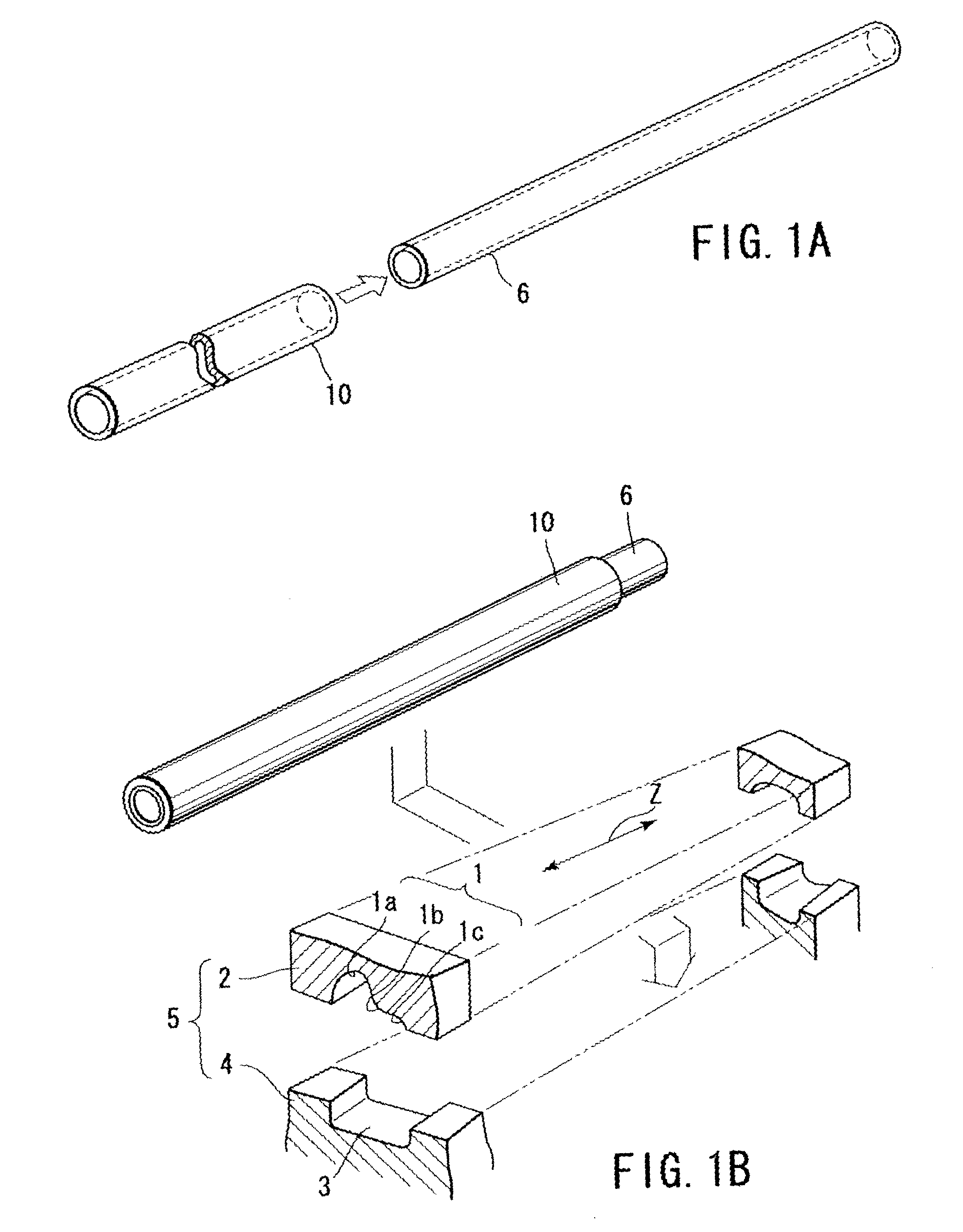

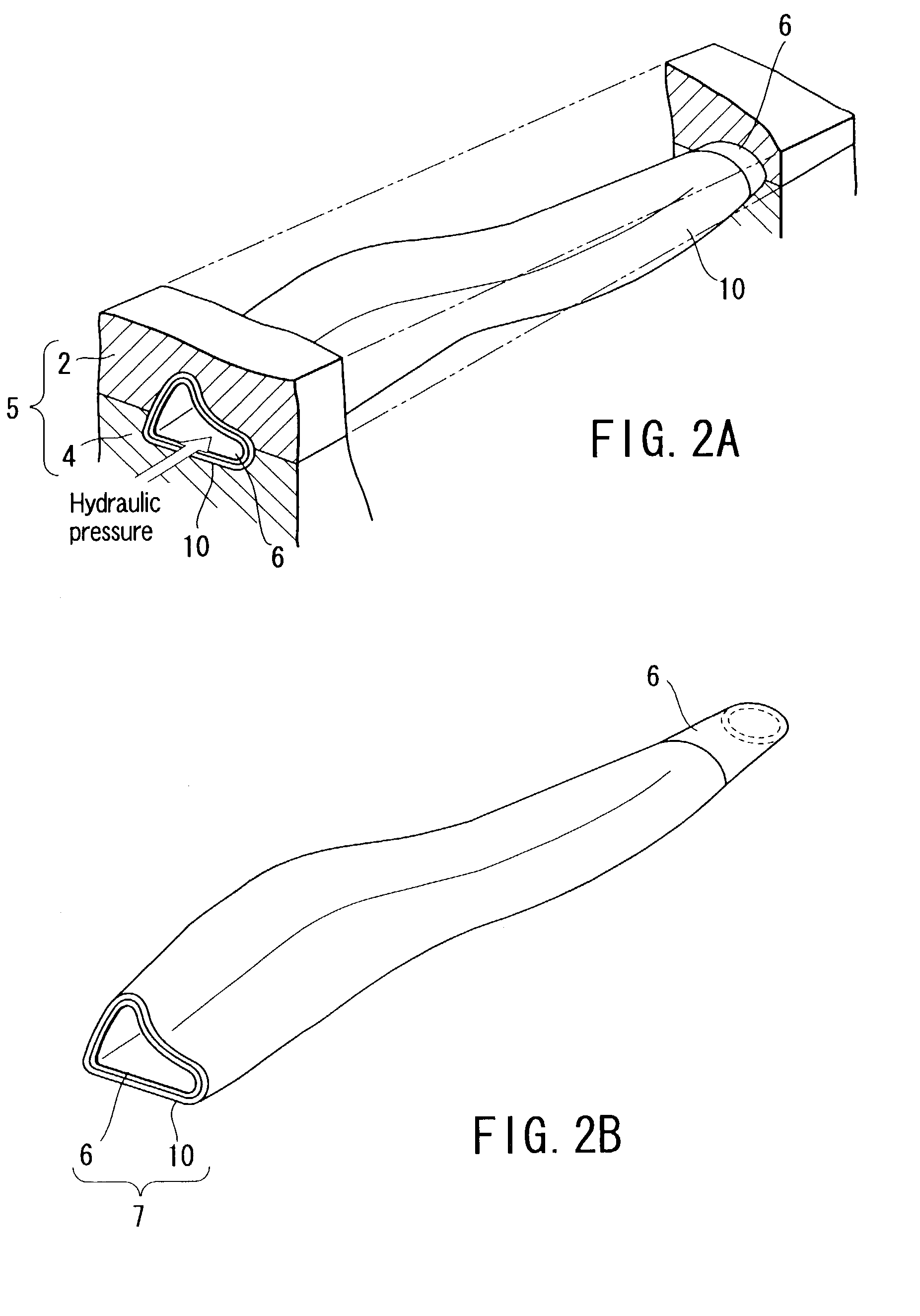

Hydroform process and hydroform product

InactiveUS7051768B2Uniform wall thicknessStretch smoothlyMetal-working apparatusFlexible pipesMetallurgyIncompressible material

When hydroforming a steel pipe, a tubular deformation assisting member made of an incompressible material softer than the steel pipe is fitted on the outer peripheral surface of the steel pipe. The deformation assisting member is attached at least to an area corresponding to a projection provided at the inner surface of the die assembly, the projection being earliest brought into contact with the outer peripheral surface of the steel pipe during hydroforming. When hydroforming the steel pipe, the material of the deformation assisting member plastically flows near corner portions at which the deformation assisting member is brought into contact with the projection.

Owner:MITSUBISHI MOTORS CORP

One trip cemented expandable monobore liner system and method

An apparatus to protect the mounting area of casing and a locating profile and optionally a sliding sleeve valve and a flow path from the outside of the valve to the annulus when subsequent attachment of an expanded liner is intended and the expanded liner is to be cemented in place. A barrier sleeve, nose, and outer sleeve define a sealed cavity having a loose incompressible material inside that covers the mounting location on the casing. A locating profile and an optional sliding sleeve valve and a flow path from the outside of the valve to the annulus can be provided. The cementing of the casing takes place through the barrier sleeve. After the cementing, the sleeve and nose are drilled out and the incompressible material is removed to the surface with the drill cuttings. A liner is inserted in the casing and is preferably expanded into sealing contact with the mounting location on the casing. After expansion a cement retainer positioned at the bottom of the expanded liner and the sliding sleeve located either above the mounting location of the liner in the casing shoe or in the liner below the mounted top section allow cement to be delivered outside the expanded liner and the displaced wellbore fluid to return into the casing through so that the liner can be cemented. The cement retainer can be delivered with either the liner or the expansion tools to allow expansion and cementing in a single trip. A shifting tool can be run on the expansion string to actuate the sliding sleeve and if necessary to allow for cement to be pumped from the drill string into the annulus through the sliding sleeve. The cement retainer can be milled out in a separate trip.

Owner:BAKER HUGHES INC

One trip cemented expandable monobore liner system and method

Owner:BAKER HUGHES INC

One trip cemented expandable monobore liner system and method

An apparatus protects the mounting area of casing and a locating profile and optionally a sliding sleeve valve and a flow path from the outside of the valve to the annulus when subsequent attachment of an expanded liner is intended and the expanded liner is to be cemented in place. A barrier sleeve, nose, and outer sleeve define a sealed cavity having a loose incompressible material inside that covers the mounting location on the casing. A locating profile and an optional sliding sleeve valve and a flow path from the outside of the valve to the annulus can be provided. The cementing of the casing takes place through the barrier sleeve. After the cementing, the sleeve and nose are drilled out and the incompressible material is removed to the surface with the drill cuttings. A liner is inserted in the casing and is preferably expanded into sealing contact with the mounting location on the casing. After expansion the liner can be cemented. A shifting tool can be run on the expansion string to actuate the sliding sleeve and if necessary to allow for cement to be pumped from the drill string into the annulus through the sliding sleeve.

Owner:BAKER HUGHES HLDG LLC

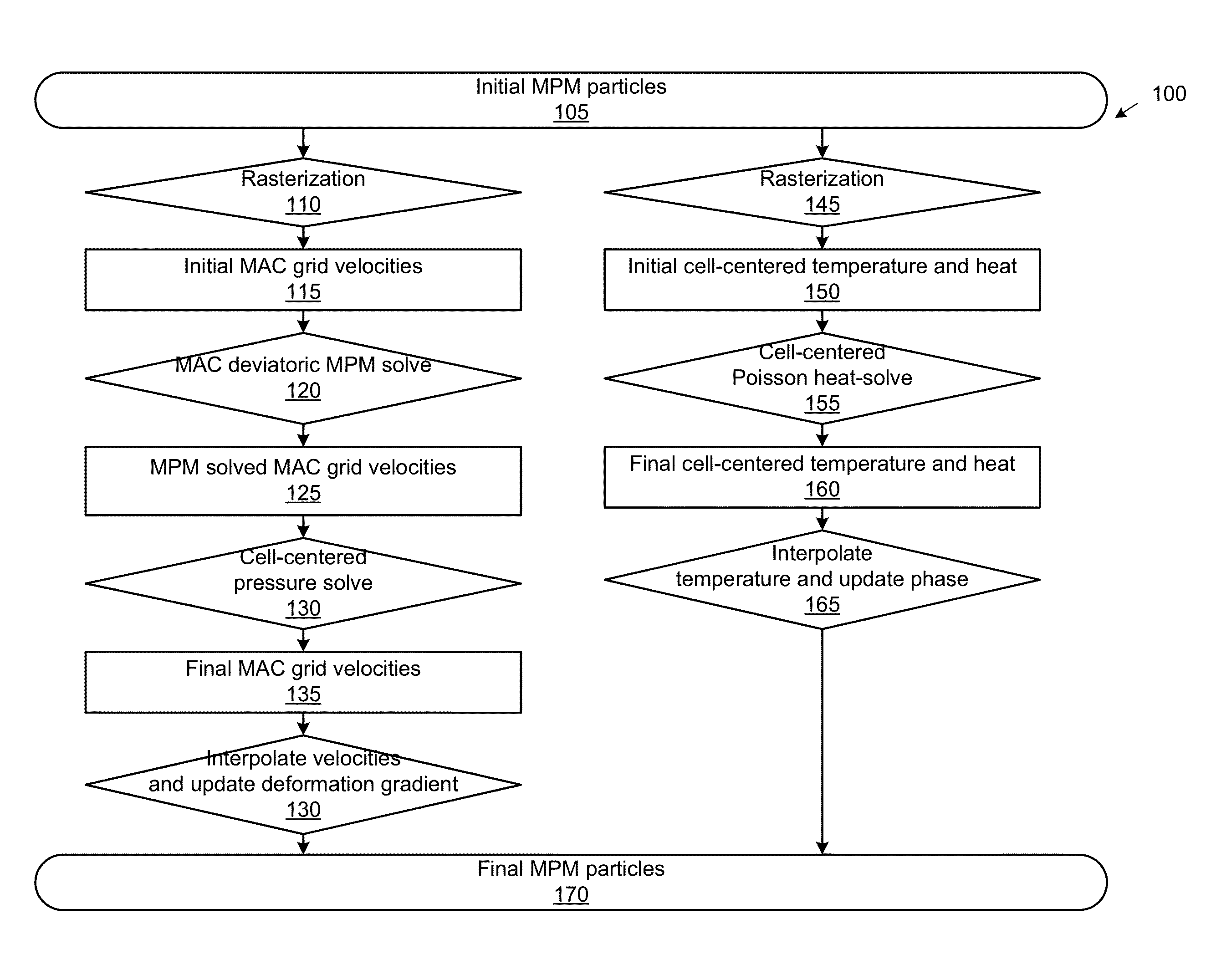

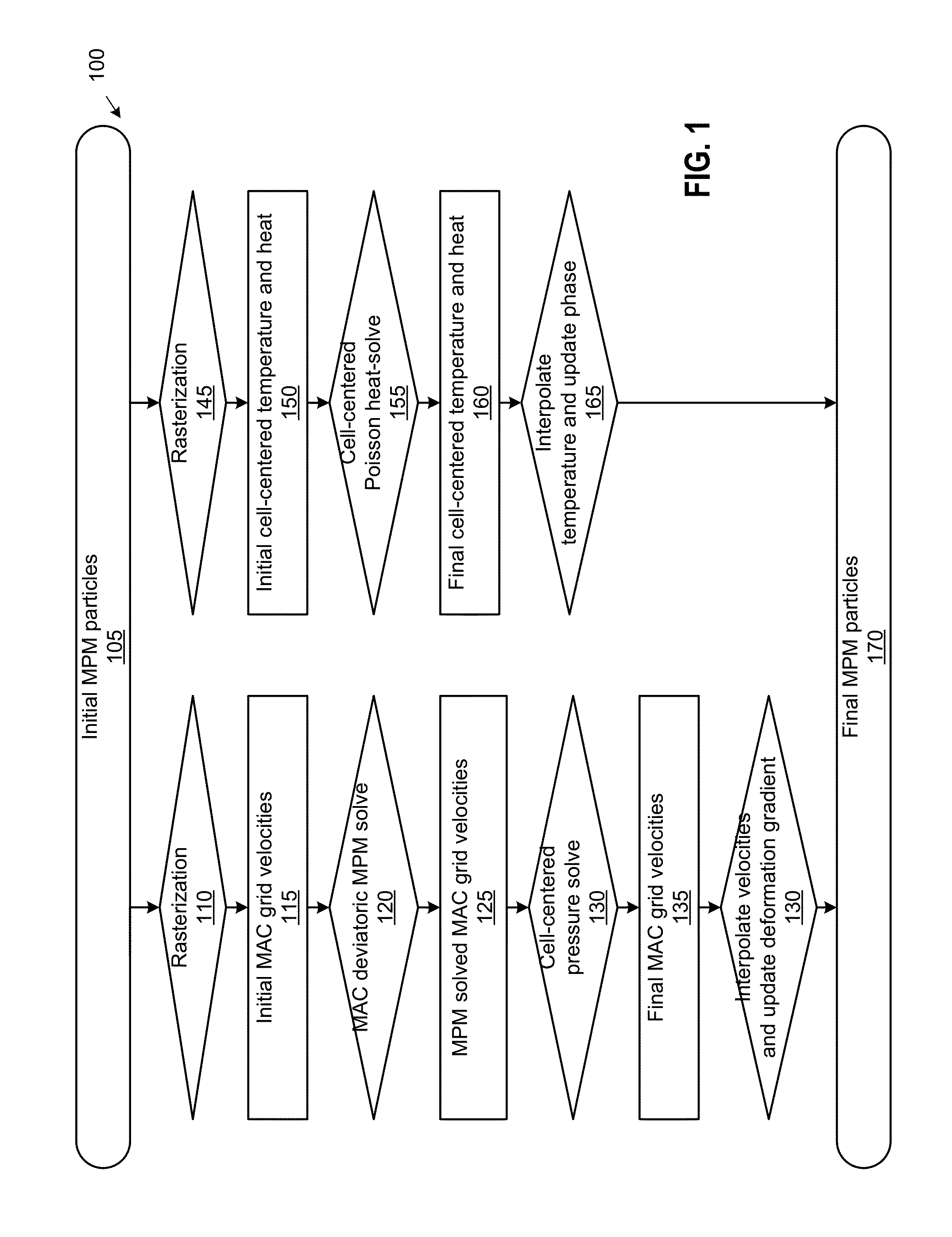

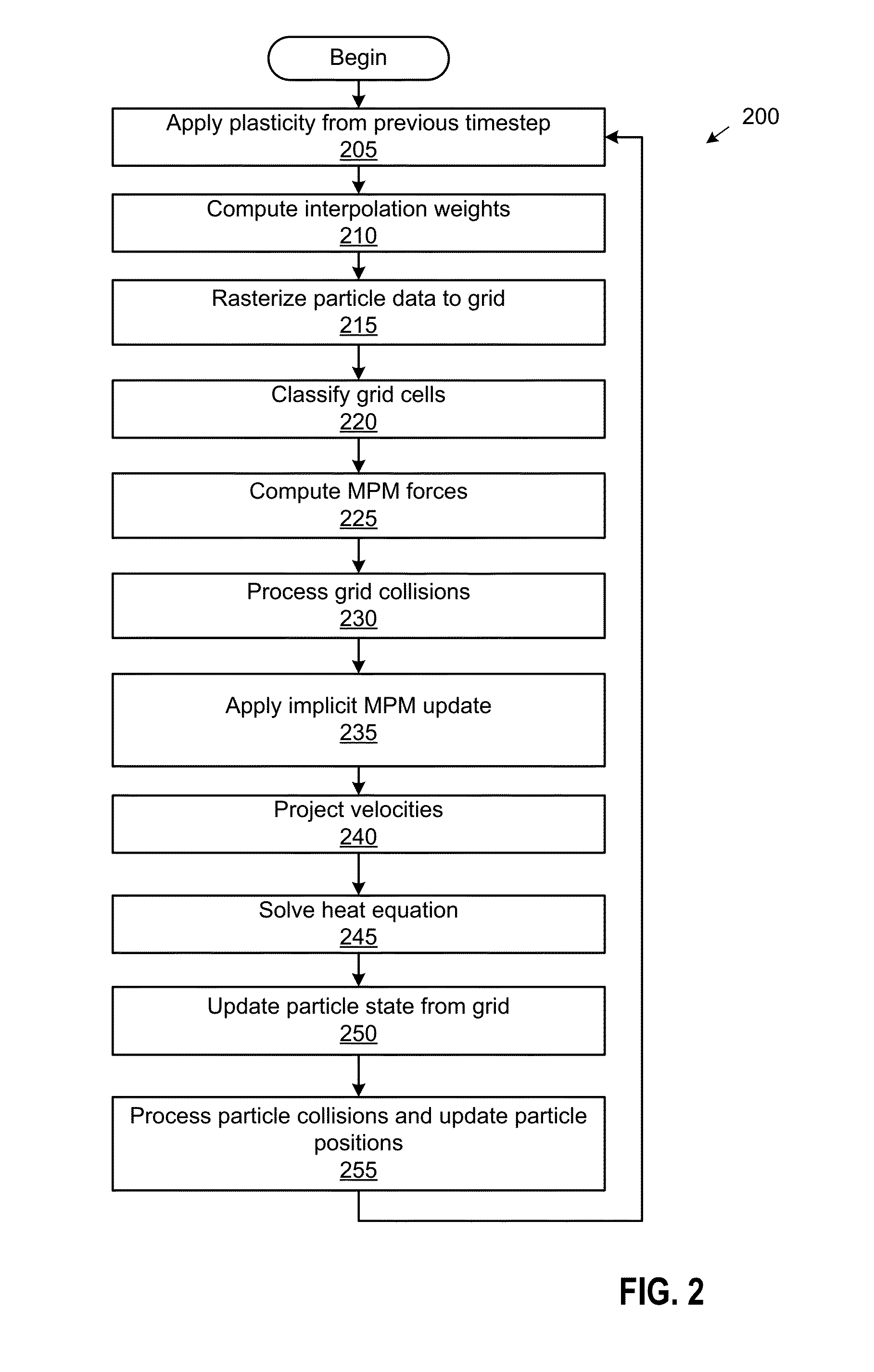

Augmented material point method for simulating phase changes and varied materials

ActiveUS20150186565A1Design optimisation/simulationSpecial data processing applicationsInterior point methodGrid based

The disclosure provides an approach for simulating and rendering materials across different states and undergoing phase transitions. In one configuration, a simulation application generates video frames depicting a material phenomenon using an augmented material point method (MPM). Traditional MPM does not handle incompressible materials such as fluids. Techniques disclosed herein augment the MPM with a Chorin-style projection technique to enable simulation of arbitrarily incompressible materials. In one configuration, this is achieved with a marker-and-cell (MAC) grid based MPM solver, a splitting of stress used in the simulation into elastic and dilational parts, a projection-like implicit treatment of the Eulerian evolution of the dilational part of the stress, and particular techniques for rasterizing and updating quantities on the MAC grid. In addition, a heat model may be coupled to the MPM solver, allowing material changes to be driven with temperature and phase changes.

Owner:DISNEY ENTERPRISES INC

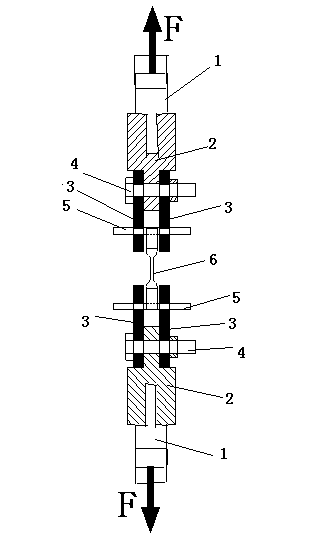

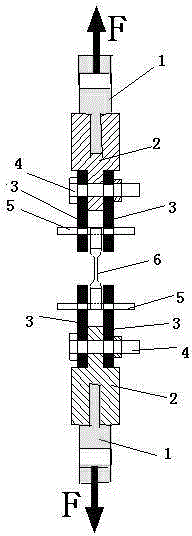

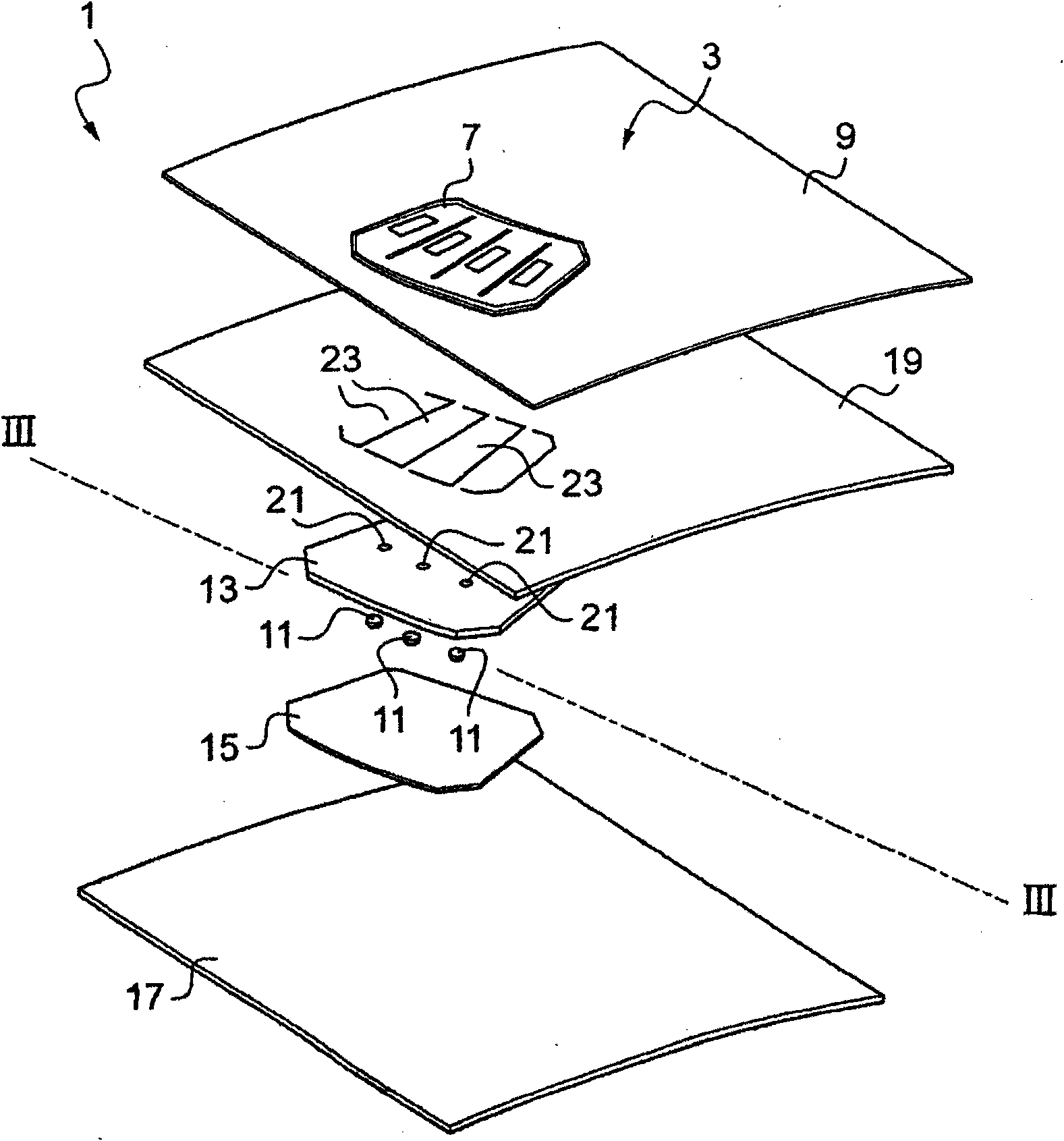

Direct tensile test jag of incompressible material

ActiveCN103175733ADirect Tensile Test ImplementationAccurately obtain mechanical performance parametersStrength propertiesCompressible materialEngineering

The invention relates to a direct tensile test jig of an incompressible material, and belongs to the field of building material test devices. The direct tensile test jig is composed of fixed joints, switch chucks, connection boards, bolts and metal rods, solves a problem of test incompletion caused by data distortion even shedding because of the sliding of a test piece at the clamping end in the direct tensile test process of a present incompressible material, can reliably realize the direct tensile test of the incompressible material to accurately obtain the mechanical property parameters of the material, and has a certain application prospect.

Owner:TONGJI UNIV

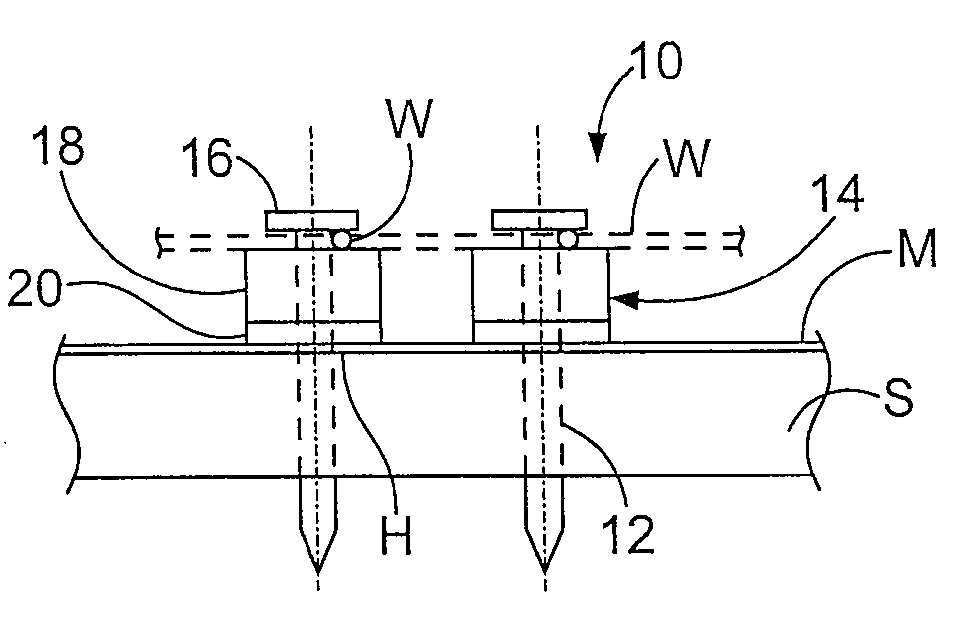

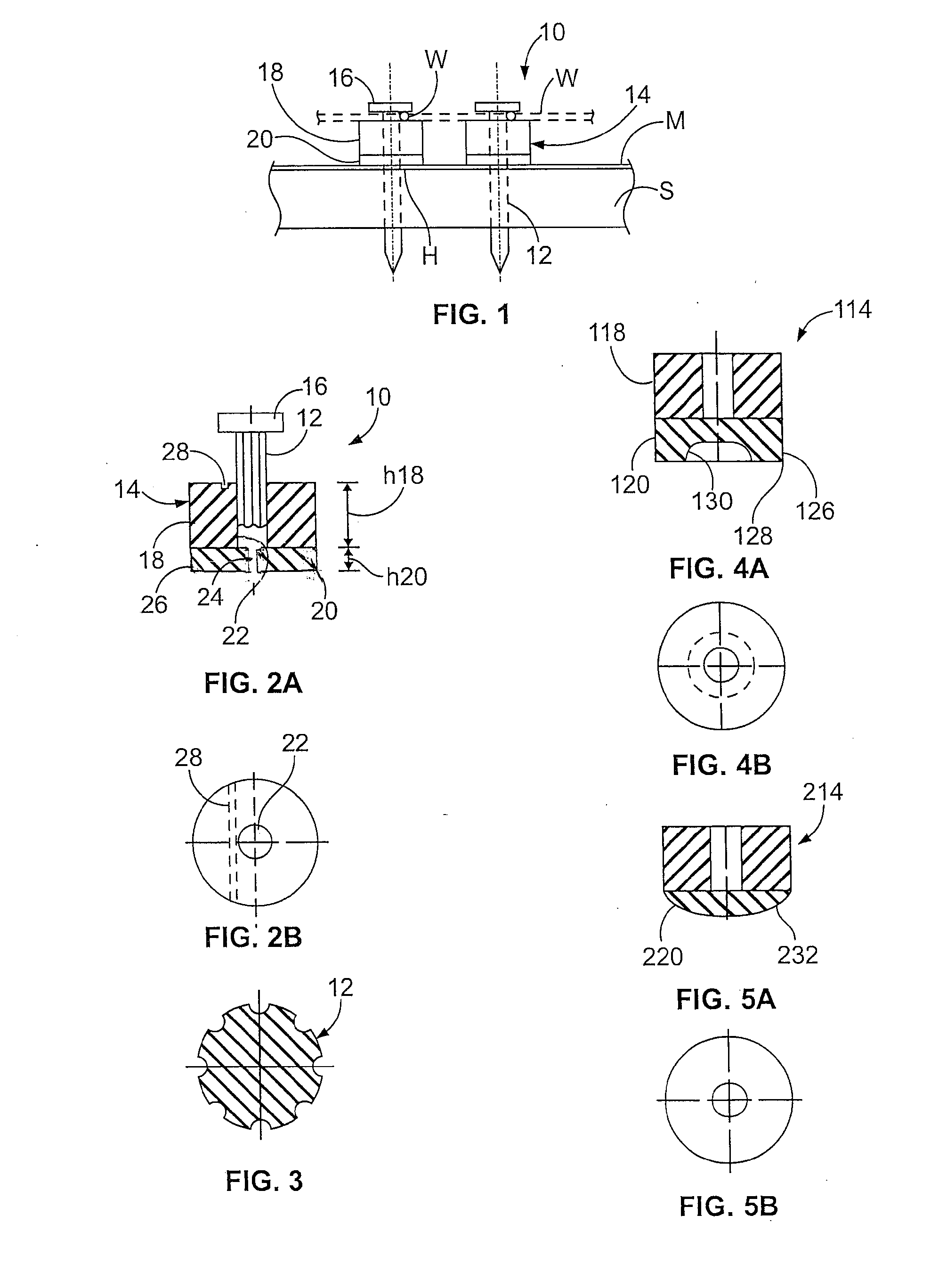

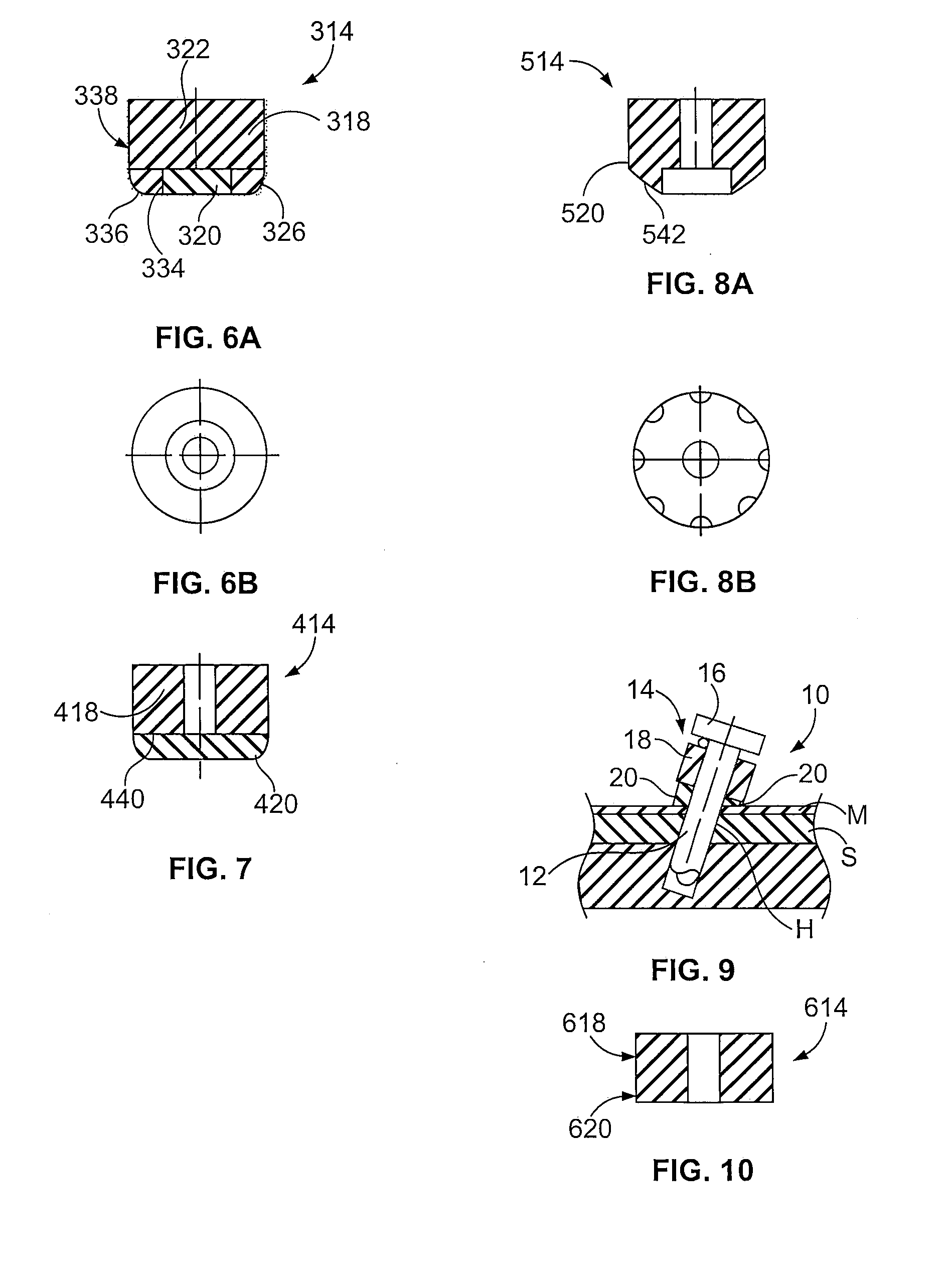

Stucco fastener

A fastener is configured for securing a lath to a surface for, for example, the application of stucco to the surface. The fastener includes a fastener having a head, a shank and a penetrating tip. The head has a diameter and the shank has a diameter less than the head diameter. The stucco fastener has a sealing / spacer assembly having spacer element and a sealing element. The spacer element is formed from a relatively incompressible material and has a diameter greater than the shank diameter. The spacer element has a bore therein having a diameter about equal to the shank diameter. The sealing element is formed from a resilient, water-resistant material and is positioned adjacent to and in contact with the spacer element. When the fastener is driven into the surface, the fastener penetrates the surface to secure the fastener to the surface and a portion of the lath is captured between the head of the fastener and the spacer element to space the lath from the surface. The sealing element contacts the surface to form a seal at the fastener penetration to prevent the incursion of liquid into the surface around the fastener penetration, and the sealing element, as least in part, conforms to the surface between the surface and the spacer element.

Owner:ILLINOIS TOOL WORKS INC

Direct tensile test jag of incompressible material

ActiveCN103175733BDirect Tensile Test ImplementationAccurately obtain mechanical performance parametersStrength propertiesCompressible materialEngineering

The invention relates to a direct tensile test jig of an incompressible material, and belongs to the field of building material test devices. The direct tensile test jig is composed of fixed joints, switch chucks, connection boards, bolts and metal rods, solves a problem of test incompletion caused by data distortion even shedding because of the sliding of a test piece at the clamping end in the direct tensile test process of a present incompressible material, can reliably realize the direct tensile test of the incompressible material to accurately obtain the mechanical property parameters of the material, and has a certain application prospect.

Owner:TONGJI UNIV

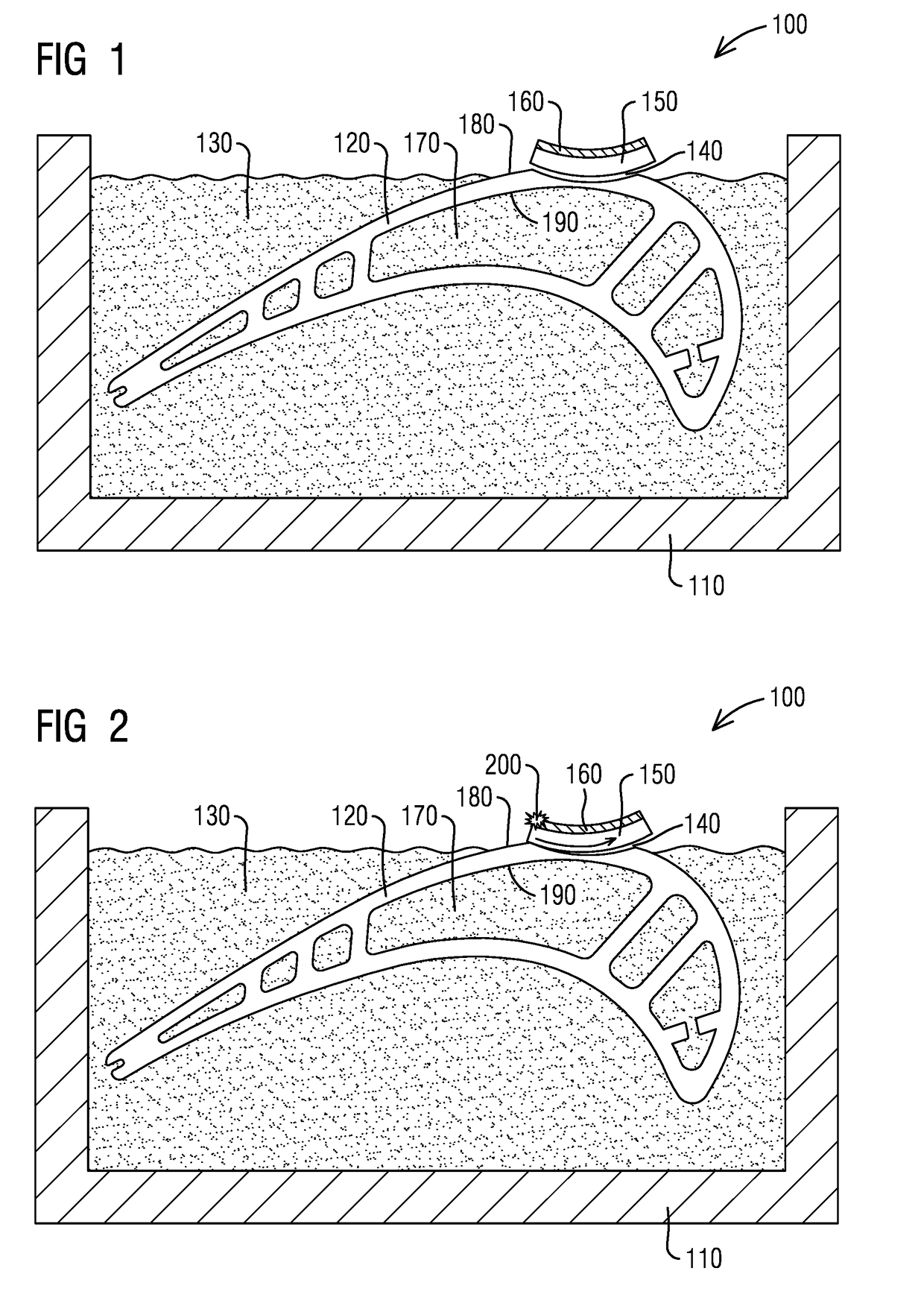

Method for reducing violence of accidental explosions in solid fuel rocket motors and other energetic devices

InactiveUS20060032562A1Reduce violencePrevent crashExplosive chargesNuclear energy generationEngineeringEnergetic material

A method and system for reducing the violence of an accidental explosive reaction of an energetic material, the method comprising: (a) obtaining a solid energetic material configured for use within an energetic device, the energetic material comprising at least one void formed therein; and (b) filling at least a portion of the at least one void with an inert, incompressible material configured to mechanically stabilize the energetic material to prevent the void from collapsing and the surface area of the energetic material from increasing in the event of an insult tending to damage the energetic the material. In one exemplary embodiment, the inert, incompressible material is configured to temporarily modify the energetic device, meaning that the inert, incompressible material is configured to be removably inserted or otherwise applied to the energetic device.

Owner:UNIV OF UTAH RES FOUND

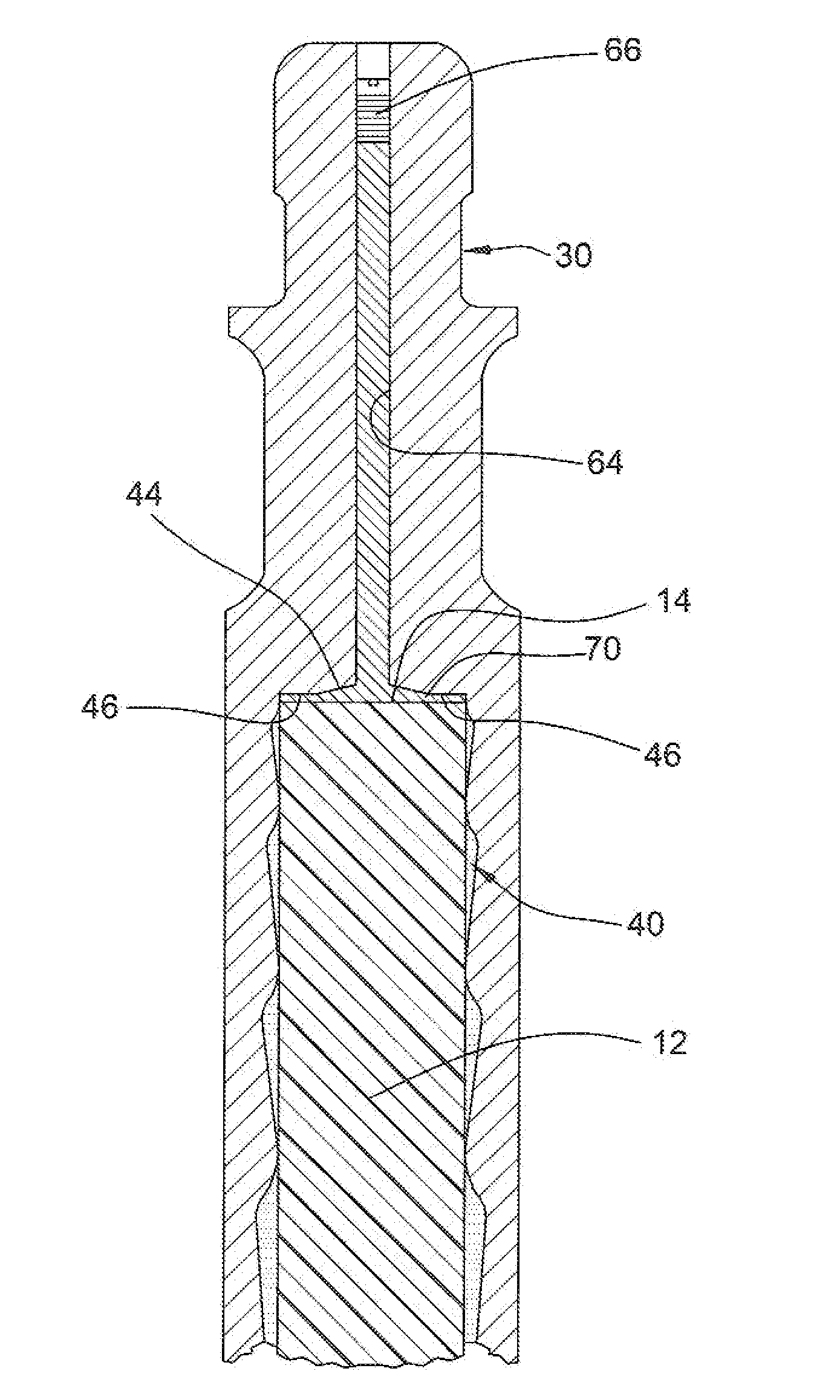

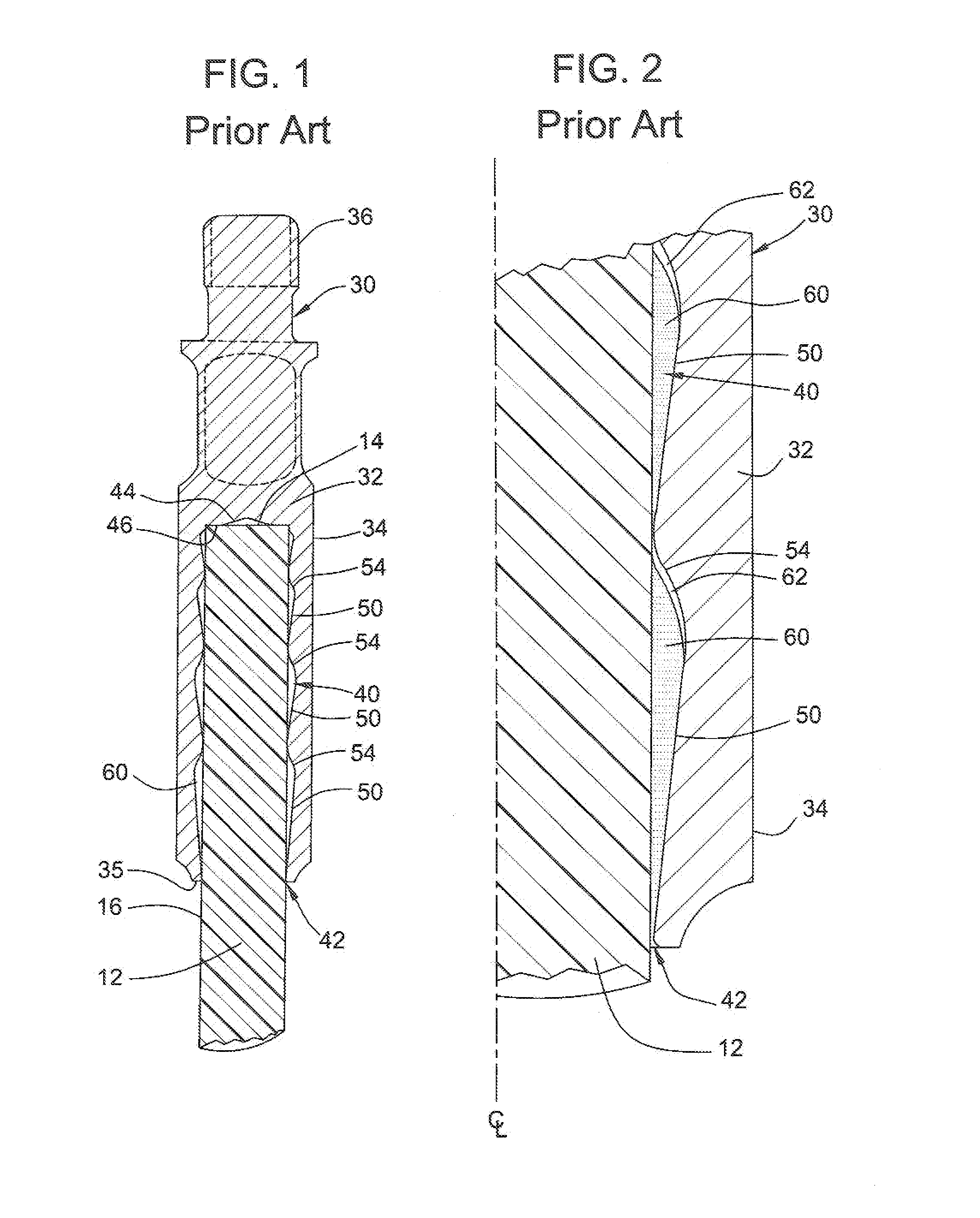

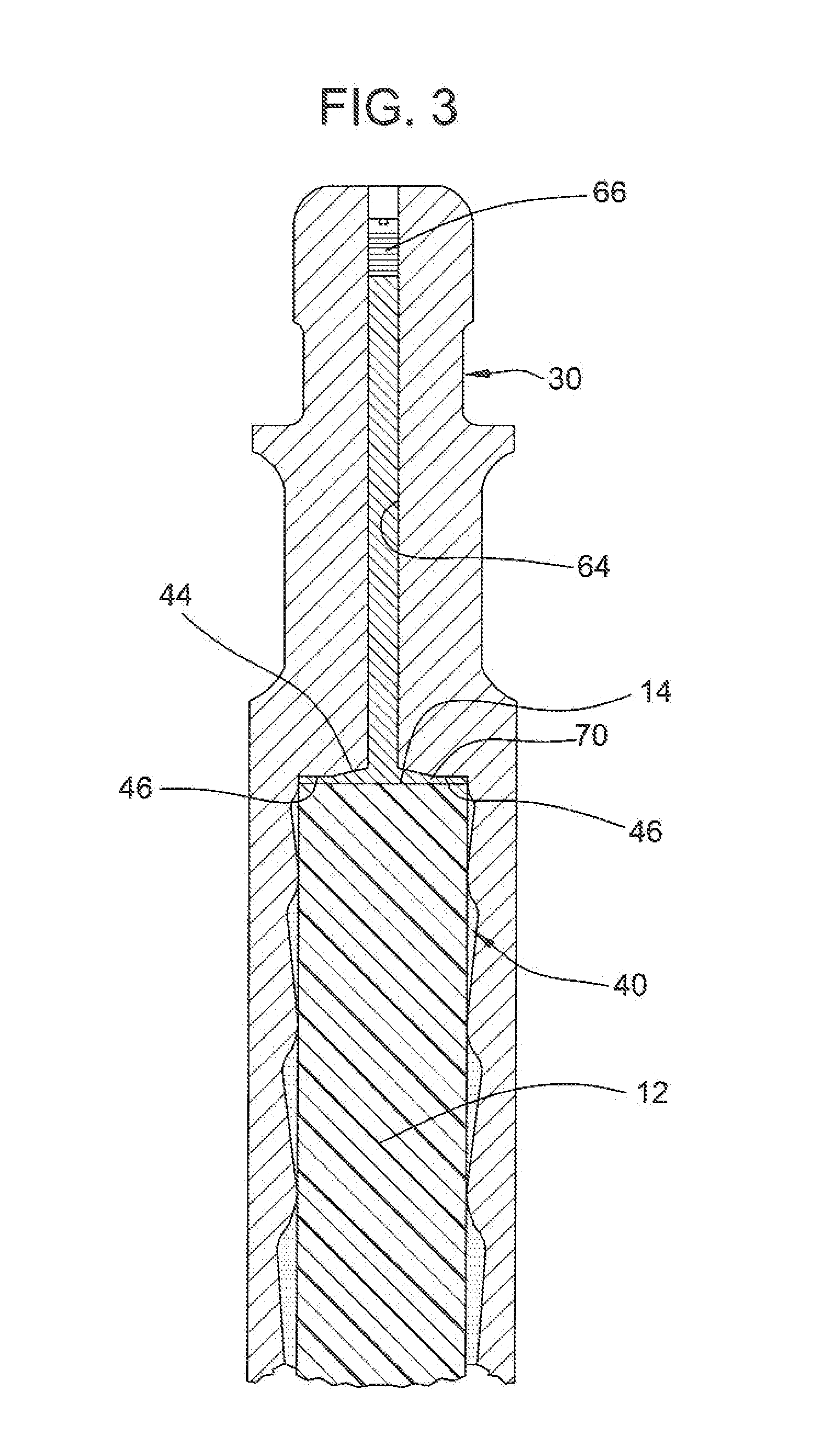

Sucker rod and end fitting with compression preset

InactiveUS20160102694A1Avoid contactEfficient transferDrilling rodsMetal-working apparatusCompressible materialEngineering

A sucker rod assembly comprising, an end fitting including a body with a rod receptacle cavity extending axially, a generally cylindrical sucker rod received within the rod receptacle cavity defining one or more annuli, a quantity of initially flowable adhesive bonded to the rod and disposed in the one or more annuli forming at least one wedge, a surface on the rod is spaced from a surface on the end fitting defining a void space therebetween, a blocking element is disposed between the surface on the end fitting and the surface on the rod, filling the void space. There is disclosed a blocking element in the form of a void filling incompressible material interposed between the end of the rod and the bottom end of the rod receptacle cavity. In one form, a collar is affixed to the rod and spaced relative to the lower open end of the rod. A blocking element is interposed between the collar and the lower open end of the end fitting.

Owner:ENDURANCE ELEVATOR SOLUTIONS LLC

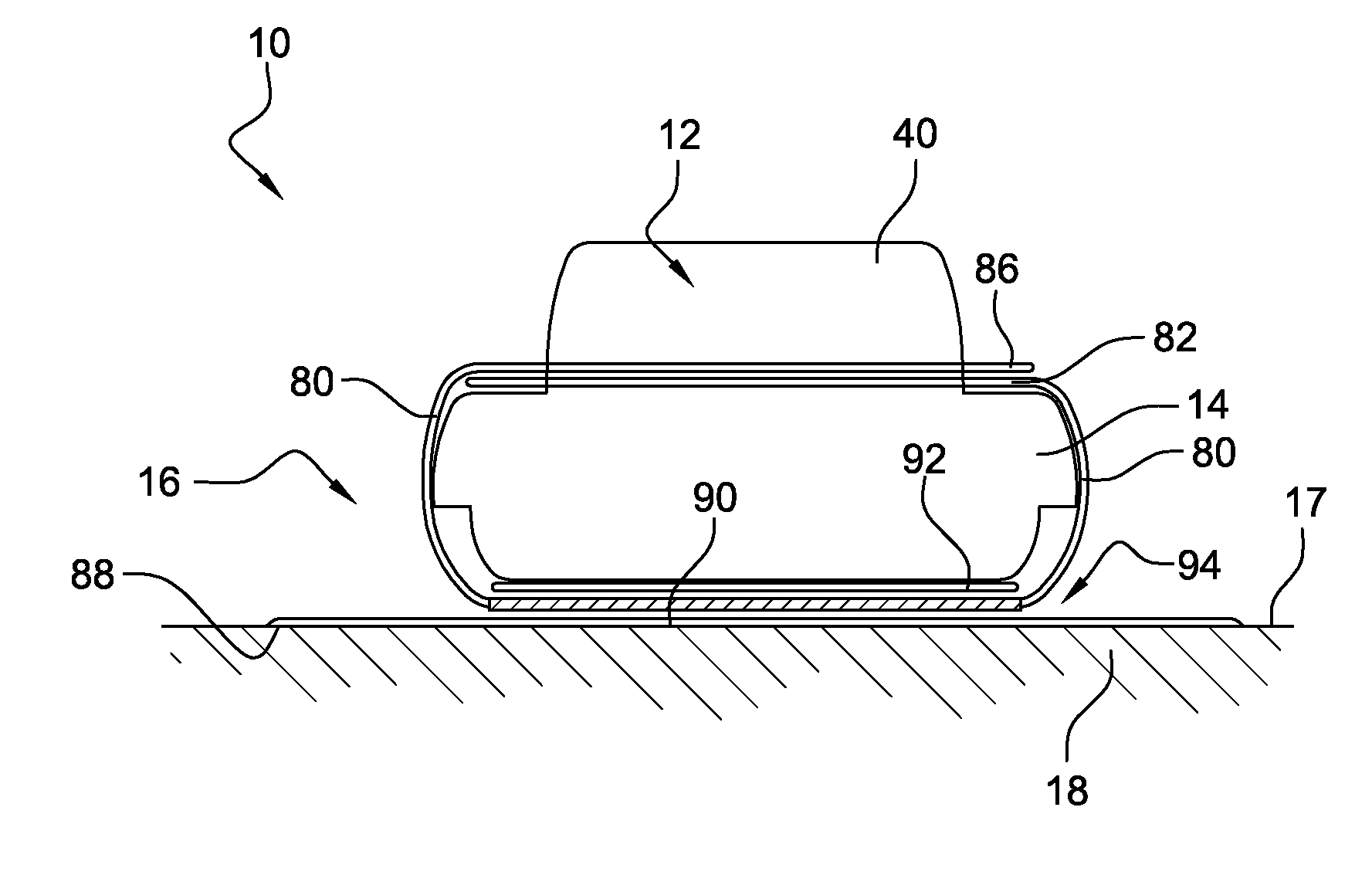

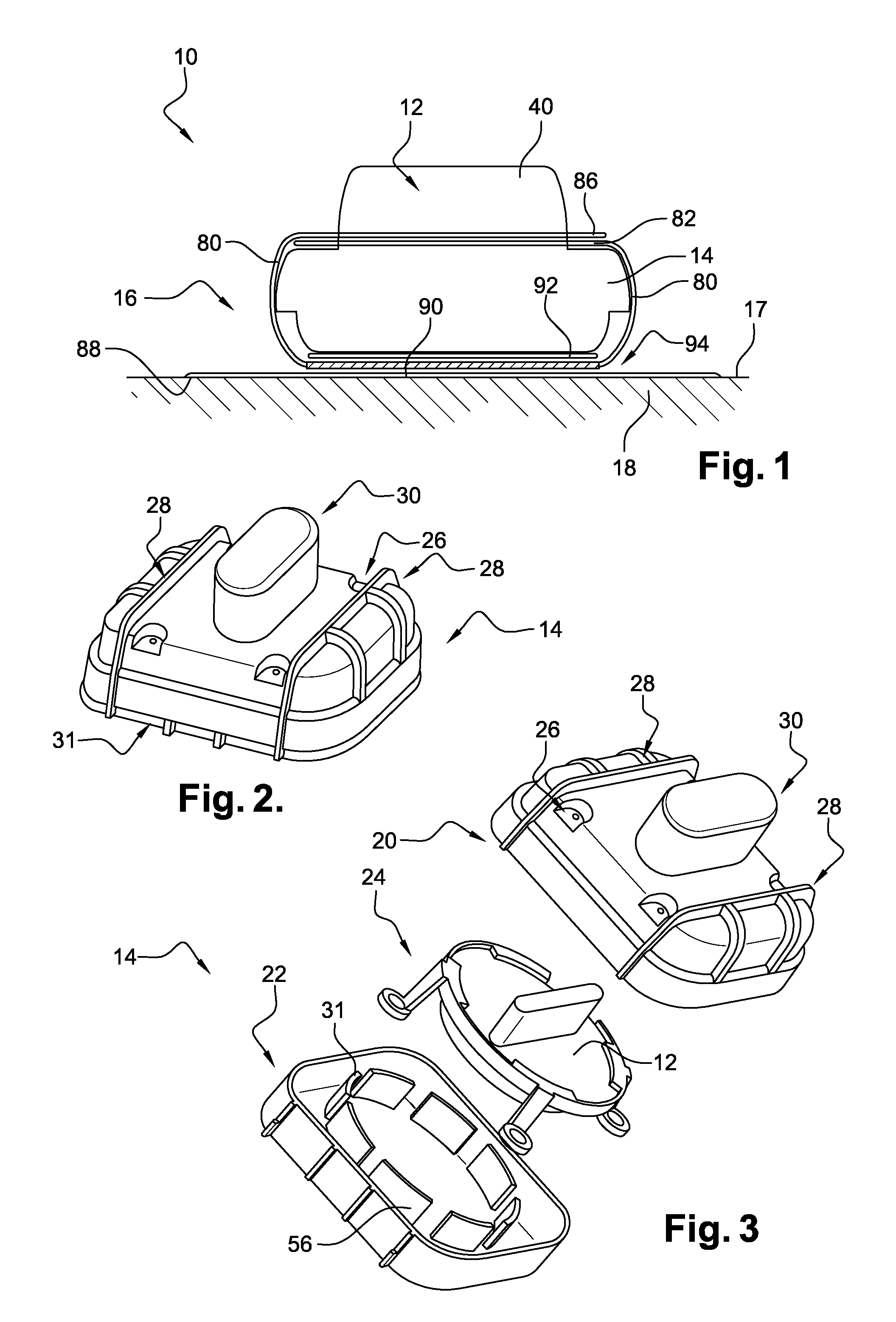

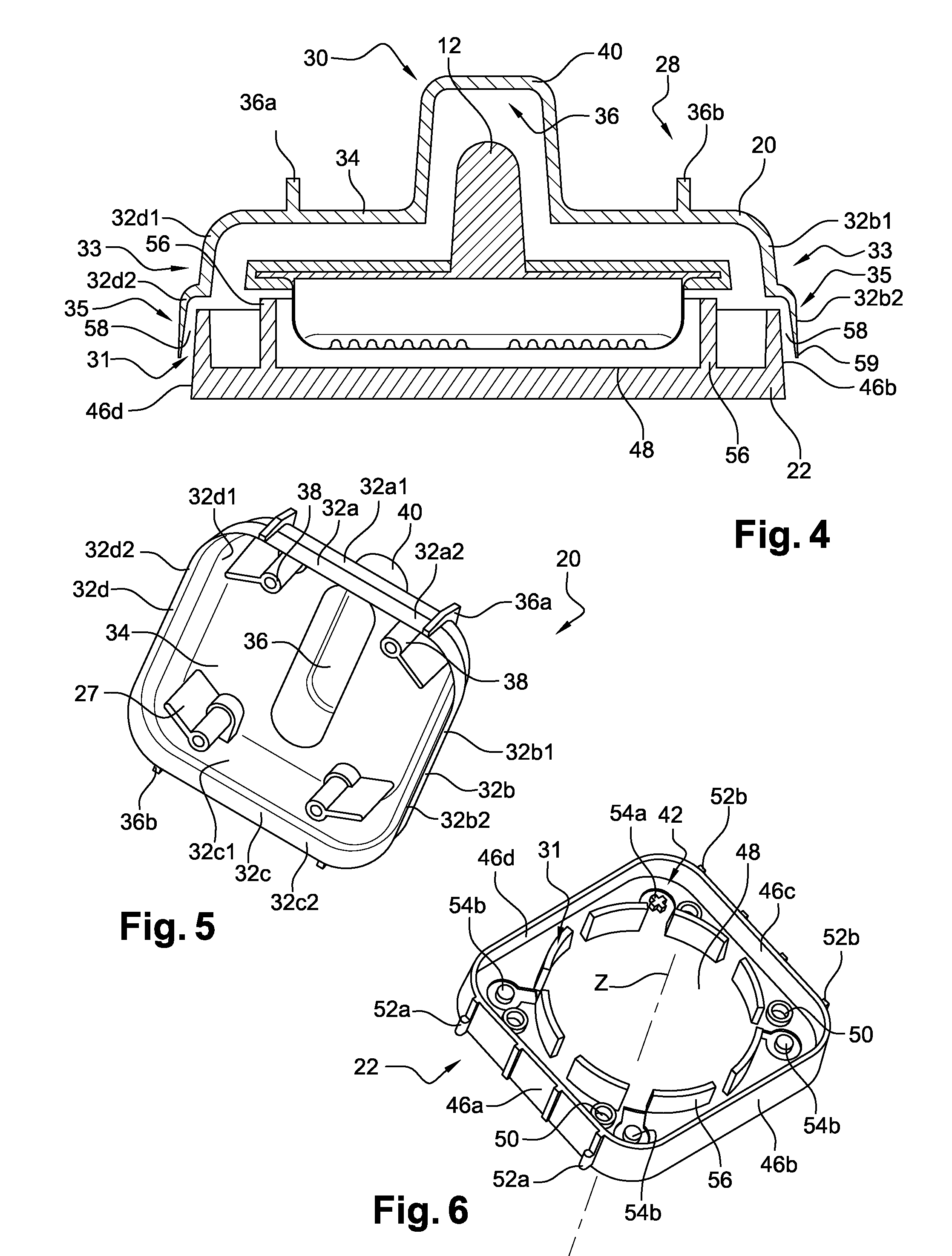

Sealed pressure-measuring member

ActiveCN102575966AInflated body pressure measurementFluid pressure measurement by electric/magnetic elementsPressure measurementEnergy storage

The invention relates to a pressure-measuring member (12) comprising: a pressure-measuring surface (106) functionally connected to a test body (96); a sealed pressure-measuring housing (100) in which the test body (96) is placed, whereby the pressure-measuring surface (106) is borne by a deformable wall (104) of the sealed pressure-measuring housing (100) that extends at a distance from the test body and the housing (100) defines an internal space (E); means (110) for transmitting the pressure between the pressure-measuring surface (106) and the test body (96), comprising a substantially incompressible material (136) that occupies all of the internal space (E); and energy storage means (101) and means (99) for processing the pressure detected by the test body (96), provided in the sealed housing (100).

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

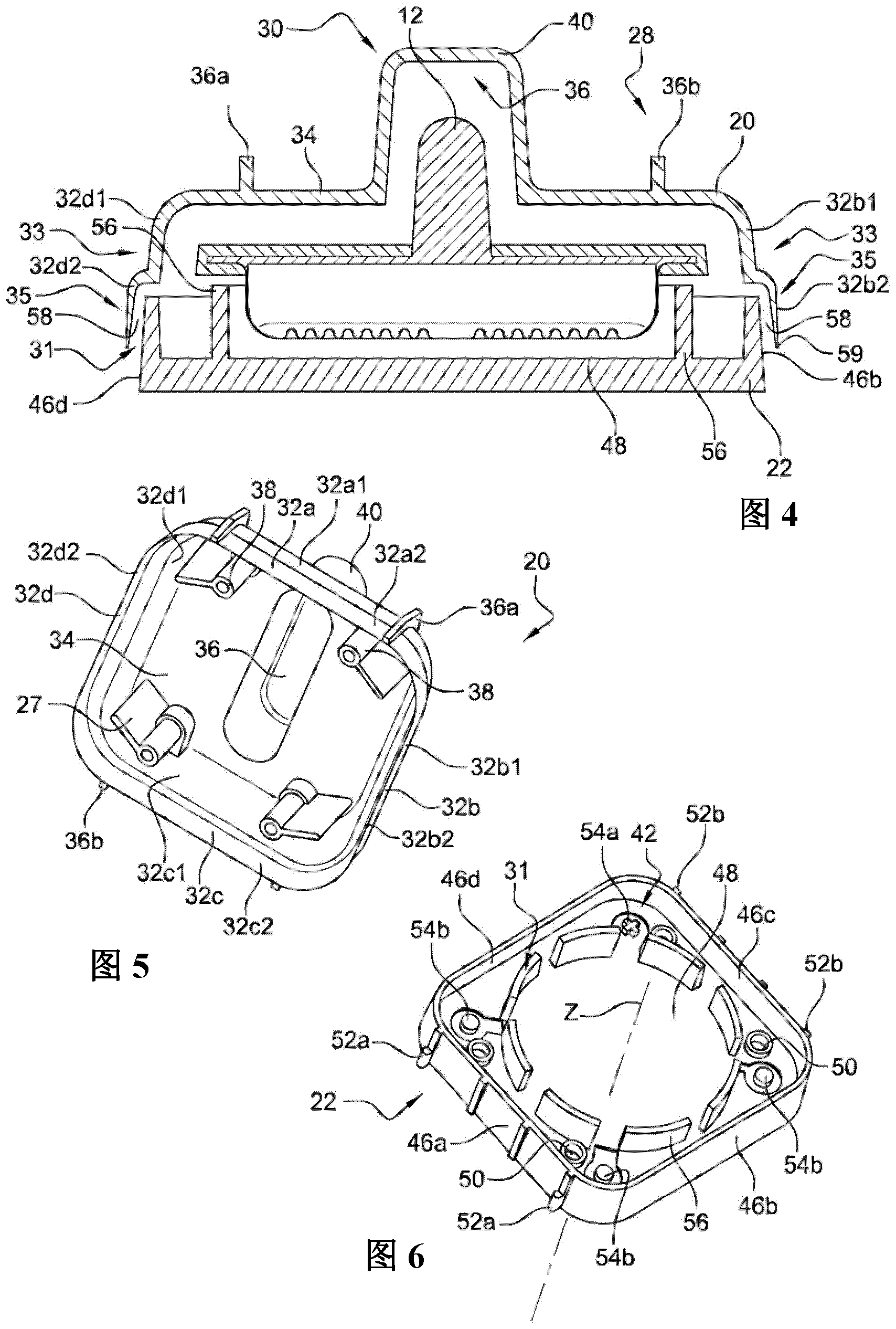

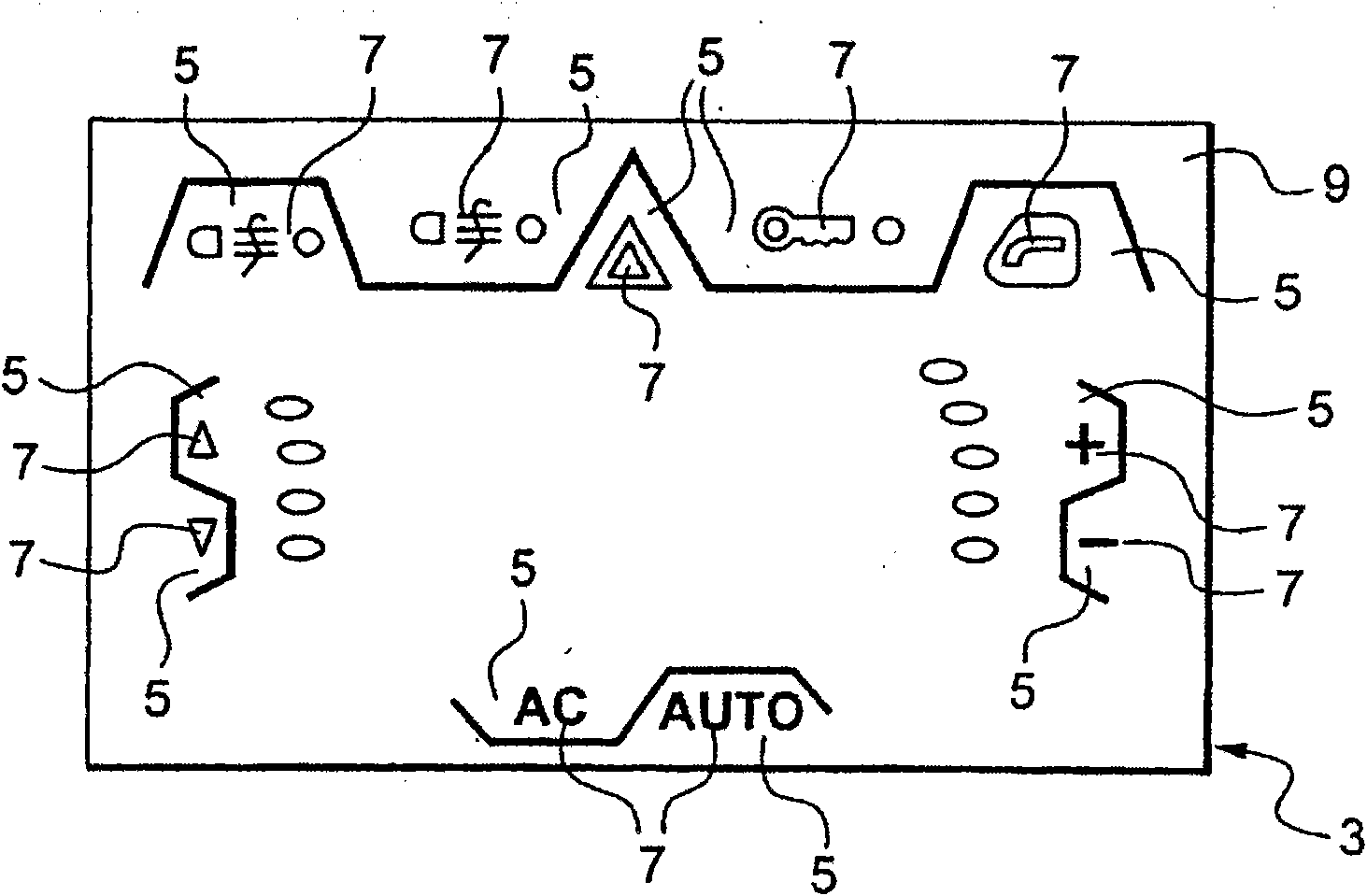

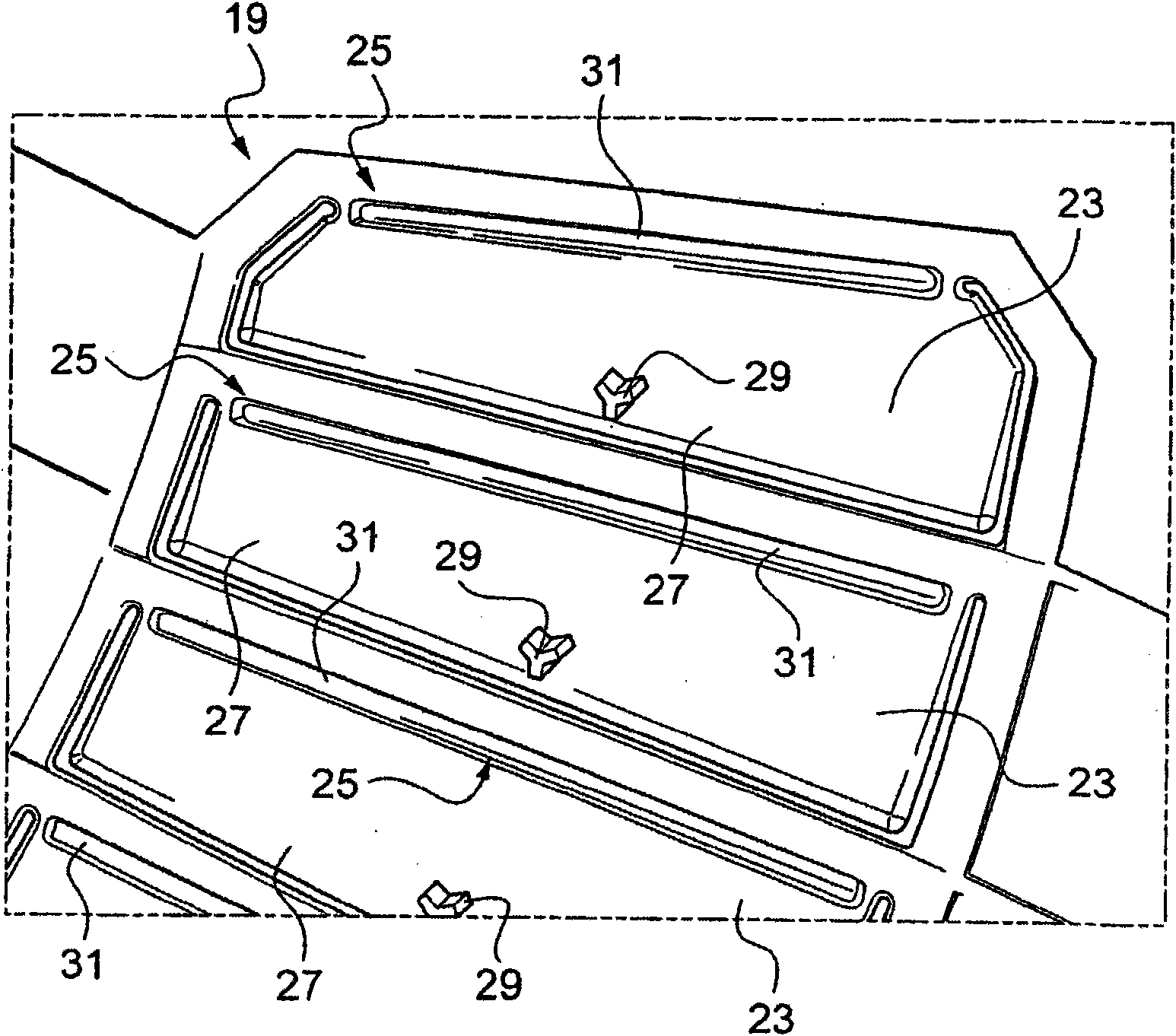

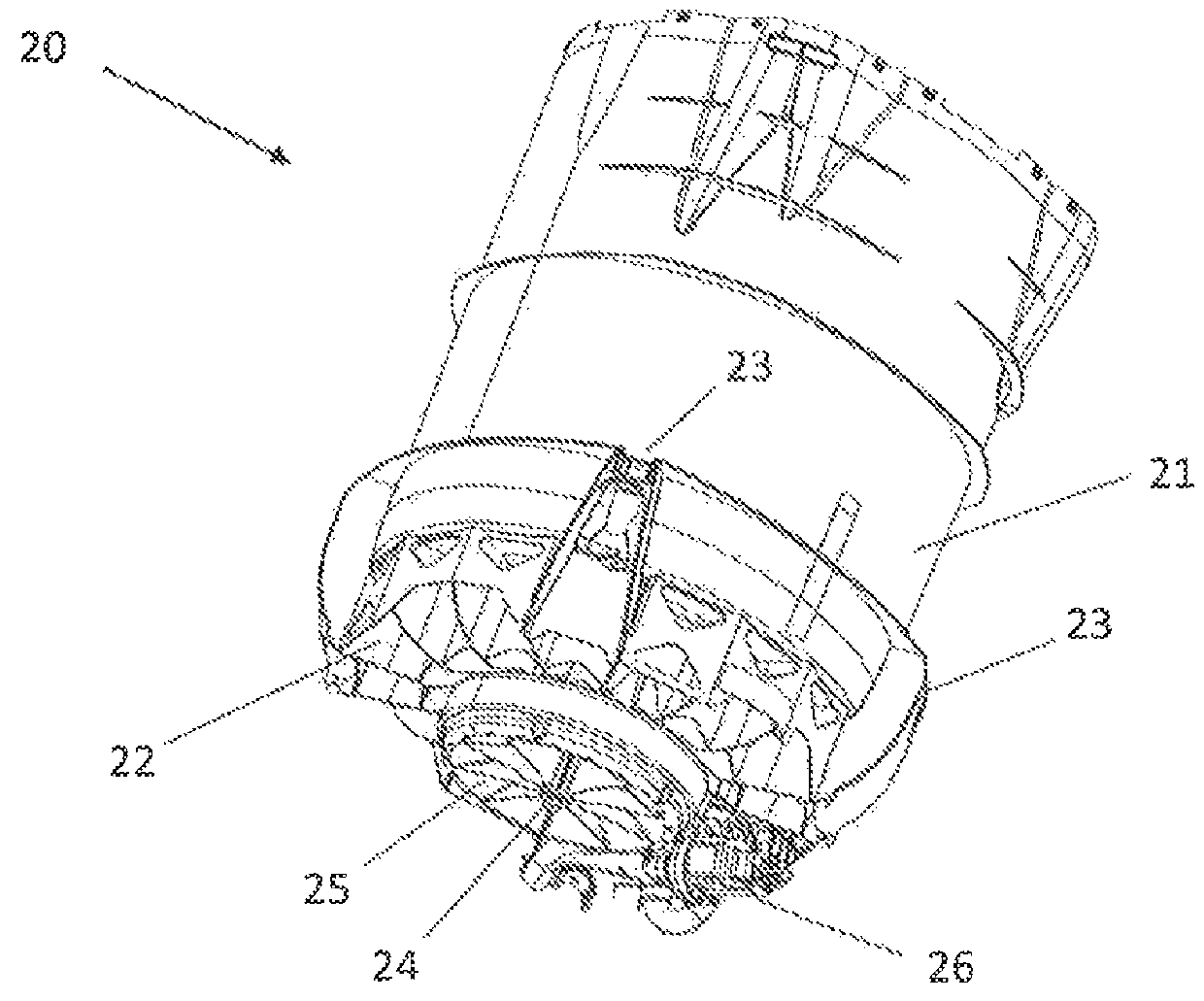

Tactile-surface control module, in particular for a motor vehicle

The present invention relates to a tactile-surface control module comprising: a flexible protection layer (9), at least one monostable switch (11) and a rigid mechanical supporting member (13) letting through the light from at least one light source and defining regions for backlighting the flexible protection layer (9), characterized in that said supporting member (13) further includes at least one passage (21) for activating the monostable switch (11), by deformation of the flexible protection layer (9), and in that the module includes a sheet (19) made of incompressible material sandwichedbetween said rigid mechanical supporting member (13) and the flexible protection layer (9), the sheet (19) defining at least one pivoting arm (23) comprising a hinge (25), joined to said supporting member (13), and a pivoting free end (27) having an actuating lug (29) placed facing a passage (21) in said supporting member (13) for actuating the monostable switch (11).

Owner:DAV

Sealed pressure-measuring member

ActiveUS9476789B2Reliable and reliableInflated body pressure measurementTyre measurementsPressure transmissionEngineering

A pressure-measurement device includes a pressure-measurement surface, which is functionally connected to a test body, and a sealed pressure-measurement housing in which the test body is arranged. The pressure-measurement surface is carried by a deformable wall of the sealed pressure-measurement housing lying at a distance from the test body. The sealed pressure-measurement housing delimits an internal space, which is a space internal to the sealed housing. The pressure-measurement device also includes a pressure-transmission object that transmits the pressure between the pressure-measurement surface and the test body. The pressure-transmission object includes a substantially incompressible material occupying all of the internal space. The pressure-measurement device further includes an energy source and a processor for processing pressure data detected by the test body. The processor is arranged in the sealed pressure-measurement housing.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

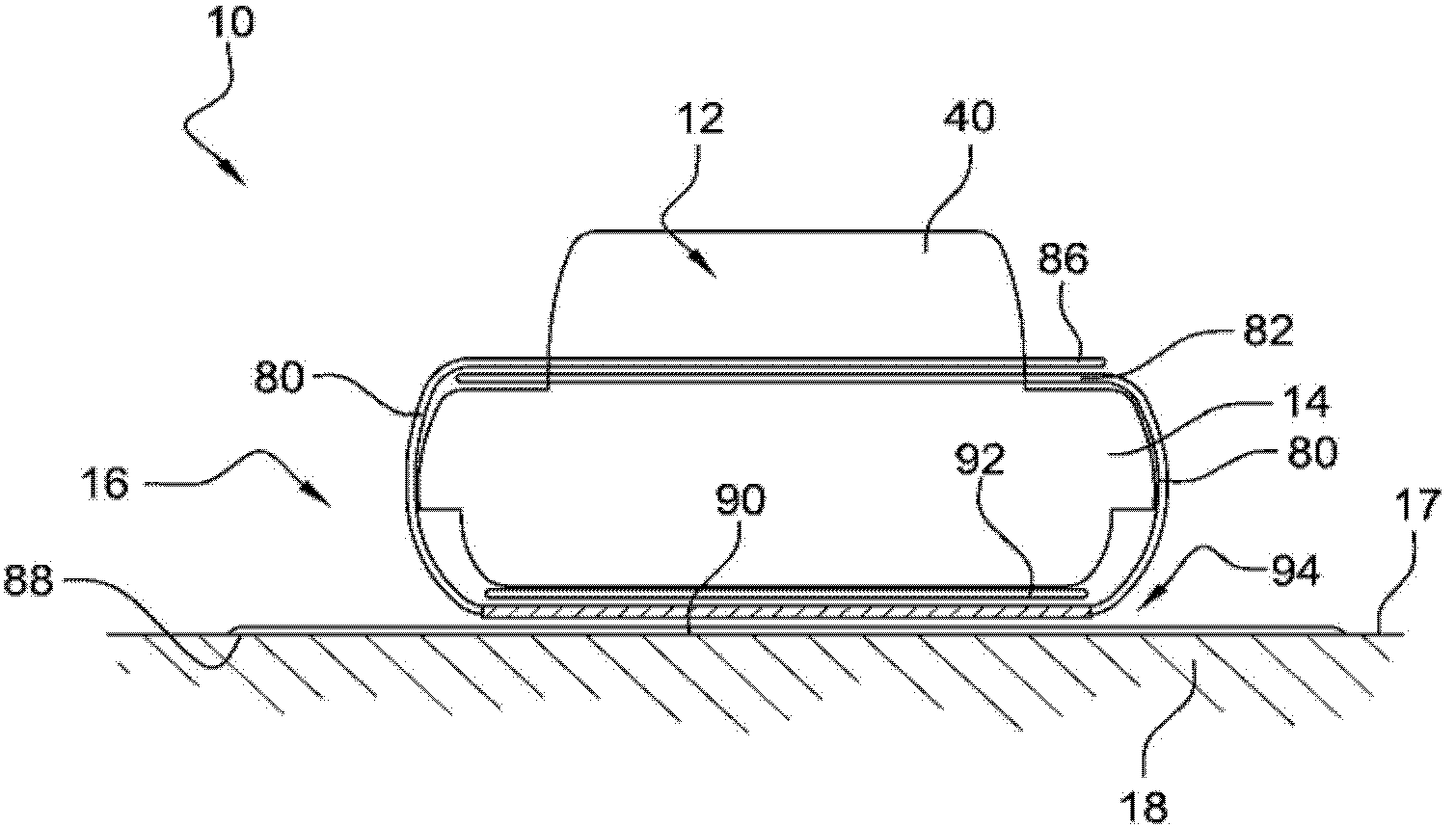

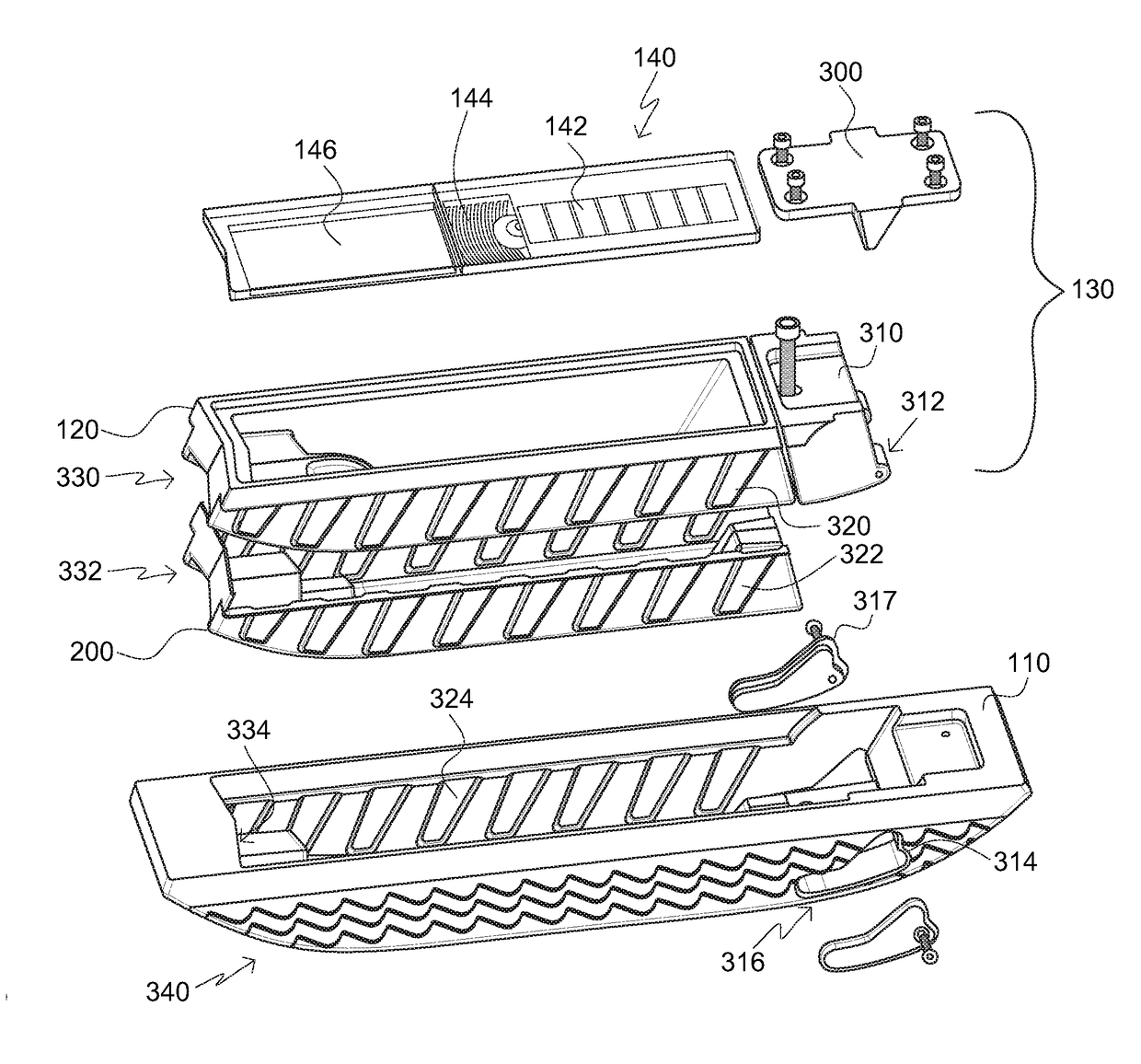

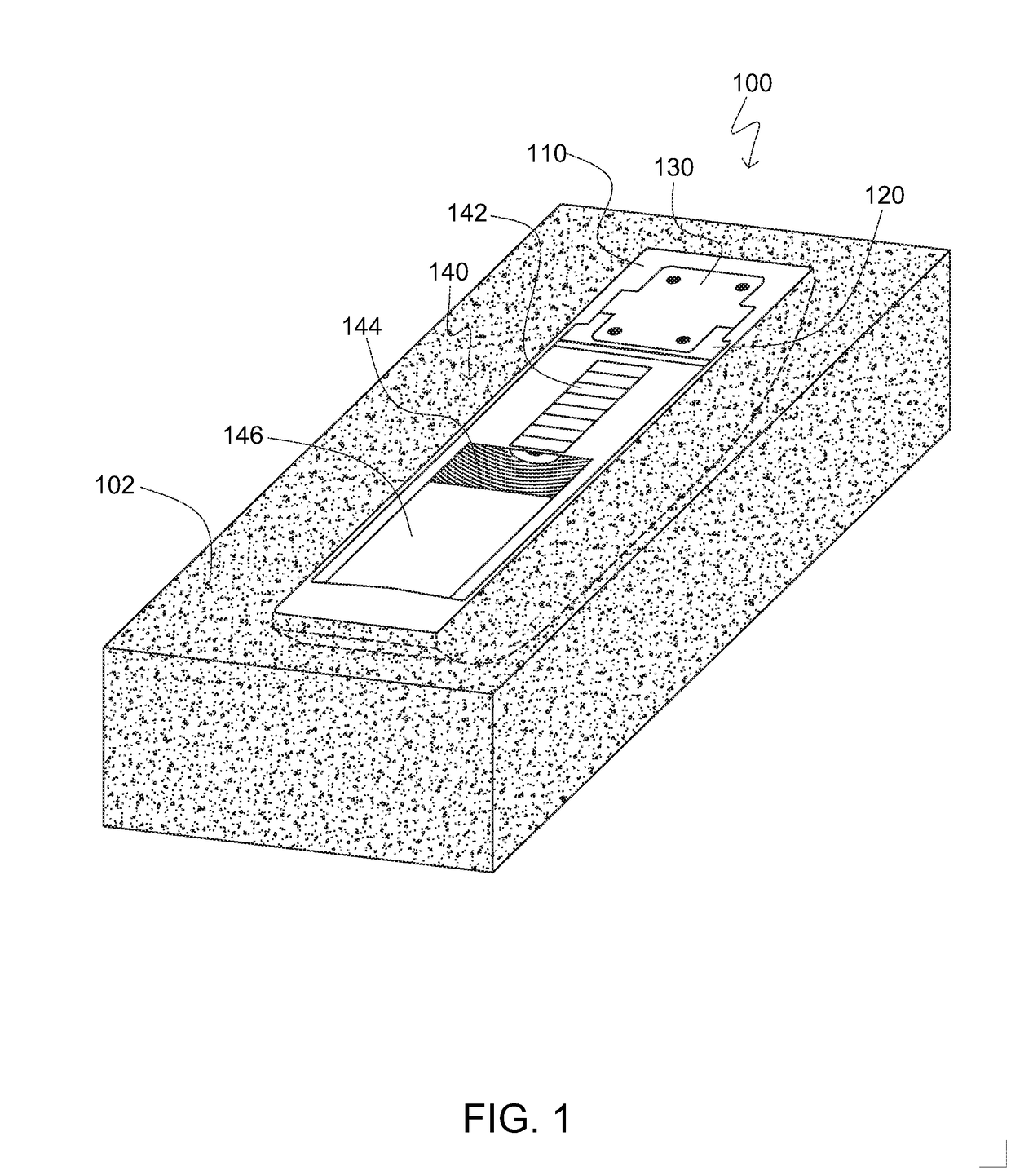

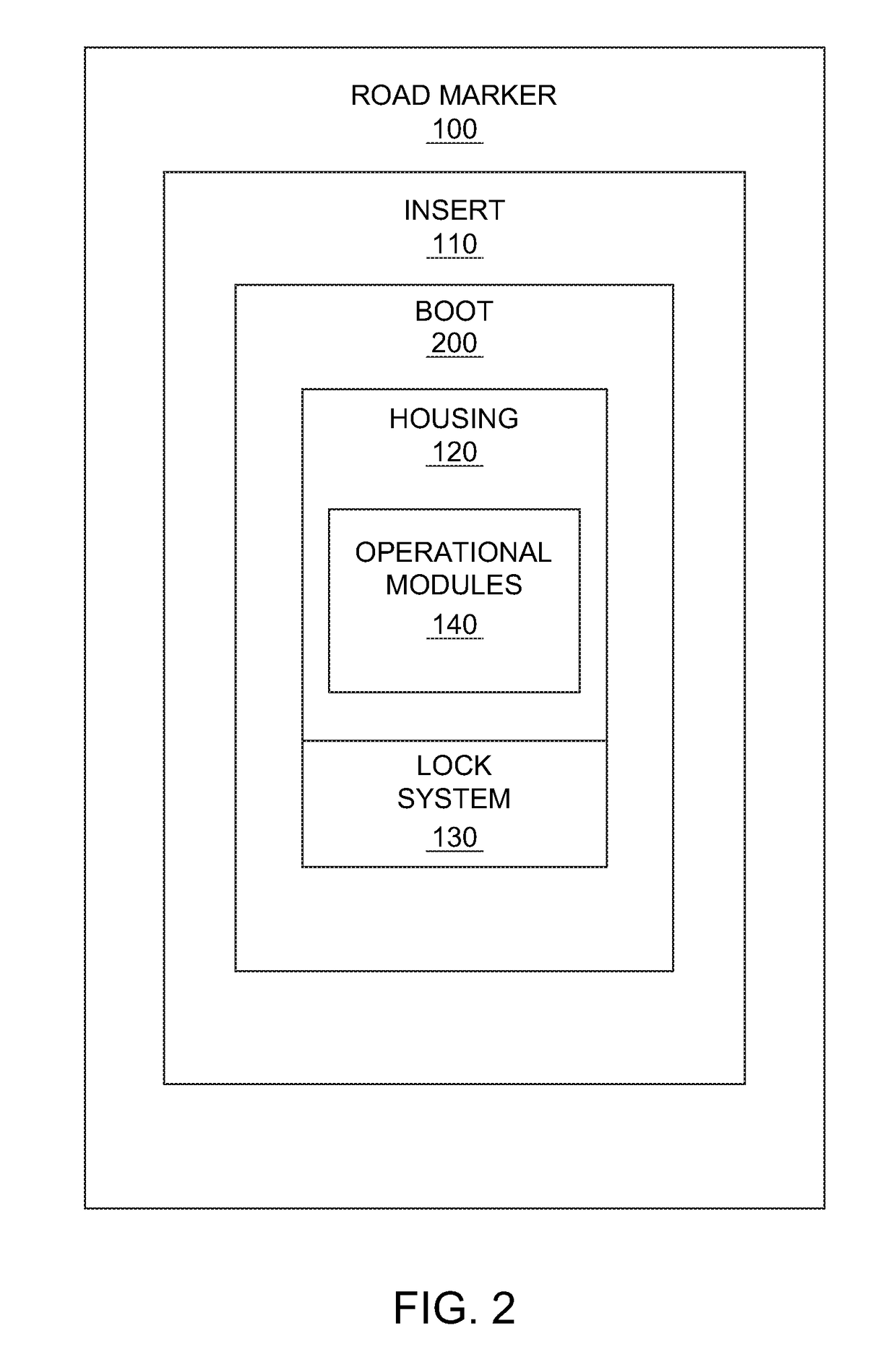

Intelligent traffic management system with all-weather, illuminated lane markings

ActiveUS20170335526A1Easy to disassemblePrevent backward displacementElectric circuit arrangementsPavement lightsComputer moduleRidge

A road marker apparatus, system and lighting module and corresponding methods of manufacture, installation and replacement. There is a road insert having upwardly facing ridges and an internal cavity with interior surface textures and a tapered front cavity; a boot of incompressible material disposed within the internal cavity of the road insert and form-fit thereto; and a housing body removably disposed within the boot cavity and form-fit thereto. An array of exterior surface textures that operate as a forward operating taper lock between the housing body and the road insert that restricts forward movement and rotation of the housing body with respect to the road insert; and a housing cavity within which one or more physical modules may be disposed. There is a rear lock behind the housing body that prevents rearward displacement of the housing body with respect to the road insert.

Owner:VIVCOR SYST INC

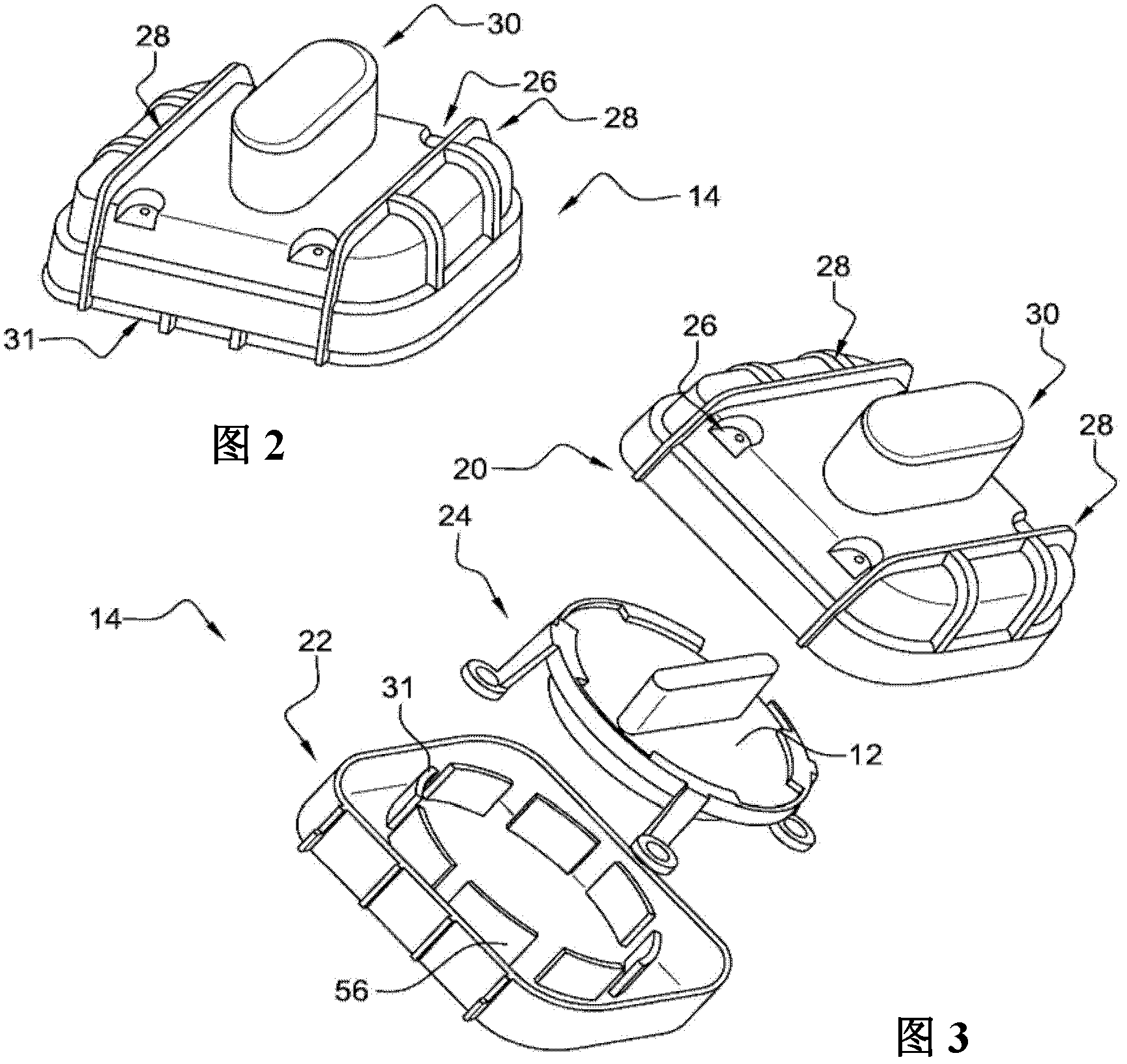

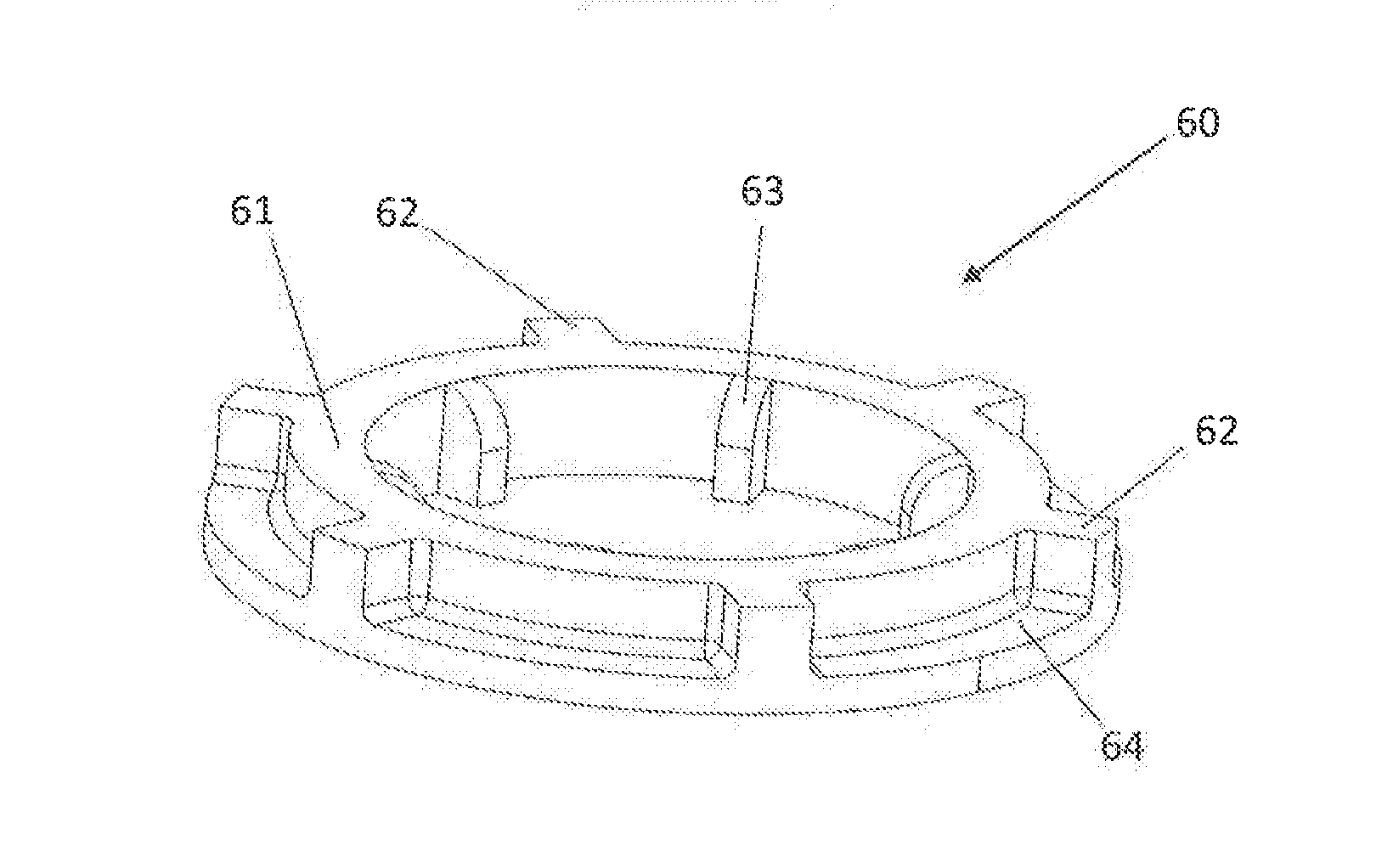

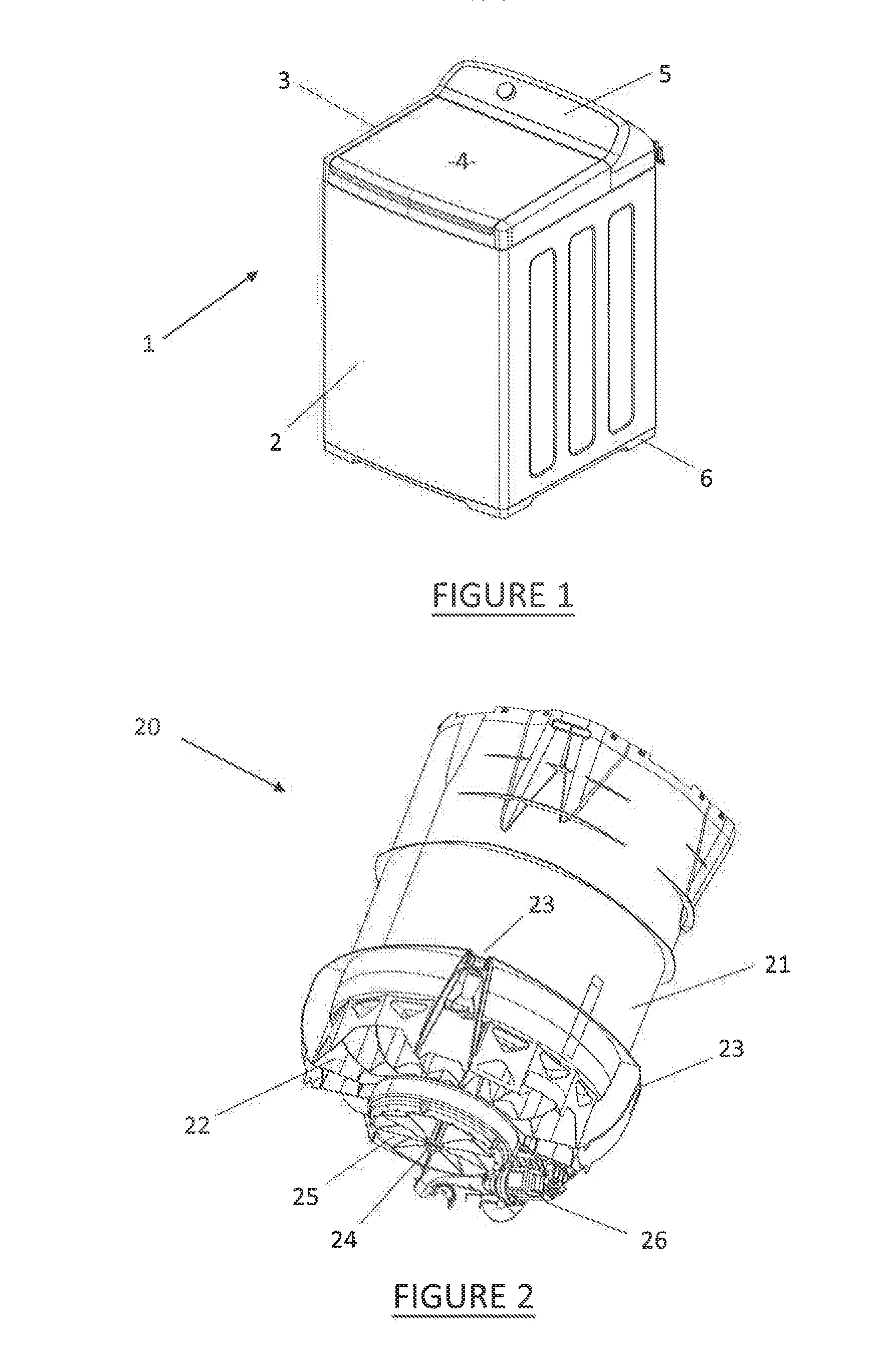

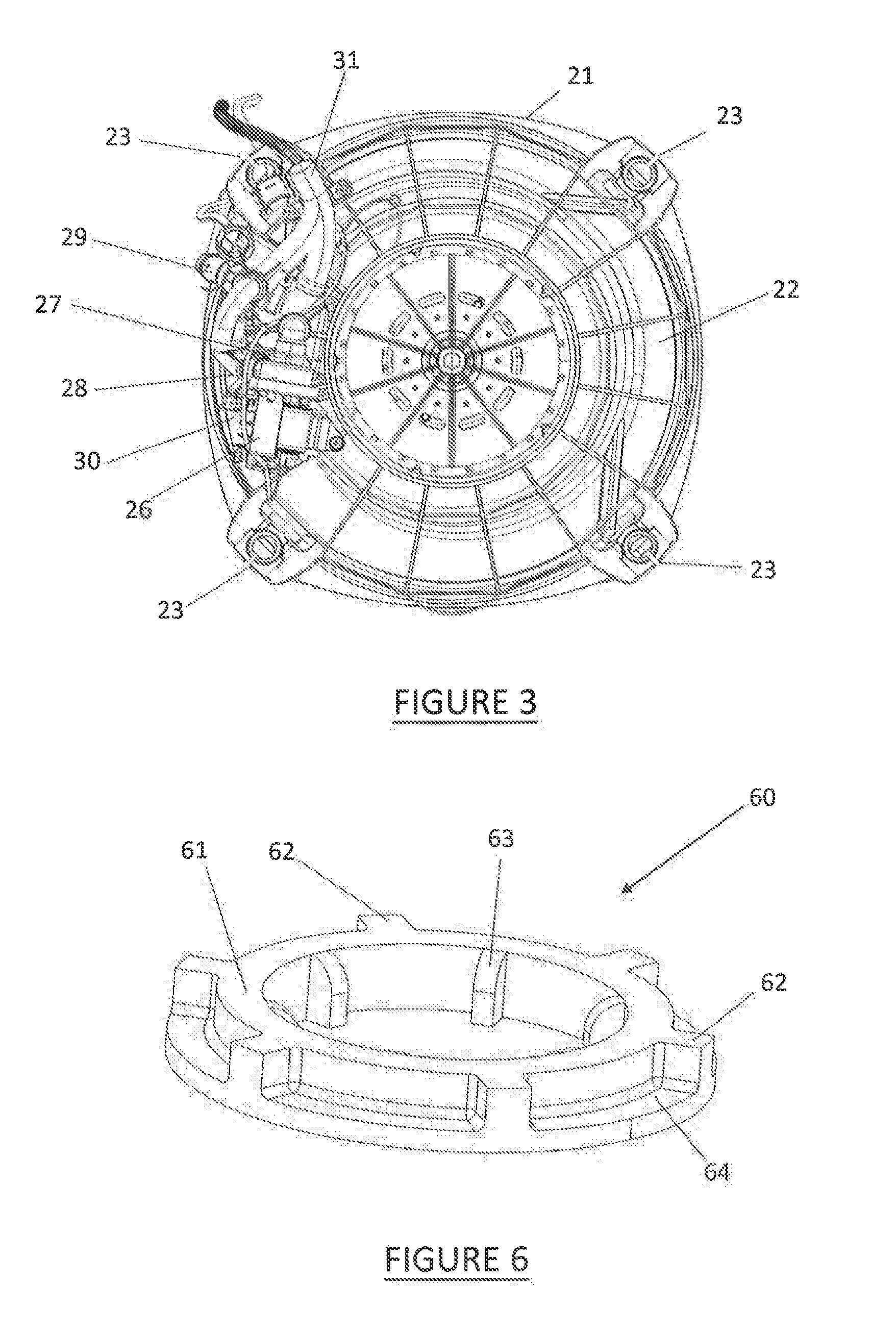

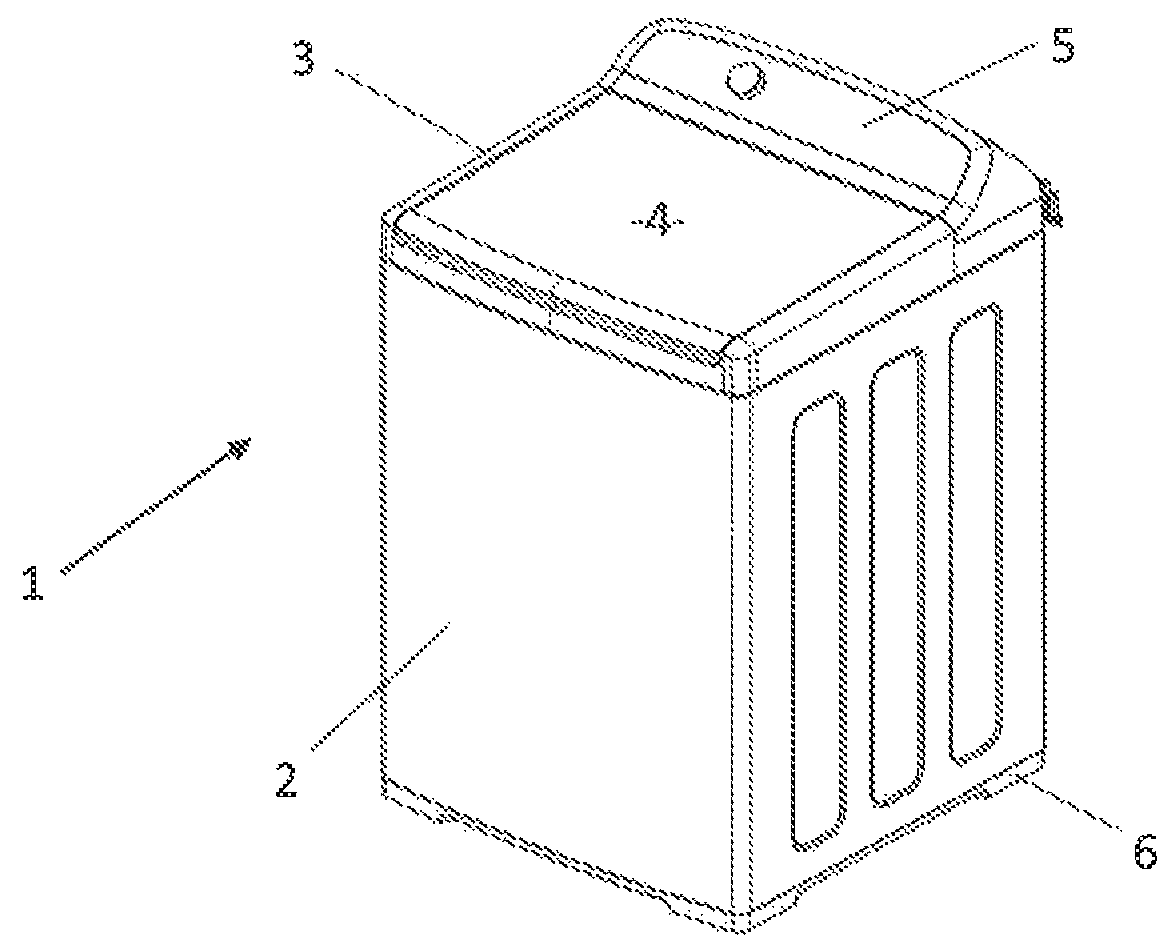

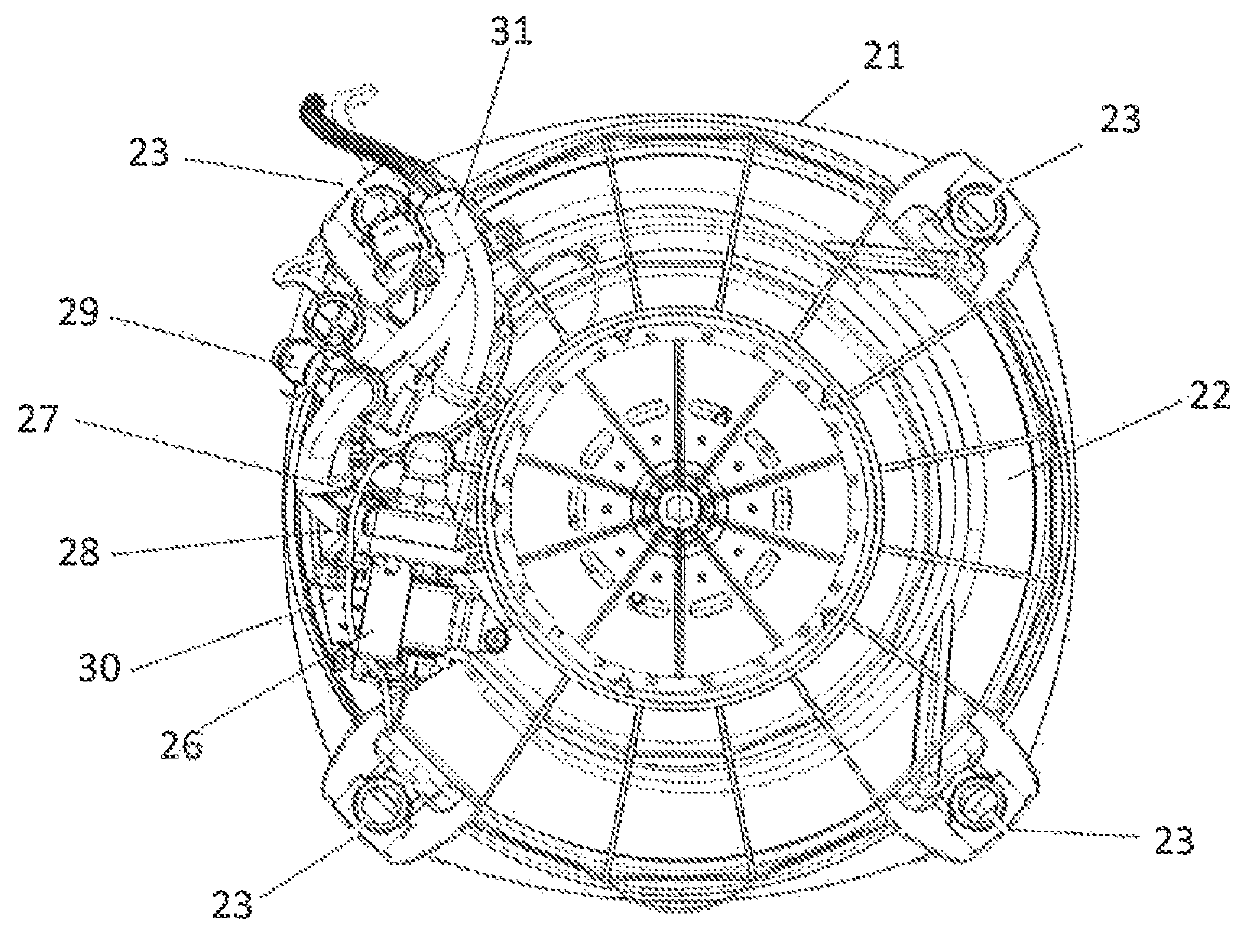

Vibration isolator

ActiveUS20160377144A1Reduce vibrationReduce the amplitudeSpringsNon-rotating vibration suppressionLaundry washing machineHome appliance

A vibration isolator suitable for isolating and / or dampening vibrations generated in a vibrating machinery component such as a motor or pump so as to minimise the unwanted effects (such as audible secondary sounds) of those vibrations. The isolator may be installed in a home appliance such as a laundry washing machine and may be a separate, unitary component installed between a motor / pump and the structure of the laundry machine or may be installed between a mounting bracket of the motor / pump and the laundry machine. Alternatively, the isolator may be integrally formed with a pump / motor mounting bracket, on upper and / or lower surfaces of a mounting flange. The isolator is preferably formed from a substantially incompressible material and in one preferred embodiment has a washer-like form with a central opening at least partially surrounded by a tubular ridge with a plurality of radial projections extending outwardly and / or inwardly from outer / inner surface(s) of the tubular ridge.

Owner:FISHER & PAYKEL APPLIANCES LTD

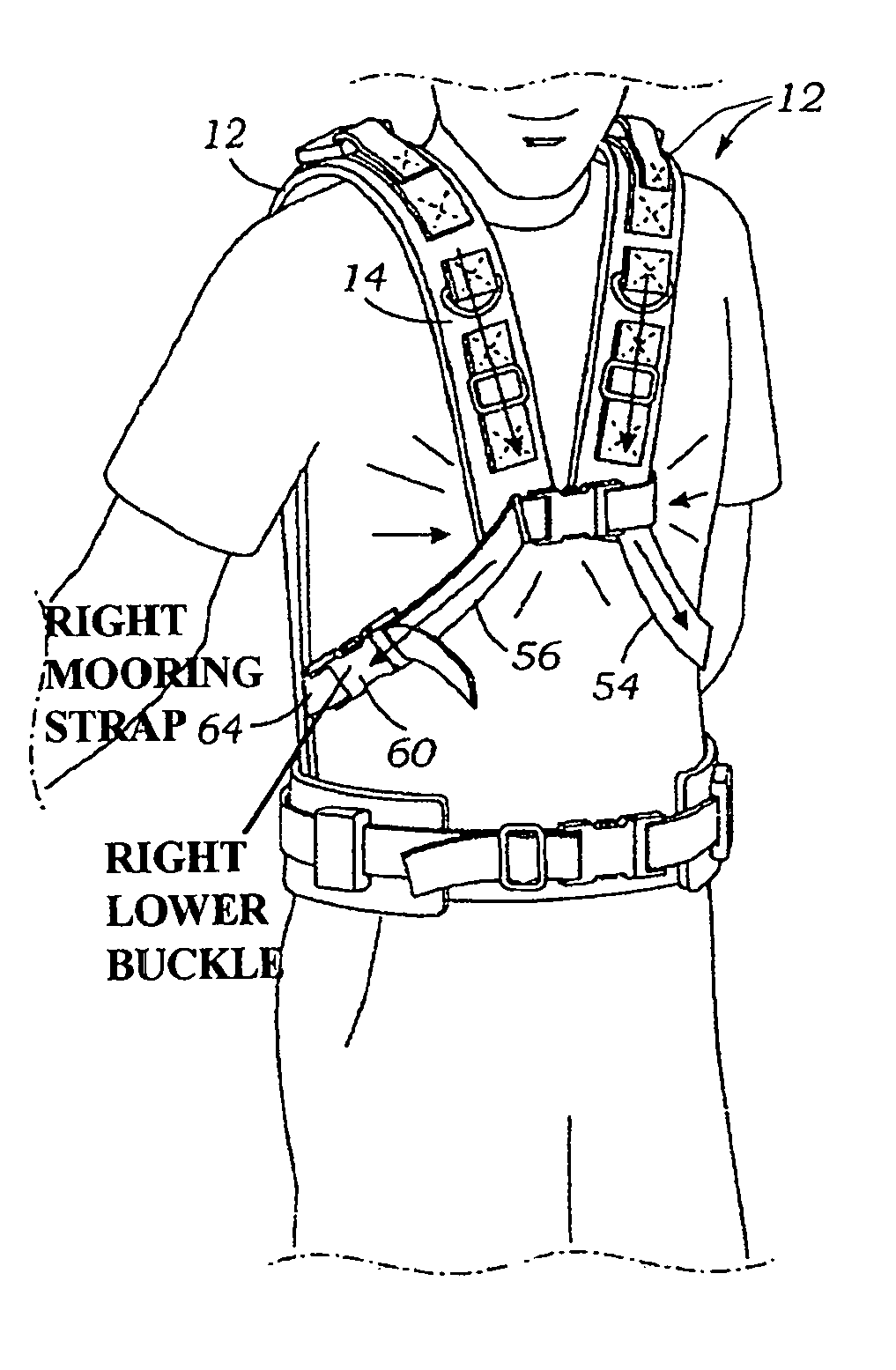

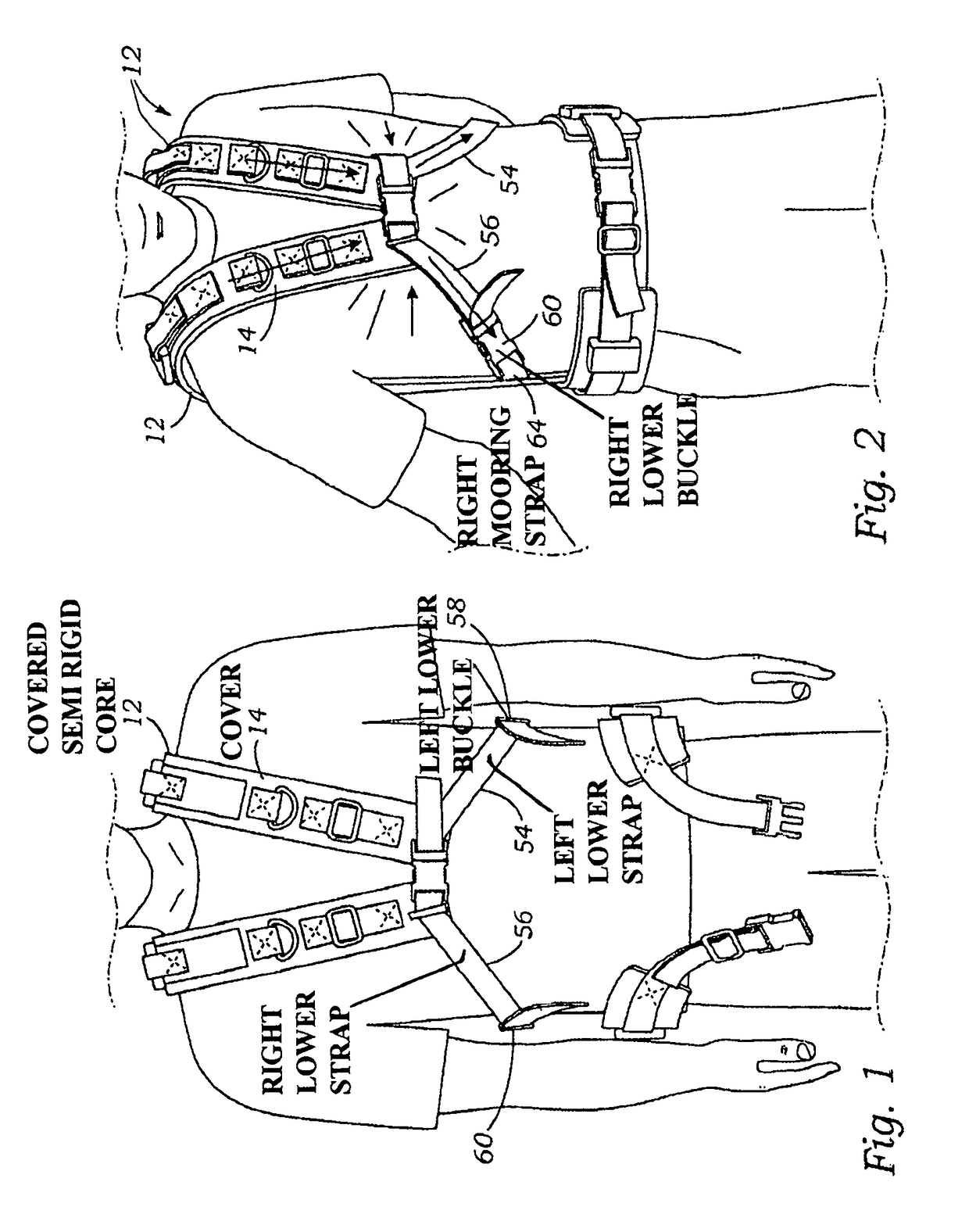

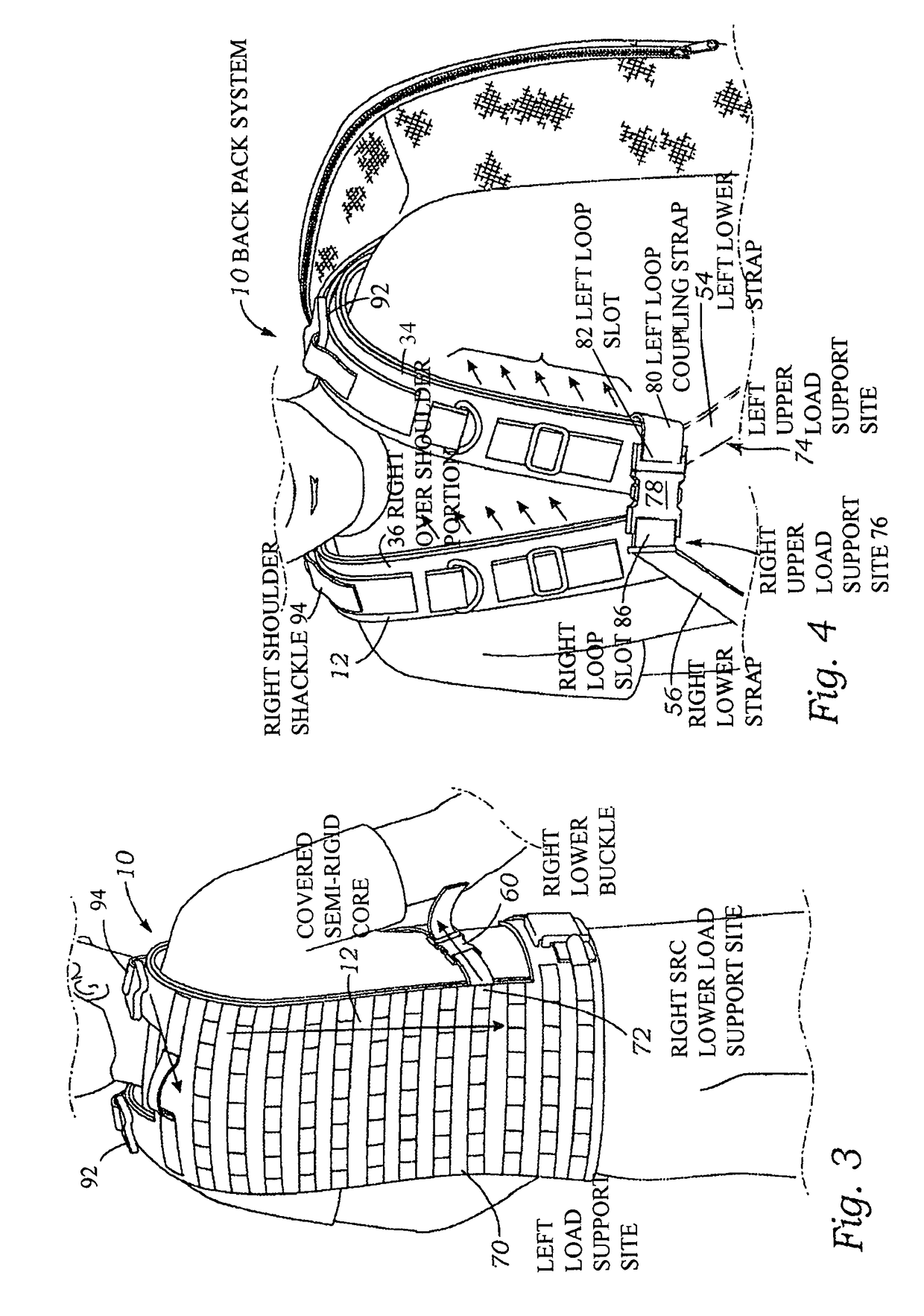

Backpack system

A heavy-duty, modular backpack system or personal load bearing system replaces shoulder straps with a lightweight, SRC (semi-rigid core) and hanger suspension system, that subjects the chest or center of the body to a compressive force to transfer the load forward while freeing up the shoulders. The SRC is provided that is made out of a semi-rigid plastic such as ABS plastic or a carbon fiber composite or any other non-compressible material with similar structural characteristics. Left and right hooks pass over, forward and downward over the chest and are joined at a central coupling at a center of the human body, the “xiphoid process”, a small extension of the sternum. Right and left lower straps extend to left and right lower support sites to form a arched cage on the user. A belt wraps around the waist on top of the hip bones to limit lateral movement.

Owner:SANTANA ZAIZAR JOSE LUIS

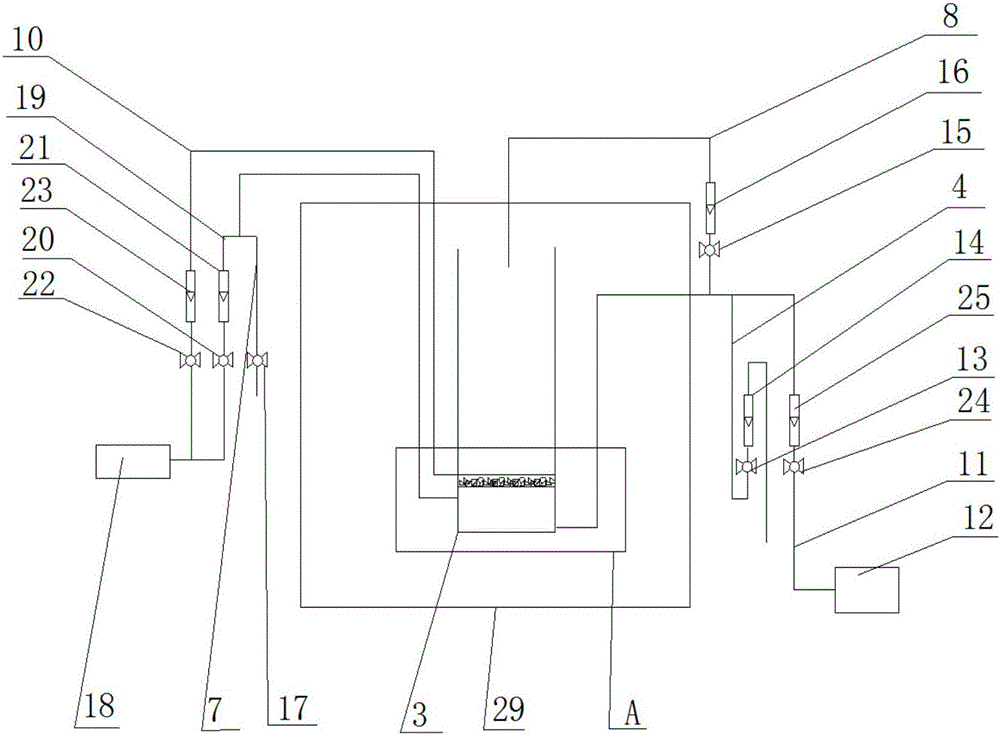

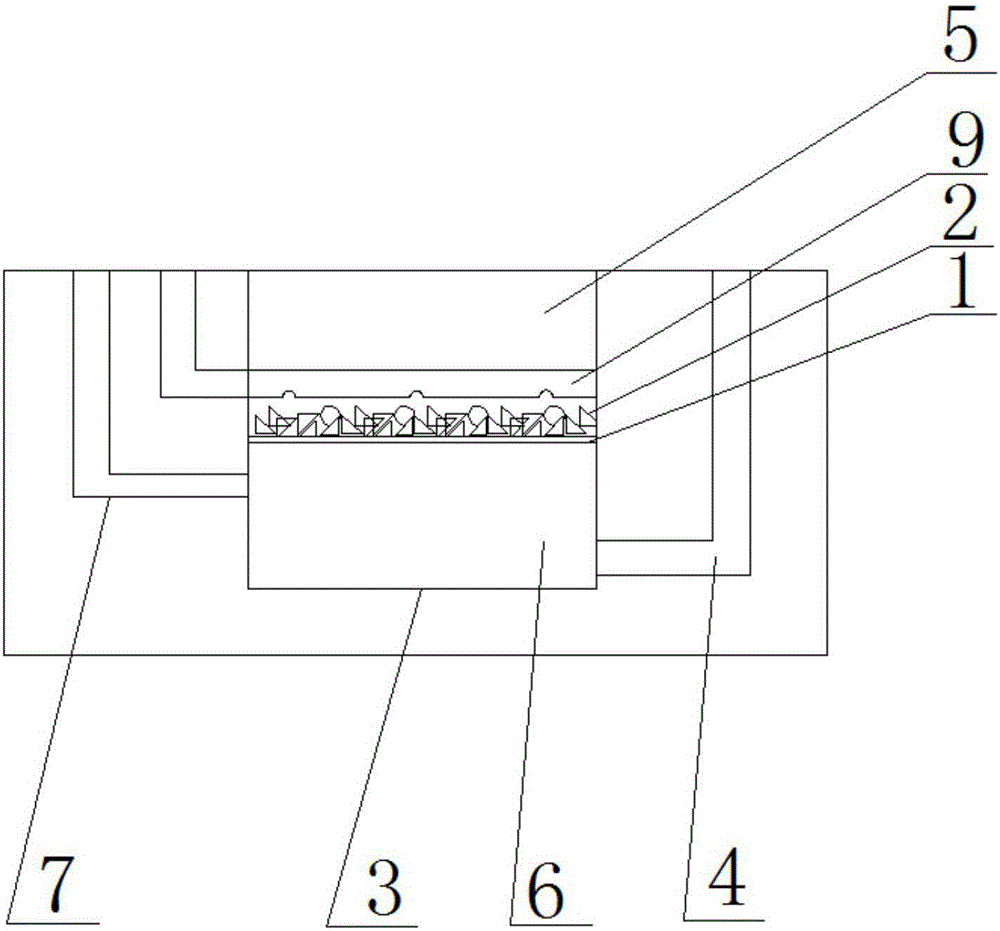

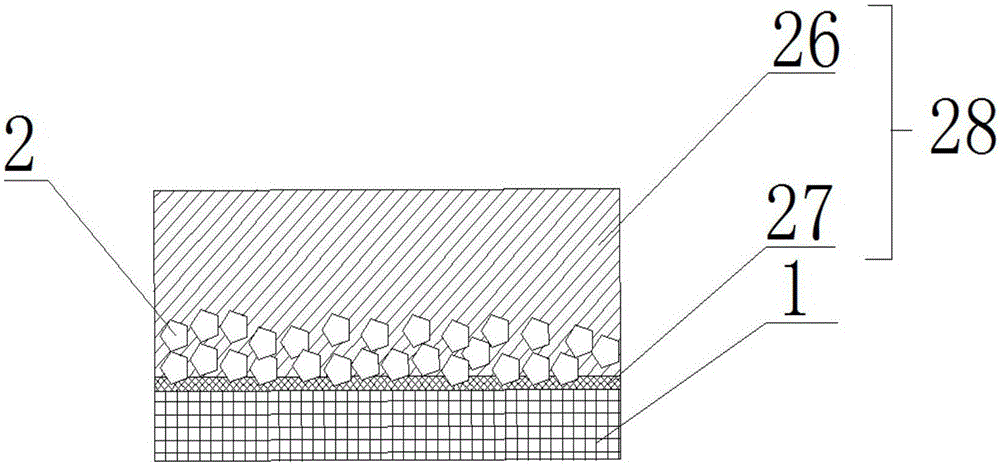

Dynamic membrane filtering device and operation method thereof

InactiveCN107174974ATo achieve the purification effectShort film forming timeSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisSludgeSewage

The invention provides a dynamic membrane filtering device and an operation method thereof and relates to the technical field of sewage treatment. The dynamic membrane filtering device comprises a supporting net, filler, a casing and a water outlet pipe, wherein the supporting net is arranged in the casing, and the inside of the casing is divided into a water inlet cavity and a water producing cavity by the supporting net; the filler is arranged on the upper surface of the supporting net; the water outlet pipe is communicated with the water producing cavity; the filler is an incompressible material and is in a particle shape. In a process that sludge mixed liquid passes through the supporting net and the filler, sludge floc is compacter by compression under action of seepage pressure. As the filler is the incompressible material, the filler has a supporting framework effect, most seepage pressure action can be offset, and the phenomenon that a filter cake layer is compressed is relieved; thus, through holes for water to pass are guaranteed and reserved, operation flux is improved, and the sewage purifying efficiency is improved. In addition, the filler can quicken an initial process that the supporting net intercepts the sludge floc to form the filter cake layer, and film formation time is effectively reduced.

Owner:TIANJIN BISHUIYUAN MEMBRANE MATERIAL CO LTD

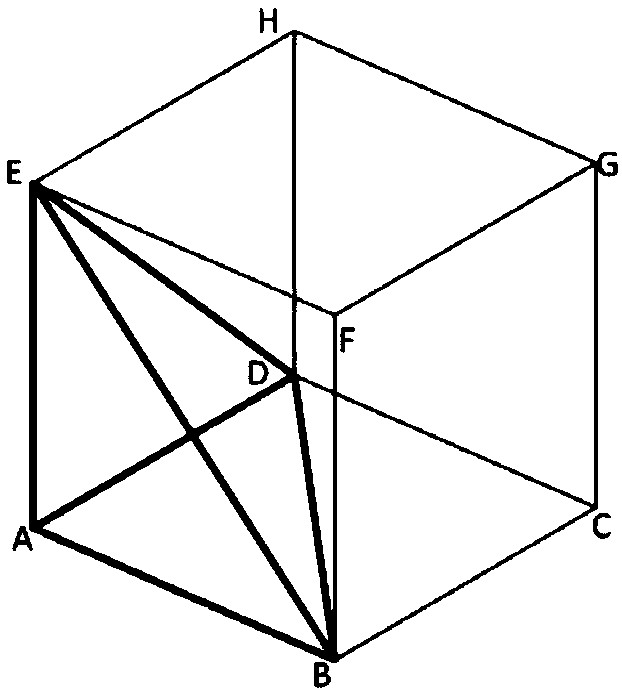

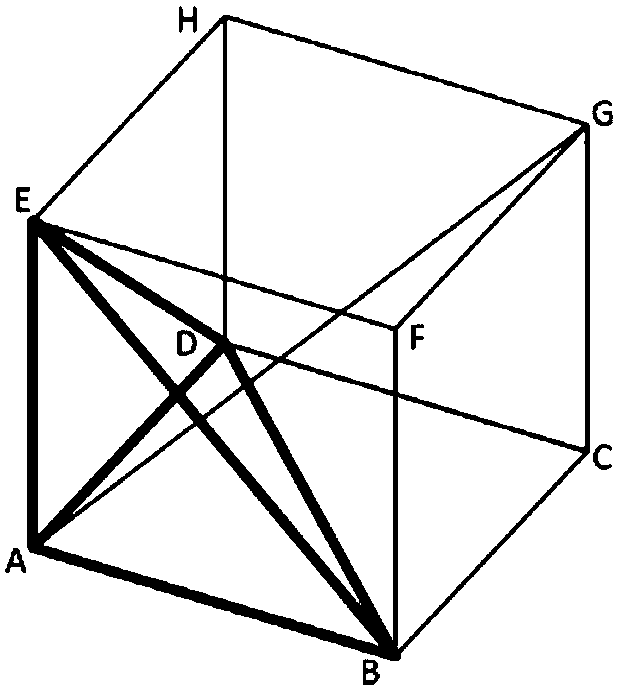

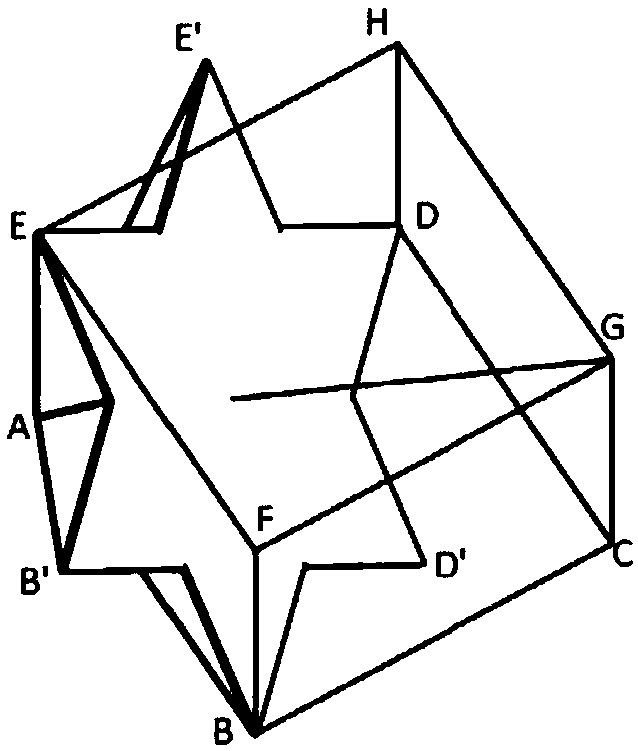

Rotary right angle tetrahedron-based test device for shearing strain and calculating method thereof

The invention provides a rotary right angle tetrahedron-based test device for a shearing strain and a strain state calculating method thereof. The device comprises a rotary right angle tetrahedron structure and rotating angle measurers. A shearing strain value is measured by measuring a corresponding right angle variation, so as to obtain a strain value of one point inside an incompressible material. Meanwhile, the invention provides a shearing strain calculating method based on a strain state of the rotary right angle tetrahedron structure. A calculating formula where a three-dimensional strain state of one point can be linearly expressed by several characteristic shearing strains is built, so that single expression of the shearing strain for the strain state is realized. The device and the method have the beneficial effects that internal characteristics of the incompressible material are reflected; a novel measure is provided for learning the yield of the material and building the model; in order to learn the strain and the stress in the incompressible material better, a direct and effective measure is provided; and the blank of calculating the three-dimensional strain state by the shearing strain is filled.

Owner:TIANJIN CHENGJIAN UNIV

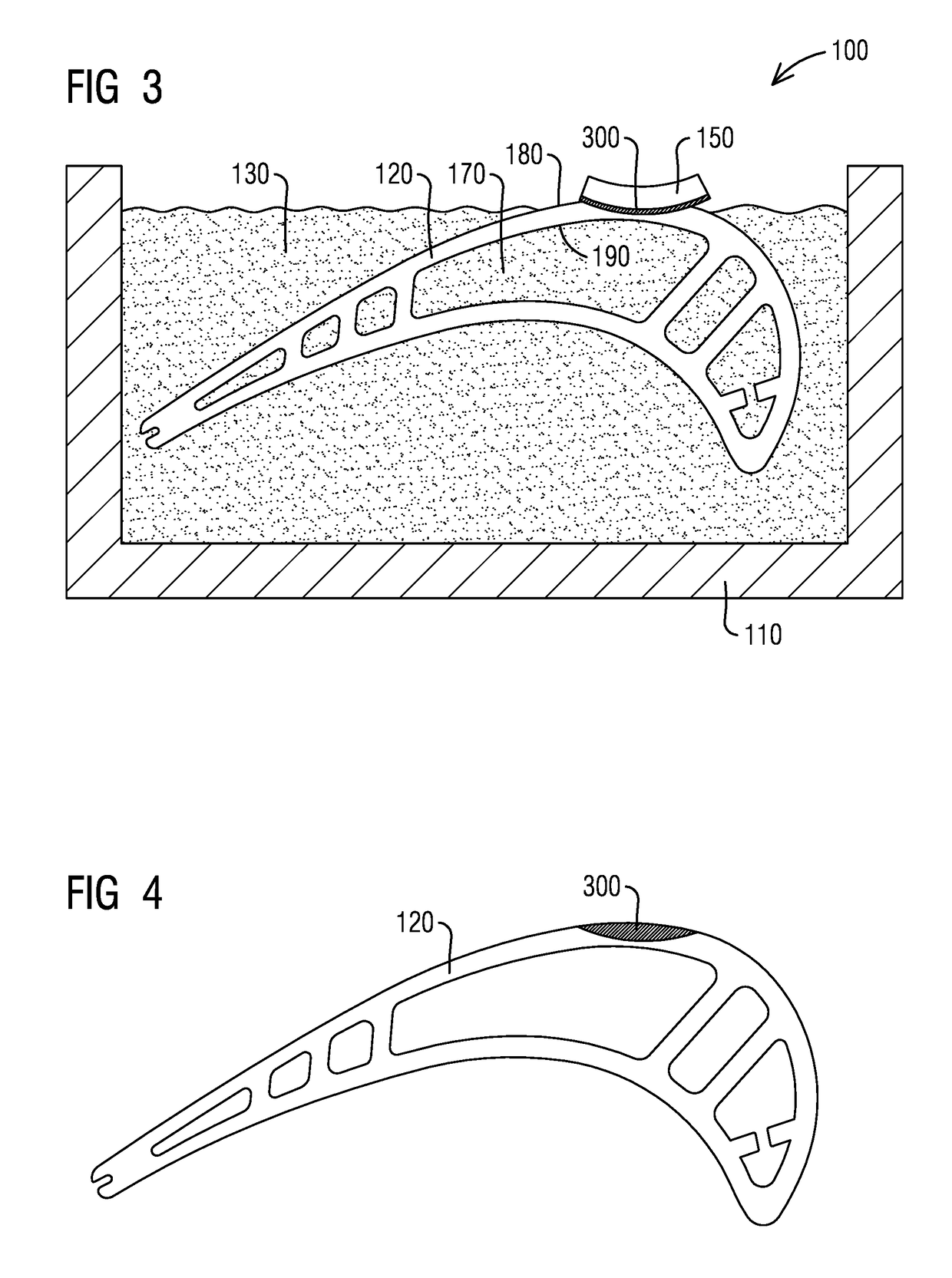

Method of impact welding repair of hollow components

InactiveUS20170216959A1Avoid deformationTurbinesWelding/soldering/cutting articlesSupporting systemSupport system

A method of impact welding a flyer to a hollow component is provided. The method includes providing the component made of a first material and including a cavity where a weld site is disposed on a first side of the component. An incompressible material is packed against a second side of the component opposite the first side facing the cavity. A flyer made of a second material is positioned onto the weld site. The flyer is then impact welded to the component. The incompressible material prevents the deformation of the component during the impact welding. A method of impact welding a cover plate to a component is provided as well as a support system for welding repair of hollow components.

Owner:SIEMENS ENERGY INC

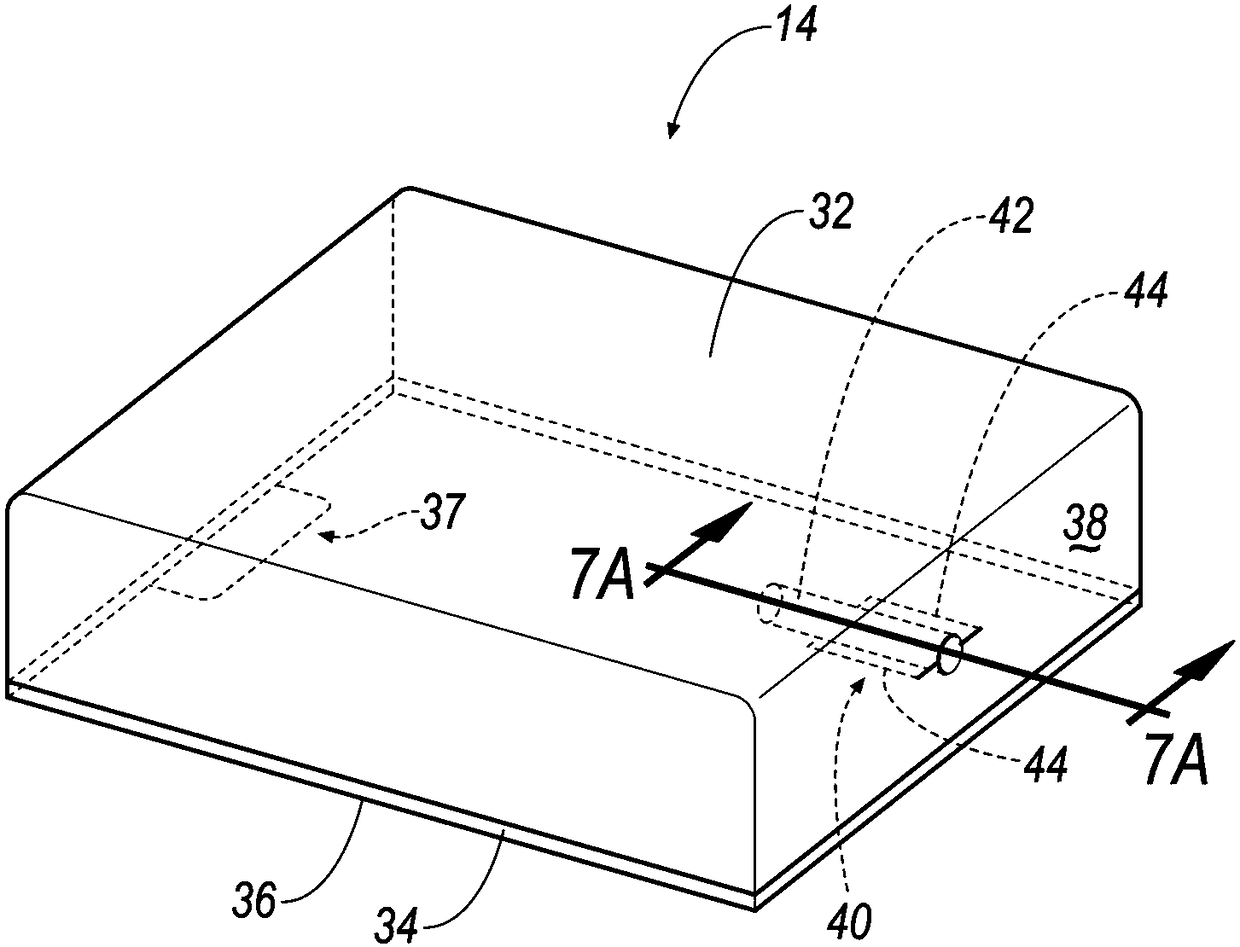

Reversible writing surface for soft armrest applications

Disclosed is a reversible writing surface for soft armrest applications. An armrest unit is disclosed that is selectively moveable between a first configuration, whereby the armrest is used as a traditional armrest, and a second configuration, whereby the armrest is usable as a writing surface. The armrest unit comprises an armrest and a mounting pin. The armrest has a first section constructed ofa compressible material and a second section connected to one side of the first section and constructed of a non-compressible material. The mounting pin engages a mounting channel in the armrest. Thearmrest is selectively rotatable about the mounting pin to move the armrest 180 degrees between the first configuration and the second configuration. A method of operating the armrest unit is also disclosed.

Owner:FORD GLOBAL TECH LLC

Shoe for expandable liner system

An apparatus to protect the mounting area of casing when subsequently attaching a tubular is disclosed. A sleeve that defines a sealed cavity having a loose incompressible material inside covers the mounting location on the casing. The cementing of the casing takes place through the sleeve. After the cementing, the sleeve is drilled out and the incompressible material is removed to the surface with the drill cuttings. A tubular is inserted in the casing and is preferably expanded into sealing contact with the mounting location on the casing. At the end of expansion, the run in shoe on the tubular is retrieved.

Owner:BAKER HUGHES INC

Vibration isolator

A vibration isolator suitable for isolating and / or dampening vibrations generated in a vibrating machinery component such as a motor or pump so as to minimise the unwanted effects (such as audible secondary sounds) of those vibrations. The isolator may be installed in a home appliance such as a laundry washing machine and may be a separate, unitary component installed between a motor / pump and the structure of the laundry machine or may be installed between a mounting bracket of the motor / pump and the laundry machine. Alternatively, the isolator may be integrally formed with a pump / motor mounting bracket, on upper and / or lower surfaces of a mounting flange. The isolator is preferably formed from a substantially incompressible material and in one preferred embodiment has a washer-like form with a central opening at least partially surrounded by a tubular ridge with a plurality of radial projections extending outwardly and / or inwardly from outer / inner surface(s) of the tubular ridge.

Owner:FISHER & PAYKEL APPLIANCES LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com