Sealed pressure-measuring member

A technology for measuring component and sealing pressure, which is applied to the measurement of tire pressure and the field of construction machinery tires, and can solve problems such as damage to the test body and unfavorable pressure measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

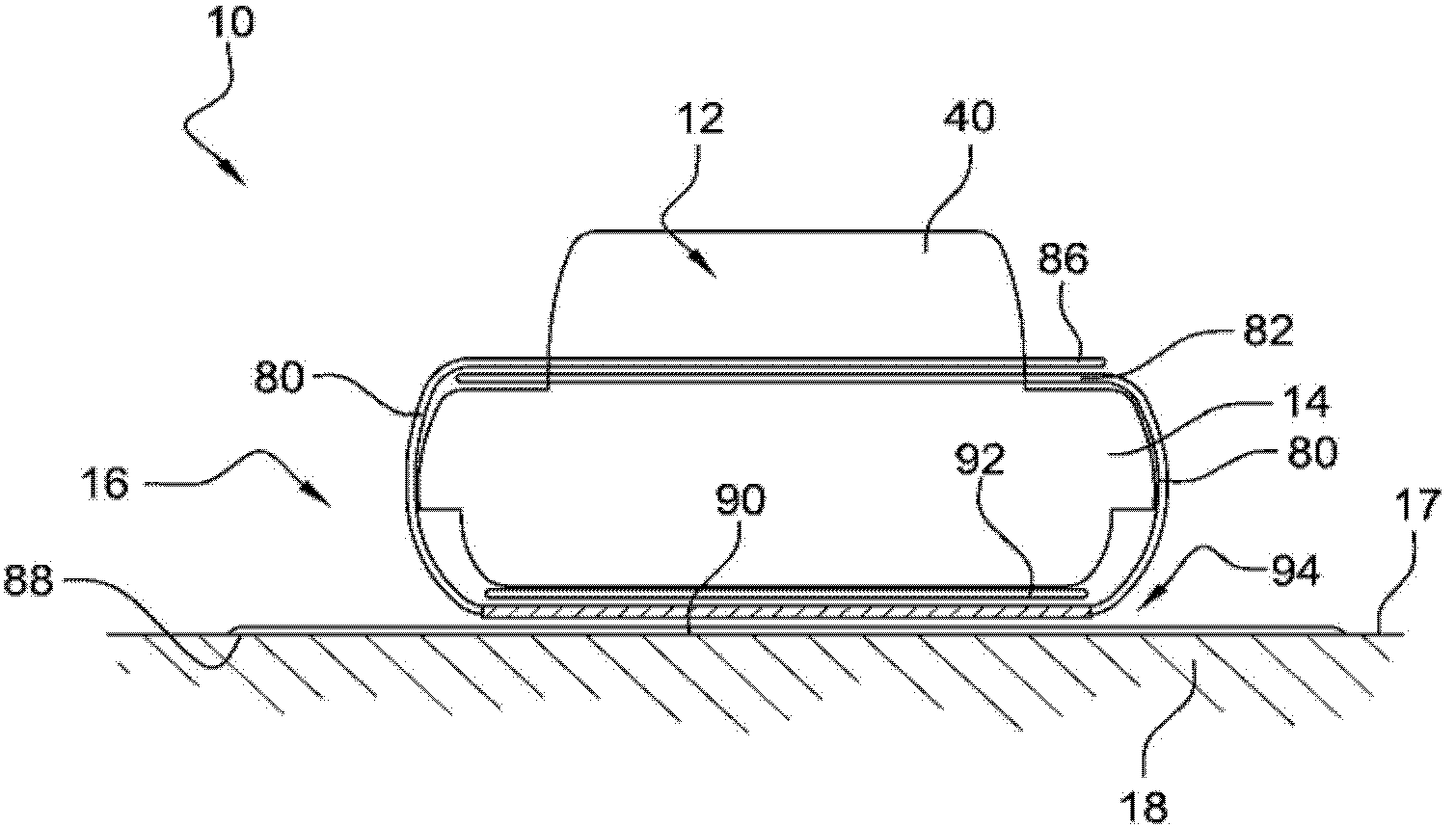

[0063] figure 1 A device according to a first embodiment is shown and is generally indicated by reference numeral 10 . The device 10 comprises a pressure measuring member 12 and a protective housing 14 for protecting the measuring member 12 . The device 10 also includes means 16 for securing the protective casing 14 to the inner surface 17 of the tire 18 . Tire 18 is used in construction work applications.

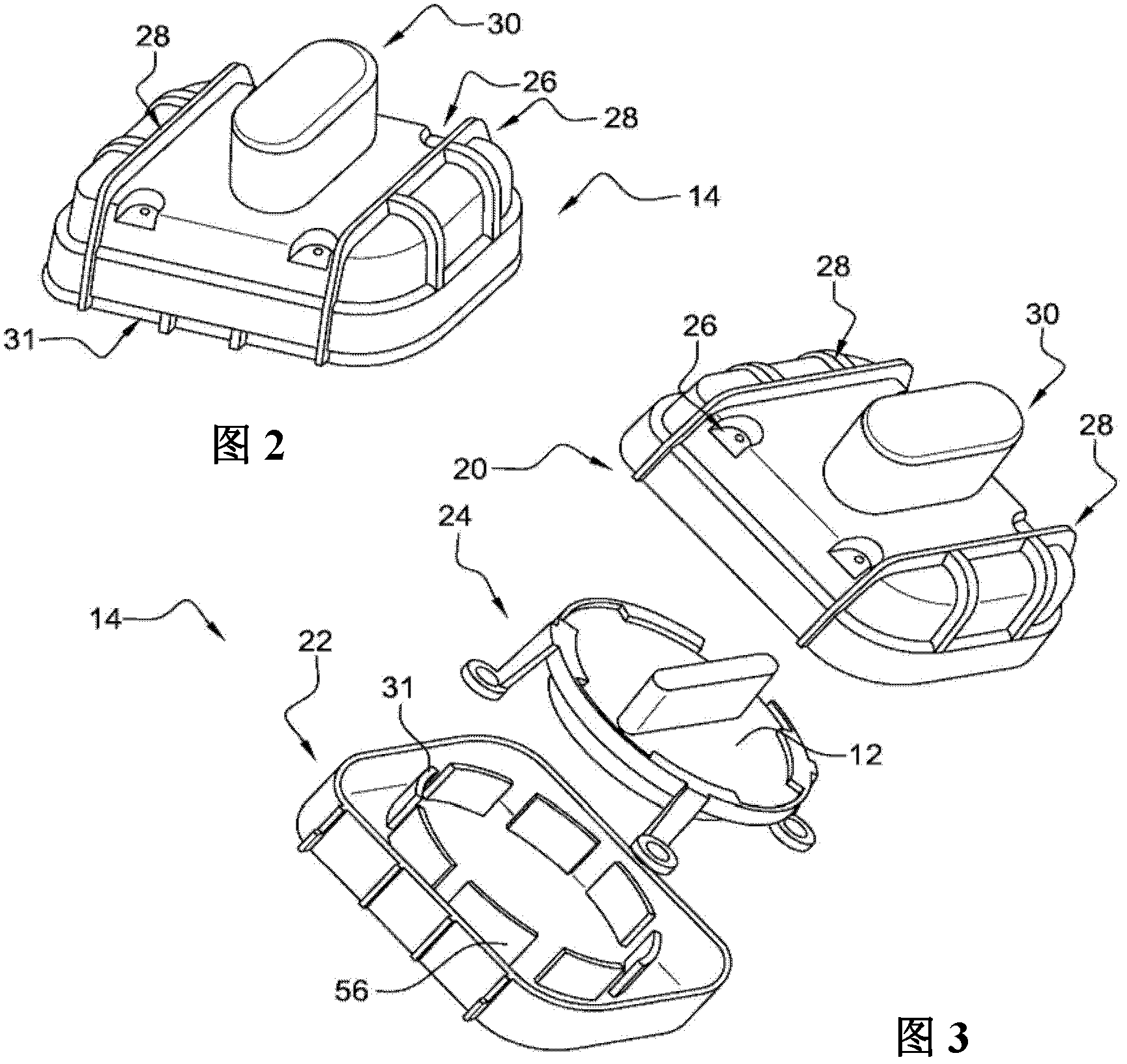

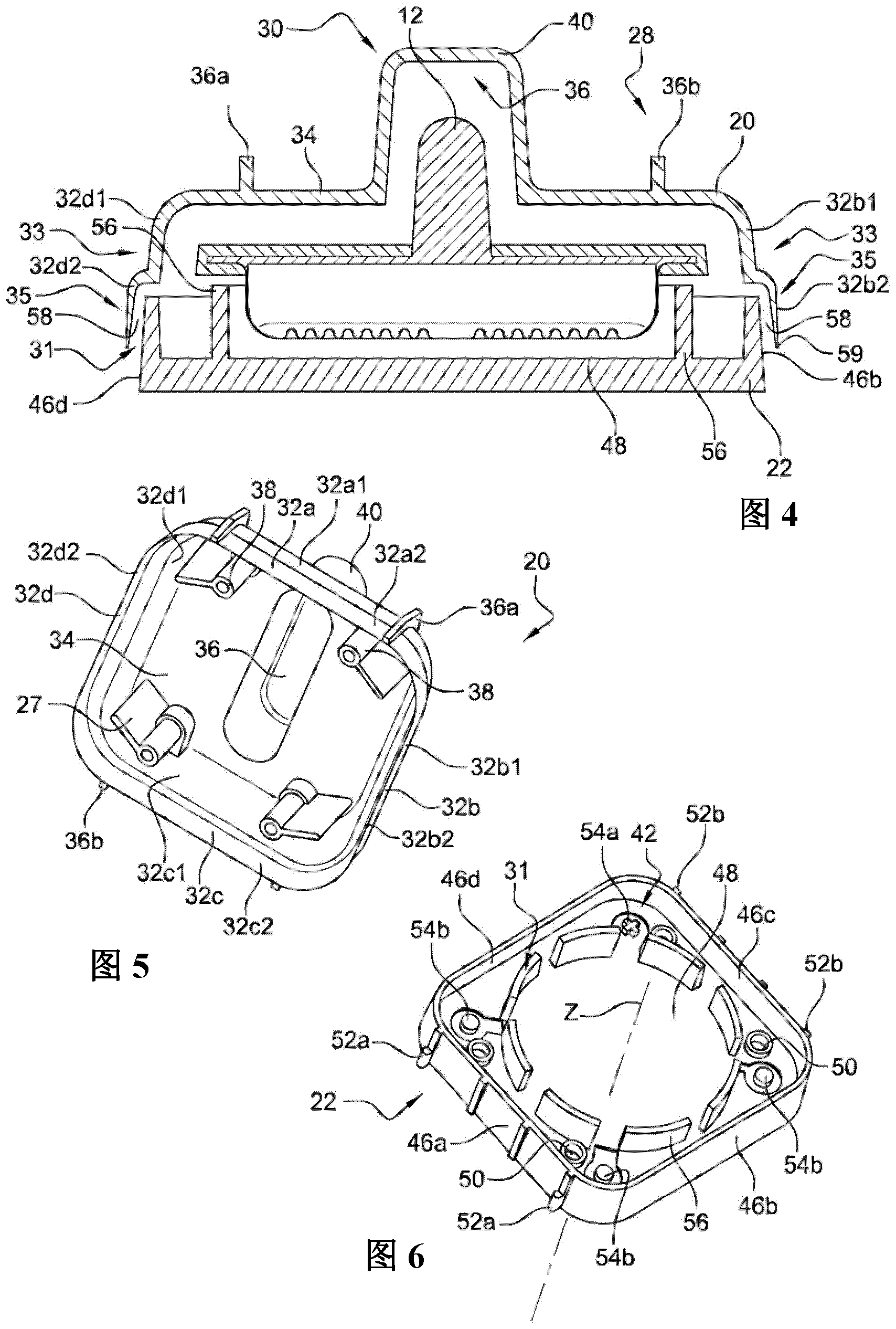

[0064] refer to Figures 2 to 4 , the protective housing 14 includes a first portion 20 and a second portion 22 . The device 10 includes a positioning support 24 for positioning the member 12 in the housing 14 . The parts 20, 22 are movable relative to each other, in this particular example disengageable from each other, and are arranged so that when they are assembled they allow air to communicate between the inside and outside of the housing 14, for example via the two parts 20, 22 space between. Portions 20, 22 can be positioned for inserting member 12 into housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com