Direct tensile test jag of incompressible material

A tensile test and fixture technology, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve problems such as large deformation of the clamping end, slip test data, distortion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further introduced below in conjunction with the accompanying drawings.

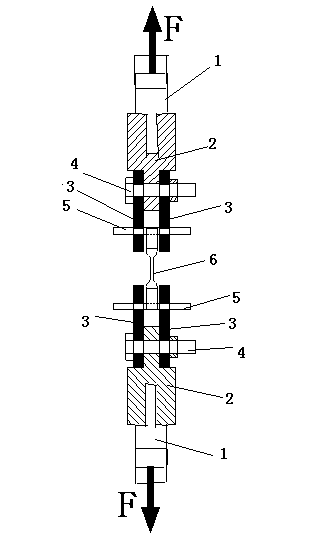

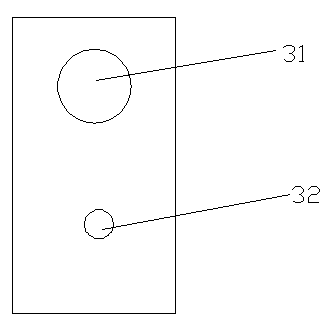

[0020] The tensile test jig of the invention is suitable for direct tensile tests on incompressible materials, has reliable clamping, and does not slip. Such as figure 1 , figure 2 As shown, the structure of the tensile test fixture is composed of two parts that are mutually symmetrical up and down, and each part is composed of six parts, which are fixed joint 1, adapter chuck 2, two connecting plates 3, bolts 4, metal rod5. The connection of the six parts in the above part is introduced as an example, among which:

[0021] The upper end of the fixed joint 1 is connected with the testing machine (not shown in the figure) through a metal rod (not shown in the figure), and the lower end of the fixed joint 1 is connected with the adapter chuck 2 through a threaded rod;

[0022] The upper section of the adapter chuck 2 has a threaded hole, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com