Method for reducing violence of accidental explosions in solid fuel rocket motors and other energetic devices

a rocket motor and explosion-related technology, applied in the field of explosives and various energetic devices, can solve the problems of increasing the violence, or rather the intensity of an explosion, and 1.1 explosives constitute a mass explosion hazard, so as to facilitate the reduction of the violence of an accidental explosion reaction and reduce the violen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example one

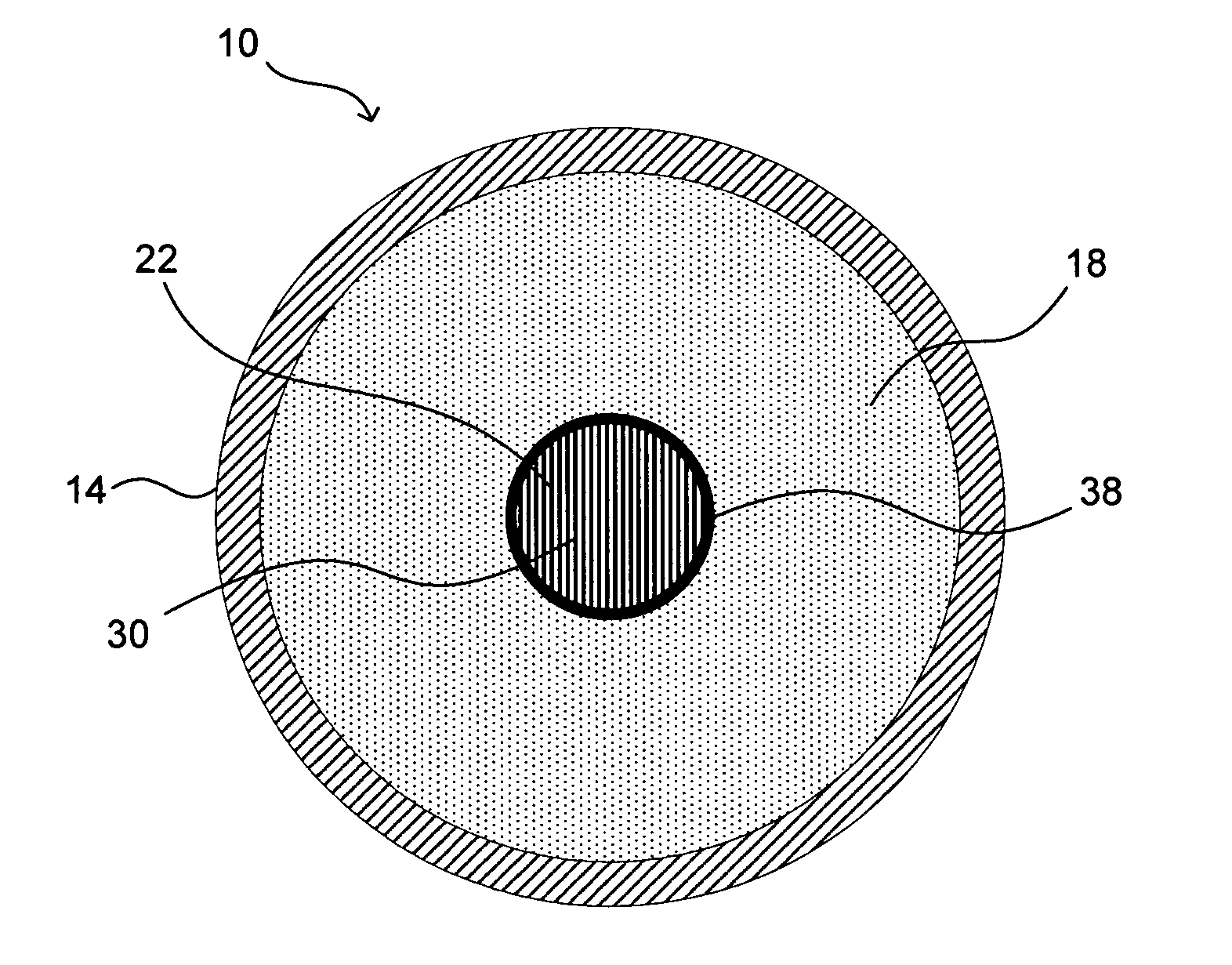

[0050] Various tests or experiments were conducted to observe the behavior and response of several energetic devices as they were subjected to a thermal insult. The purpose of the tests was to determine the time-to-explosion and the degree of violence or intensity of the explosive response of the energetic devices in response to different levels of external heat flux. The tests also showed the results of utilizing an inert, incompressible material as taught and suggested herein. The experiments were carried out using a four-inch diameter cylindrical steel support structure filled with PBX-9501 propellant as the energetic material. The PBX-9501 propellant was heated electrically with electrical heating mantels. Voltages between 110 and 220 volts were supplied to the energetic device for a duration of time between 1 and 30 minutes. For the various tests, a molded high energy PBX-9501 propellant was used and configured as follows:

[0051] 1) Test One—the core of a PBX-9501 material was ...

example two

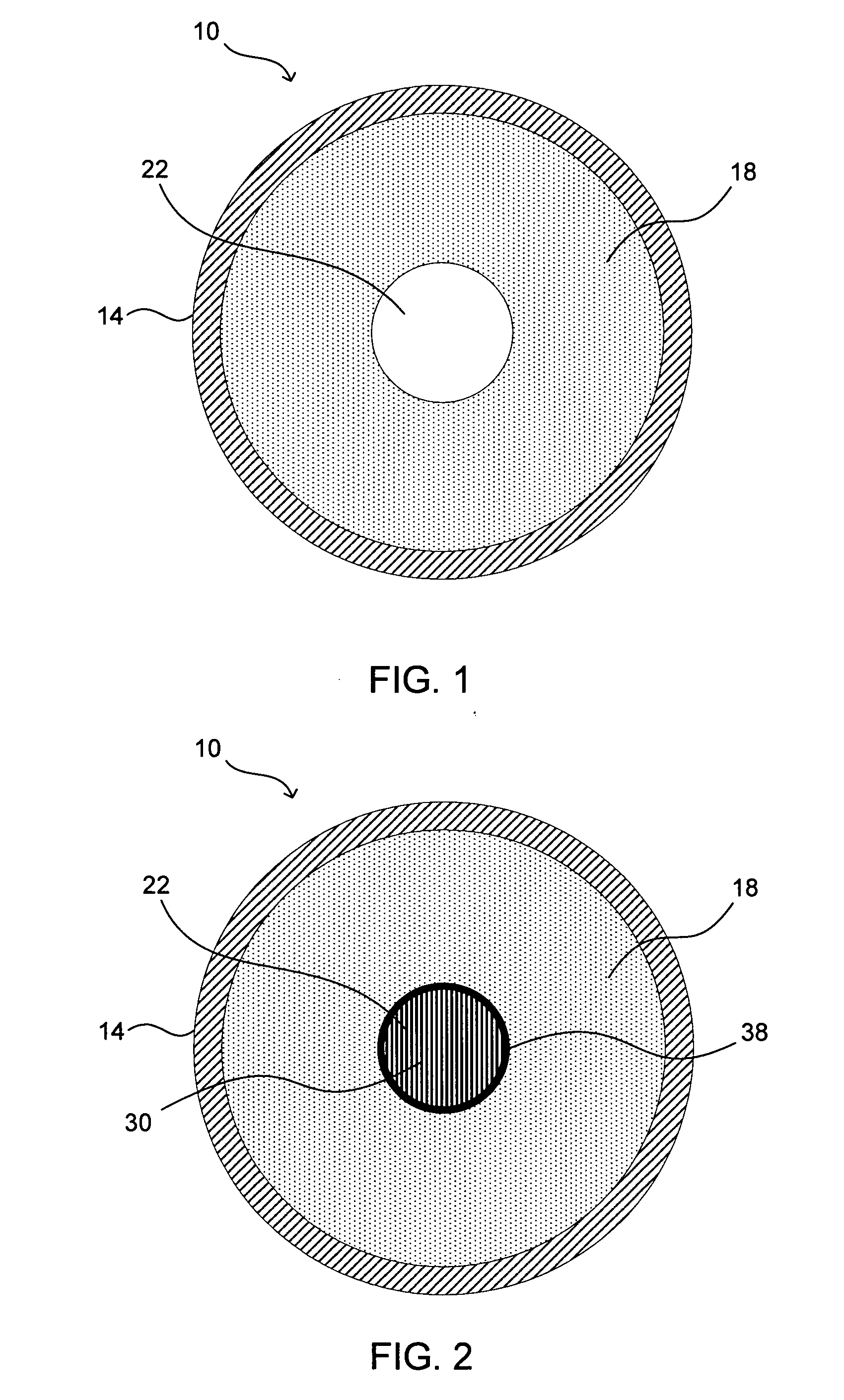

[0058] A high-temperature inert, incompressible sealant was injected into the central bore hole of a steel container filled with a PBX 9501 propellant and fitted with a 110 volt electric heating band to fill the core. The sealant was allowed to set up overnight. Test was conducted in a similar manner as set forth above in Example One. The time-to-explosion was 23 minutes and the steel container did not fragment or burst open, but rather bulged. A large piece of unreacted material was recovered. This piece comprised a portion of the core with the sealant material still contained within the core. As such, the core had not collapsed. This test indicates that the inert, incompressible sealant inserted into the central bore hole or core stabilized the core such that it did not collapse, thus largely preserving the structural integrity of the steel container. In addition, much of the PBX-9501 material was not consumed, but left intact. By preventing the core from collapsing, the resulting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com