Patents

Literature

381results about "Sewing needles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

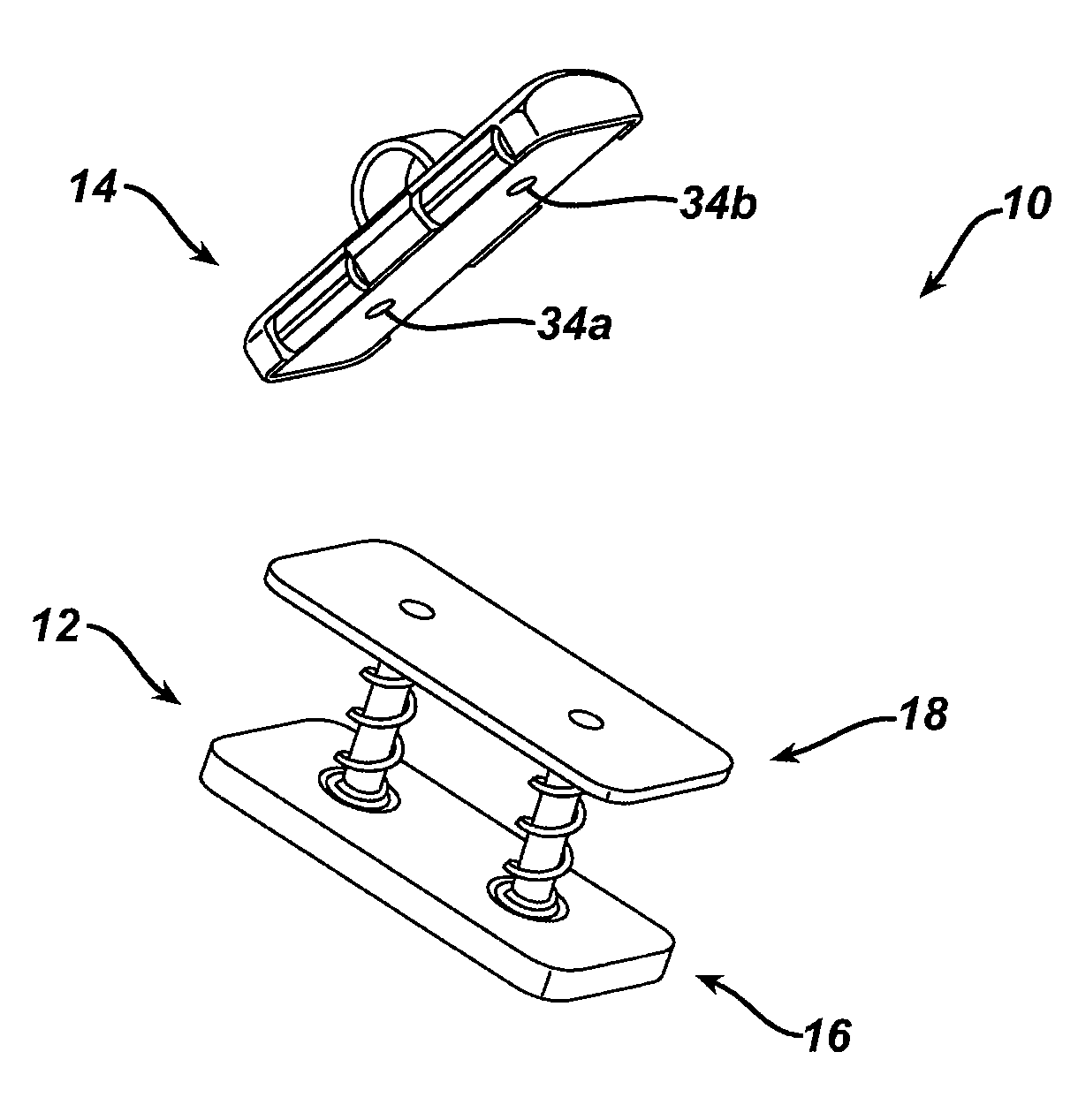

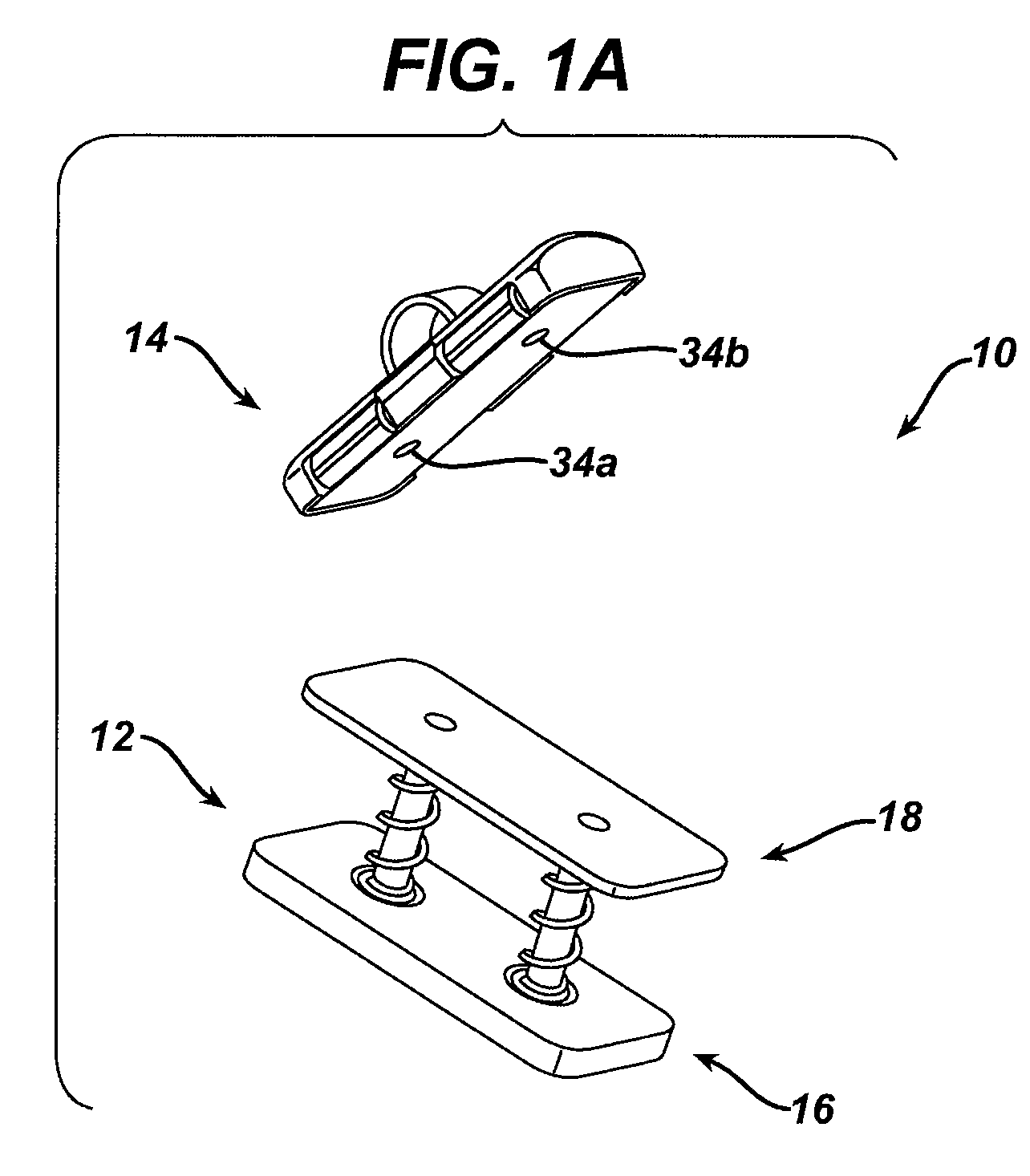

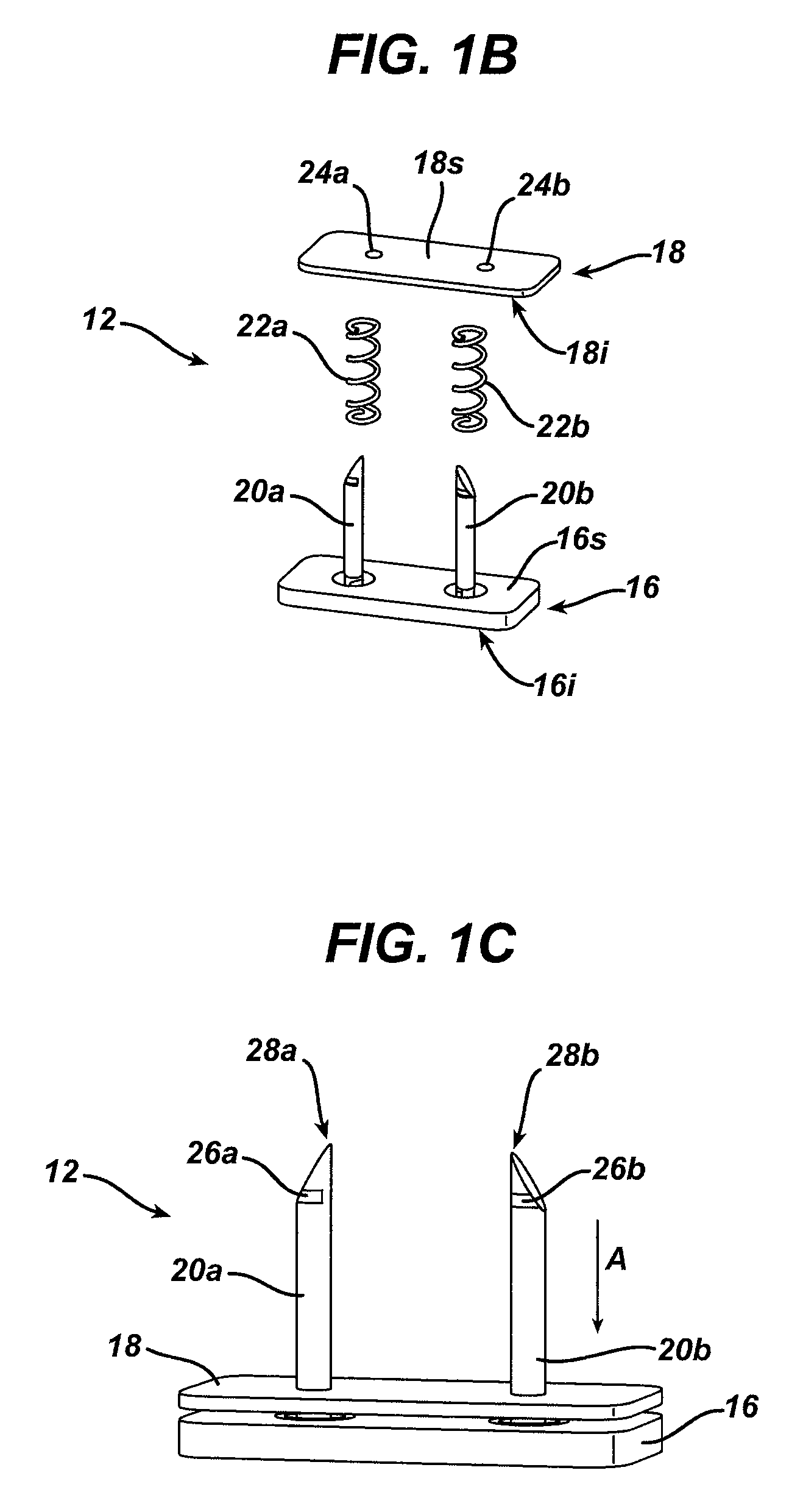

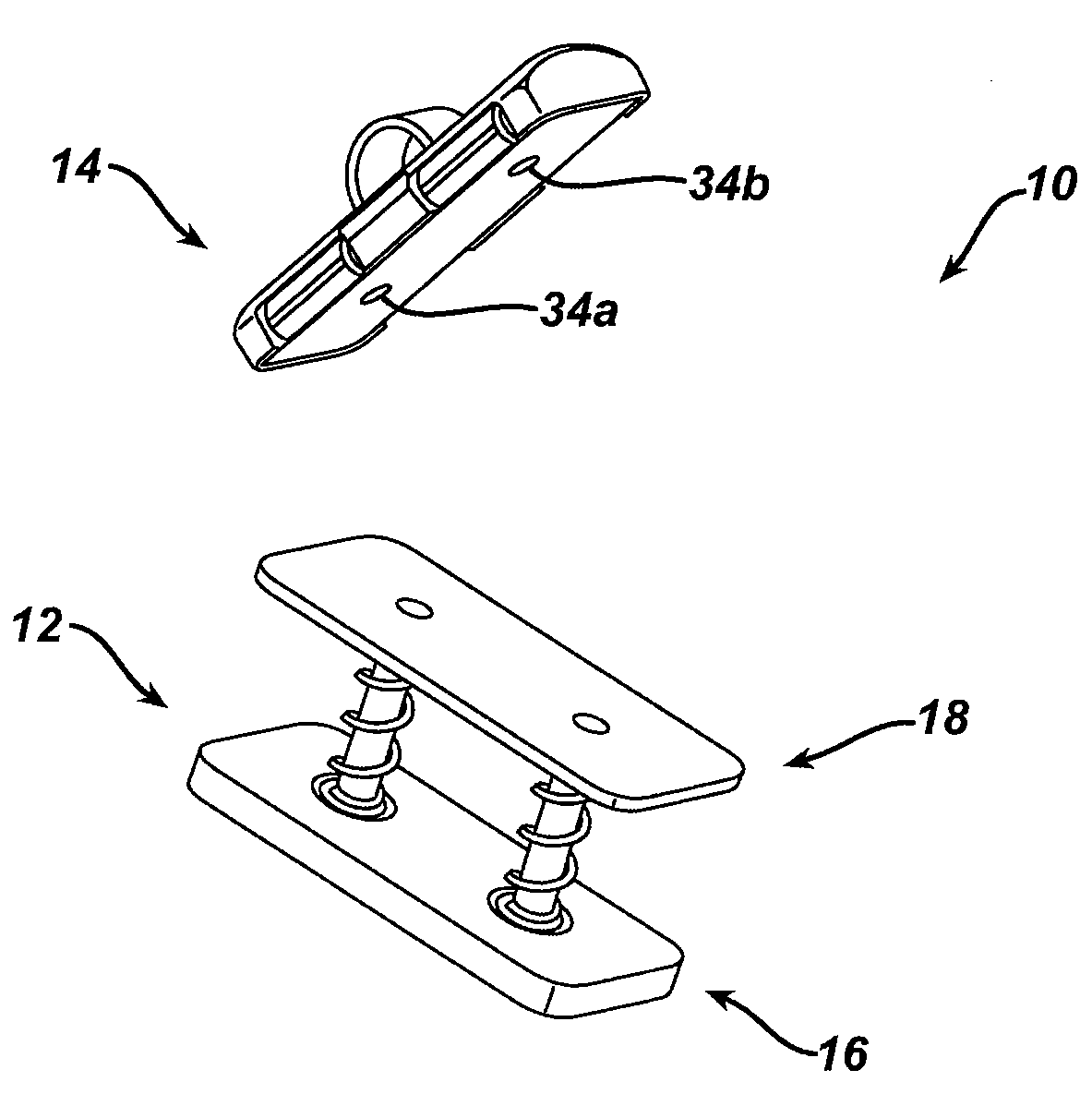

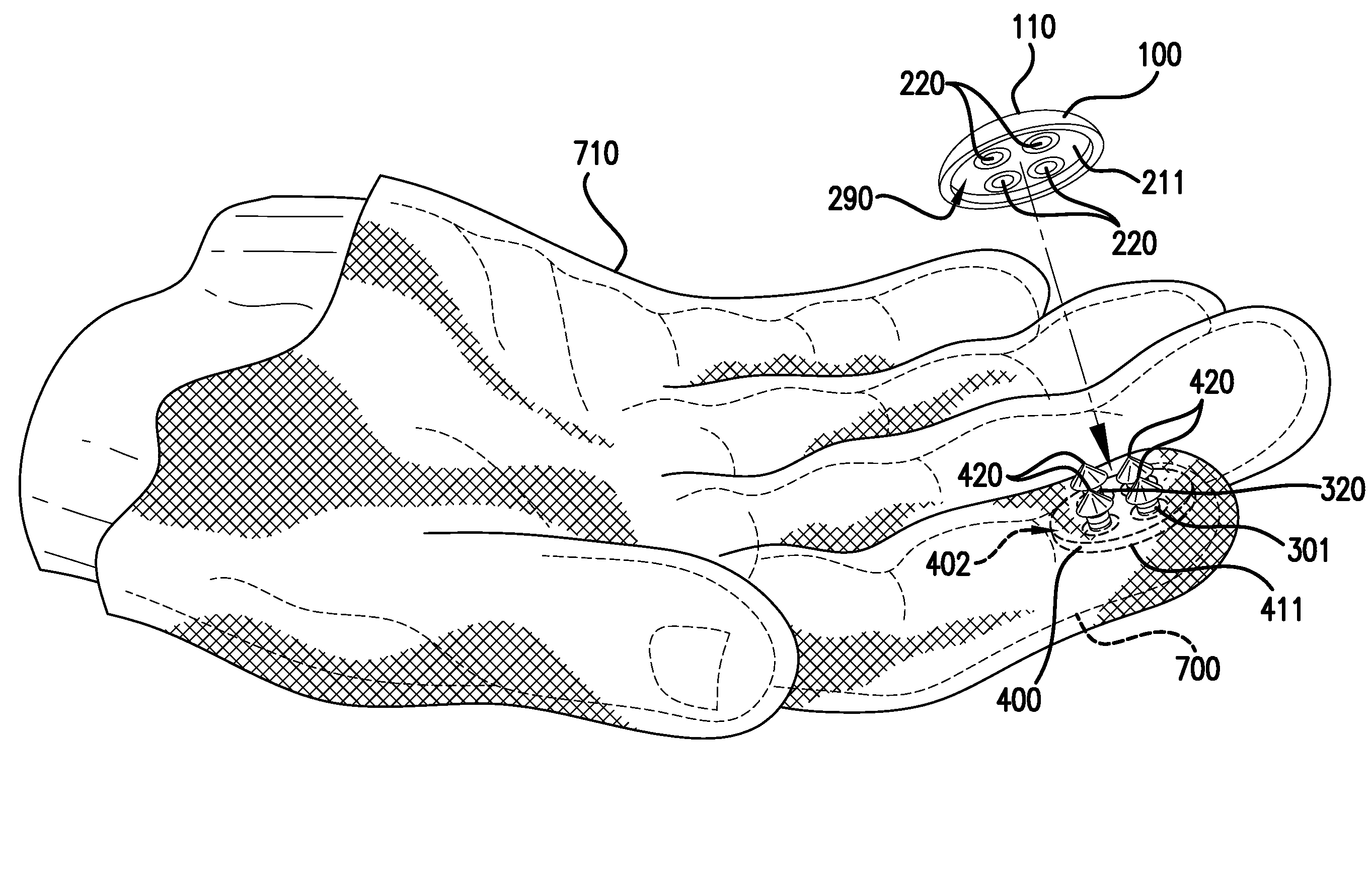

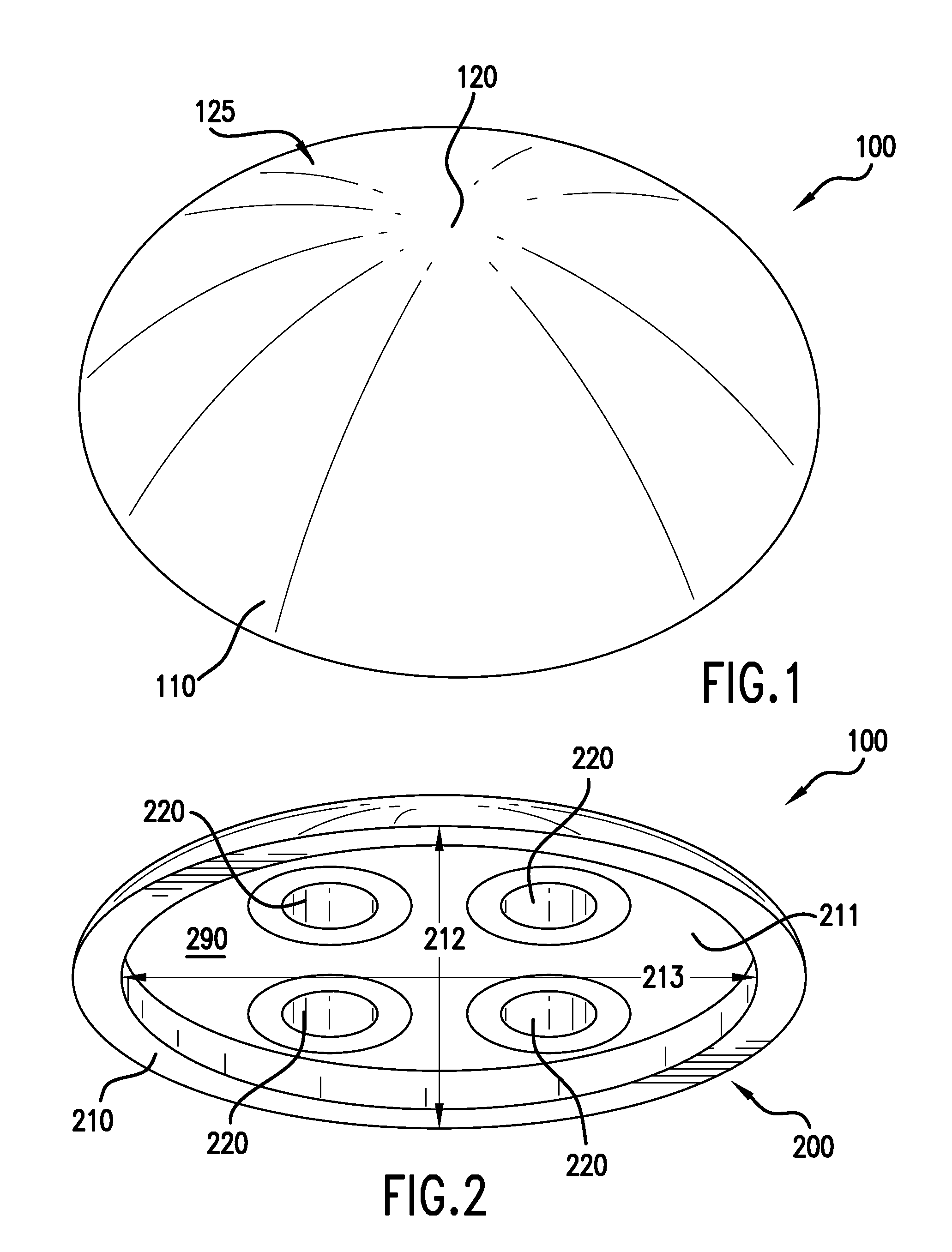

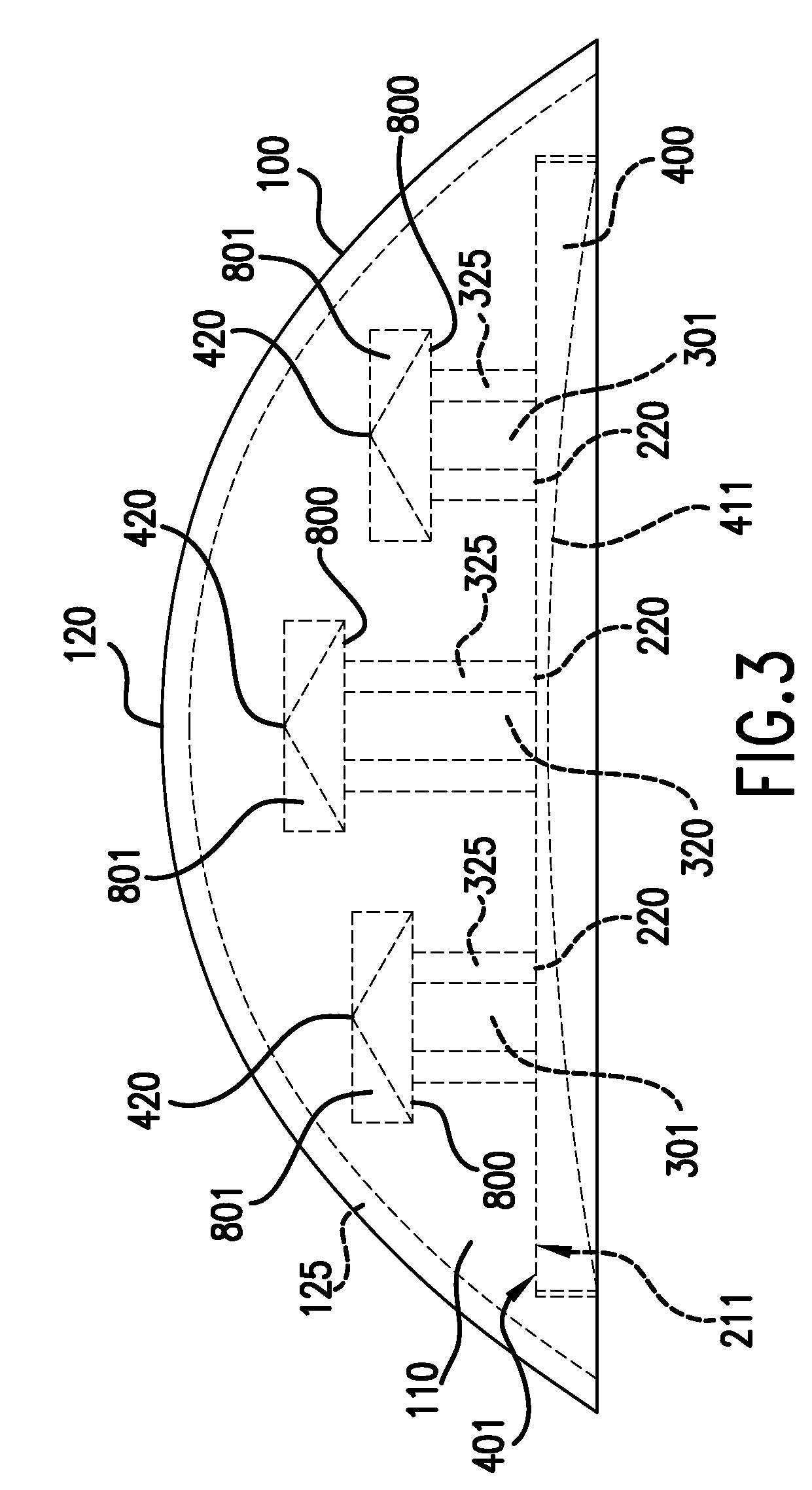

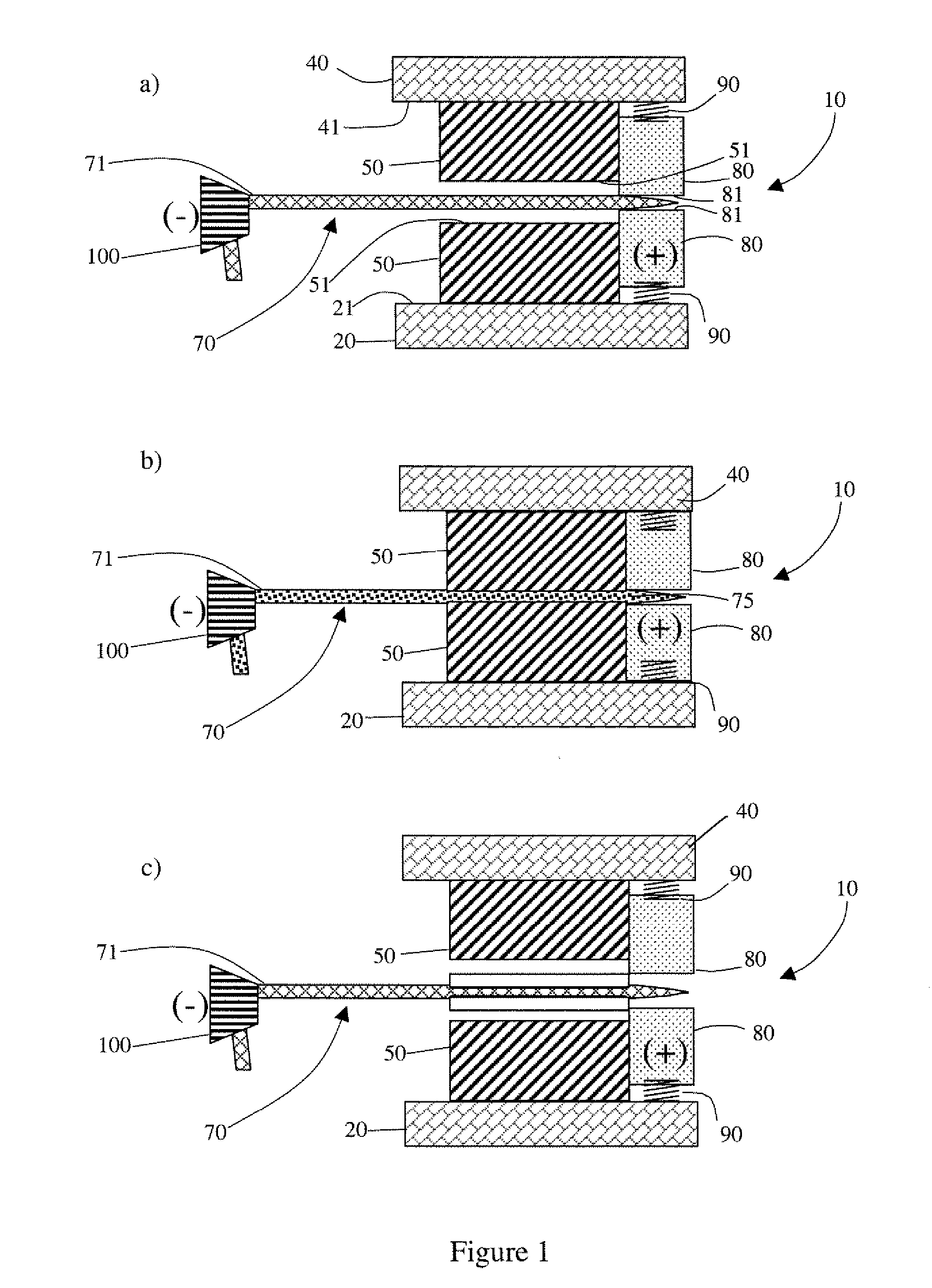

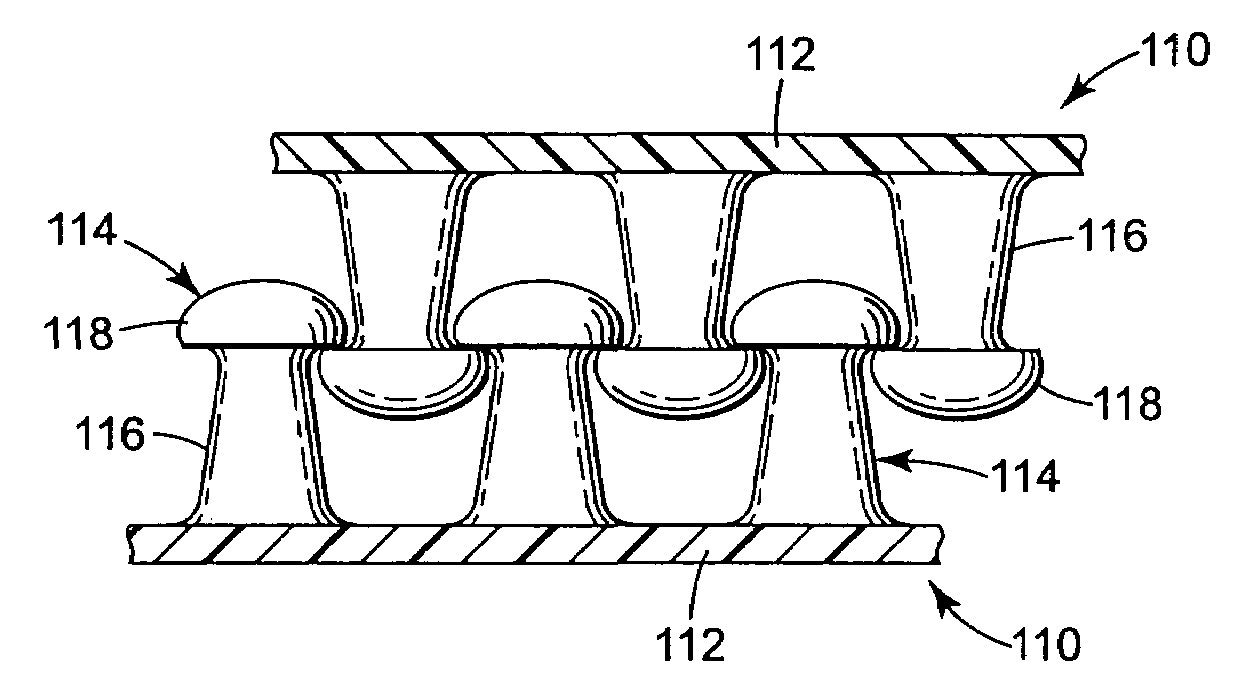

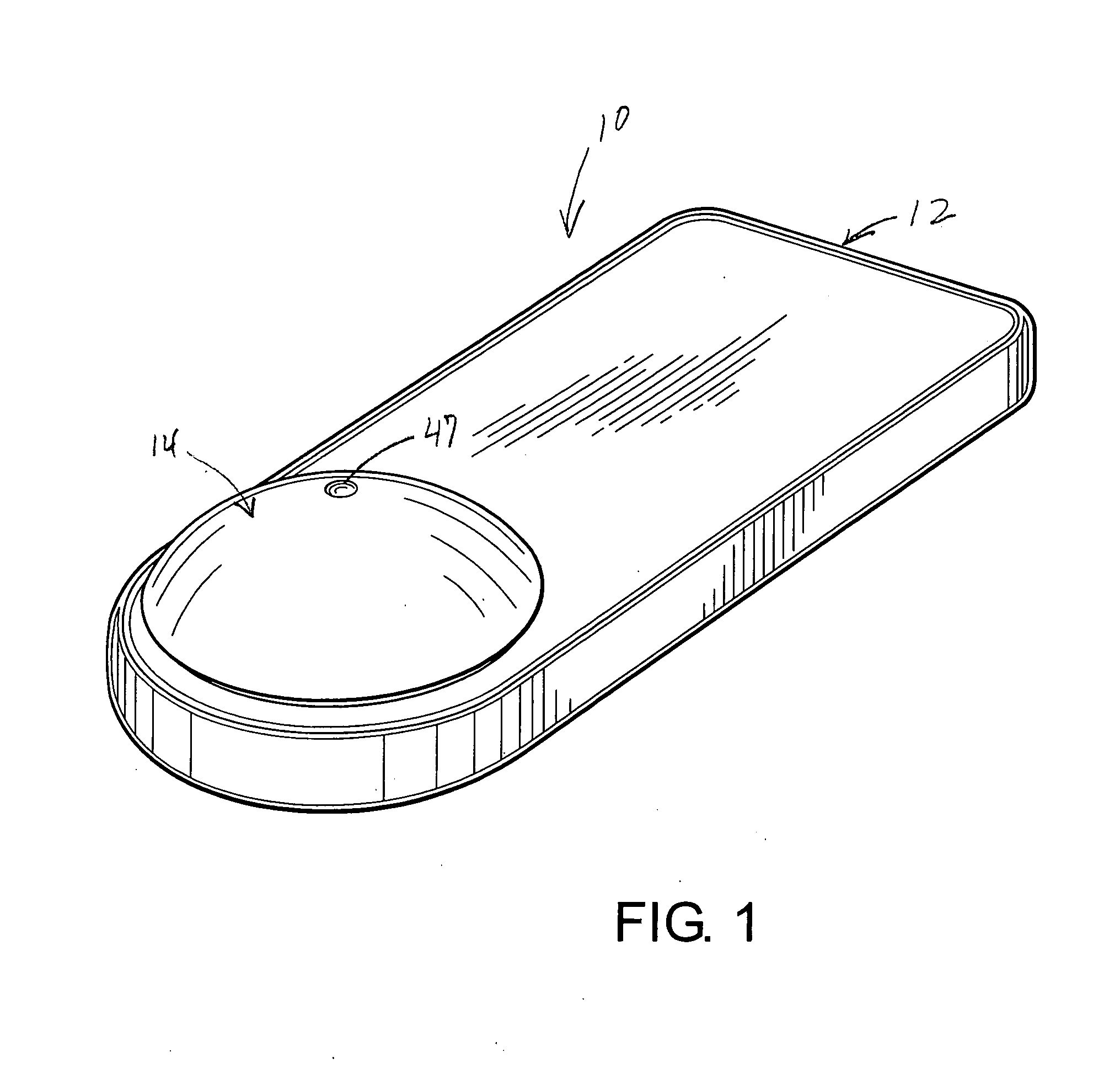

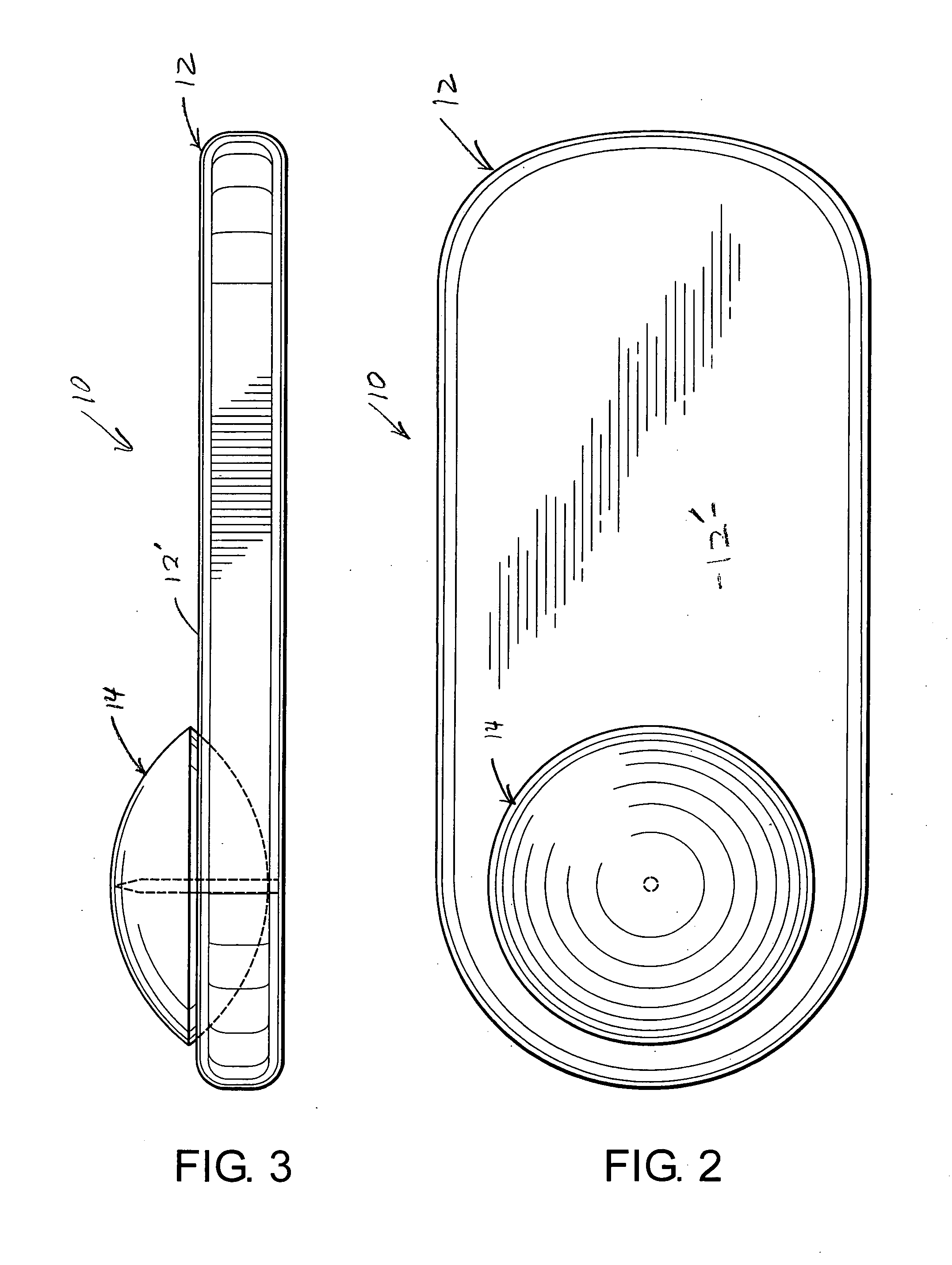

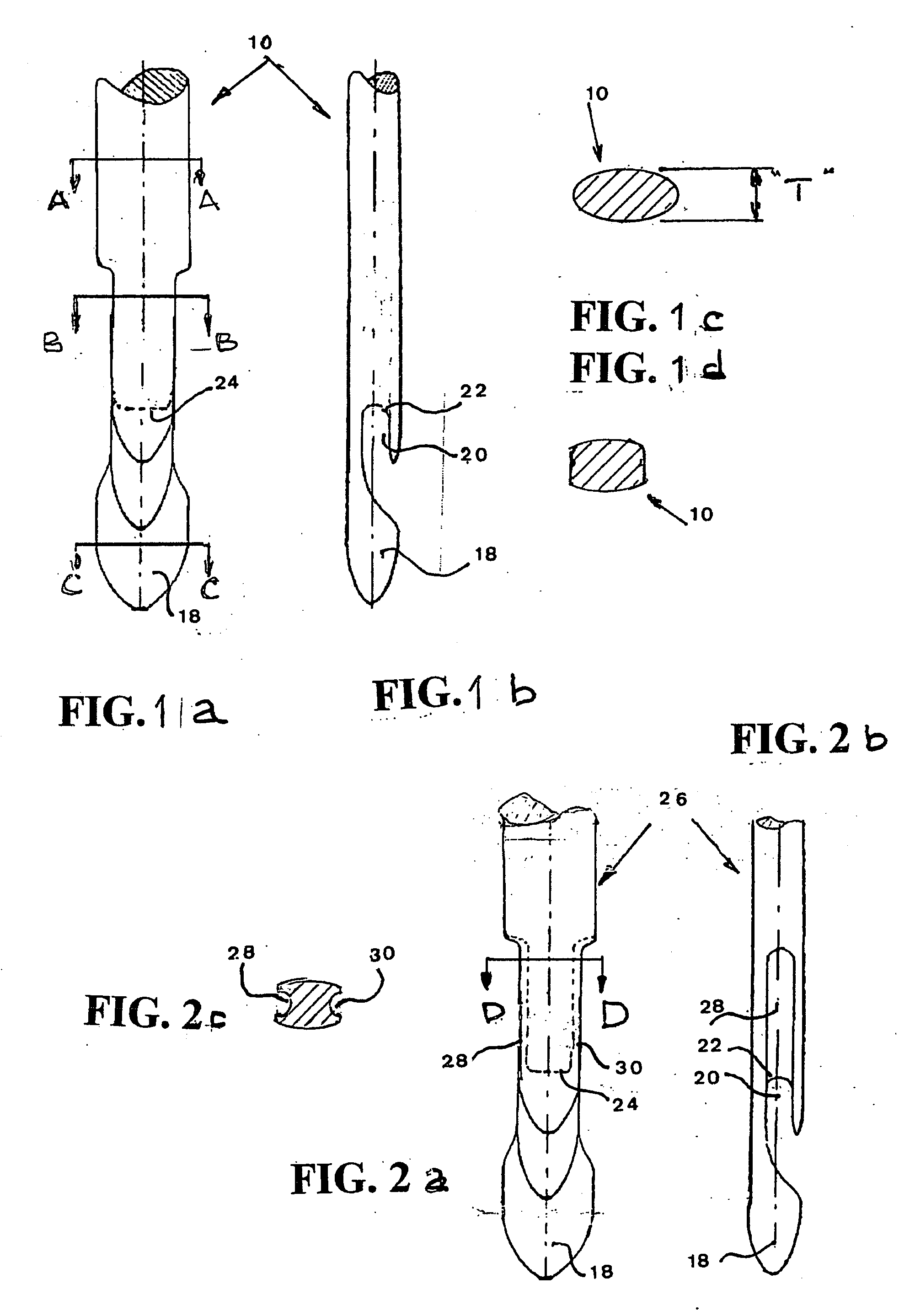

Safety fastener for tissue apposition

ActiveUS8114100B2Prevent penetrationPrevents collateral tissue damageSewing needlesScarvesBiomedical engineeringFastener

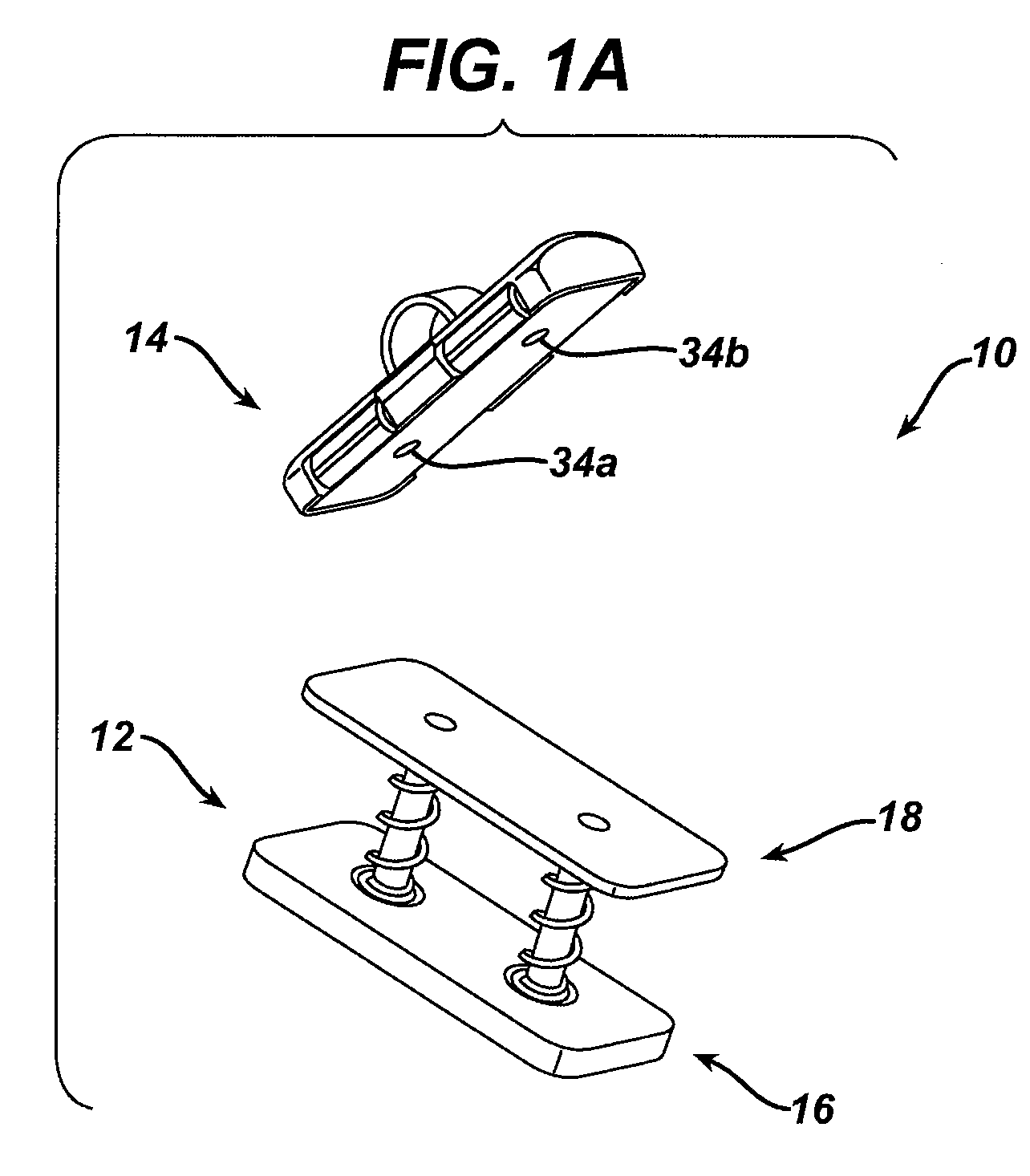

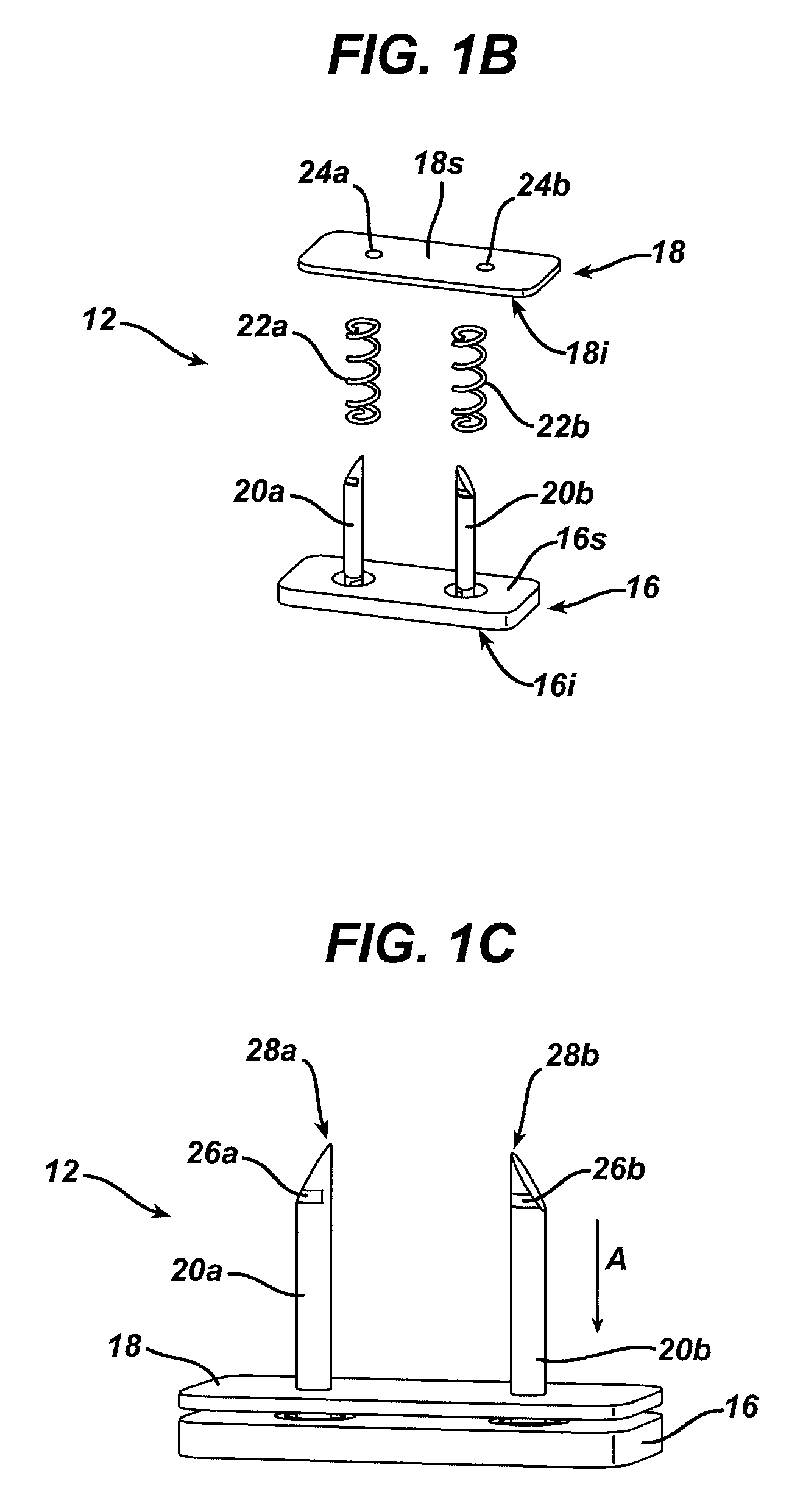

Methods and devices for fastening tissue are provided. In one exemplary embodiment, a tissue fastener is provided and includes a male fastening member having a base plate with at least one post extending therefrom and having a tissue-piercing tip. A protective member is coupled to the male fastening member and is movable between an open position in which the tissue-piercing tip is enclosed within the protective member such that the tissue-piercing tip is prevented from penetrating tissue, and a compressed position in which the tissue-piercing tip is exposed to penetrate tissue. A female fastening member is configured to mate to the male fastening member and to engage tissue therebetween.

Owner:ETHICON ENDO SURGERY INC

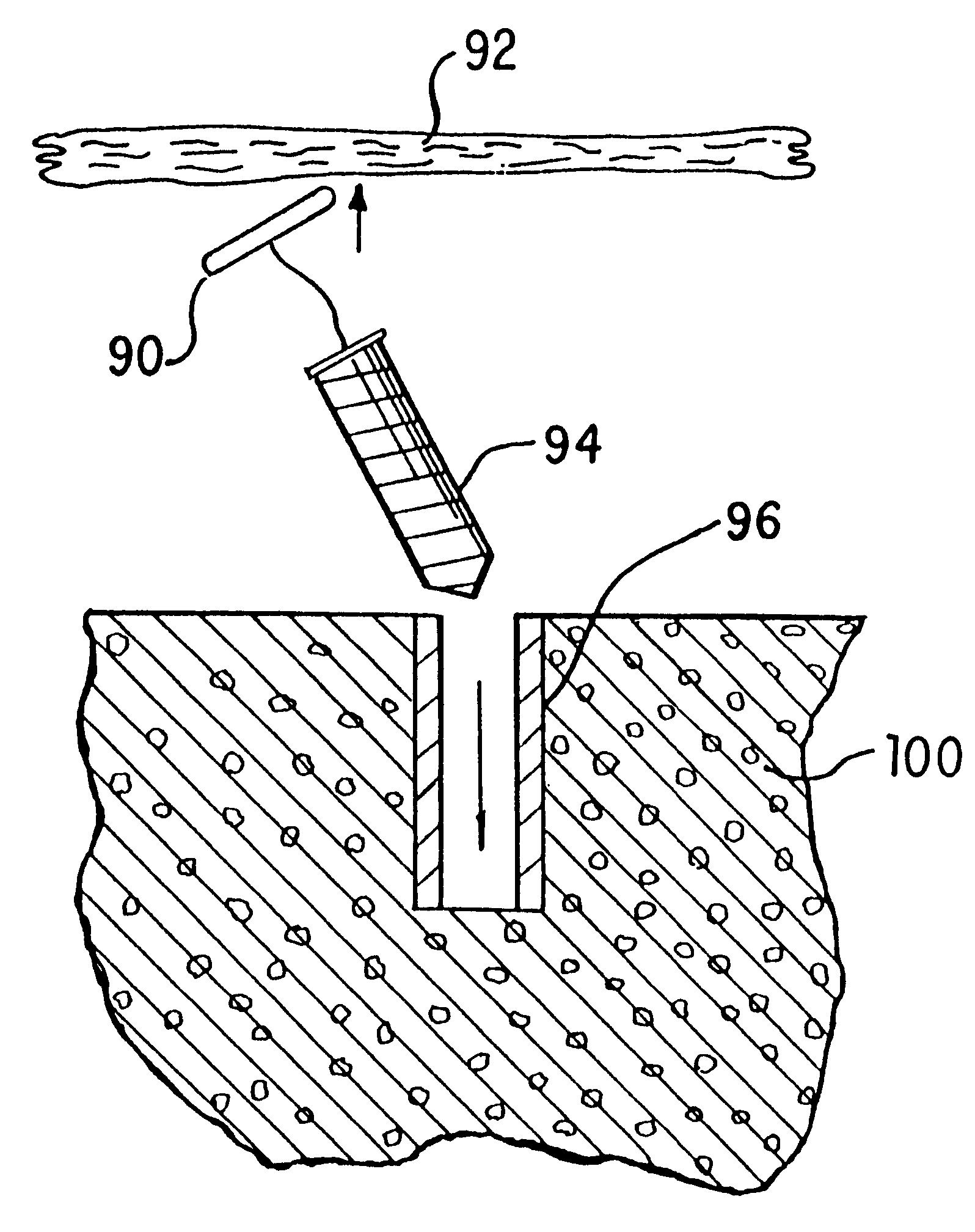

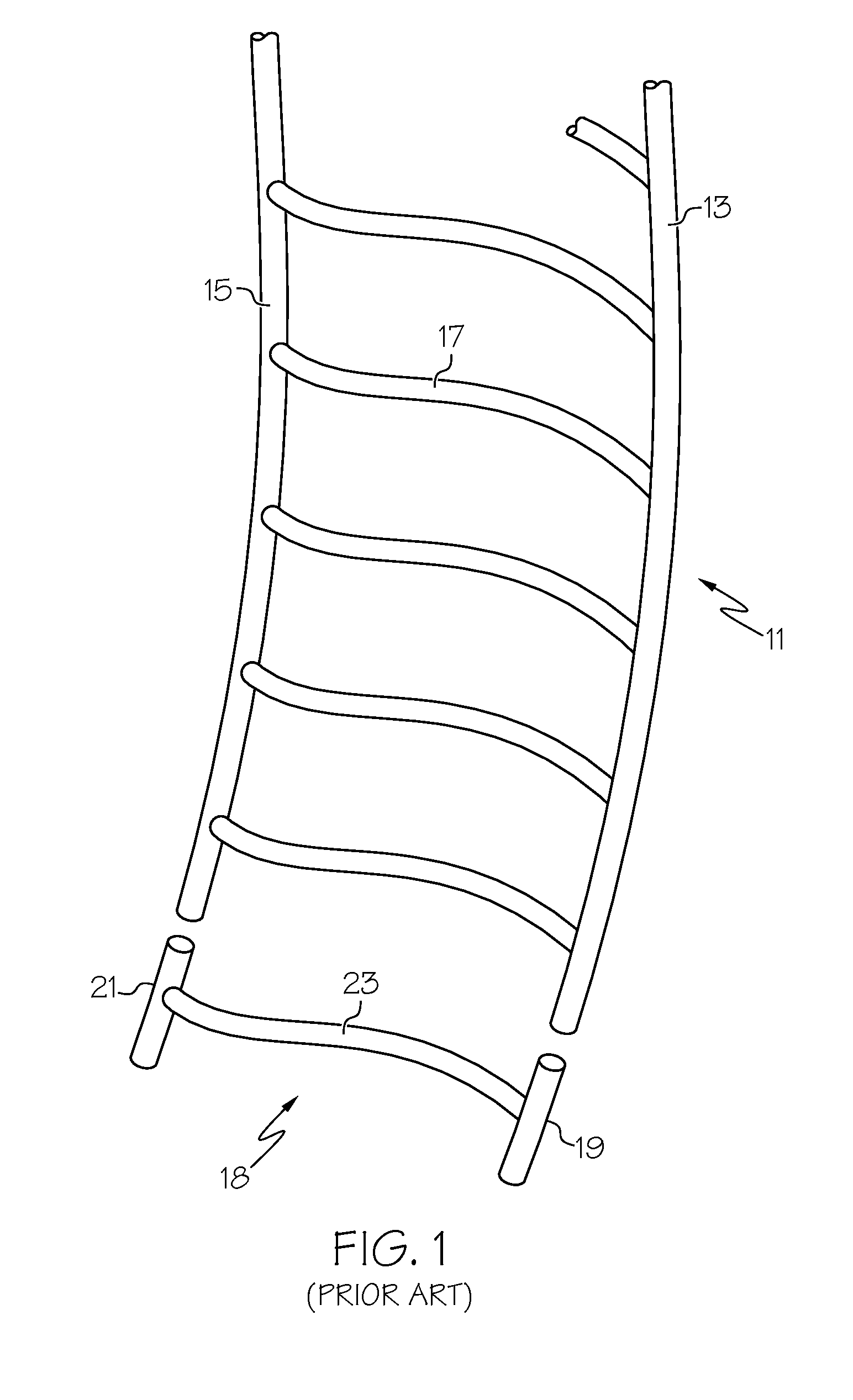

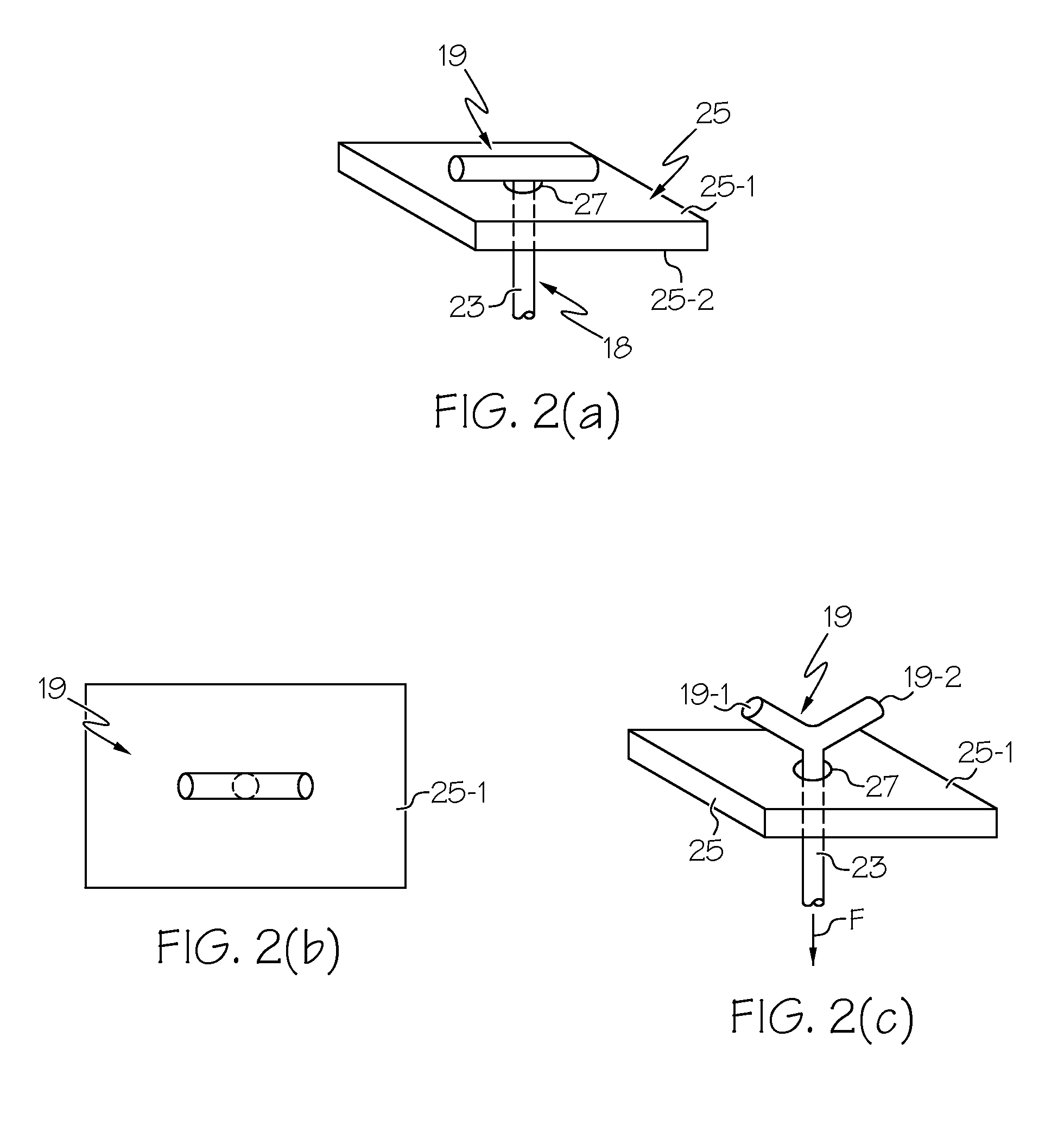

Knotless suture anchor assembly

InactiveUSRE37963E1Eliminate needPrevent excessive insertion depthSuture equipmentsSnap fastenersSuture anchorsSurgical department

A one-piece or two-piece knotless suture anchor assembly for the attachment or reattachment or repair of tissue to a bone mass. The assembly allows for an endoscopic or open surgical procedure to take place without the requirement of tying a knot for reattachment of tissue to bone mass. In one embodiment, a spike member is inserted through tissue and then inserted into a dowel-like hollow anchoring sleeve which has been inserted into a bone mass. The spike member is securely fastened or attached to the anchoring sleeve with a ratcheting mechanism thereby pulling or adhering (attaching) the tissue to the bone mass.

Owner:THAL RAYMOND

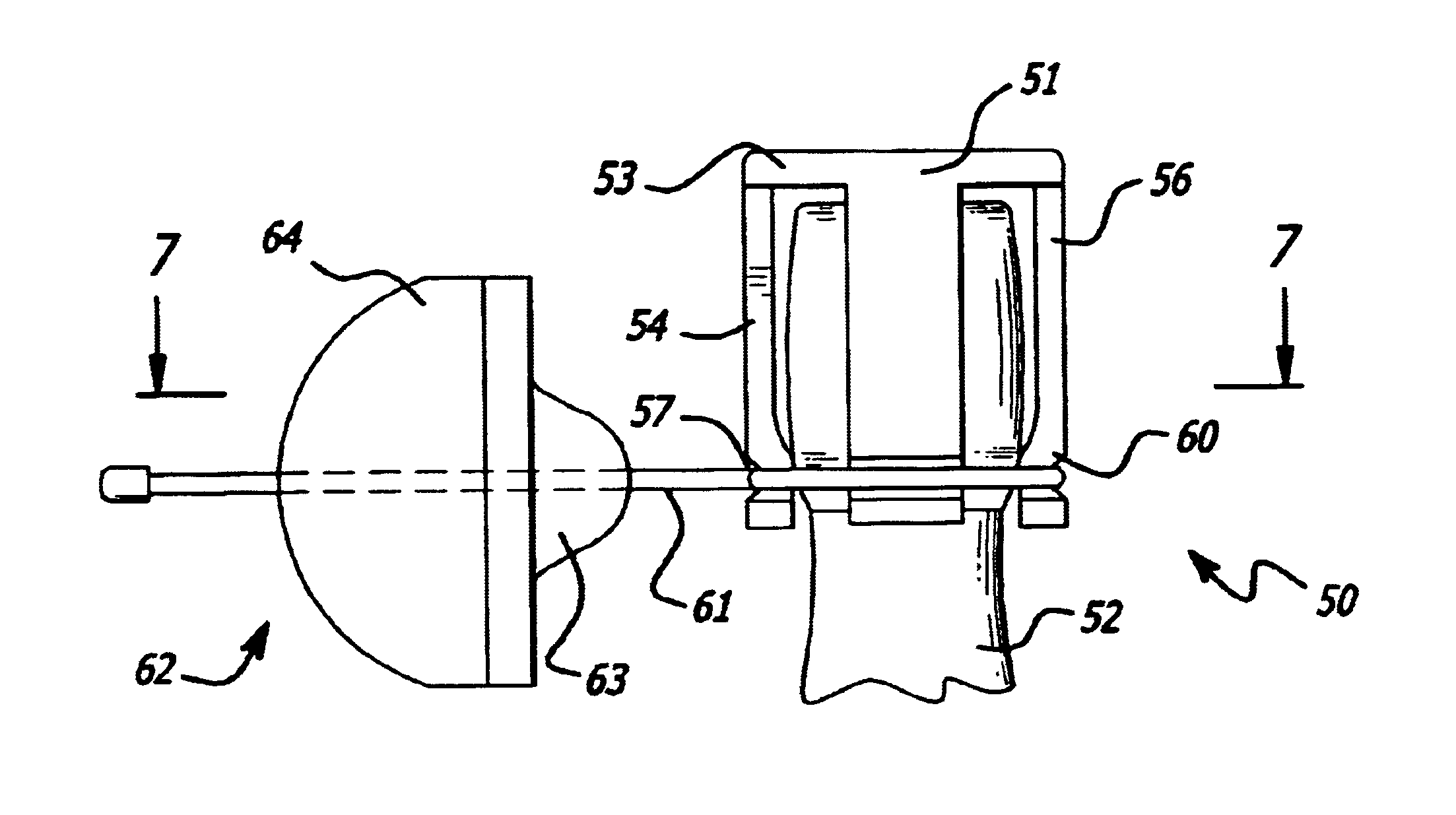

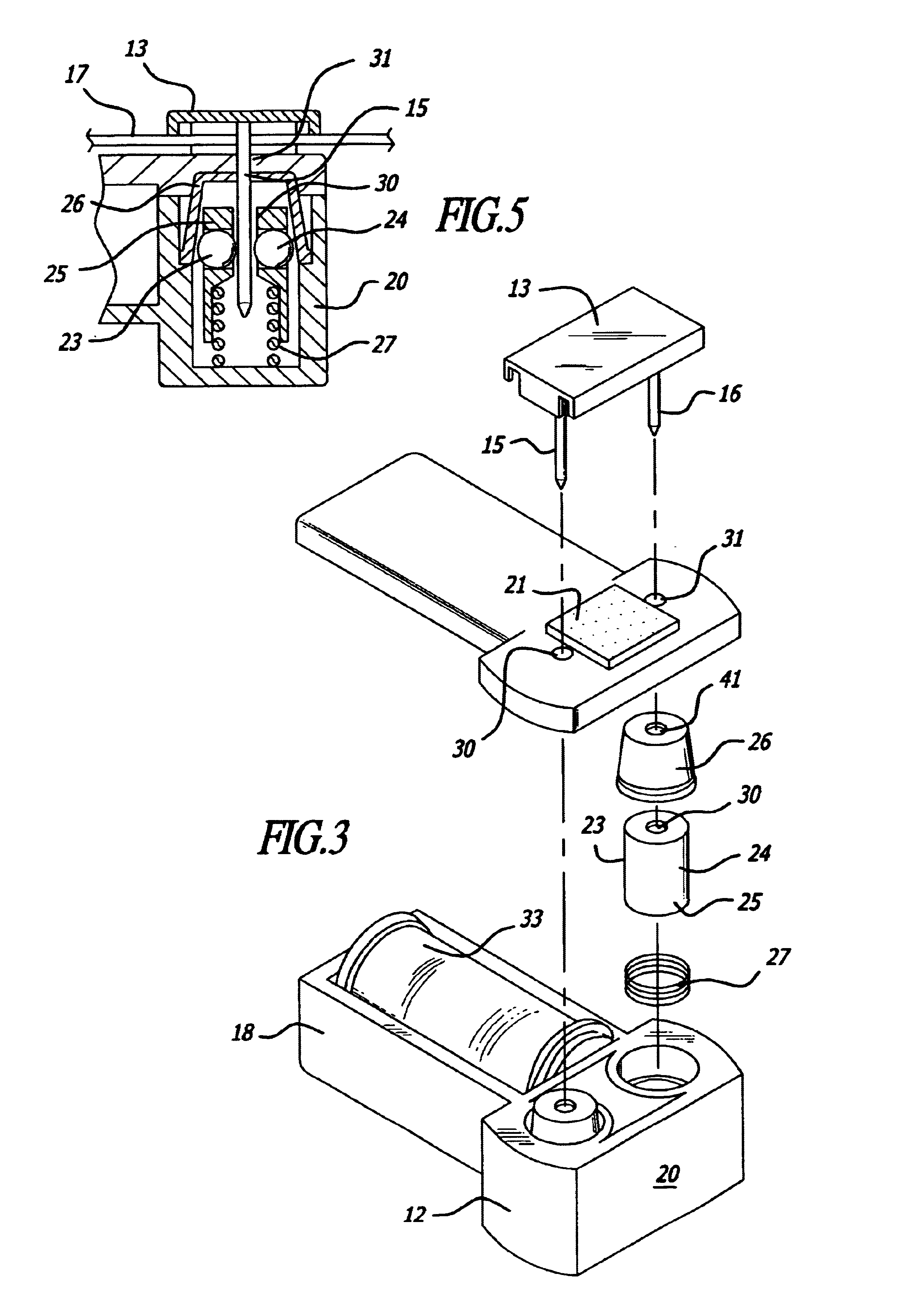

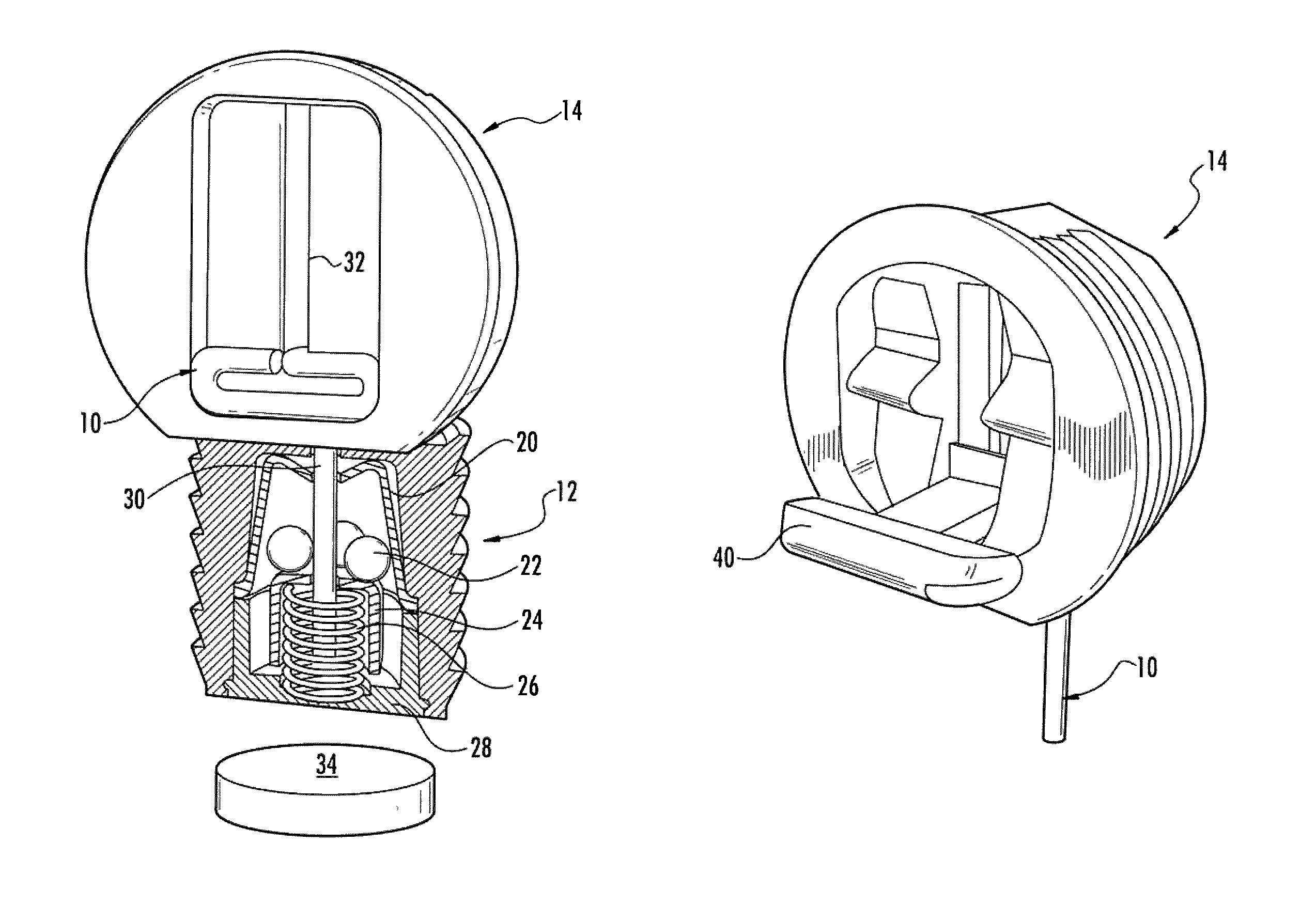

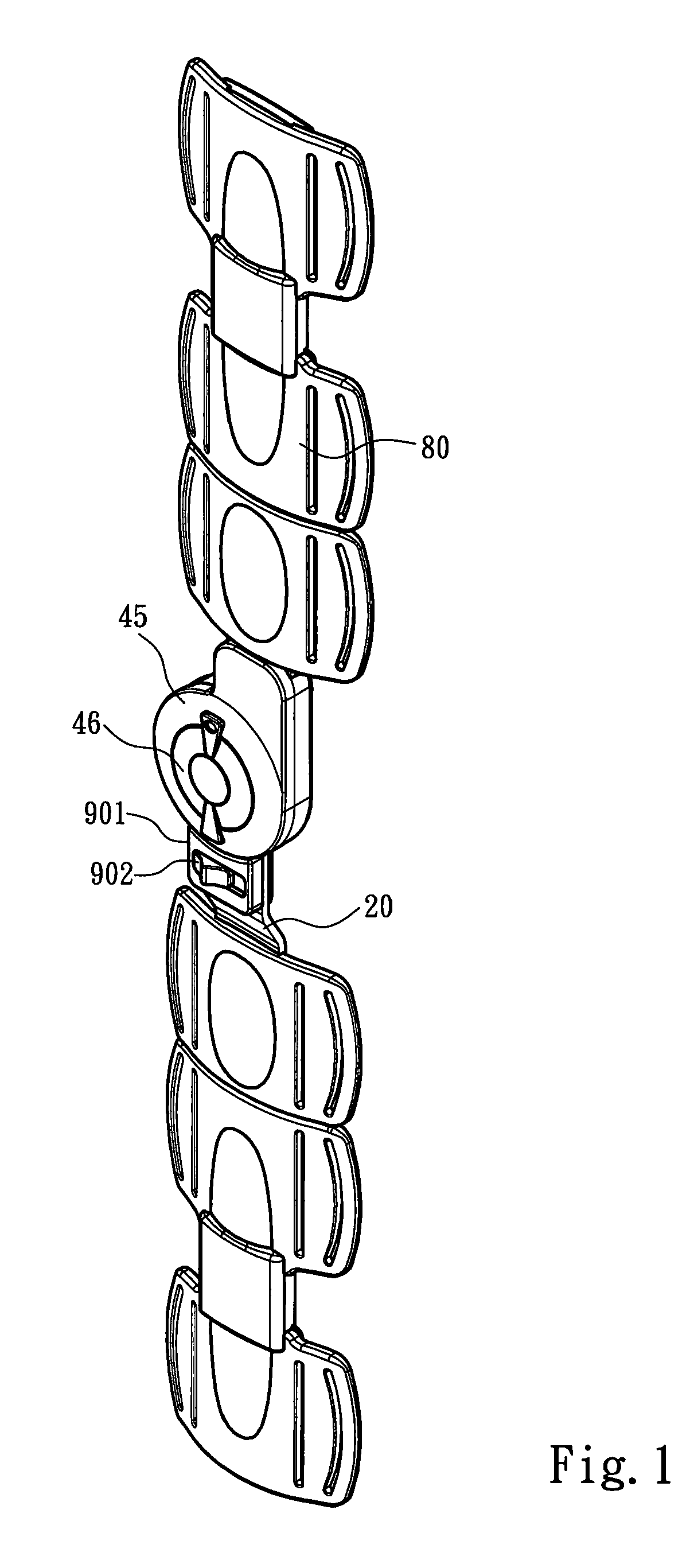

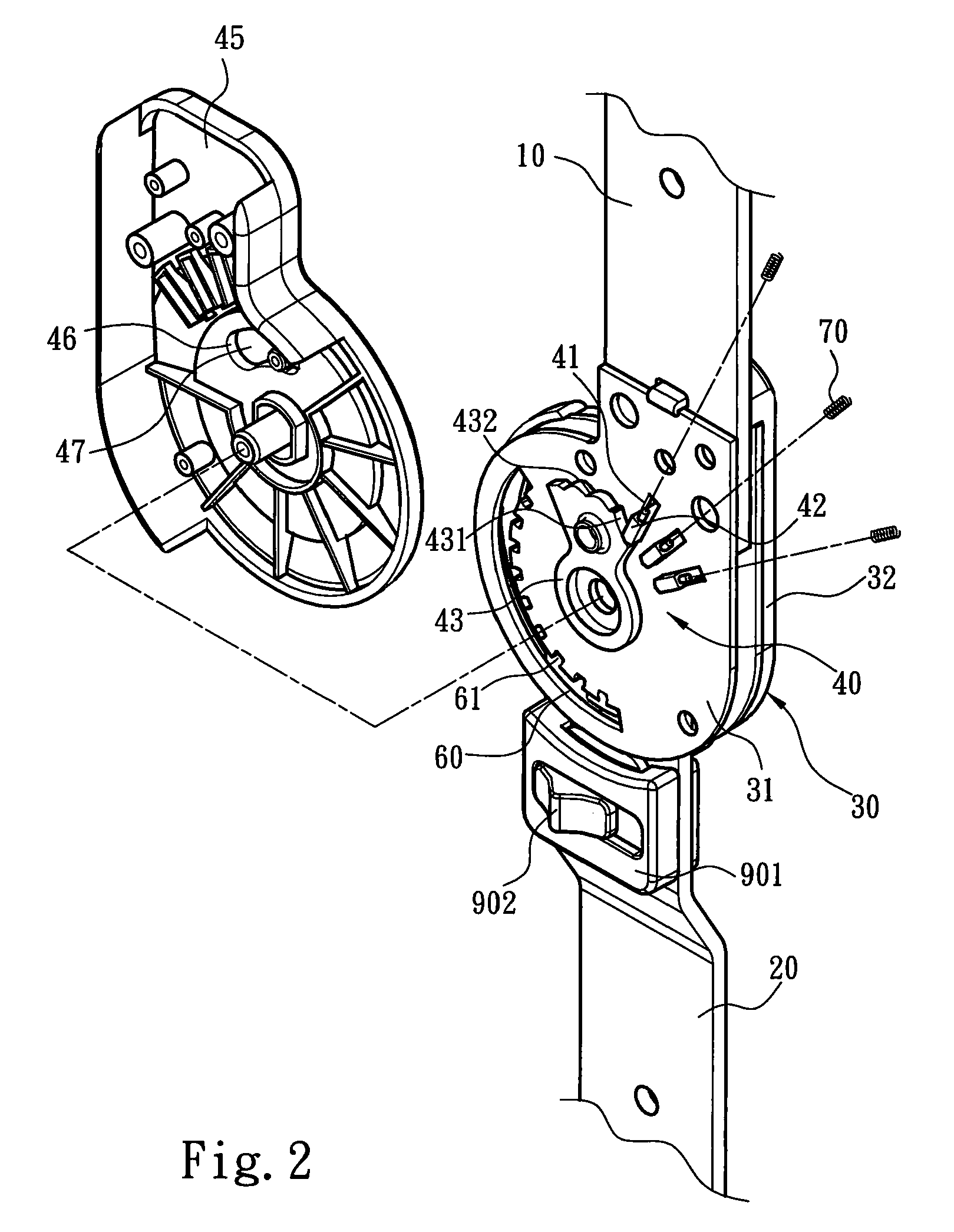

Anti-theft product tag with ball clutch

InactiveUS6631629B1Suppress retentionLocks for portable objectsNon-mechanical controlsEngineeringClutch

An article surveillance includes a pair of components that are detachably connected together having a releasably grasping device engaging with an article intended to be protected. The device is coupled between the two components with a selected one of the components having an elongated prong insertably received within the other component and is held thereto by a ball clutch mechanism. The mechanism includes a tapered housing with an internal tapered wall surface enclosing a plug member having at least two balls carried in opposing grooves. The tapered housing and the plug member include a coaxial passageway for insertably receiving the elongated prong from the first component. The plug member is resiliently biased to a first position by an expansion spring causing the balls to bear against the tapered inner wall of the housing, restricting the passageway. When the prong of the first component is occupying the passageway, the sides of the prong force the balls outwardly as the plug member moves to compress the spring. The widened mouth of the housing permits the balls to expand or separate and does not place any restriction on the pin. Should the first component with the pin be withdrawn by unauthorized personnel, the plug member will be pushed into the tapered recess of the housing by expansion of the spring and the balls will contract and restrict the shaft or pin member of the first component, so as to hold the component together.< / PTEXT>

Owner:FUSS ARTHUR +1

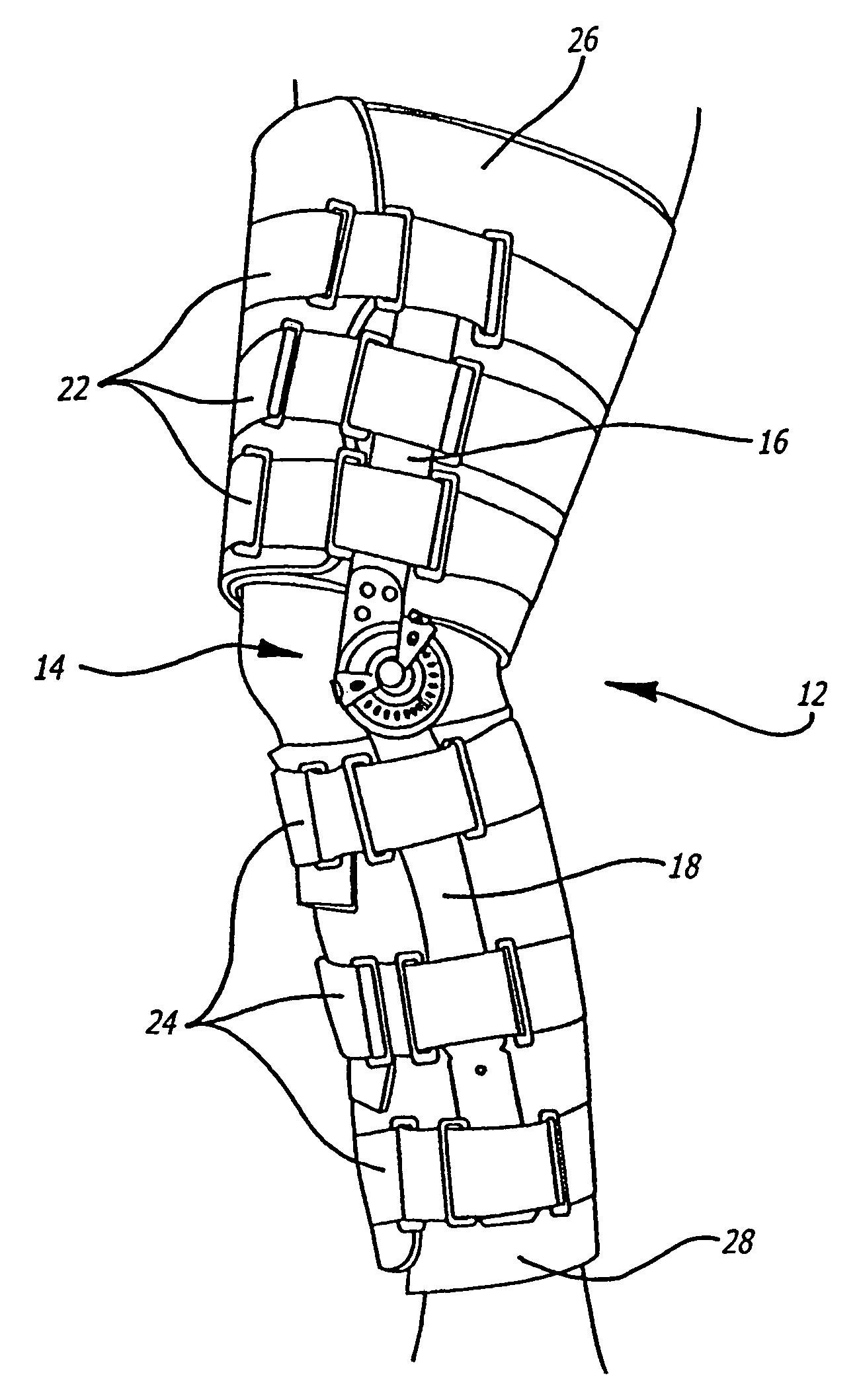

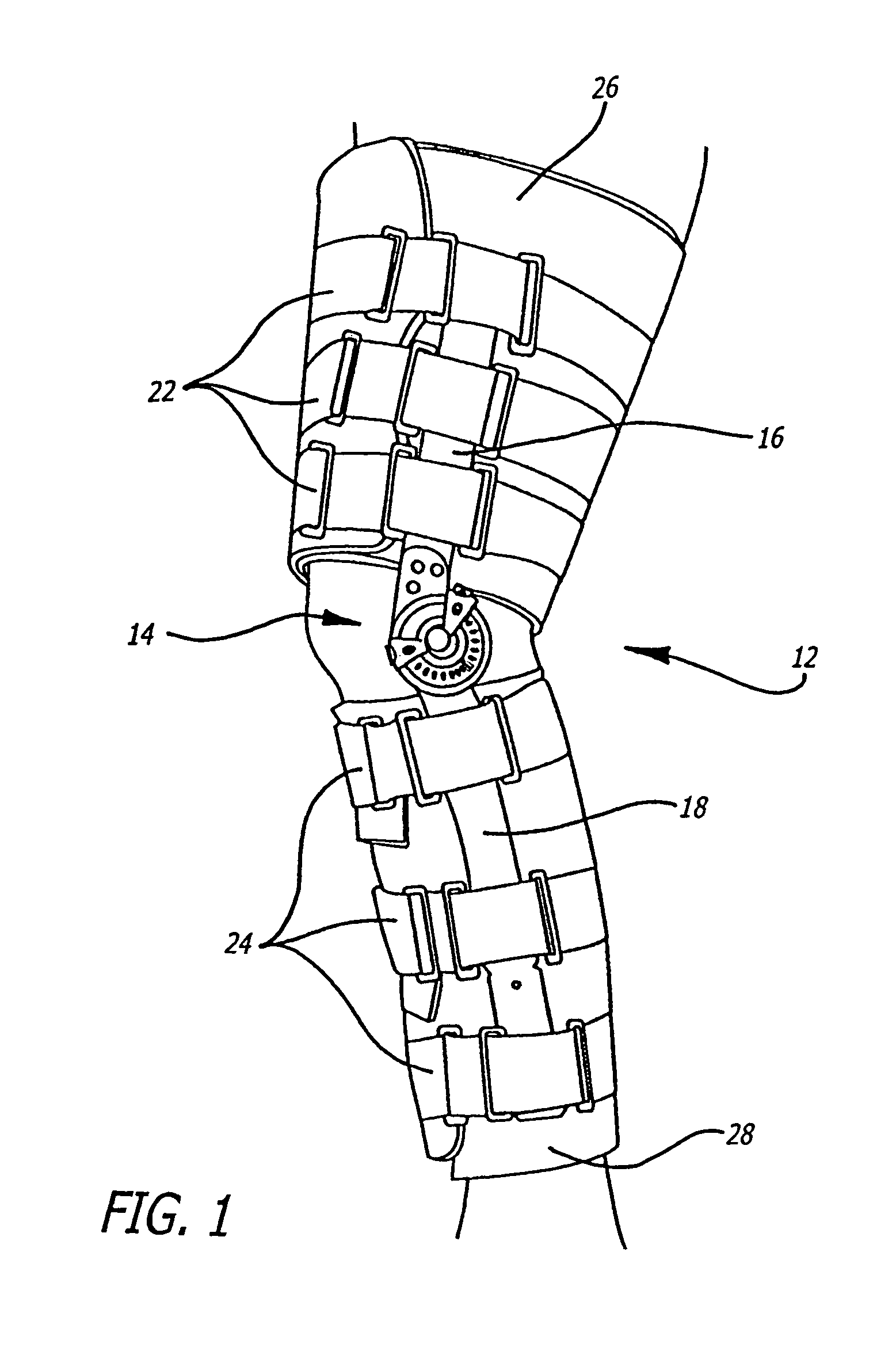

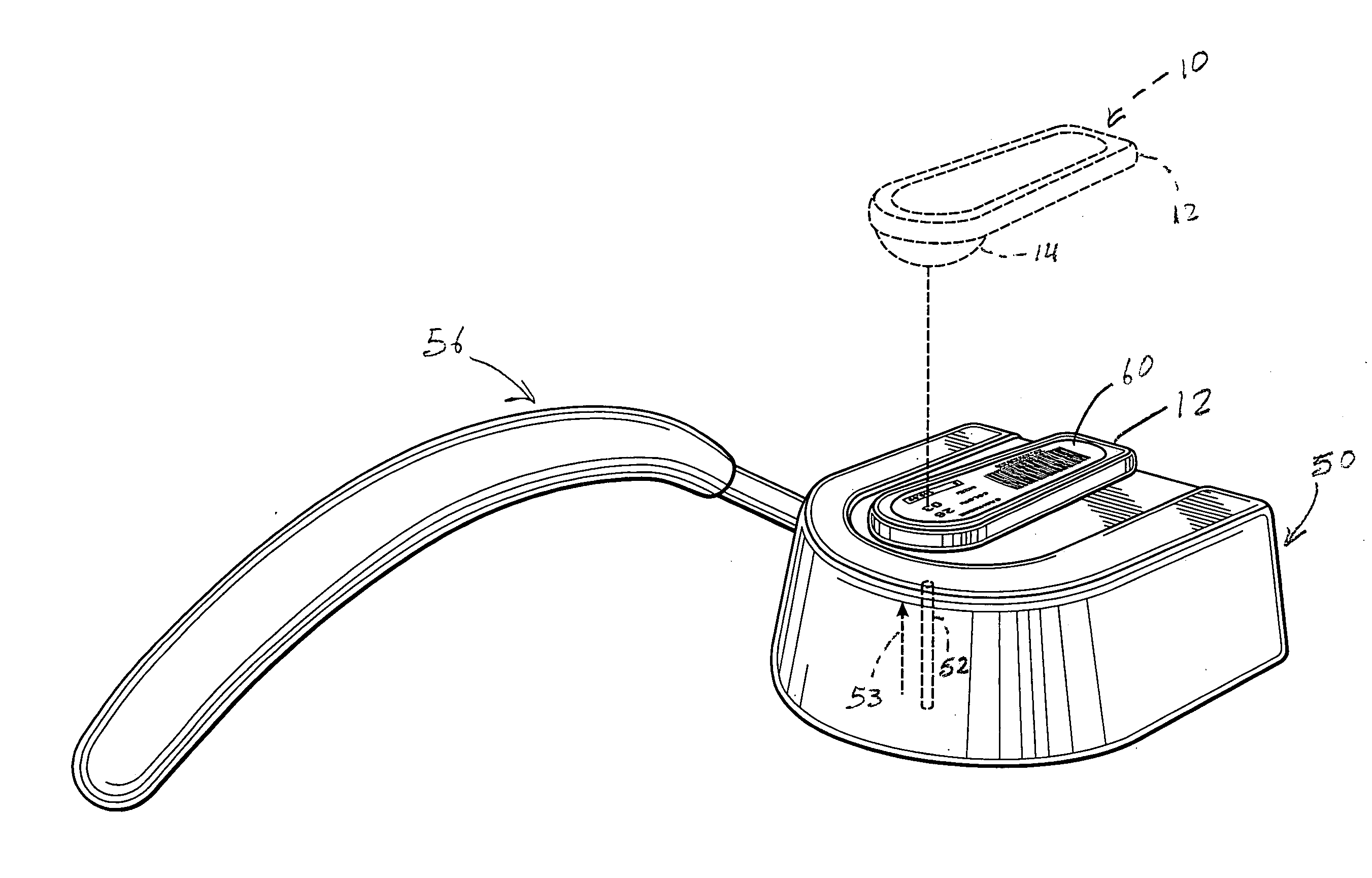

Adjustable ergonomic brace

A knee brace is provided with push button actuatable stops, wherein the stops are biased outward into angular locking positions and inwardly directed pressure on the push buttons releases the stops and permits angular adjustment of the stops. A pair of catch plates with locking recesses facing inward, are provided, and outwardly biased locking pins engage the recesses in both catch plates. Each of the stop assemblies has an outwardly directed plate extending over the outer cover plate, and this plate is coupled to the physical stop member around the outer edge of the outer cover plate. The cover plate has angular indicia thereon, which may be viewed through windows in the outwardly extending plate portions of the stop assemblies.

Owner:KAUPTHING BANK

Electronic article surveillance (EAS) tag compatible with mechanical and magnetic unlocking detachers

InactiveUS7073236B2Eliminate disadvantagesStrength adjustableLocks for portable objectsSewing needlesLocking mechanismEngineering

A security tag includes a tag body and an attaching pin for attaching the tag body to a protected article. The security tag further includes a locking mechanism for releasably preventing the attaching pin from being removed from the protected article. The locking mechanism is provided for mechanically or magnetically released the attaching pin for detaching the tag body from the article. In a preferred embodiment, the locking mechanism further includes a plurality of balls for tightly holding to the attaching pin for releasably preventing the attaching means from being removed from the article. The locking mechanism includes a mechanical unlocking probe finger for applying a mechanical force to release the balls from the attaching pin. The locking mechanism further includes an unlocking magnet for applying a magnet force to release the balls from the attaching pin.

Owner:XUE HUA J +1

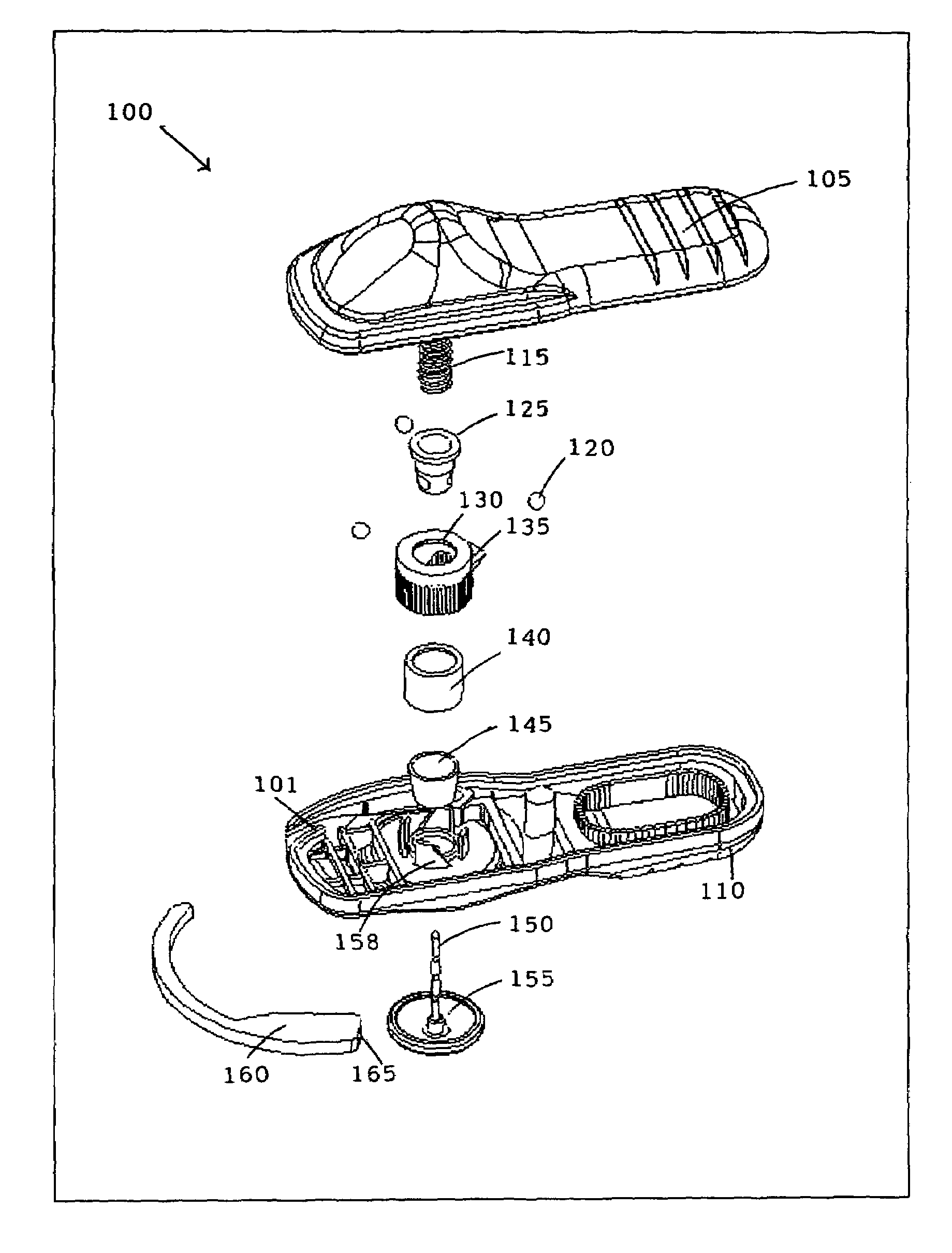

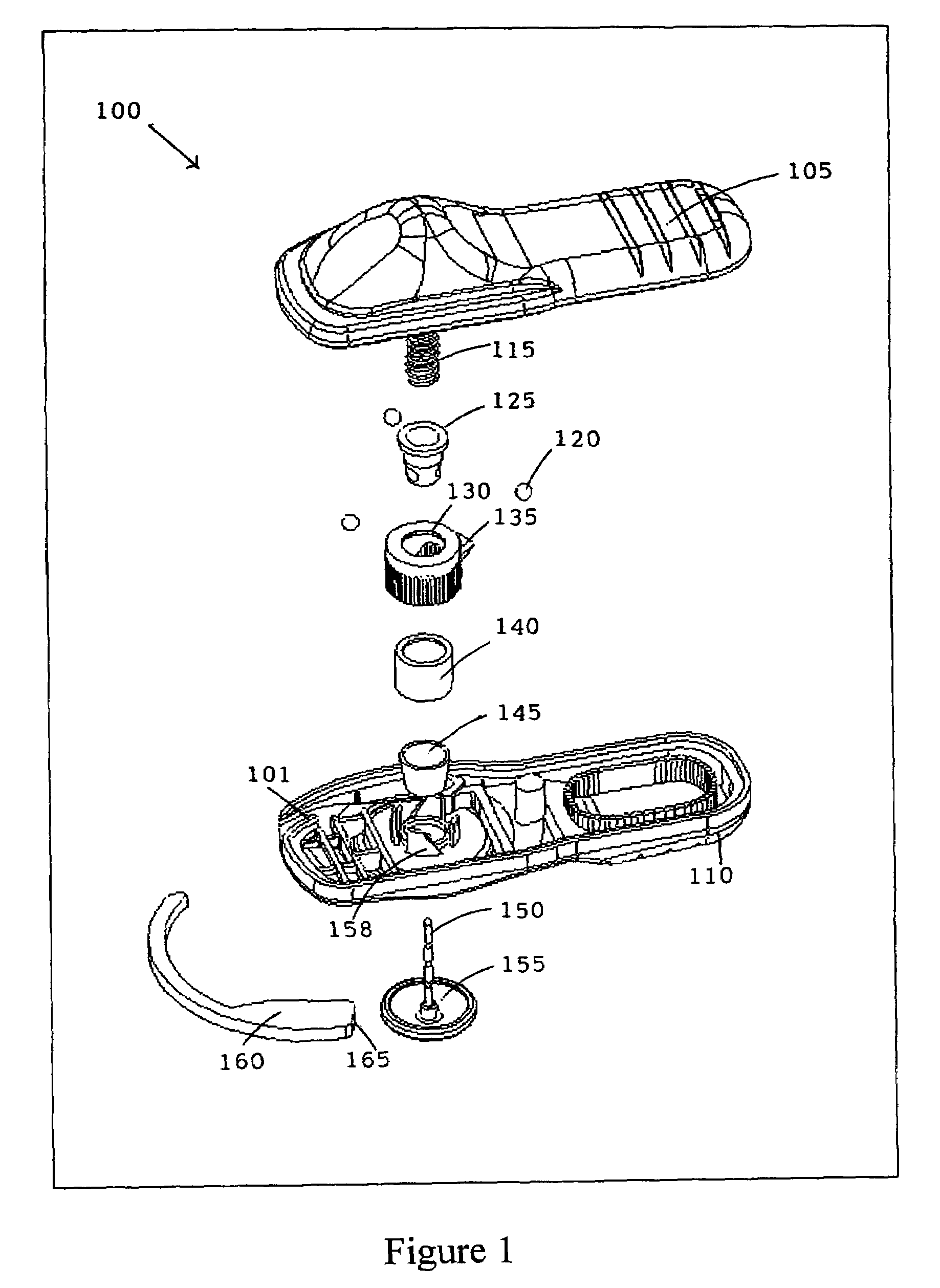

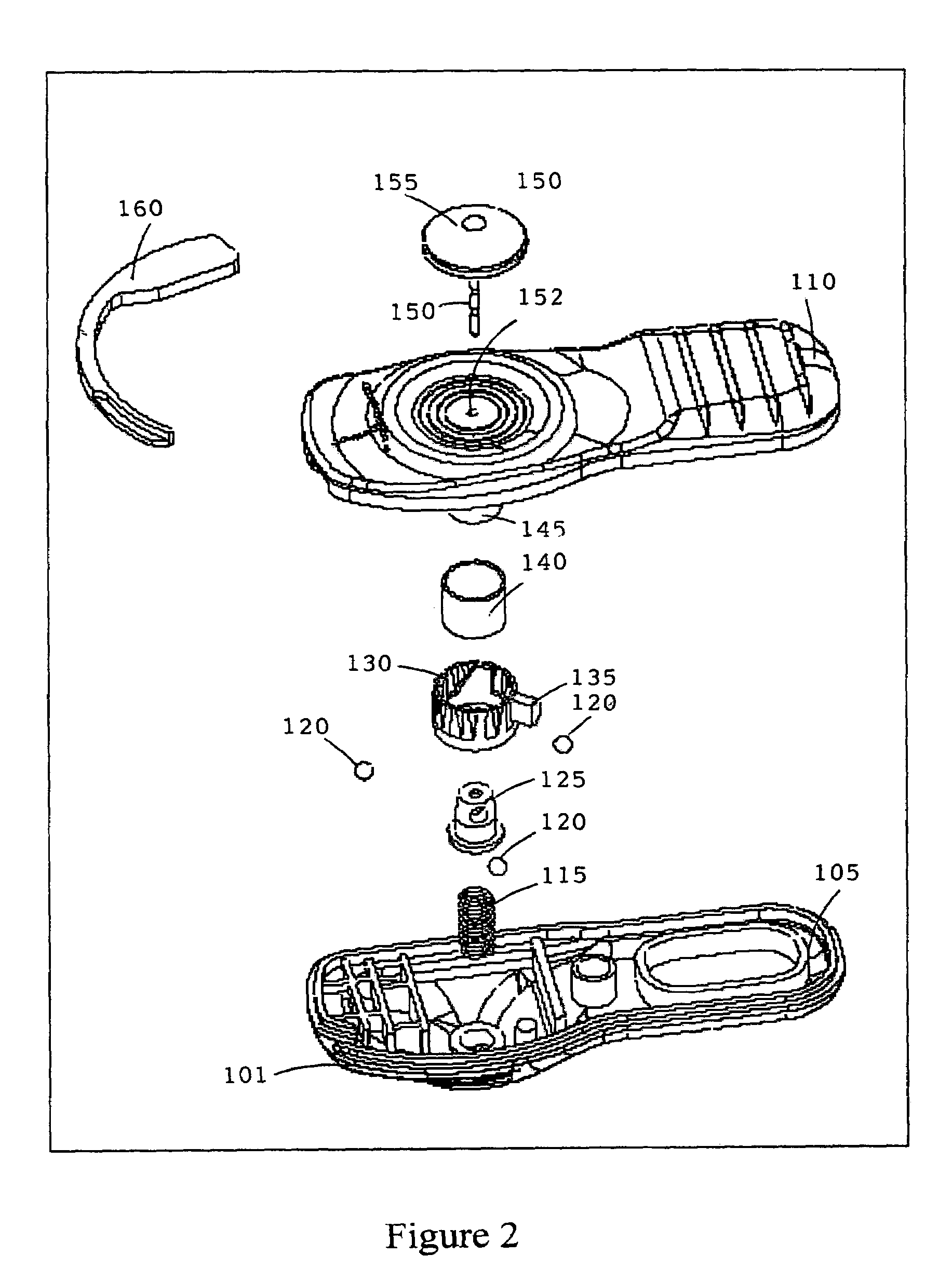

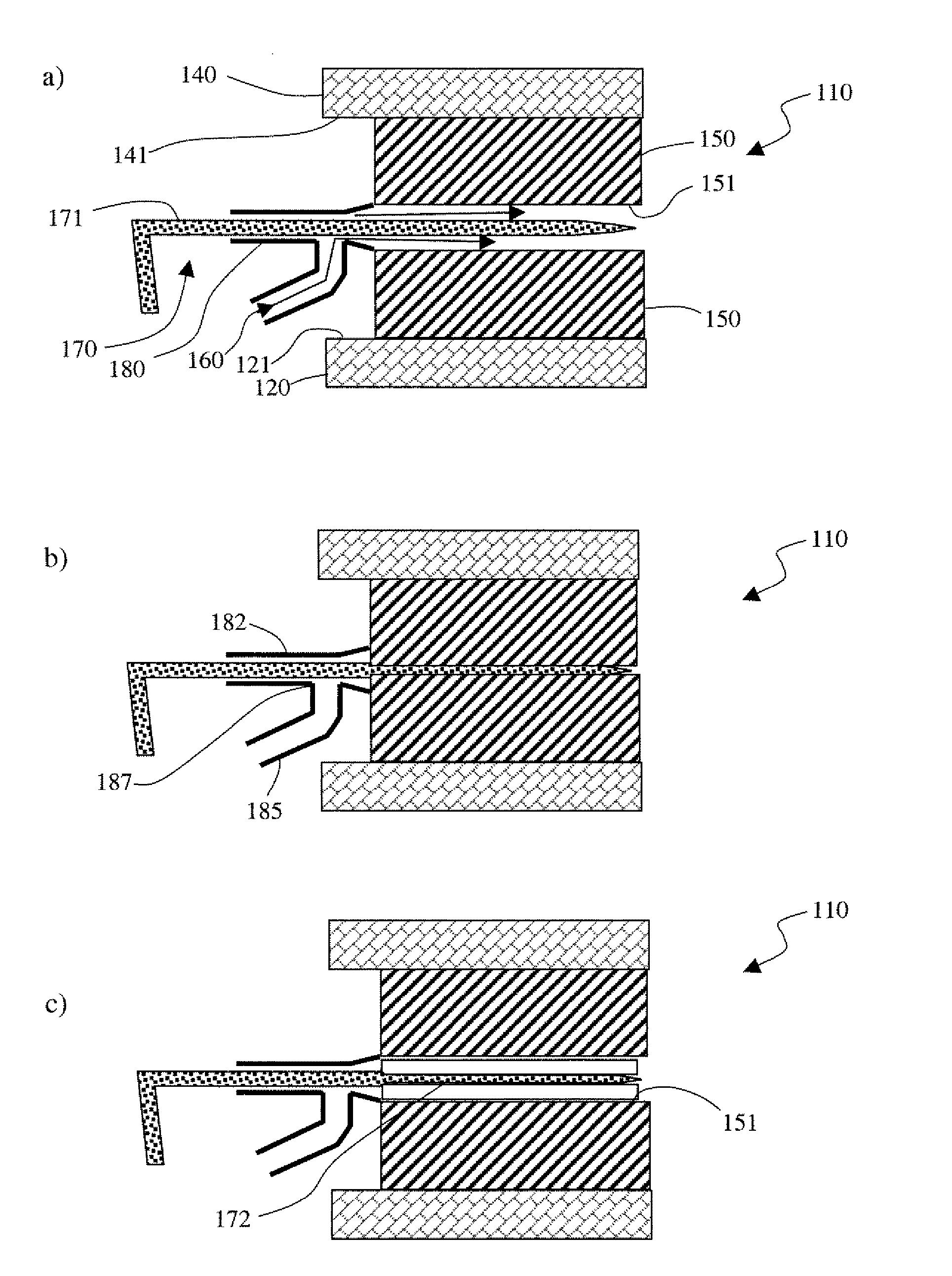

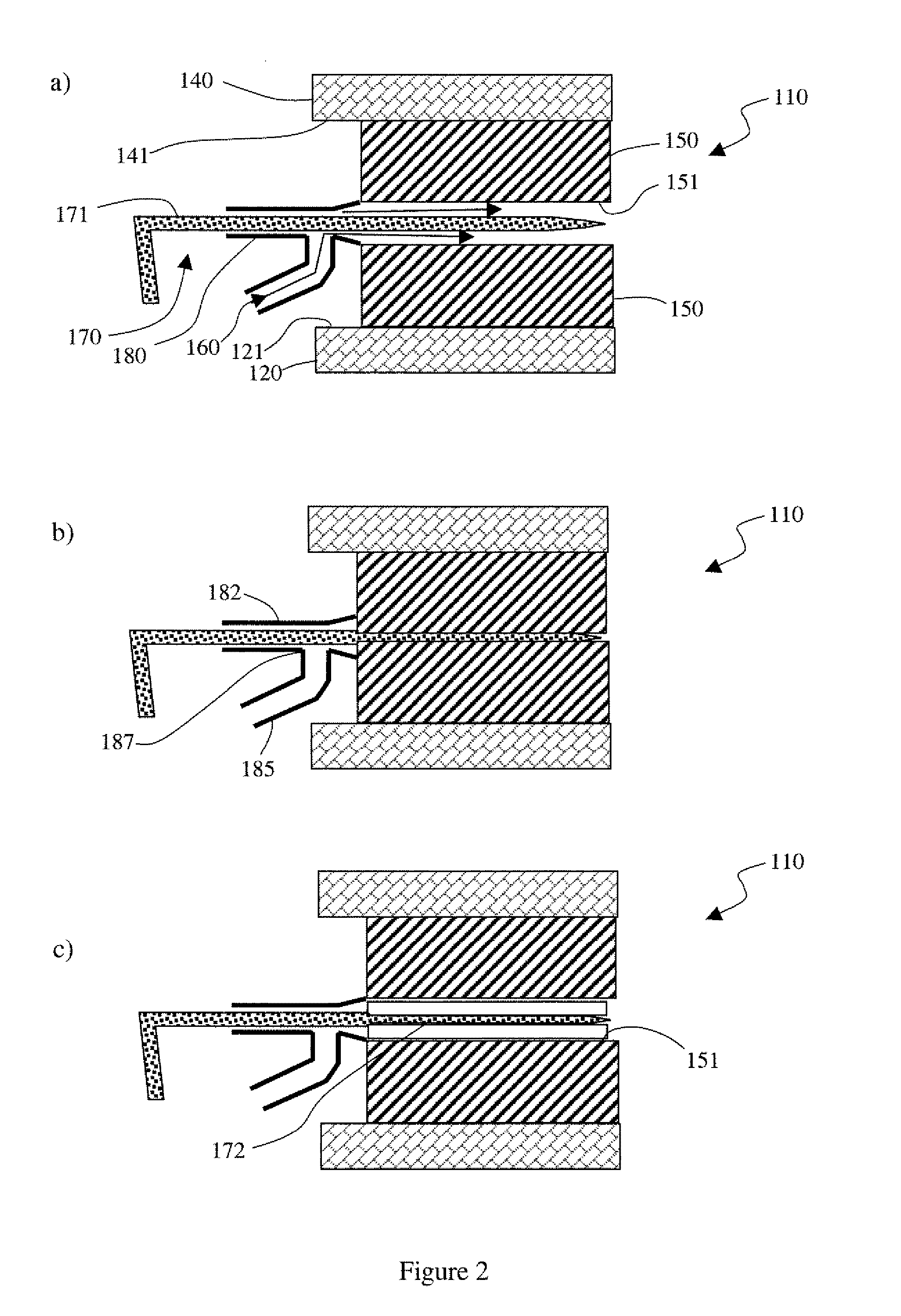

Safety fastener for tissue apposition

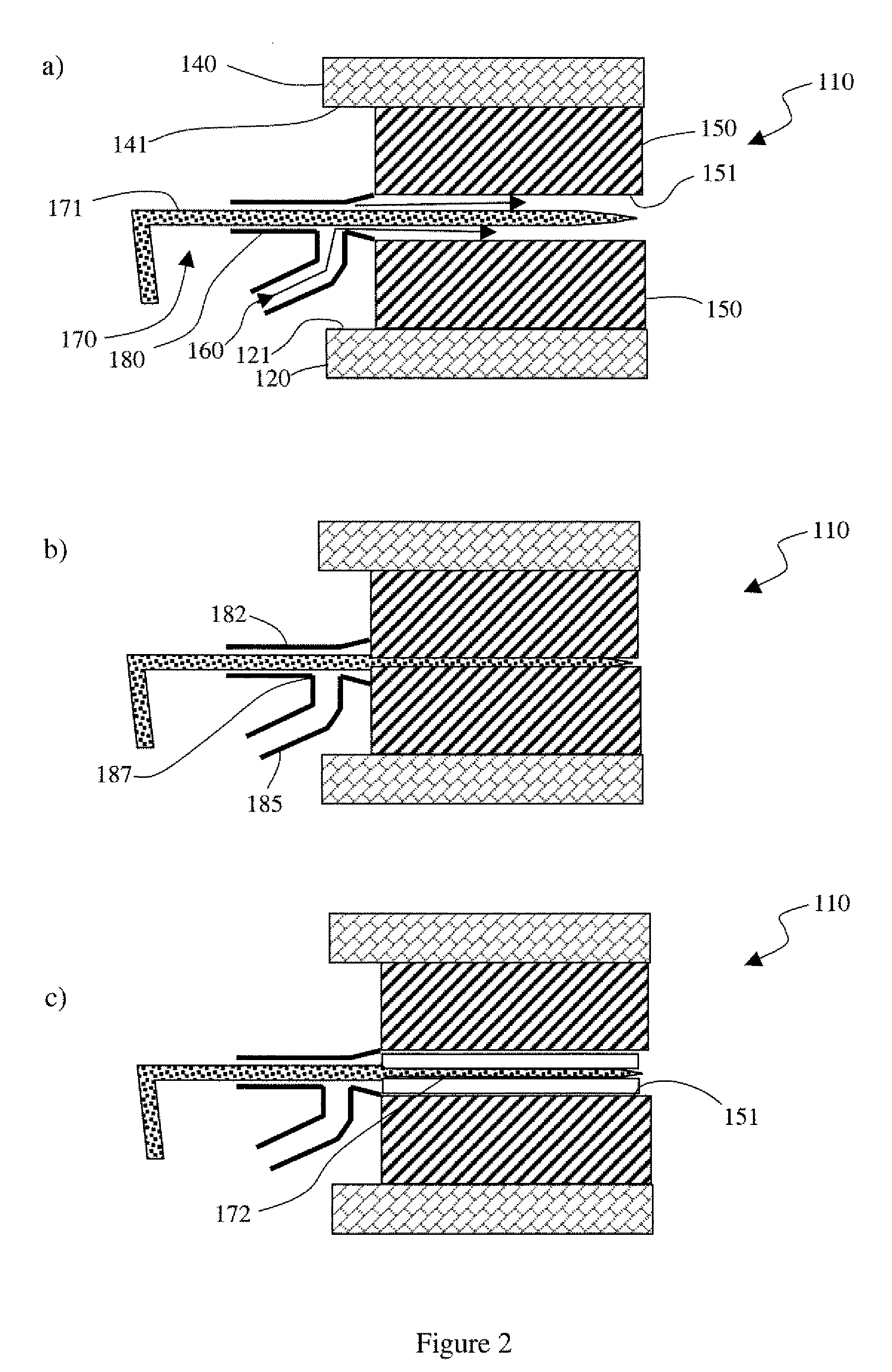

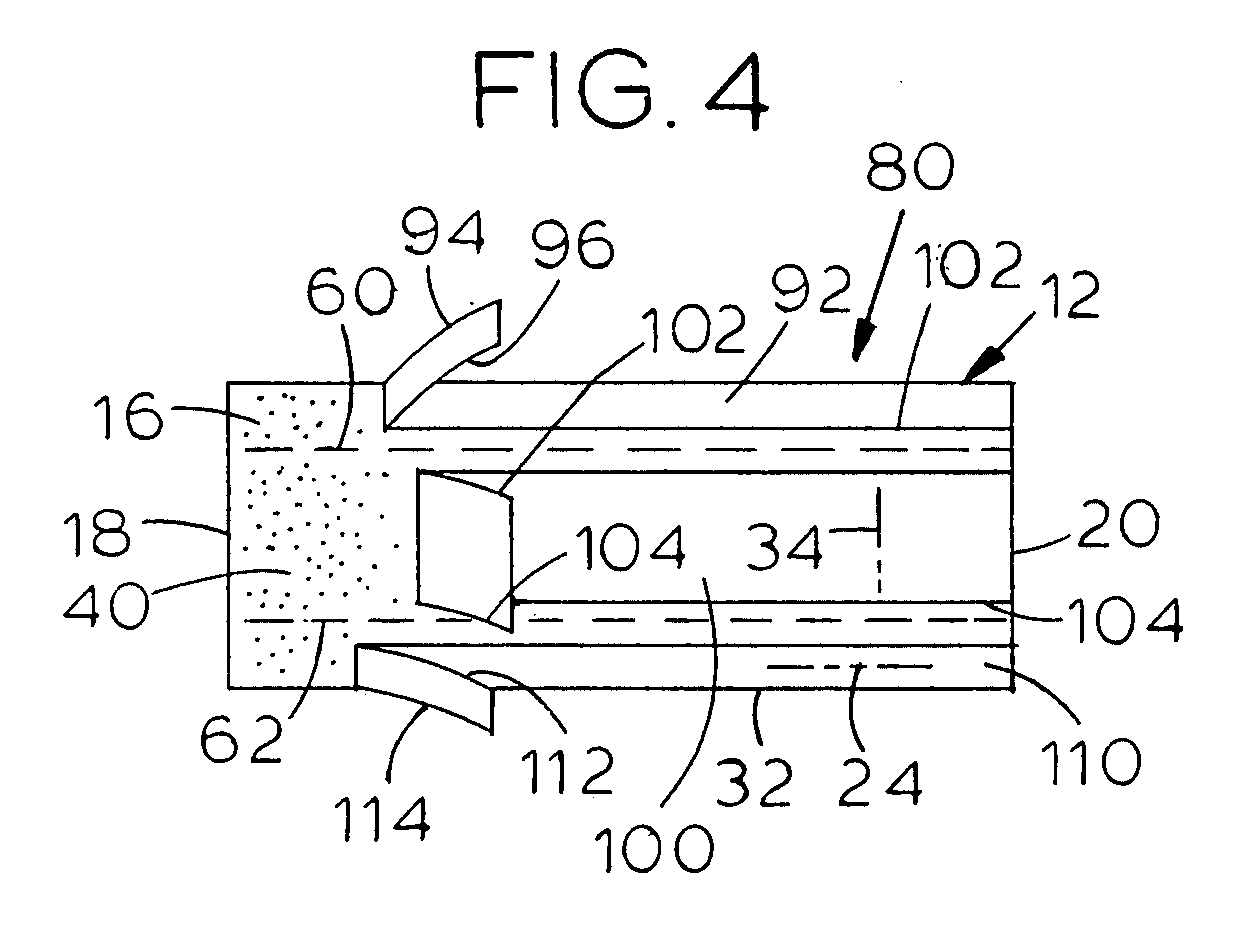

ActiveUS20080140095A1Prevents collateral tissue damageAvoid tissue damageSewing needlesScarvesAppositionBiomedical engineering

Methods and devices for fastening tissue are provided. In one exemplary embodiment, a tissue fastener is provided and includes a male fastening member having a base plate with at least one post extending therefrom and having a tissue-piercing tip. A protective member is coupled to the male fastening member and is movable between an open position in which the tissue-piercing tip is enclosed within the protective member such that the tissue-piercing tip is prevented from penetrating tissue, and a compressed position in which the tissue-piercing tip is exposed to penetrate tissue. A female fastening member is configured to mate to the male fastening member and to engage tissue therebetween.

Owner:ETHICON ENDO SURGERY INC

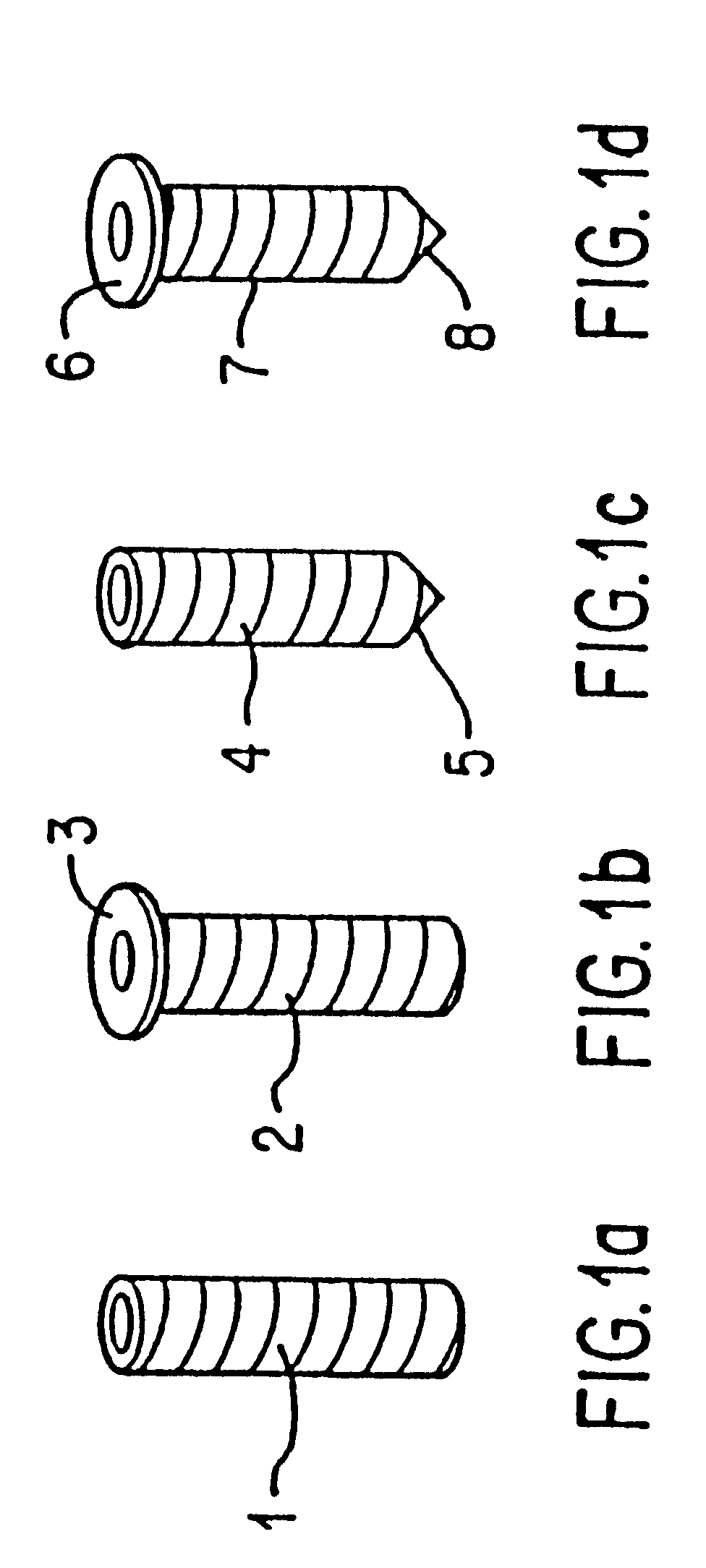

Thermal forming of refractory alloy surgical needles

A method of thermal forming of refractory alloy suture needles is disclosed. Needle blanks made from refractory alloys are used to form surgical needles, which are heated to a temperature above the ductile to brittle transition temperature but below the recrystallization temperature of the refractory alloy. The heated needle blanks are then mechanically formed into a surgical needle.

Owner:ETHICON INC

Hardware for furniture assembly

A hardware system is provided for use in ready-to-assembly (RTA) furniture that allows assembly thereof without the need for tools. The system includes a pin fastener and a pin receiver assembly. The pin receiver assembly is installed into one panel of the RTA furniture while the pin fastener is installed into another panel or component that is to be fastened to the first panel. The pin receiver includes a retaining means therein that serves to releasably engage the pin fastener when it is inserted therein. The pin receiver includes a body having engaging members therein that engage the pin shaft when the pin shaft is inserted into the pin receiver. In a preferred embodiment the pin receiver can be disengaged from the pin fastener using a magnet.

Owner:HAZZARD TRACY LEIGH

Conductive cap

Owner:NING ALICE

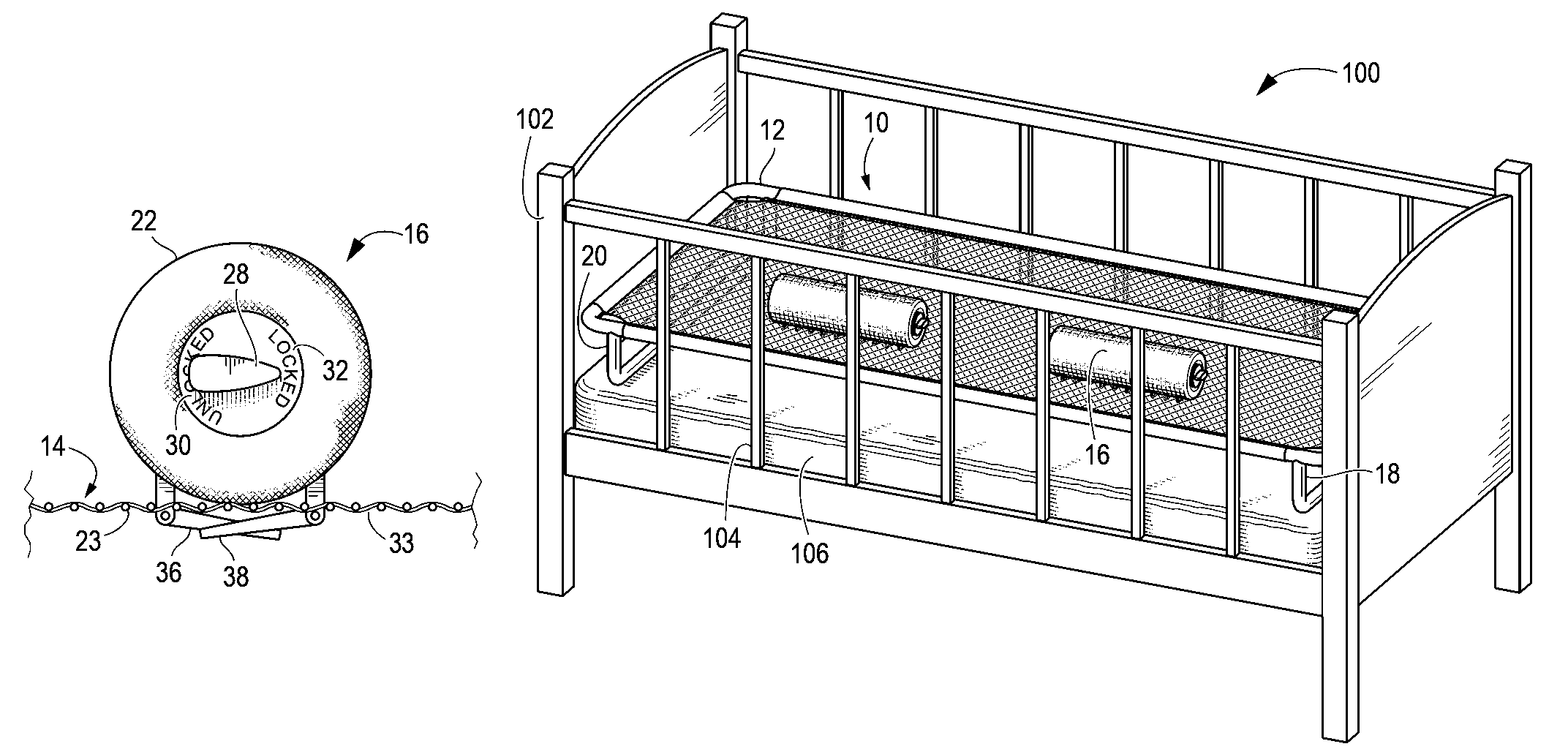

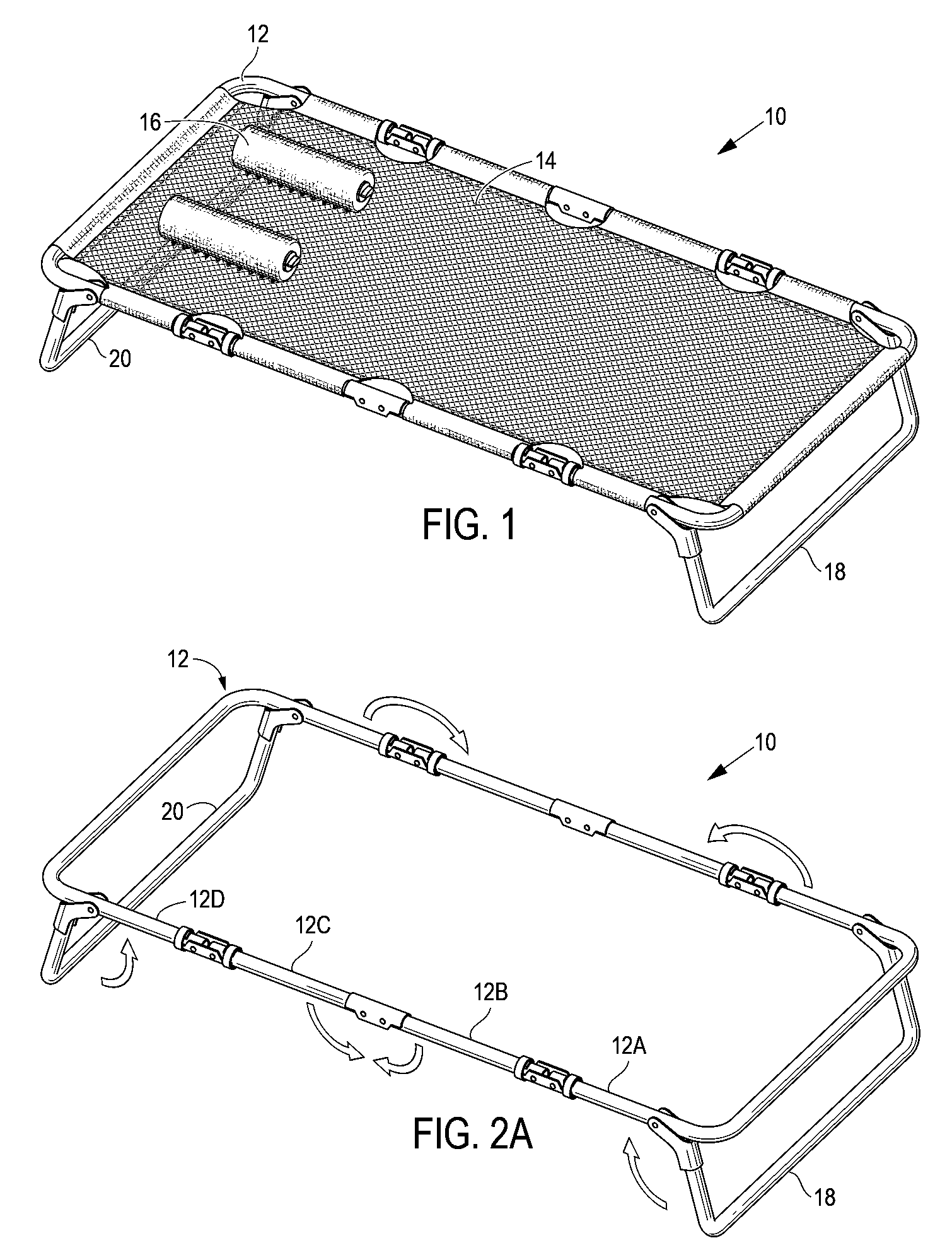

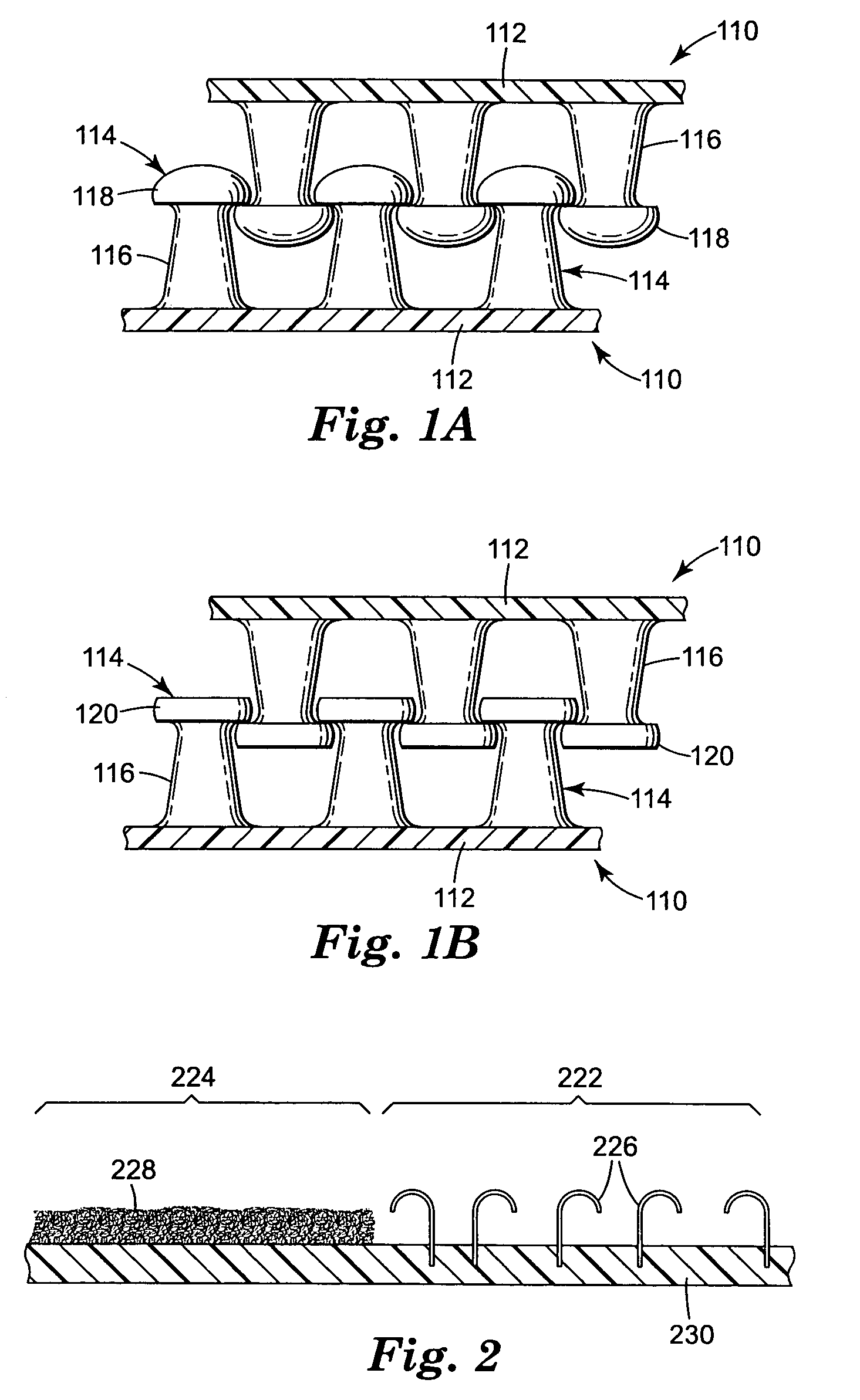

Support system with repositionable bolsters

ActiveUS7614098B1Promotes healthy positioningEasy to eatSnap fastenersStuffed mattressesElastomerSupporting system

A support system with repositionable bolsters with a panel of material, which can comprise elastomeric mesh, and bolsters repositionably securable to the panel of material. The panel of material can be retained relative to a bed or other structure or by a frame, which can be foldable. The bolsters, which can be formed with a breathable mesh shell, can be secured to the panel of material by a plurality of extendable and retractable fingers for being received through apertures in the panel of elastomeric material, by at least one expansible structure for being received through the apertures in the panel of elastomeric material and expanded, or by pivotable arms adjustable between generally parallel and non-parallel dispositions. The support system can be used independently or incorporated within a crib, bassinet, car seat, high chair, swing, bouncing seat or support, or any other support structure.

Owner:QUARRY VERONICA

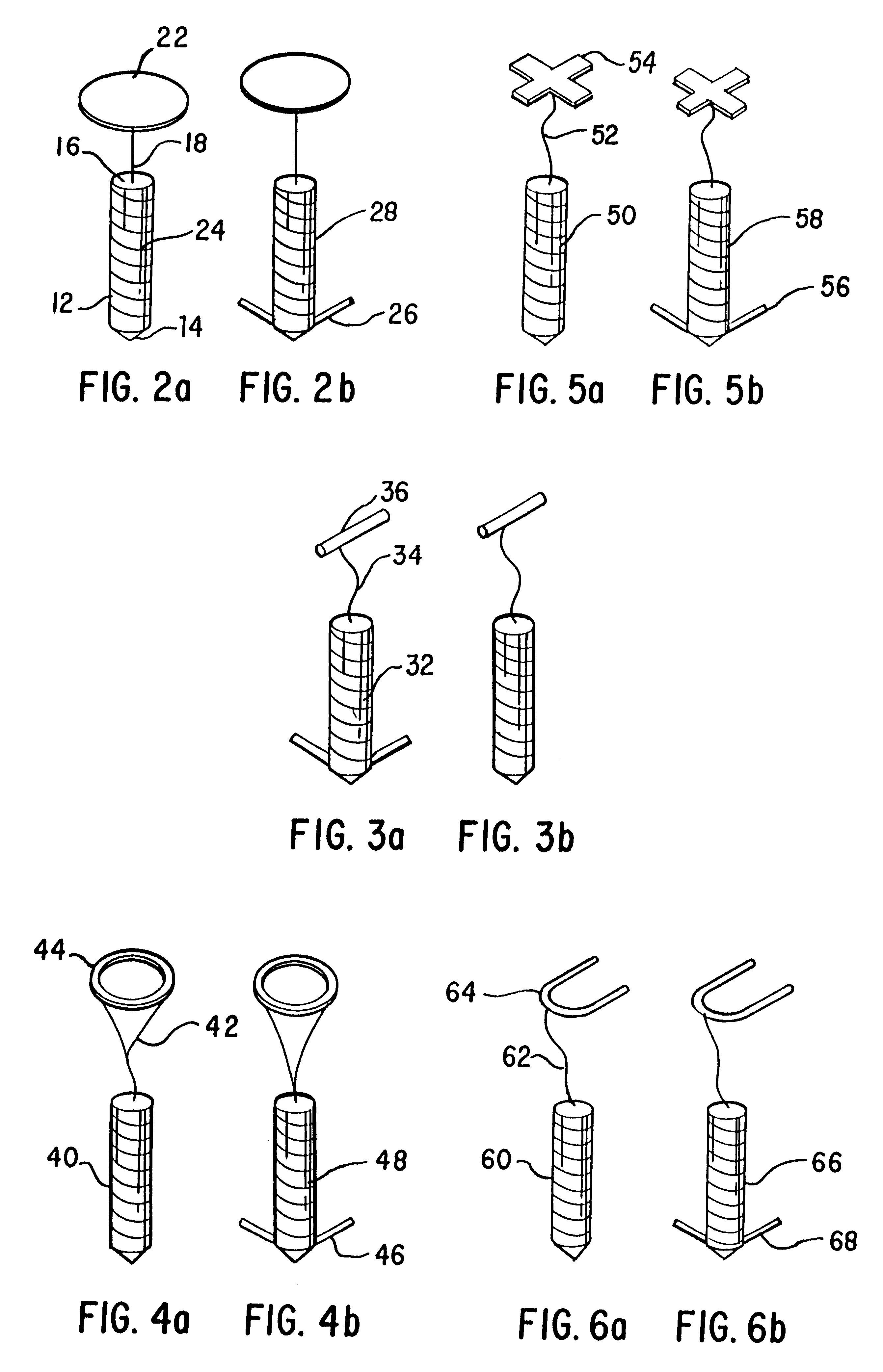

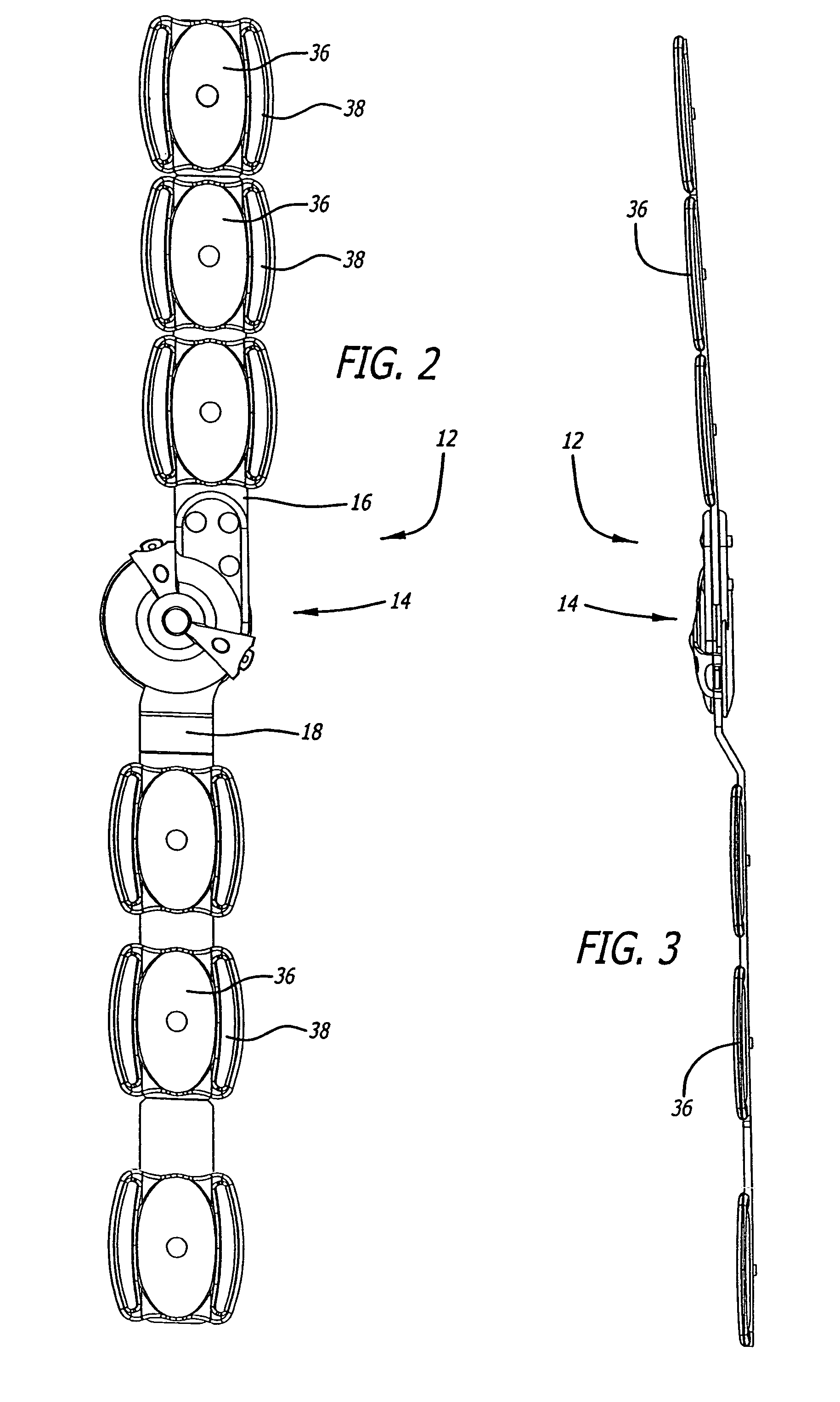

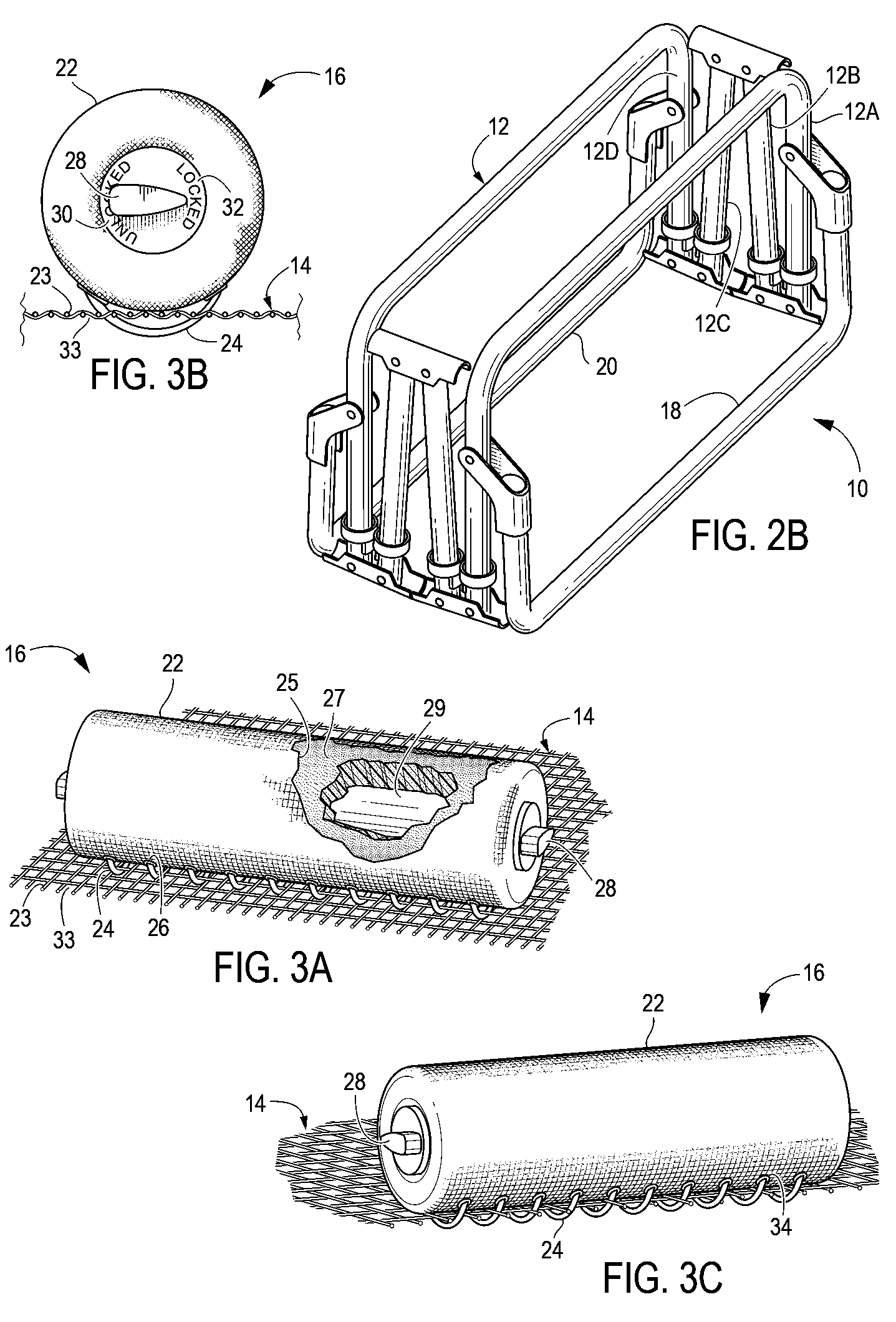

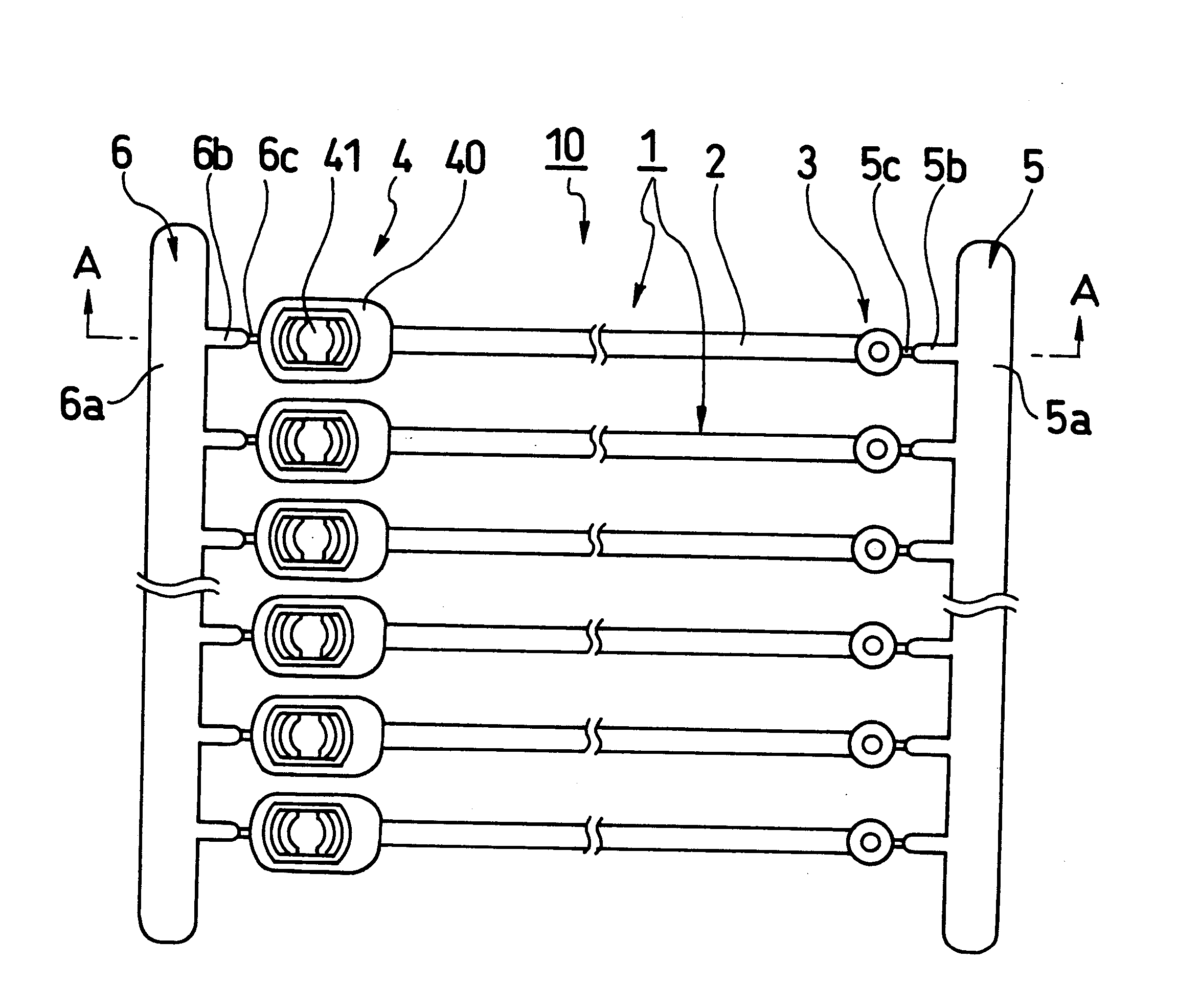

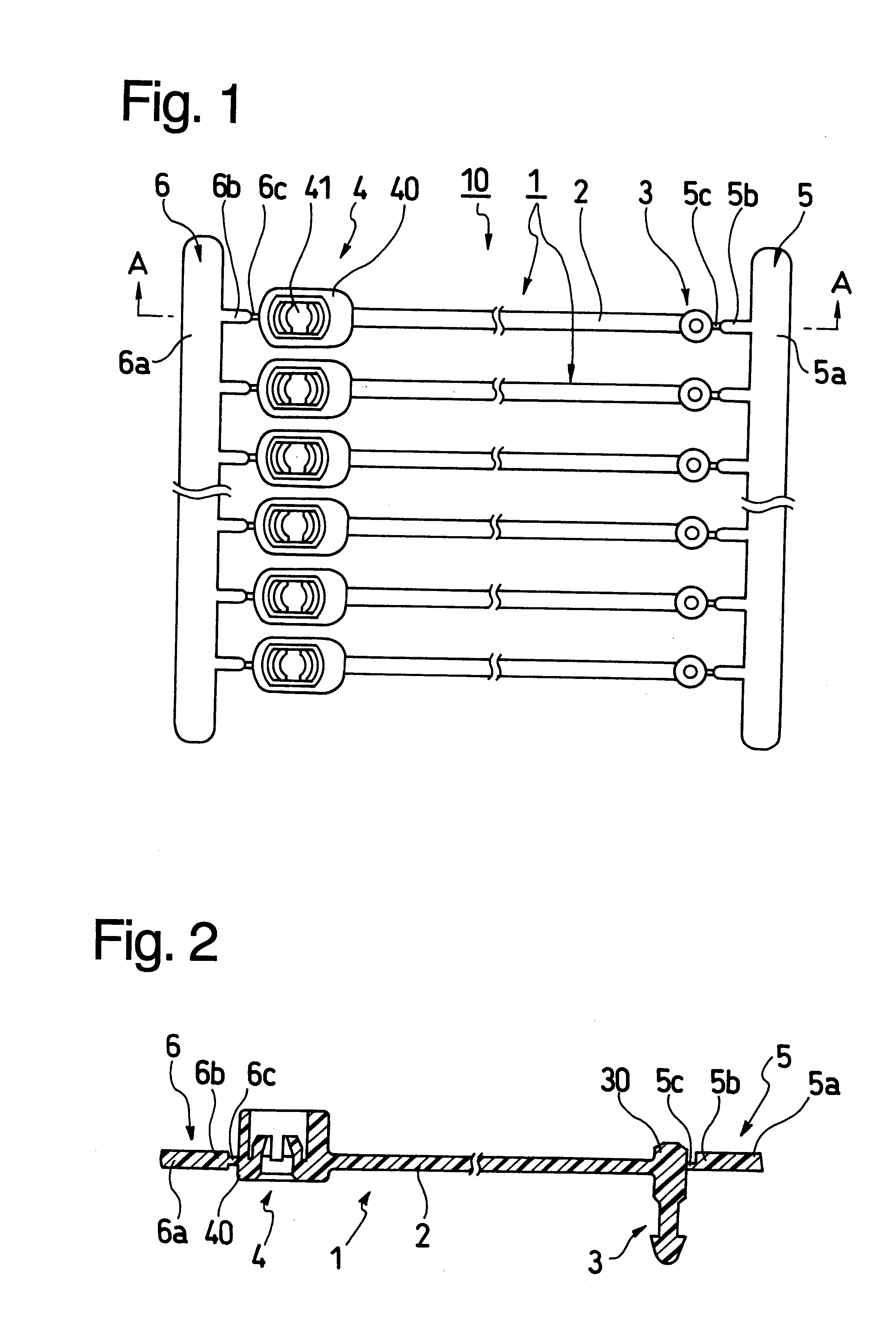

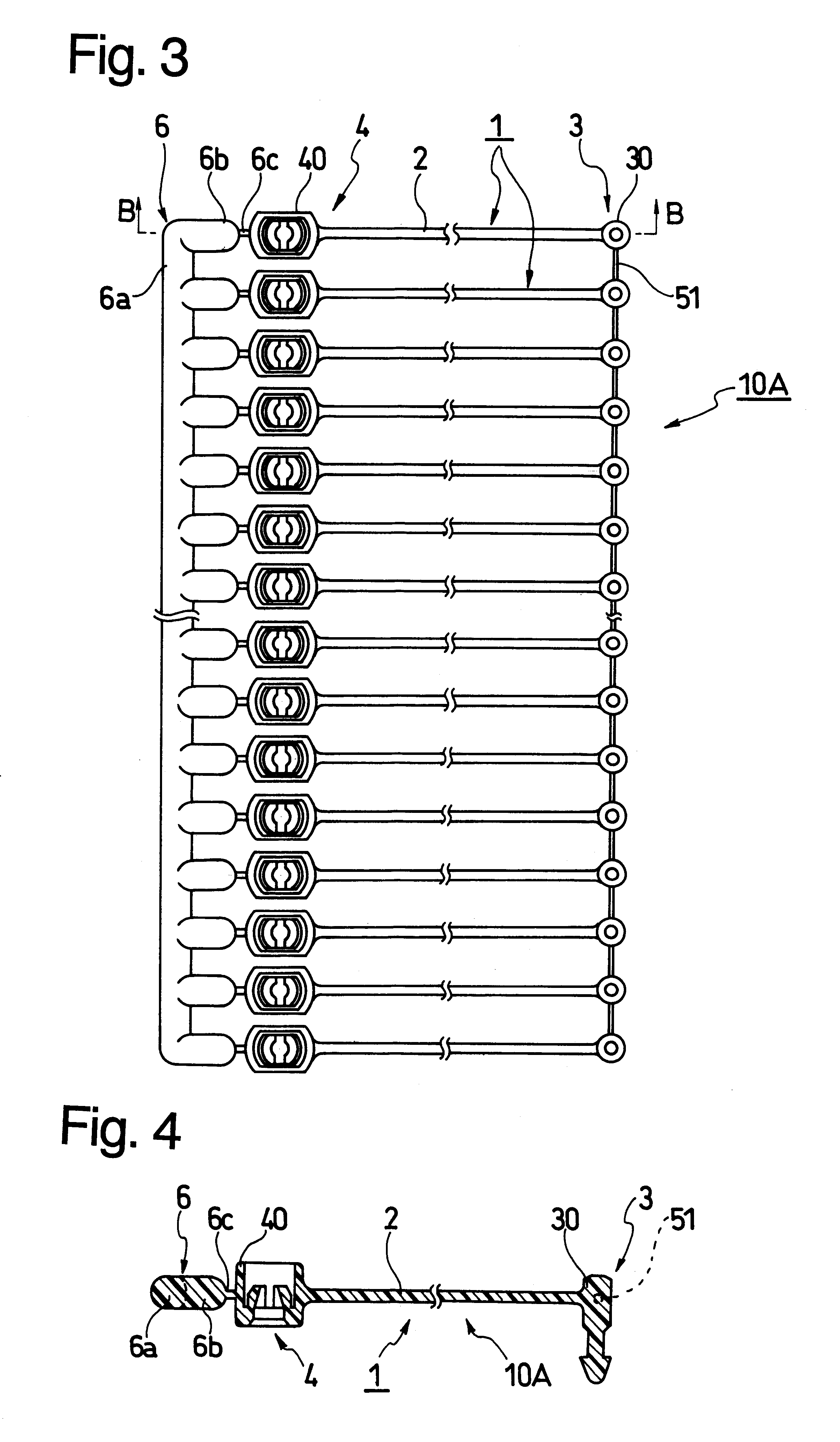

Fastener assembly

InactiveUS6220434B1Simplify the disassembly processEasy to engageStampsWire articlesEngineeringFastener

A fastener assembly which includes a plurality of fasteners each having a retaining projection which has a longitudinal axis, a fitting portion formed with an engaging hole which also has an axis in which the retaining projection can engage, and a filament portion arranged between the retaining projection and the fitting portion. A first joint member is connected with the retaining projections of the fasteners through first cutting portions each having a reduce sectional area. A second joint member is connected with the fitting portions through second cutting portions. In this manner, the fasteners are fixed to and securely supported by the first and second joint members to be arrayed in a plane. The axes of the retaining projections and the axes of the fitting holes of the fitting portions are formed perpendicular to the plane of the fasteners. An attaching device can be simply charged with the fastener assembly in a set and in an array and can be disassembled in the device into individual fasteners so that each of these fasteners is enabled to attach a price tag or label to a commodity with a loop of its filament portion by inserting its retaining projection easily to engage with the fitting portion. In the alternative, the fastener assembly can be manually used by disassembling it easily by hand into individual fasteners and can be held in the array state without any entanglement while it is being transported or stored.

Owner:TOSKA

Thermal Forming of Refractory Alloy Surgical Needles

A method of thermal forming of refractory alloy suture needles is disclosed. Needle blanks made from refractory alloys are used to form surgical needles, which are heated to a temperature above the ductile to brittle transition temperature but below the recrystallization temperature of the refractory alloy. The heated needle blanks are then mechanically formed into a surgical needle.

Owner:CICHOCKI FR R +2

Curable mechanical fasteners

Curable mechanical fasteners of the invention comprise a fastening surface comprising a curable material, wherein the fastening surface is capable of being repeatedly attached and unattached to a complementary fastening surface, and when attached to the complementary fastening surface and cured, the curable mechanical fastener is capable of becoming permanently attached to the complementary fastening surface. The curable mechanical fastener may also further comprise the complementary fastening surface.

Owner:3M INNOVATIVE PROPERTIES CO

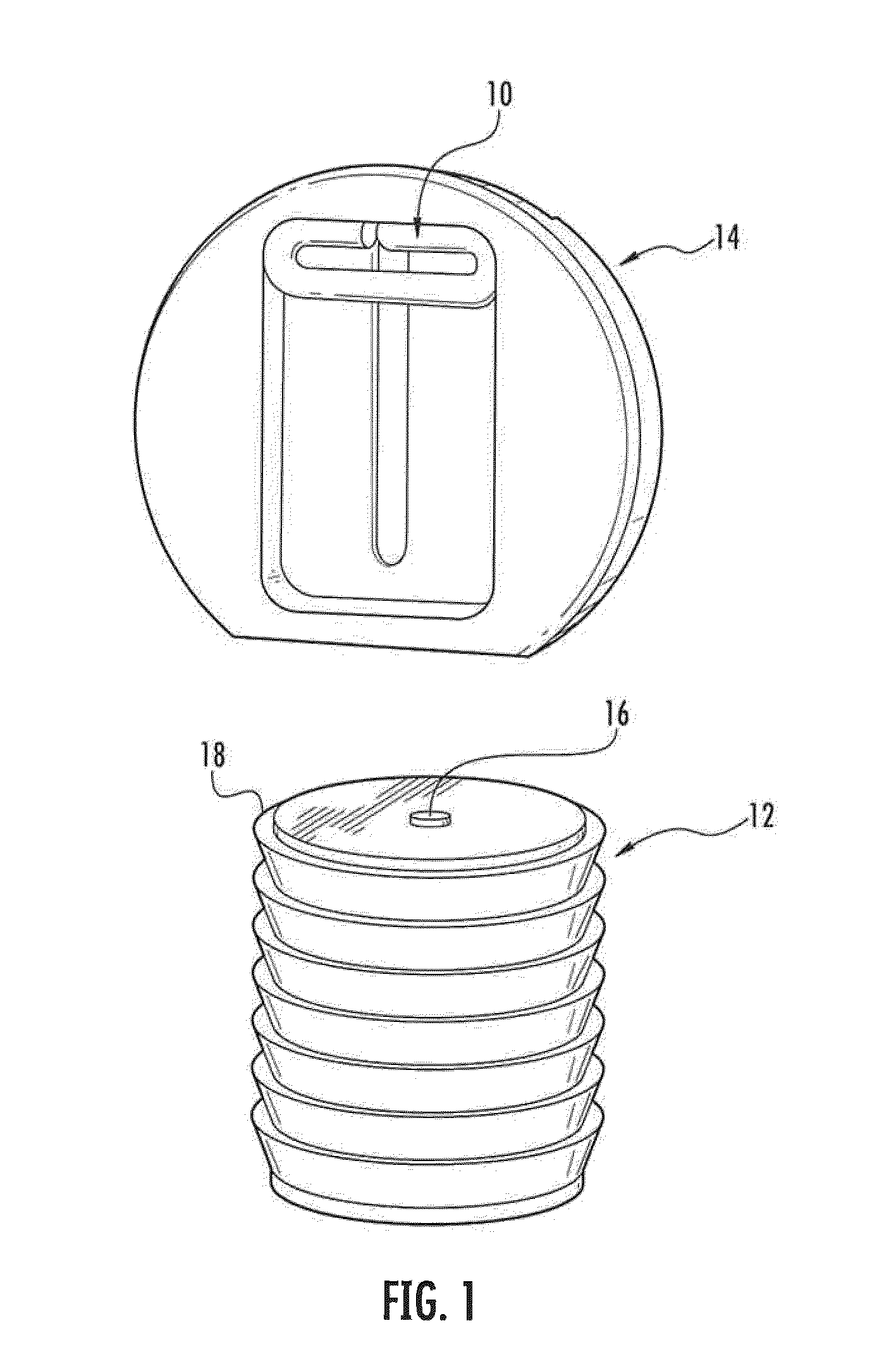

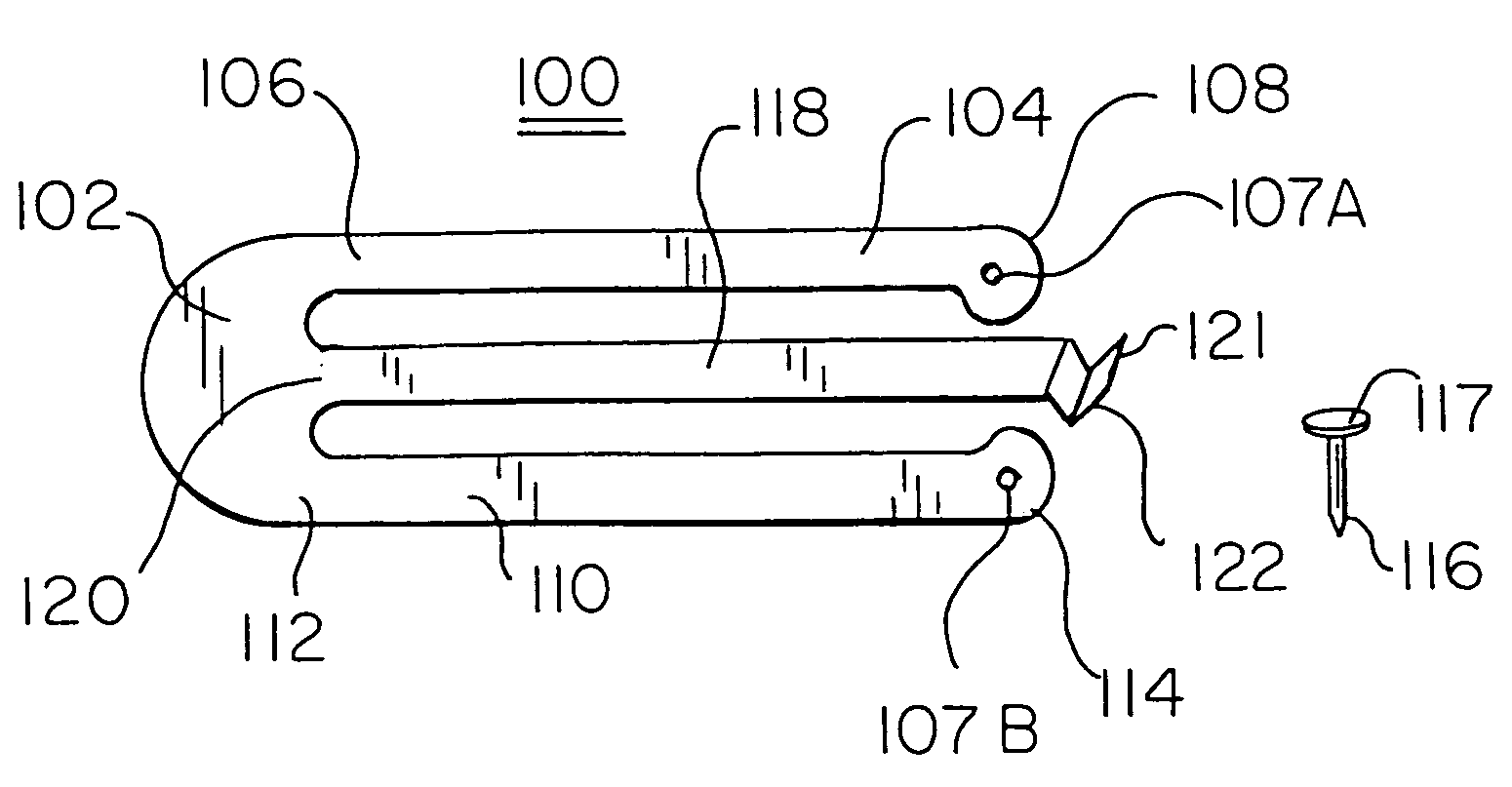

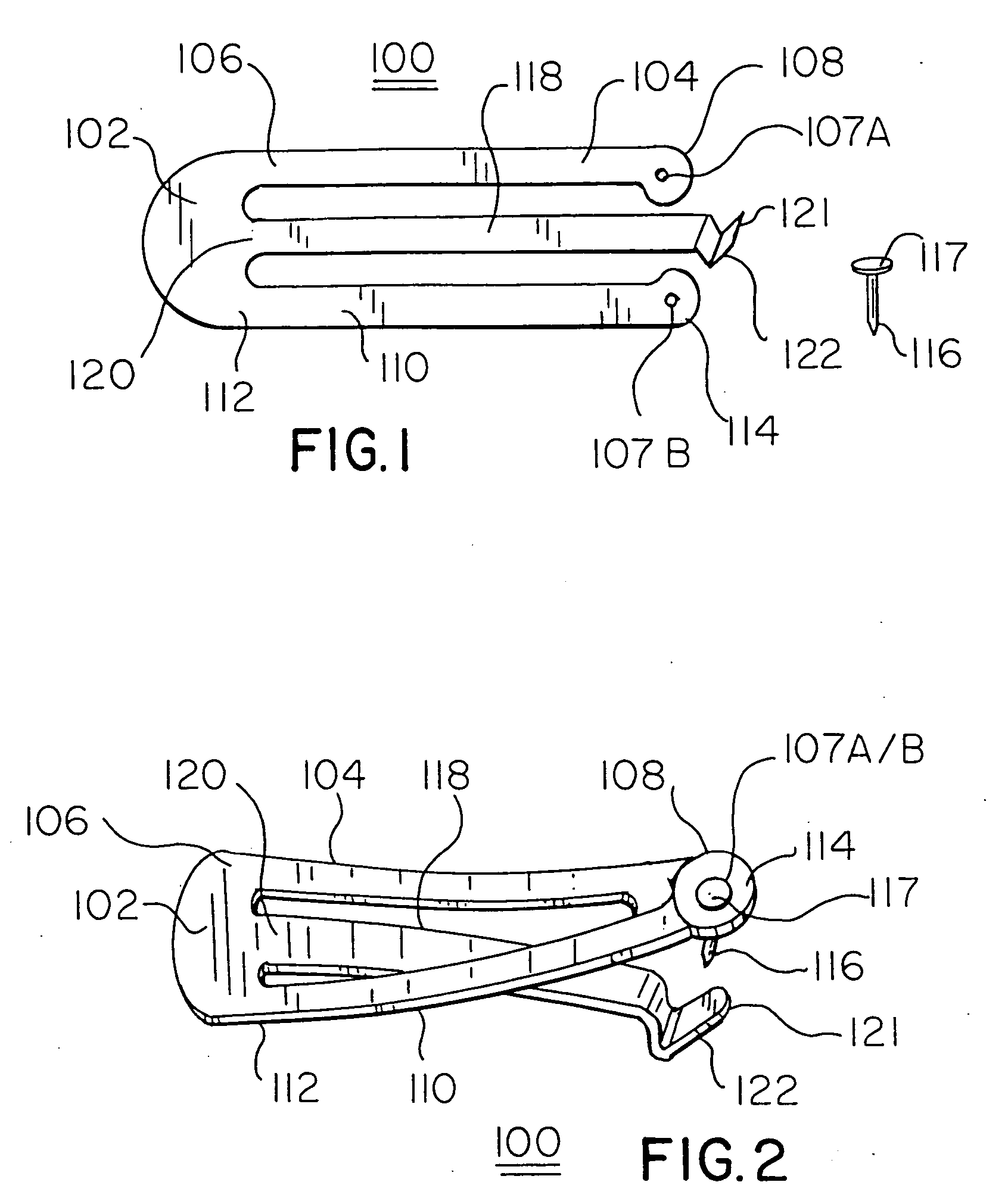

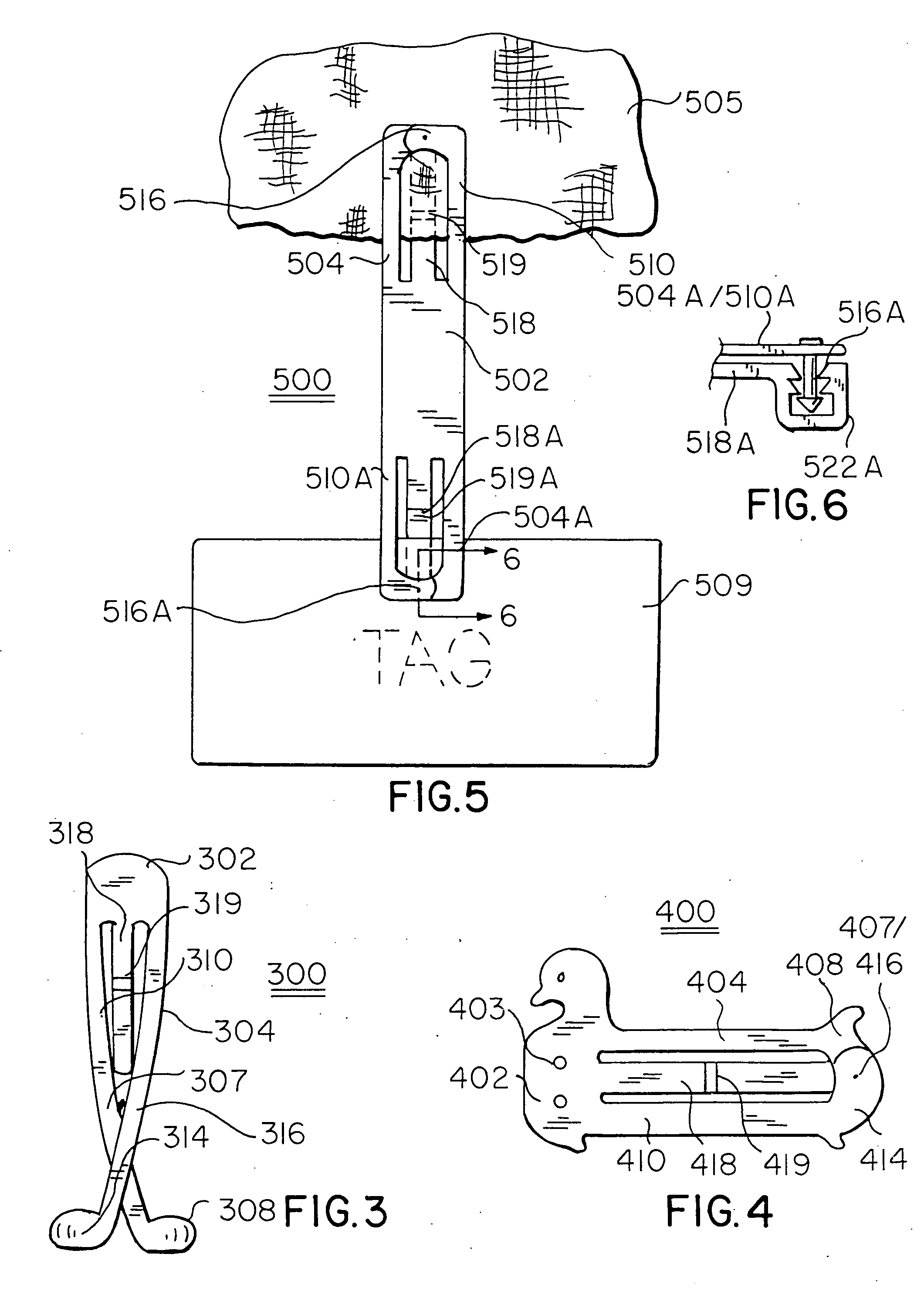

Security tag assembly

InactiveUS20060139176A1Low costShorten the timeSnap fastenersLocks for portable objectsEngineeringBiological activation

A security tag assembly structured to prevent the unauthorized removal of merchandise from a given area such as a retail establishment comprising a base and an attachment member. A connector pin is secured to a seat portion of the base and extends outwardly there from into engagement with a locking assembly on an interior of the attachment member. The locking assembly restricts movement of the connector pin outwardly from the attachment member and is structured to be destructively detached from the pin when the base and the attachment member are forcibly separated thereby requiring the attachment member to be disposed of and replaced. The base is re-useable and includes a display field for exposing predetermined merchandise data or other information on an exterior of said base. An RF communication / signaling structure may be combined with the base for tracking and / or alarm activation purposes.

Owner:SKJELLERUP JOHAN +1

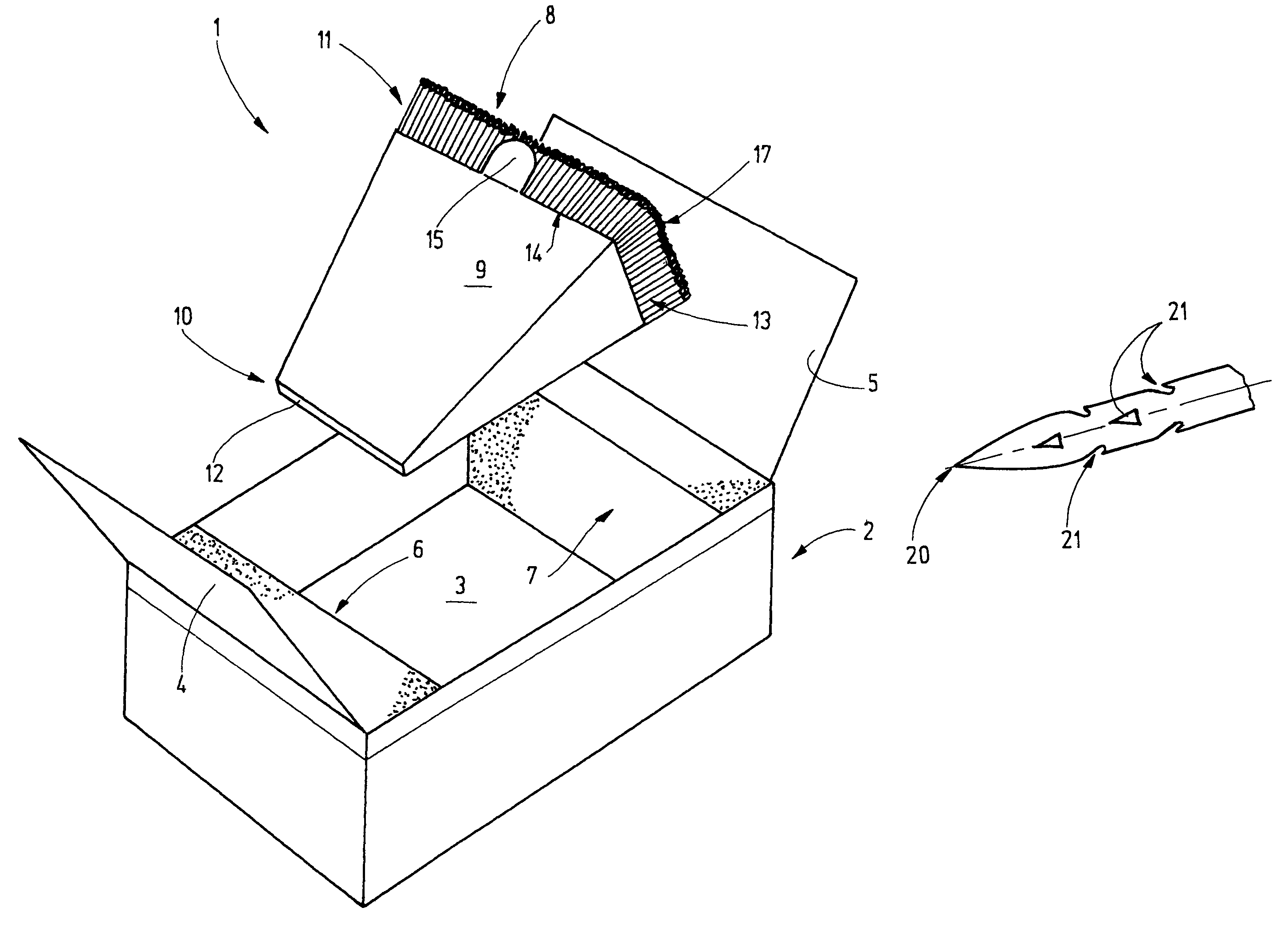

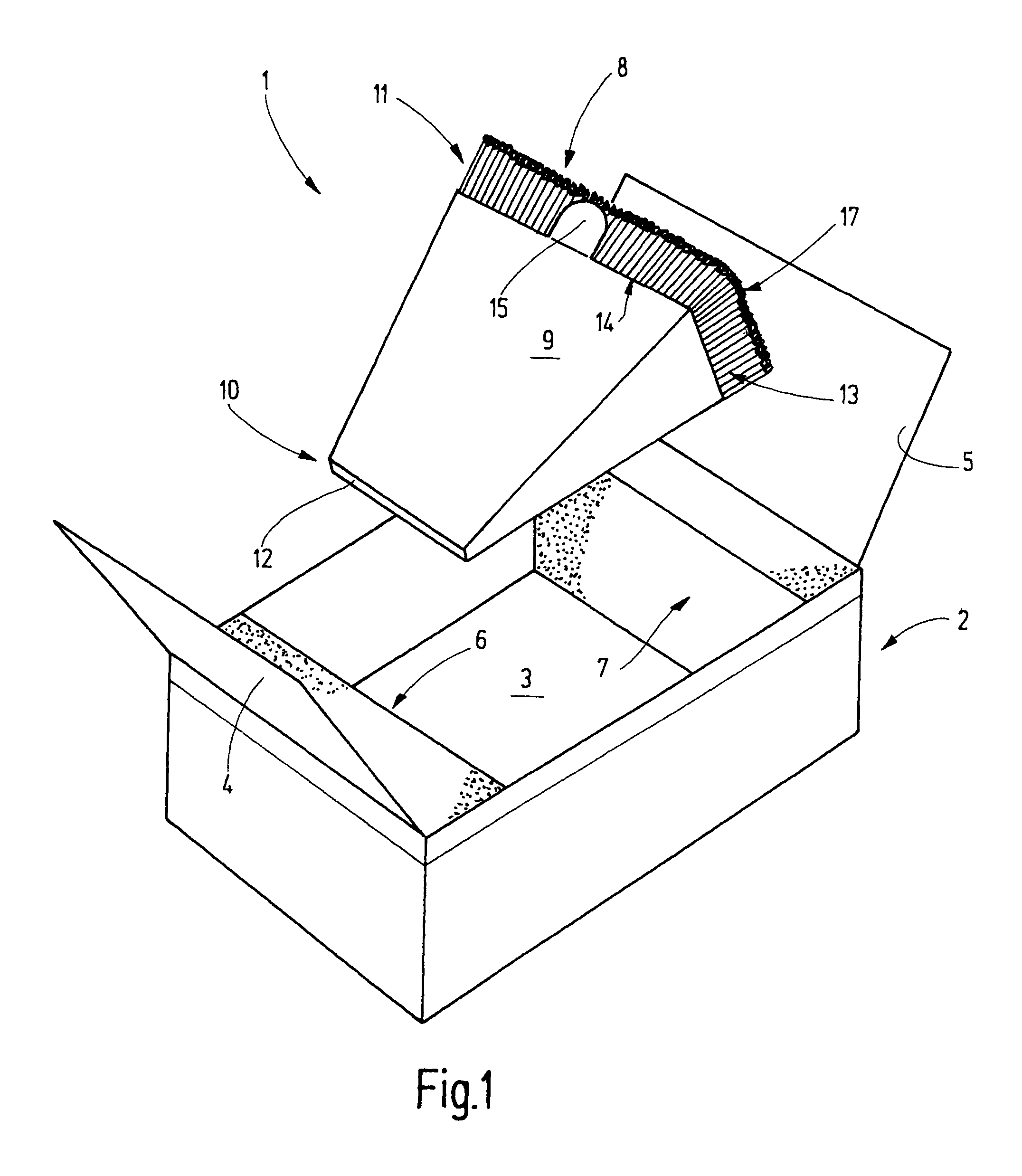

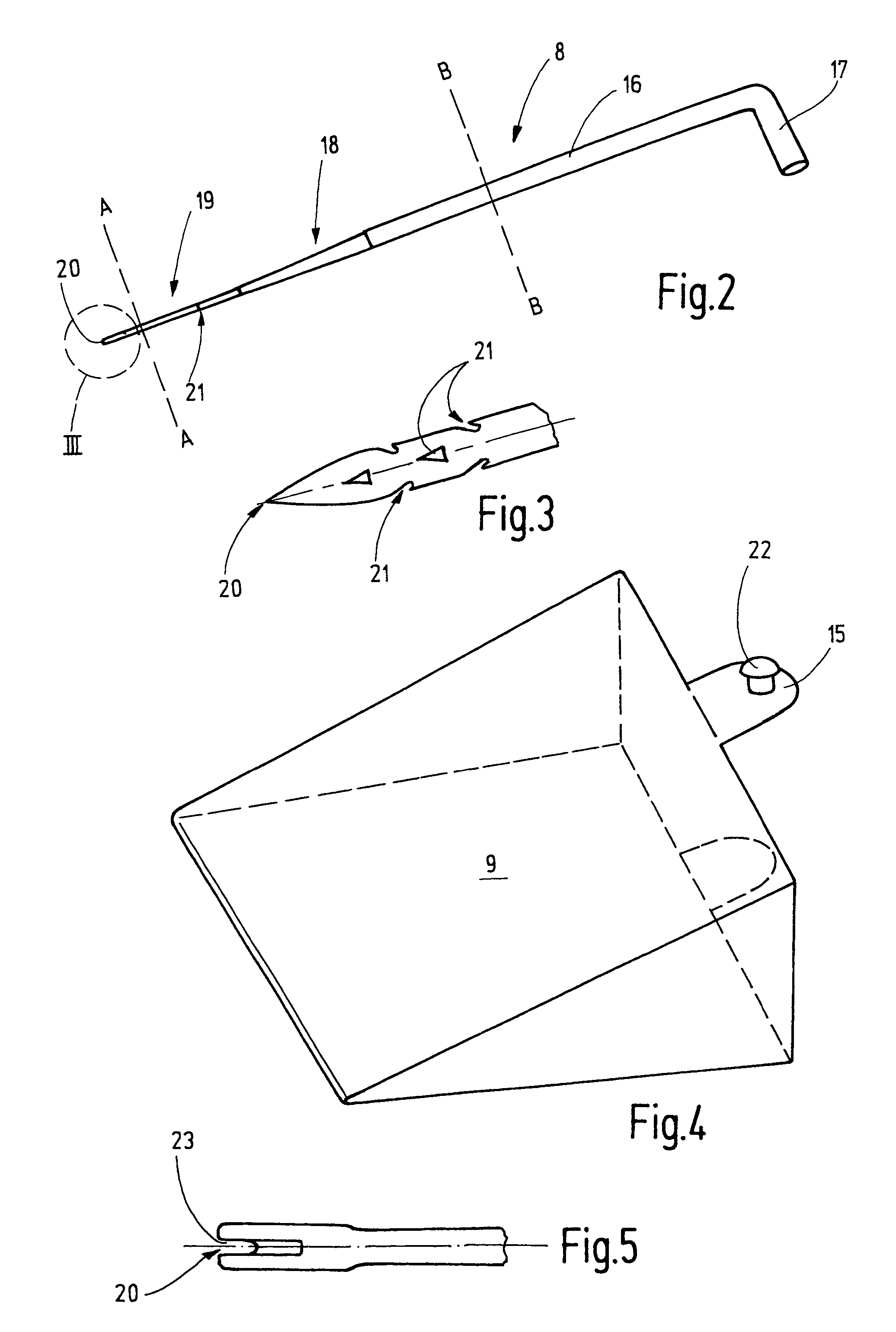

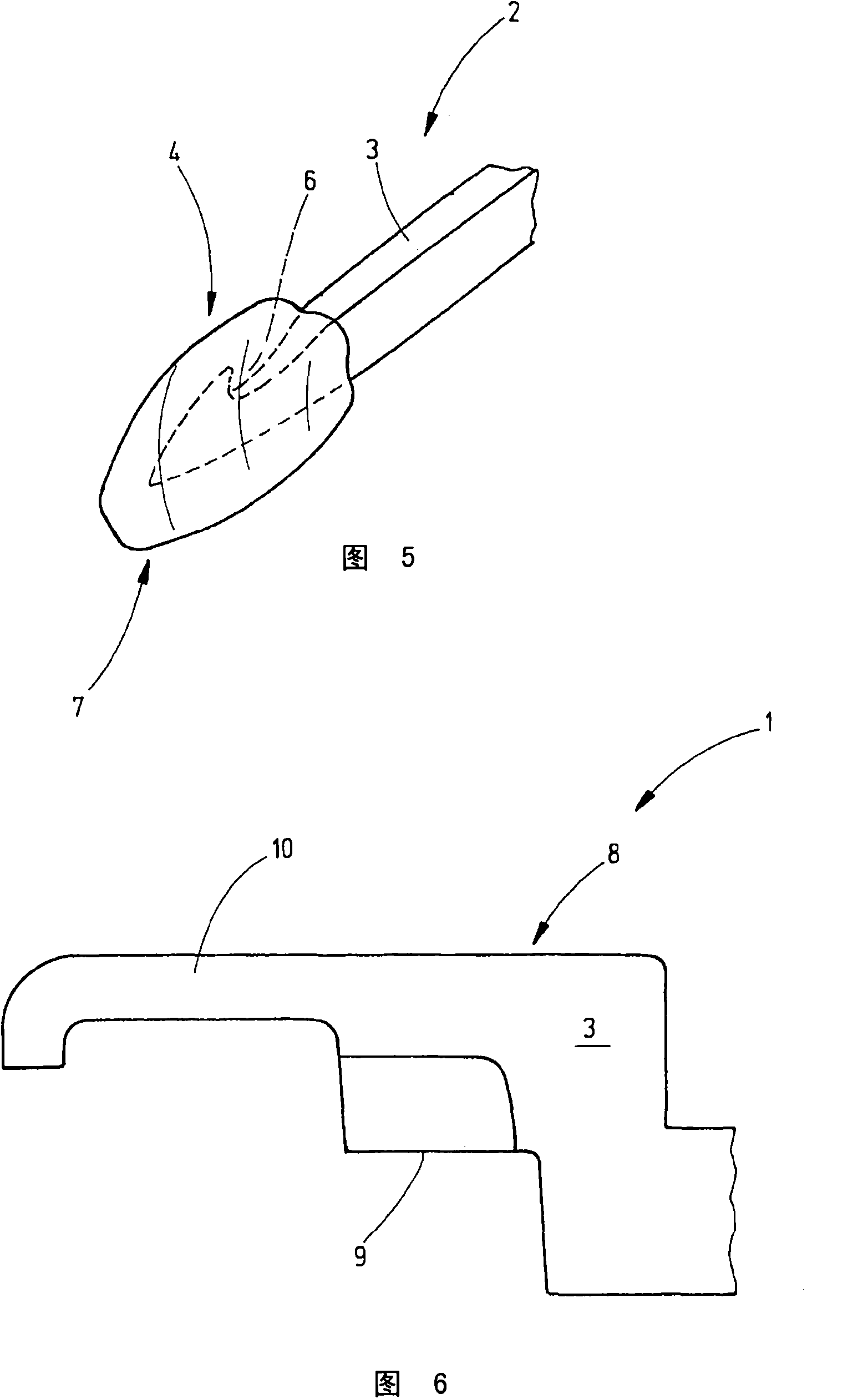

Package for felting needles

ActiveUS7798325B2Easy to handleReduce riskSewing needlesOther accessoriesEngineeringMechanical engineering

A wedge-shaped receptacle (9) is provided for packaging felting needles (8). The wedge shape is configured in such a manner that the felting needles lie in the receptacle in a mutual lateral engagement, that is, they are held approximately parallel to one another and they firmly clamp one another without their tips abutting against the receptacle body. This, on the one hand, results in a particular protection of the felting needles (8) during transportation and, on the other hand, results in a simple handling with the lowest danger of injuries.

Owner:GROZ BECKERT KG

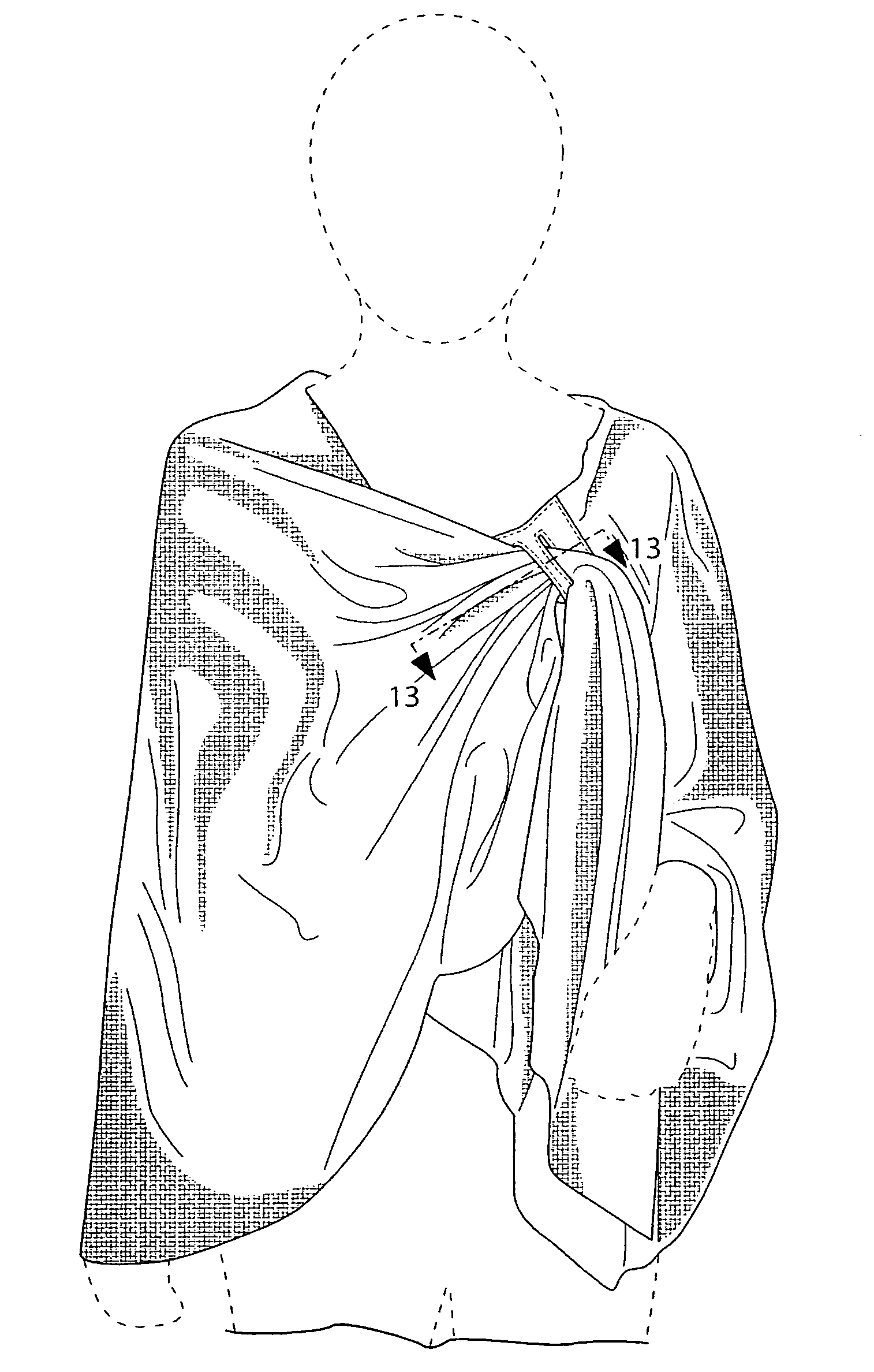

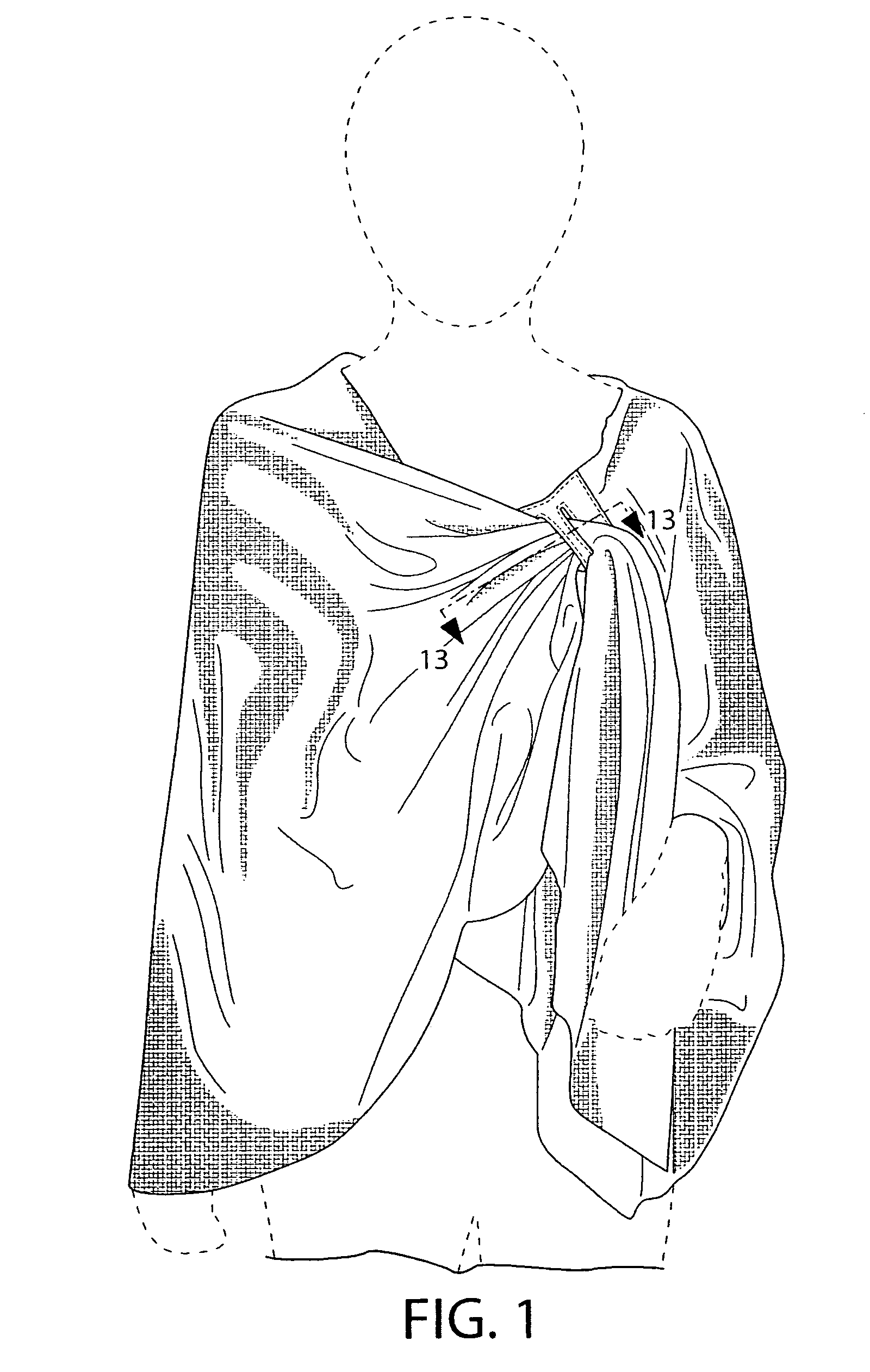

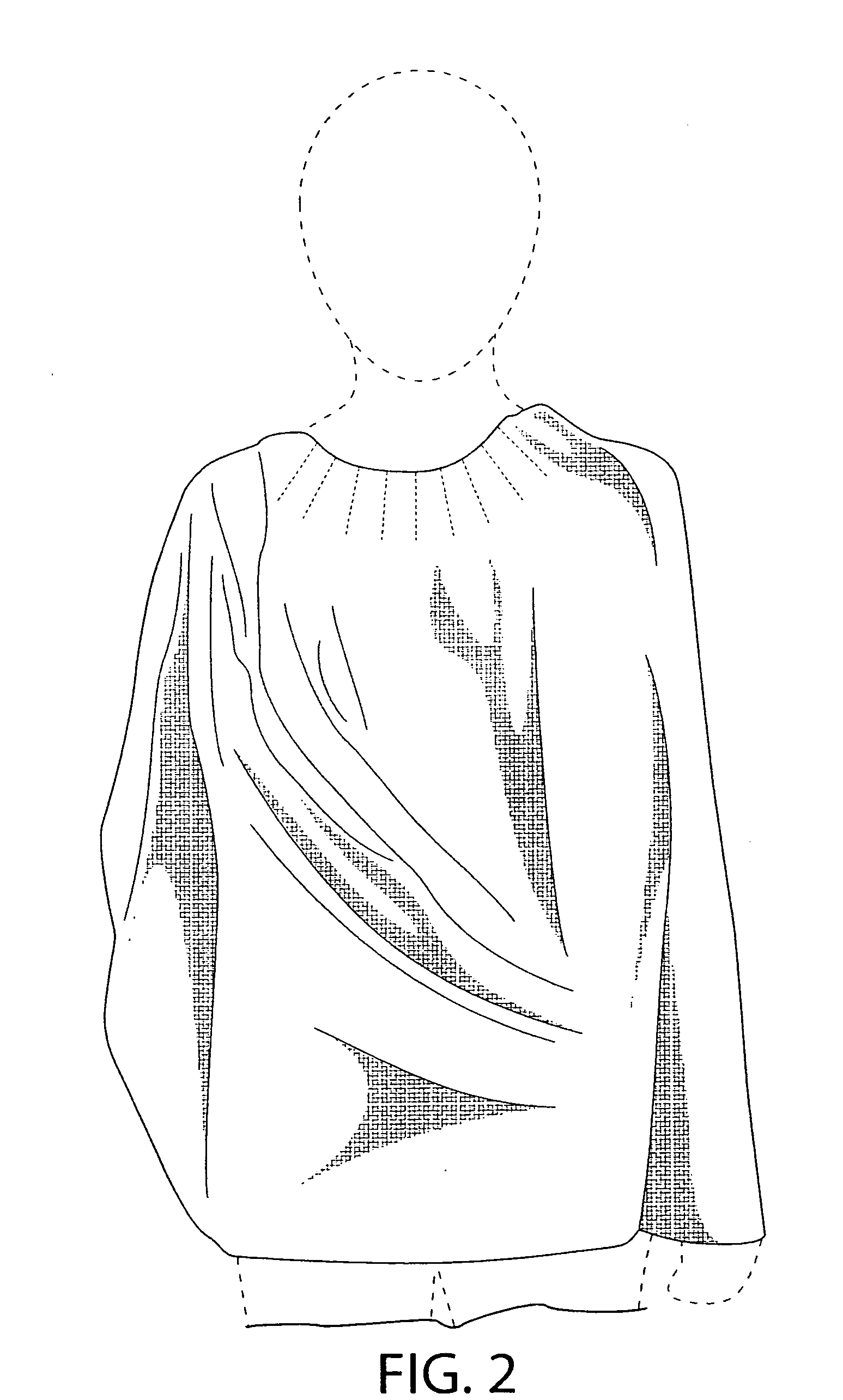

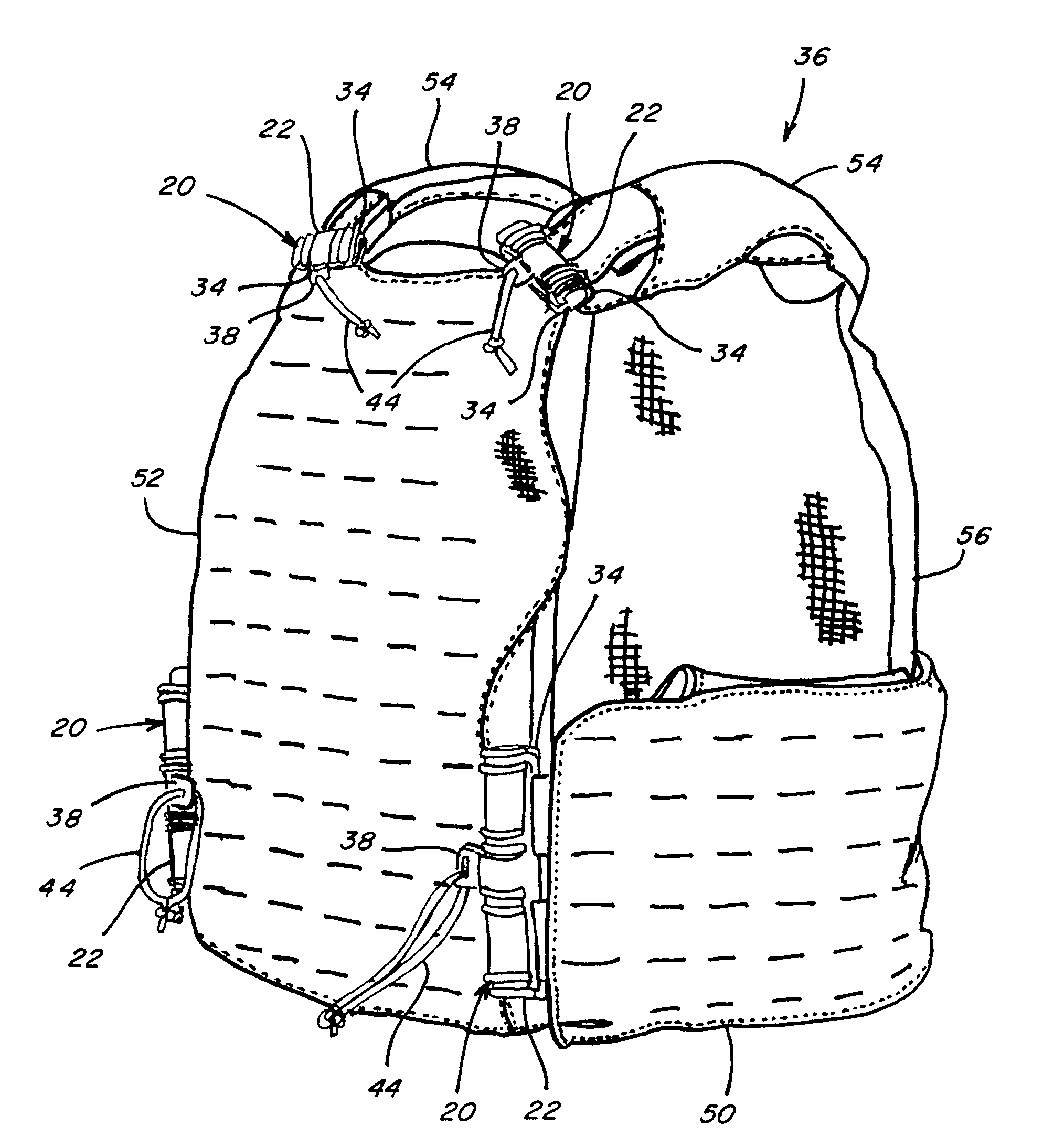

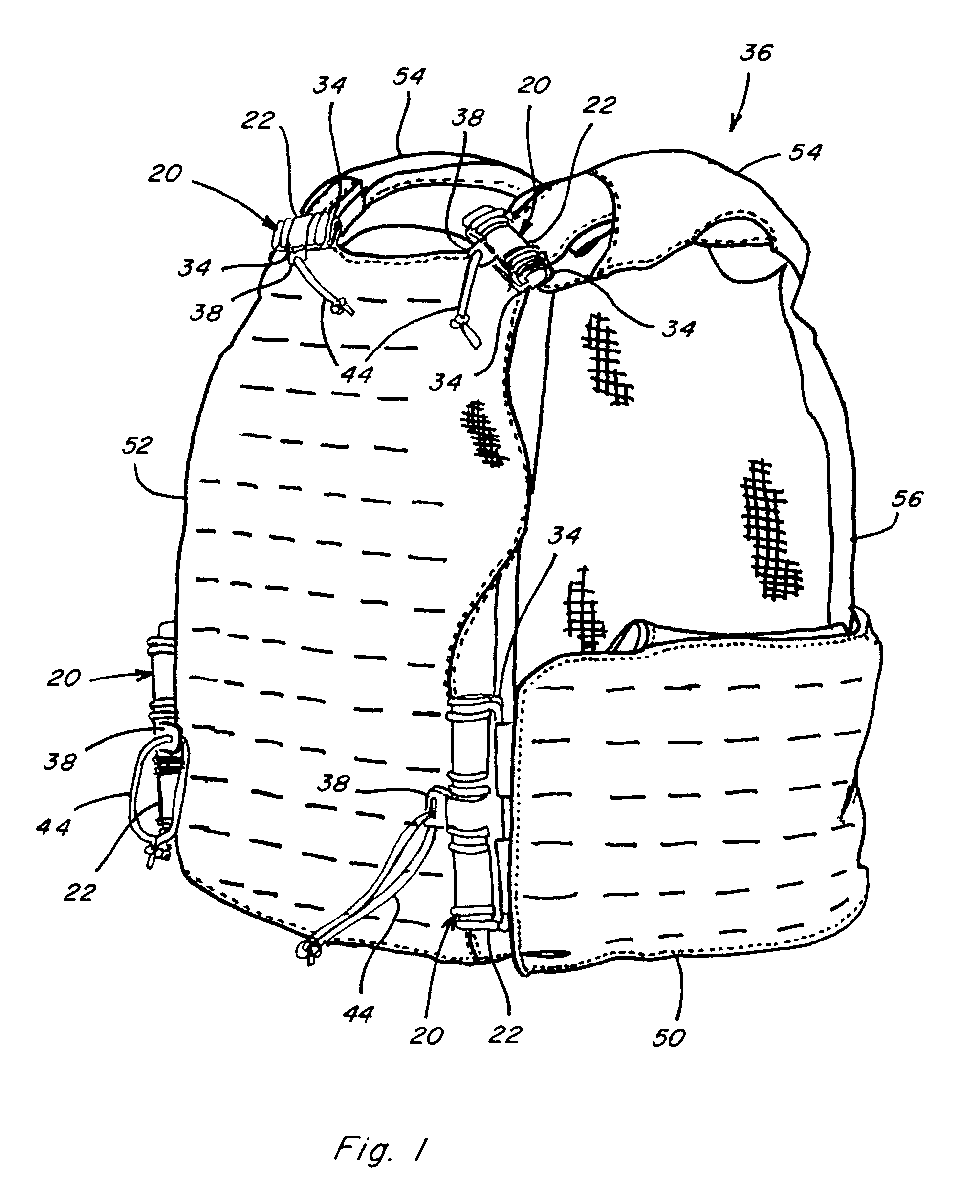

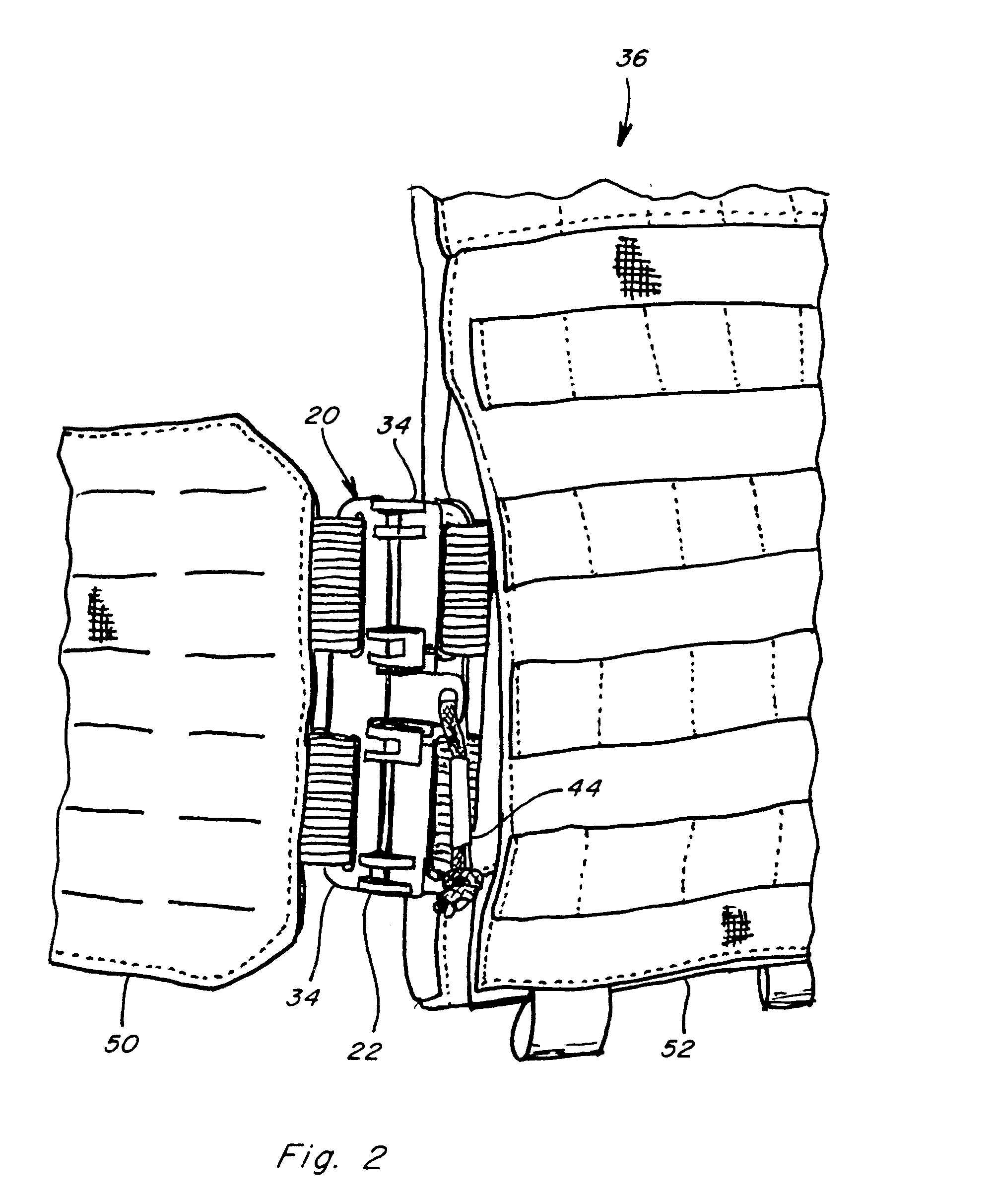

Shawl or wrap with closure mechanism

The garment shown in the following FIGS. 1-15 is a shawl or wrap worn around the neck, arms or shoulders and draped loosely around the body. The shawl may or may not include sleeves or armholes for the hands or arms. The shawl may or may not include pockets, zippers or other openings for the convenience of the wearer. The adjustable friction side clasp closure shown which has an extra layer of reinforcement to provide a notion free bag or garment closure can be used on products like a garment, shawl or wrap making it safe for small children, and quiet when fastening. Other possible uses of the friction side closure are in objects to which it's closing including but not limited to scarves, gloves, wallets, coats, purses, trousers, shirts, skirts, dresses, belts, bags, luggage, parachutes, and sleeping bags.

Owner:COHEN STACEY ALYSE

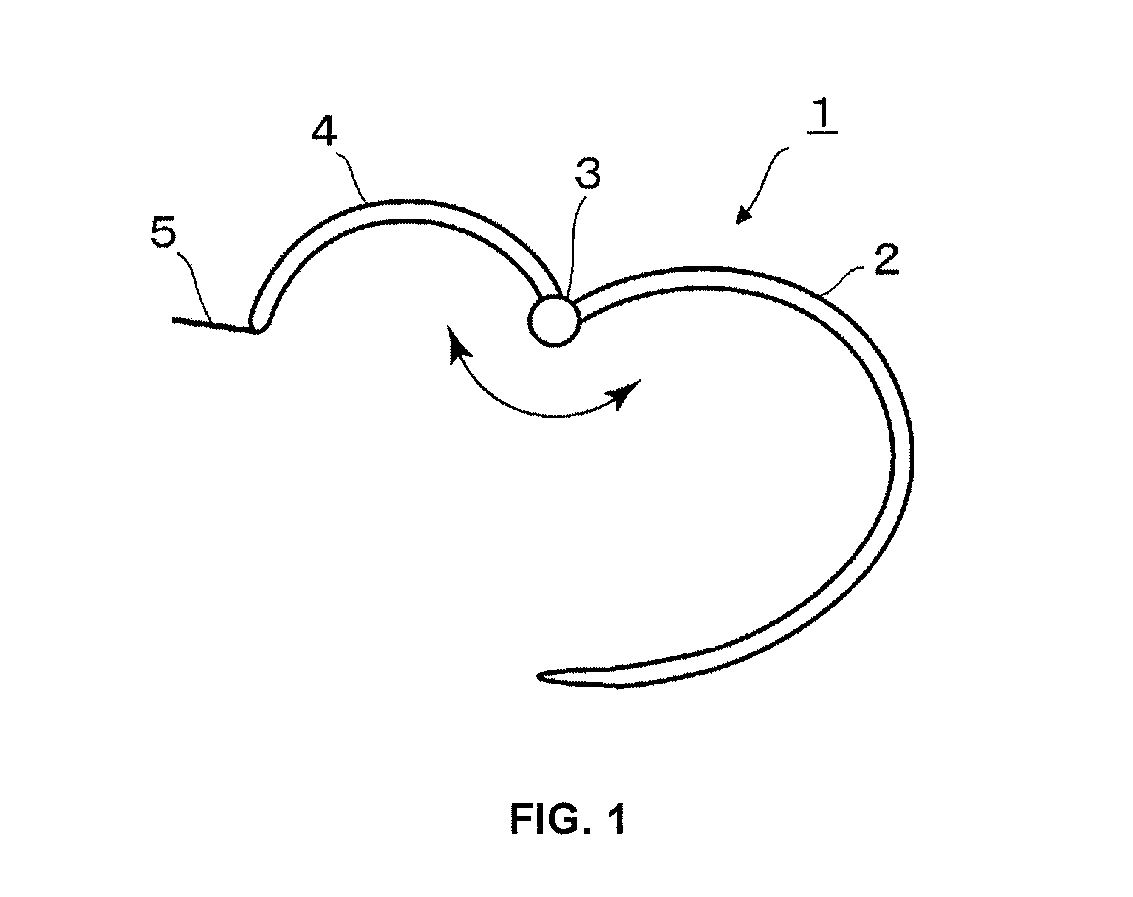

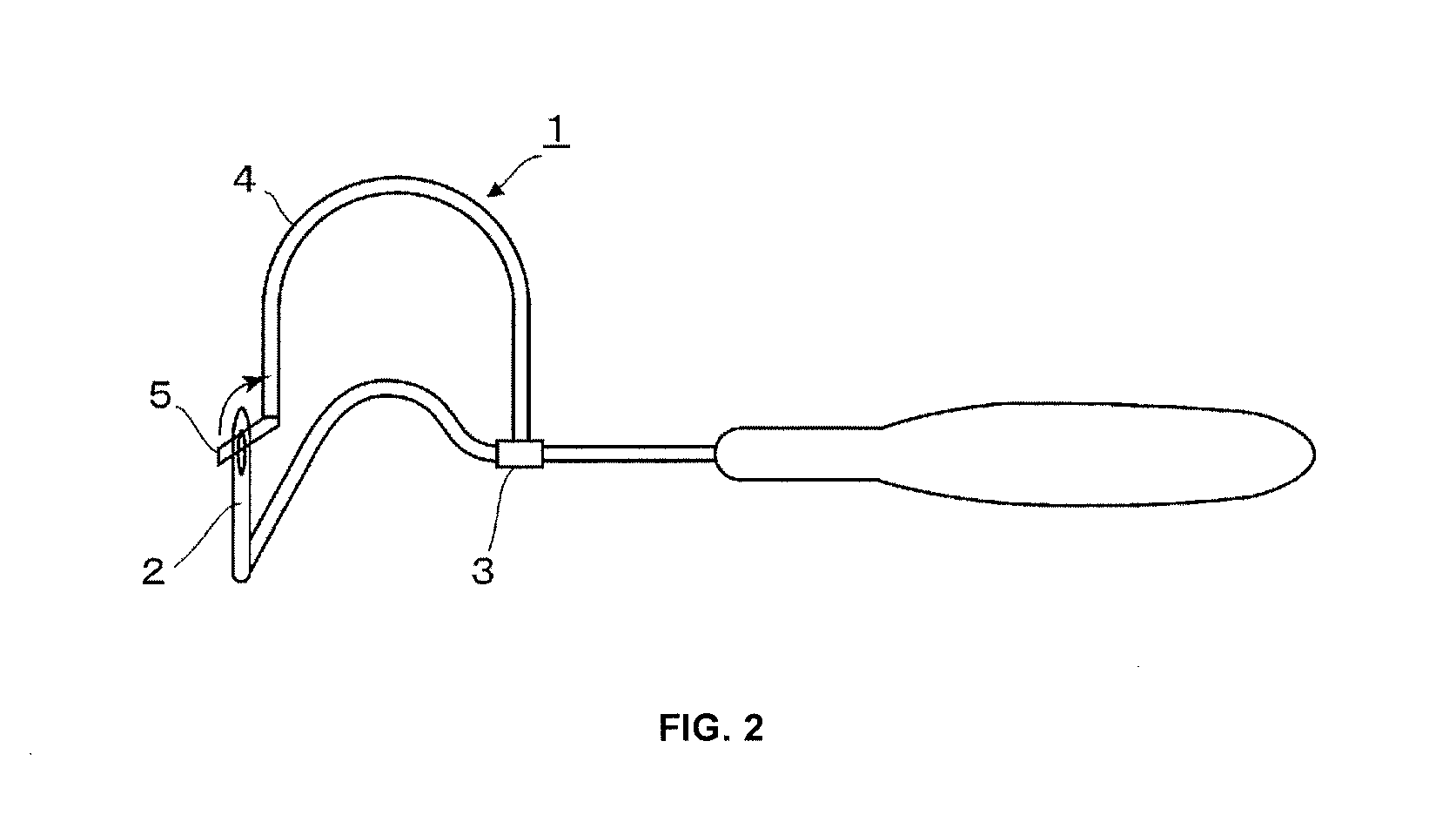

Garment assembly and release apparatus and method

ActiveUS20140332572A1Securely holdConvenient and simple manual pulling motionSnap fastenersGarment special featuresDetentEngineering

The assembly and release apparatus and method utilizes a C-shaped clip defining a channel and a smaller slot extending along the channel, both open at at least one end, attachable to a first location on a garment. A pin of the apparatus is slidably receivable in the channel through the open end to assemble the C-shaped clip and the pin together. The pin has a tab or strip that extends through the slot, for attaching the pin to a second location on the garment. The apparatus includes at least one detent element associated with one of the C-shaped clip and the pin, cooperatively engageable with the other of the C-shaped clip and the pin for retaining the pin in the channel, and releasable in a predetermined manner to allow slidably removing the pin from the channel through the open end, to provide a quiet and rapid manner of operation.

Owner:FIRSTSPEAR TUBES LLC

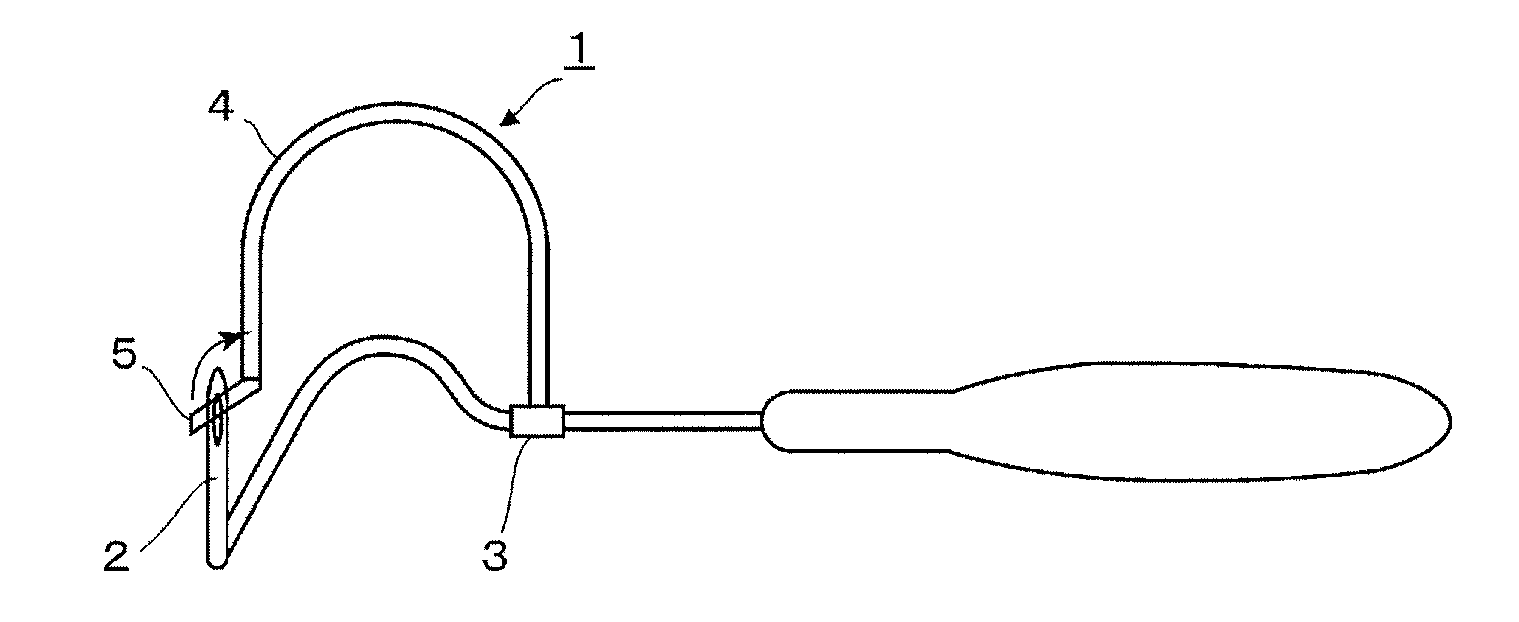

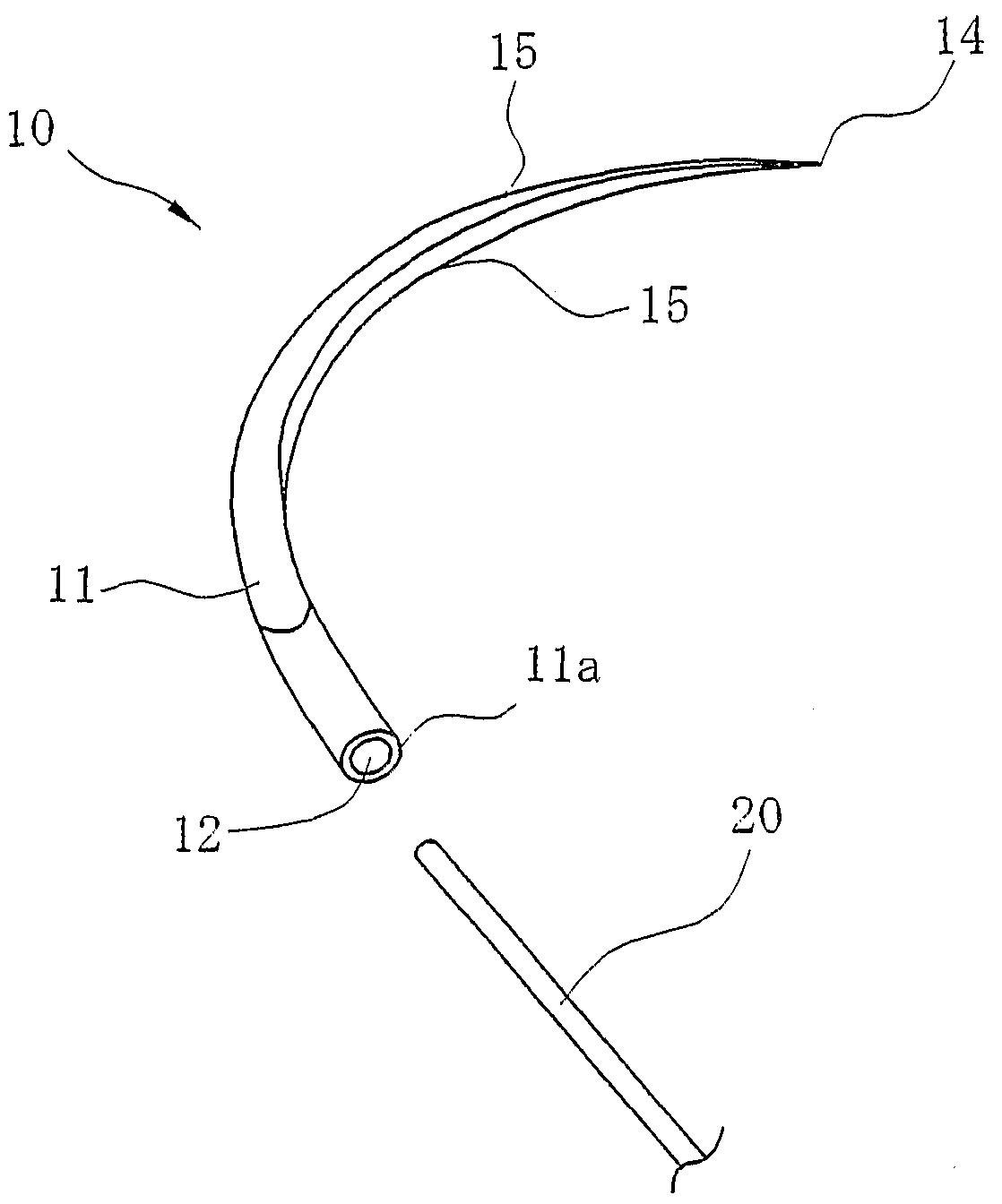

Insertion needle

InactiveUS20130023725A1Drawn reliablyShort timeSuture equipmentsSurgical needlesPelvic organsInsertion angle

An insertion needle that is turnably mounted on a handle, which holds the insertion needle, wherein the insertion needle includes a turn arm that turns so as to face the tip of the insertion needle, and a target site that guides the insertion needle provided on the tip of the turn arm, and is further provided with: through-holes in two locations that are provided separated in the longitudinal direction of the tip of the insertion needle; an indentation formed between these through-holes; and a groove in the direction from the tip of the insertion needle toward the base of the insertion needle. Furthermore, the insertion needle is suitably used in urinary incontinence surgery, pelvic organ prolapse surgery or the like.

Owner:UNIVERSITY OF MIYAZAKI

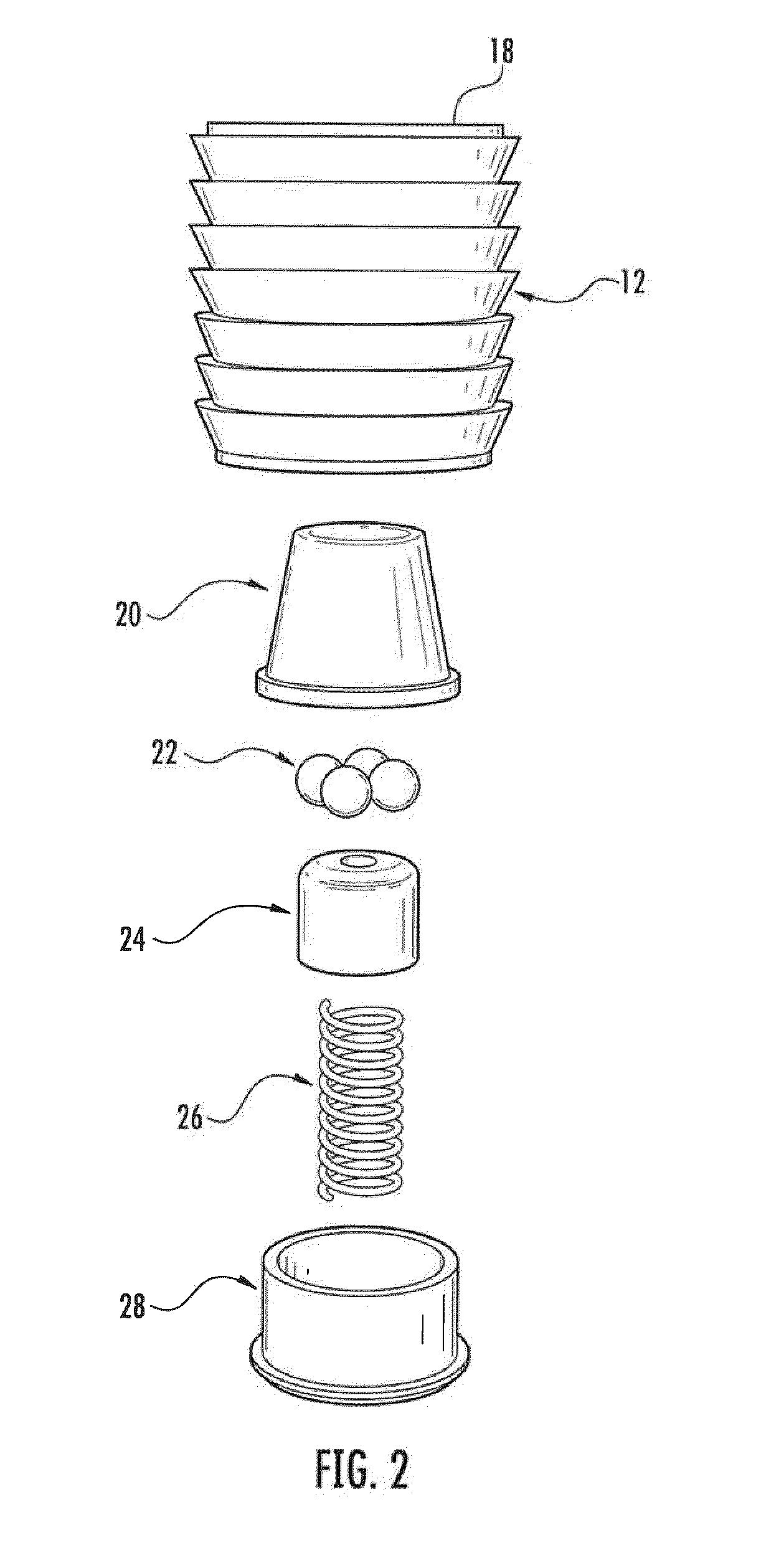

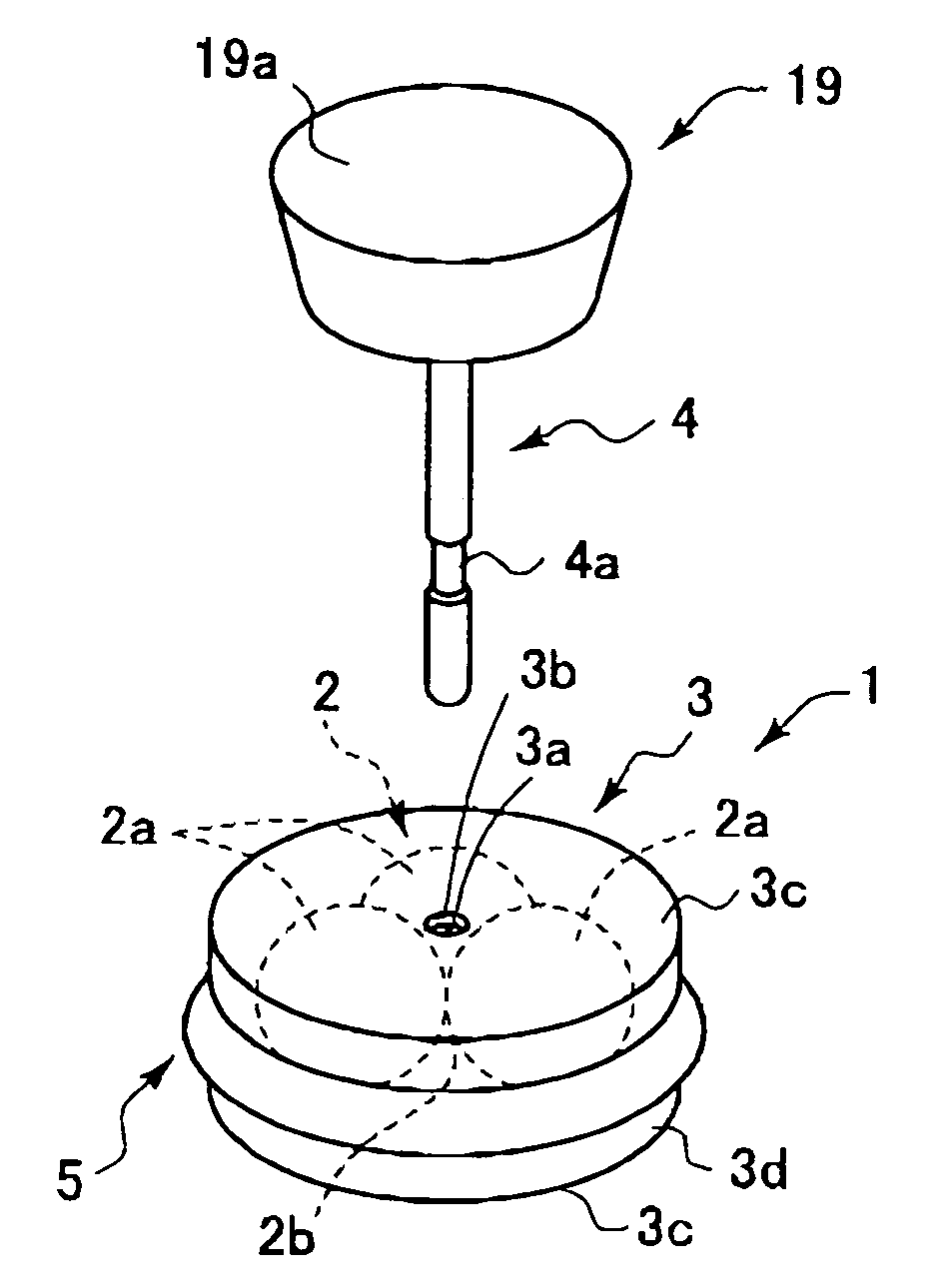

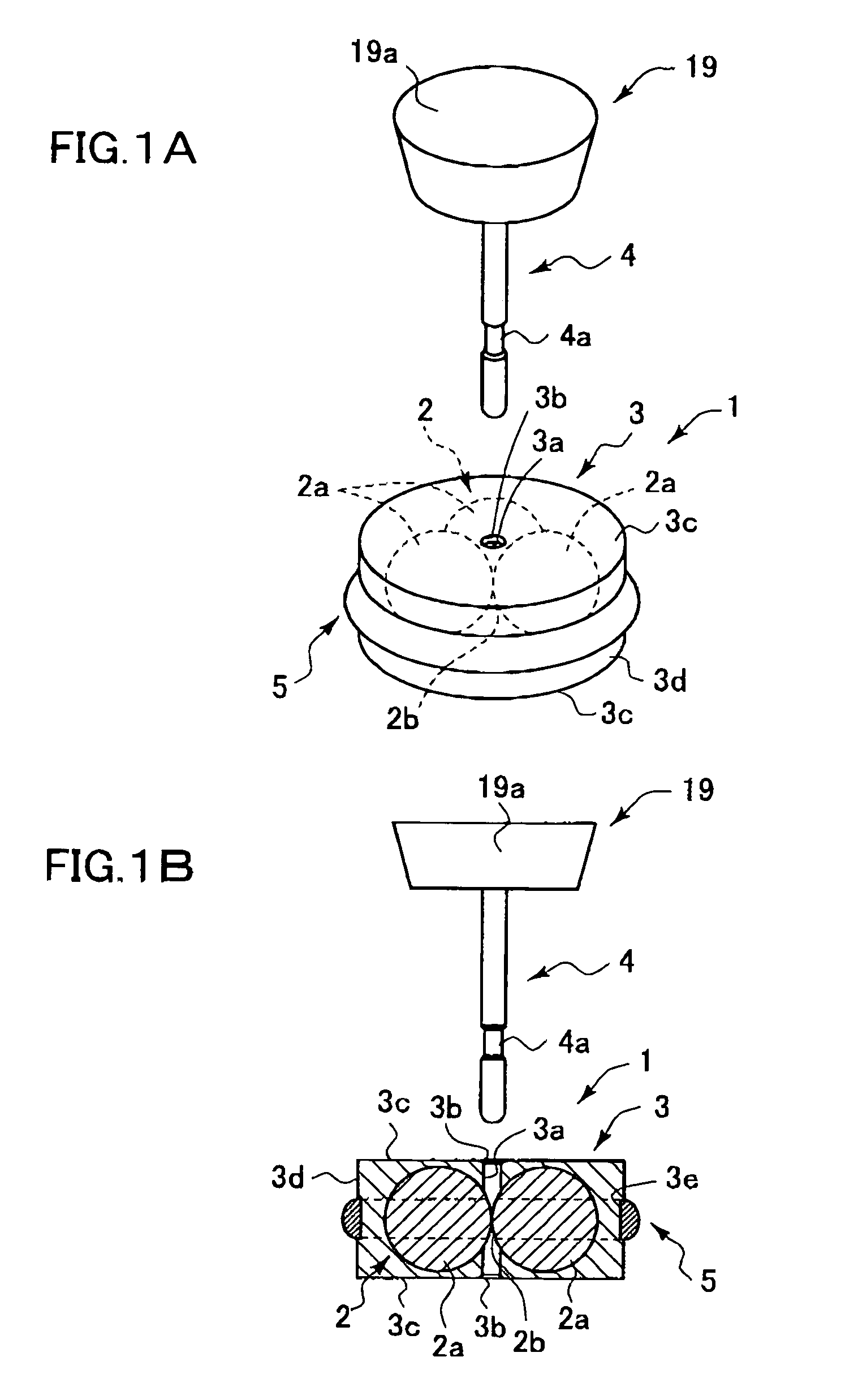

Fastener and ornament including the fastener

InactiveUS7617576B2Lower capability requirementsIncreased durabilitySewing needlesScarvesAs elementEngineering

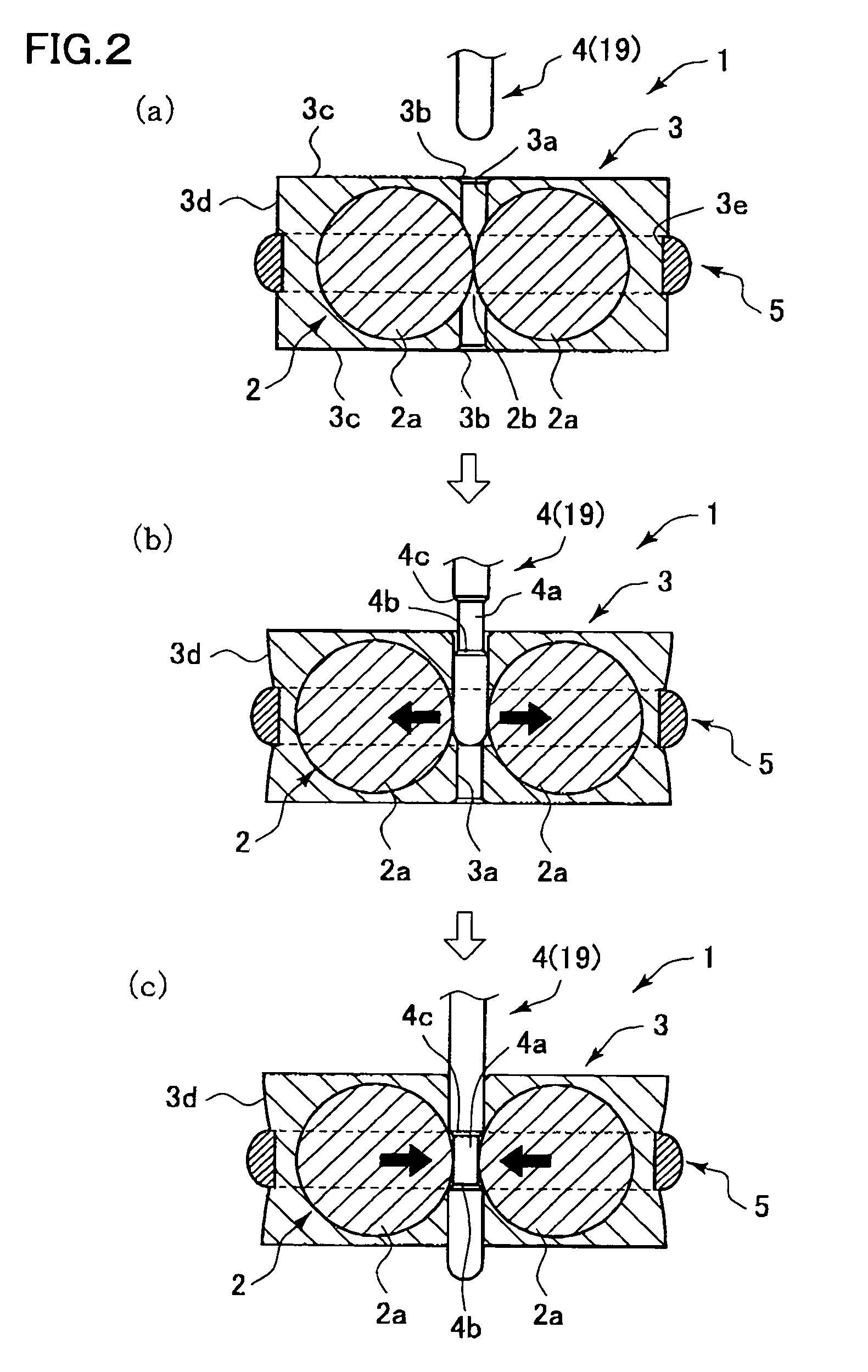

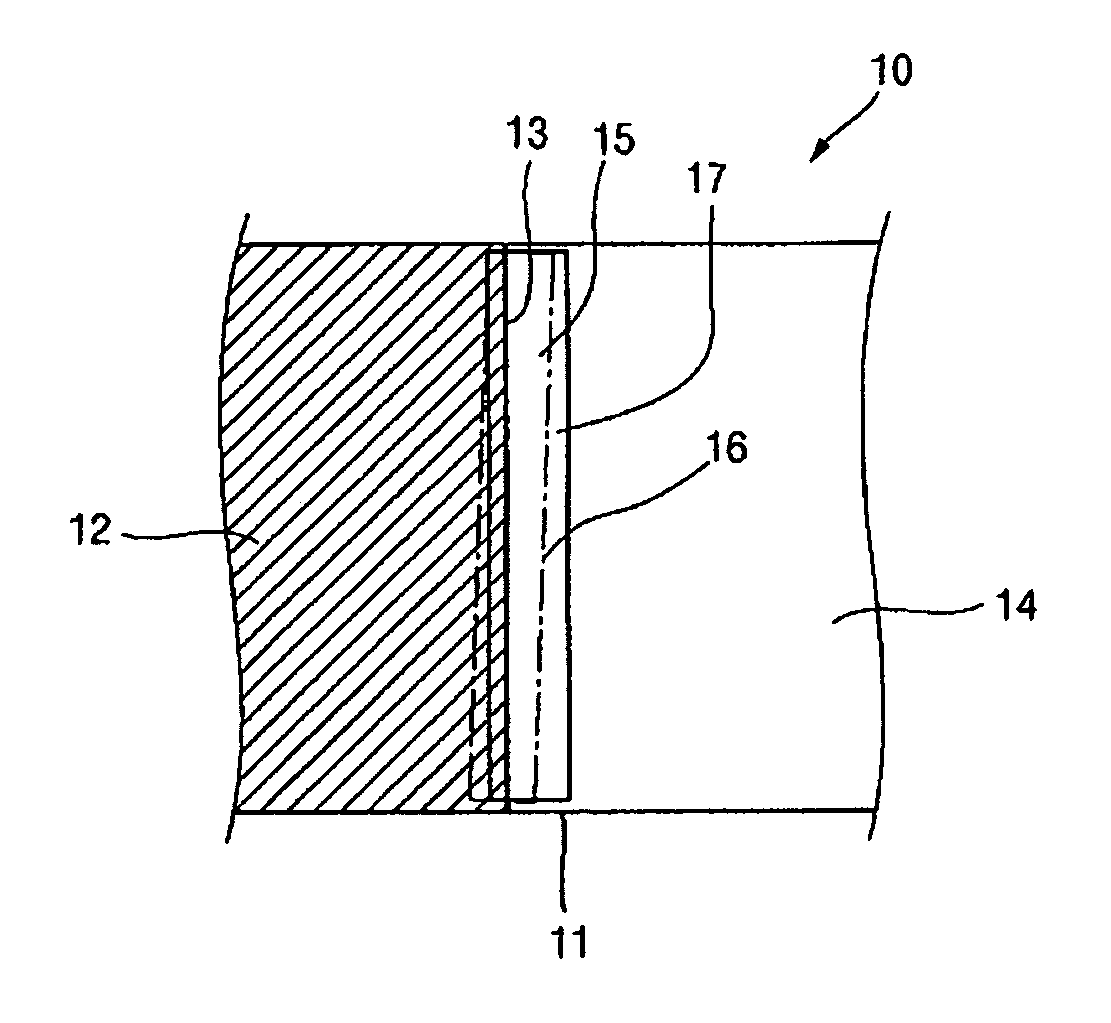

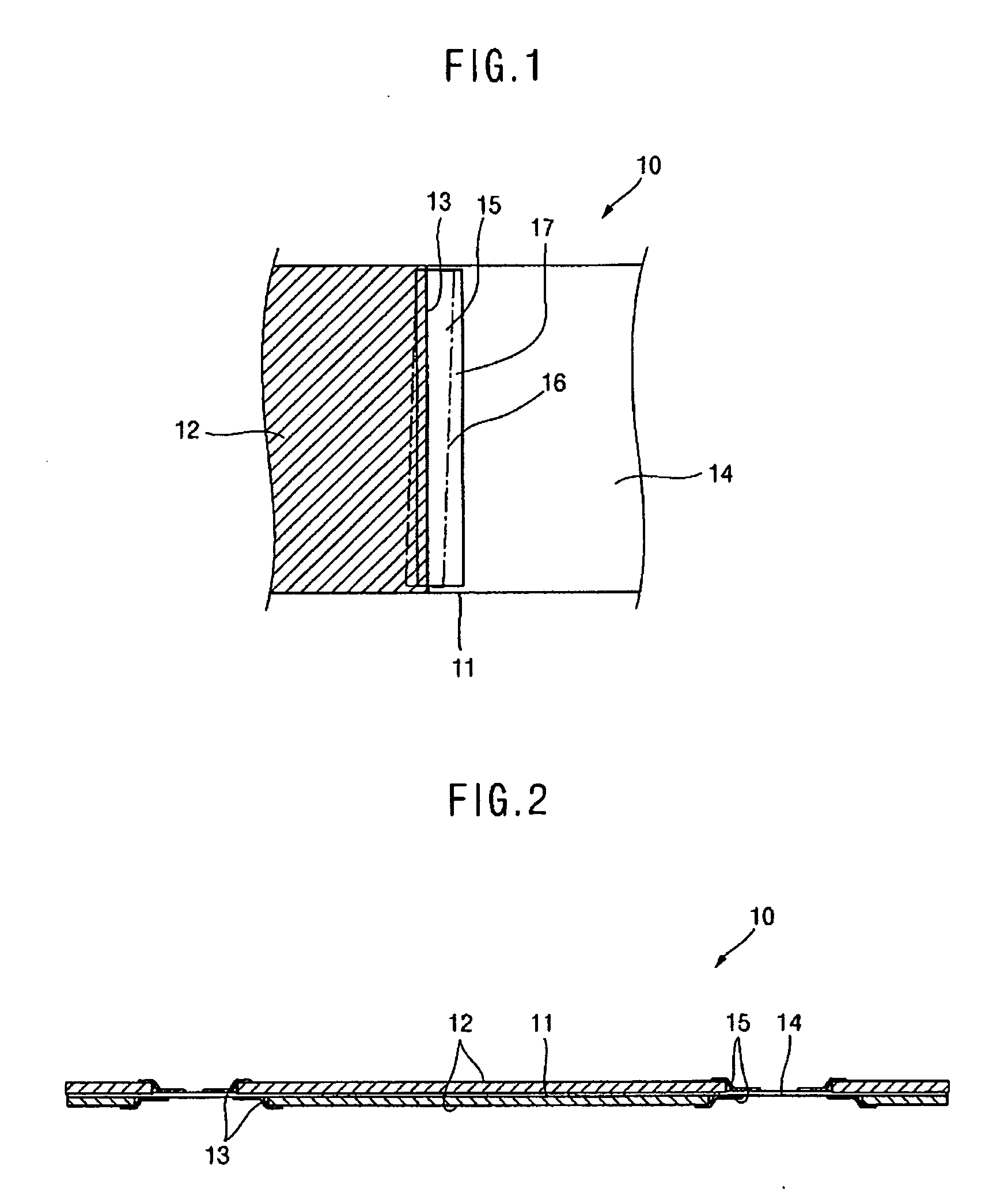

A pierced earring fastener 1 has: a pinching member 2 made of three balls 2a, 2a, 2a; a holder 3 that is a rubber-like elastic member; and a ring 5 for tightening the pinching member 2 and the holder 3. The three balls 2a, 2a, 2a are disposed in a ring shape at intervals of 120 degrees in a circumferential direction, as elements that form the pinching member 2. These balls are retained at predetermined positions by means of the holder 3. The holder completely surrounds the circular pinching member 2 formed by the three balls 2a. A through hole 3a penetrating a center of both of end faces 3c, 3c is formed via a gap 2b formed at the center of a ring formed by the pinching member 2 closed inside thereof.

Owner:RIGHT PLANNING

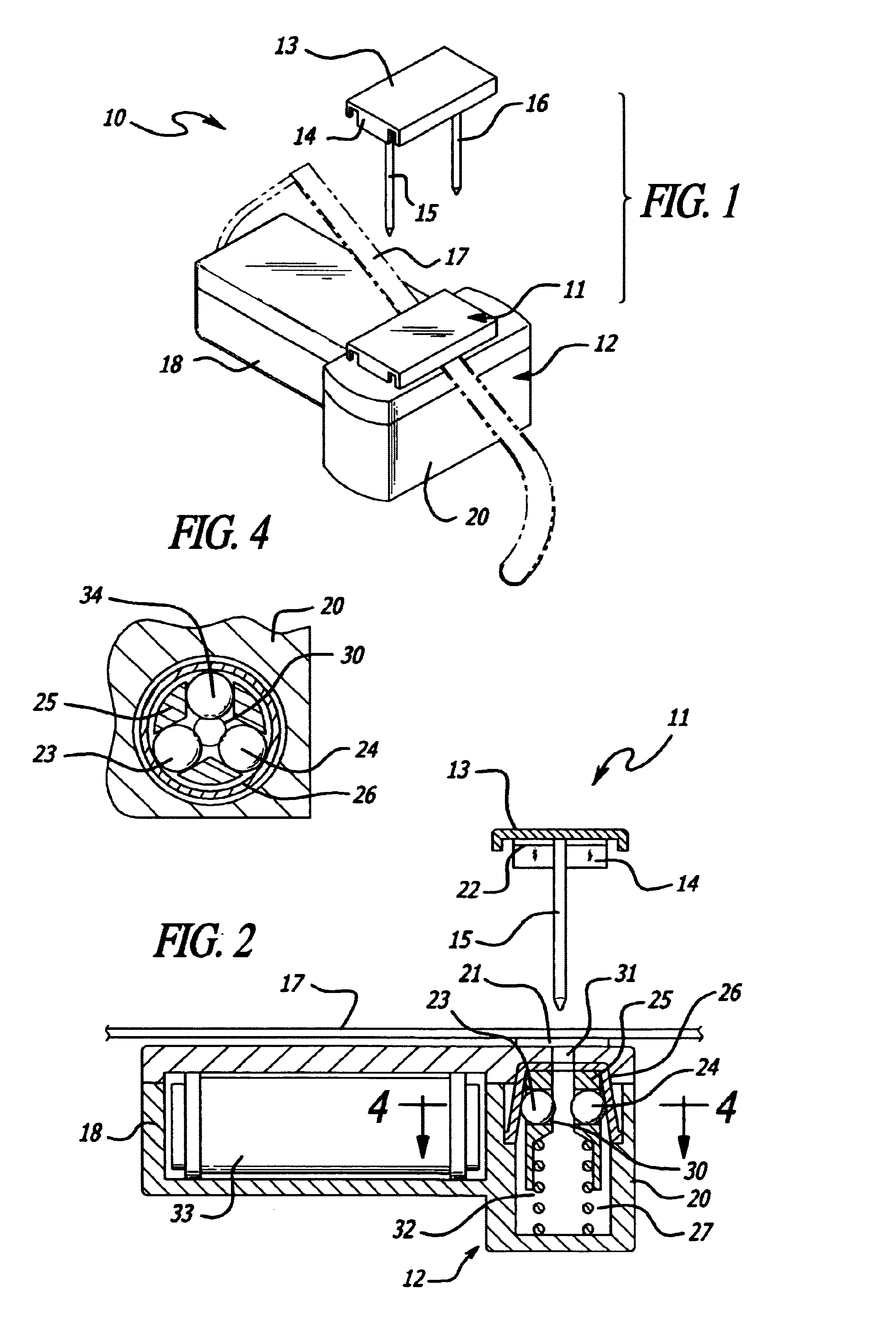

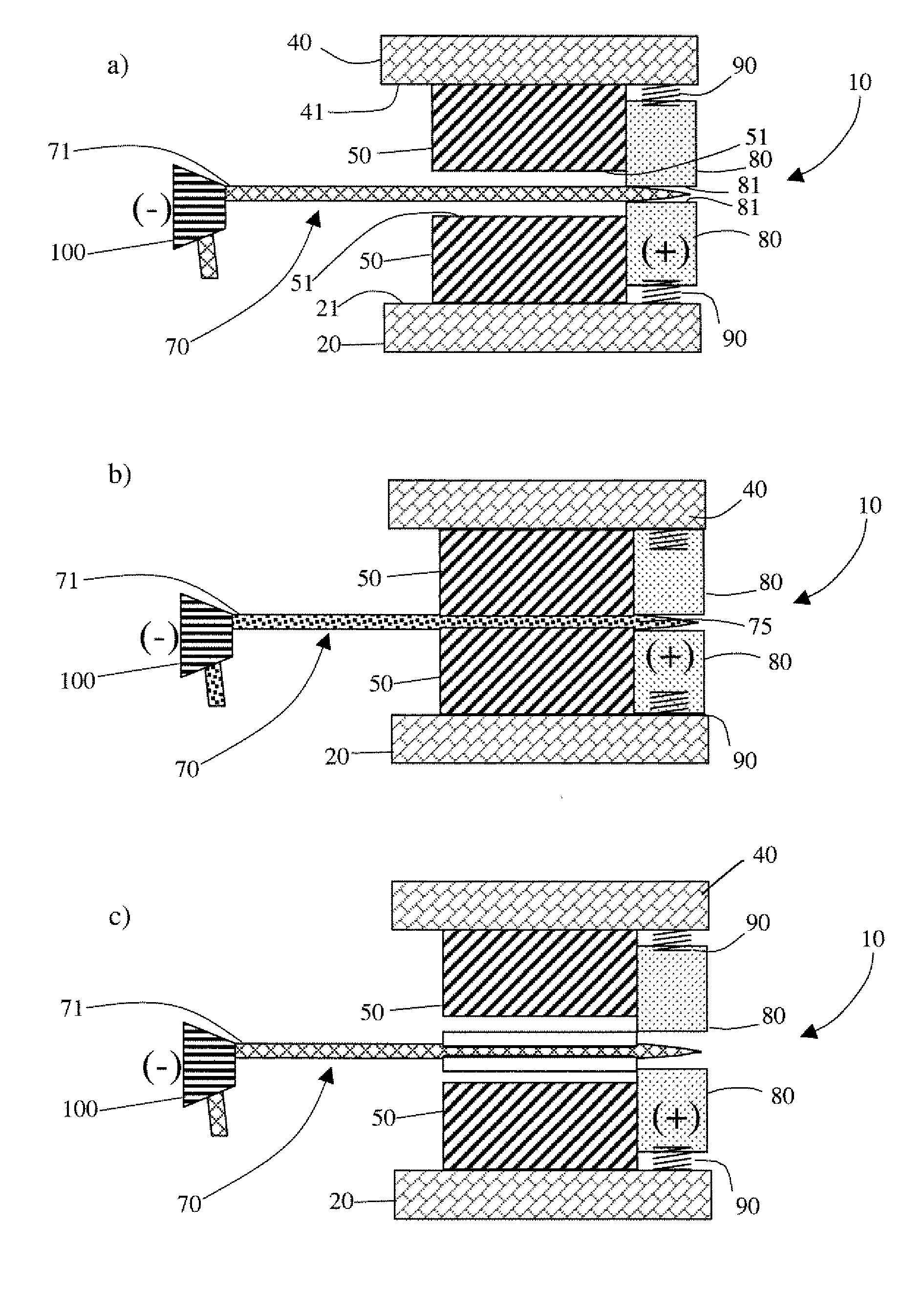

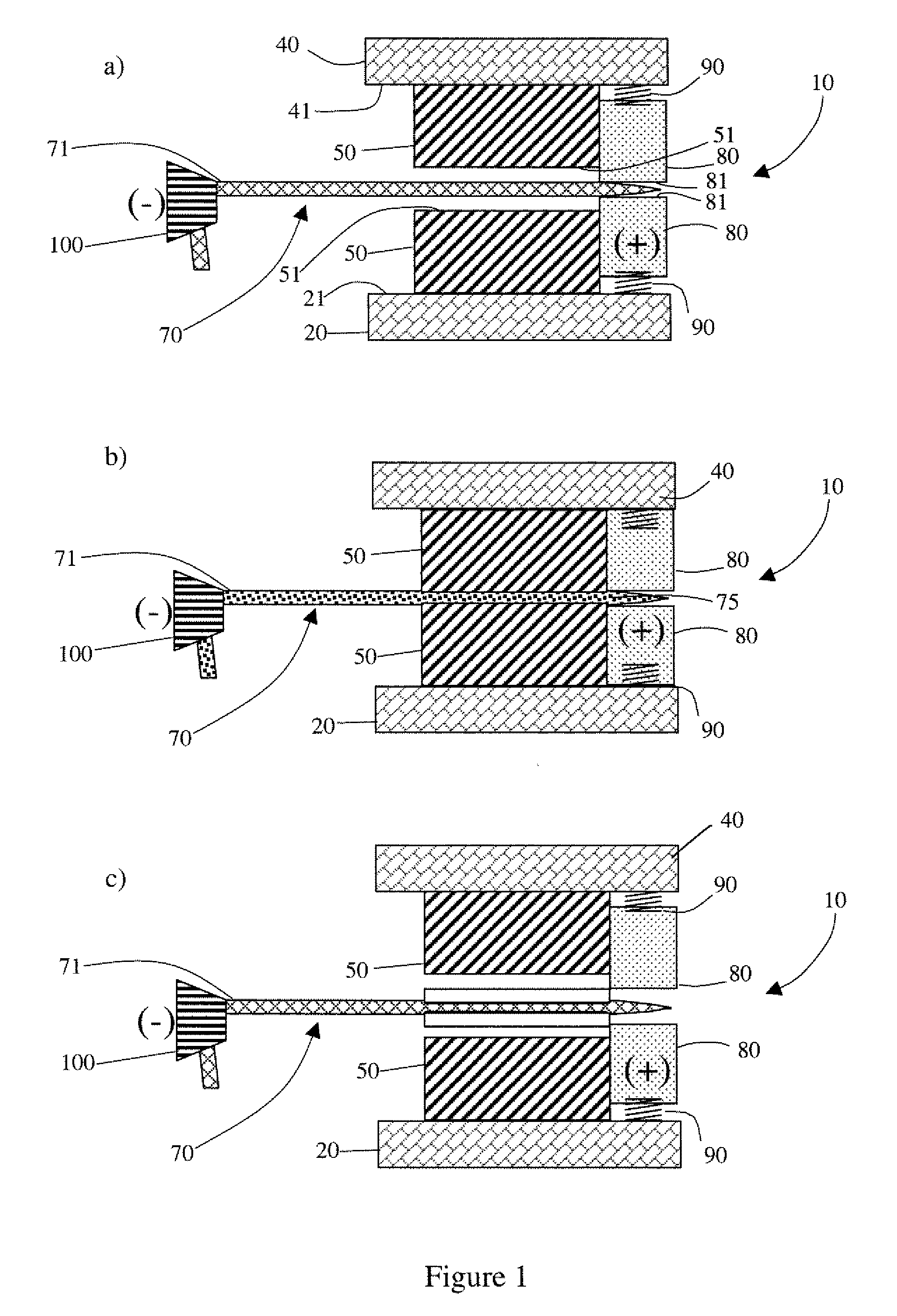

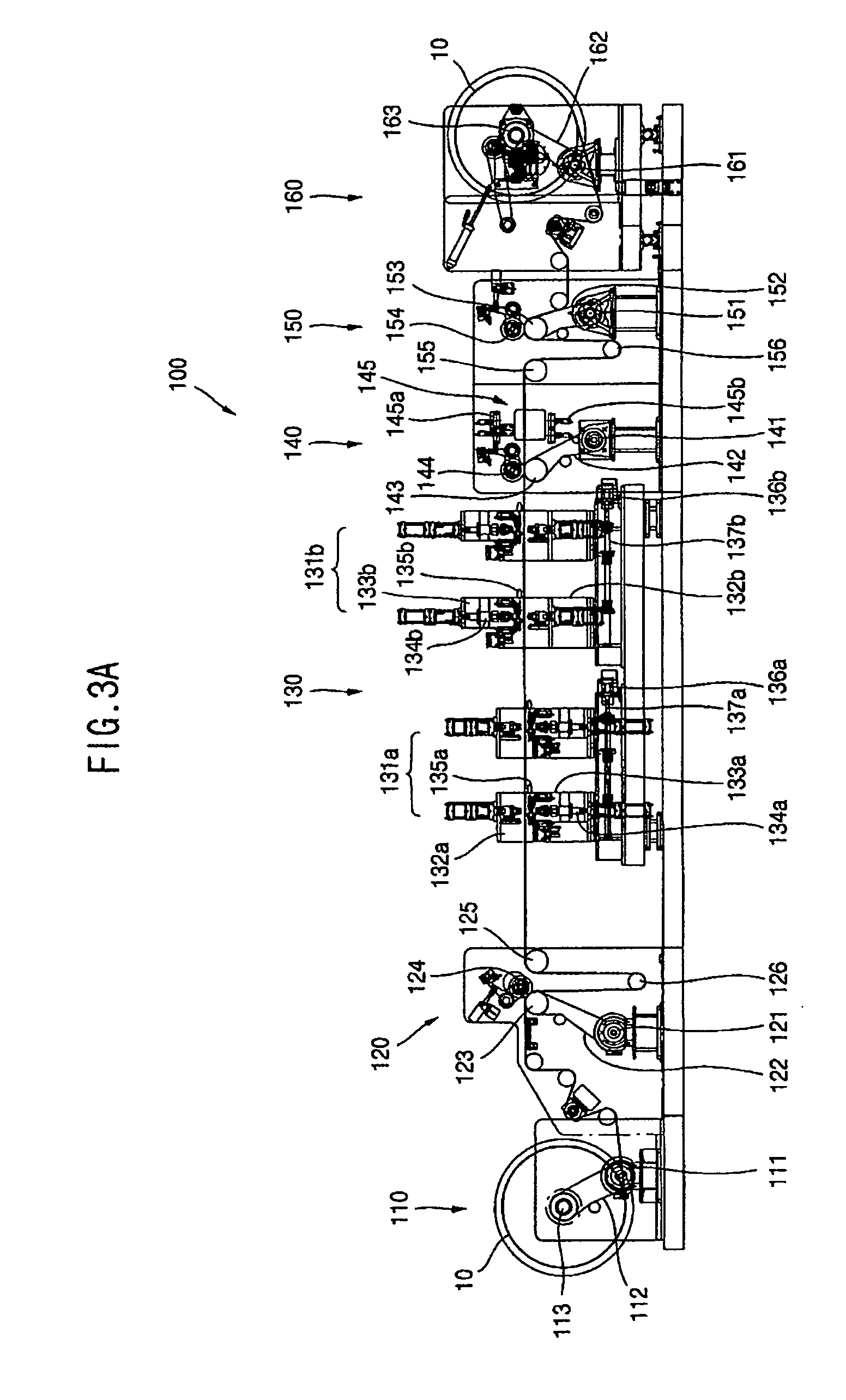

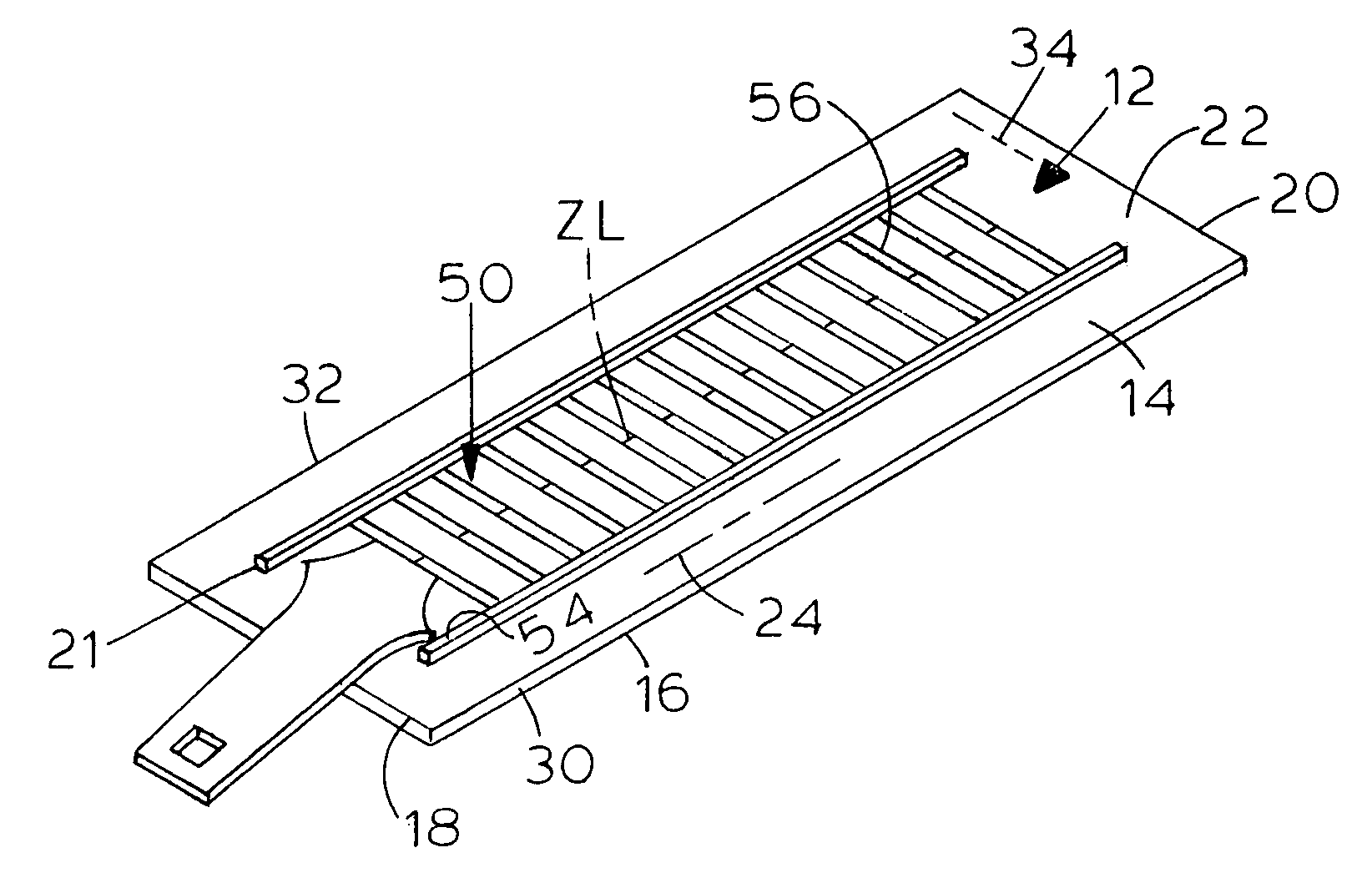

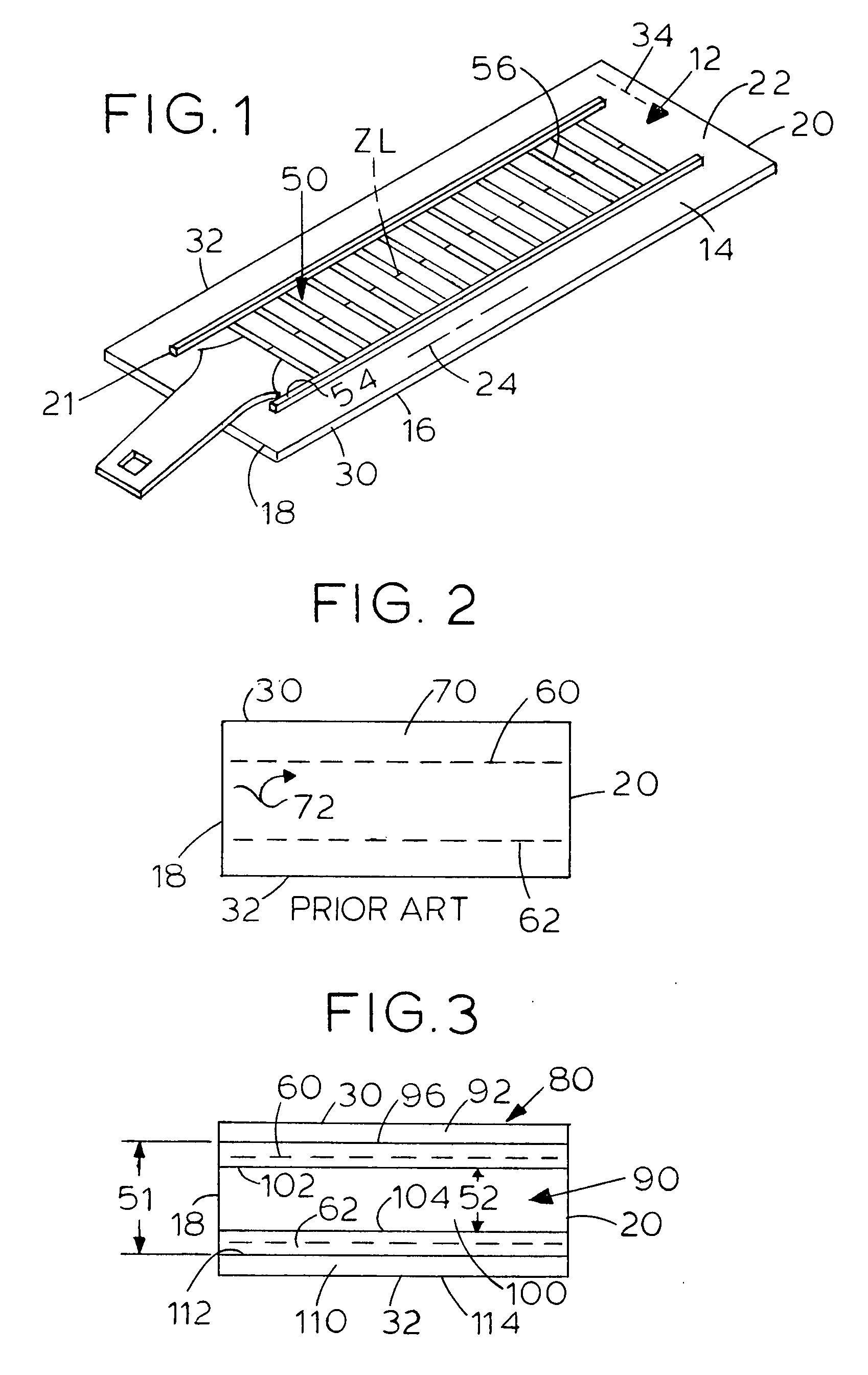

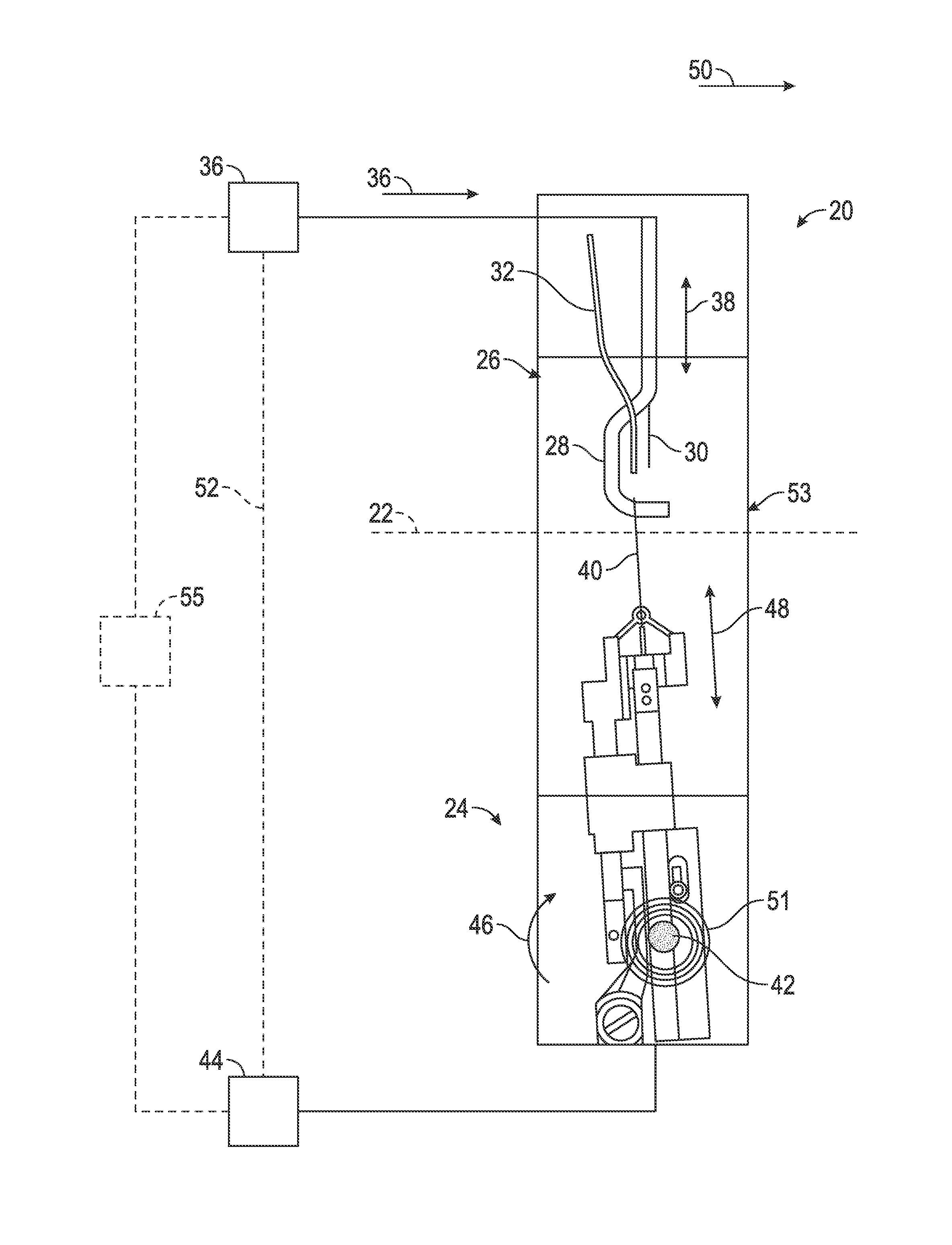

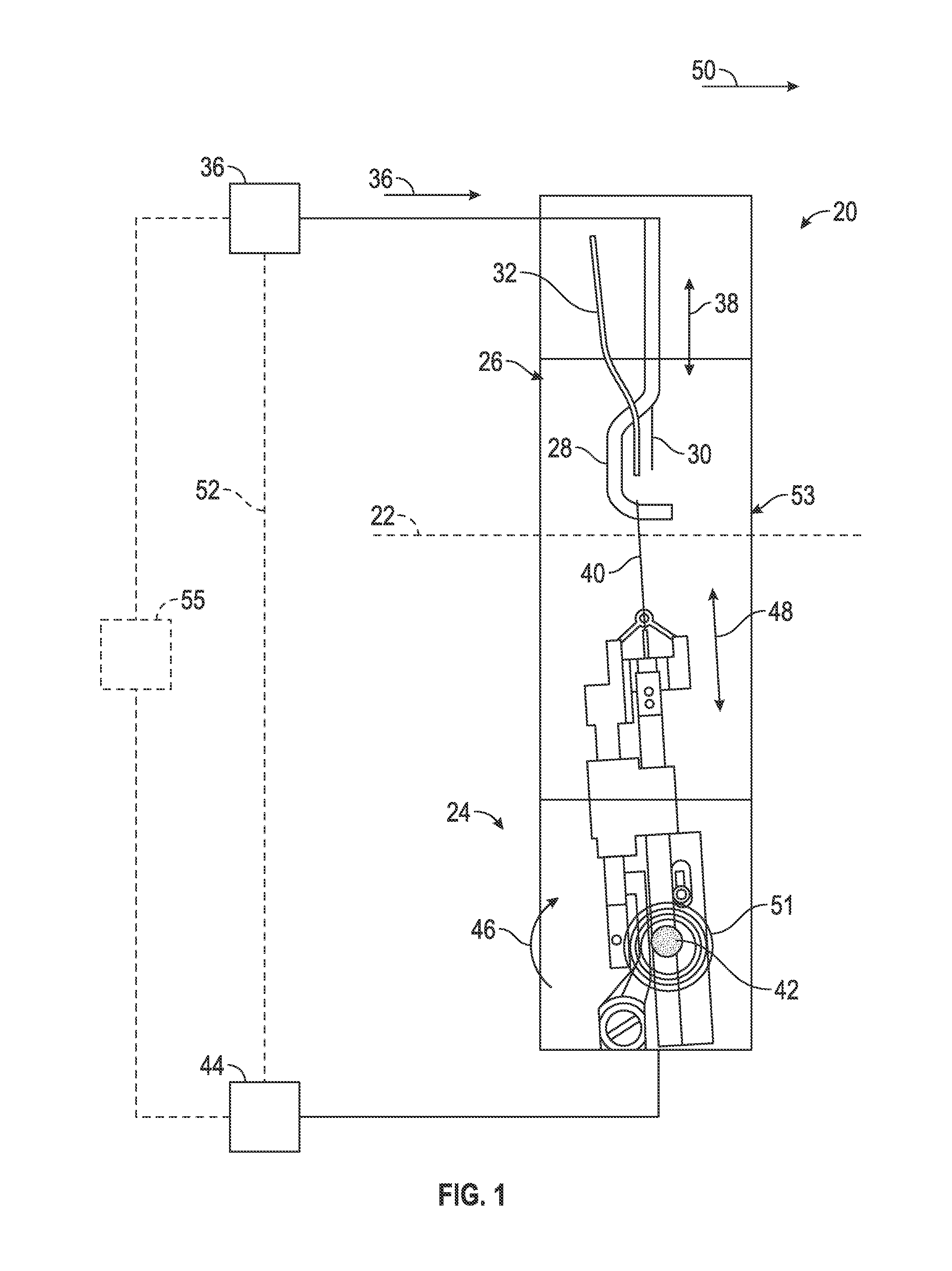

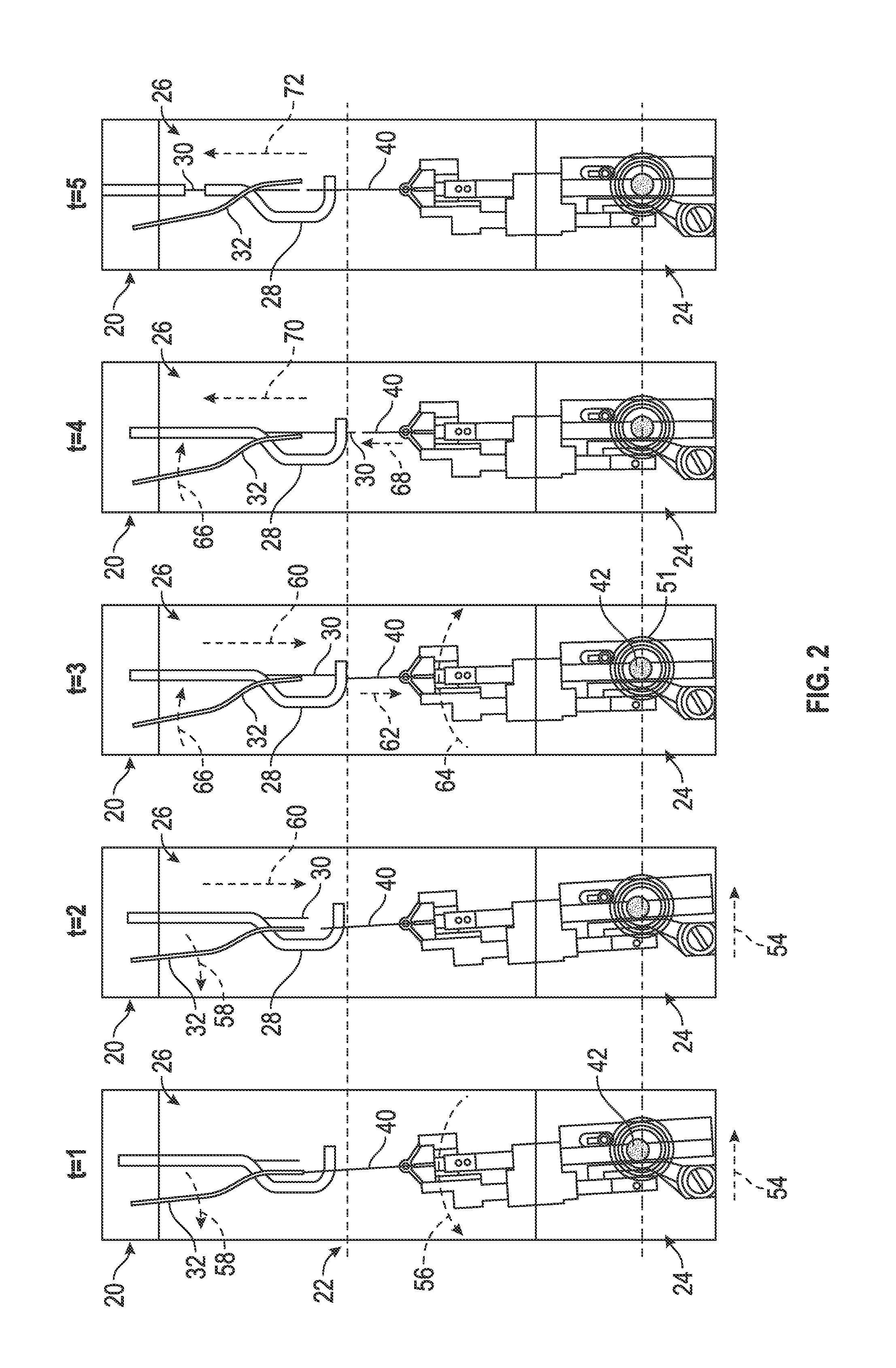

Apparatus and method for laminating tape on electrode of rechargeable battery

ActiveUS20060289453A1Electrode manufacturing processesLamination ancillary operationsRechargeable cellConductor Coil

An apparatus for laminating tape on an electrode for a rechargeable battery includes a supplying section for supplying an electrode having a current collector with surfaces on which active materials are coated at constant distances from each other. The electrode is wound a plurality of times on the supplying section. The apparatus also includes a first buffering section for carrying the electrode from the supplying section at a constant rate and a laminating section for receiving the electrode from the first buffering section and stopping movement of the electrode for a predetermined time. The laminating section laminates tape on end portions of the active materials after stopping the movement. A feeding section conveys the electrode from the laminating section at a desired pitch. A second buffering section carries the electrode from the feeding section at a predetermined rate and a winding section receives the electrode from the second buffering section.

Owner:SAMSUNG SDI CO LTD

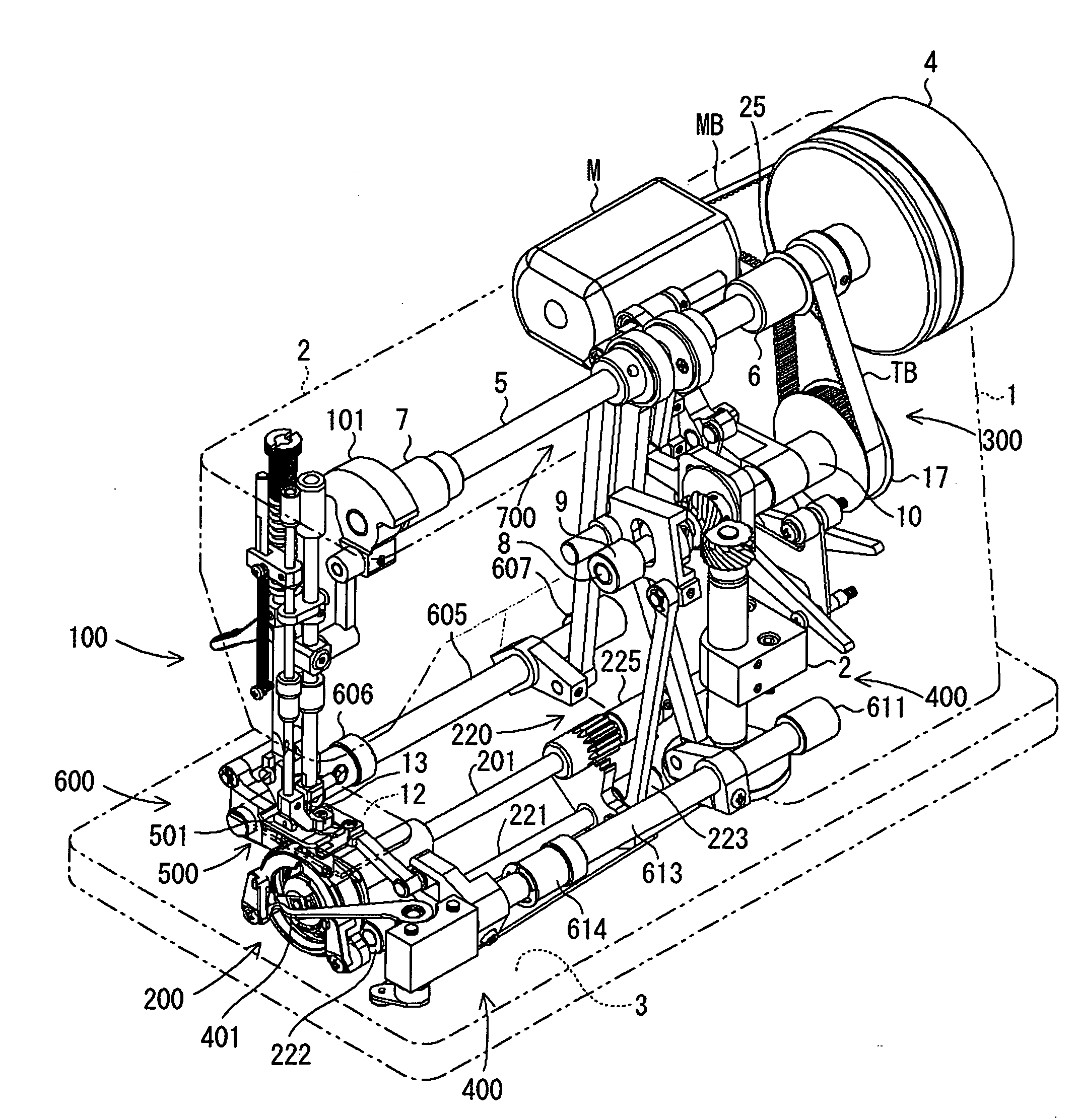

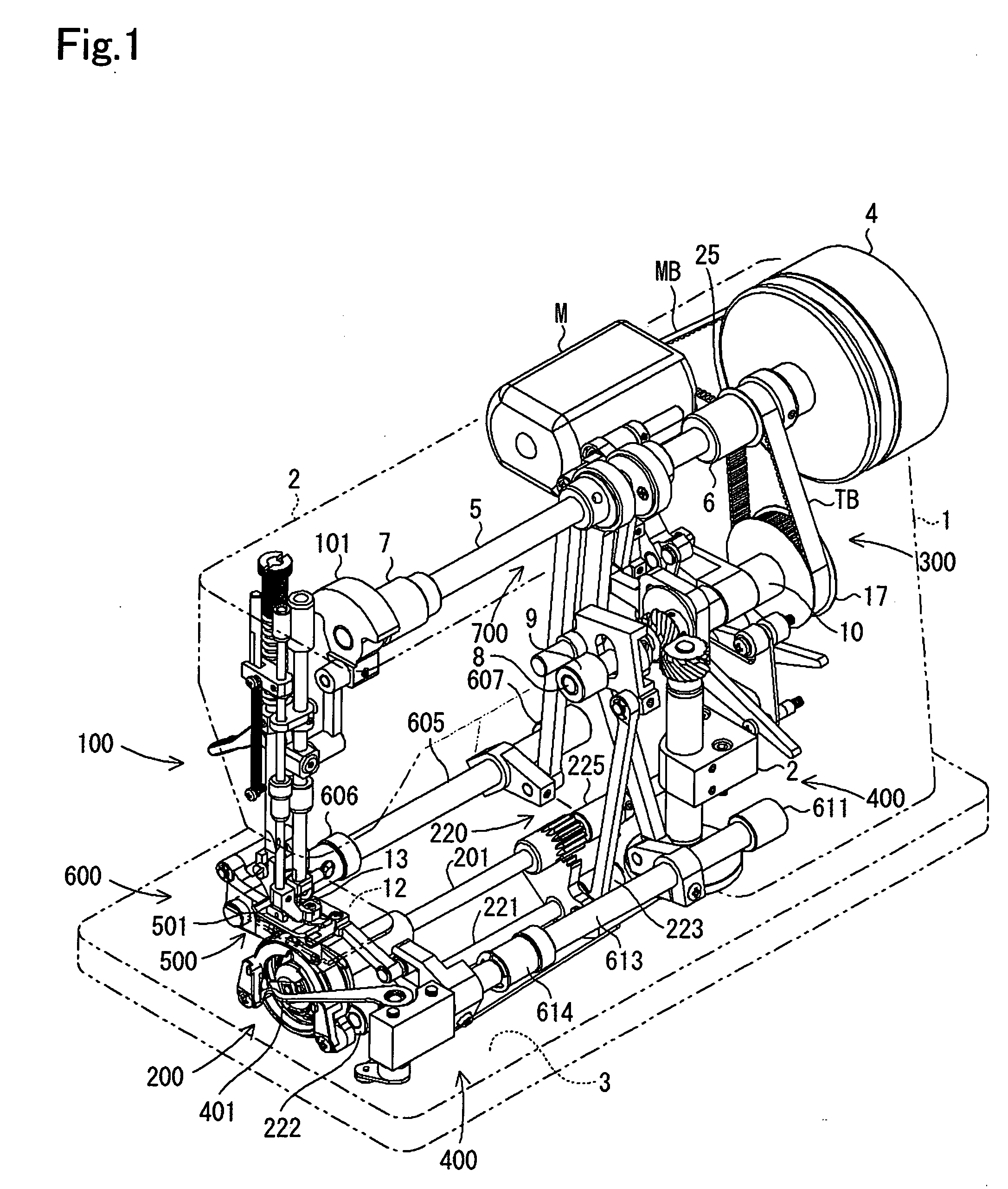

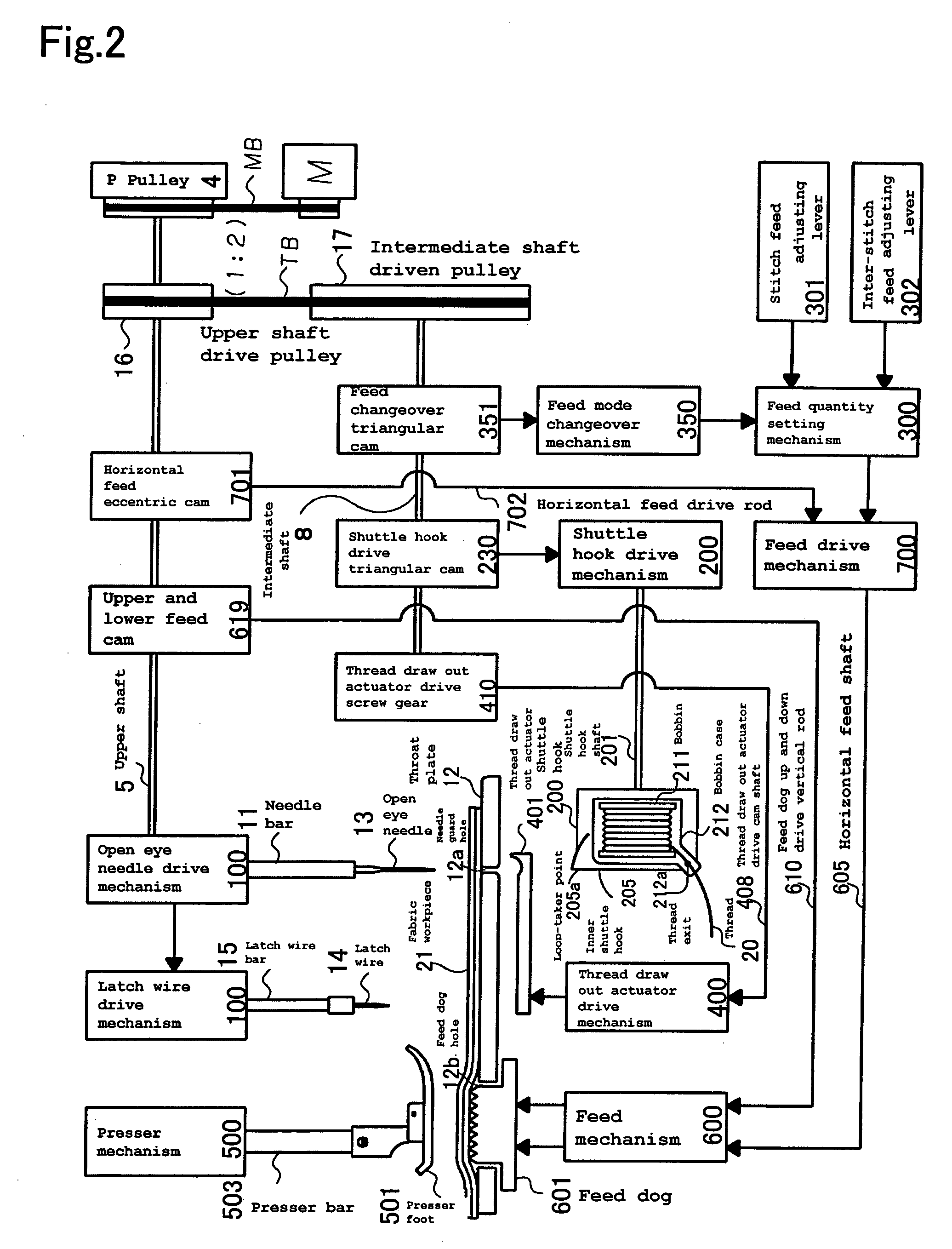

Method and Sewing Machine for Forming Single-Thread Locked Handstitches

ActiveUS20090007830A1Confirm positionAccurate sewingProgramme-controlled sewing machinesWork-feeding meansEye needlesEngineering

A sewing thread (20) can be captured certainly with a thread capturing open eye (13a) of an open eye needle (13) and the stitches are formed in the inner space of a sewing machine bed (3). A handstitch and a locked stitch are formed, respectively, on the front surface and the back surface of a fabric workpiece (21) as a skip stitch set through cooperation of the open eye needle (13), a shuttle hook (200) and a thread draw out actuator (401). A feed dog (601) feeds the fabric workpiece by a stitch length (P1) for handstitch during a first stroke of the open eye needle (13), and feeds the fabric workpiece by an inter-stitch pitch (P2) between the handstitches during a second stroke of the open eye needle (13).

Owner:SUZUKI MFG CO LTD

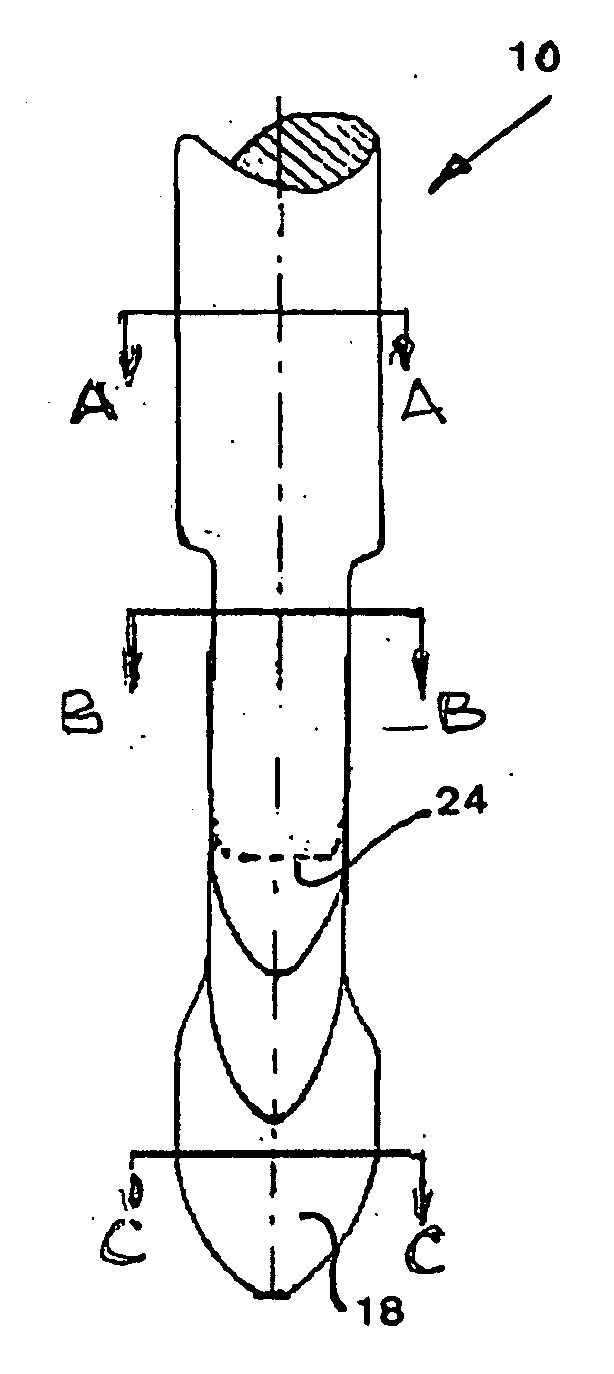

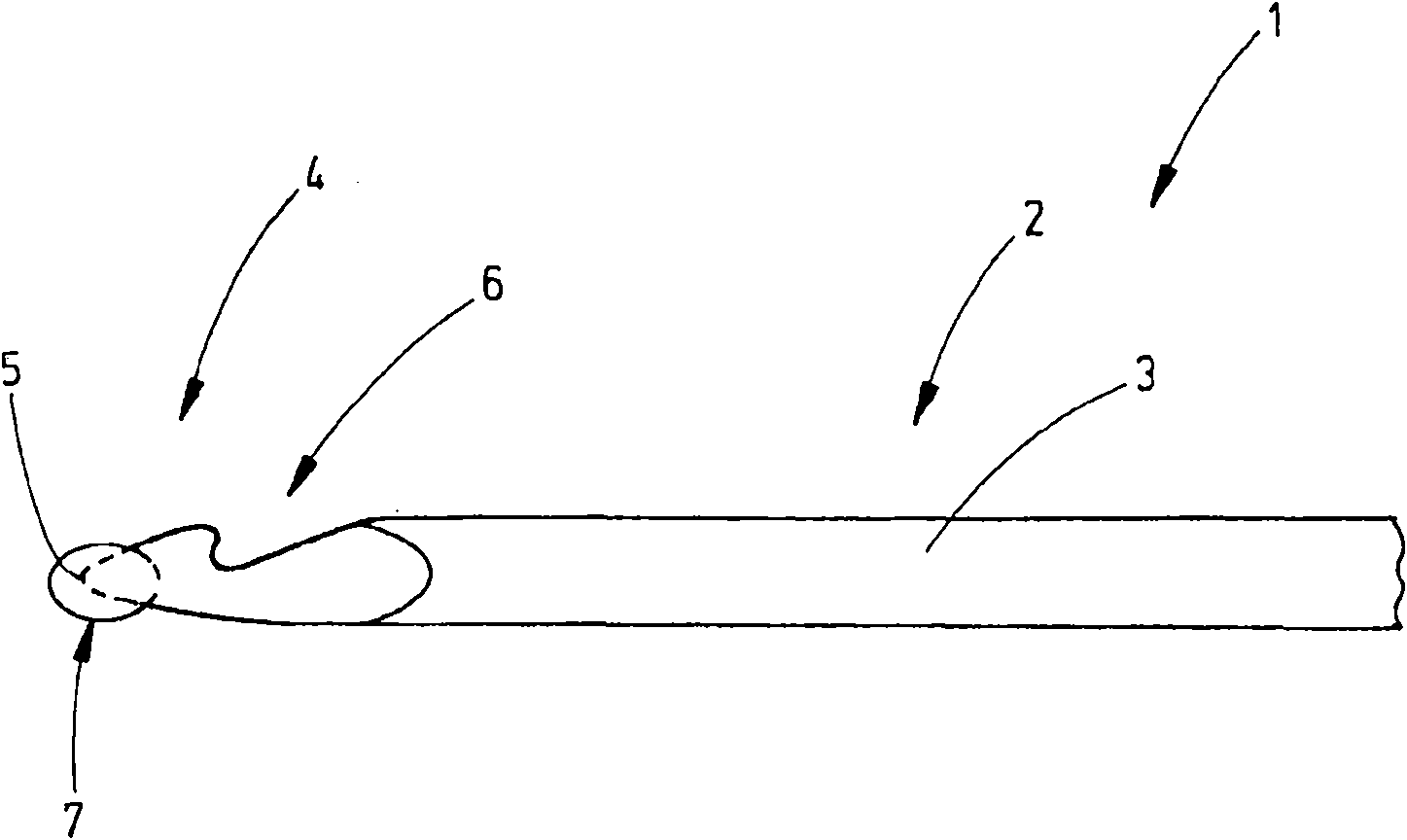

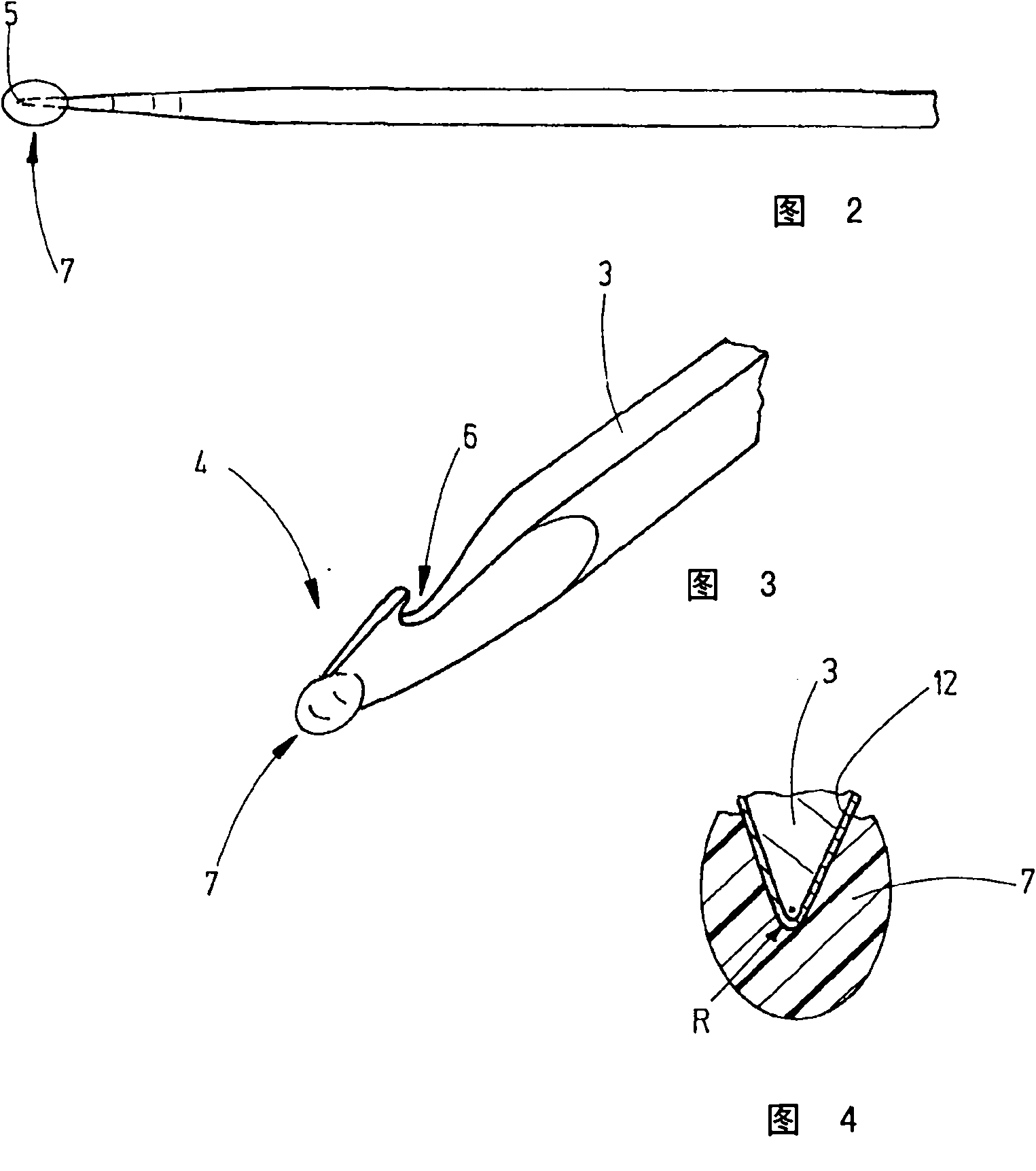

Needle for machine stitching with a composite thread

InactiveUS20060112867A1Prevent sharp bending of said brittle threadSewing needlesFiberBiomedical engineering

The invention relates to the joining of fabrics made of advanced fibers for making pre-forms for composite materials. The invention provides a sewing machine needle which can be used to join fabrics by stitching with a brittle thread. The needle, according to the invention, for stitching a brittle fiber thread through at least one layer of fibrous fabric, being characterized by the head (point) thereof having an (open eye) slit proximate to the needle point for receipt and release of the brittle thread, the slit of the needle having an arc shape with a radius of curvature of not less than 1 mm, to prevent sharp bending of the brittle thread when the thread is in contact with the slit.

Owner:SHENKAR COLLEGE OF ENG & DESIGN

Zipper attachment and a method of making the improved zipper attachment

ActiveUS20070169318A1Easily and cleanly removeSnap fastenersSlide fastenersEngineeringMechanical engineering

A zipper mechanism is stitched to one side of a base which has a layer of adhesive on the other side. A release liner covers the adhesive and includes a plurality of rows of slits which define sections which are separated from each other. The zipper mechanism is attached to the base by rows of stitches with the rows of stitches being located between sections of the release liner so the release liner can be separated from an adhesive layer covering position in sections without interference by the stitching. The zipper mechanism is formed by a method which slits the release liner just prior to stitching the zipper mechanism to the base and locating each row of stitches between adjacent rows of slits defined in the release liner.

Owner:ZIP UP PROD

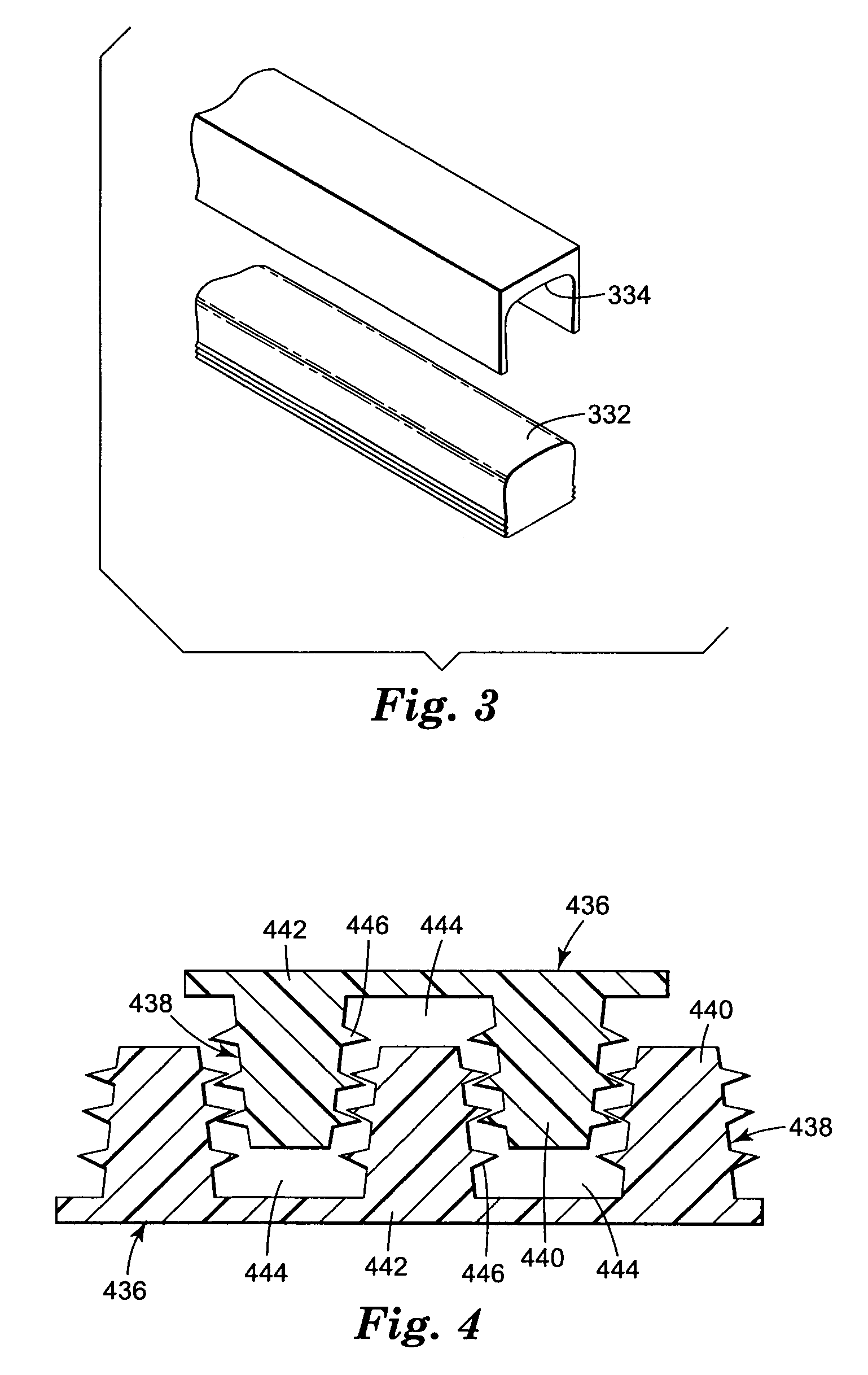

Fastening system

InactiveUS20050193527A1Easy to optimizeImproved hair clipSnap fastenersStampsEngineeringMechanical engineering

A fastening system includes a straight pin having a cap end, a shank and a pointed end; a planar border having a base and two integrally formed substantially parallel planar flexible peripheral legs of like length, distal ends of each of the legs having apertures proportioned for slidable receipt of the shank of the straight pin; and an elongate securement leg integrally dependant from the base in a direction of the distal ends of the flexible legs, a distal end of the securement leg including a female surface press-fittably complemental about the pointed end of the straight pin. The pin may be inserted through the apertures when they are aligned with each other, and then held by the female surface to enable securement of a planar peripheral legs to each other.

Owner:GOULD SHELDON D

Apparatus for stitching vehicle interior components

An apparatus for stitching a component is provided. The apparatus includes an awl bar assembly coupled to a first drive device. The awl bar assembly is moved from a first position to a second position along the stitch path with an external drive device. A second drive device is coupled to the first drive device. A needle bar assembly is provided having a needle. The needle moves between an inserted and a withdrawn position, the needle bar assembly being pivotally coupled to the second drive device, the needle bar assembly moves from the first position to the second position with the same external drive device driving the awl bar assembly. A biasing member is coupled to the needle bar assembly, the biasing member being arranged to pivot and align the needle bar assembly in the second position in response to the needle bar being moved to the withdrawn position.

Owner:INTEVA PRODUCTS LLC

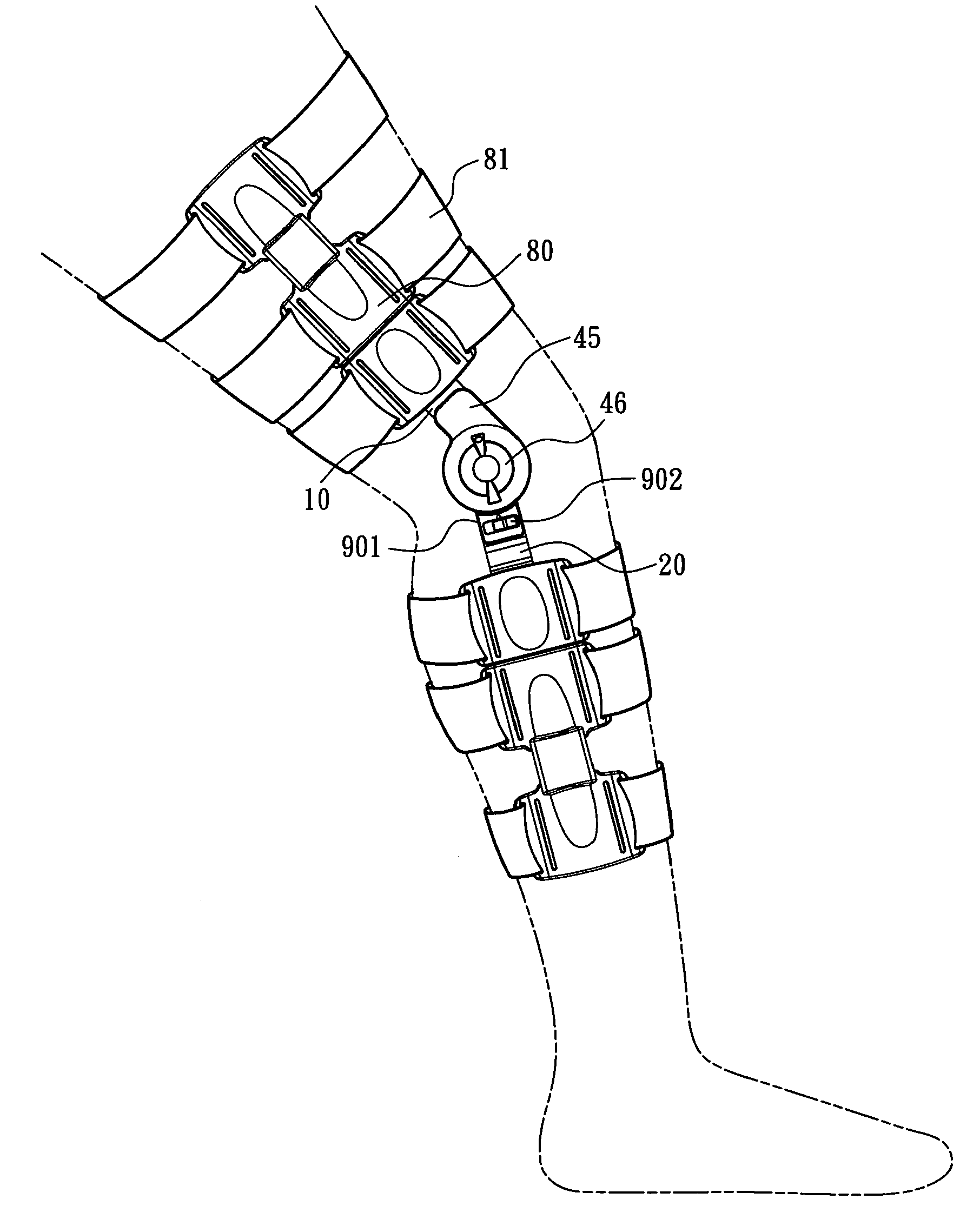

Joint brace adjustable device

InactiveUS20100130899A1Improve adaptabilityLimit movement of jointSnap fastenersSewing needlesEngineeringTarsal Joint

Owner:HUNTEX

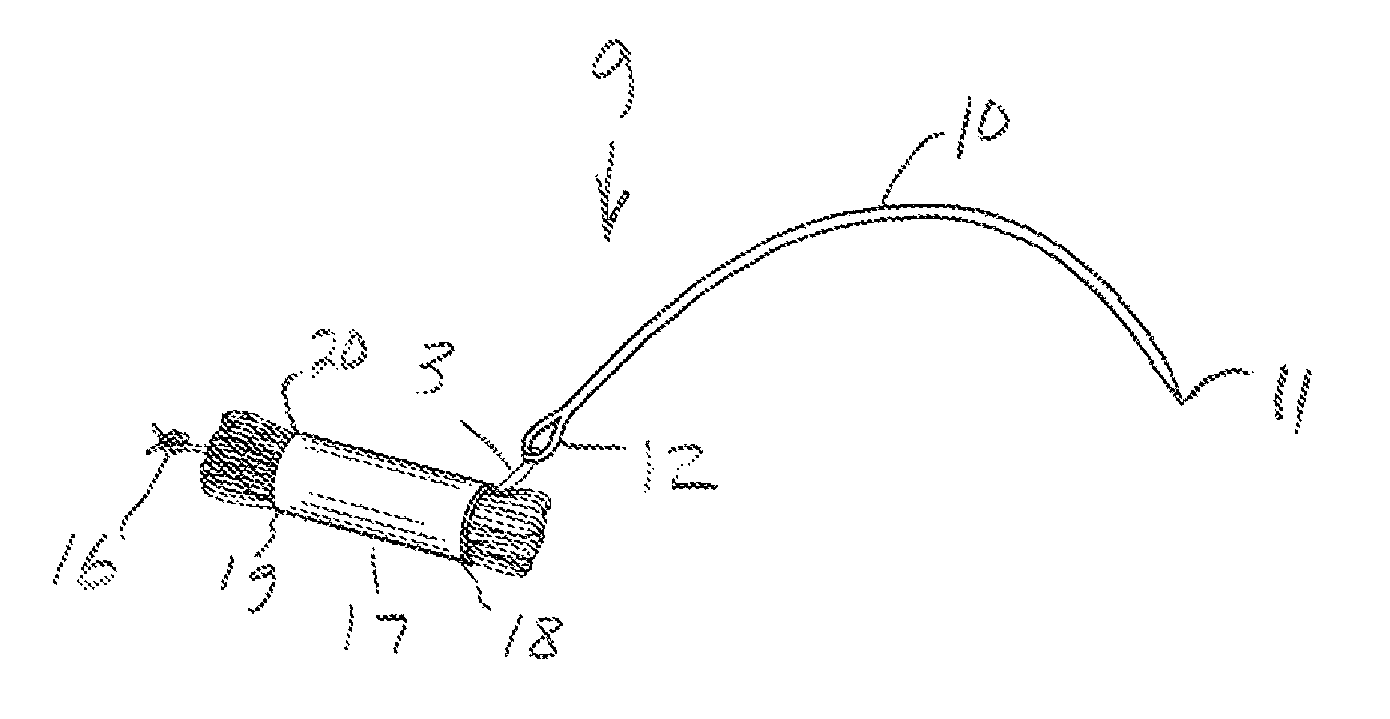

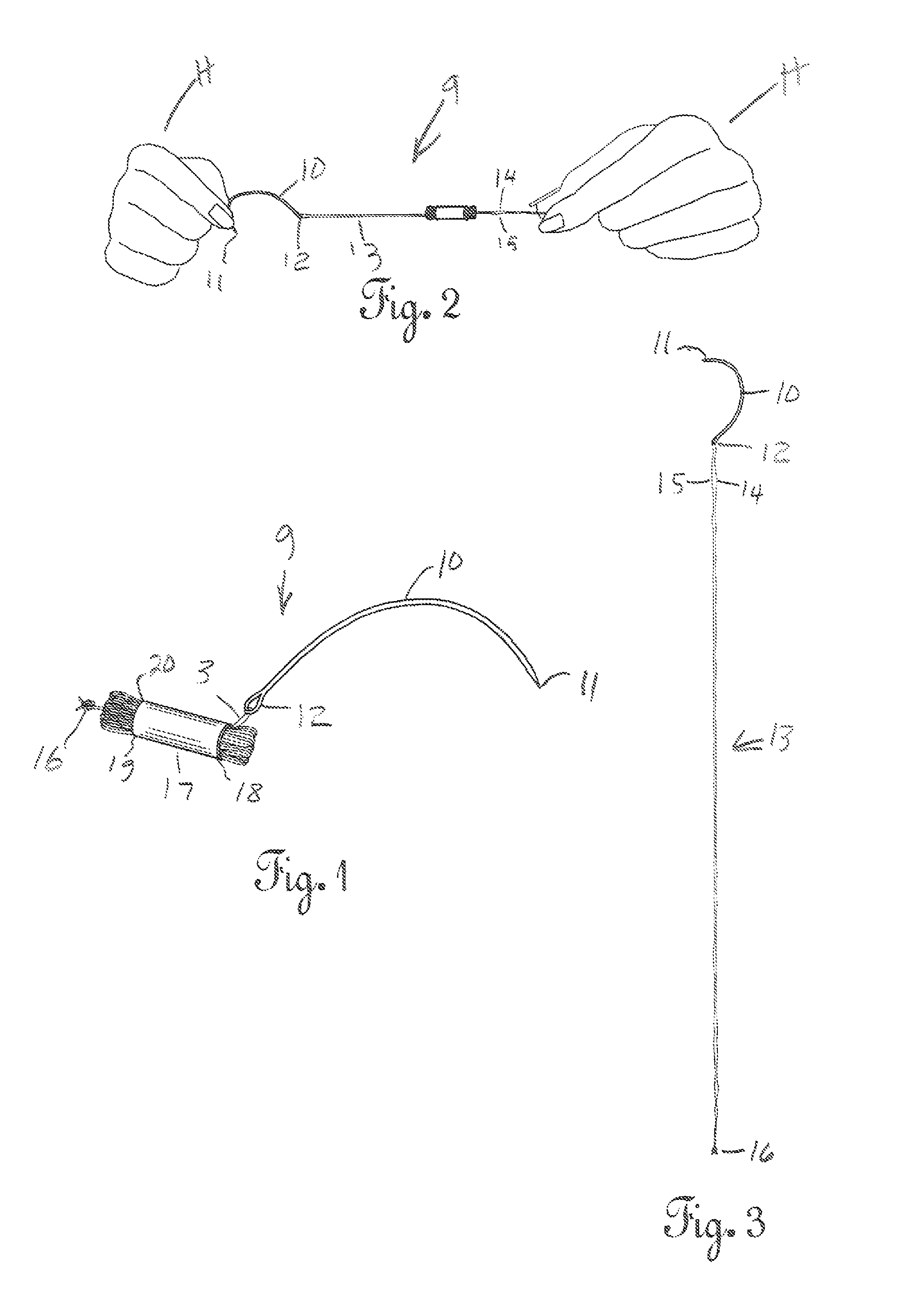

Pre-threaded and knotted hair weaving needle and method

Owner:SMITH TANISHA SHANAE

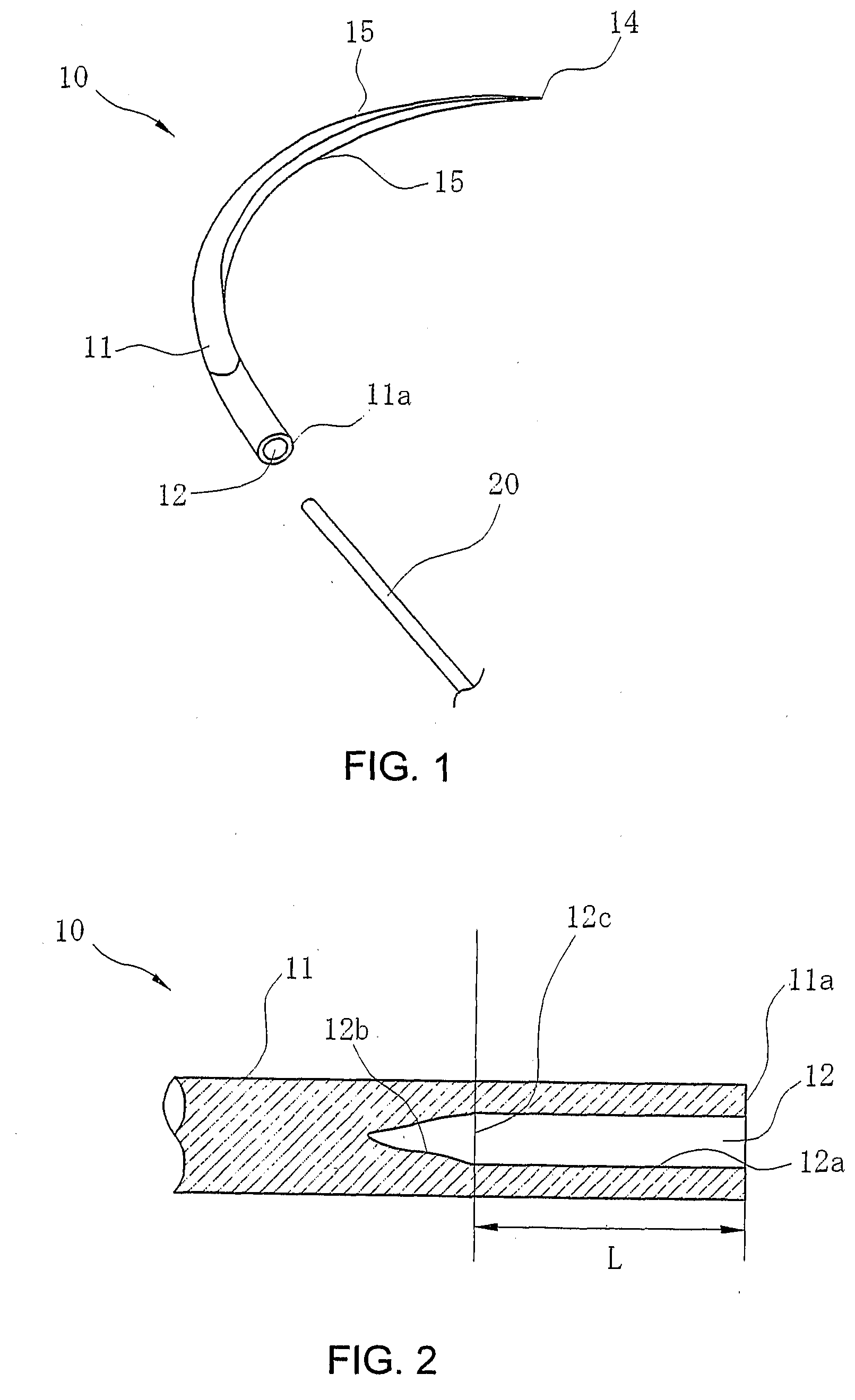

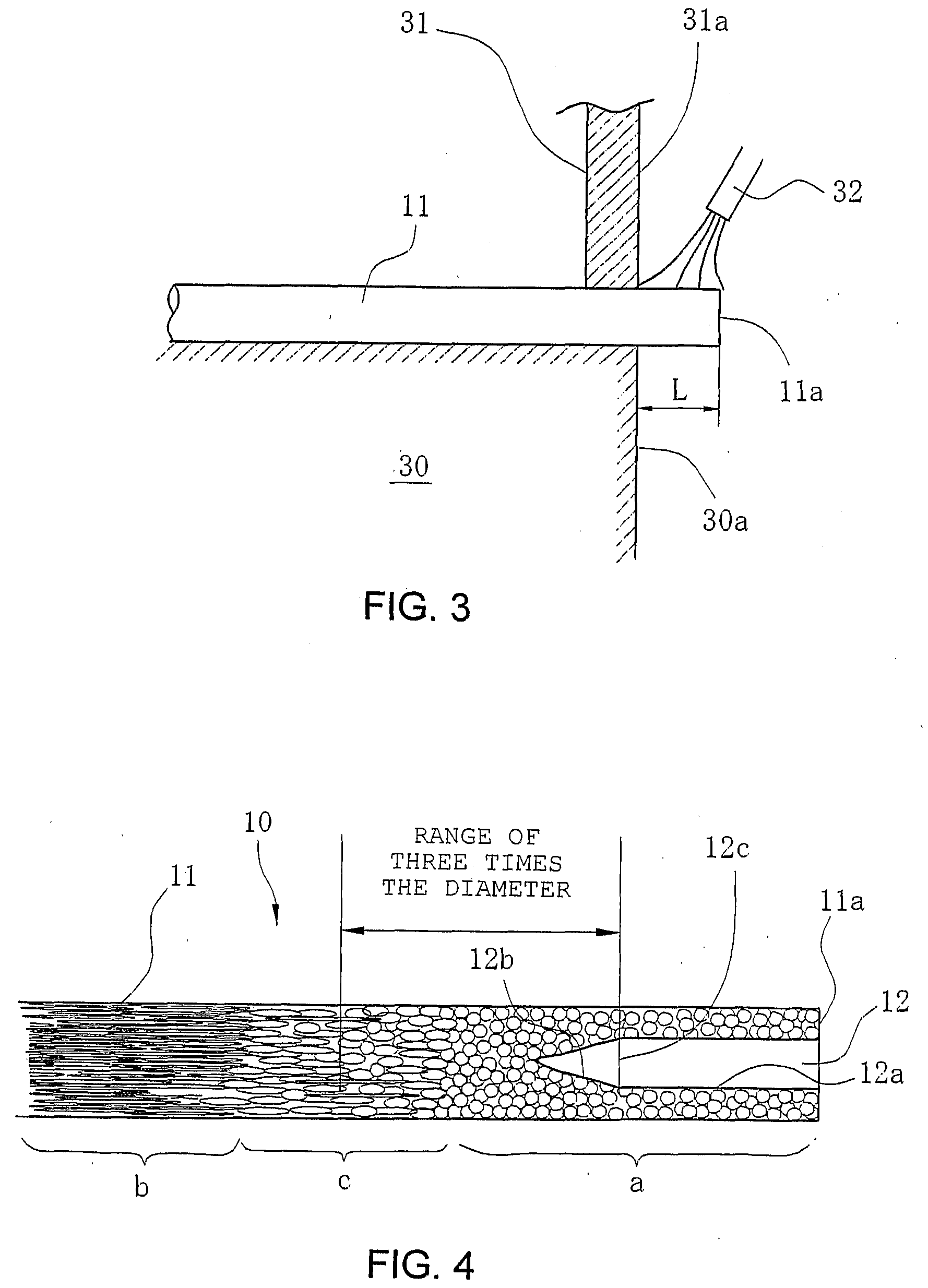

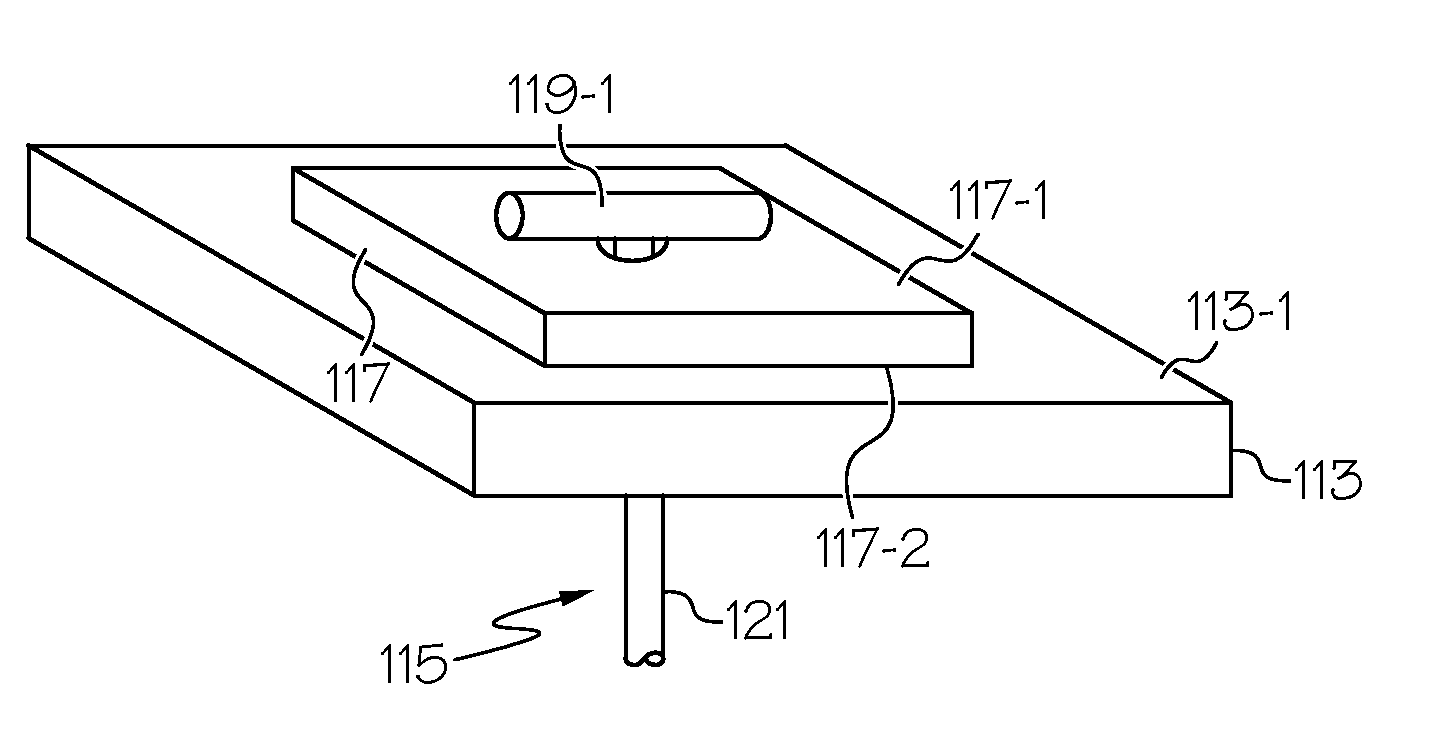

Eyeless Sewing Needle and Fabrication Method for the Same

ActiveUS20090039117A1Easy to bendEasy to operateSurgical needlesSewing needlesHeat-affected zoneSewing needle

In an eyeless sewing needle, a periphery of an axial hole at the base end is heated to make a fibrous structure be a granular structure without directionality, and at least a part of a heat-affected zone made between the fibrous structure and the granular structure due to the heating is within a range that is three times the diameter of the sewing needle and that extends from an effective base of the axial hole towards the needlepoint. This allows provision of a flexible sewing needle so that the hole periphery can be processed while keeping a hard state at the position of the needlepoint slightly away from the axial hole.

Owner:MATSUTANI SEISAKUSHO CO LTD

Fastener assembly

A fastener assembly for coupling together two or more articles includes a plastic fastener and an anchoring member. The plastic fastener includes a pair of parallel cross-bars that are interconnected by a transverse filament. The anchoring member is constructed as a unitary, solid, plastic disc with opposing flattened surfaces. In use, the anchoring member is disposed against an outer surface of the articles to be coupled together. During the fastener dispensing process, the ejected cross-bar penetrates through the articles as well as the anchoring member. Upon completion, the ejected cross-bar lies directly upon the exposed surface of the anchoring member. As such, the stiffened anchoring member provides structural integrity to articles that are deformable in construction. In this manner, the anchoring member prevents intact removal of a dispensed fastener by either intentional or unintentional widening of the hole in the articles through which the fastener extends.

Owner:AVERY DENNISON CORP

Textile tool with temporary protection

ActiveCN101988235APrevent wear attacksAvoid harmWeft knittingTufting apparatusEngineeringMechanical engineering

The present invention relates to a textile tool with temporary protection. An anti-abrasion layer (12) is provided on the textile tool (1). The anti-abrasion layer extends and covers a cutting edge (9) or a top end (5). A cap (7) or a cap (11) which is made of protection material is provided for the top end (5) or the cutting edge (9). The protection material is preferably constructed to have viscoplasticity or damping characteristic. Preferably, the cap (7,11) can be easily removed. For instance, in a first using process of the textile tool, the cap is integrally or partially separated from the textile tool (1). Preferably, the protection material is molten impregnated material, such as molten impregnated material based on thermoplasticity.

Owner:GROZ BECKERT KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com