Patents

Literature

337results about How to "Simplify the disassembly process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

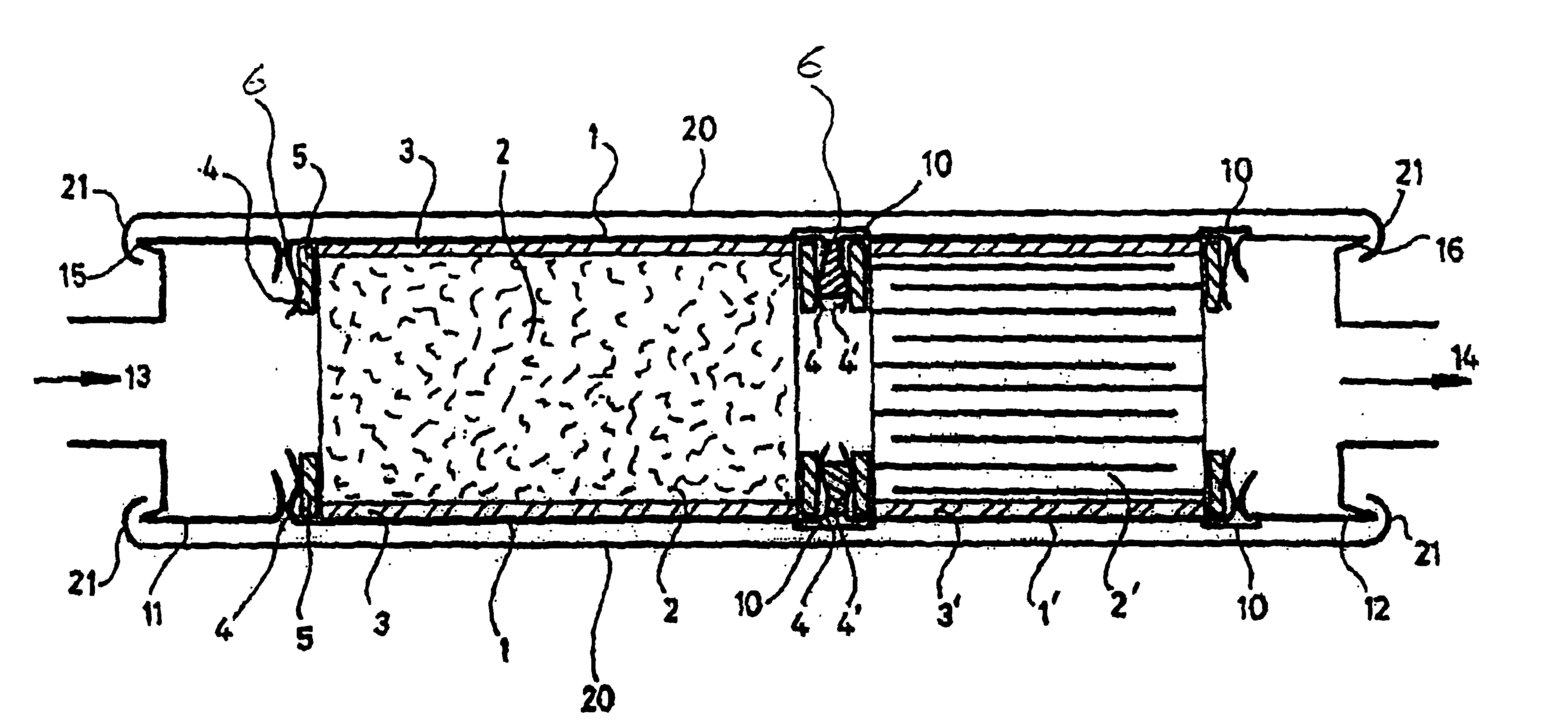

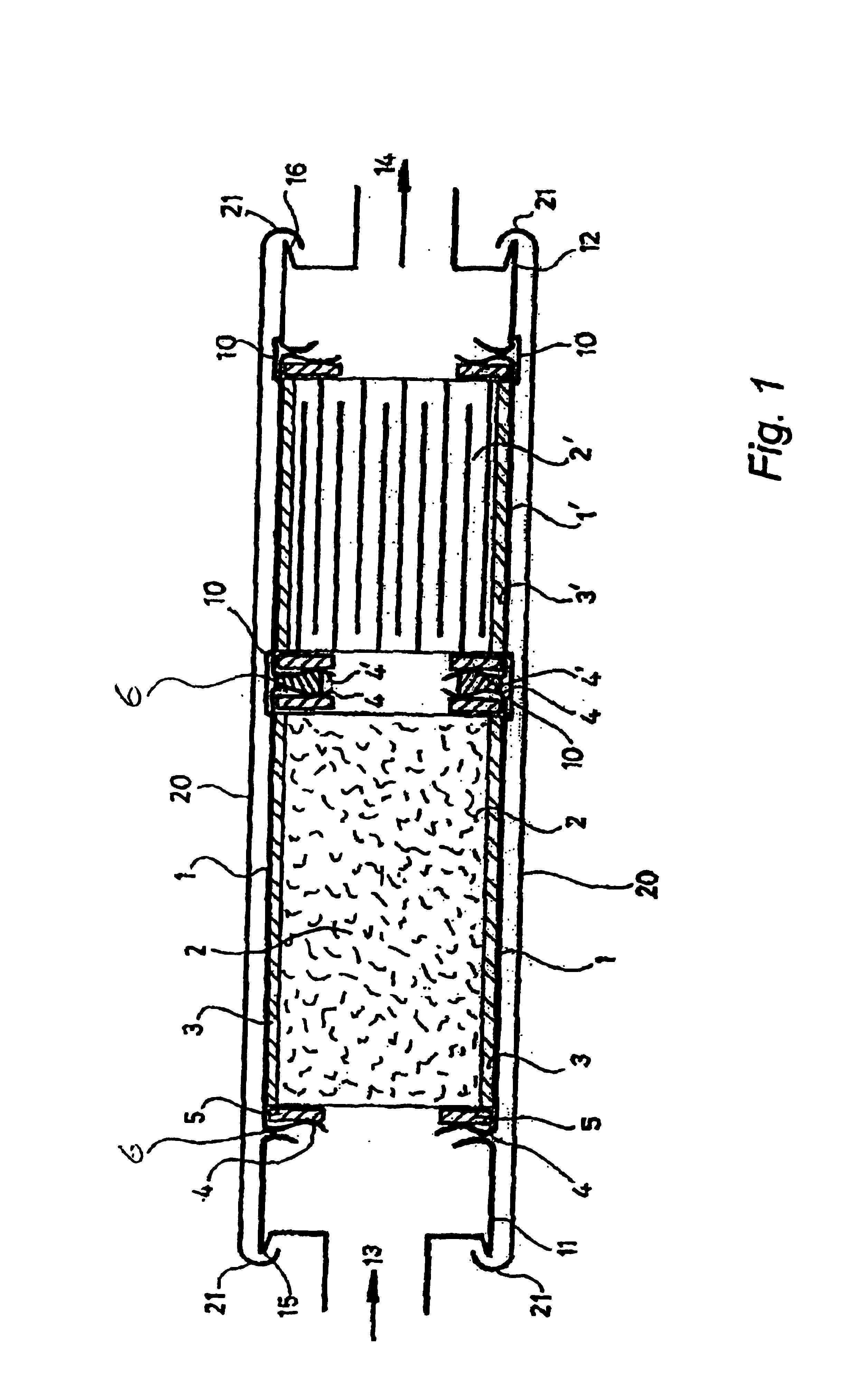

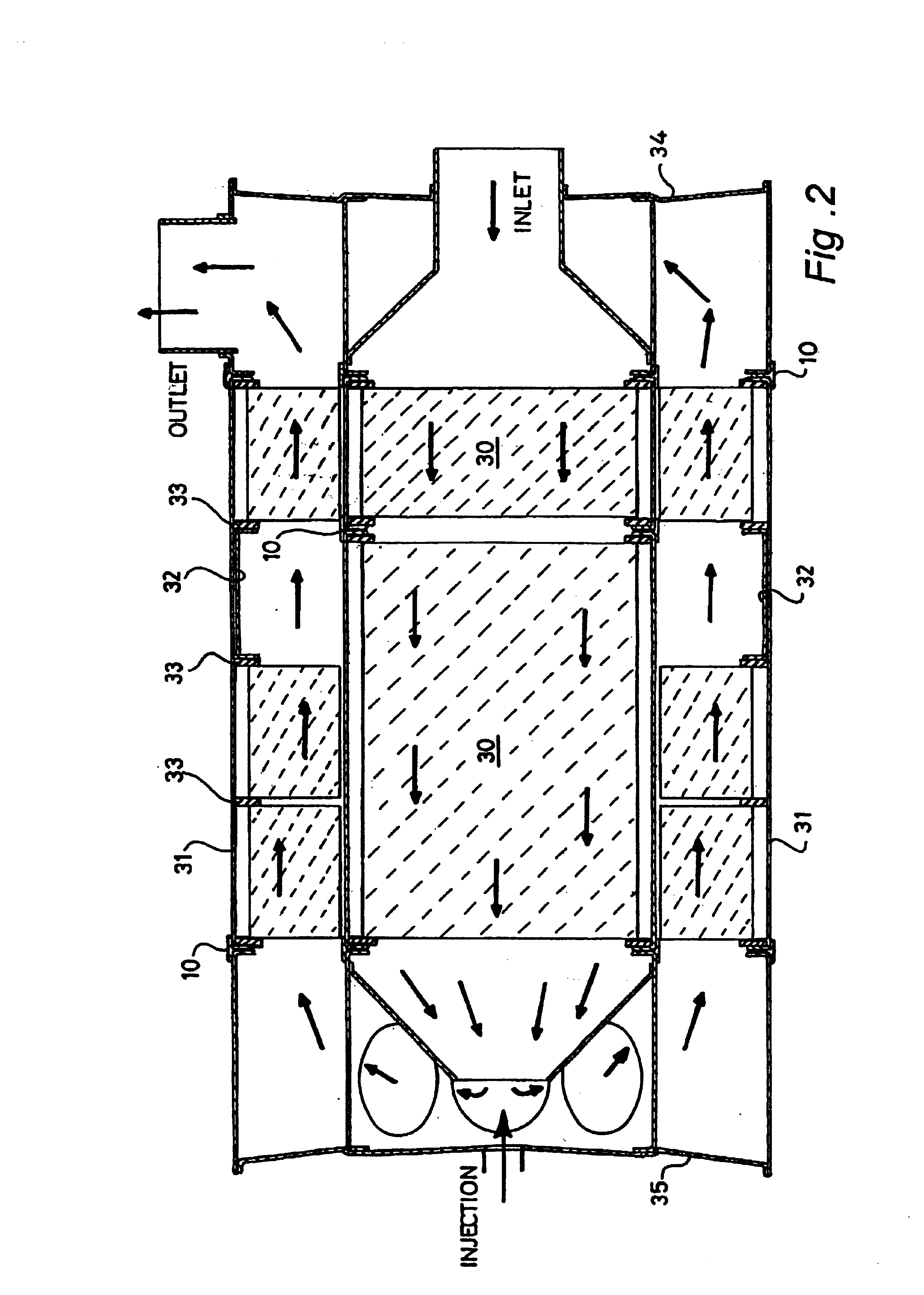

Apparatus for treating a gas stream

InactiveUS6837336B2Reduce tensionEasy to hookCombination devicesDispersed particle filtrationEngineeringInternal combustion engine

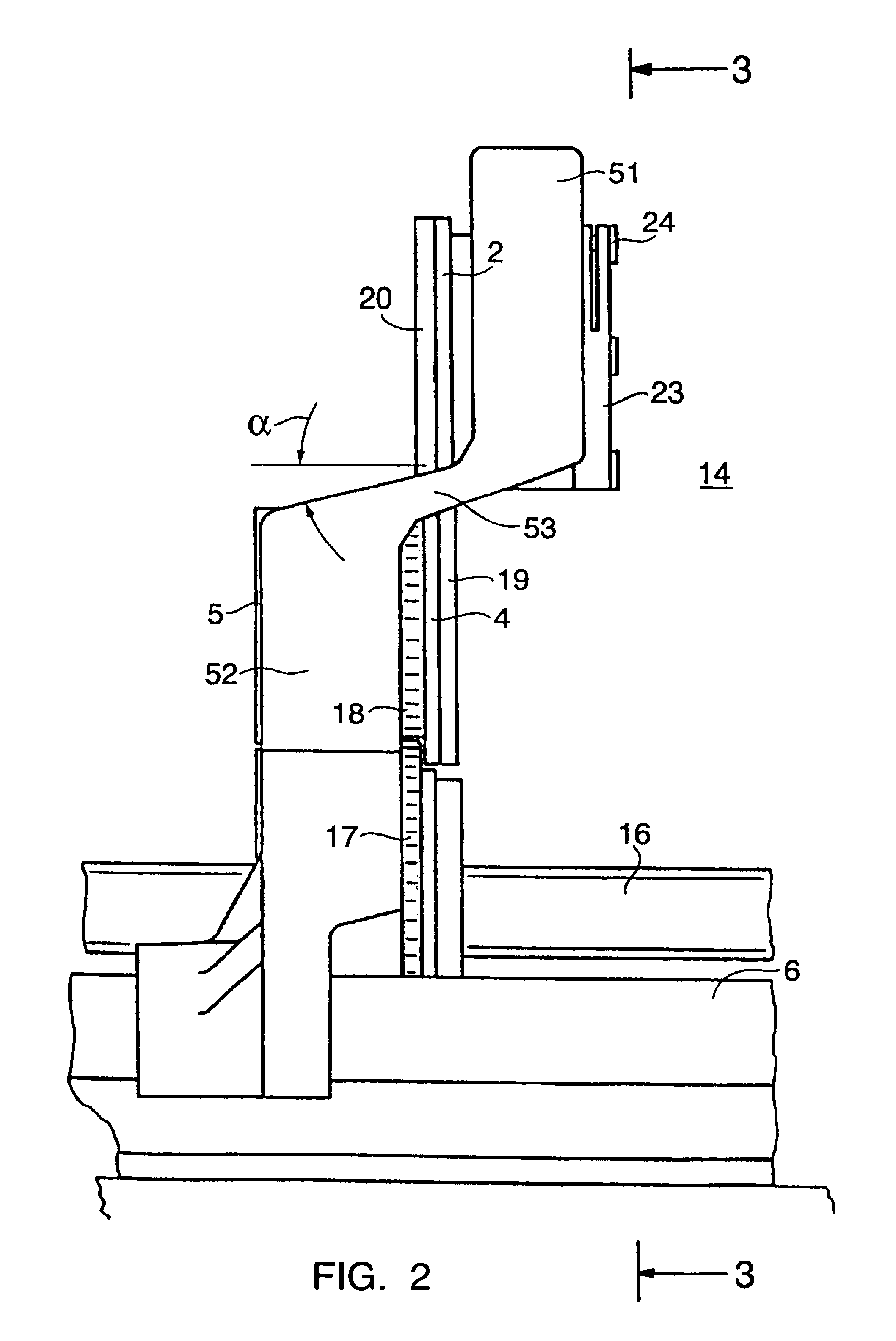

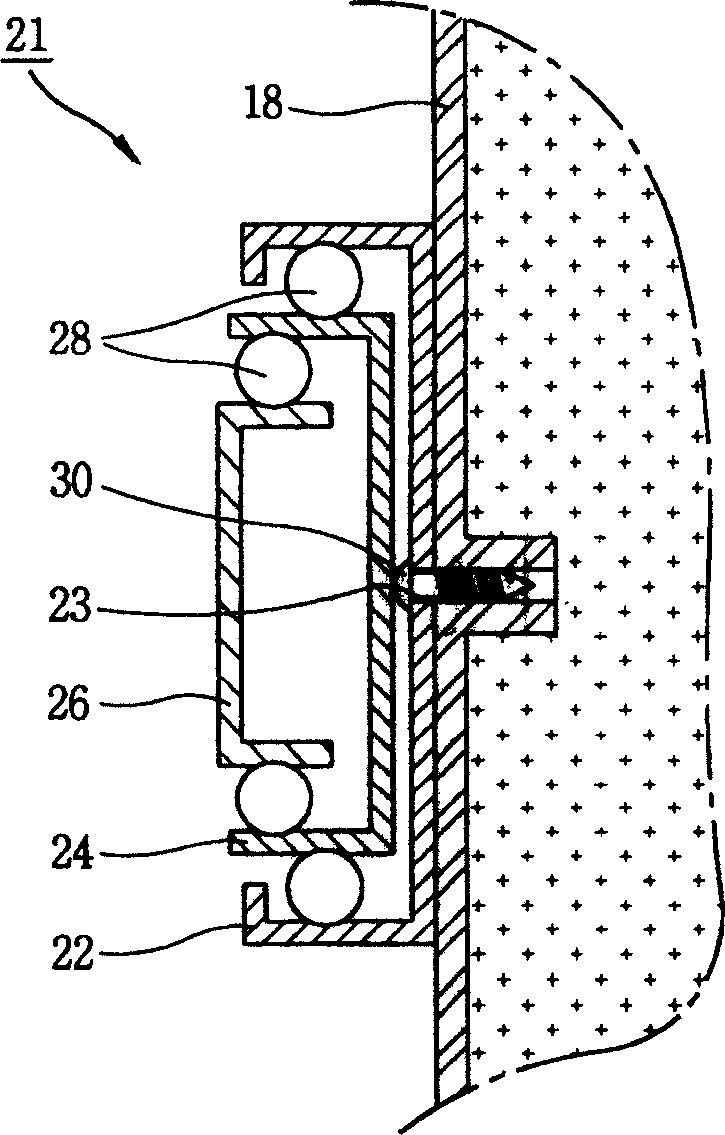

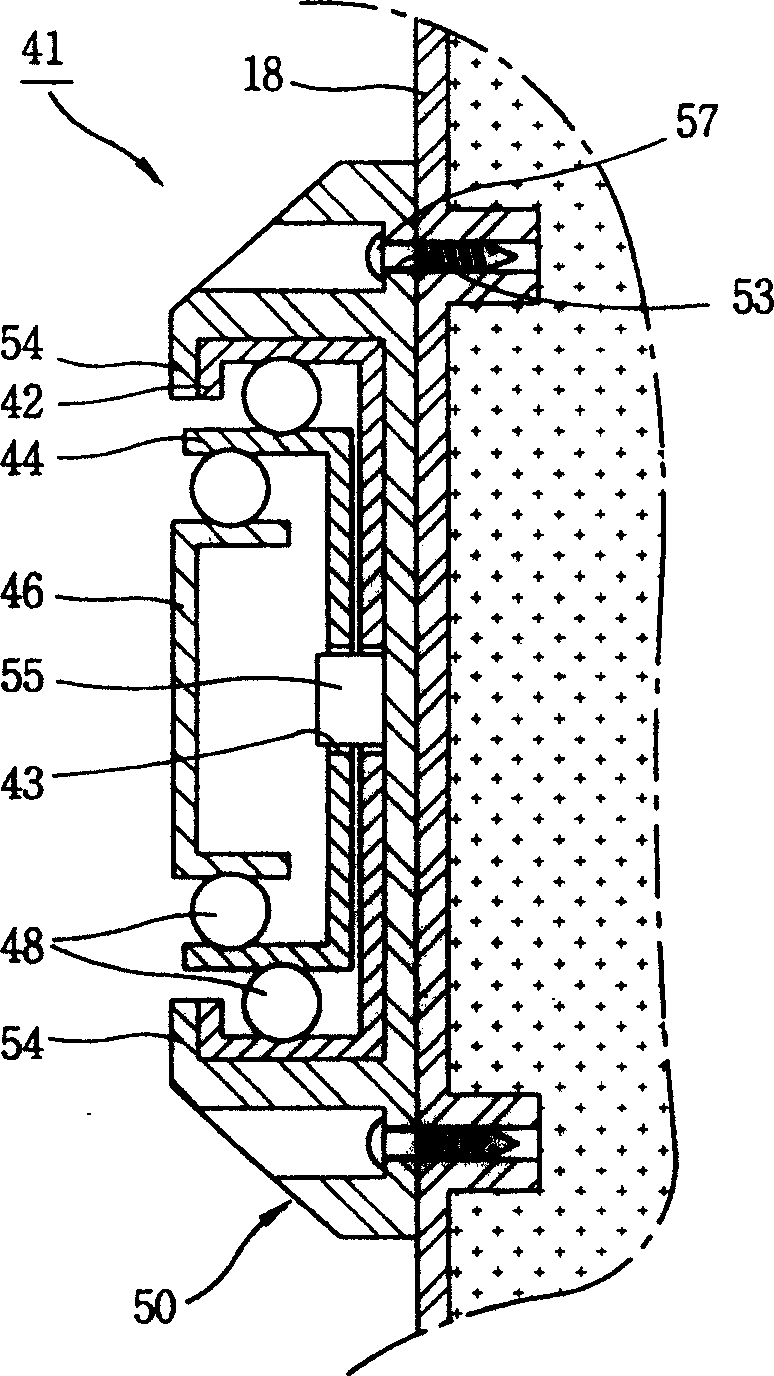

The invention provides apparatus for treating a gas stream, notably a silencer assembly for use to treat the exhaust gasses from an internal combustion engine, which apparatus comprises a plurality of compartments within which one or more treatments are to be performed on a gas stream passing through the compartment, and through which the gas stream is to flow sequentially, characterised in that:a. At least two of said compartments each comprises a tubular body member containing or carrying a treatment element which is restrained against axial movement relative to the body member; andb. The tubular body members of the adjacent compartments are provided with radially outwardly and / or inwardly extending terminal flanges, at least some of which flanges provide a shoulder against which the opposing terminal portion of the adjacent compartment bears so as to form an axially extending structure comprising at least two compartments in axial or coaxial relationship to one another; andc. One or more clamping members which extend axially over substantially the length of the said structure and act upon the axial structure to secure the two adjacent compartments together in gas-tight engagement by an axial clamping action.

Owner:GAULT ANTHONY JOHN +1

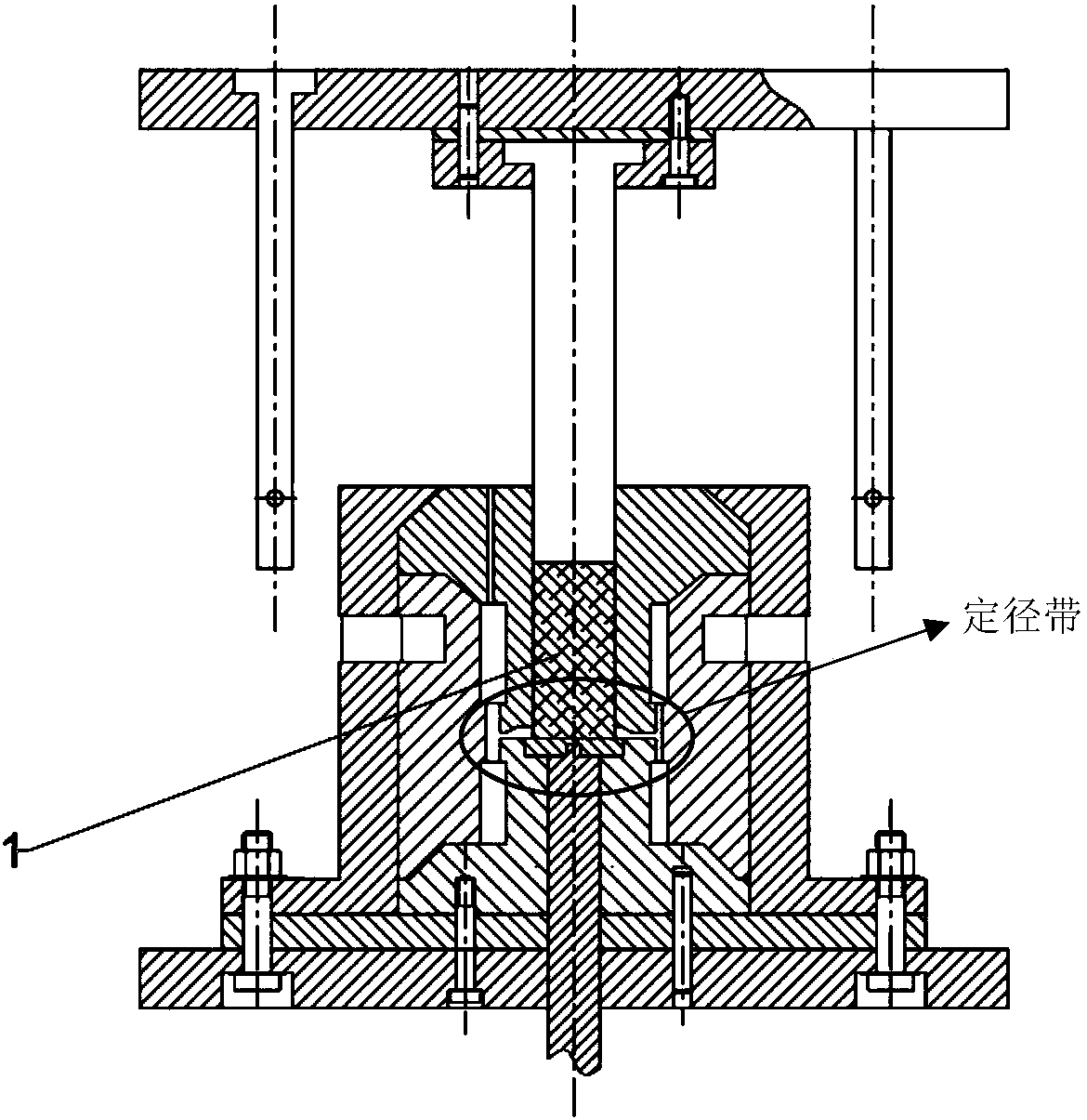

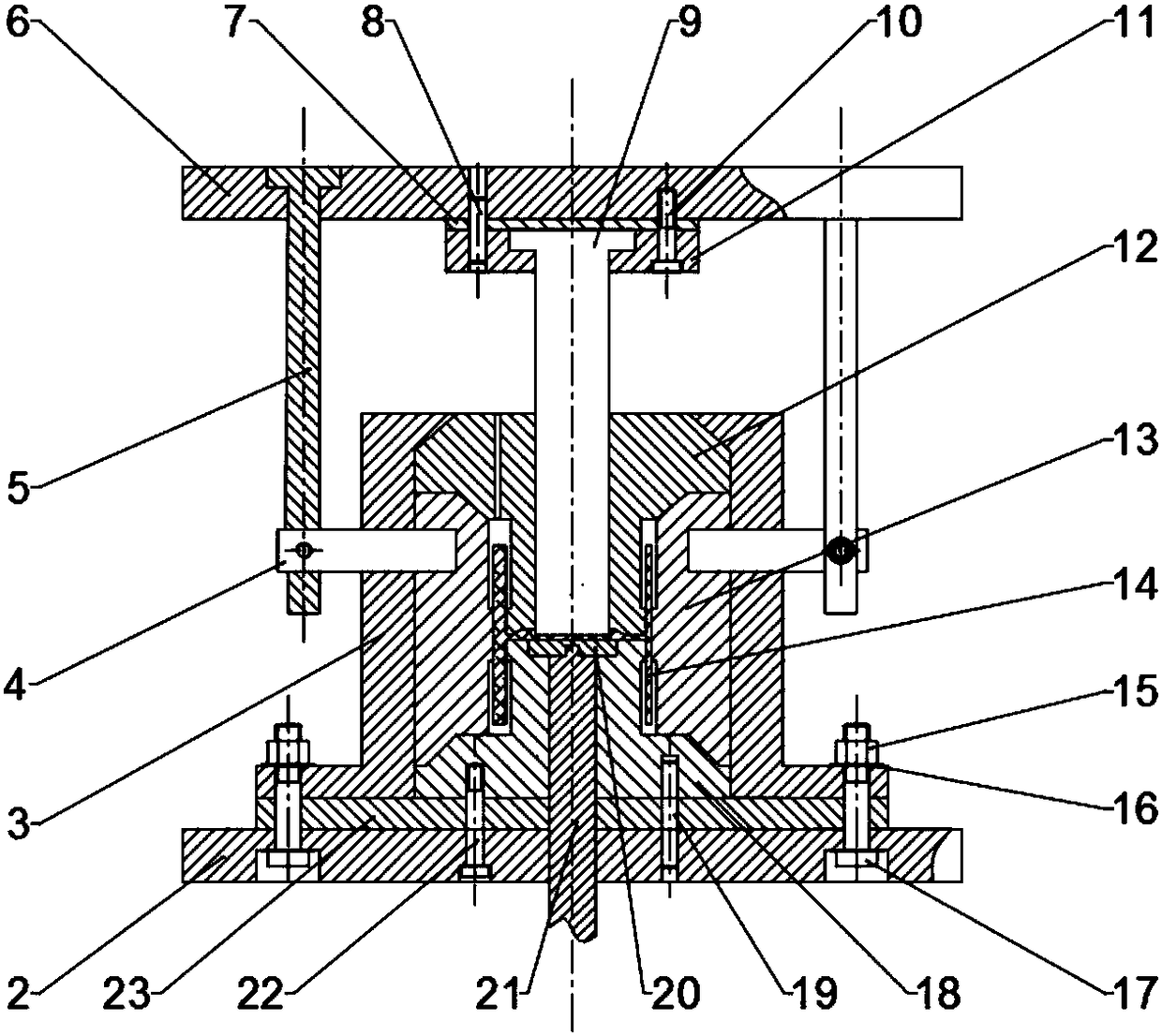

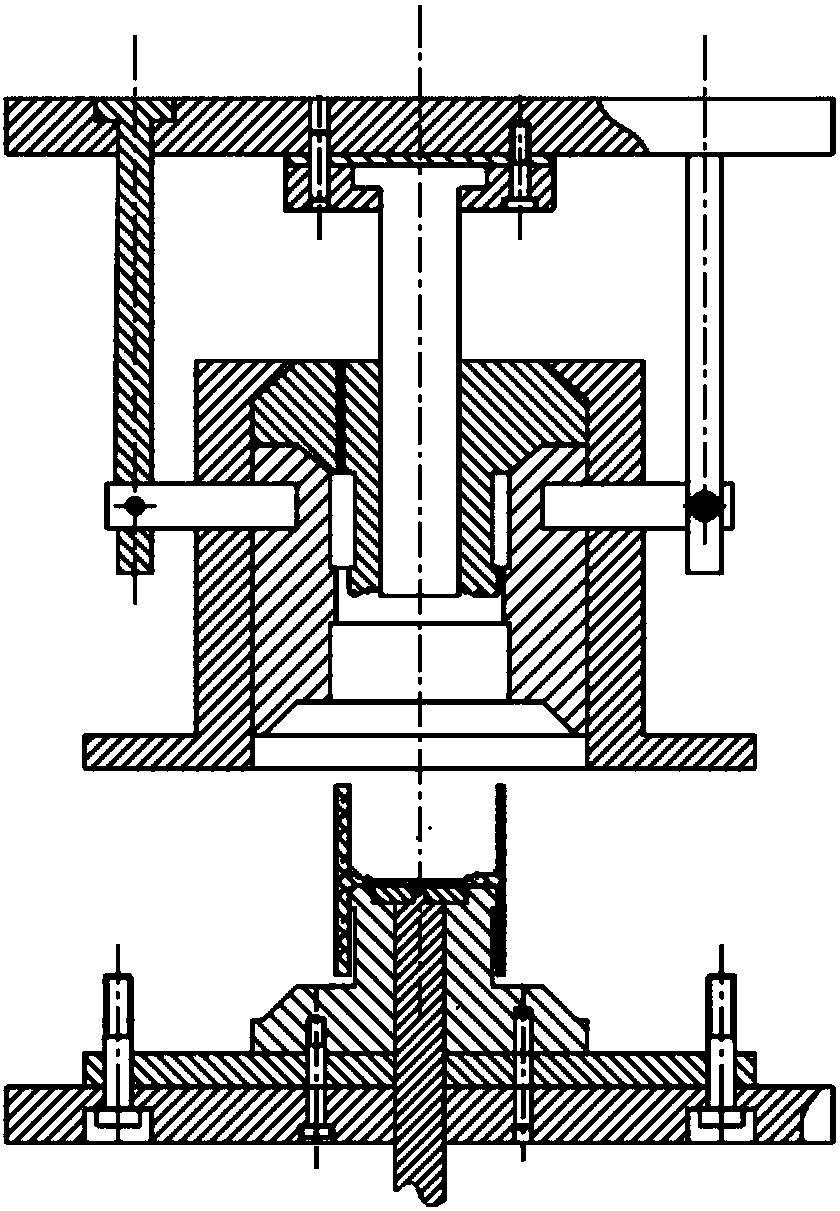

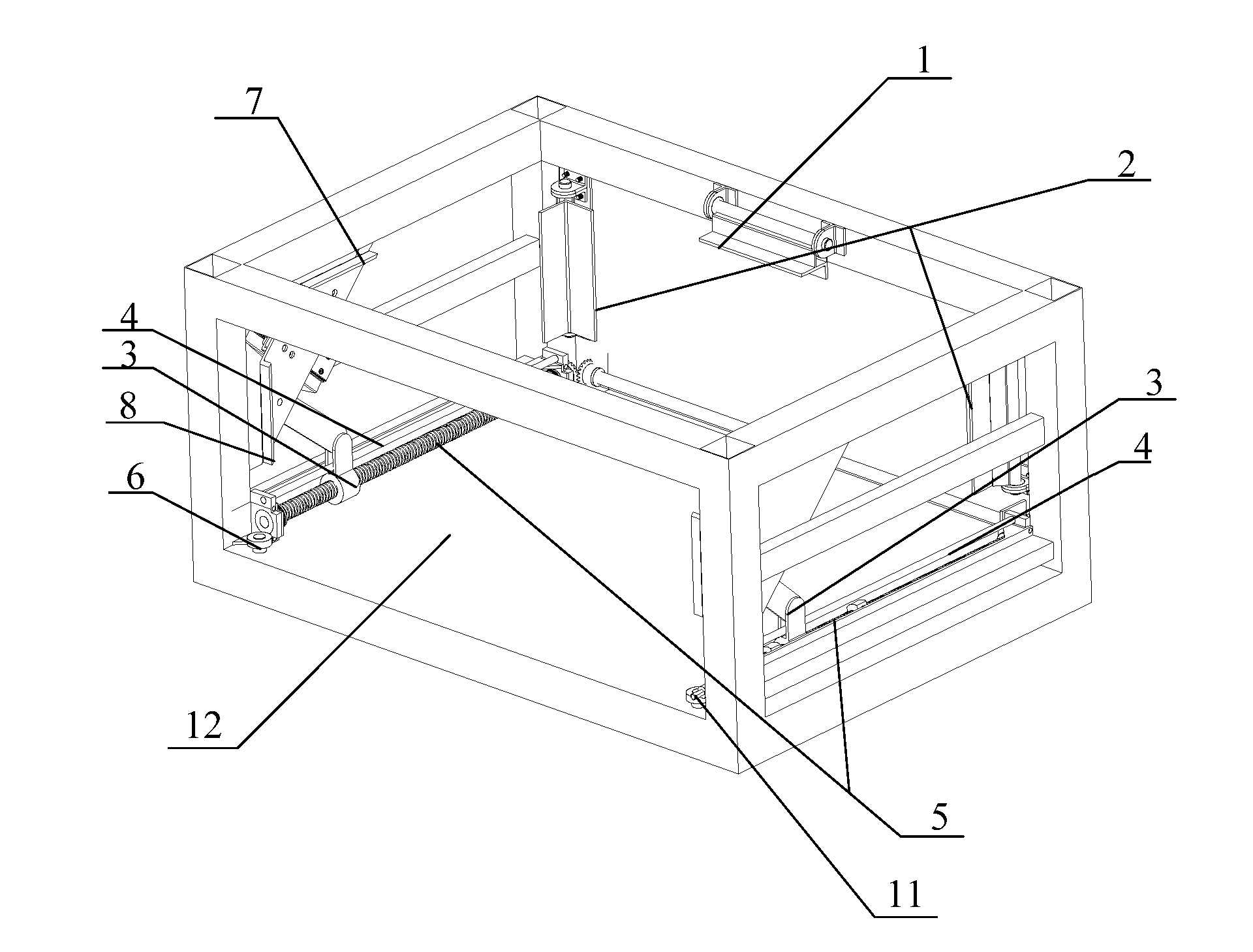

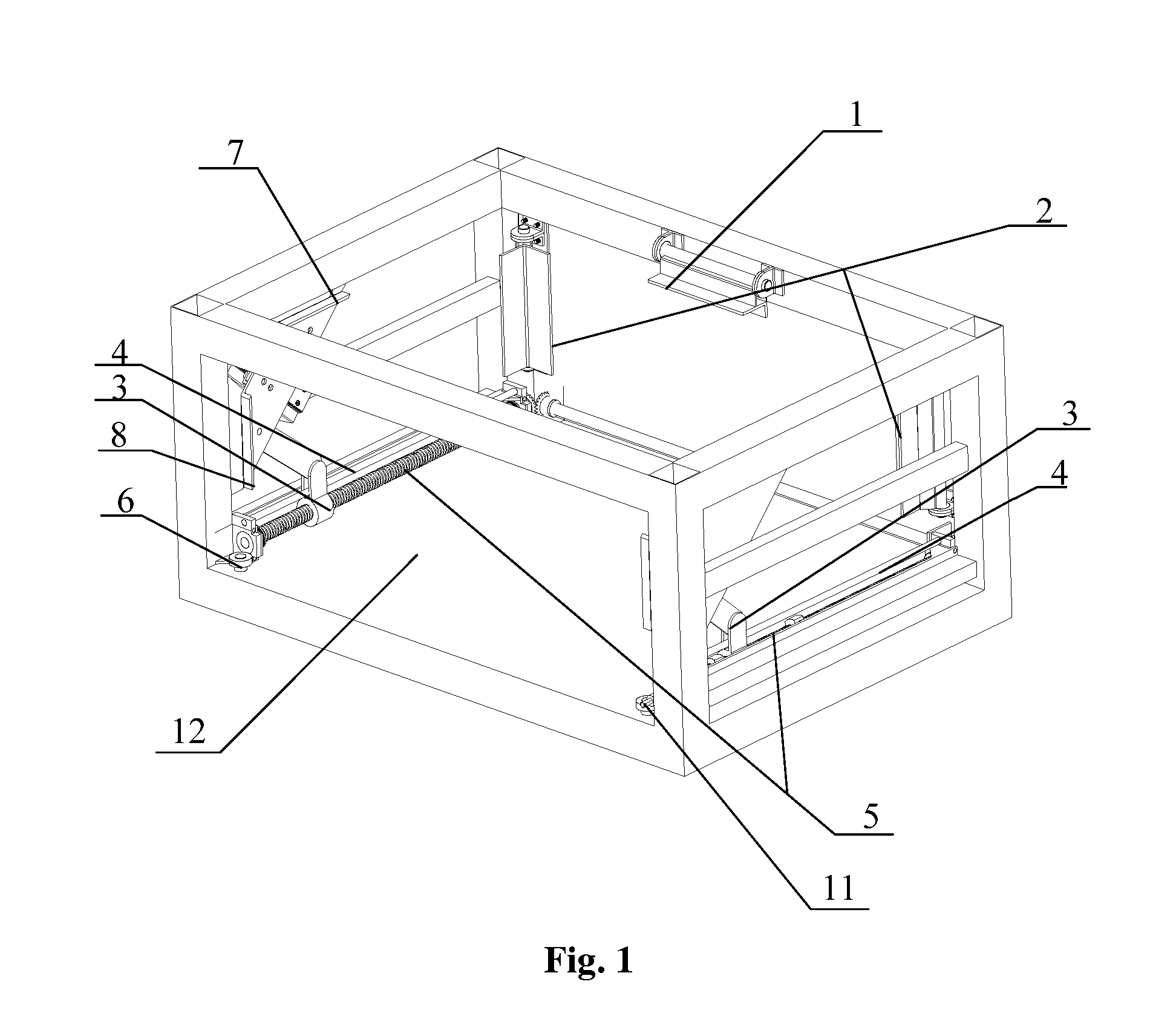

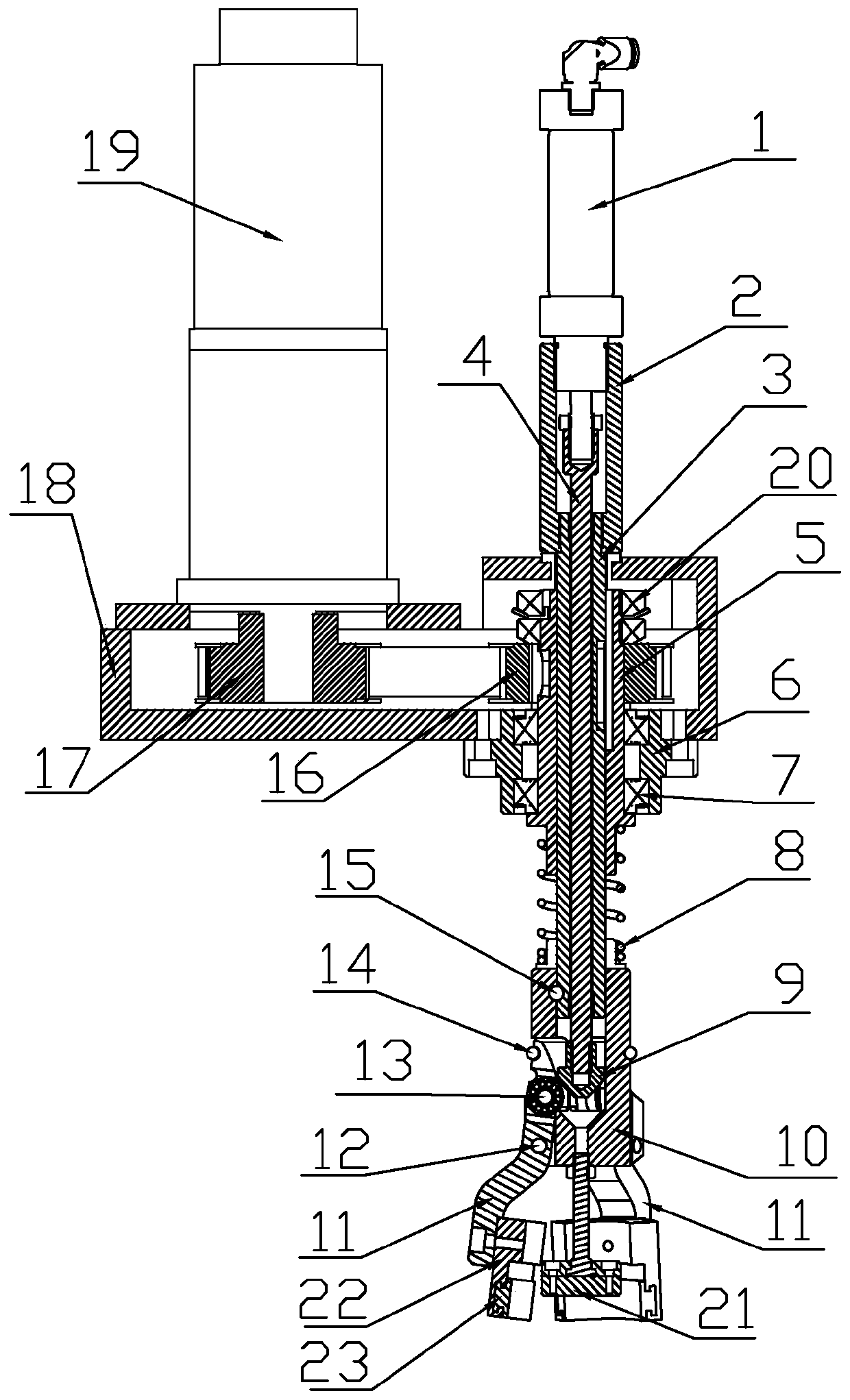

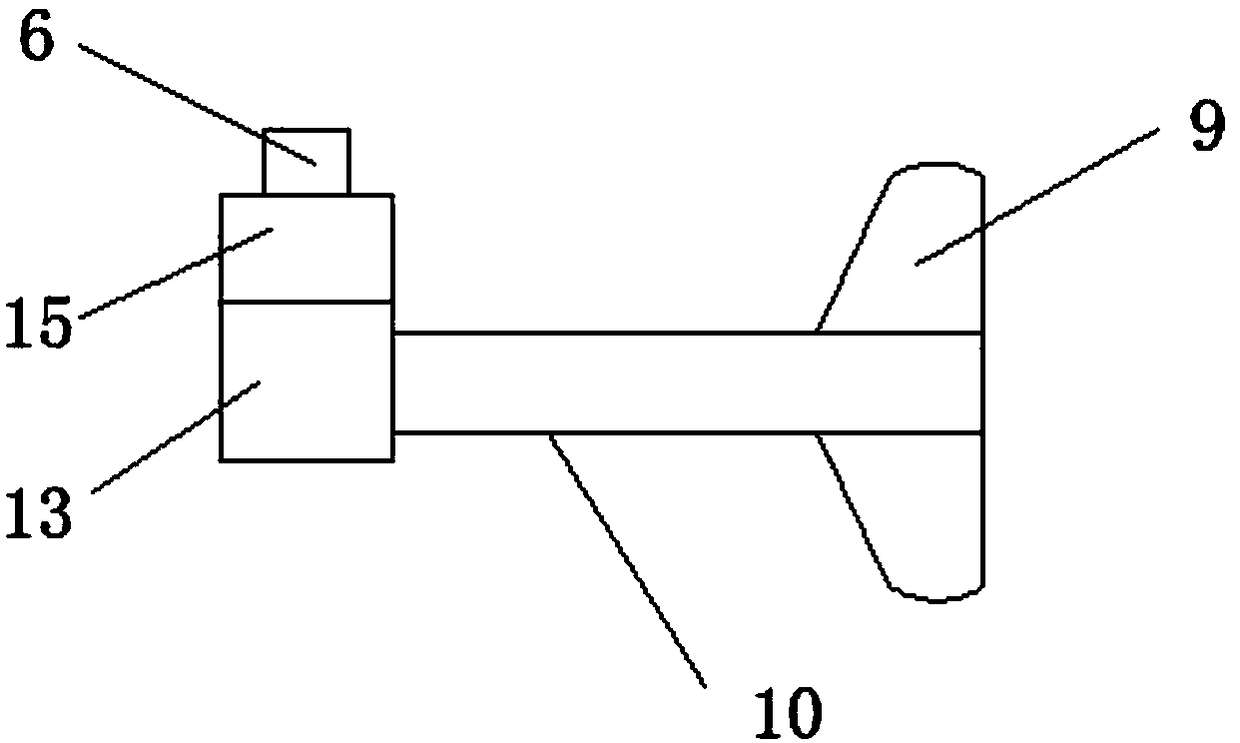

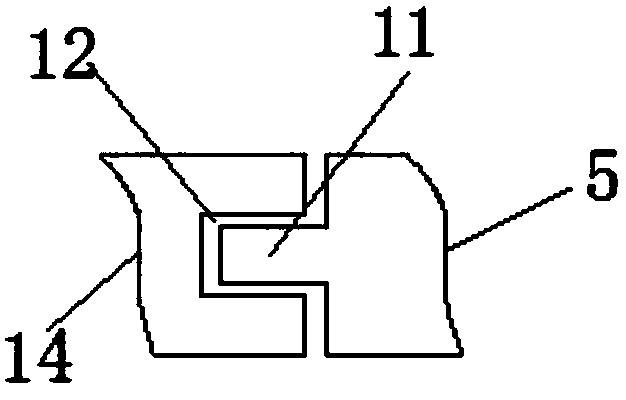

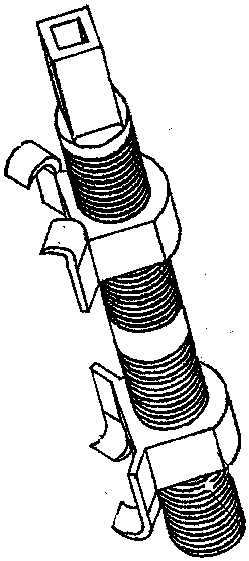

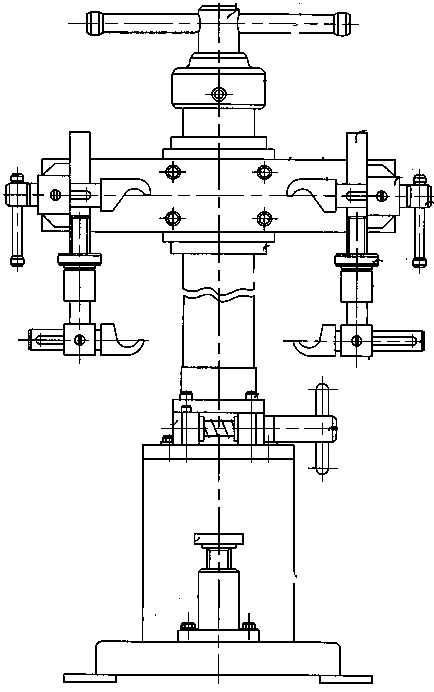

Strong plastic deformation extrusion molding device and method for magnesium alloy band rib barrel-type part

The invention provides a strong plastic deformation extrusion method and a molding device for magnesium alloy band rib barrel-type part, belonging to the technical field of plastic processing. A columnar billet is subjected to channel-changing corner extrusion for the first time to extend to a circumferential direction to form a circular rib and then subjected to the channel-changing corner extrusion for the second time to enter an up-down mold cavity to form a thin-walled cylinder provided with four longitudinal ribs. When a material is subjected to corner extrusion for multiple times, crystalline grains are constantly refined to generate strong plastic deformation to cooperate with the mold cavity to realize extrusion molding once and obtain the high-strength magnesium alloy band rib barrel-type part. The length of a diameter fixing band of an extrusion mold is shrunk so as to reduce friction between a formed part and a mold to decrease forming force. A longitudinal pull rod and a transverse shaft pin for special purpose are designed and cooperate with a mold structure, and after part molding is completed, the return stroke of a workbench on an extruder is utilized to disassemblethe mold and take out the formed part. A magnesium alloy barrel-type part, which has high strength, can be molded once, a circular rib and longitudinal bars therein can be used as support structures,and the designed part taking structure can be used for effectively solving the problem that a barrel-type extrusion part is difficult to take out.

Owner:UNIV OF SCI & TECH BEIJING

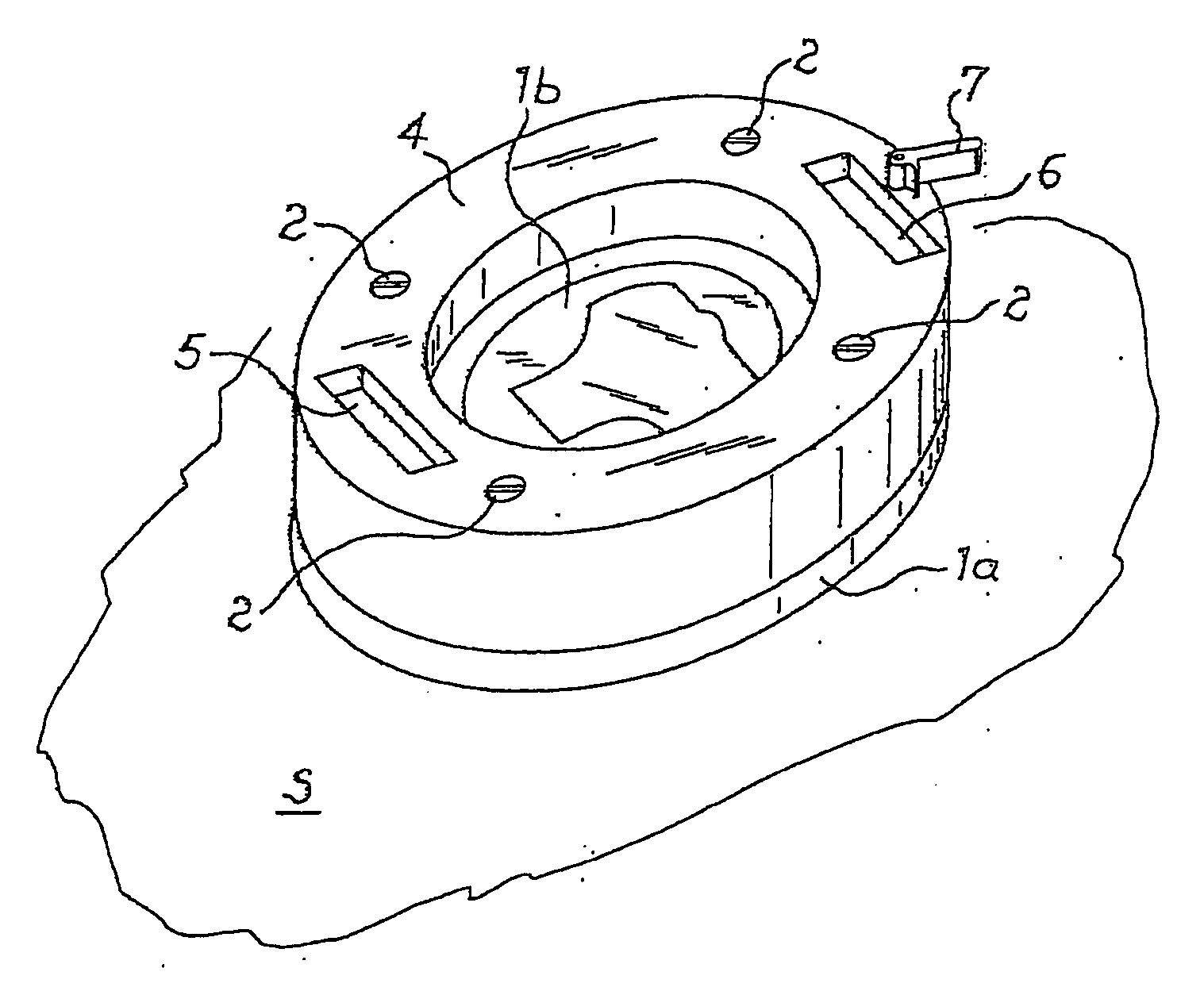

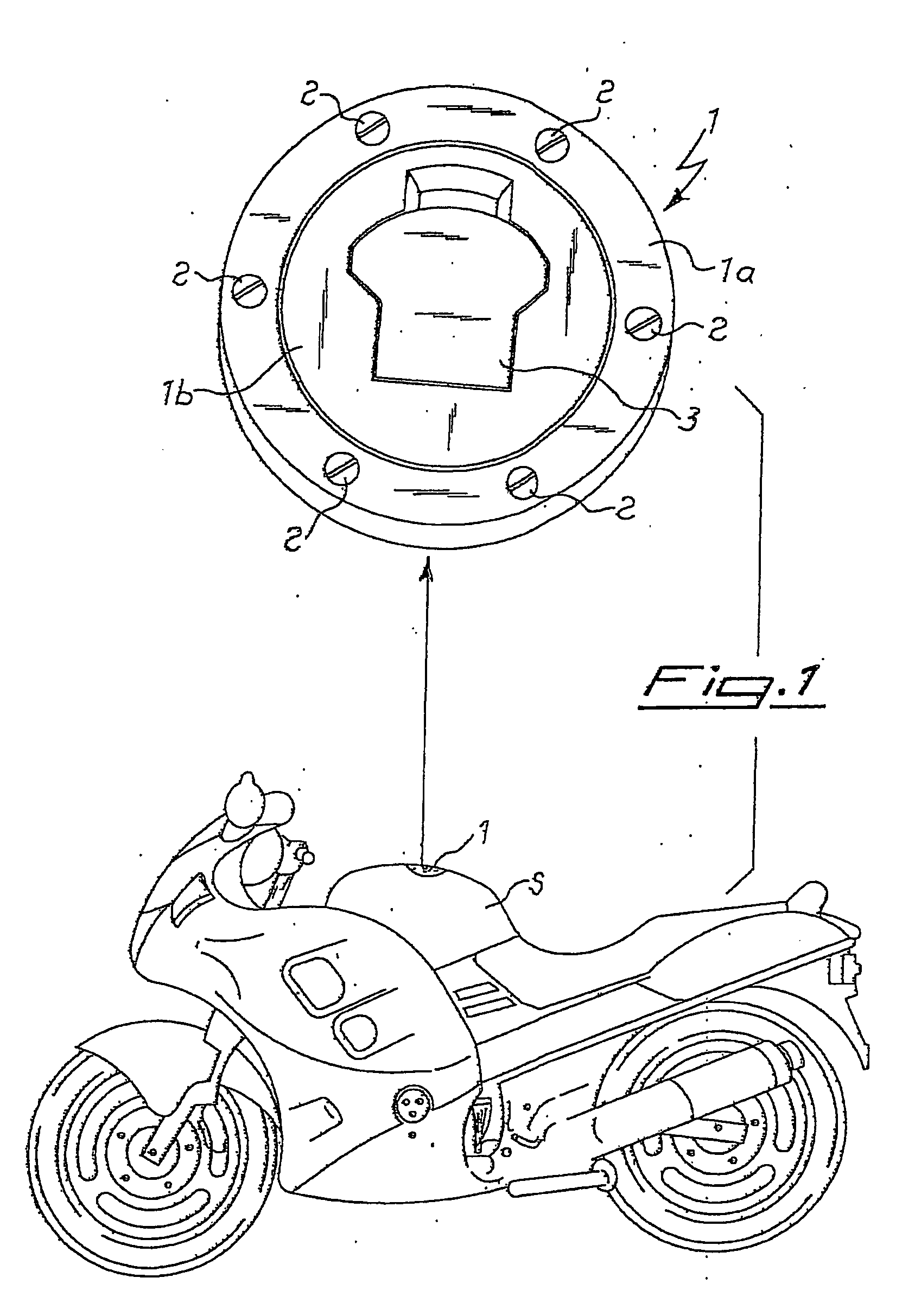

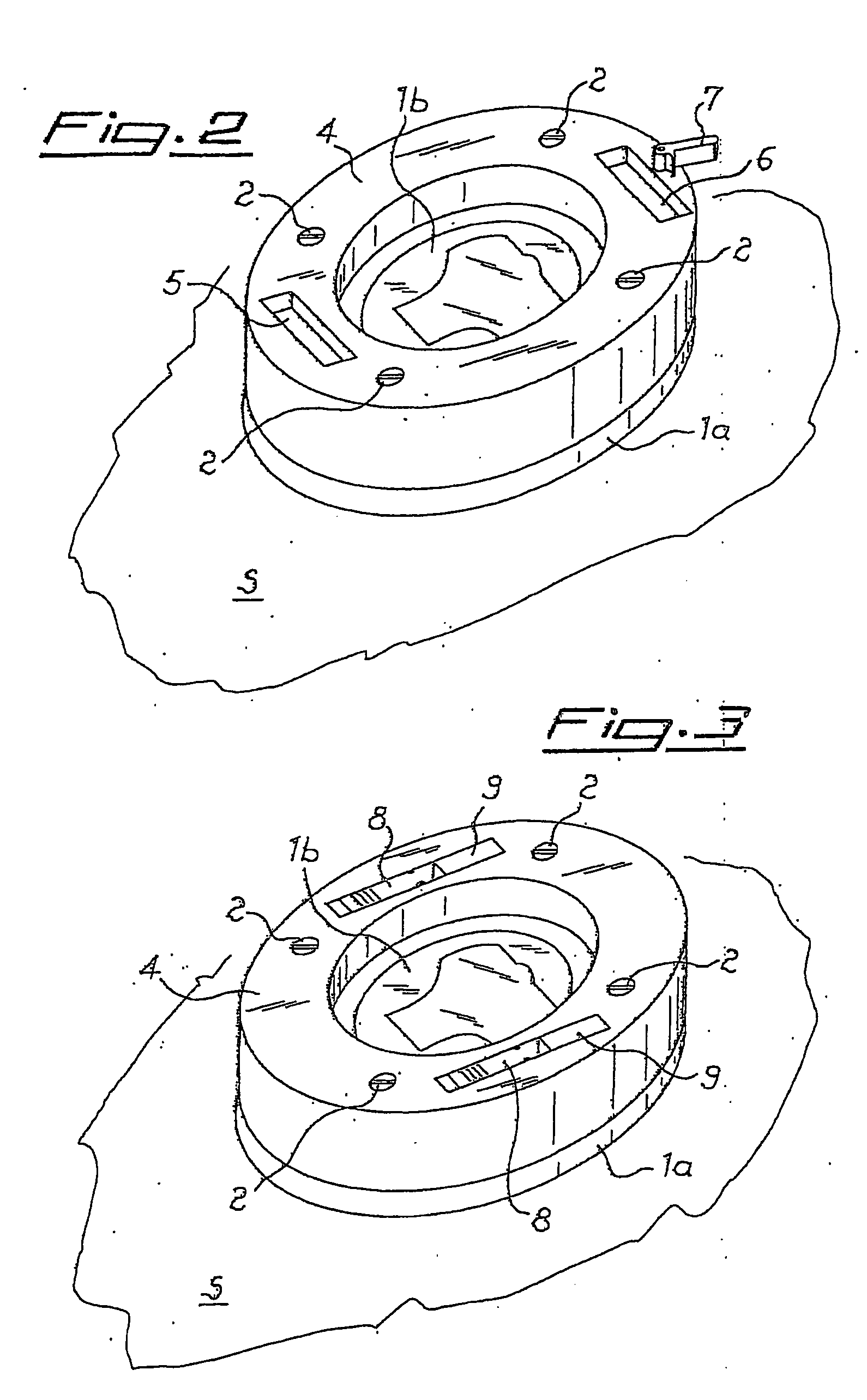

Multipurpose support system for motorcycle equipment

InactiveUS20060118585A1Effective coverageImprove stabilityLuggage carriersFuel tanksSupporting systemFuel tank

The invention relates to a universal support device (4; 12; 27) for motorcycle accessories characterised by being directly fixed to the cap (1) of the motorcycle fuel tank. The support can be made by a ring nut, supports or pins, fixed to the outer crown (1a) of the cap, and fitted with anchorage means for various objects such as, for example, bags, rucksacks, suitcases, trolleys, gadgets, helmet holder sacks, containers of various kinds, motorcycle cover tarpaulins, electronic appliances, cellular telephones, video cameras, satellite navigators, anti-theft systems, etc.

Owner:OGNISSNTI STEFANO

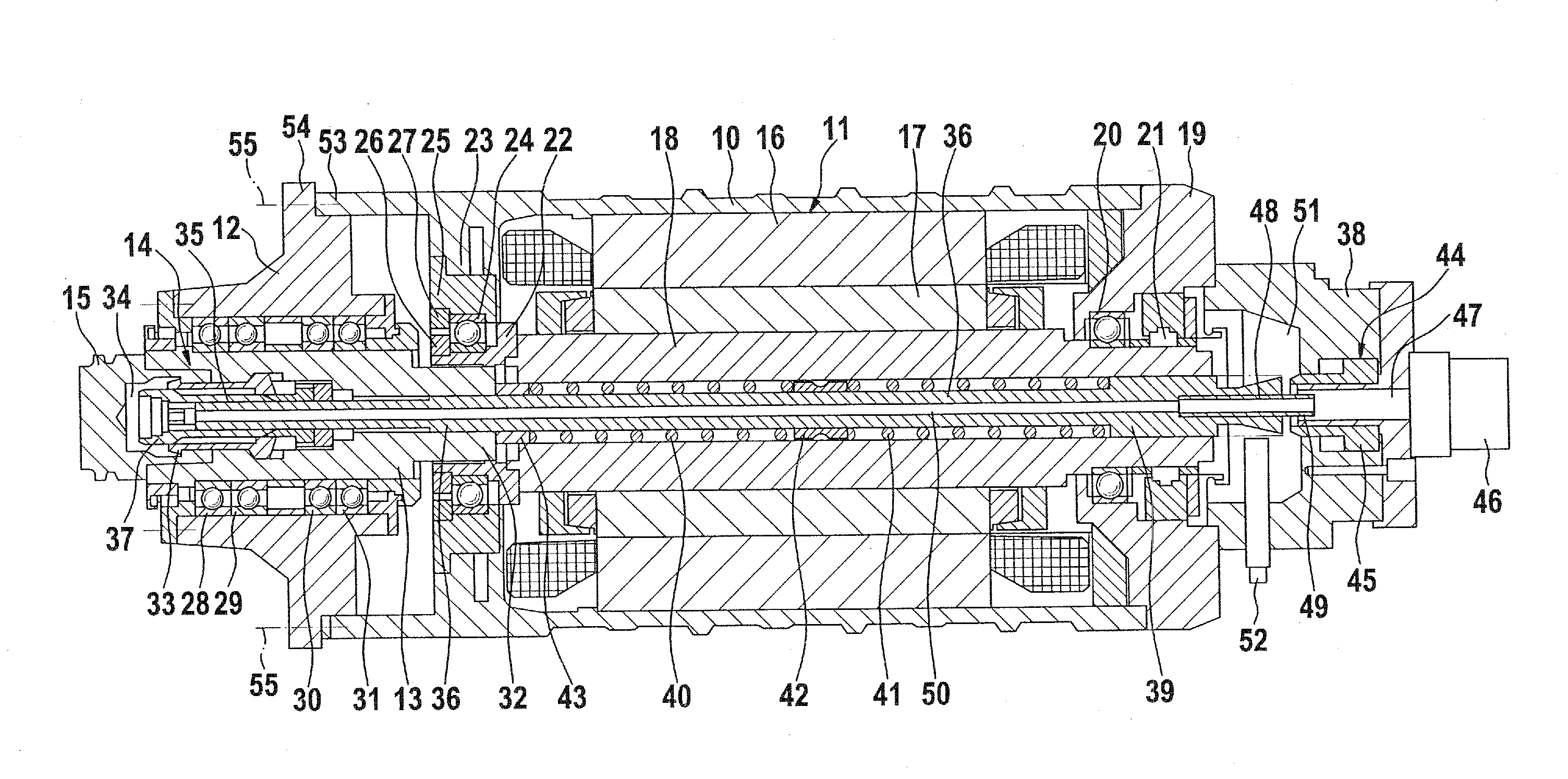

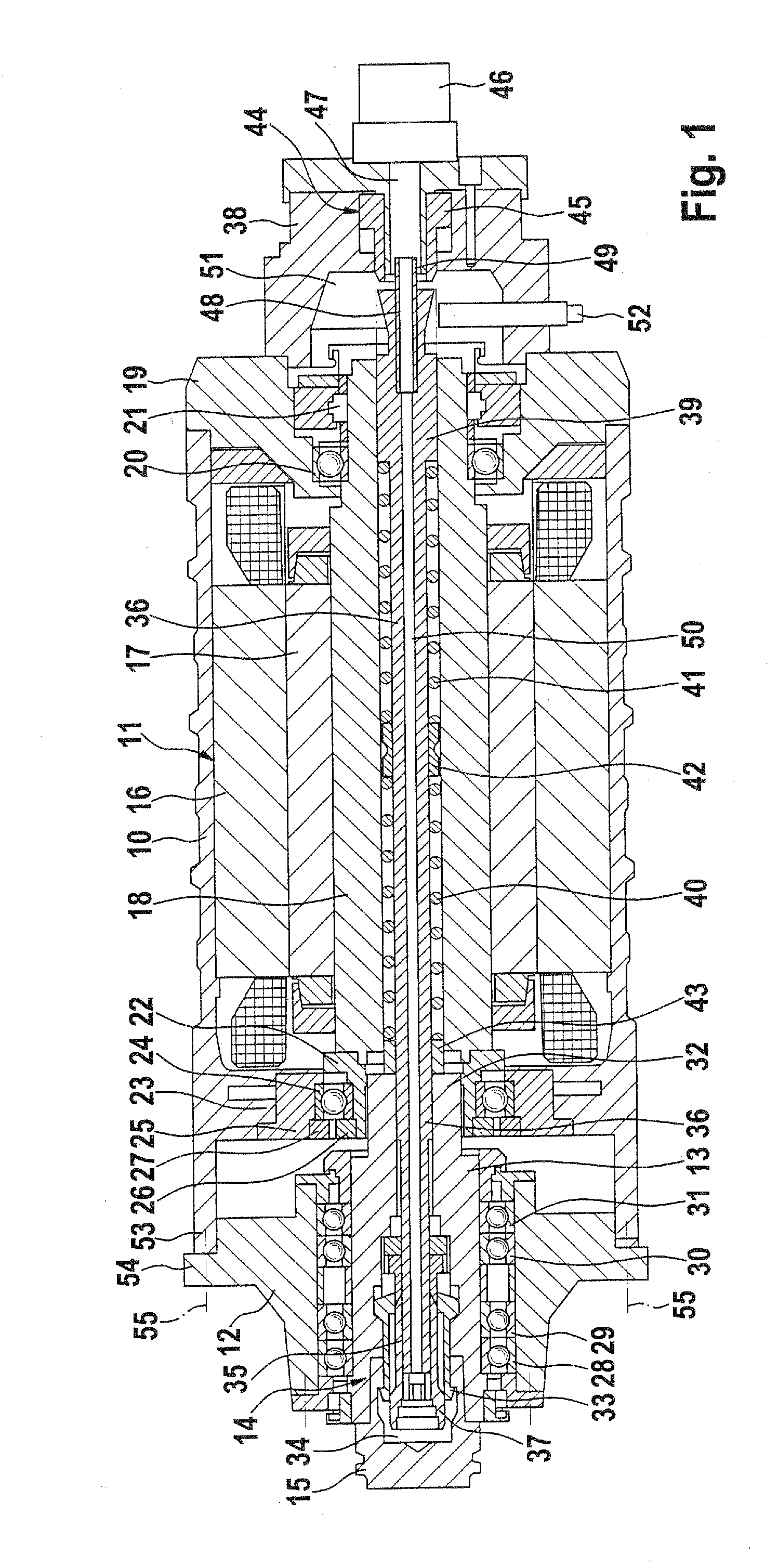

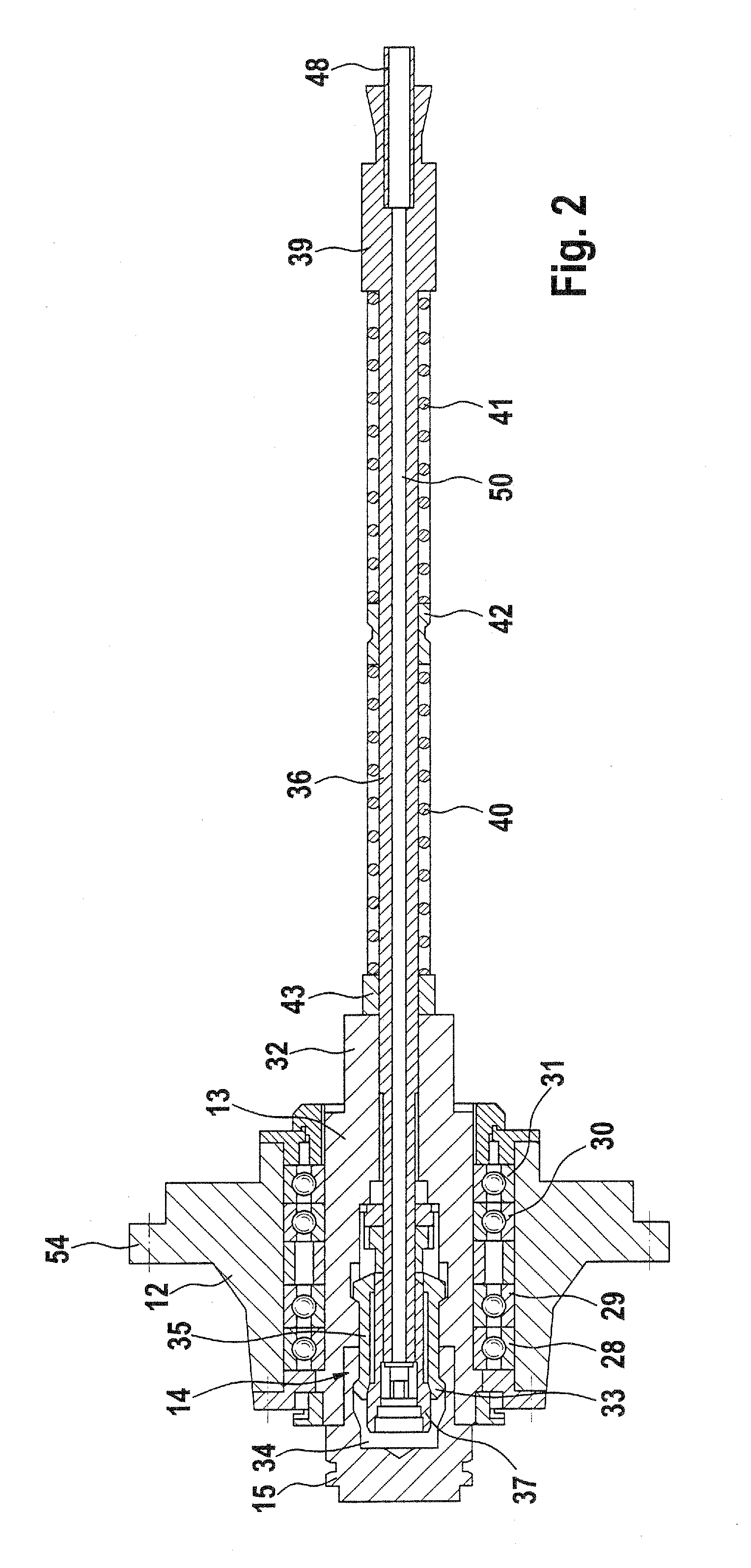

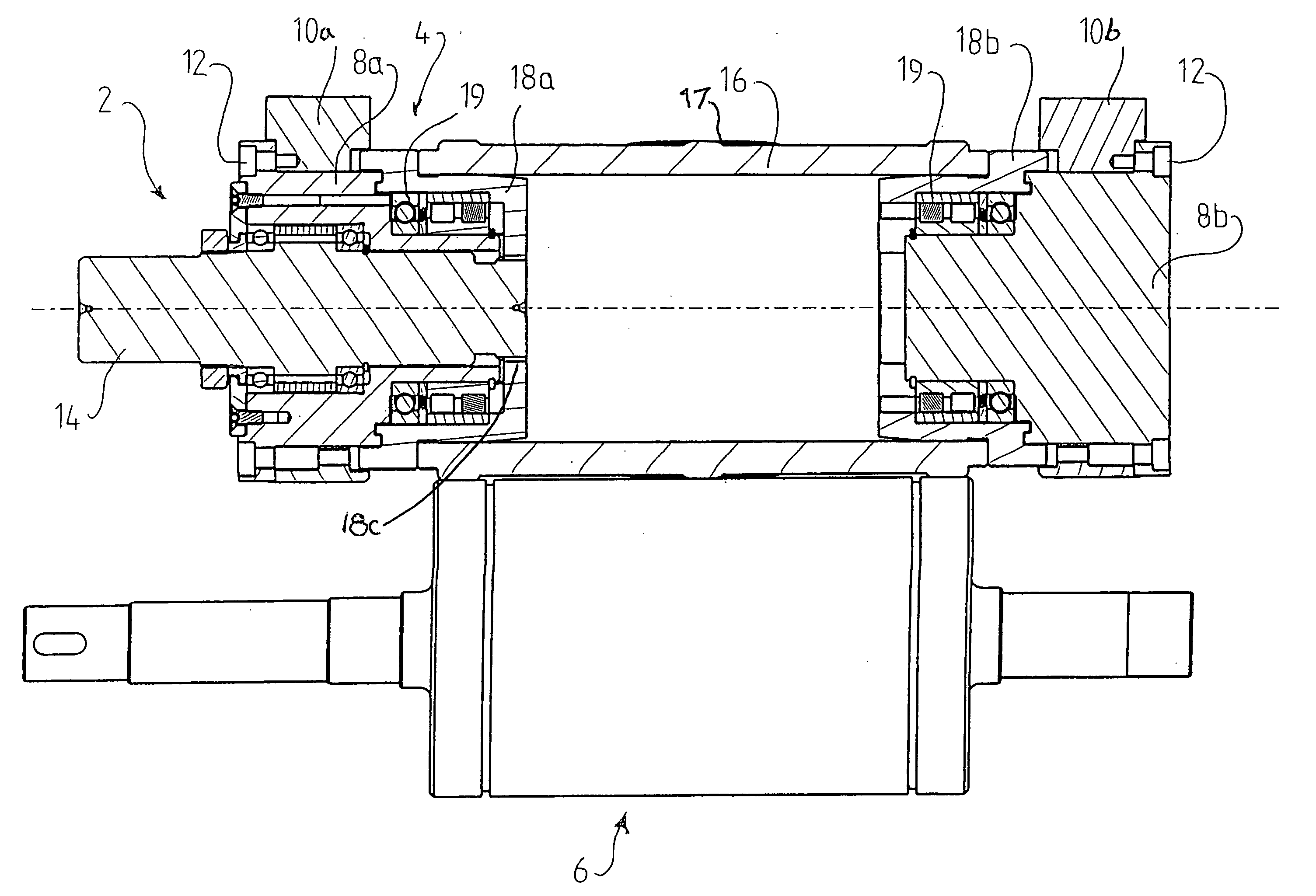

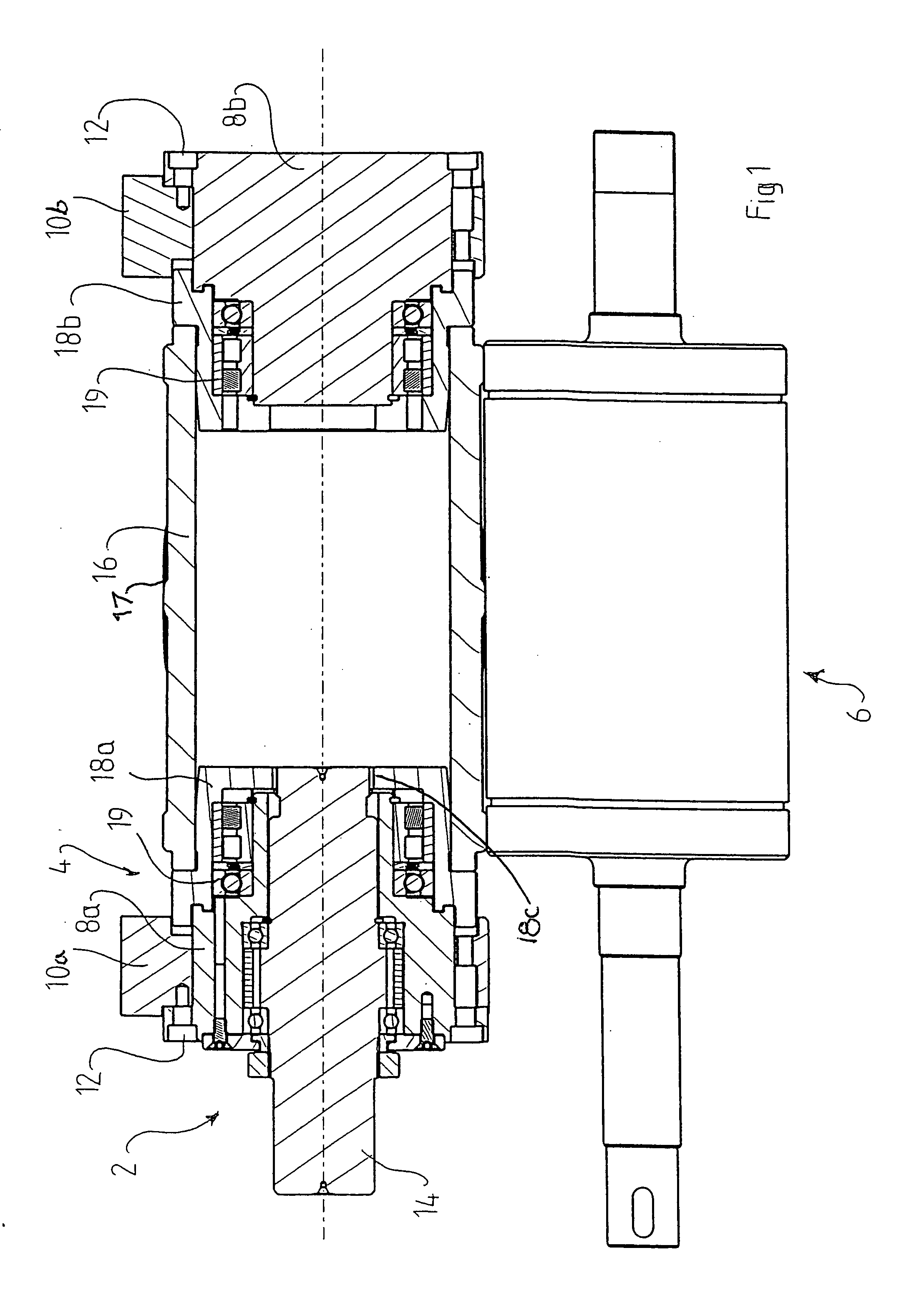

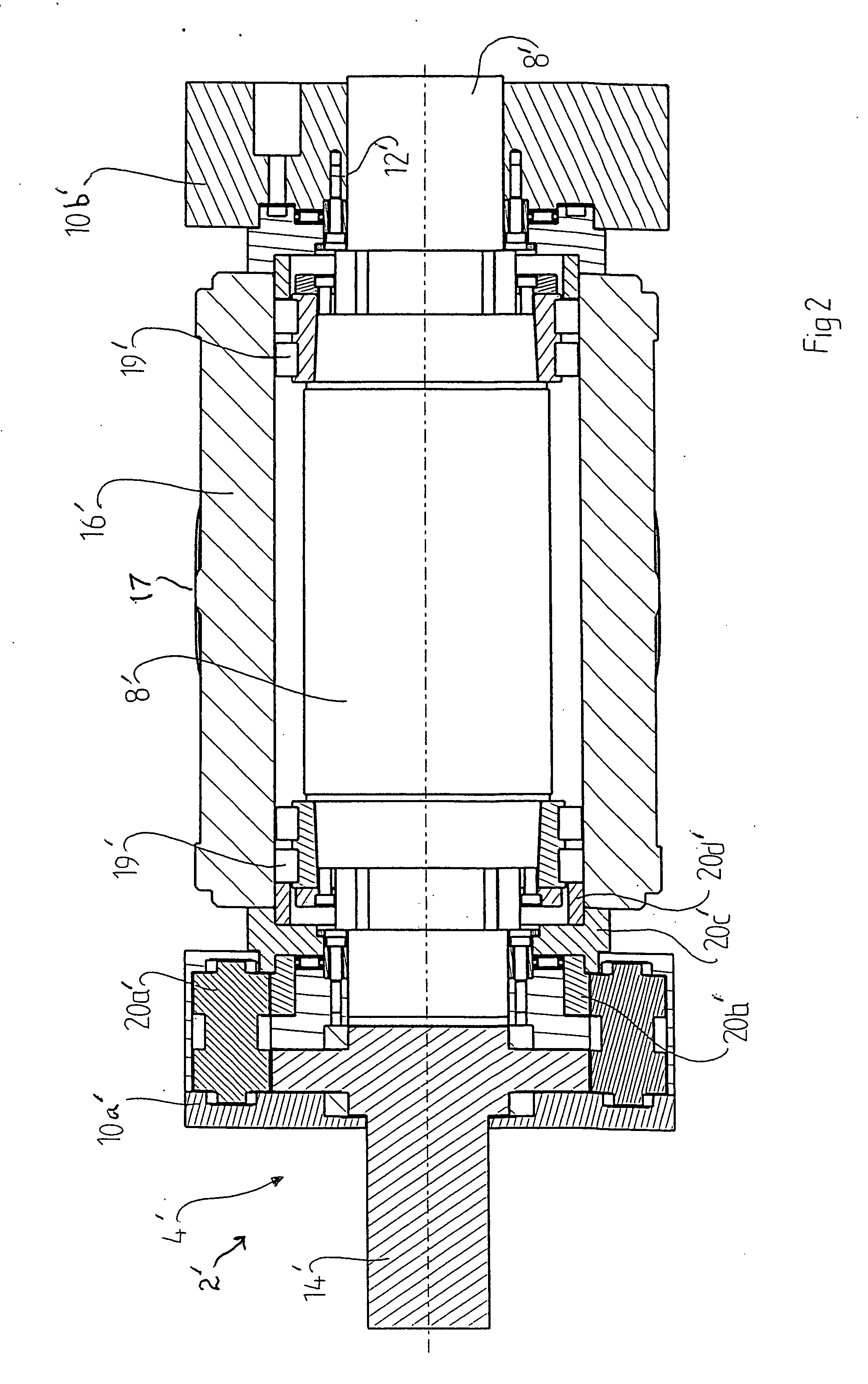

Motor spindle as a rotary drive for tools on a machine tool

InactiveUS20080080943A1Simplify the disassembly processThe process is simple and fastAttachable milling devicesMilling machinesEngineeringMotor shaft

A motor spindle for causing rotation of tools on a machine tool has a spindle motor with a motor shaft and a spindle shaft driven by the motor shaft and having a tool clamping means. From the tool clamping means there extends through the spindle shaft and the motor shaft an axially sliding draw rod for clamping tools or tool receiving means. The motor shaft is supported in a rotatable fashion, independently of the spindle shaft in a motor housing and the spindle shaft is supported independently from the motor shaft in a spindle housing, which is attached to the motor housing in a detachable manner. The spindle shaft is coupled in an interlocking manner in the direction of rotation with the motor shaft but is able to freely slide in it. The spindle housing constitutes a single structural unit with the tool clamping means and its draw rod, such draw rod being accommodated in the motor shaft for free sliding motion with the result that the entire structural unit can be removed without the spindle motor or its bearing means being impaired in any way or having to be detached.

Owner:MASCHFAB BERTHOLD HERMLE

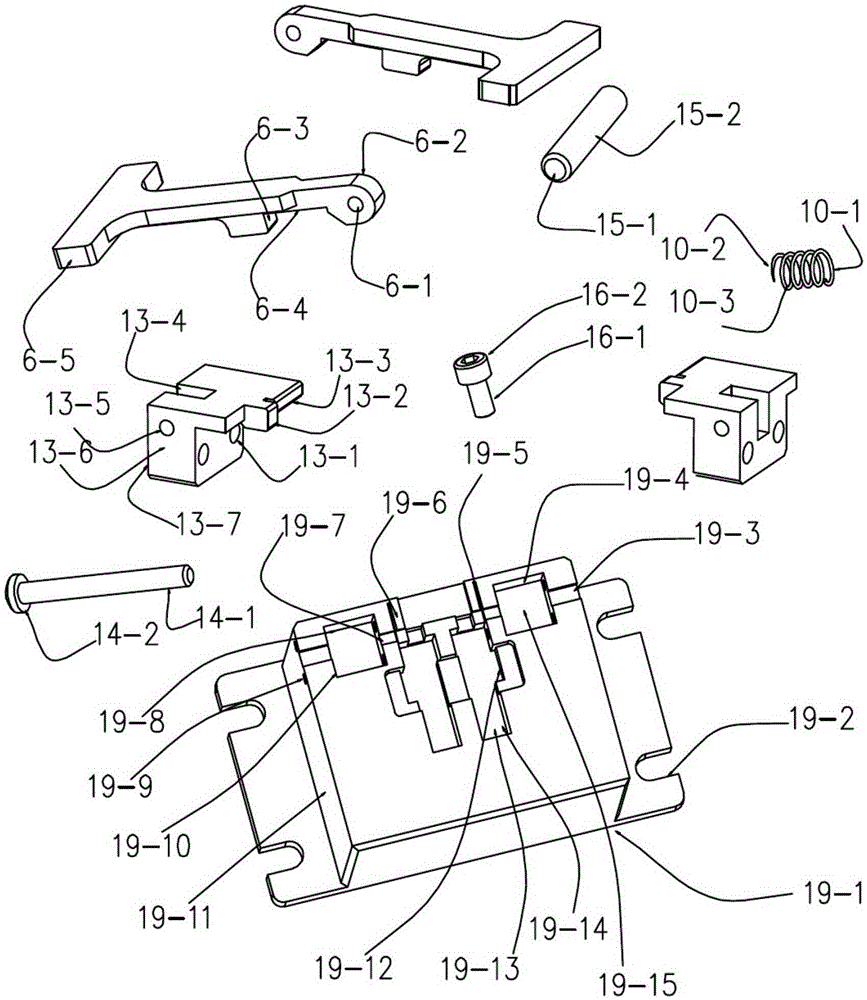

New energy vehicle and battery locking device thereof

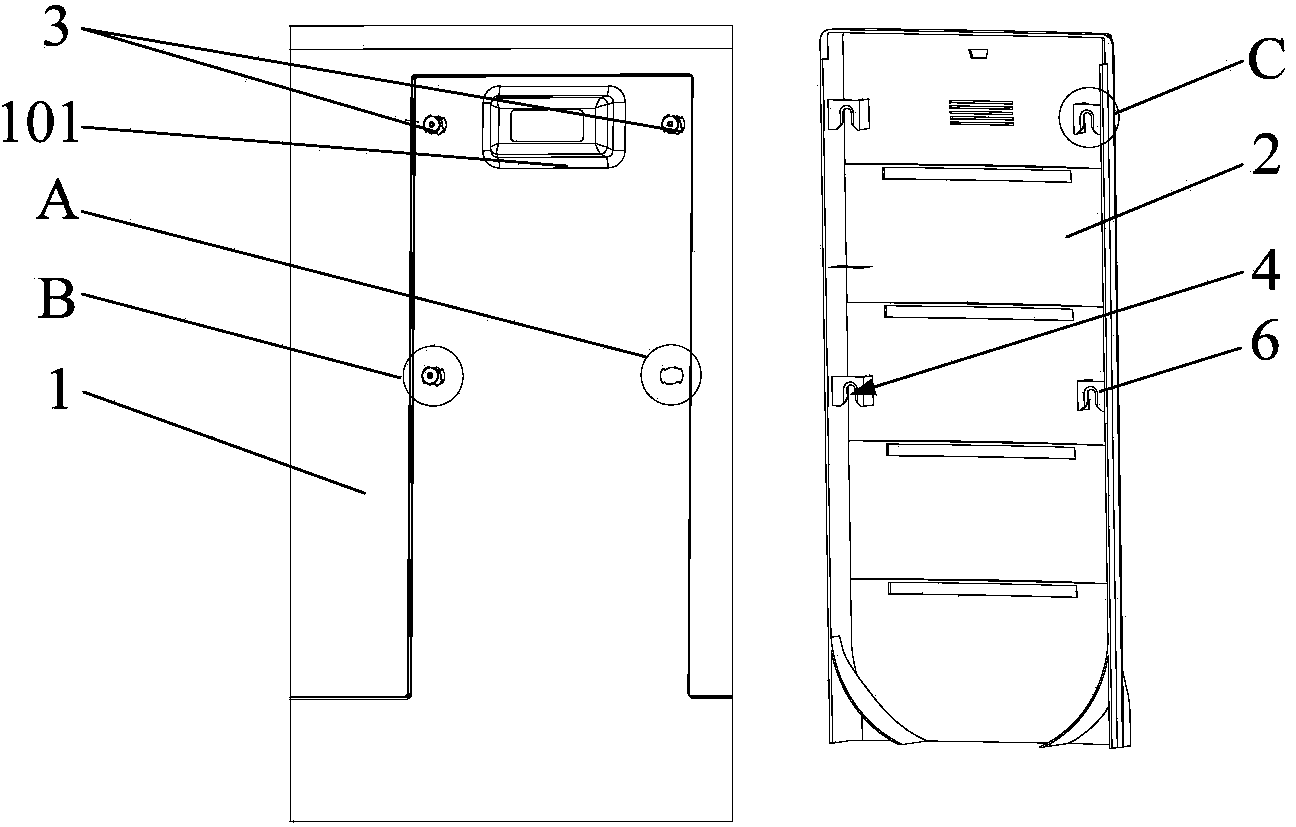

ActiveUS20150030899A1Shorten the timeQuick assemblyCell component detailsBatteriesNew energyAlternative fuel vehicle

A battery locking device for a new energy vehicle including: a battery compartment fit for a battery, the battery compartment being provided with a battery inlet; and a battery clamping device provided on the battery compartment and controlled by a linkage mechanism. Since the battery clamping device is controlled by the linkage mechanism, during the mounting or removing of the battery, the battery can be integrally clamped or released by merely operating an operating end of the linkage mechanism. Compared with the prior art in which the battery is fixed through bolts, the battery can be integrally clamped or released by the battery locking device through a single operation, which greatly simplifies the disassembling or assembling process of the battery and reduces the time required for replacing the battery. A new energy vehicle provided with the above battery locking device has the same advantages.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD HANGZHOU POWER SUPPLY CO +2

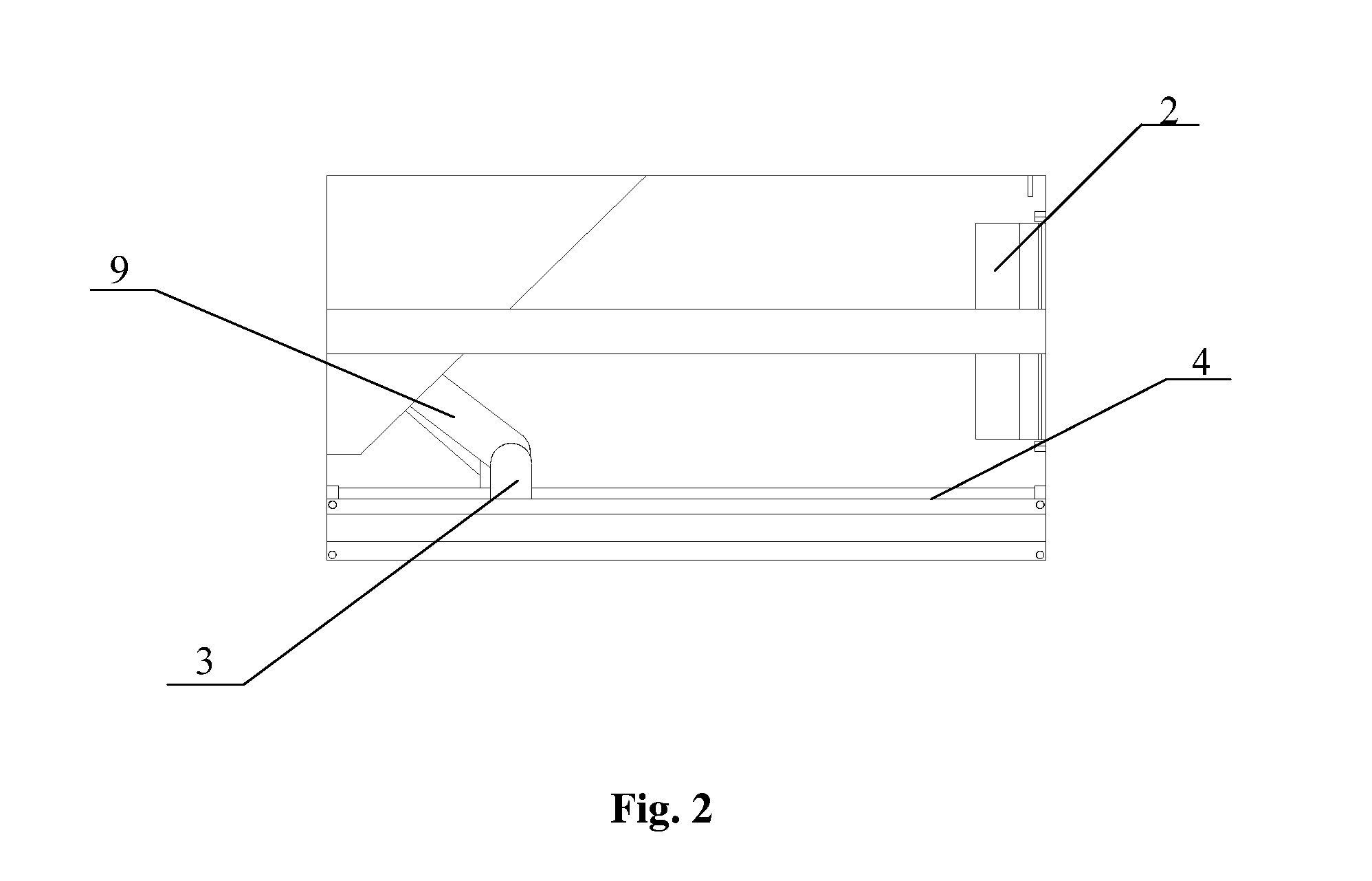

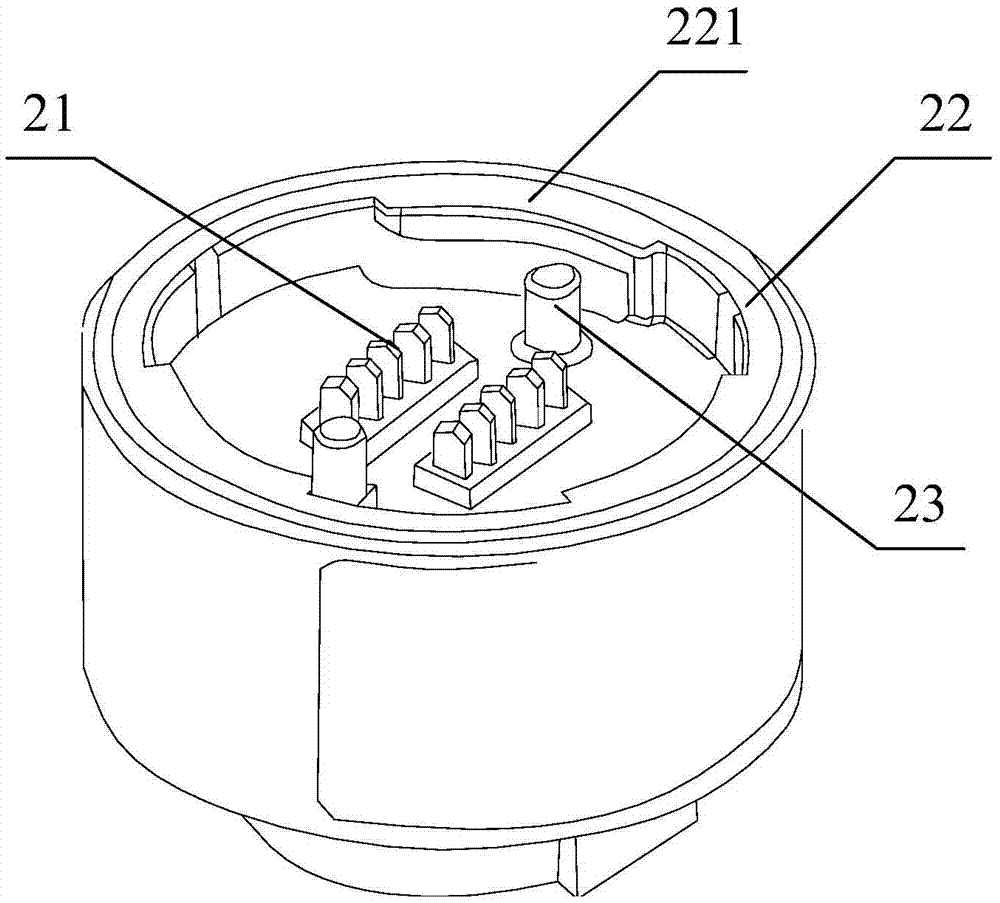

Axial gap type motor

InactiveUS7821169B2Increase productionFurther miniaturizationMagnetic circuit stationary partsSuperconductor devicesEngineeringMagnetic flux

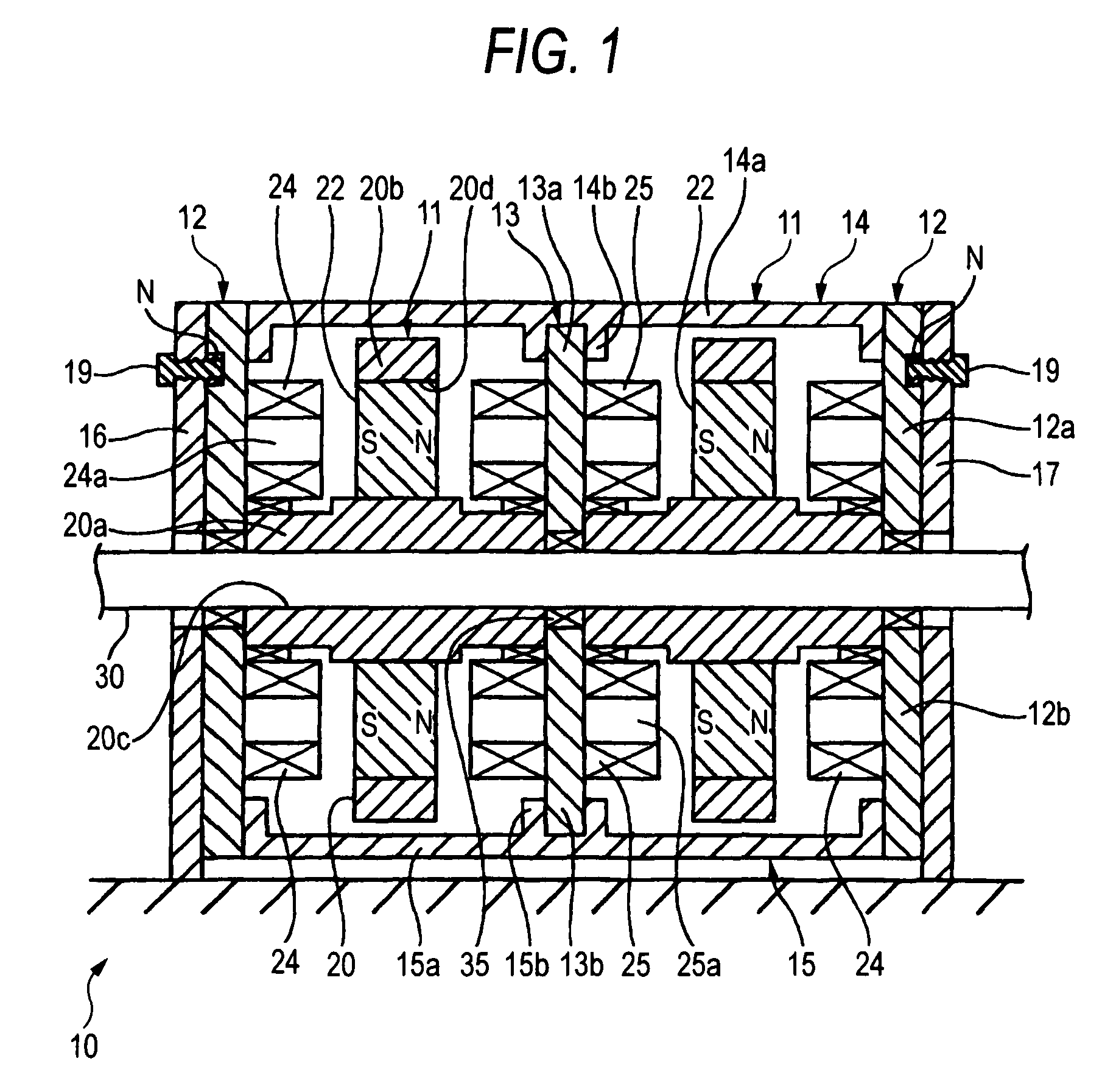

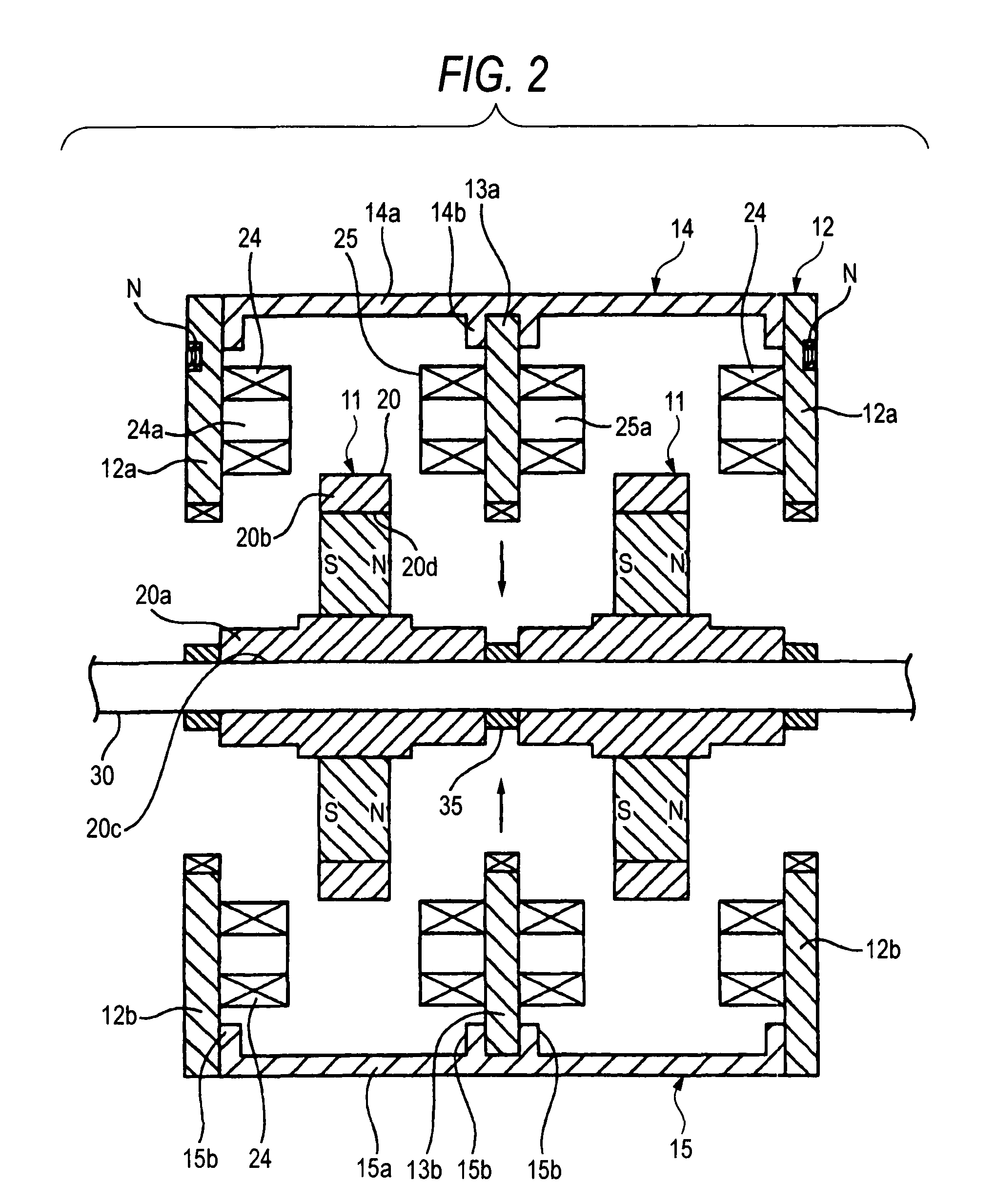

A series coupling synchronous axial gap type motor where rotors and stators are alternately stacked with required air gaps in the axial direction of a rotary shaft as a main shaft, is provided. The rotors are fixed to the rotary shaft, and the stators are disposed such that they cannot be interlocked with the rotary shaft. A plurality of rotary field bodies are attached to each of the rotor around the axis, and a plurality of armature coils are made to face the rotary field bodies with an air gap therefrom and are attached to each of the stators around the axis such that their magnetic-flux directions are directed toward the axial direction. The armature coils have an empty core, or a core member composed of a magnetic body attached thereto.

Owner:SUMITOMO ELECTRIC IND LTD +1

Butt-joint location device for mechanical part welding

InactiveCN106670717ADoes not affect normal weldingPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingButt joint

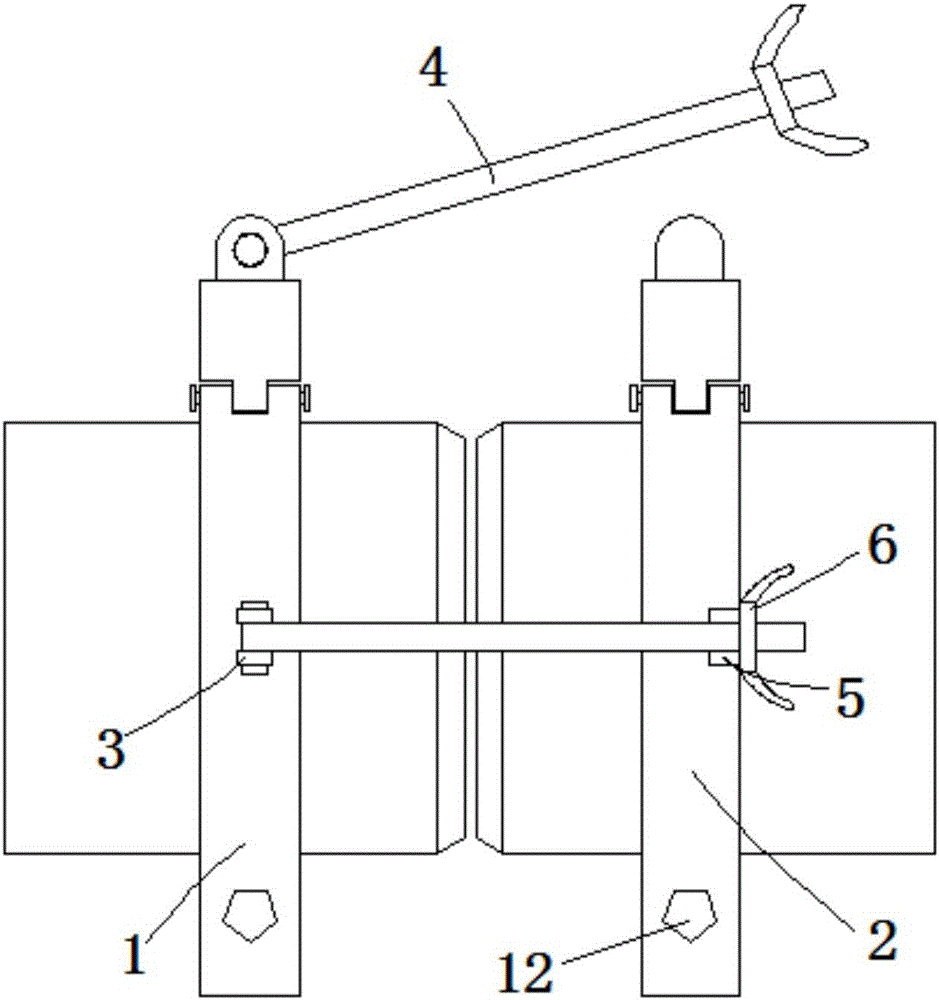

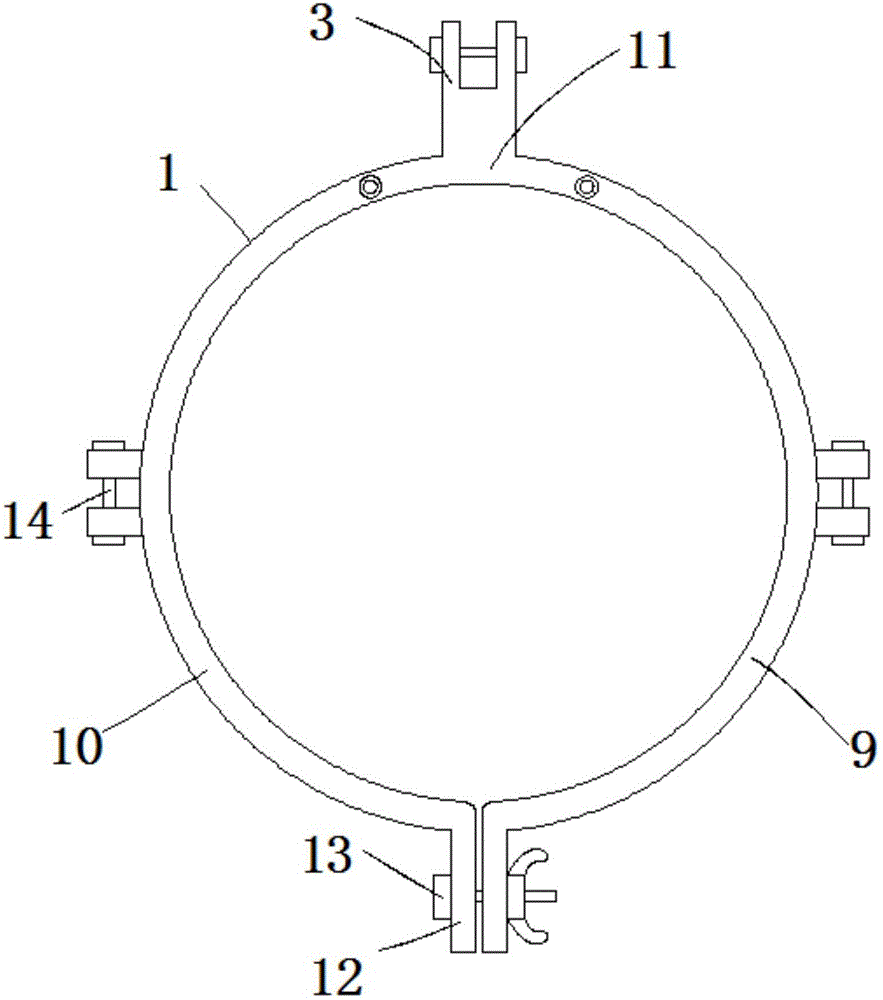

The invention relates to the technical field of location devices, and particularly relates to a butt-joint location device for mechanical part welding. The butt-joint location device for mechanical part welding comprises a first hoop and a second hoop, wherein the first hoop and the second hoop are both connected to the surface of a pipe fitting to be welded in a sleeving manner through fastening bolts; a U-shaped fastener is fixedly connected to the outer wall of the first hoop; a rotary shaft is fixedly connected to the U-shaped fastener; a thread rod is rotationally arranged on the rotary shaft; a clamping block is vertically arranged on the outer wall of the second hoop; a U-shaped groove is formed in the clamping block; one end away from the U-shaped fastener, of the thread rod, is inserted in the U-shaped groove; the outer wall of the thread rod is in thread connection with a fastening nut; and the thread rod is in fastening connection with the clamping block through the fastening nut. The butt-joint location device for mechanical part welding is quite convenient to use during butt-joint location for the pipe fitting, and has the advantages of being accurate and rapid in location; and meanwhile, disassembly-assembly processes are simple and convenient to operate, and free from influence on the normal welding of workers.

Owner:吴涛

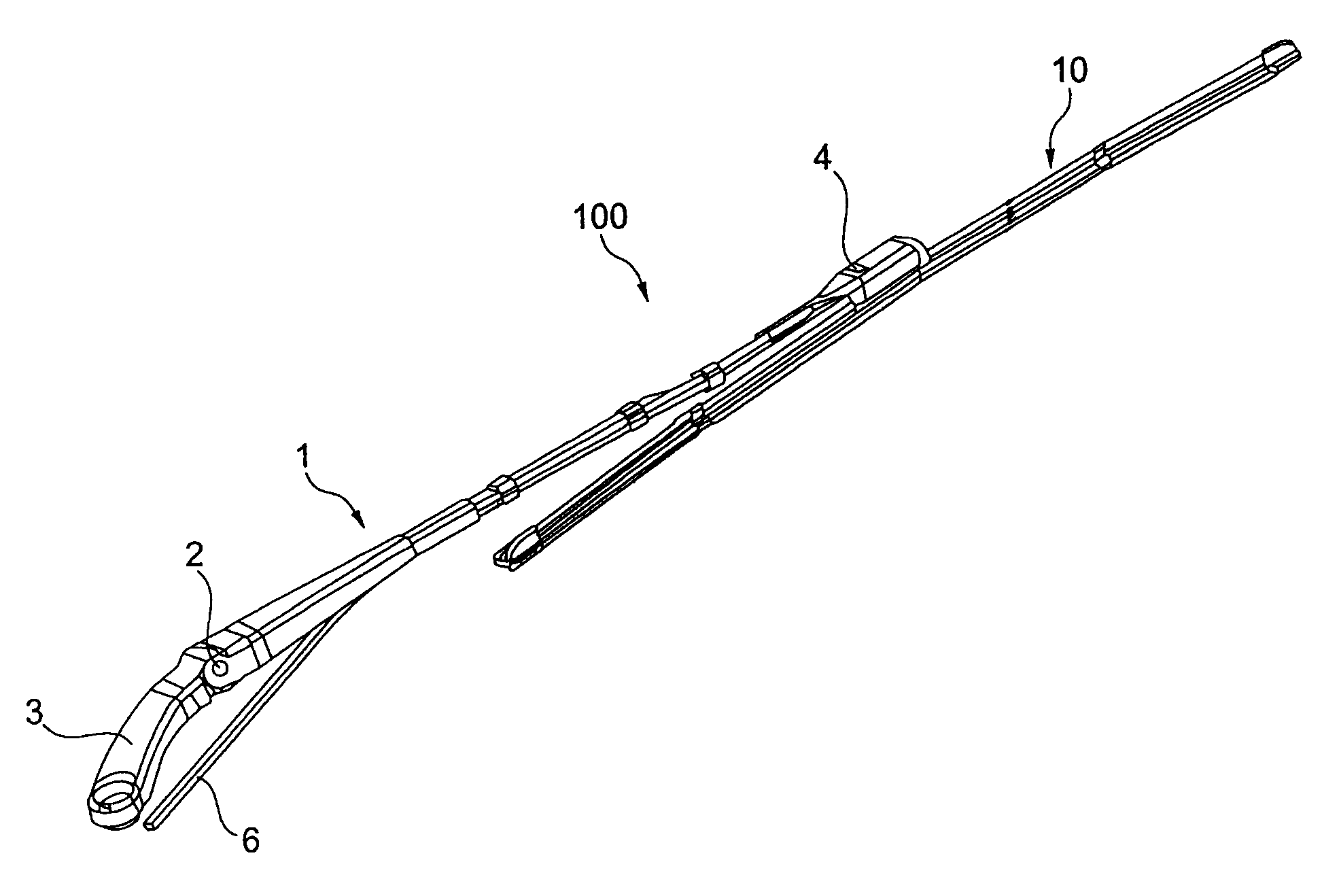

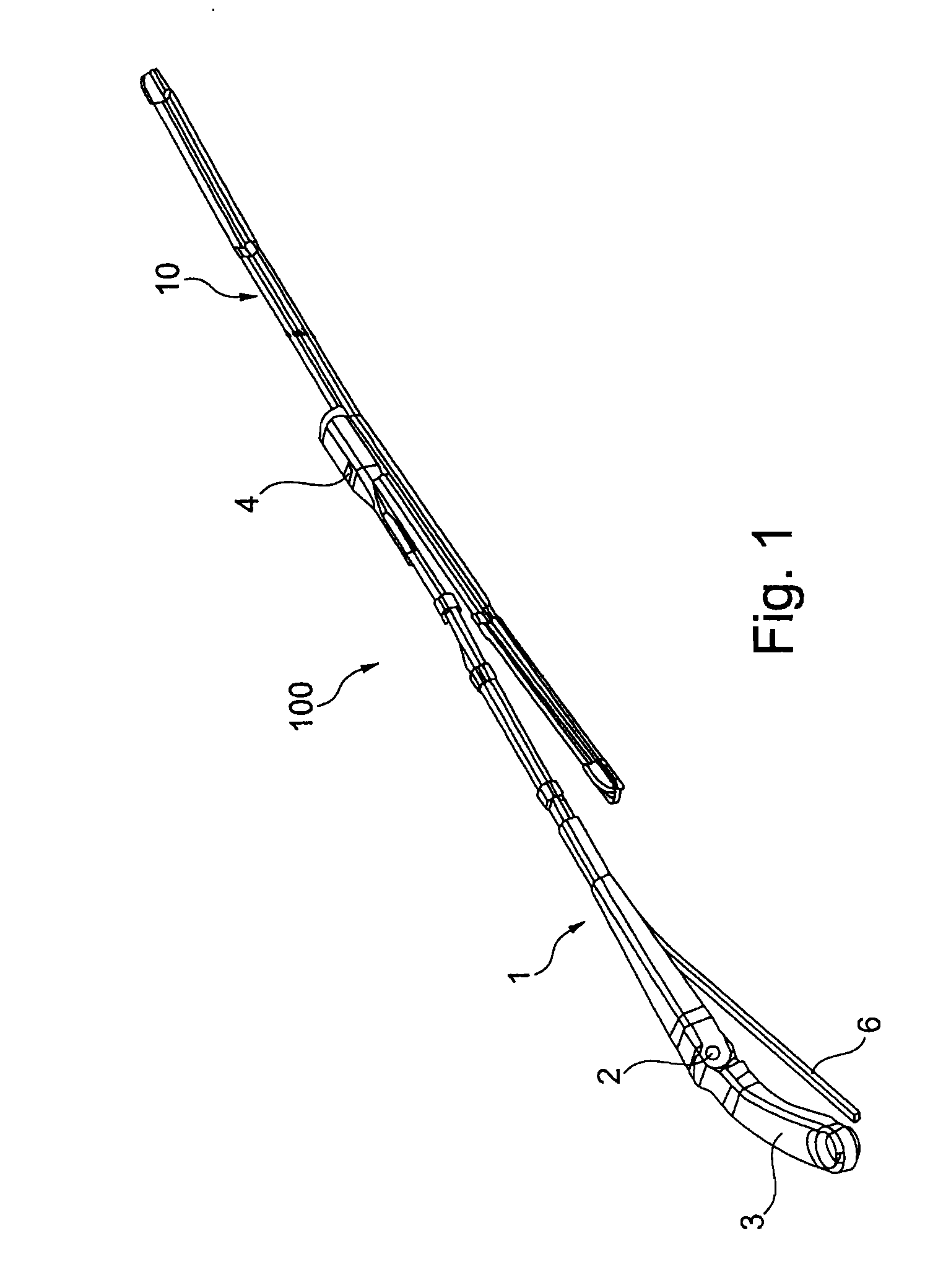

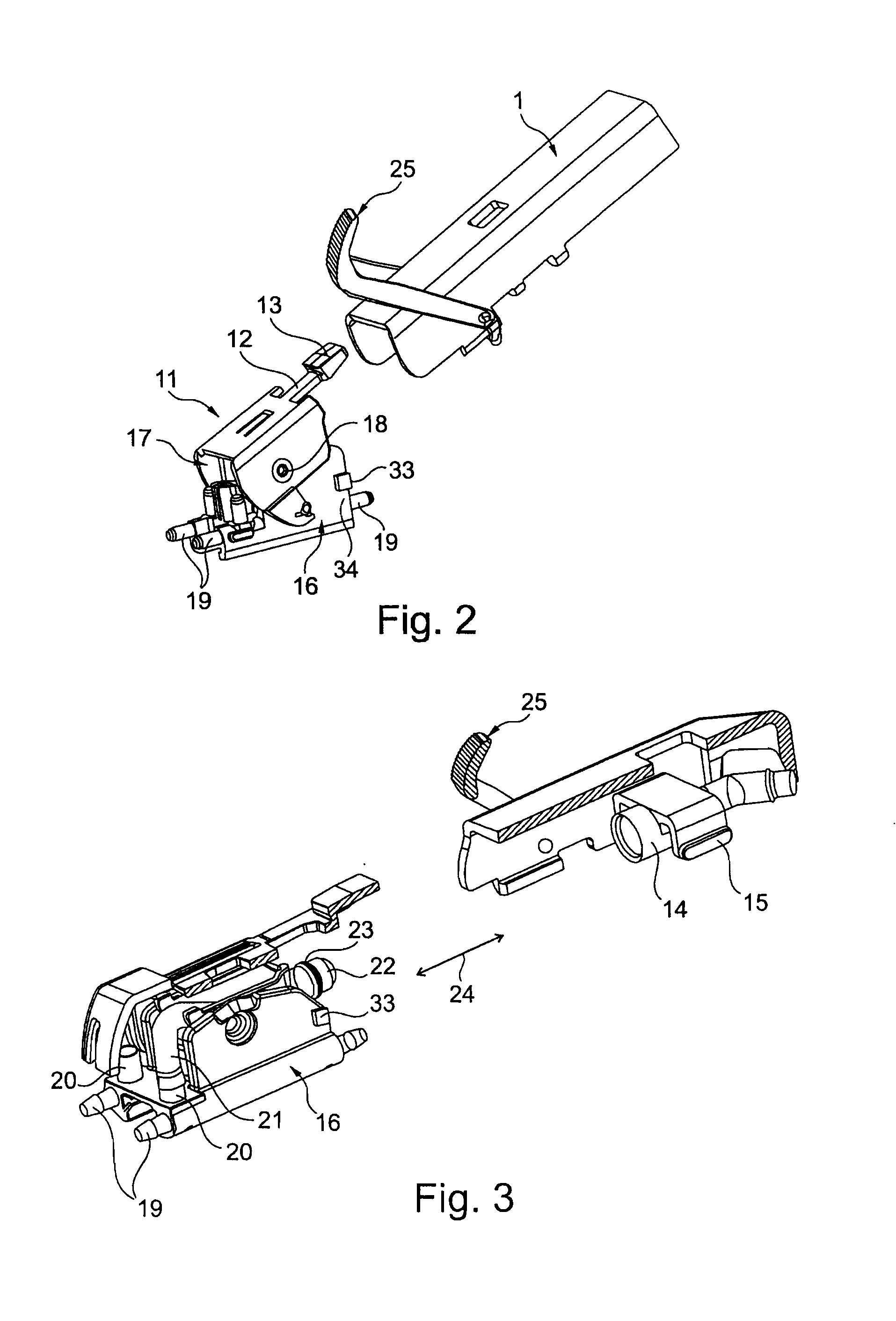

Wiper Blade for Cleaning Windows of Motor Vehicles and Wiper Arm

InactiveUS20120167326A1Simplify the disassembly processEasy to installWindow cleanersVehicle cleaningDetentEngineering

A wiper blade for cleaning windows of motor vehicles, with an adapter for fastening the wiper blade on a wiper arm, wherein the adapter consists of an adapter element on the wiper arm side and of an adapter element on the wiper blade side, which are arranged so as to be pivotable with respect to each other, and wherein the adapter element on the wiper arm side is connected together with the wiper arm via a detent connection. Provision is made that the adapter has at least one support surface for an auxiliary element, which serves for separating the adapter from the wiper arm.

Owner:VALEO SYST DESSUYAGE

Cable pulling assembly having a cable connector and a pulling device

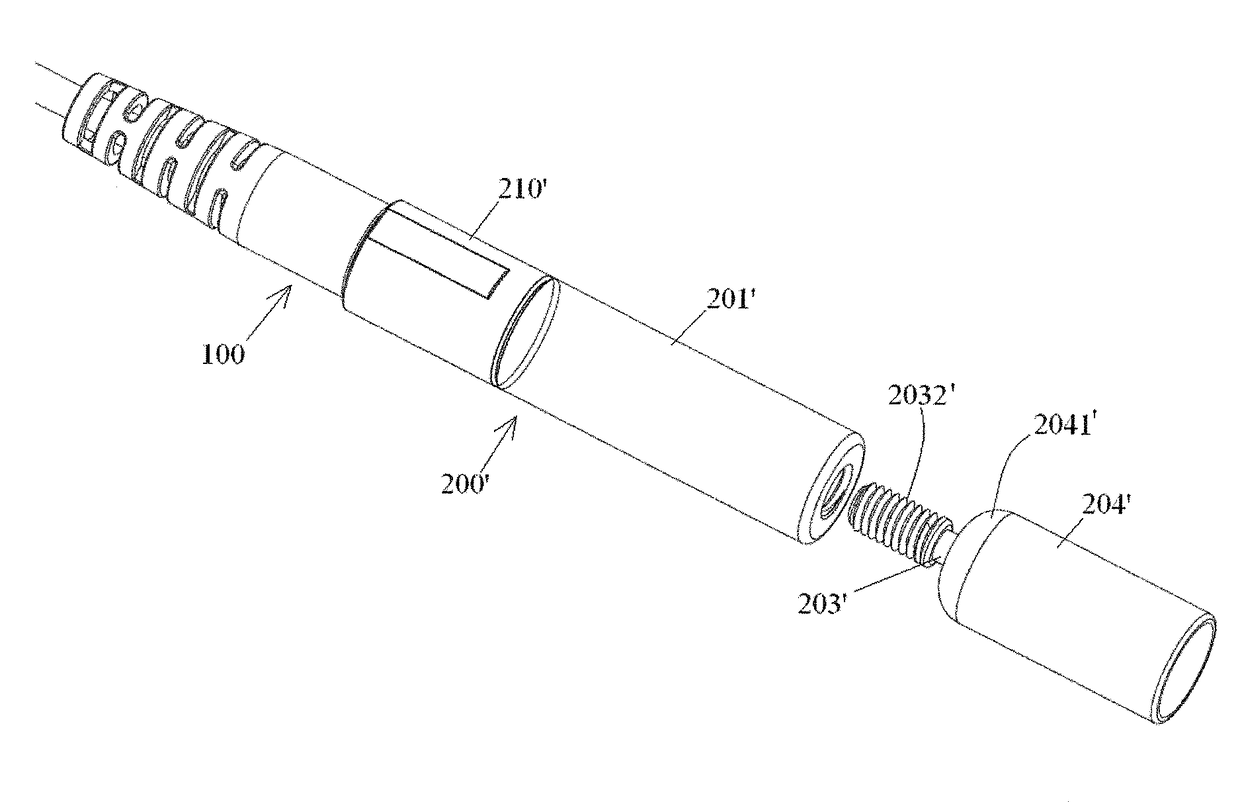

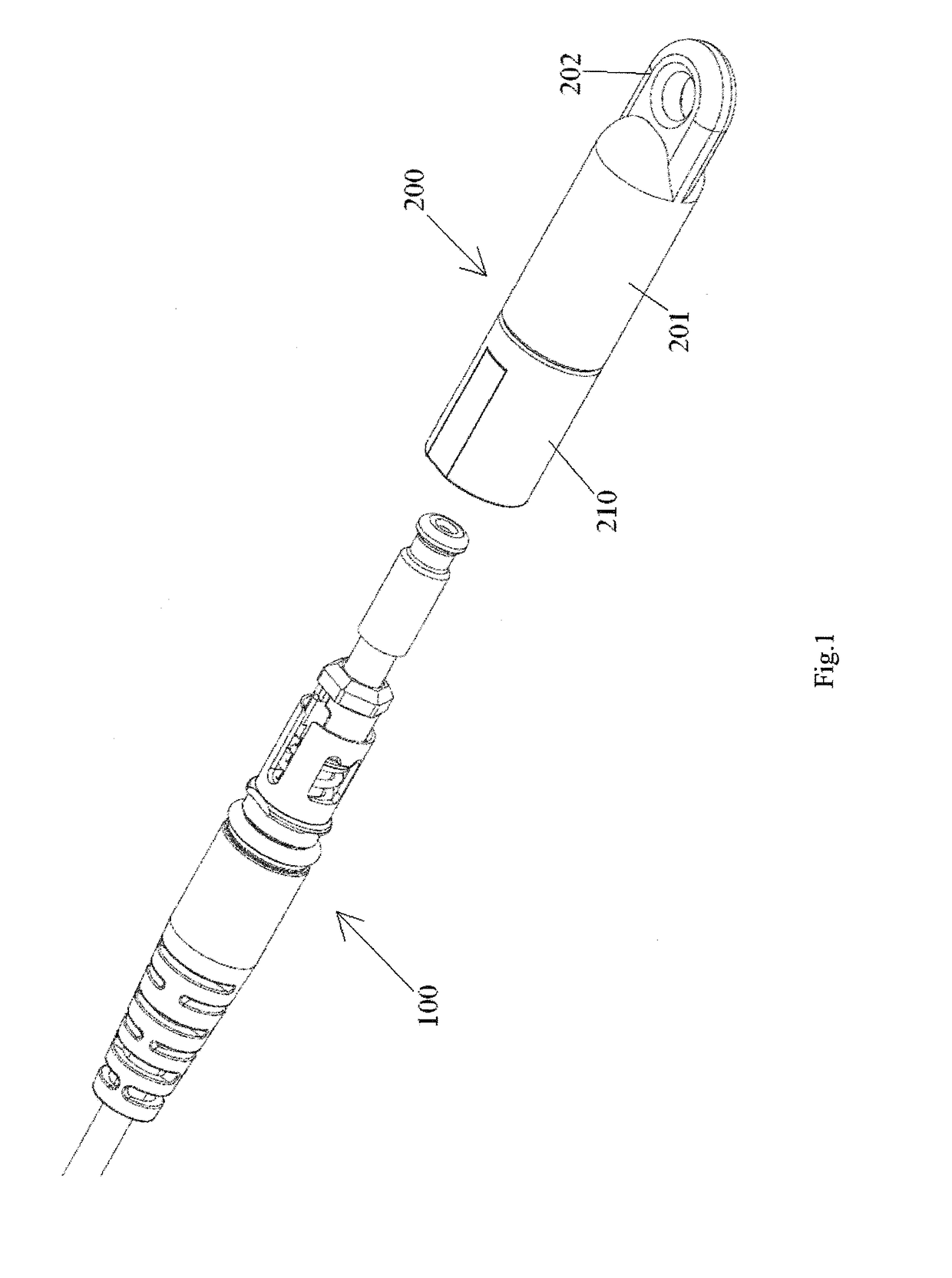

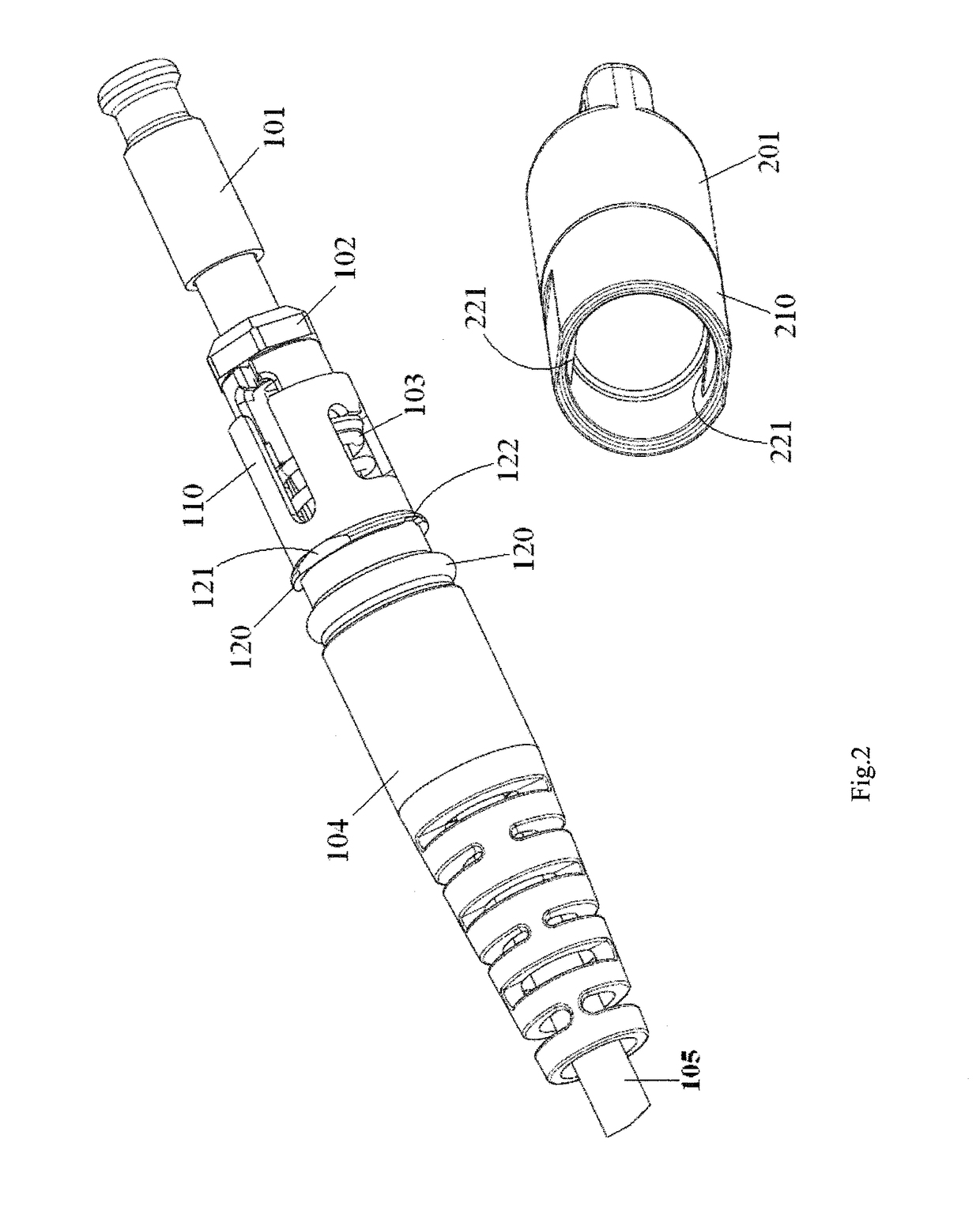

ActiveUS10018797B2Easy to assembleSimplify the disassembly processCoupling light guidesFibre mechanical structuresEngineeringMechanical engineering

The present invention discloses a cable pulling assembly, comprising: a connector connected to an end of a cable; and a pulling device connected to a housing of the connector, wherein a first engagement portion is formed on an inner wall of the pulling device, a second engagement portion, adapted to be engaged with the first engagement portion, is formed on an outer wall of the housing of the connector, and when the pulling device is sleeved on the housing of the connector and when the first and second engagement portions are engaged with each other, the pulling device is connected to the housing of the connector. The pulling device can be simply and quickly assembled to and disassembled from the housing of the connector in the field.

Owner:COMMSCOPE TELECOMM (SHANGHAI) CO LTD

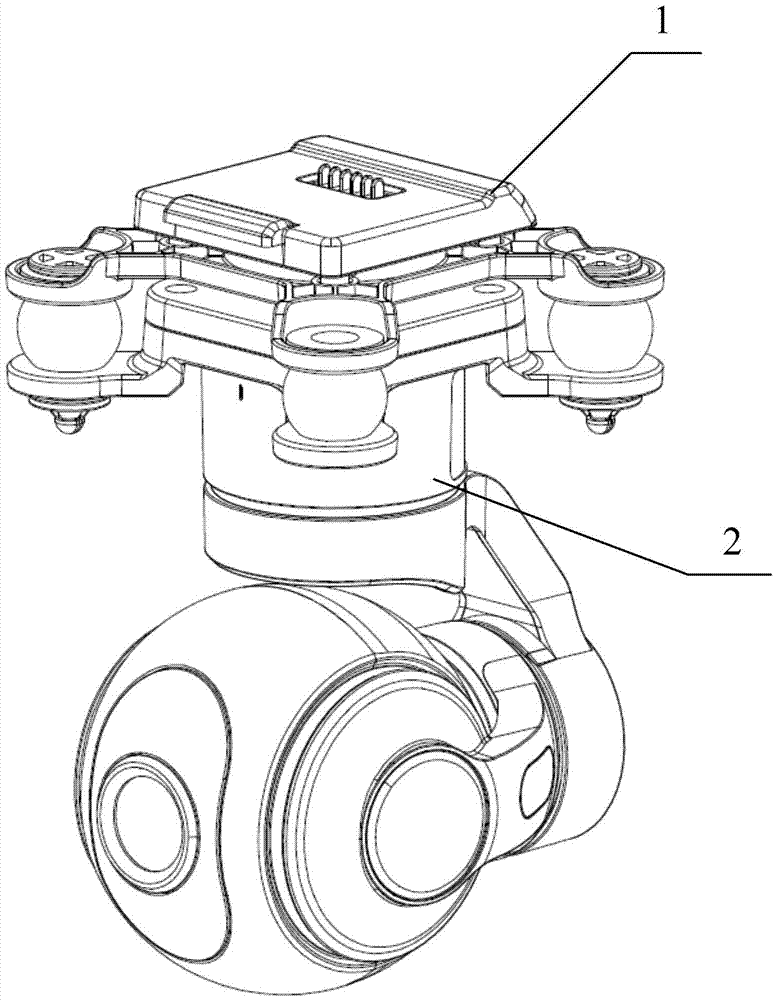

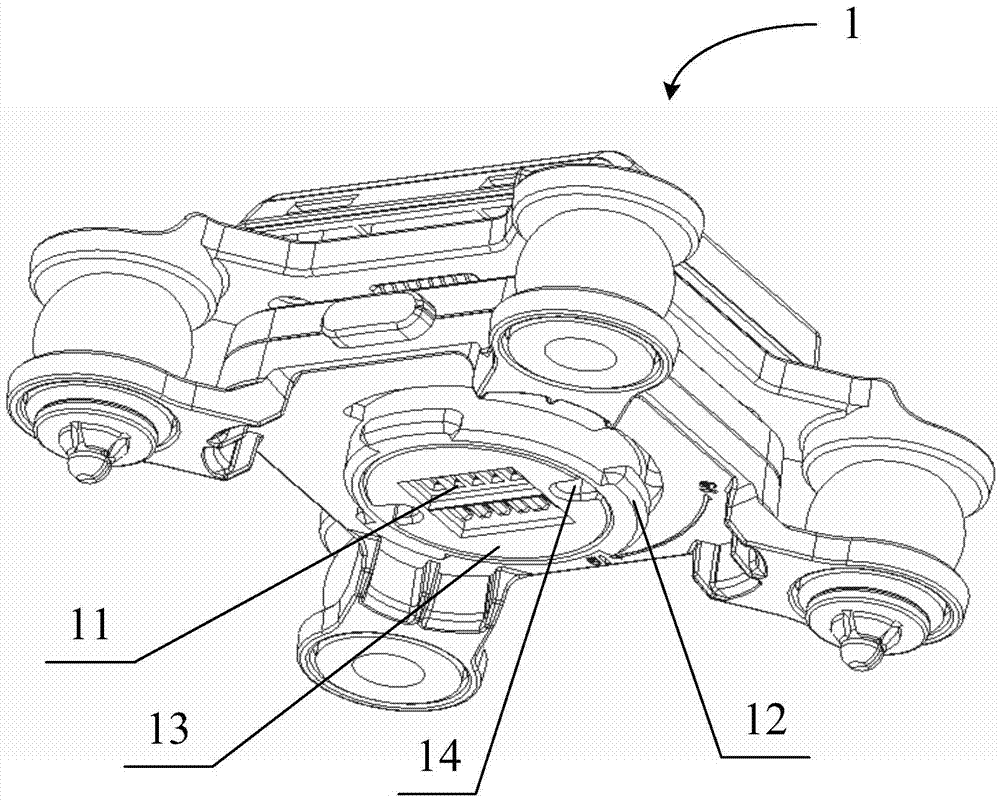

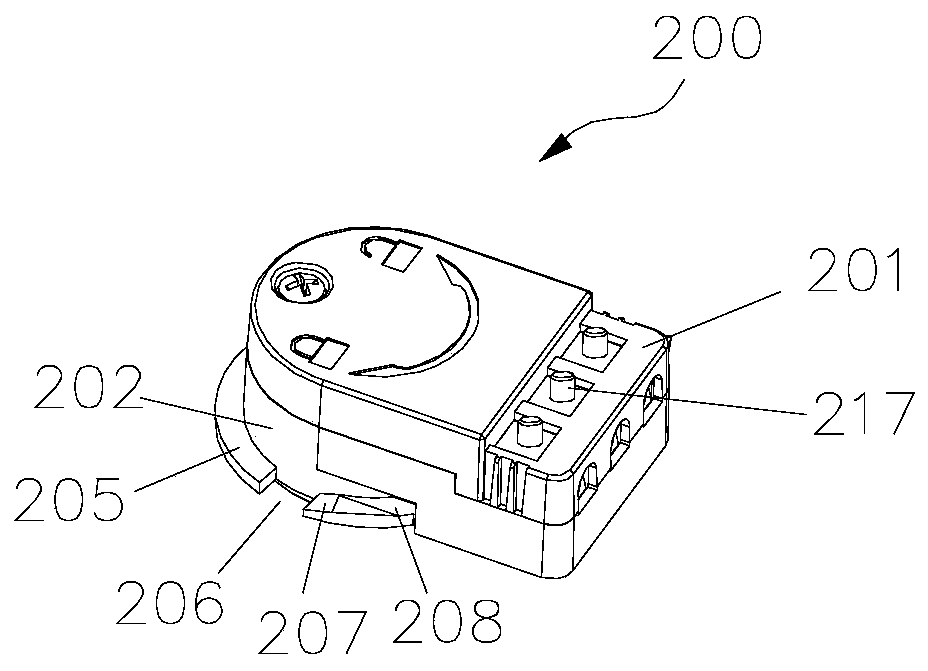

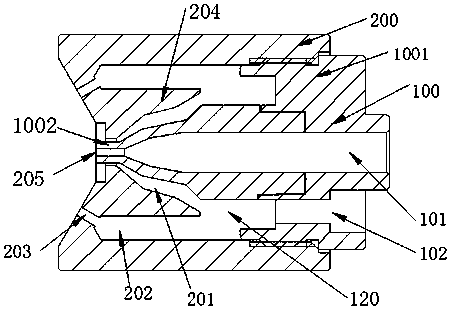

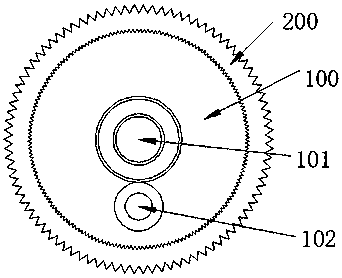

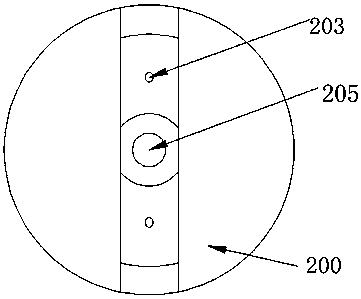

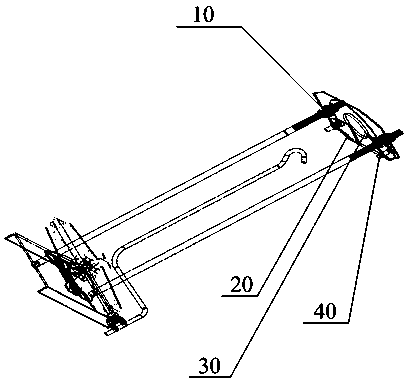

Quick disassembly and assembly structure of holder and unmanned aerial vehicle

ActiveCN105438491ASimplify the disassembly processFirmly assembledAircraft componentsAssembly structureTripod head

The invention discloses a quick disassembly and assembly structure of a holder and an unmanned aerial vehicle; and the quick disassembly and assembly structure of the holder is used for quick disassembly and assembly of the holder structure and the belonged unmanned aerial vehicle. The quick disassembly and assembly structure of the holder comprises a hanging part; when a first preset rotating angle formed by the holder structure corresponding to a vibration reducing connecting structure is failed, the hanging part enables a power supply interface to be connected with a power supply interface; and after the power supply interface is connected with the power supply interface, and a second preset rotating angle formed by the holder structure corresponding to the vibration reducing connecting structure is effective, the hanging part limits the holder structure to move in the vertical direction. The quick disassembly and assembly structure of the holder further comprises a locking part; when the hanging part is effective, the locking part can lock relative positions between the holder structure and the vibration reducing connecting structure to limit the rotation of the holder structure in the horizontal direction.

Owner:XIAOMI INC +1

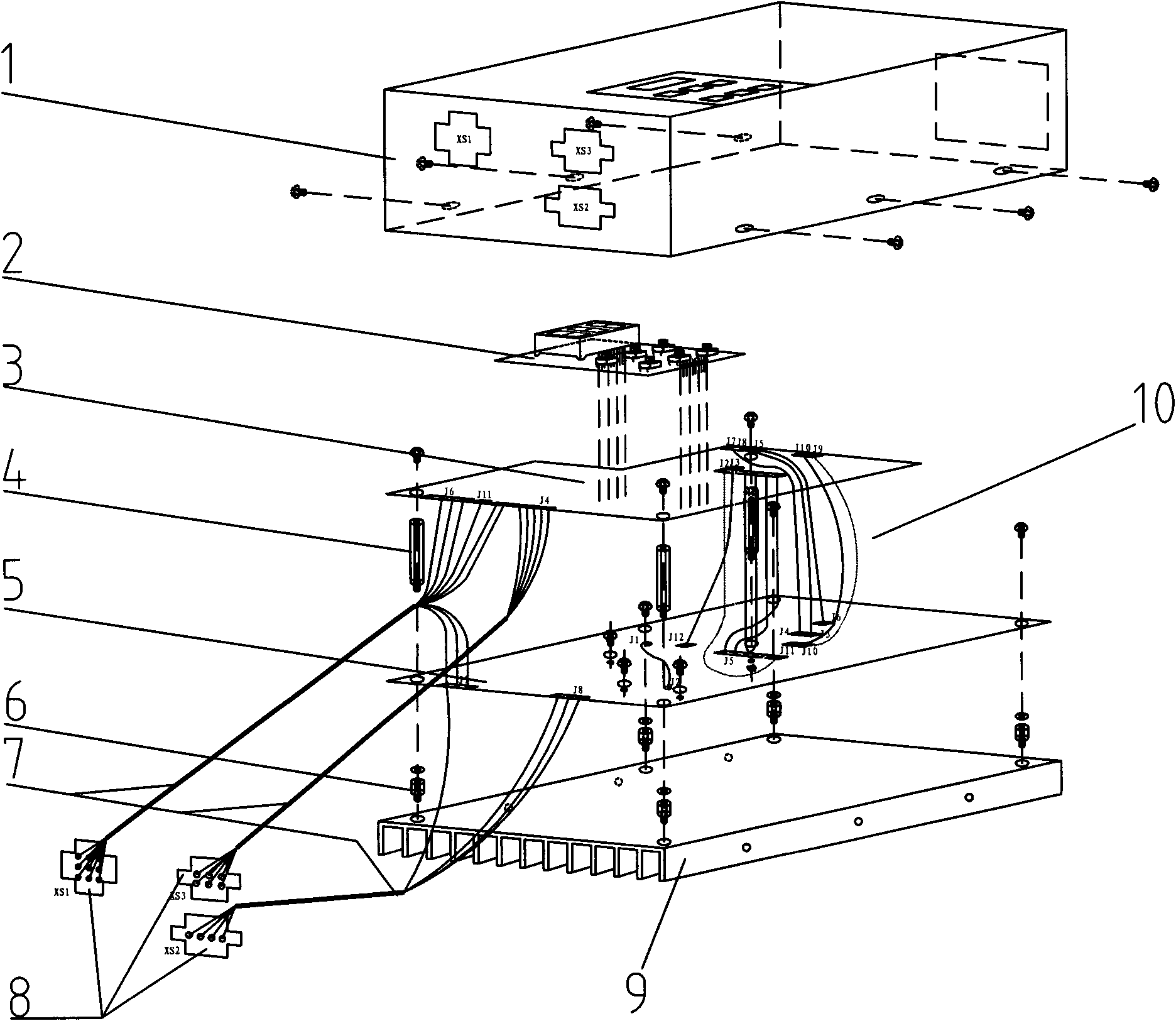

Shielded laminated variable frequency controller of lift door

The invention relates to a shielded laminated variable frequency controller of a lift door, solving the problems of no shielded casing, easy damage, inconvenient debugging and maintenance, and the like of the prior lift door controller. The shielded laminated variable frequency controller comprises a casing, a power driving plate, a main control circuit board, a man-machine interactive circuit board and cooling ribs, wherein the casing is provided with an external interface socket, and the power driving plate, the main control circuit board, the man-machine interactive circuit board and the cooling ribs are assembled in the casing. The shielded laminated variable frequency controller is characterized in that the casing is a shielded casing and forms an integral shielded space together withthe cooling ribs arranged on the bottom of the casing; the power driving plate is fixed on the upper surfaces of the cooling ribs by insulating struts; the cooling ribs are in direct contact with high-power heating elements on the power driving plate; the main control circuit board is connected with the power driving plate by the insulating struts and connecting wires; the man-machine interactivecircuit board is fixedly assembled on the upper surface of the main control circuit board; and the external interface socket arranged on the shielded casing is respectively connected with the main control circuit board and the power driving plate by the connecting wires. The invention has the advantages of reasonable integral structure, shielded function of the casing, obviously improved protection grade and convenient installation and maintenance.

Owner:SHENYANG YUANDA INTELLECTUAL IND GRP CO LTD

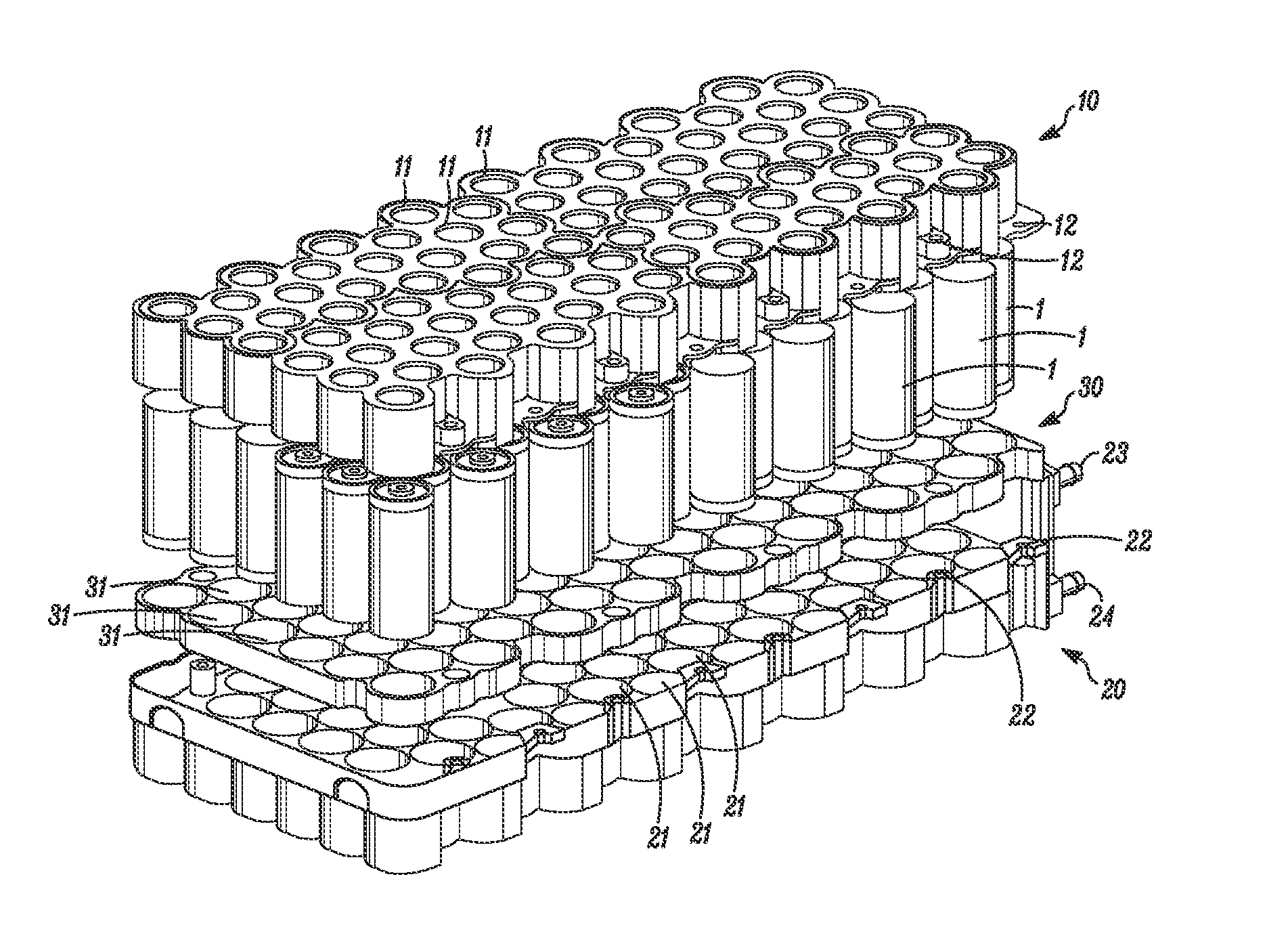

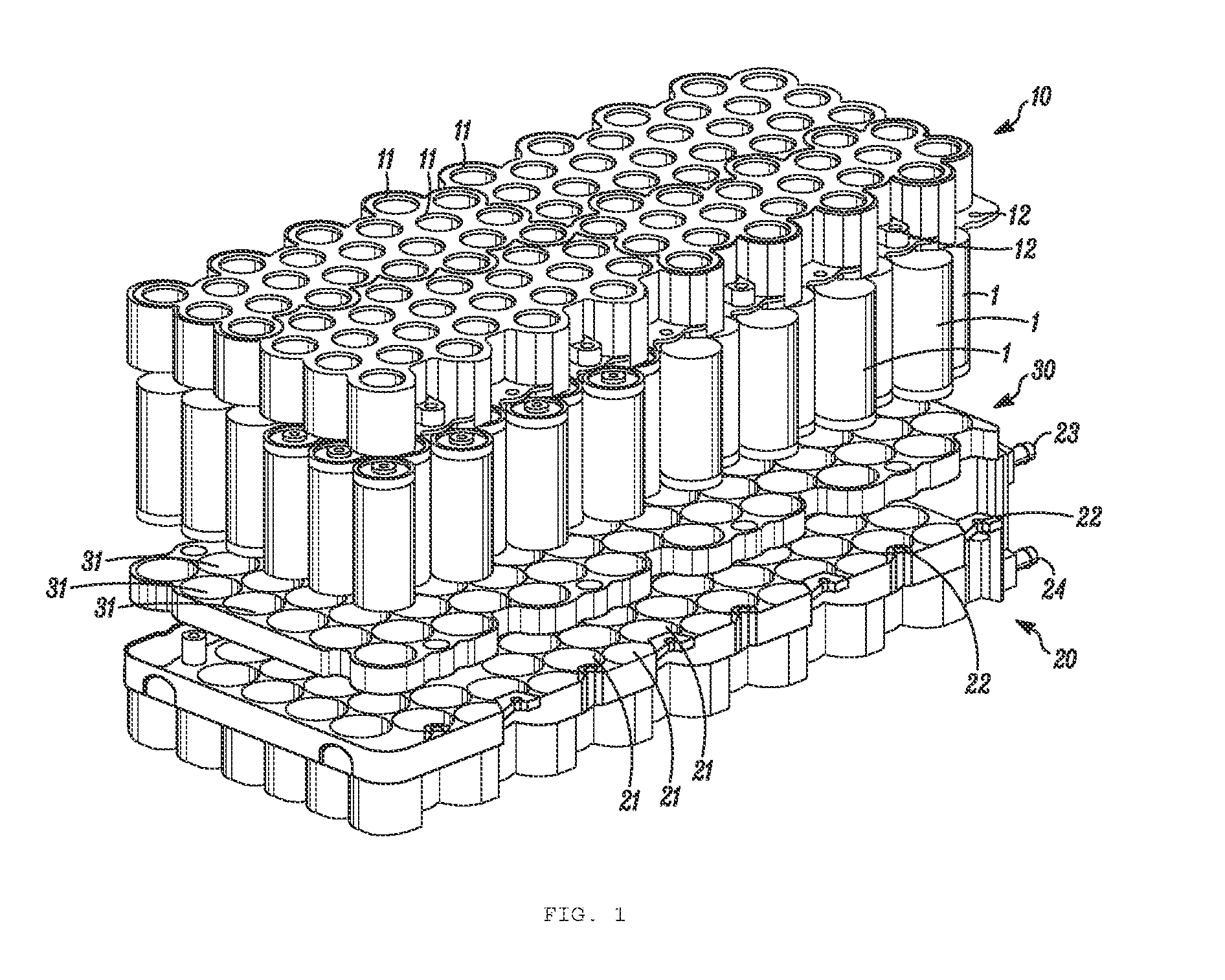

Fixing battery cells in place by compressed cell fixture

ActiveUS20150236315A1Avoid service lifeEasily adaptedPrimary cell to battery groupingFinal product manufactureEngineeringElectrical and Electronics engineering

A method for fixing battery cells includes positioning each battery cell in a respective opening of a cell fixture; inserting a first side of each battery cell into a respective opening of a first cell carrier; inserting a second side, opposite to the first side, of each battery cell into a respective opening of a second cell carrier, such that the cell fixture is positioned between the first and second cell carriers; and pressing the first and second cell carriers together to compress the cell fixture.

Owner:LISA DRAXLMAIER GMBH

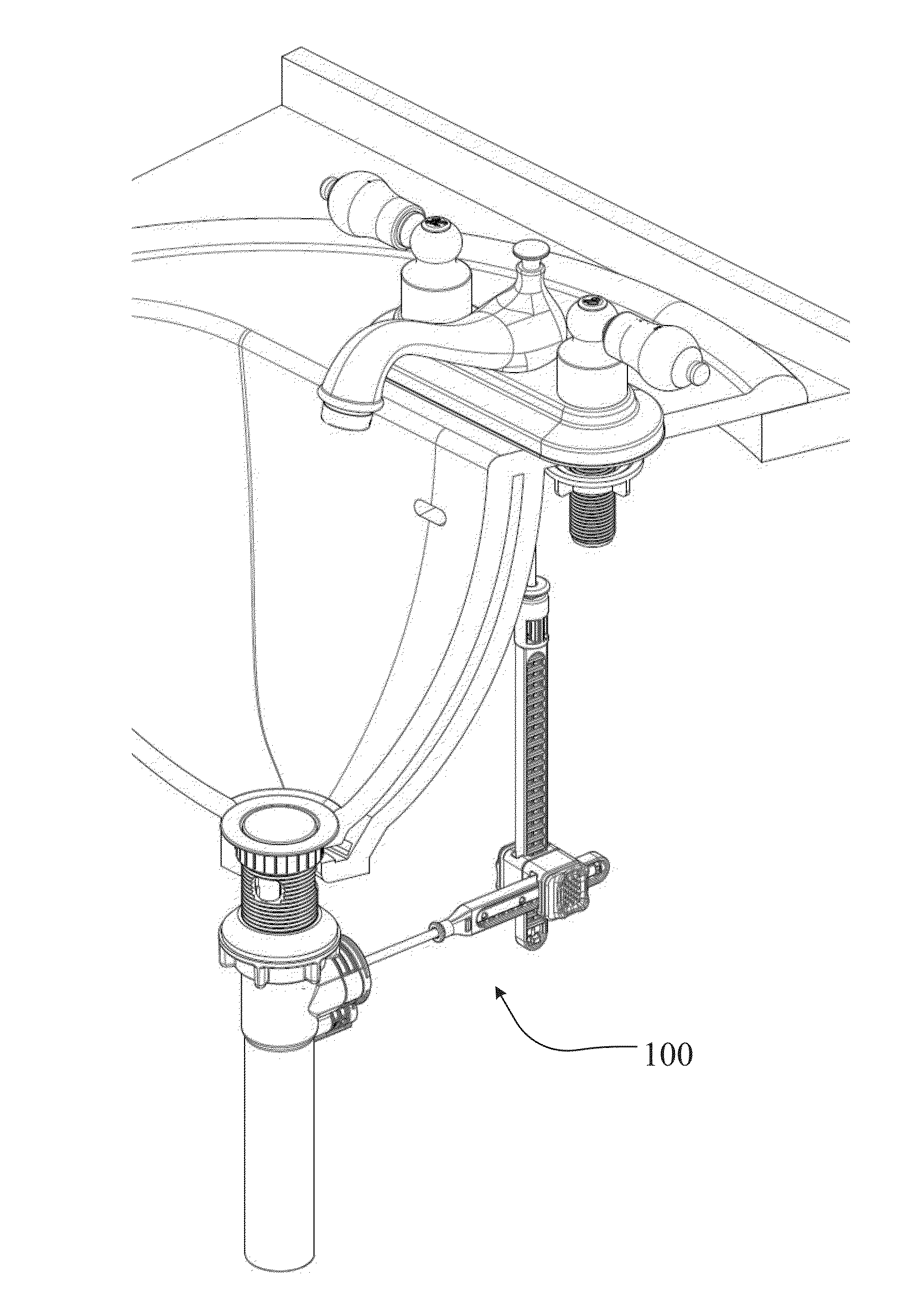

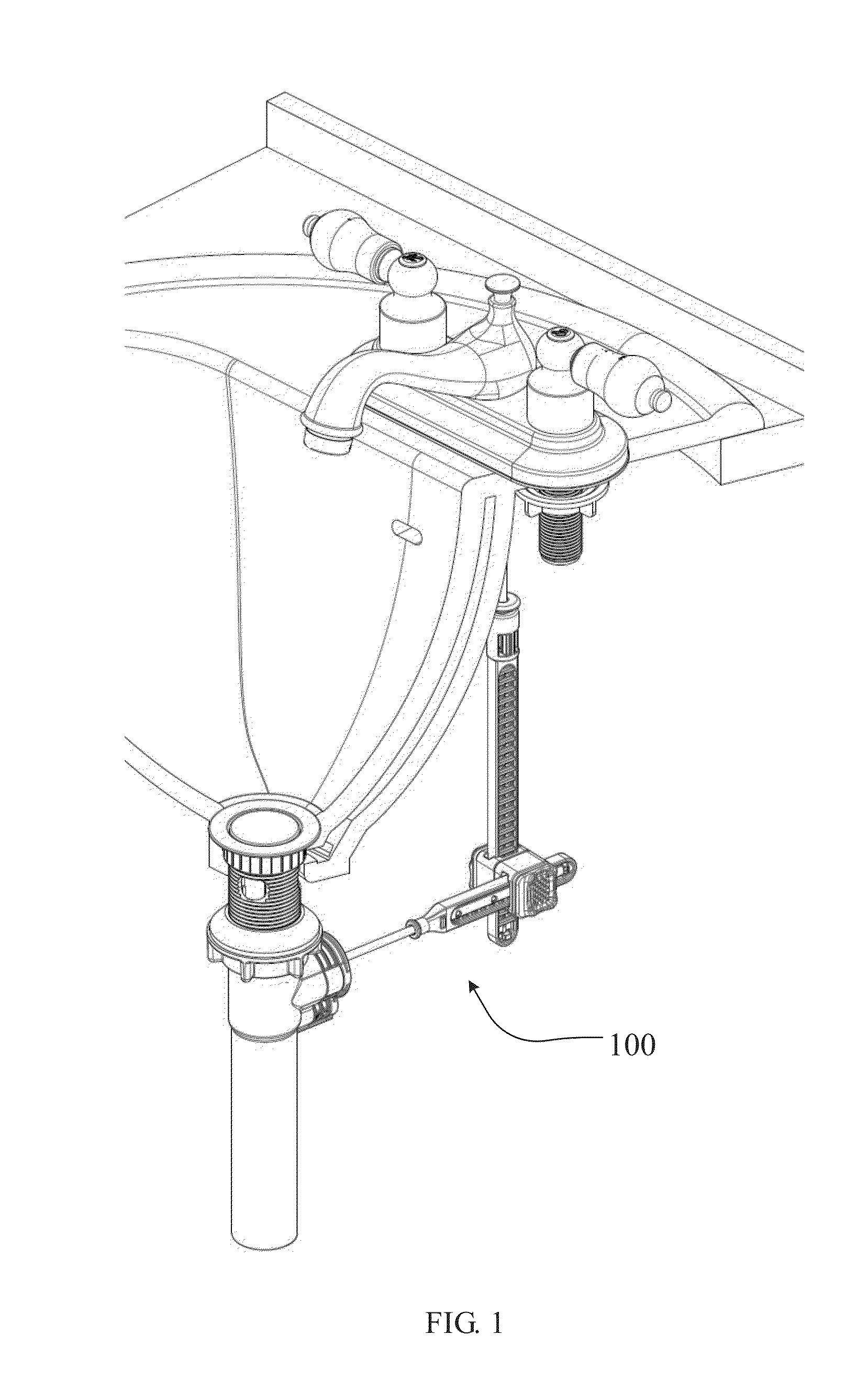

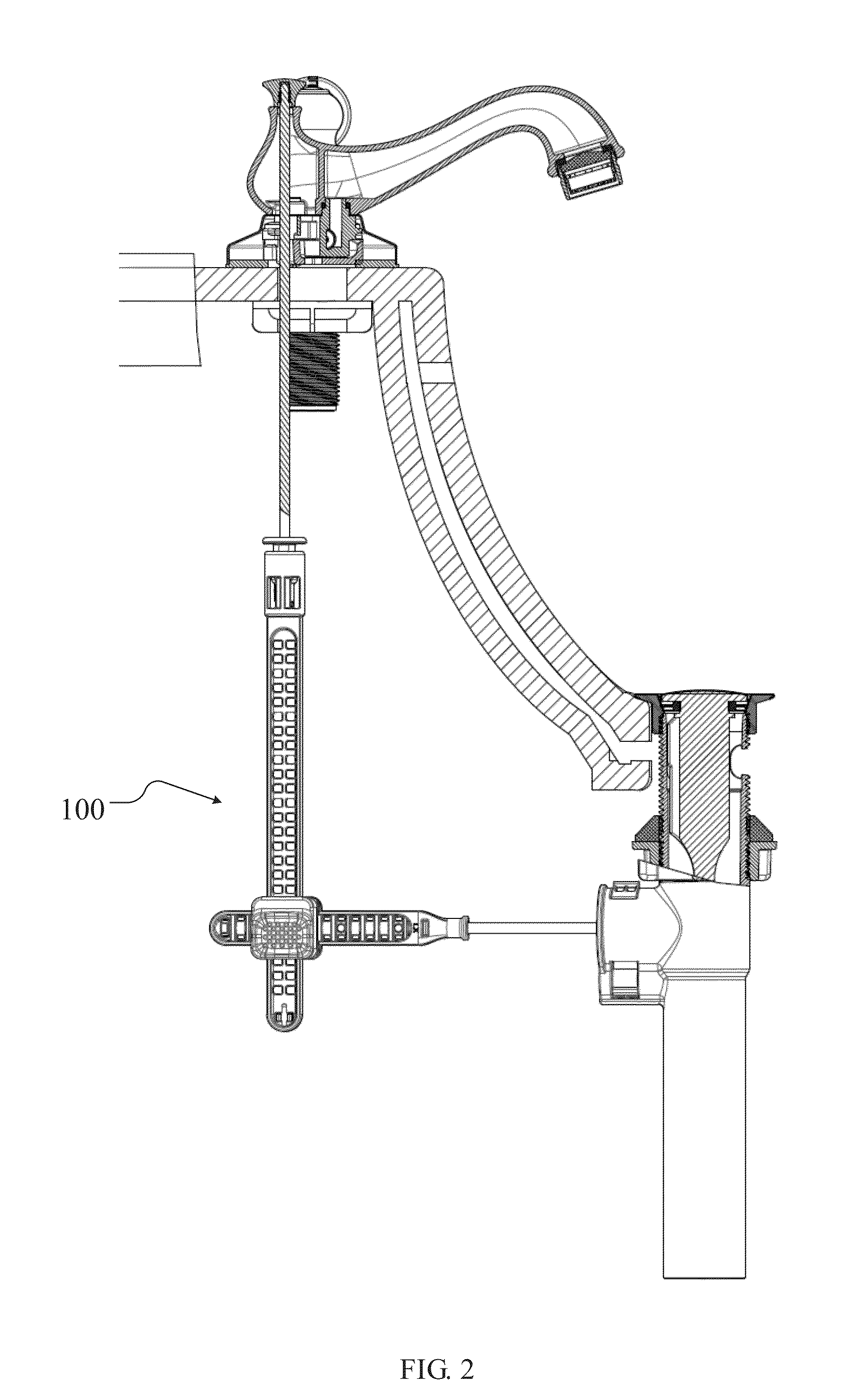

Drain plug linkage device

ActiveUS20140310864A1Solve the real problemEasily withdrawnWash-standsDomestic plumbingEngineeringExpansion joint

In the invention a drain plug linkage device (100) is provided, comprising: a drain plug (4) at least partially disposed in a pipe body (5); a pull rod assembly including a pull rod, a link rod (2) and a pull rod connector (9), wherein the link rod (2) at its upper end comprises a receiving portion, the pull rod connector (9) comprises a central hole and adapted to be snapped into the containing portion, and the pull rod at its bottom comprises a snap portion adapted to be snapped into the central hole; and a lever member (3) comprising a first end operatively connected to the link rod (2), and a second end extending into the pipe body (5) and configured to operate the drain plug (4); wherein the receiving portion comprises an expansion portion (22) for expanding the central hole, and the pull rod connector (9) is configured, when snapped into the receiving part, to be movable between a position where the central hole is unexpanded and a position where the central hole is expanded by the expansion portion (22).

Owner:XIAMEN LOTA INT CO LTD

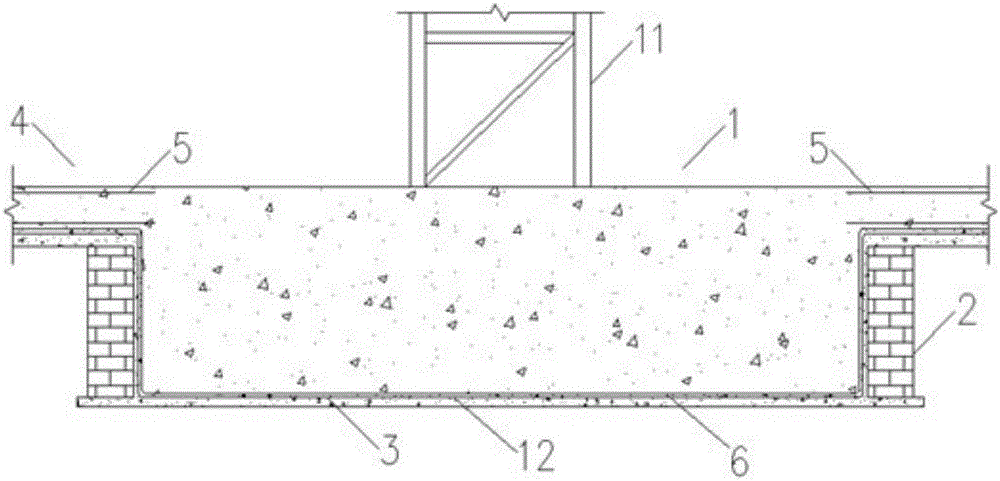

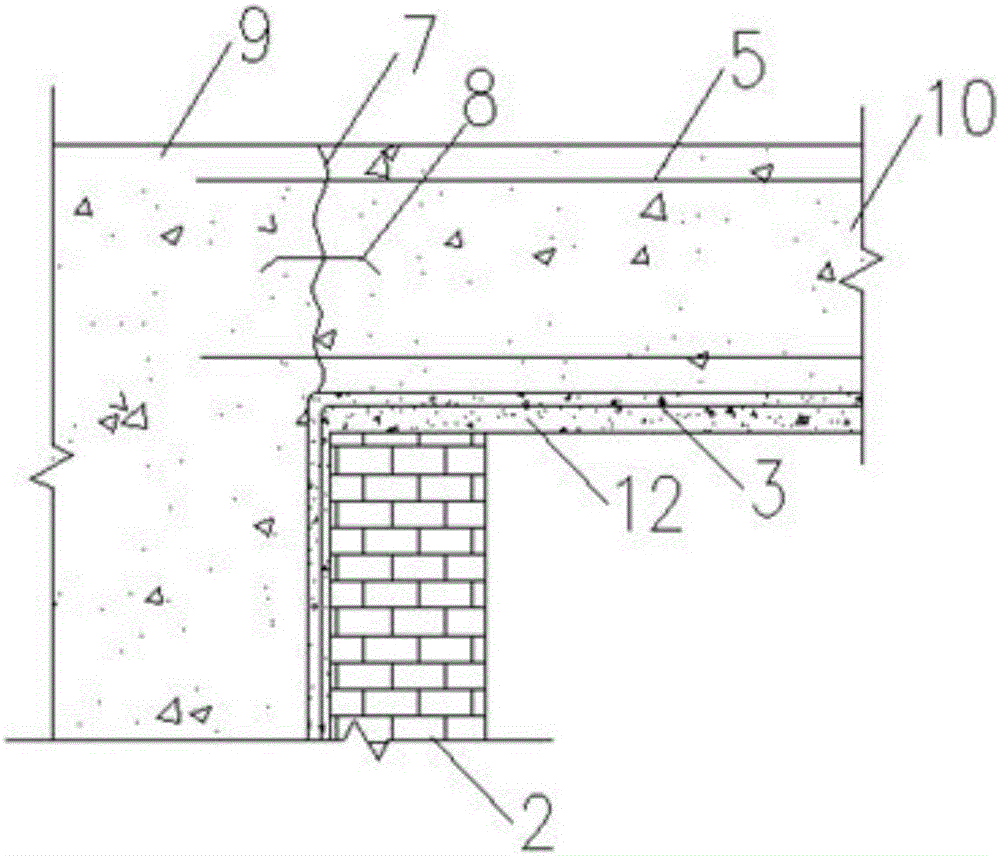

Leakage-proof construction method combining tower crane foundation and basement floor

InactiveCN106120872AEliminate potential safety hazards such as rustAvoid prolonged water accumulationProtective foundationProof constructionBrick

The invention discloses a leakage-proof construction method combining a tower crane foundation and a basement floor. The method comprises the following steps: excavating an earthwork groove and building a brick membrane along an inner wall of the earthwork groove, laying a waterproof material, distributing a foundation reinforcement cage, mounting supporting feet of a tower crane, mounting a grounding device, pouring concrete, mounting standard sections of the tower crane and the like. The leakage-proof construction method has the advantages that problems in a utilization process of the tower crane that the standard sections of a tower body are immersed in water for a long period to cause potential safety hazards including rusting and the like and the water is deposited in an installation position of the tower crane for a long period are effectively avoided, a dismounting procedure of the tower crane is simplified and the stability of connection between the earthwork groove and the basement floor is increased after the concrete is poured into the earthwork groove; and the leakage-proof construction method has very good leakage-proof effect and is suitable for being applied to a tower crane construction process of various types of mid-rise buildings and high-rise buildings.

Owner:TIANJIN 20 CONSTR

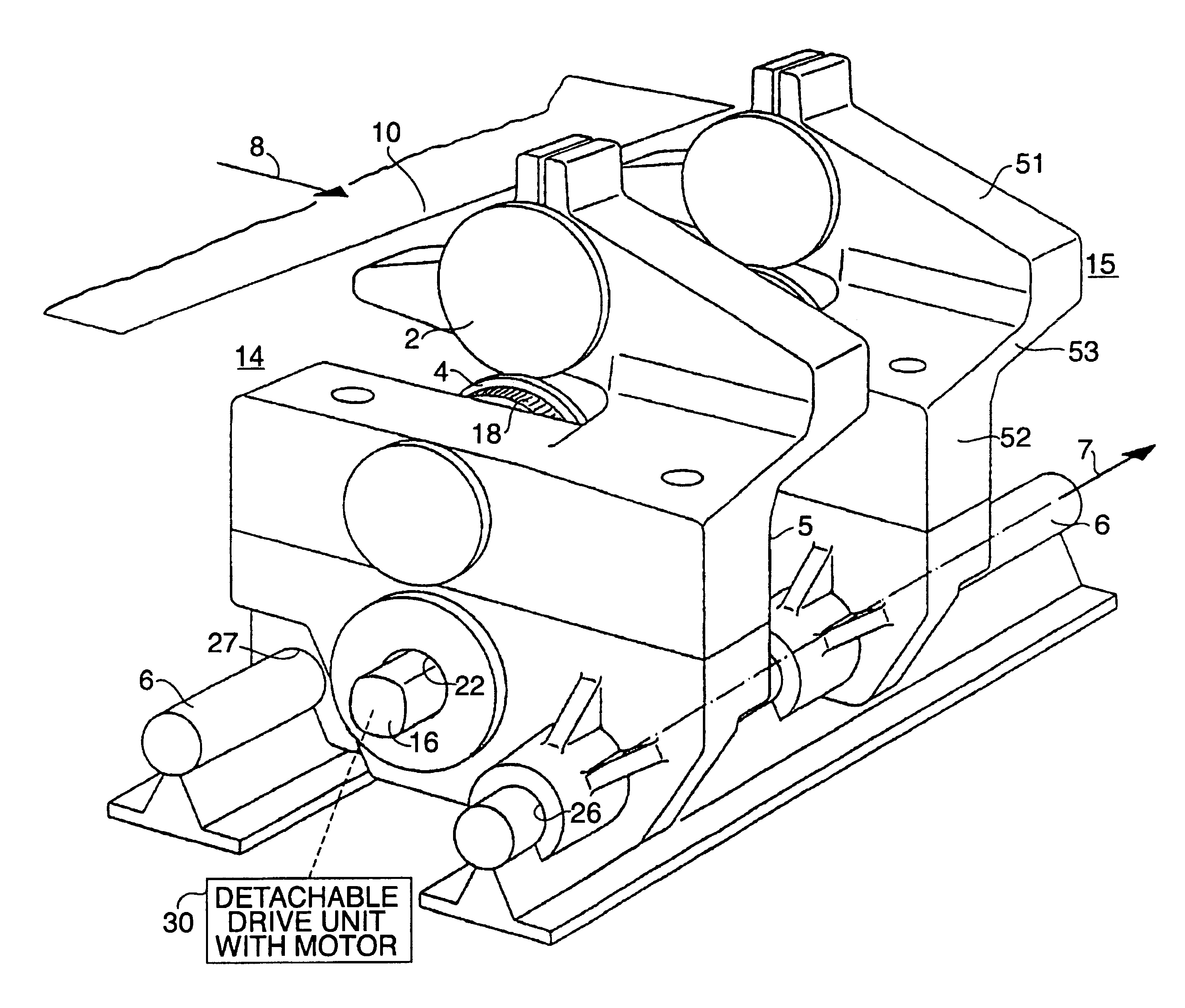

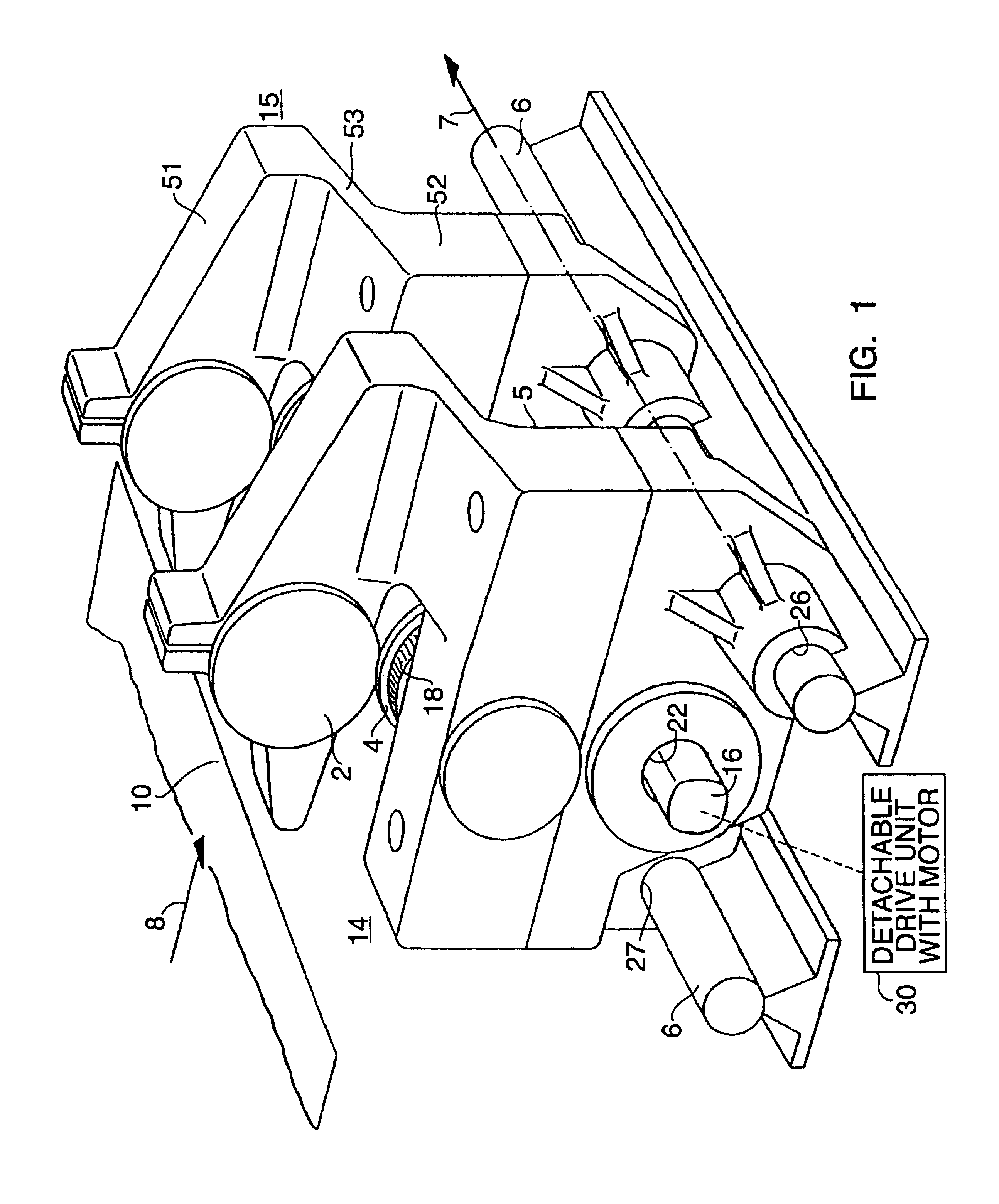

Rotary cutting unit

InactiveUS7028596B1Improve usabilityReduced conversion timeShearing machinesMetal working apparatusIn planeAcute angle

A circular-cutter unit for equipment cutting flat lengths of material and sheet metal in a horizontal plane has upper and a lower circular blades both in planes perpendicular to the horizontal plane and in a longitudinal direction, carried by an upper and lower blade shaft, respectively, which are parallel with the horizontal plane and perpendicular to the longitudinal direction. The two blade shafts are rigidly and rotatably mounted in a common frame. The frame is U-shaped with the upper and lower legs connected by a flat yoke intersecting the horizontal plane at an acute angle. Several cutter units are mounted in a single apparatus and driven by a common drive from which the units can be individually detached for servicing.

Owner:ELPATRONIC AG

Air-cooled refrigerator

ActiveCN104180592ASimplify the installation processInstalled and disassembledLighting and heating apparatusDomestic refrigeratorsPulp and paper industryRefrigerated temperature

Owner:HEFEI HUALING CO LTD

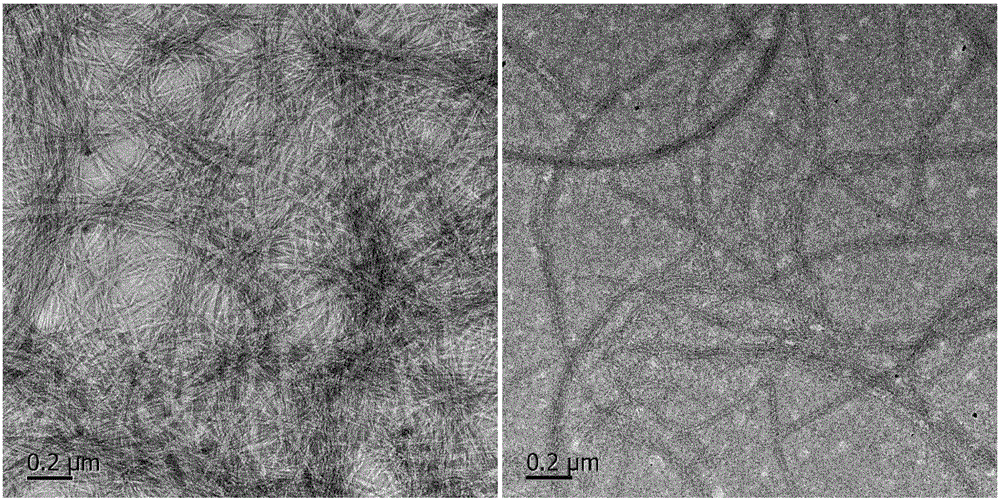

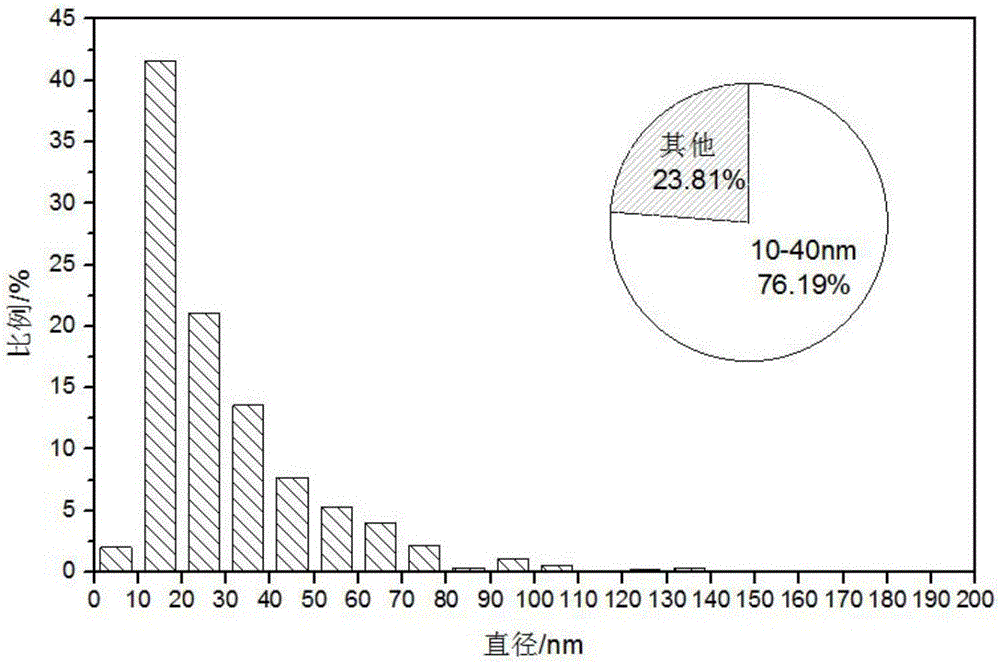

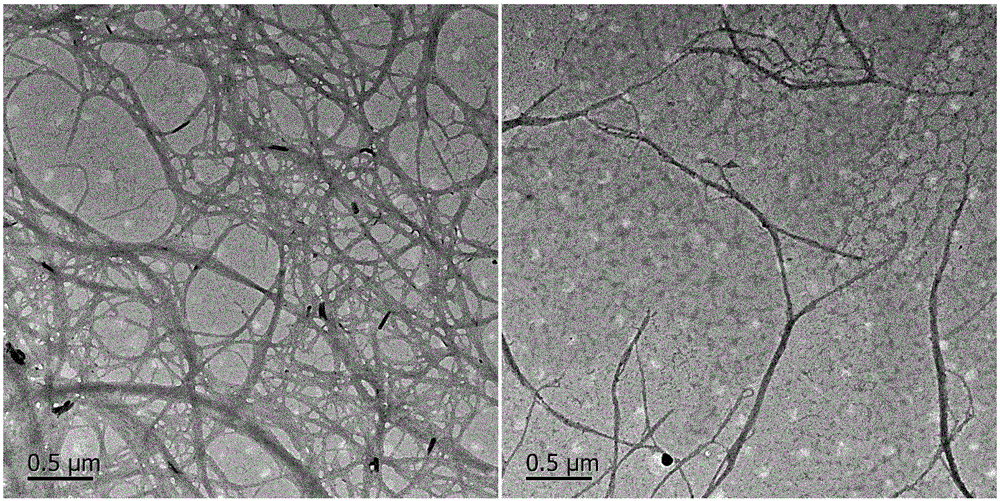

Beet pulp cellulose nanofibril and preparation method thereof

ActiveCN106087507AIncrease profitAvoid destructionPulp bleachingRaw material divisionEthanol precipitationCell wall

The invention relates to beet pulp cellulose nanofibril, pectin and a preparation method thereof. The preparation method comprises the following steps: beet pulp is used as a raw material, and pretreatment with steam explosion is carried out for removing pectin substances and hemicellulose in cell walls; bleaching with hydrogen peroxide or high shear homogenizing treatment is carried out for removing lignin and other impurities; and finally high speed stirring treatment and high strength ultrasonic treatment are used for preparing the cellulose nanofibril. The preparation method has the advantages of cleaning, high efficiency, simple technology, and few chemical reagents without waste liquid treatment and other problems. Explosion liquid after pretreatment with ethanol precipitation is used for recovery of pectin substances, so that multipurpose utilization rate of the beet pulp is improved, and added value of the product is increased. The beet pulp cellulose nanofibril is a typical cellulose I type crystal structure whose diameter is 10-50nm, and length is at least more than 1[mu]m.

Owner:SOUTH CHINA UNIV OF TECH

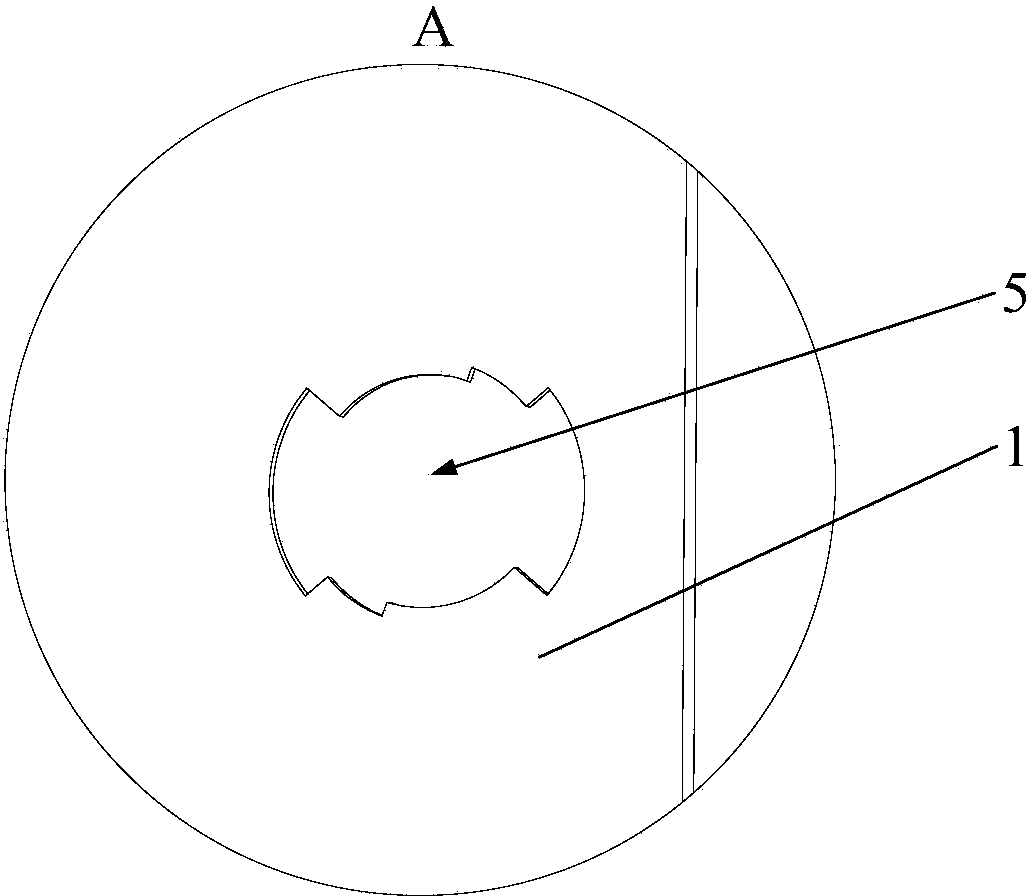

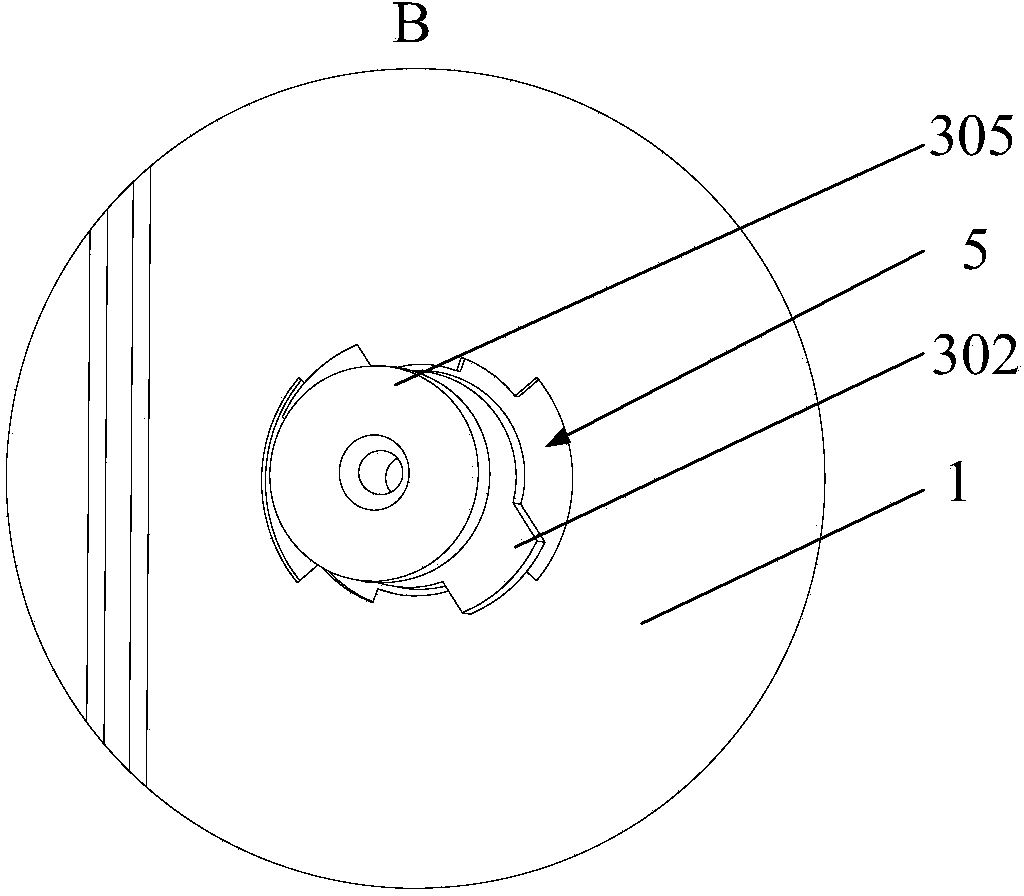

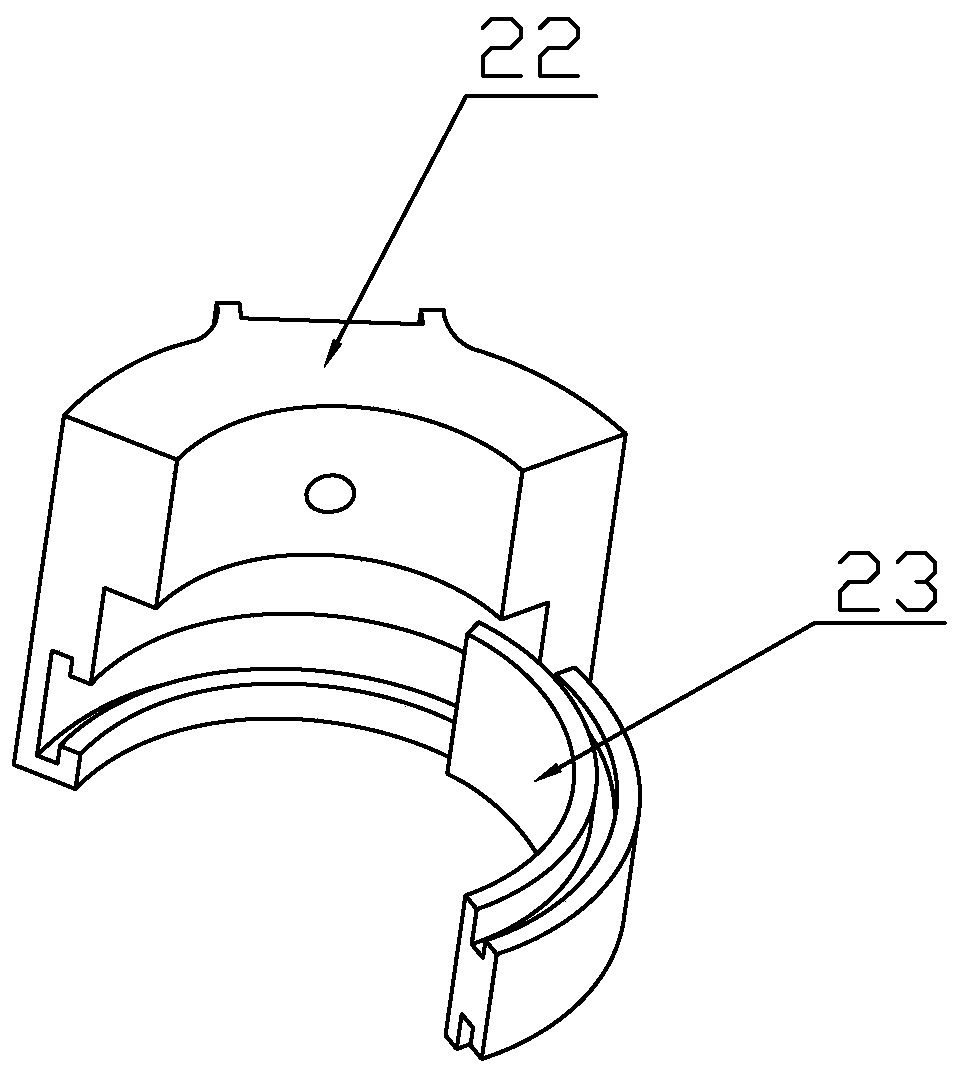

Detachable disassembly and assembly cap screwing mechanism of cap screwing machine

PendingCN110143555AEasy to replaceEasy to removeCapsThreaded caps applicationWear resistantEngineering

The invention discloses a detachable disassembly and assembly cap screwing mechanism of a cap screwing machine. According to the detachable disassembly and assembly cap screwing mechanism of the cap screwing machine, a cap clamping device and a supporting rotary shaft can be assembled and disassembled quickly and conveniently through an axial plug pin. A clamping claw block is detachably installedon the inner side of the lower end of a clamping claw arm. Wear-resistant rubber is arranged on the inner side of the clamping claw block. In the process of clamping a cap and screwing the cap, if the clamping claw arm bumps the bottle cap accidently, the clamping claw arm will be pushed to move upwards, and a power head is controlled to lose power and stop rotating through an infrared travel switch; when the bottle cap dimensions need to be changed, a clamping claw base sleeve can be quickly and conveniently detached just by pulling out the axial plug pin, and in other words, the cap clamping device can be easily and conveniently detached and replaced; and because the clamping claw block and the wear-resistant rubber are of a plug-in structure according to designing, replacement and processing can be conveniently carried out, and assembly, disassembly and processing can be carried out on the cap clamping device much more easier. No tools are needed for replacing the cap clamping device, quickness and convenience are achieved; and when the rubber in the clamping claw block needs to be replaced, it is only needed that a rubber strip is directly inserted into a T-shaped groove of the clamping claw block, no tools or glue is needed, the designing is exquisite, simpleness and practicability are achieved, the operation of workers is facilitated to a great extent, and the efficiencyis improved.

Owner:孙方卓 +1

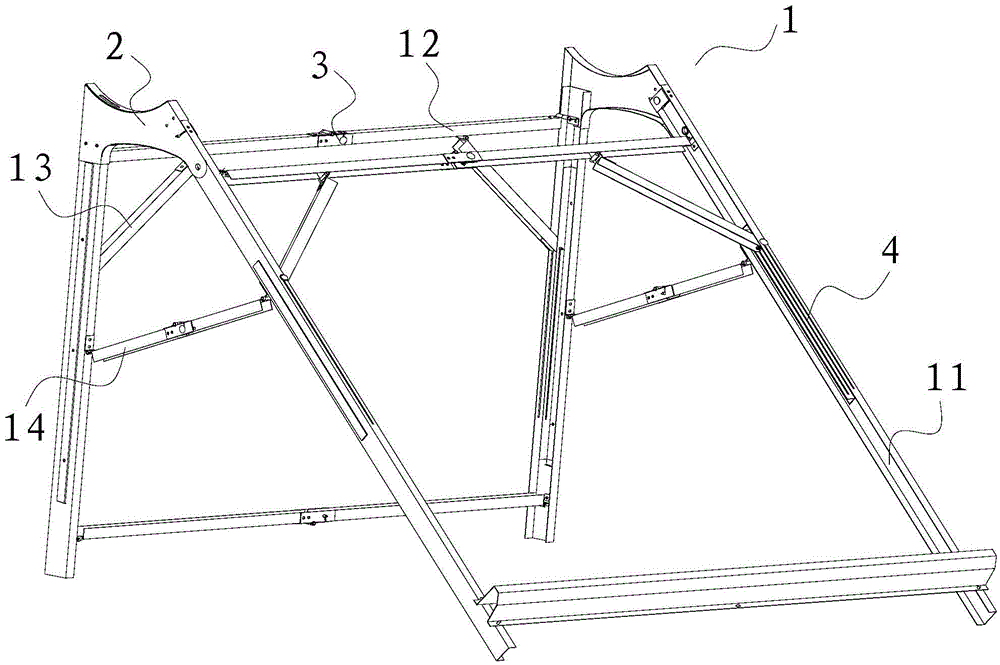

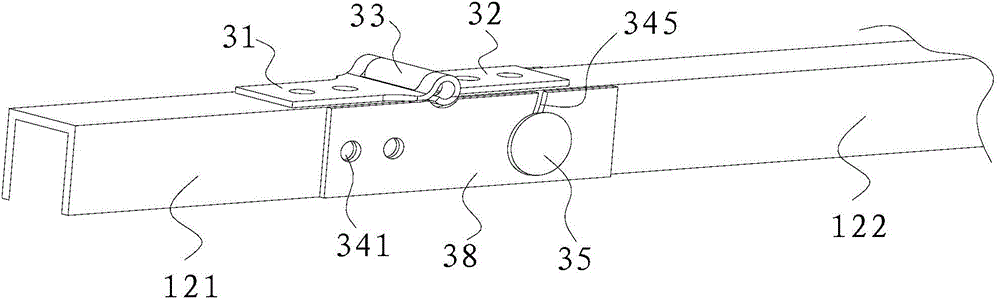

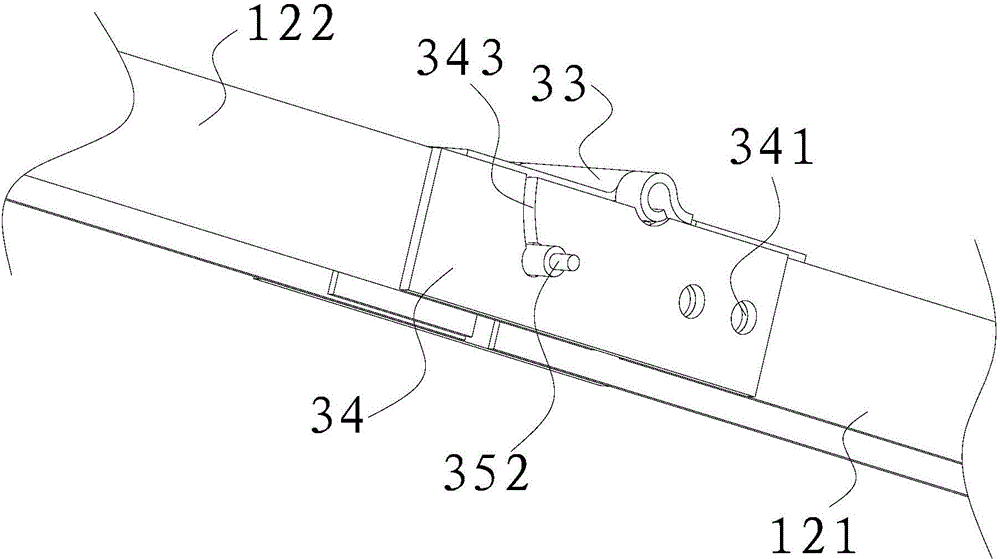

Folding structure of solar water heater support and solar water heater

ActiveCN105333634ASimplify the disassembly processThe effect of clamping the second rod body is goodSolar heat devicesSolar thermal energy generationSolar waterEngineering

The invention discloses a folding structure of a solar water heater support and a solar water heater, and belongs to the field of solar water heaters and accessories of the solar water heaters. The folding structure of the solar water heater support and the solar water heater are designed for solving the problems that existing devices are inconvenient to disassemble and assemble and the consumed time is long. The folding structure of the solar water heater support comprises a first rod body, a second rod body and a hinge part arranged at the end adjacent to the first rod body and the second rod body, and the second rod body can rotate around the hinge part; a locking part is arranged between the first rod body and the second rod body; when the second rod body is unfolded, the locking part can fix the second rod body relative to the first rod body. The solar water heater comprises a water tank, heat collection pipes and the support. The support comprises the folding structure of the solar water heater support. The folding structure of the solar water heater support and the solar water heater have the advantages that the disassembly and assembly processes are simple, the time and the labor are saved, and the clamping and fixing effect is good.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

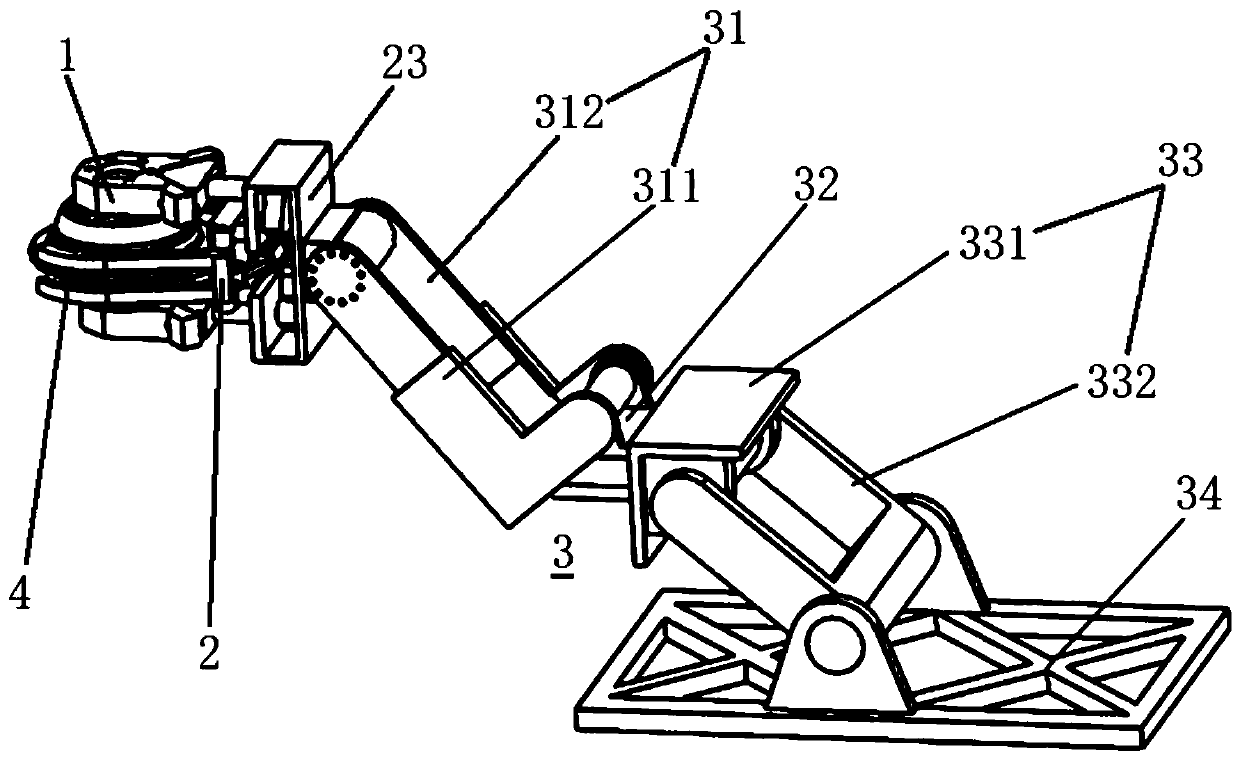

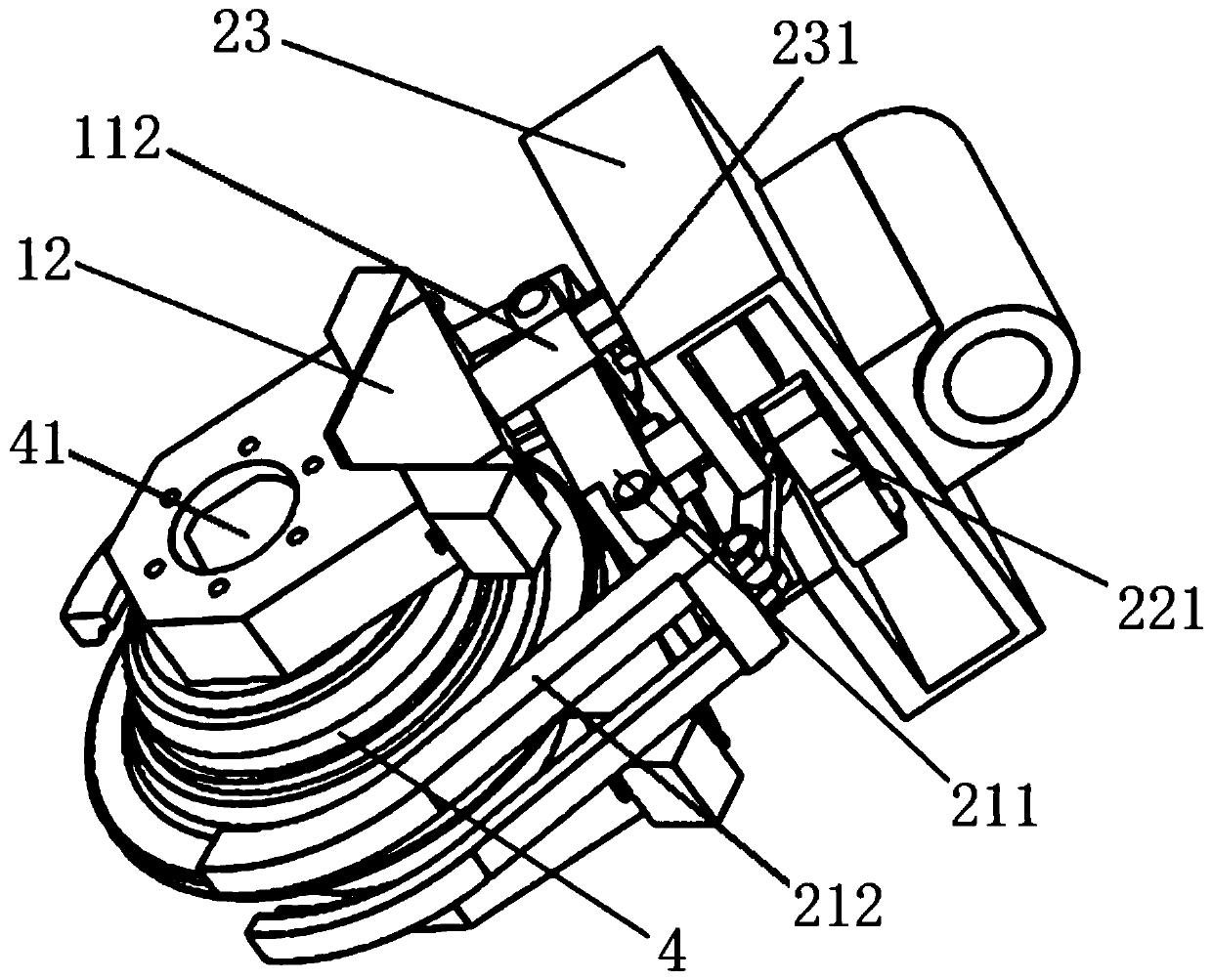

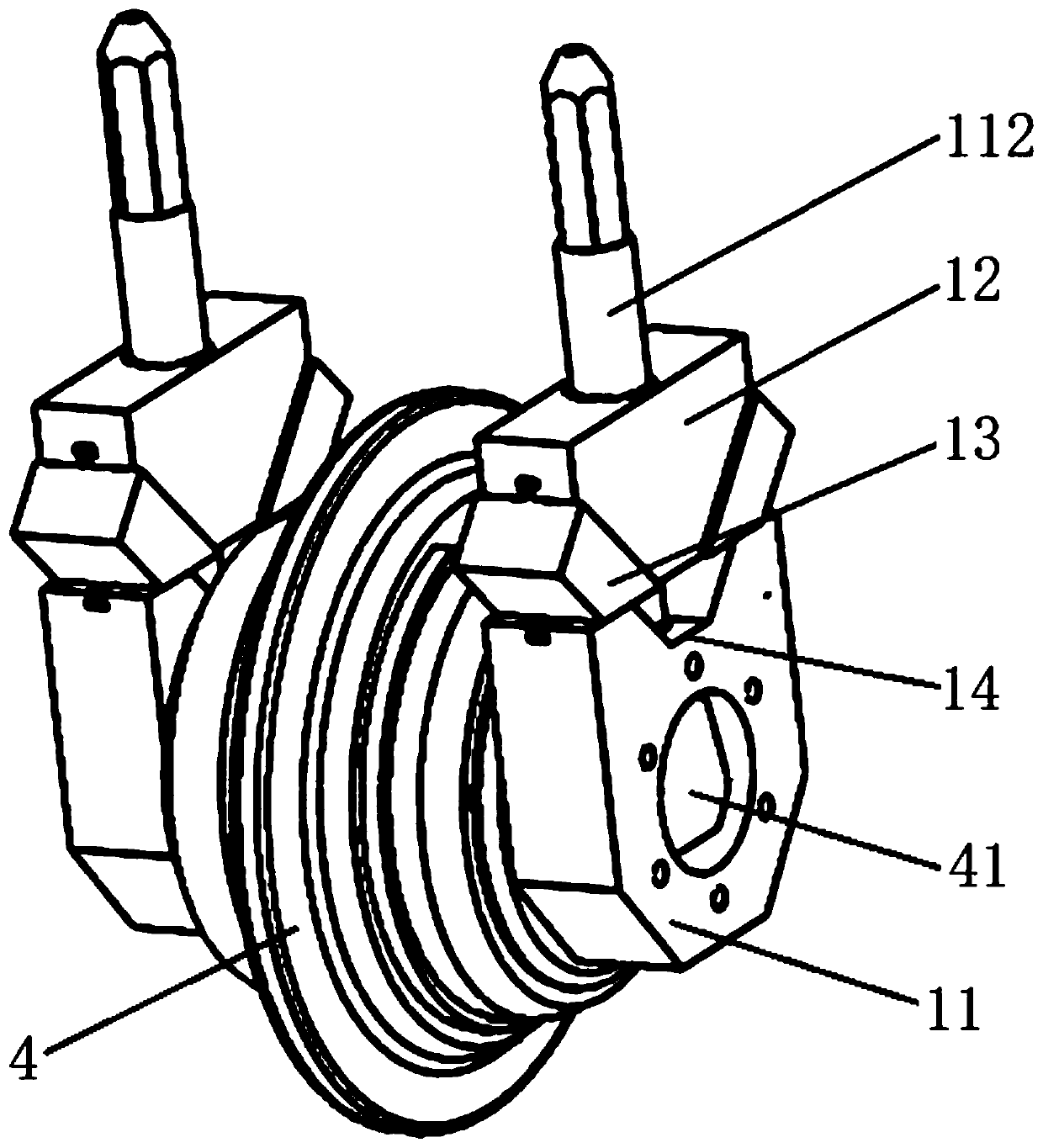

Cutter changing robot execution mechanism suitable for shield

ActiveCN111468932ARealize machine tool change operationImprove construction efficiencyProgramme-controlled manipulatorGripping headsHobbingRobot hand

The invention provides a cutter changing robot execution mechanism suitable for a shield. The cutter changing robot execution mechanism comprises a hobbing cutter dismounting and mounting mechanism, acutter changing mechanical arm and an action execution mechanism. The hobbing cutter dismounting and mounting mechanism is connected with a hobbing cutter and meanwhile is detachably connected with acutter box on a cutter disc of a shield tunneling machine. The cutter changing mechanical arm is arranged at the execution end of the action execution mechanism, the state of the hobbing cutter dismounting and mounting mechanism can be switched, so that the hobbing cutter dismounting and mounting mechanism and the cutter box are locked or loosened, meanwhile, the cutter changing mechanical arm can clamp the whole hobbing cutter and hobbing cutter dismounting and mounting mechanism, and movement along the cutter changing path is achieved through drive of the multi-freedom-degree action execution mechanism. According to the cutter changing robot execution mechanism, machine cutter changing work of the shield narrow space is achieved, dismounting, mounting and changing of the hobbing cutterof the total disc face of the cutter disc can be completed, traditional manual tool changing is completely replaced, the cutter changing efficiency and the shield overall construction efficiency are improved, and safety of shield construction is guaranteed.

Owner:CENT SOUTH UNIV +1

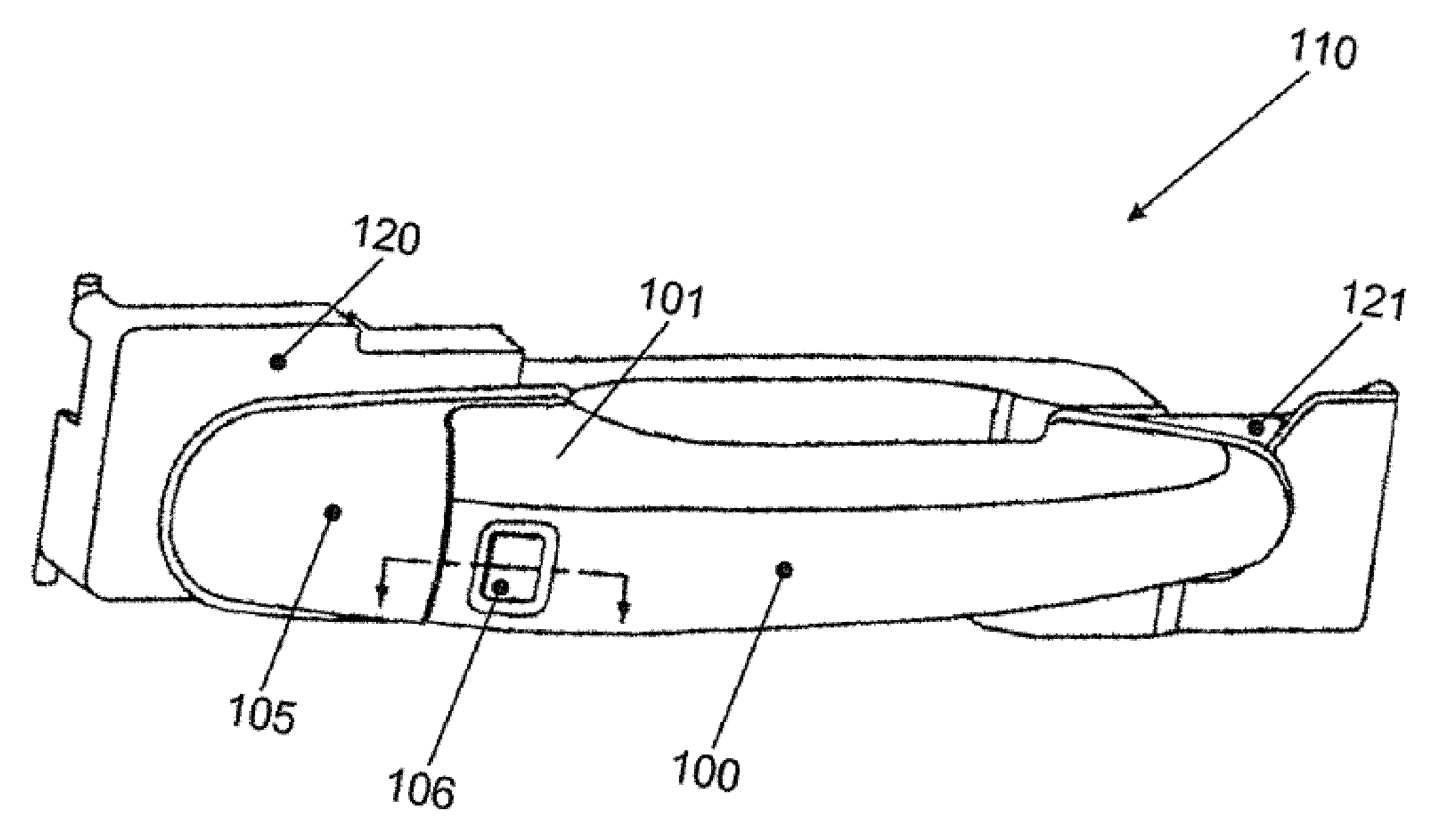

Method for the production of an exterior door handle

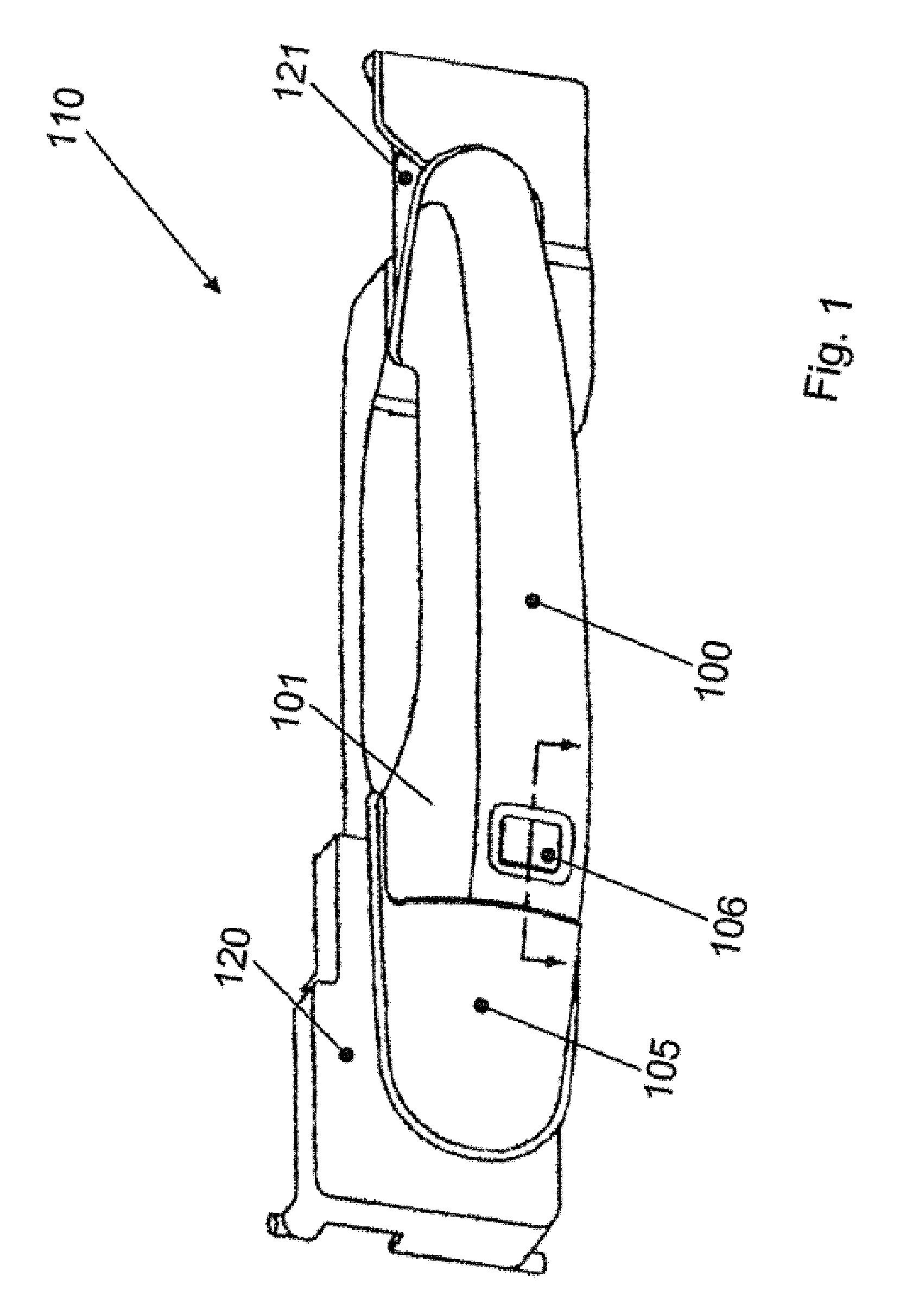

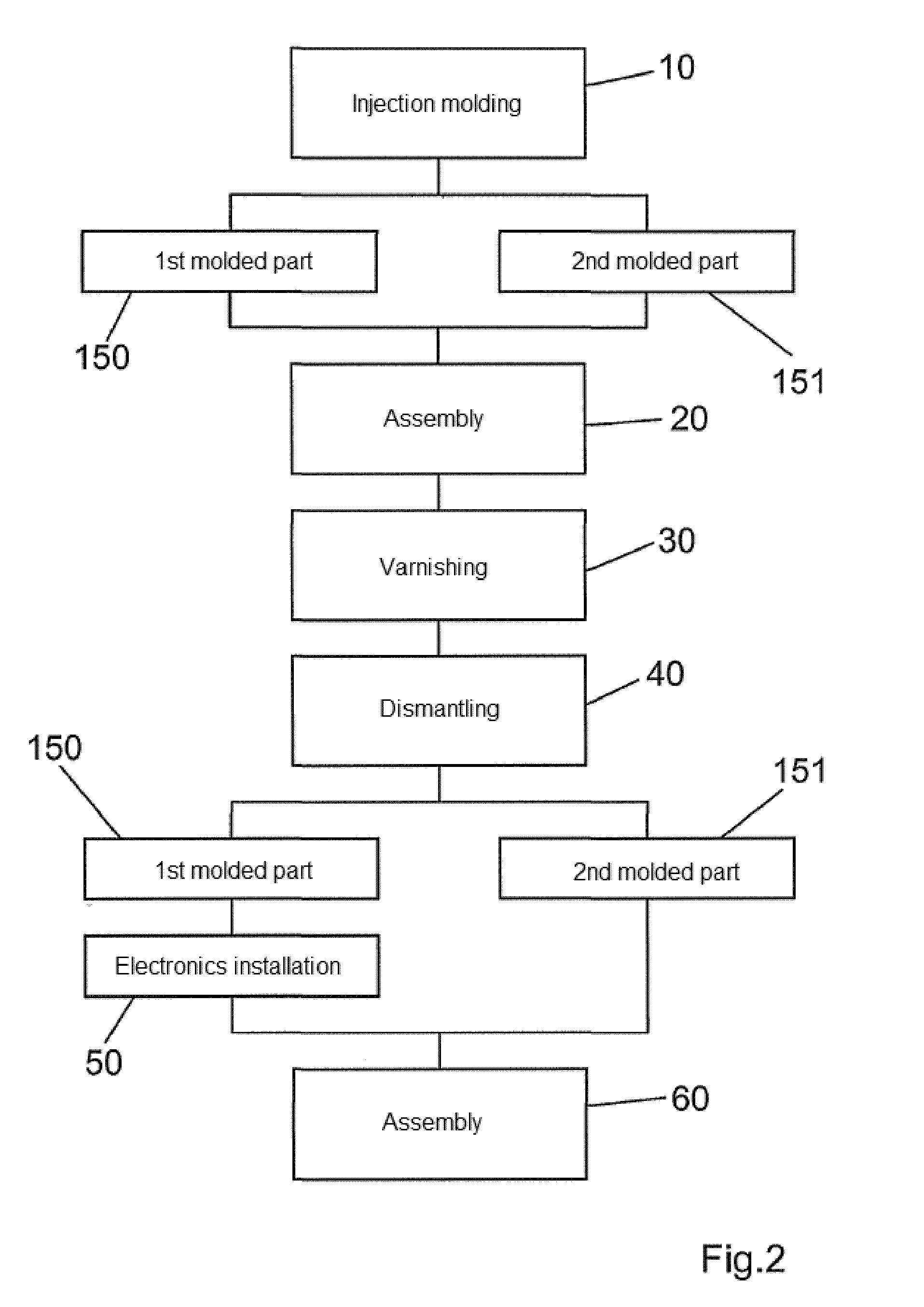

InactiveUS20100132162A1Shorten production timeShorten the timeVehicle arrangementsTravelling carriersInjection mouldingMotorized vehicle

The invention relates to a method for the production of an exterior door handle (100) for a motor vehicle, wherein the method comprises the following steps: (a) injection molding (10) of at least one first mold part (150) and one second mold part (151) using a plastic mass; (b) building (20) the exterior door handle (100) from the at least two mold parts (150, 151); c) painting (30) a surface of the exterior door handle (100); (d) disassembling (40) the exterior door handle (100) into the at least two mold parts (150, 151); (e) installing (50) an electronic unit in at least one of the two mold parts (150, 151); (f) assembling (60) the at least two mold parts (150, 151) and the electronic unit to form the exterior door handle (100).

Owner:HUF HULSBECK & FURST GMBH & CO KG

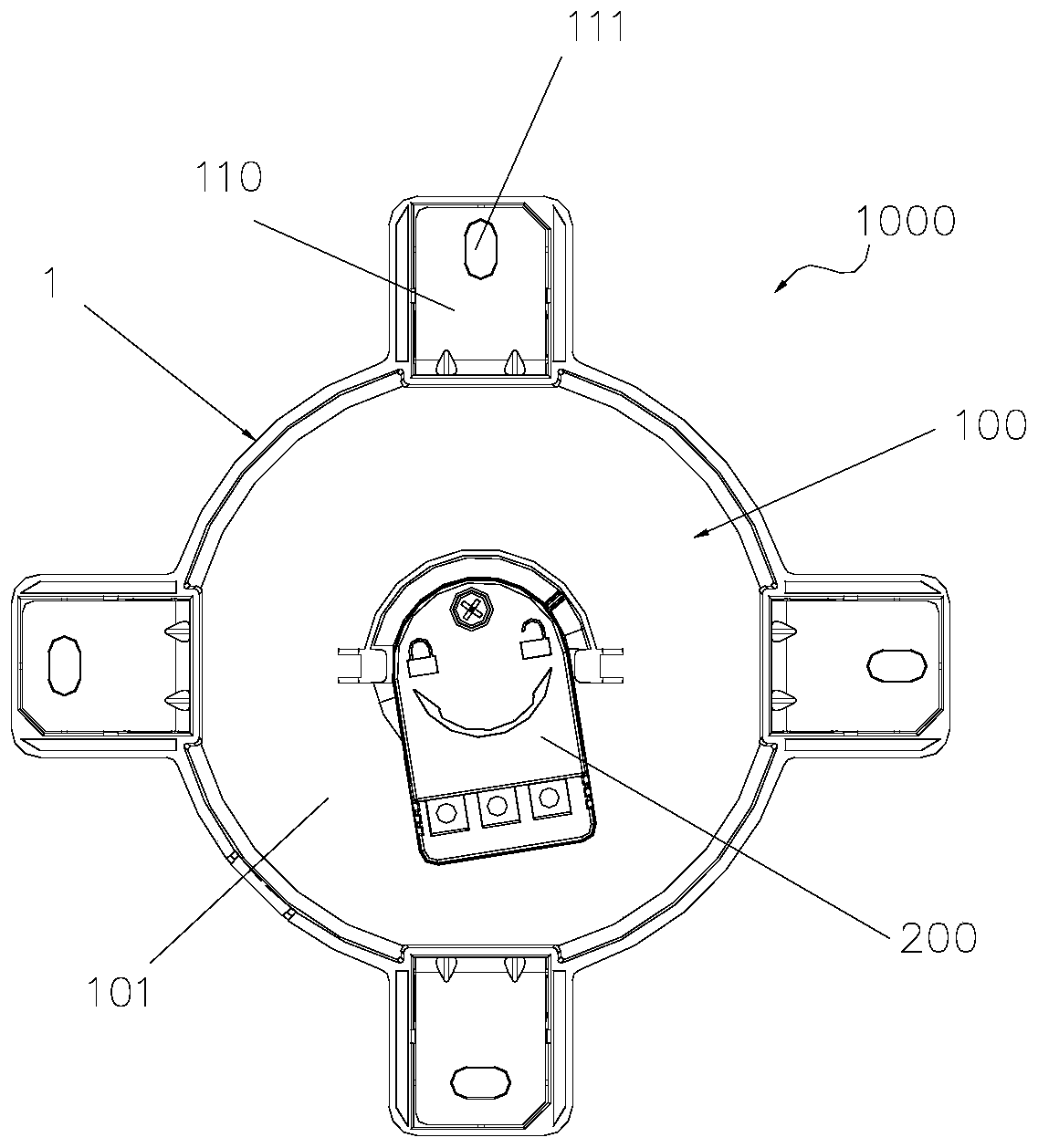

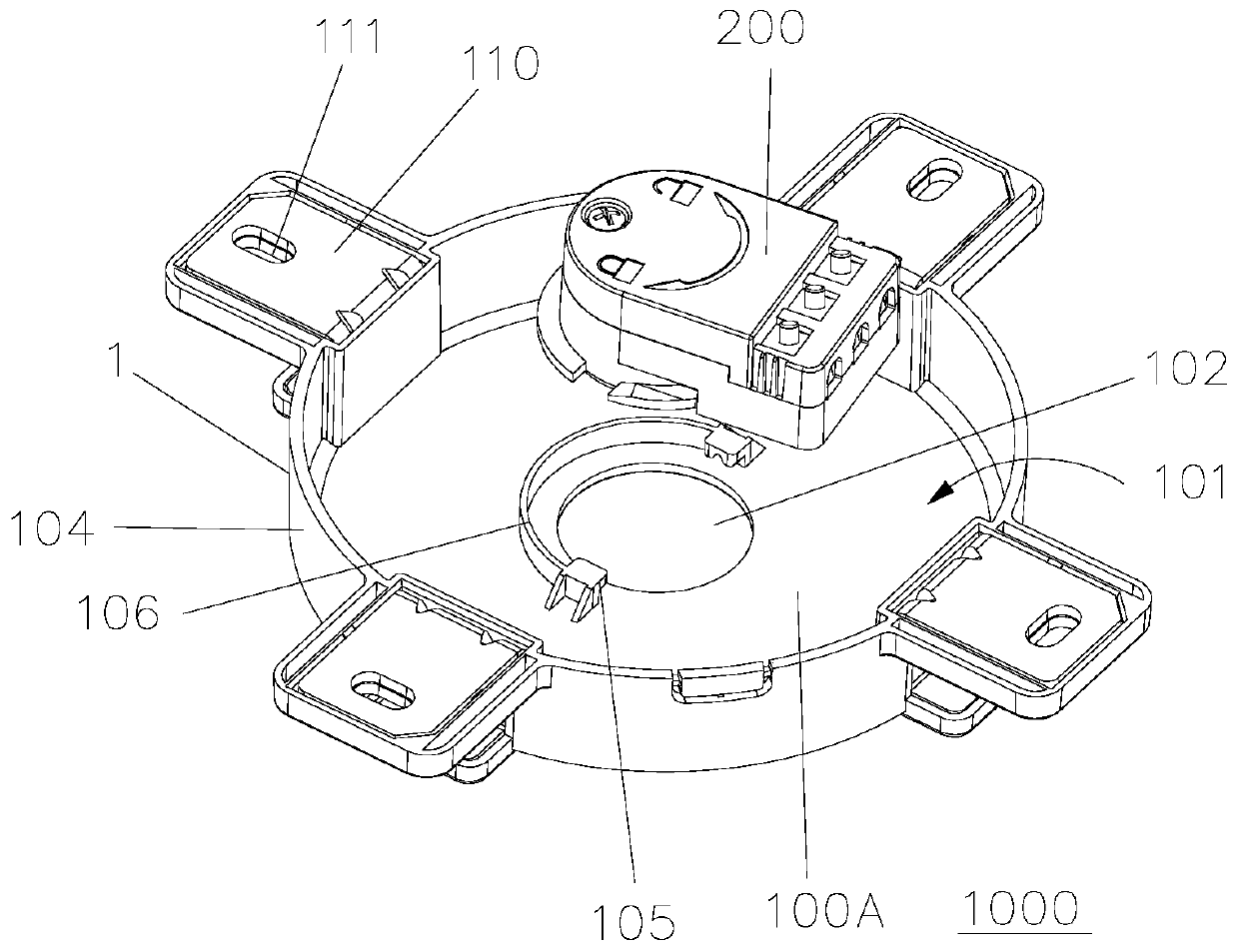

Fixed base, lamp fixing device and lamp

PendingCN110762492AEasy to removeQuick installationLighting support devicesElectric circuit arrangementsElectrical connectionEngineering

The invention discloses a fixed base, a lamp fixing device and a lamp. The fixed base comprises a first body part and a junction box. The first body part comprises a containing cavity used for containing the junction box, first combination parts and first detachable connection parts used for being directly and detachably connected with the junction box. A first electrical connection part and second detachable connection parts used for being detachably matched with the first detachable connection parts are arranged on the junction box. Each first detachable connection part and the correspondingsecond detachable connection part are detachably connected in the manner that the first detachable connection part and the second detachable connection part relatively rotate around a rotation shaft.The junction box can be detachably fixed in the containing cavity through cooperation of the first detachable connection parts and the second detachable connection parts. The lamp fixing device comprises a connection base connected with a lamp body and the fixed base. The lamp comprises the lamp body and the lamp fixing device. The lamp body is fixedly connected with the connection base. By meansof the fixed base, the lamp fixing device and the lamp which are provided by the embodiment, the wiring operation can get rid of space limitation of the containing cavity.

Owner:OPPLE LIGHTING +1

External mixing type atomization nozzle

InactiveCN108284009ASimplify the disassembly processEasy to cleanLiquid spraying apparatusEngineeringInjection air

The invention discloses an external mixing type atomization nozzle. The external mixing type atomization nozzle comprises a liquid cap and an air cap, wherein one end of the liquid cap extends outwards to form a connecting part; the connecting part is provided with a through air inlet; a hollow part of the liquid cap is a liquid cavity; one end of the liquid cavity is a water spraying cavity; theair cap is of an internal concave structure; a nozzle is arranged at the bottom of the internal concave structure; a bump is formed around the nozzle in a convex manner; the connecting part is connected to a port part of the air cap; an air cavity is formed between the liquid cap and the air cap; the air cavity is divided into a first air cavity and a second air cavity through the bump; one end ofthe first air cavity communicates with the water spraying cavity; and air injection holes are formed in one end of the second air cavity. The external mixing type atomization nozzle has the beneficial effects that the structure is simplified, simple disassembly and cleaning maintenance of the nozzle are achieved, the problems that air and a liquid leak and the liquid flows back to an air channelare solved, and besides, even though the liquid flows back, the liquid can be well cleaned through the design.

Owner:DONGGUAN CHANGYUAN SPRAYING TECH

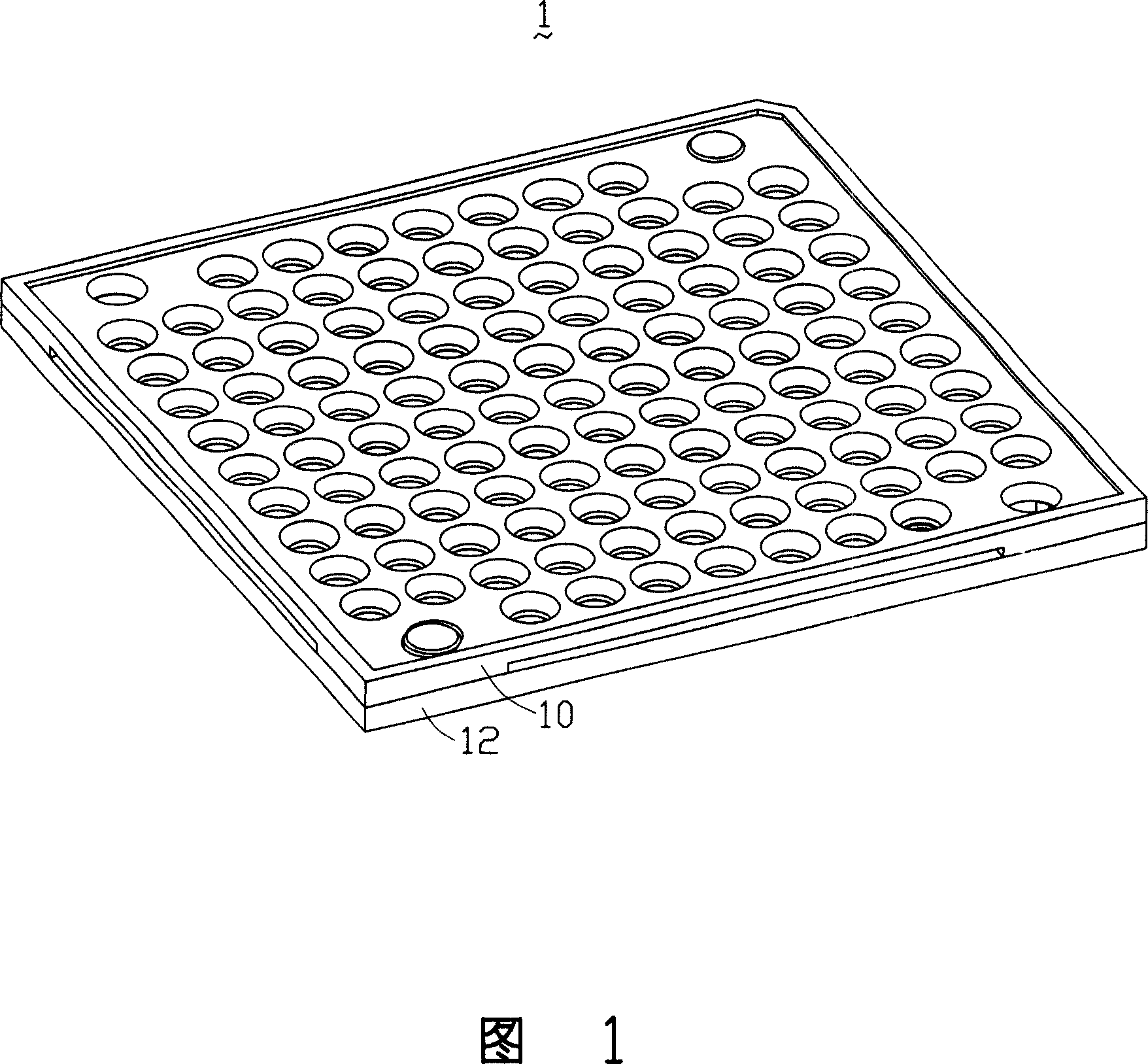

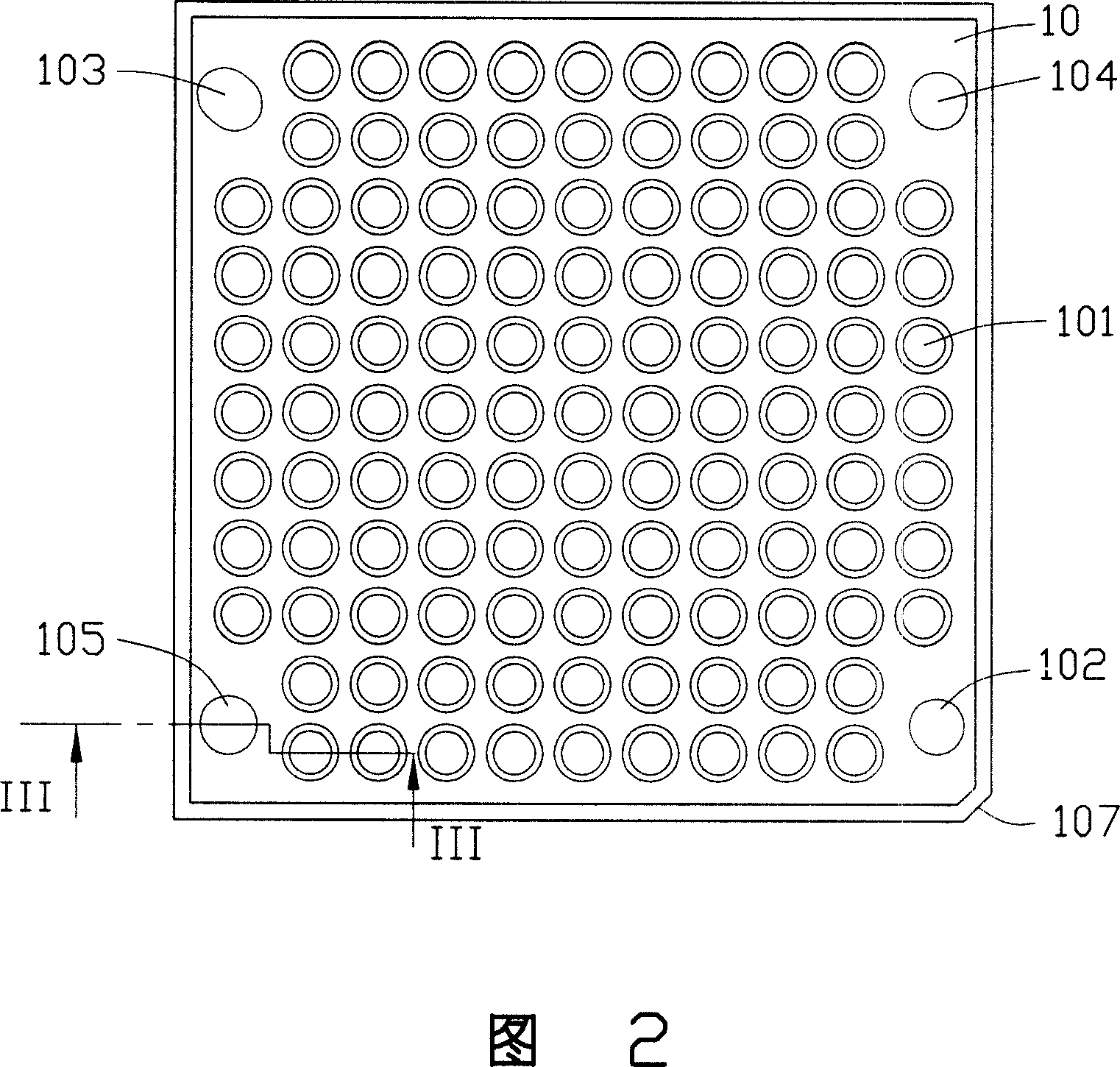

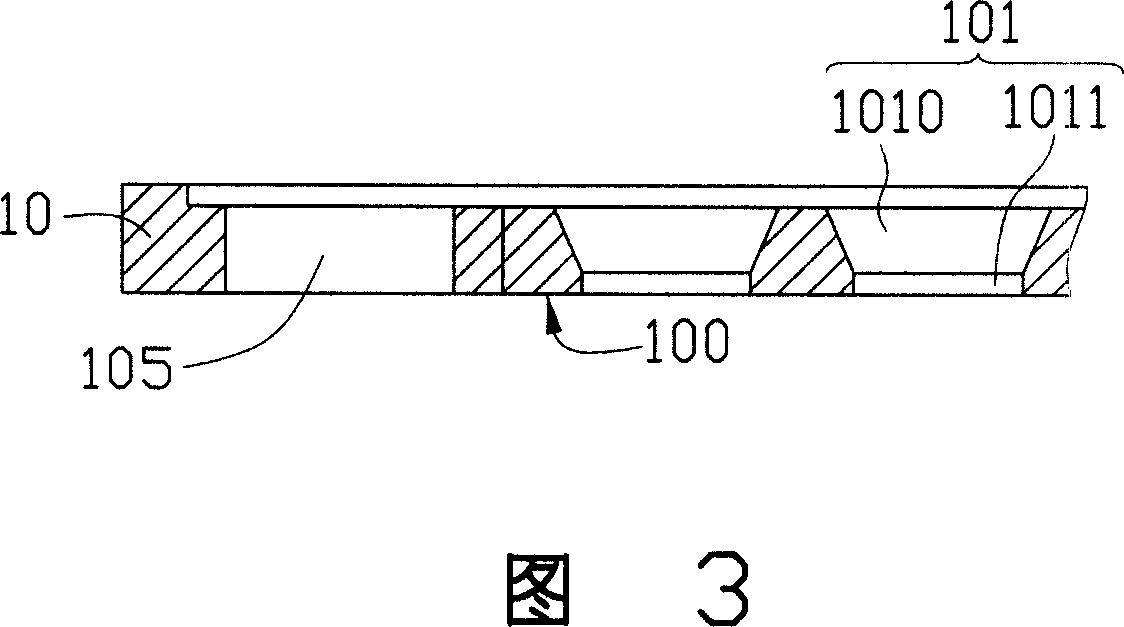

Salver for loading lens

The invention discloses a tray loading lens, including a covered body and ontology. The tray can be used to cut lens, lens coating, lens assembly or more processes. The bulk loading including a lens for the bearing hole formed in the body and covered the body linked to the surface and extends to the medial. Diameter of the carrying hole is greater than the aperture adjacent hole. Using this type of pallet can reduce costs while streamlining cumbersome process, save processing time.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

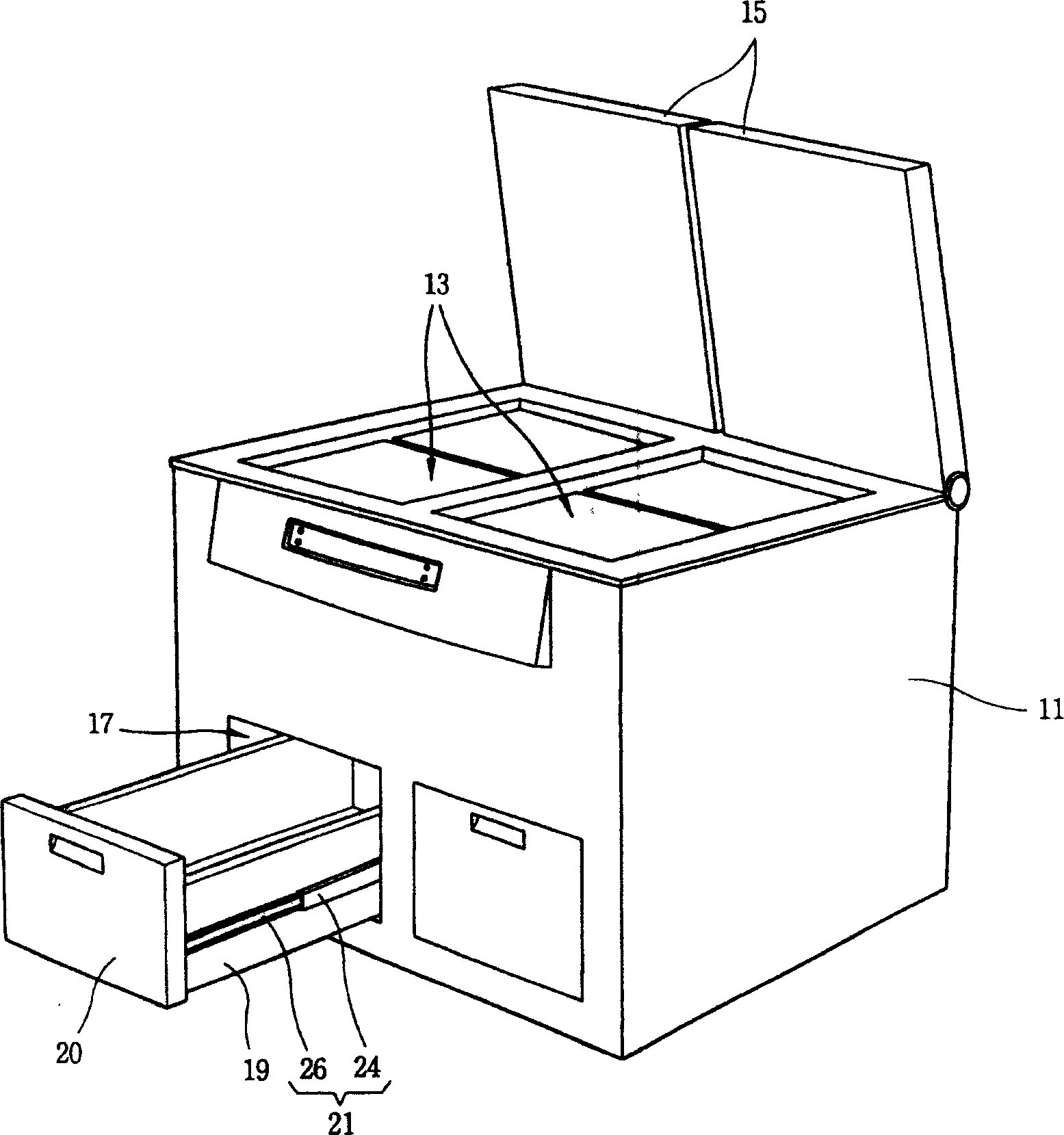

Rails for drawer of refrigerator for preserving pickled vegetable

InactiveCN1690623AEasy to disassembleSimplify the installation processLighting and heating apparatusSupportEngineeringRefrigerated temperature

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

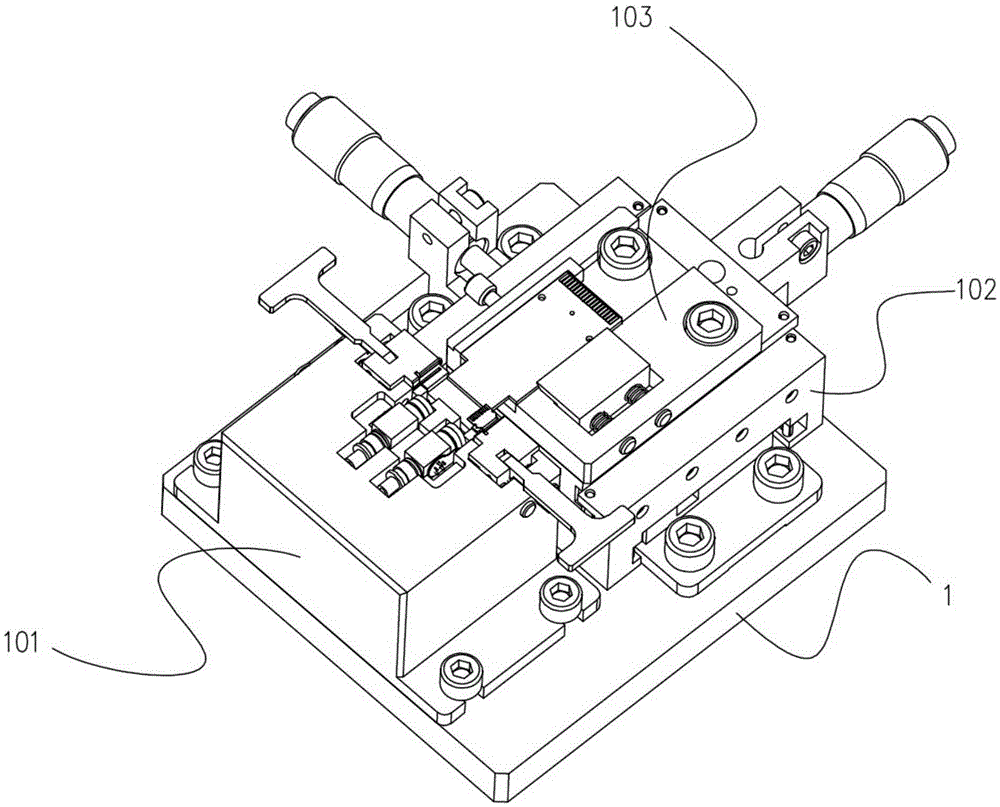

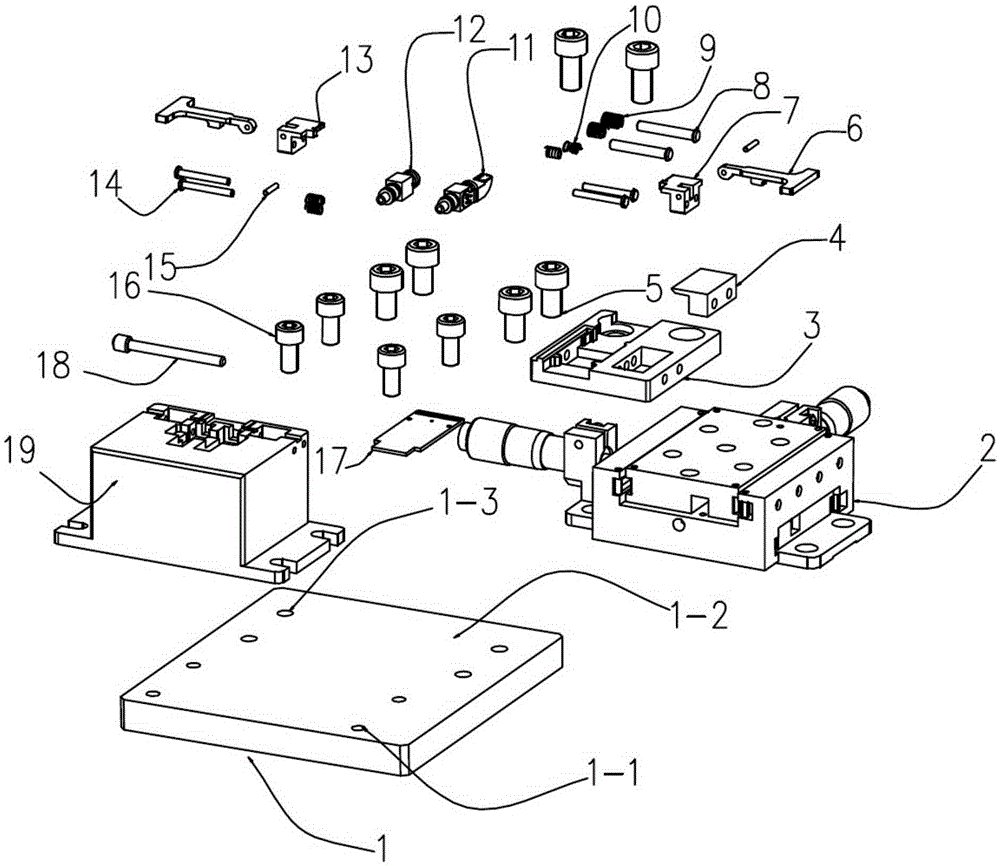

Efficient detector soft belt forming welding jig

ActiveCN105328386AImprove yieldEfficient weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPrinted circuit board

The invention discloses an efficient detector soft belt forming welding jig. The efficient detector soft belt forming welding jig comprises a soft belt positioning mechanism, a fine adjustment alignment mechanism and a printed circuit board (PCB) clamping mechanism which are disposed on a bottom plate, wherein the soft belt positioning mechanism is fixed to a plane of the front side of the bottom plate through small screws and comprises a base which is provided with a positioning groove; the positioning groove can clamp a bi-directional optical sub-assembly (BOSA) device; the fine adjustment alignment mechanism can achieve front-back and right-left displacement through fine adjustment and is fixed to a plane of the rear side of the bottom plate through large screws relative to the soft belt positioning mechanism; the PCB clamping mechanism is disposed on the upper surface of the fine adjustment alignment mechanism and comprises a fixing block and a clamping block; the fixing block is provided with a positioning surface and a boss surface for clamping a PCB; the clamping block is provided with an inclined pressing surface and a stepped stand and can cooperate with the fixing block to clamp the PCB on the PCB clamping mechanism. By means of the structure, accurate alignment and convenient welding of the BOSA device clamped on the base are achieved, and effects of convenient and fast welding and improvement of product yield are also achieved.

Owner:WUHAN TELECOMM DEVICES

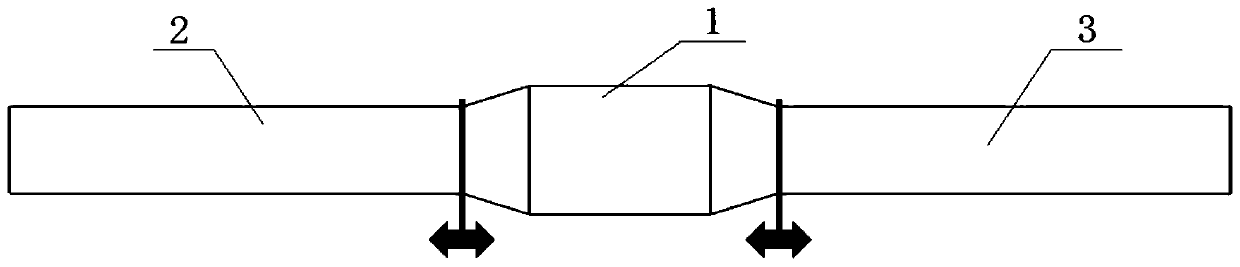

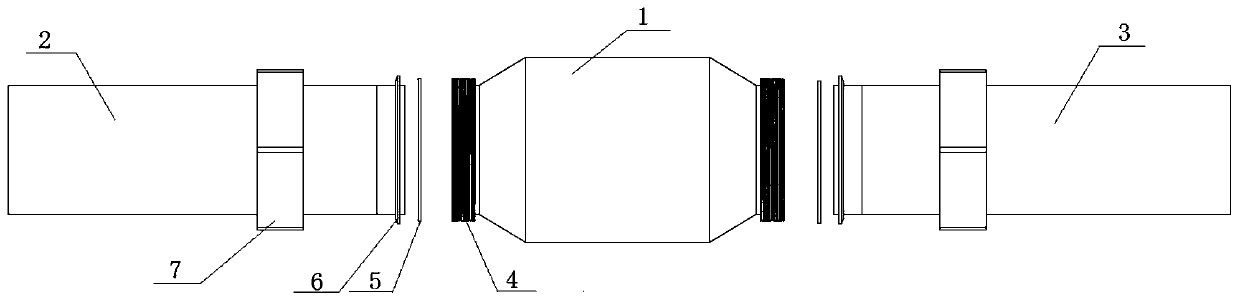

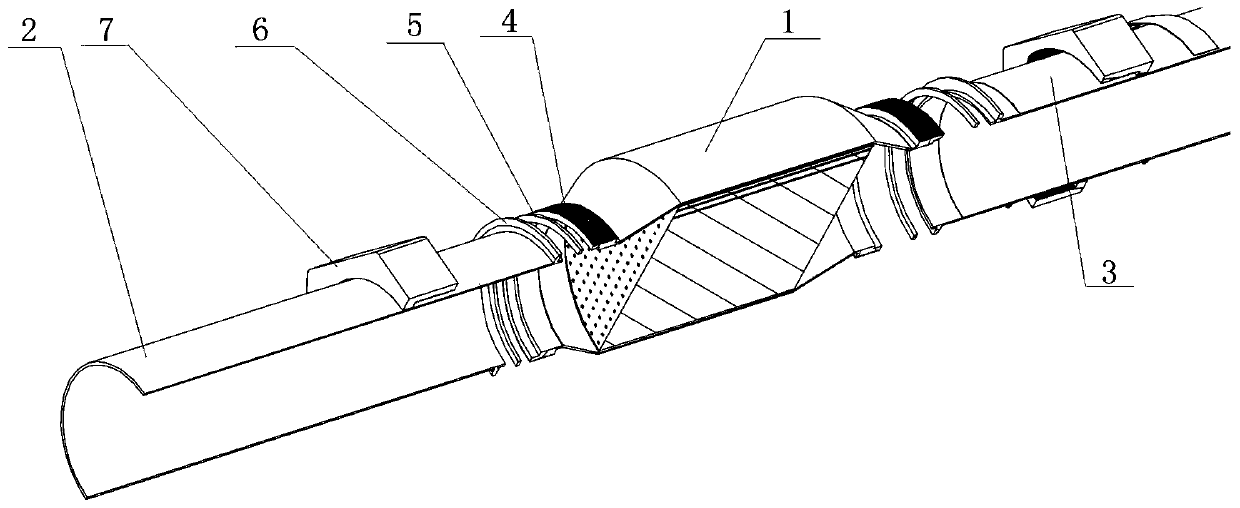

Quick disassembling method for particle catcher of gasoline engine and auxiliary device thereof

ActiveCN110625553ASimplify the installation processShorten the development cycleAssembly machinesWork holdersLocking mechanismGasoline

The invention discloses a quick disassembling method for a particle catcher of a gasoline engine and an auxiliary device thereof. The method comprises the following steps: transforming the particle catcher of the gasoline engine and front and back exhaust air ducts of an original integrated structure; clamping the front and back exhaust air ducts through the auxiliary device and coaxially aligningthe front and back exhaust air ducts to the particle catcher of the gasoline engine in the same direction; putting the particle catcher of the gasoline engine between the front and back exhaust air ducts and placing a sealing gasket; compressing the front and back exhaust air ducts to two ends of the particle catcher of the gasoline engine separately through the auxiliary device; locking a reverse locking mechanism of the auxiliary device; fixedly and hermetically connecting the particle catcher of the gasoline engine to the front and back exhaust air ducts through fastening nuts, separately;and detaching the auxiliary device which is composed of a base, a pipeline clamping mechanism, a pipeline translational transmission mechanism and the reverse locking mechanism. The quick disassembling method simplifies the disassembling process of the particle catcher of the gasoline engine and the disassembling process can be finished by a single person independently, so that the disassemblingefficiency is improved obviously.

Owner:CHINA FIRST AUTOMOBILE

Rotary cutter and rotary cutting apparatus provided with the rotary cutter

ActiveUS20060048621A1Raise the possibilityLow costStock shearing machinesMetal working apparatusMechanical engineering

A rotary cutter for a rotary cutting apparatus. The rotary cutter includes a shaft and a mantle having at least one cutting member. The shaft is non-rotatable, and the mantle is rotatably mounted to the shaft and can be removed therefrom in an axial direction. The shaft is adapted to be rigidly mounted in a frame part, wherein the mantle is rotatably arranged relative to the shaft. The shaft may be in the form of a single piece, or a pair of axially spaced shaft portions.

Owner:HYPERION MATERIALS & TECH SWEDEN AB

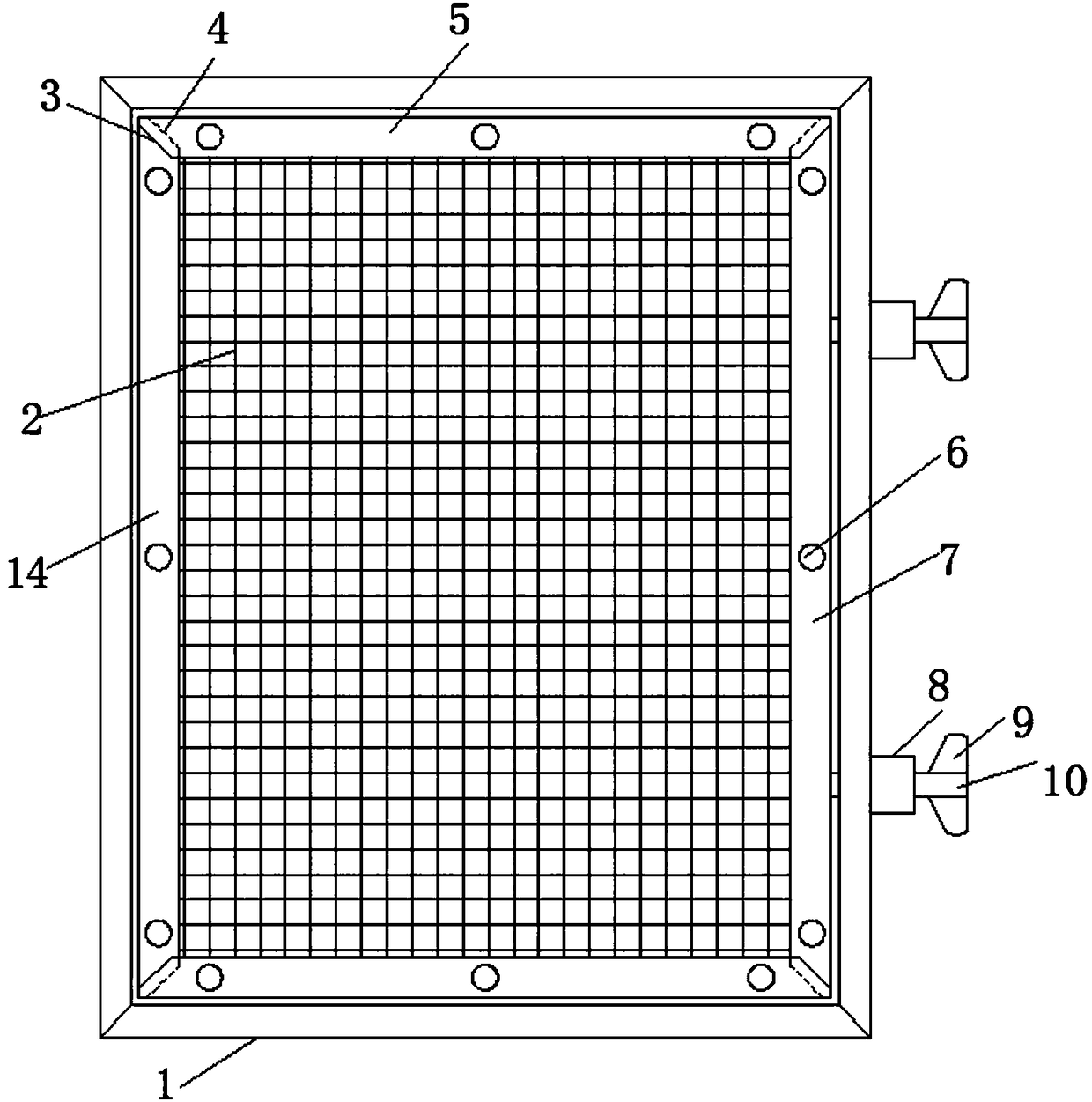

Window frame with yarn mesh convenient to replace

The invention discloses a window frame with yarn mesh convenient to replace, and relates to the technical field of window frames. The window frame with the yarn mesh convenient to replace comprises anouter frame. A sunken area is arranged on the outer frame. A compacting device is connected to the sunken area in a detachable mode. The compacting device is used for clamping the yarn mesh. According to the window frame with the yarn mesh convenient to replace, the disassembling and assembling of the yarn mesh are simple, the operation is convenient, and at the same time, compared with a pressing strip, a pressing plate can be used for a long time without replacing; the resource and cost are saved; and through the design of the upper and lower pressing plates and a tensioning device, the loosened yarn mesh can be easily tensioned again, the recycling of the yarn mesh is realized, and the resource and cost are saved.

Owner:利辛县逸安新能源有限公司

Portable automotive suspension disassembly and assembly device and disassembly and assembly method thereof

InactiveCN103722523ASimplify the disassembly processEasy to operateMetal-working hand toolsAutomotive engineeringJackscrew

The invention provides an automotive suspension disassembly and assembly device and a disassembly and assembly method thereof. The automotive suspension disassembly and assembly device comprises an upper plate and a lower plate, wherein the upper plate and the lower plate are connected through at least one vertical column. The upper plate is provided with a movable plate and a locating pin, one end of the movable plate is connected with the upper plate through a bolt, an installation hole matched with the locating pin is formed in the other end, and a hole is formed in the middle of the upper plate. The lower plate is provided with a jack and a rocking lever used for controlling the height of the jack. The automotive suspension disassembly and assembly device has the advantages that the operation is easy, convenient, safe and reliable. The disassembly and assembly process of a suspension is simple, and the automotive suspension disassembly and assembly device can be used without training. In addition, the automotive suspension disassembly and assembly device can bear large compression force and restoration force, is stressed uniformly, and is safe and reliable.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com