External mixing type atomization nozzle

A technology of atomizing nozzles and nozzles, which is applied to spray devices, liquid spray devices, etc., can solve the problems of liquid backflow to the air passage, air leakage and liquid leakage, complicated maintenance, etc., to simplify the structure, increase the spray area, and seal good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

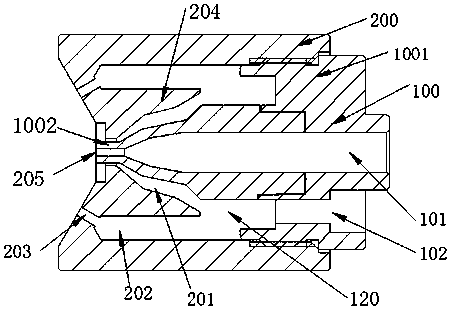

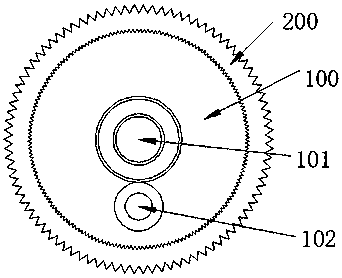

[0027] like Figure 1-3 As shown, the present invention consists of a liquid cap 100 and an air cap 200 . One end of the liquid cap 100 protrudes outward to form a connecting portion 1001 , and the other end shrinks toward the center. The liquid cap 100 is a middle-pass structure, and its inside is a liquid cavity 101, and one end of the liquid cavity 101 shrinks inwardly and is the same end as the aforementioned contracting end, and the end portion is a water spray cavity 1002; There are axial through holes as air inlets.

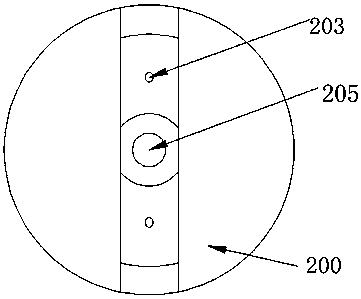

[0028] The air cap 200 has a concave structure, and a nozzle 205 is opened at the bottom of the concave part, and a bump 204 is formed around the nozzle 205 .

[0029] The liquid cap 100 is connected with the air cap 200 through the connection part 1001. After the two are connected, a space is formed between the two as the air cavity 120, and the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com