Portable automotive suspension disassembly and assembly device and disassembly and assembly method thereof

A technology of automobile suspension and assembly method, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of inability to use alone, complicated operation, and inconvenient operation, and achieves the improvement of work efficiency, the overall structure is simple, and the operation is simple and convenient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

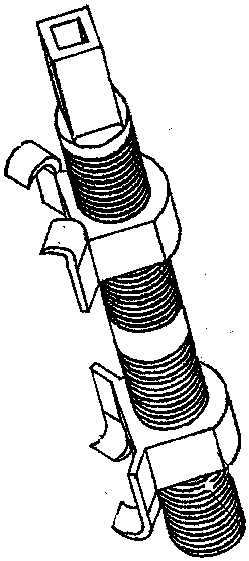

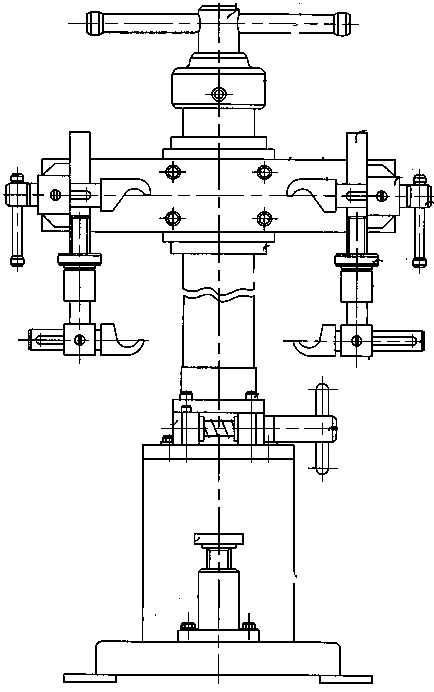

[0065] like image 3 and Figure 4 Shown, a kind of portable automobile suspension dismounting device is made up of upper plate 10, movable plate 20, lower plate 90, circular column 70, jack 80, rocking bar 60 etc. There is a hole 30 in the middle of the upper plate 10, and the upper plate 10 can adjust the assembly height of the suspension assembly through the nut 50 on the upper part of the circular column 70; , the movable plate 20 can rotate around the bolt 50, the positioning pin 51 needs to be buckled when the upper plate 10 is closed, and the positioning pin 51 needs to be taken out when the upper plate 10 is opened; The surface and the upper surface of the movable plate 20 are smooth; the jack 80 is connected and fixed with the lower plate 90 by nuts, and the center of the jack 80 is aligned with the center of the hole 30 of the upper plate 10 to ensure that the parts of the suspension assembly are in the same vertical position during the disassembly process. in a st...

Embodiment 2

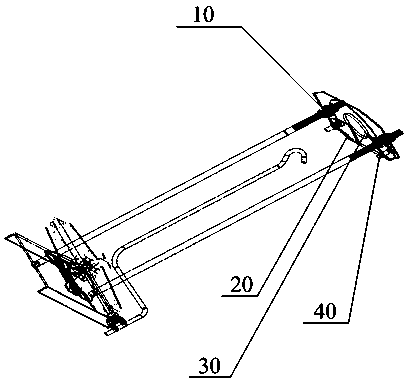

[0067] like Figure 5 Shown, by the first upper plate 11, the second upper plate 12, lower plate 90, square column 41, jack 80, rocking bar 60 forms. A round hole 21 is arranged between the first upper plate 11 and the second upper plate 12, and the first upper plate 11 and the second upper plate 12 can adjust the assembly height of the suspension assembly through the threaded nut at the upper thread of the square column 41; The first upper plate 11 and the second upper plate 12 are positioned and connected together by threaded nuts, connecting reinforcing plates 71 and bolts and nuts 81, wherein the threaded nuts play a positioning role, and a certain gap is left between the upper and lower nuts to facilitate the first The first upper plate 11 and the second upper plate 12 are disassembled and taken out, and the connecting reinforcement plate 81 and the bolts and nuts 81 are connected and fixed; the jack 61 is connected and fixed with the lower plate 91 by bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com