Quick disassembling method for particle catcher of gasoline engine and auxiliary device thereof

A technology of particle trap and disassembly method, which is applied in the direction of workpiece clamping device, assembly machine, metal processing, etc., can solve the problems of surge in development workload, cumbersome disassembly process, low test efficiency, etc., and achieve clamping process Efficient and reliable, simplifies the assembly and disassembly process, and shortens the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

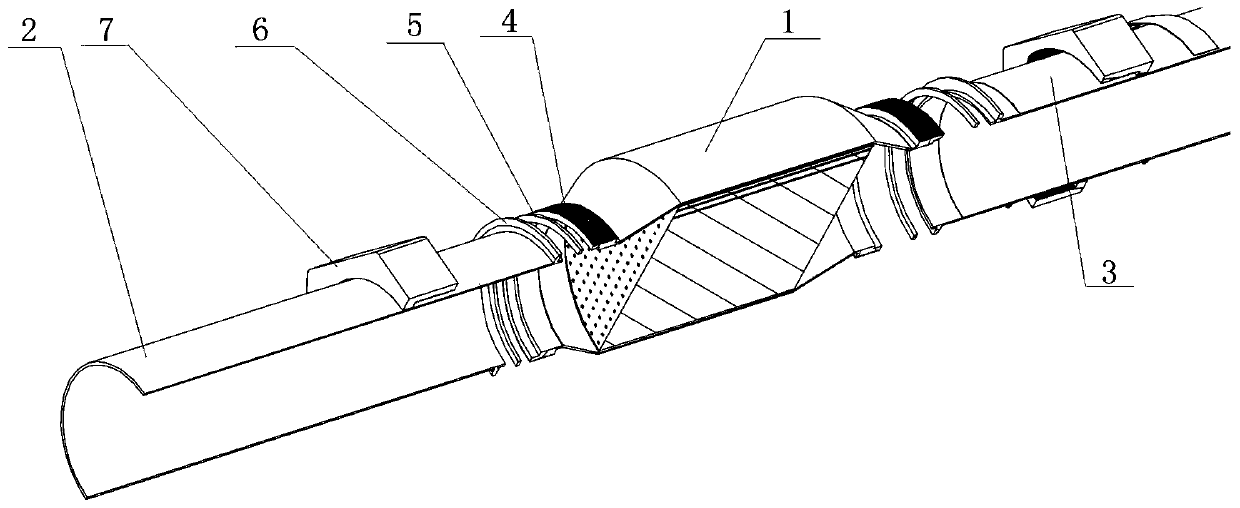

[0056] In order to clearly and completely describe the technical solution of the present invention and its specific working process, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

[0057] The present invention provides a quick disassembly and assembly method of a gasoline engine particulate filter and its auxiliary device. The specific process of the disassembly method is as follows:

[0058] In the disassembly method, the specific process of installing the gasoline engine particulate filter is as follows:

[0059] Step 1: Renovate the original one-piece gasoline engine particulate filter and the front and rear exhaust pipes;

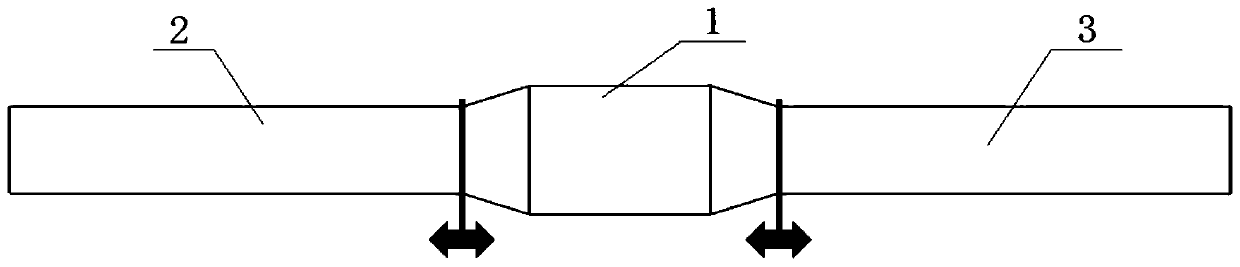

[0060] 1.1 as figure 1 As shown, the original gasoline engine particle filter and the front and rear exhaust pipes are divided into three parts: front exhaust pipe 2, gasoline engine particle filter 1 and rear exhaust pipe 3;

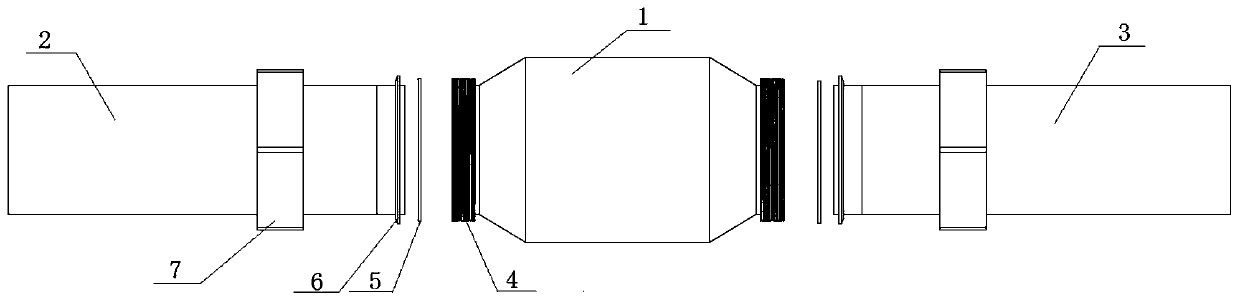

[0061] 1.2 as figure 2 As shown, the collector connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com