Salver for loading lens

A tray and lens technology, applied in lens, installation, optics, etc., can solve the problems of lens damage, frequent disassembly and assembly by operators, inconvenient lens transportation and storage, etc., and achieve the effect of simplifying disassembly or replacing trays and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

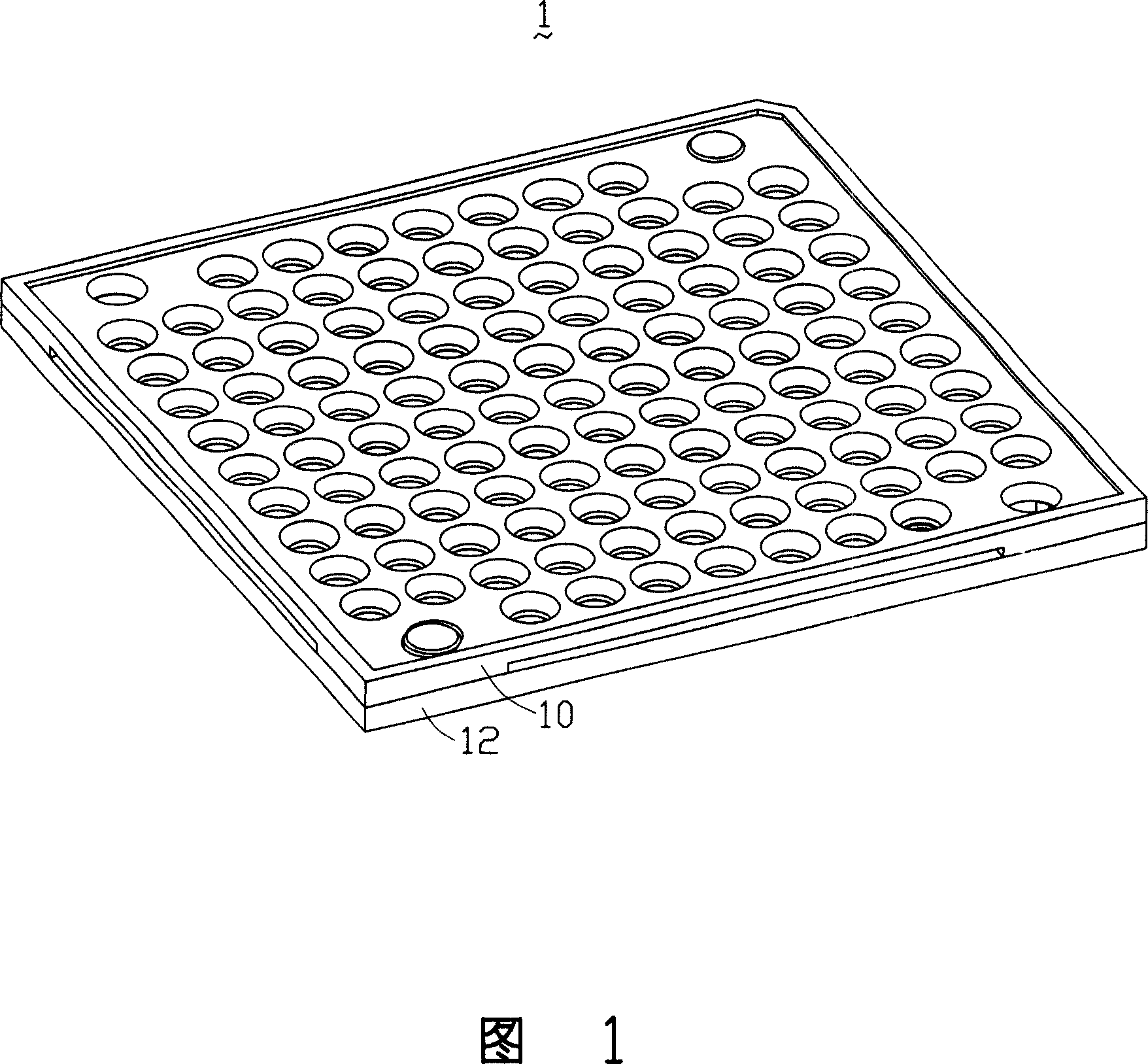

[0017] Referring to FIG. 1 , the lens loading tray 1 provided in this embodiment is roughly square in shape, and includes a cover 10 and a body 12 , and the cover 10 fits with the body 12 . The tray 1 can be made of metal material or plastic material. Aluminum can be used as the metal material; antistatic materials such as modified polyphenylene ether (Modified Polyphenylene Ether; MPPE for short) can be used as the plastic material; Fiber) polycarbonate and glass fiber mixture and other non-antistatic materials.

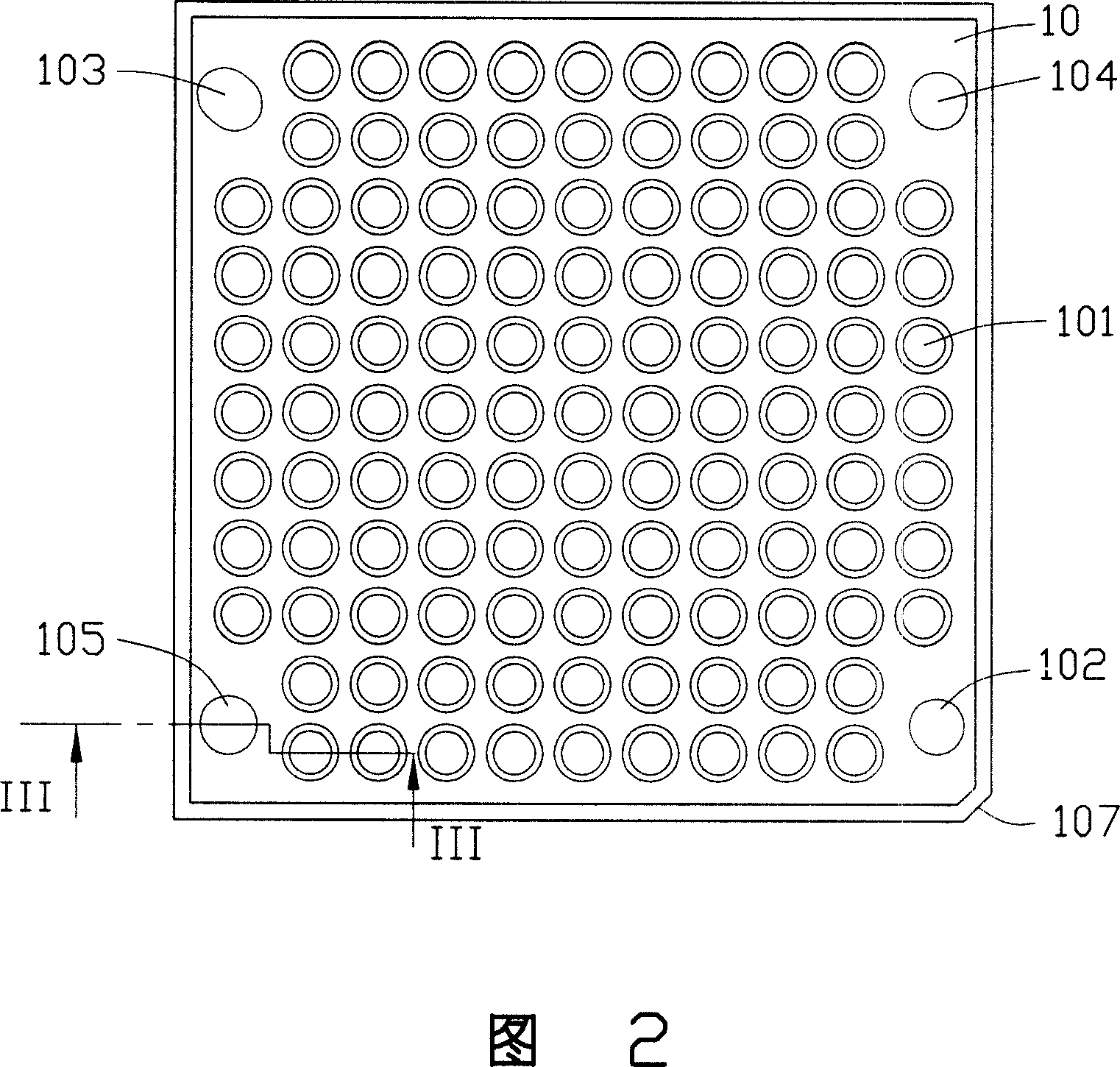

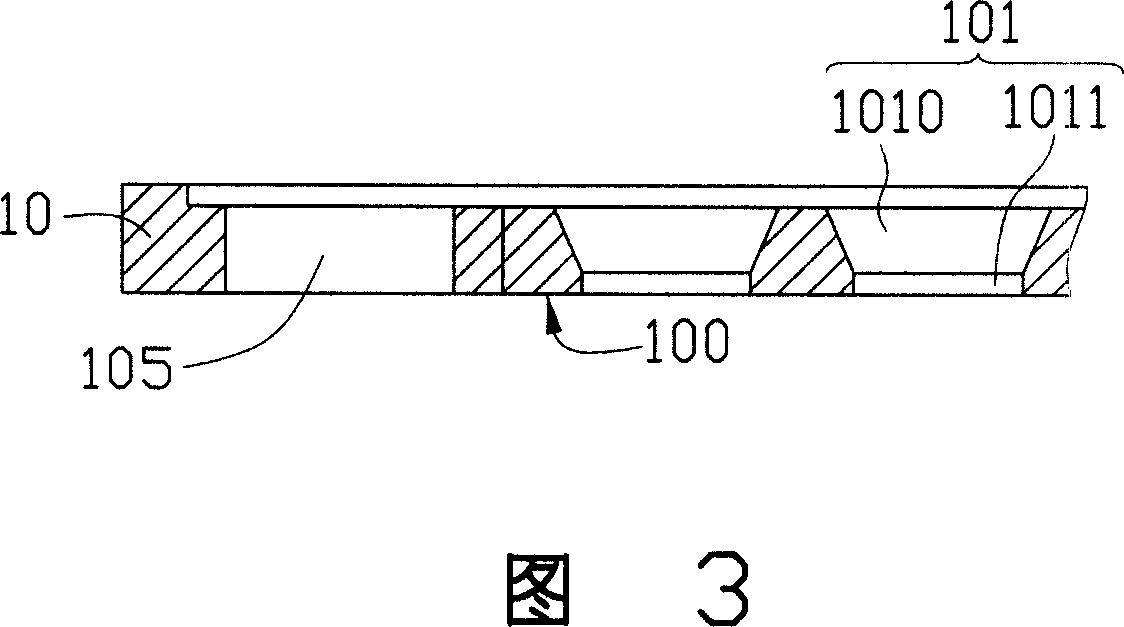

[0018] Please refer to FIG. 2 , FIG. 3 and FIG. 4 , the cover body 10 includes a top surface (not shown in the figure), an opposite bottom surface 100 , and a plurality of first through holes 101 . Wherein, the bottom surface 100 is a surface matched with the body 12; the plurality of first through holes 101 can be distributed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com