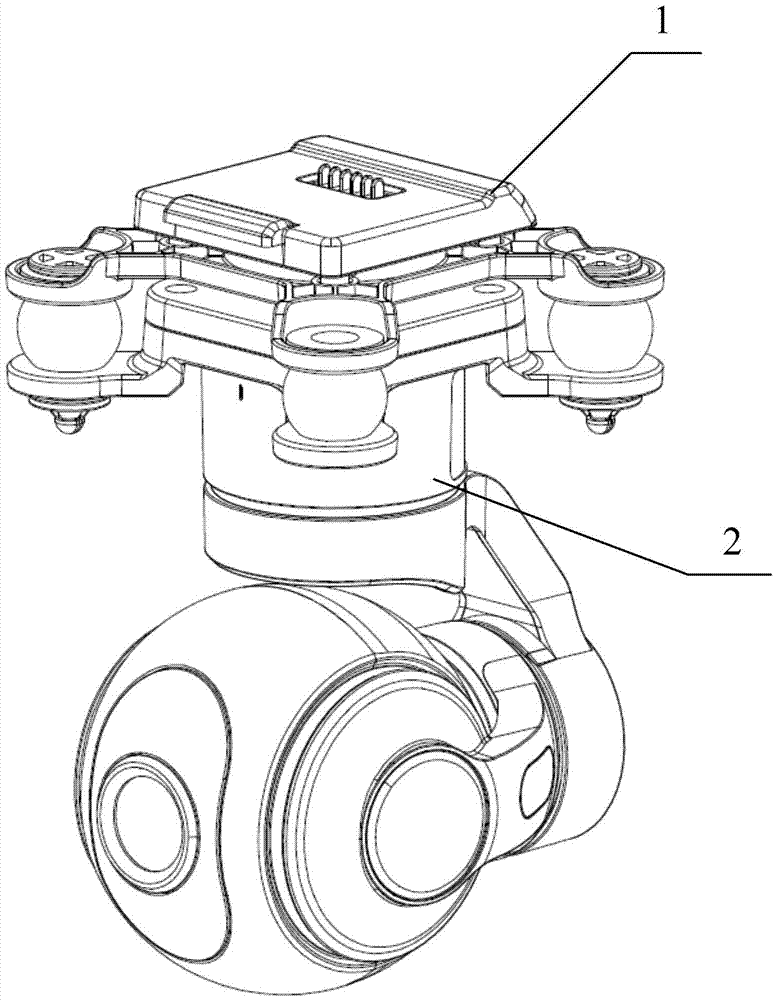

Quick disassembly and assembly structure of holder and unmanned aerial vehicle

A technology of drones and gimbals, applied in the field of drones, can solve problems such as difficult operation by ordinary users, cumbersome disassembly process, etc., and achieve the effect of quick disassembly, simplified disassembly process, and firm assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

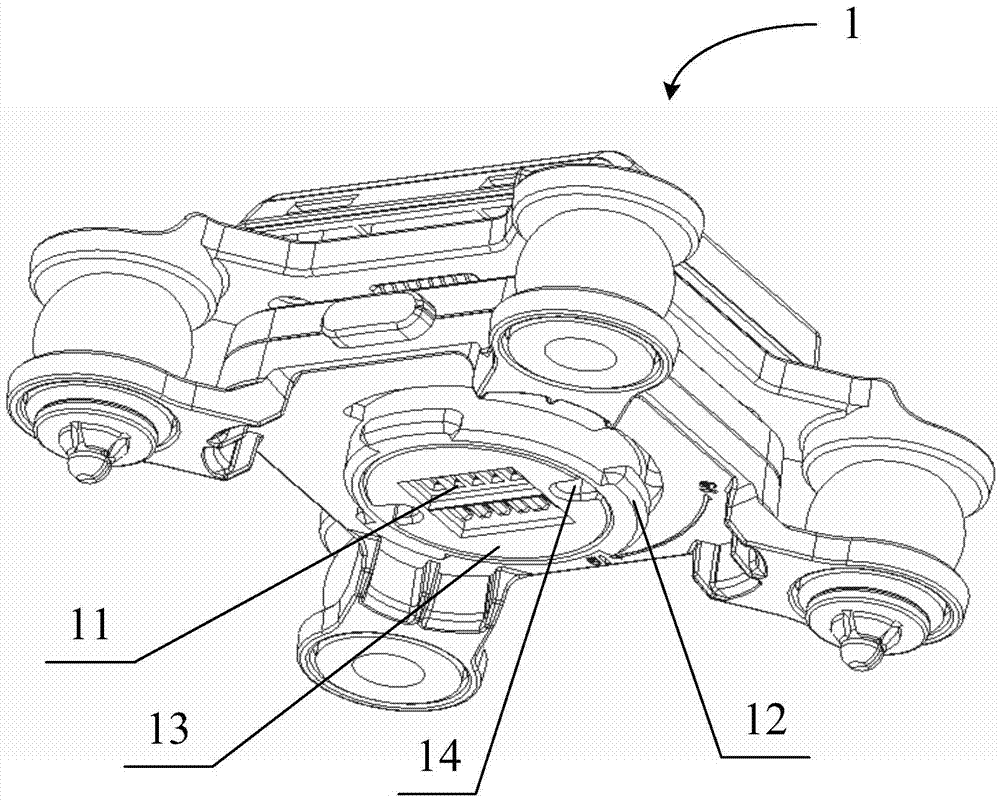

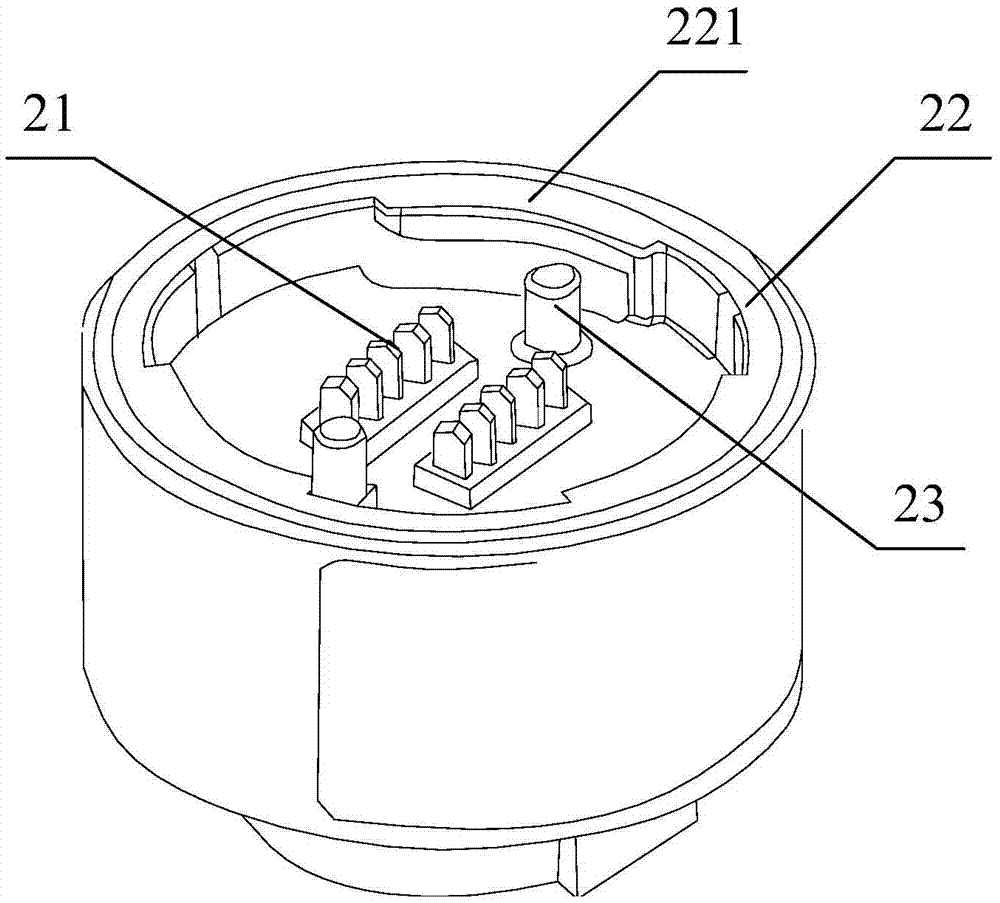

[0050] In an exemplary embodiment, the hooking part may include: figure 2 At least one protrusion 12 at the bottom of the shown shock-absorbing connection structure 1 and image 3 At least one notch 221 is formed on the annular protrusion 22 at the top of the platform structure 2 shown.

[0051] Among them, such as figure 2 As shown, the protrusion 12 is located on the bottom outer wall of the shock-absorbing connection structure 1 and is arranged along the radial direction at the corresponding position; at the same time, as image 3 As shown, the annular protrusion 22 is located at the top inner wall of the platform structure 2 and is set along the radial direction at the corresponding position; Set in the horizontal direction.

[0052] Since the power supply port 11 and the power interface 21 are respectively located inside the shock-absorbing connection structure 1 and the cloud platform structure 2, and the protrusion 12 and the notch 221 are respectively located at t...

Embodiment 2

[0058] In another exemplary embodiment, similar to Embodiment 1, the hooking part may include: at least one protrusion arranged radially on the top outer wall of the platform structure 2 , and at least one protrusion along the bottom inner wall of the shock-absorbing connection structure 1 . A radially arranged annular protrusion, and at least one notch is provided on the annular protrusion; wherein, the protrusion can pass through when the pan-tilt structure 2 forms a first preset rotation angle relative to the shock-absorbing connection structure 1 pass through the notch, and the protrusion can hang on the upper end surface of the annular protrusion where the notch is not provided when the pan-tilt structure 2 forms a second preset rotation angle relative to the shock-absorbing connection structure 1 . Since only the positions of the protrusion and the notch are reversed, the rest of the structure and matching process are the same as those in Embodiment 1, so no more details ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com