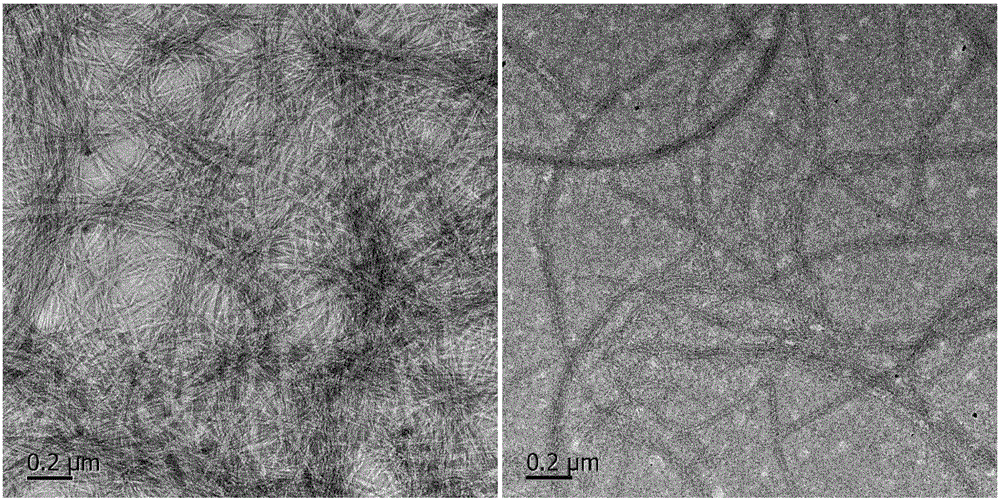

Beet pulp cellulose nanofibril and preparation method thereof

A technology of beet pulp and cellulose, applied in the post-processing of cellulose pulp, fiber raw materials, fiber raw material processing and other directions, can solve the problems of high cost, complex chemical pretreatment process, environmental pollution, etc. Component separation and structural changes, the effect of a simple disassembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A method for preparing sugar beet pulp cellulose nanofibers in this embodiment comprises the following steps:

[0054] (1) Pretreatment of sugar beet meal

[0055] Wash the sugar beet granules with cold water, dry at 50°C, pulverize, pass through 100-mesh and 200-mesh sieves, collect materials between 100 mesh and 200 mesh to obtain sugar beet meal powder, and seal and store for later use.

[0056] (2) Steam explosion pretreatment

[0057] Measure 500mL of deionized water, add it to the steam explosion reaction tank, weigh 30g of beet meal powder, wrap it with copper mesh and put it on a tripod, then put it in the explosion reaction tank, and assemble the steam explosion reaction tank After sealing, heat at 220°C for 35 minutes, then open the valve, depressurize instantaneously for blasting, collect the blasted material and centrifuge (10000rmp, 10min) and then suction filter, dry the obtained filter residue at 50°C, and set aside, the filtrate Set aside, repeat the a...

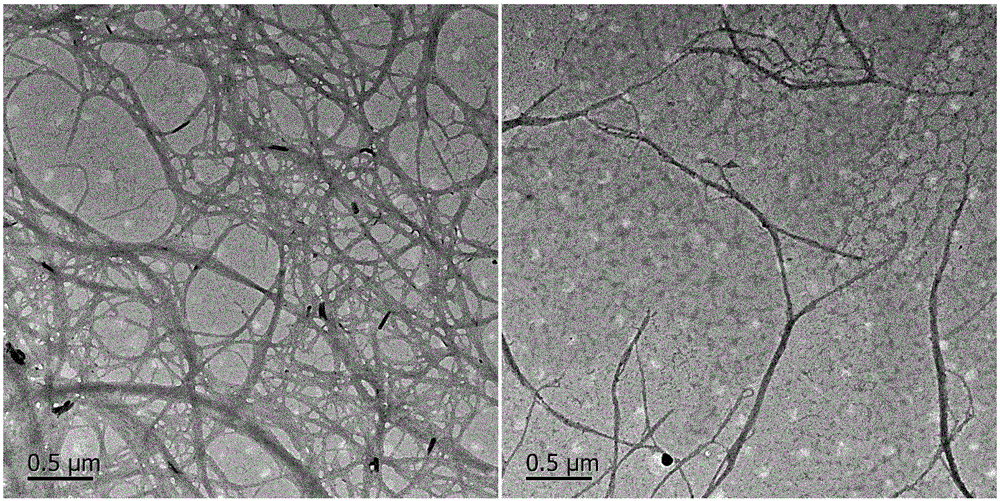

Embodiment 2

[0068] A method for preparing sugar beet pulp cellulose nanofibers in this embodiment comprises the following steps:

[0069] (1) Pretreatment of sugar beet meal

[0070] Wash the sugar beet granules with cold water, dry them at 50°C, crush them, pass through 100-mesh and 200-mesh sieves, collect materials between 100 mesh and 200 mesh, and obtain sugar beet meal powder, which is sealed and stored for later use;

[0071] (2) Steam explosion pretreatment

[0072] Measure 500mL of deionized water, add it to the steam explosion reaction tank, weigh 40g of beet meal powder, wrap it with copper mesh and put it on a tripod, then put it in the explosion reaction tank, and assemble the steam explosion reaction tank After sealing, heat at 220°C for 35 minutes, then open the valve, depressurize instantaneously for blasting, collect the blasted material and centrifuge (10000rmp, 10min) and then suction filter, dry the obtained filter residue at 50°C, and set aside, the filtrate Set asi...

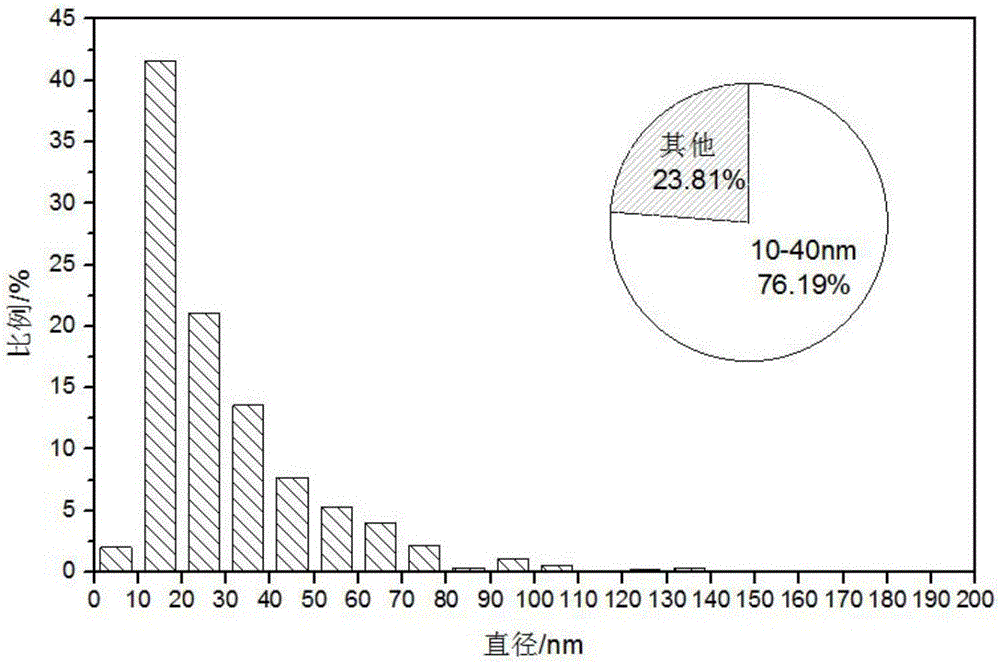

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com