Textile tool with temporary protection

A technology for tools, protective materials, used in textiles, textiles and paper, knitting, etc., to solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

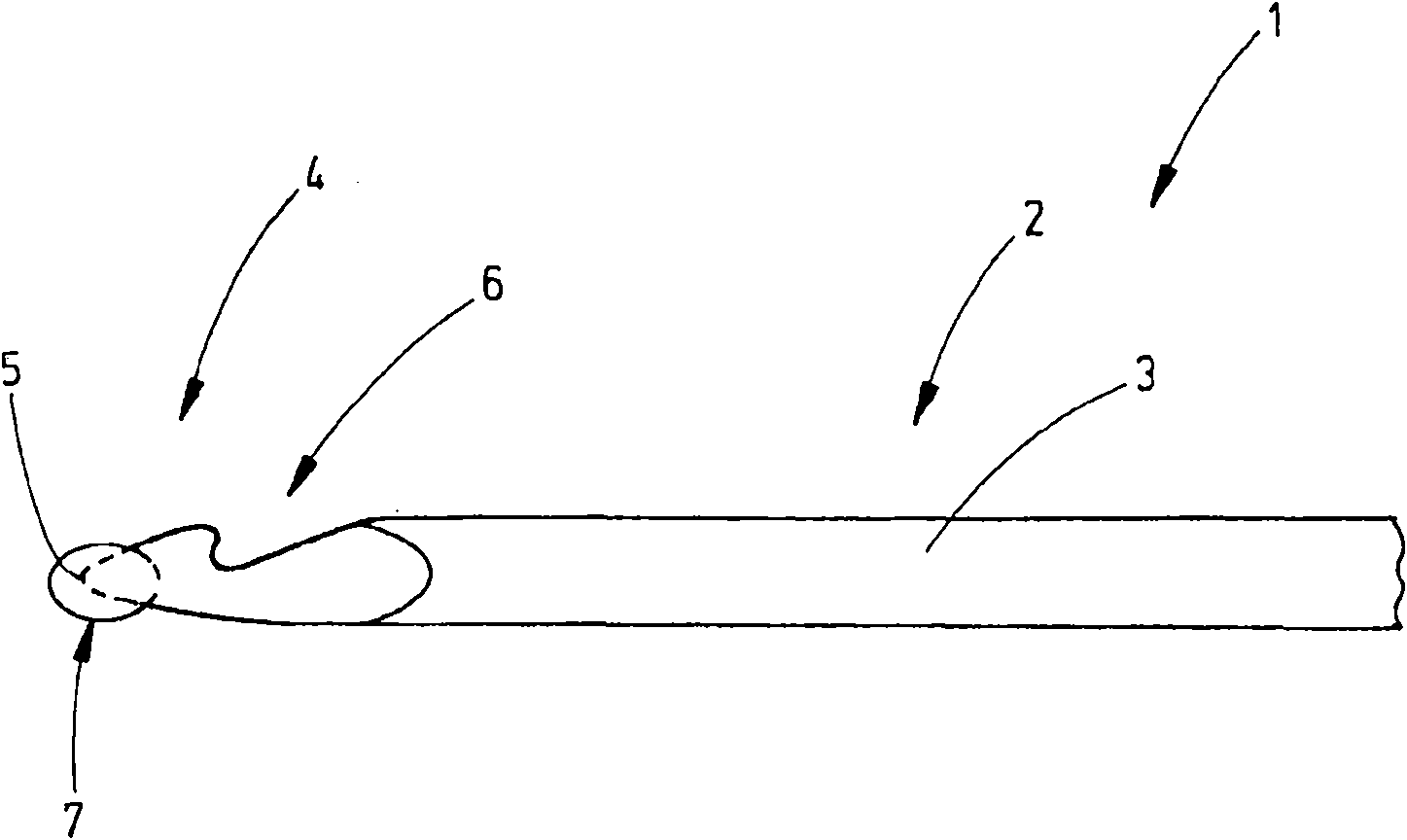

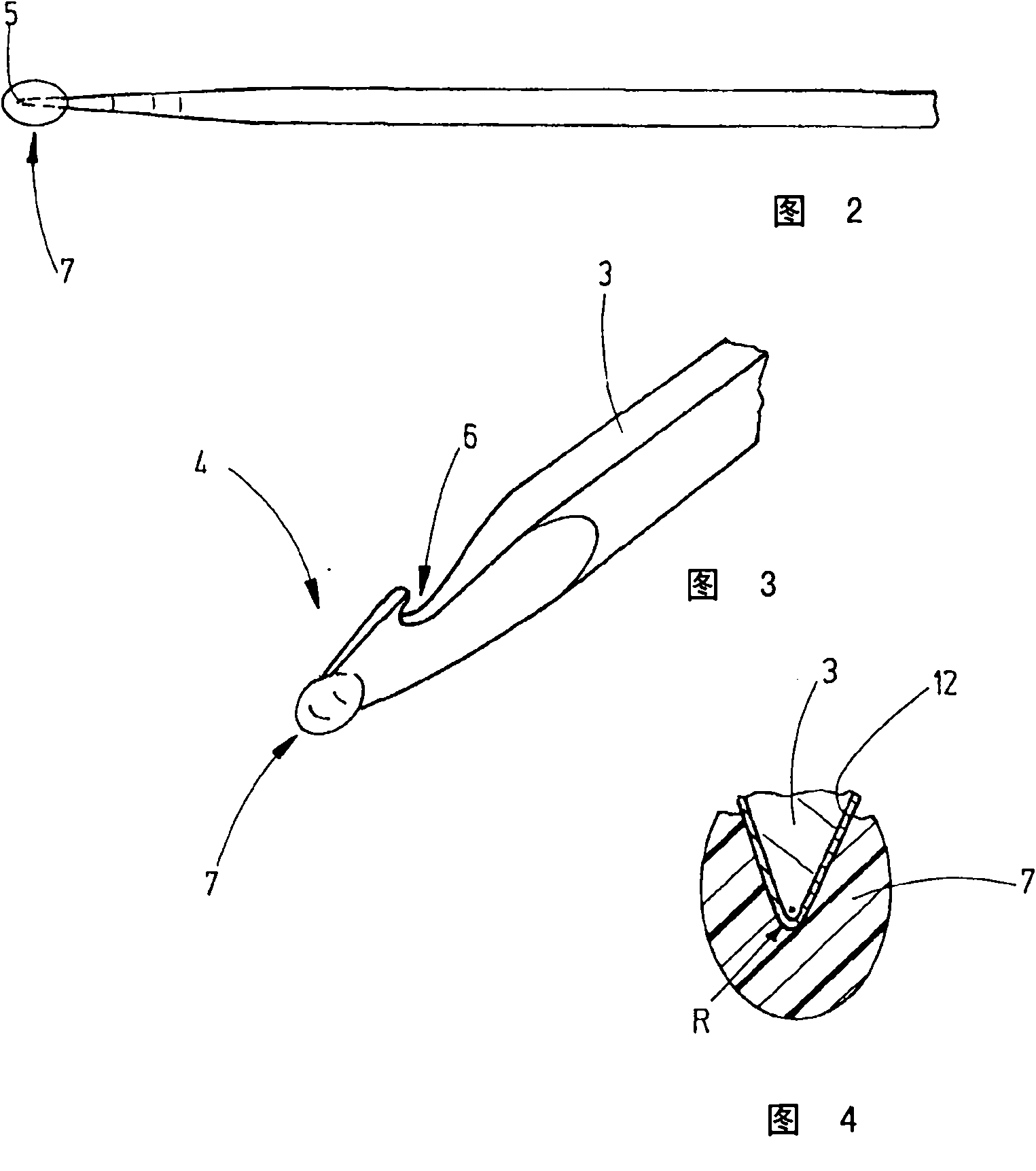

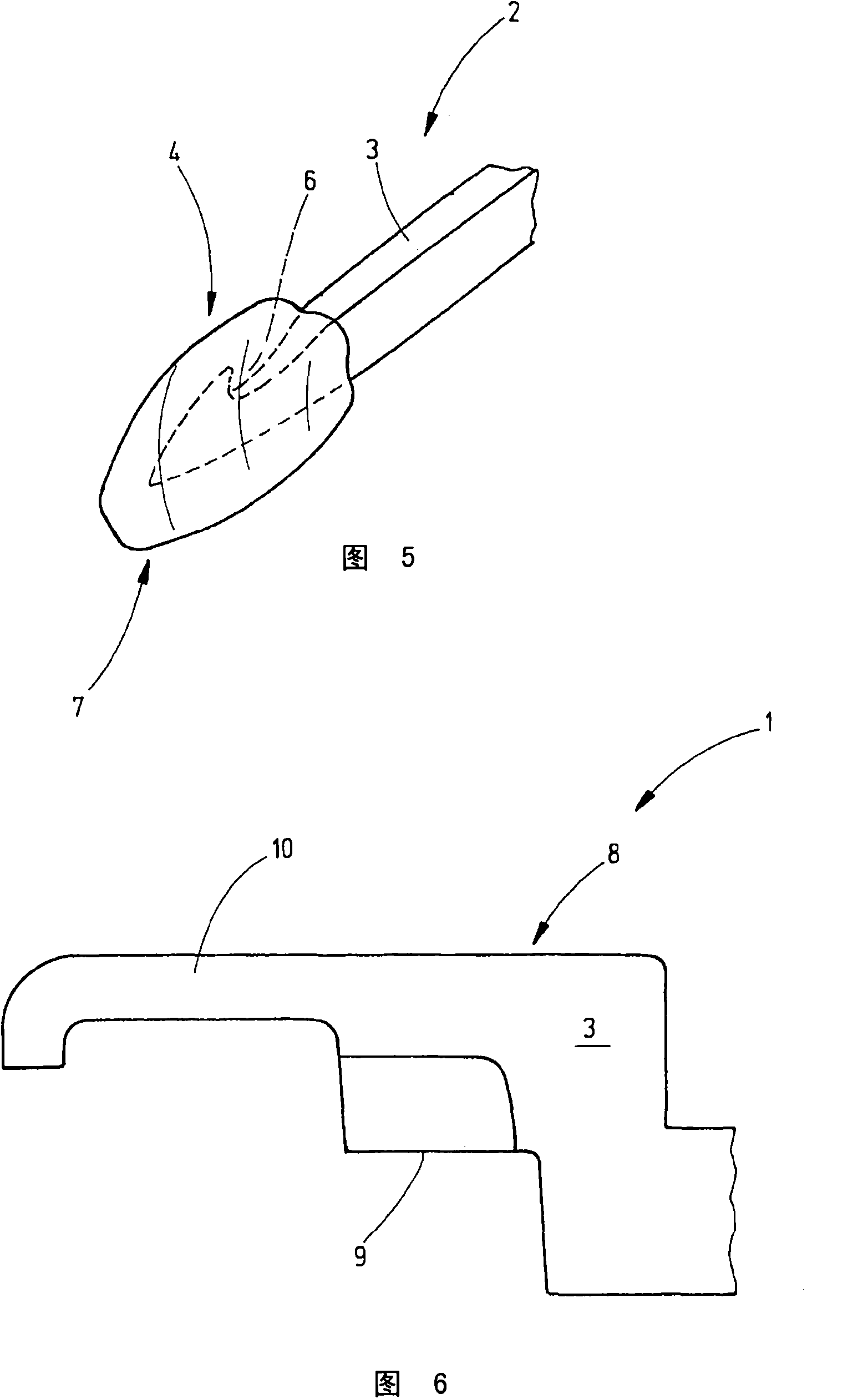

[0022] attached figure 1 Details of a representative embodiment of a textile tool 1 , namely a knitting needle 2 are shown. However, the term "textile tool" 1 is understood as any common tool used in the textile industry to act on threads or materials made of threads. Textile implements in this sense are in particular: knitting needles, e.g. tongue needles or slider needles or non-latch needles; sewing needles; trocar needles; milling needles; tufting needles; loop catchers; tufting blade; heddle; sheet; or the like.

[0023] The knitting needle 2 has a body 3, preferably made of steel. At the end 4 arranged to act on the textile material and the thread and thus representing the working part, the body 3 has a tip 5, whereby a needle hook 6 can be provided in the vicinity of said tip. At least in the region of the tip 5, but preferably at the entire end 4 or on a larger surface of the body 3 or on the entire surface of said body, the main body 3 is provided with an anti-wear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com