Patents

Literature

108 results about "Needle track" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Injection devices that provide reduced outflow of therapeutic agents and methods of delivering therapeutic agents

Injection devices are provided, which reduce potential outflow of therapeutic agents from an injection site. Devices are provided having at least a first lumen containing one or more therapeutic agents and a second lumen containing a second material for injection into tissue. Other devices are provided having an inner lumen with an injection needle to inject a therapeutic agent and an outer lumen that provides a vacuum seal between the injection needle and the needle track. Further provided are methods of delivering a therapeutic agent to tissue.

Owner:BOSTON SCI SCIMED INC

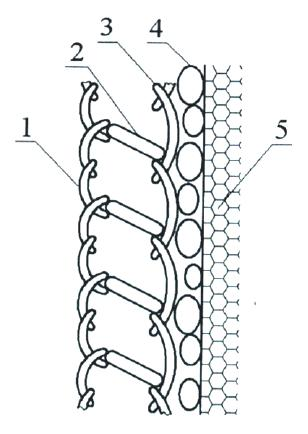

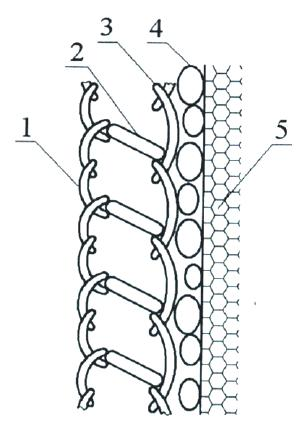

Water-repellent anti-contamination hygroscopic perspiratory composite tissue knitted fabric and production method thereof

ActiveCN102031622AGood water repellency and antifouling functionGood moisture wicking functionWeft knittingBleaching apparatusYarnNatural fiber

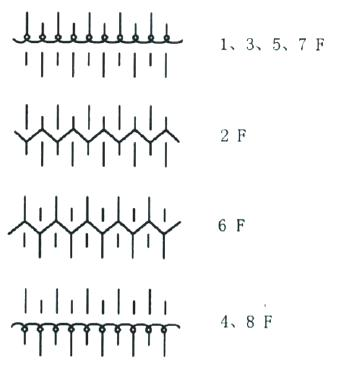

The invention relates to a water-repellent anti-contamination hygroscopic perspiratory composite tissue knitted fabric produced in knitting industry and a production method thereof. An outer coil of the knitted fabric is made of yarn treated by water-repellent anti-contamination technology; a coil at a middle connection layer is made of natural fiber yarn with good hygroscopic and water absorbent performance; an inner coil is made of hygroscopic fiber yarn, and the hygroscopic fiber yarn is treated by hydrophilicity, has a microcellular structure and is in a deformed cross section; the fabric tissue is double-rib double-layer composite tissue, and is knitted on a 2+2 needle track double-surface circular knitting machine; and the knitted fabric is subjected to preforming, degreasing and cleaning, softening, dewatering, expanding, drying, forming and the like. The outer layer of the provided knitted fabric has excellent water-repellent anti-contamination function, and the inner layer has excellent hygroscopic perspiratory function; the knitted fabric has soft hand feel, good permeability and elasticity and antistatic performance, and is widely applied to sportswear, summer clothing, work clothes of hotels and oil field, regimentals and the like; three-tissue structure of the knitted fabric is formed by one-step knitting so that the production technology has easiness in control and the product quality is reliable.

Owner:ANHUI HAOBO INT UNDERWEAR +1

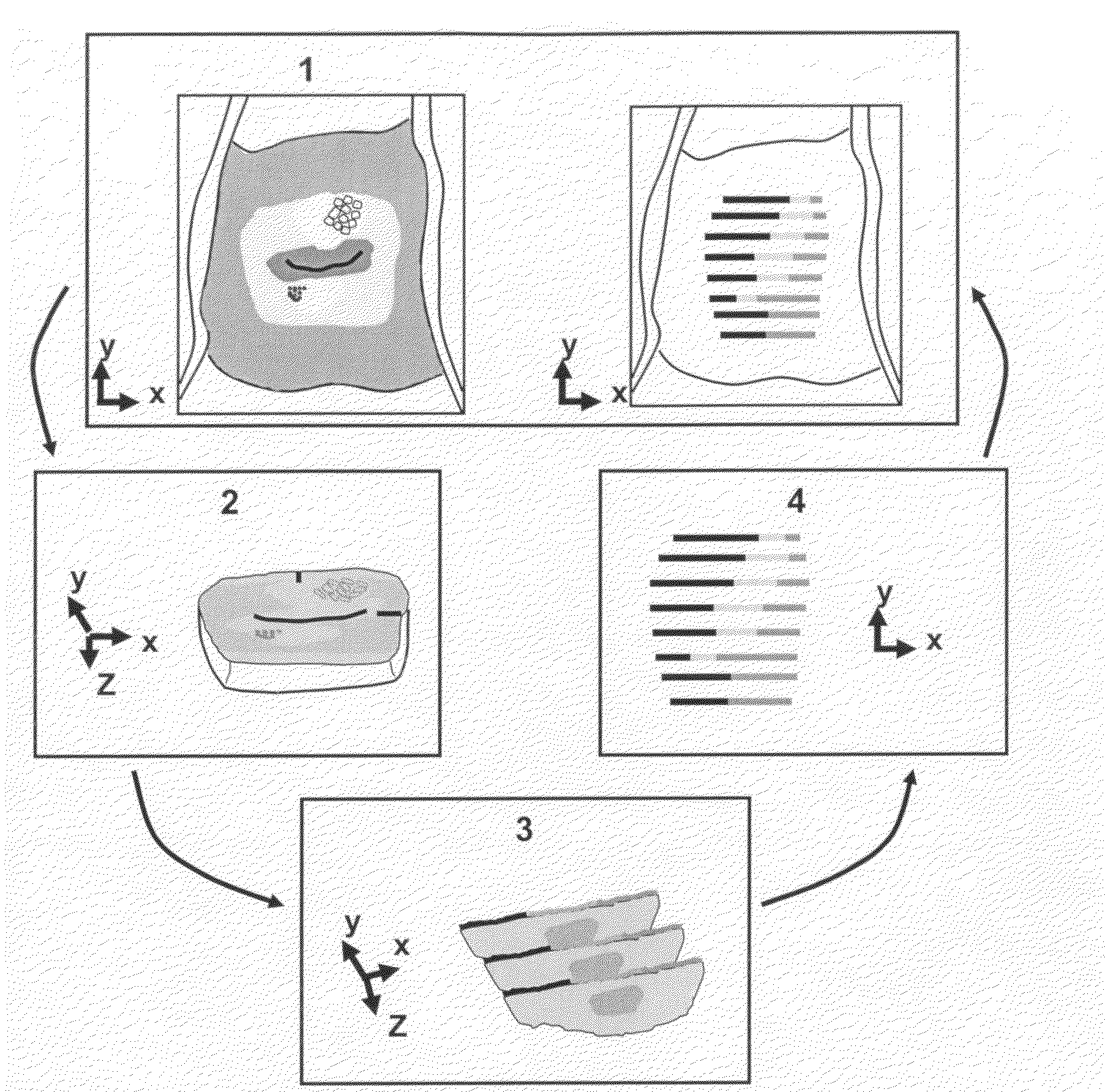

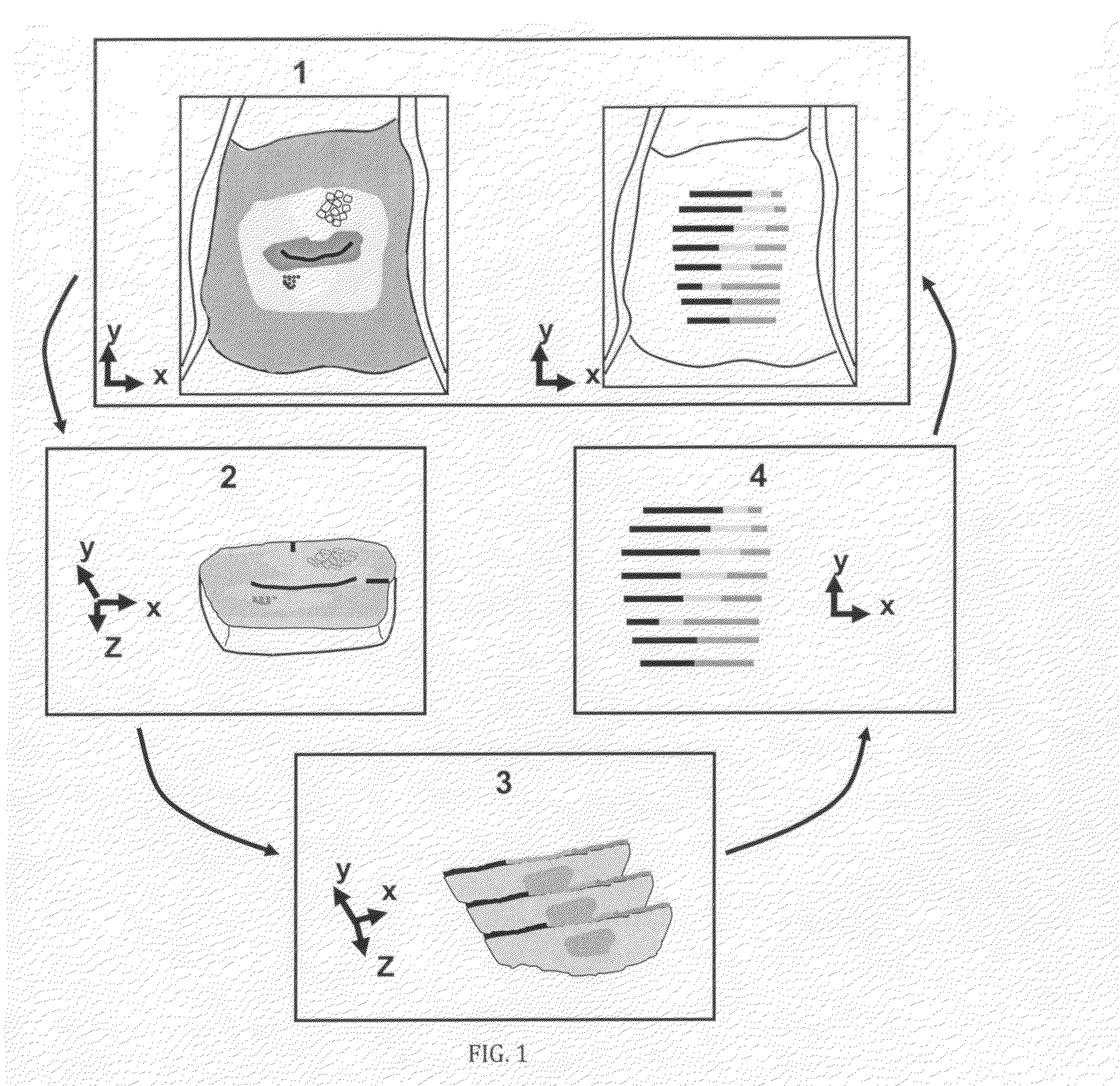

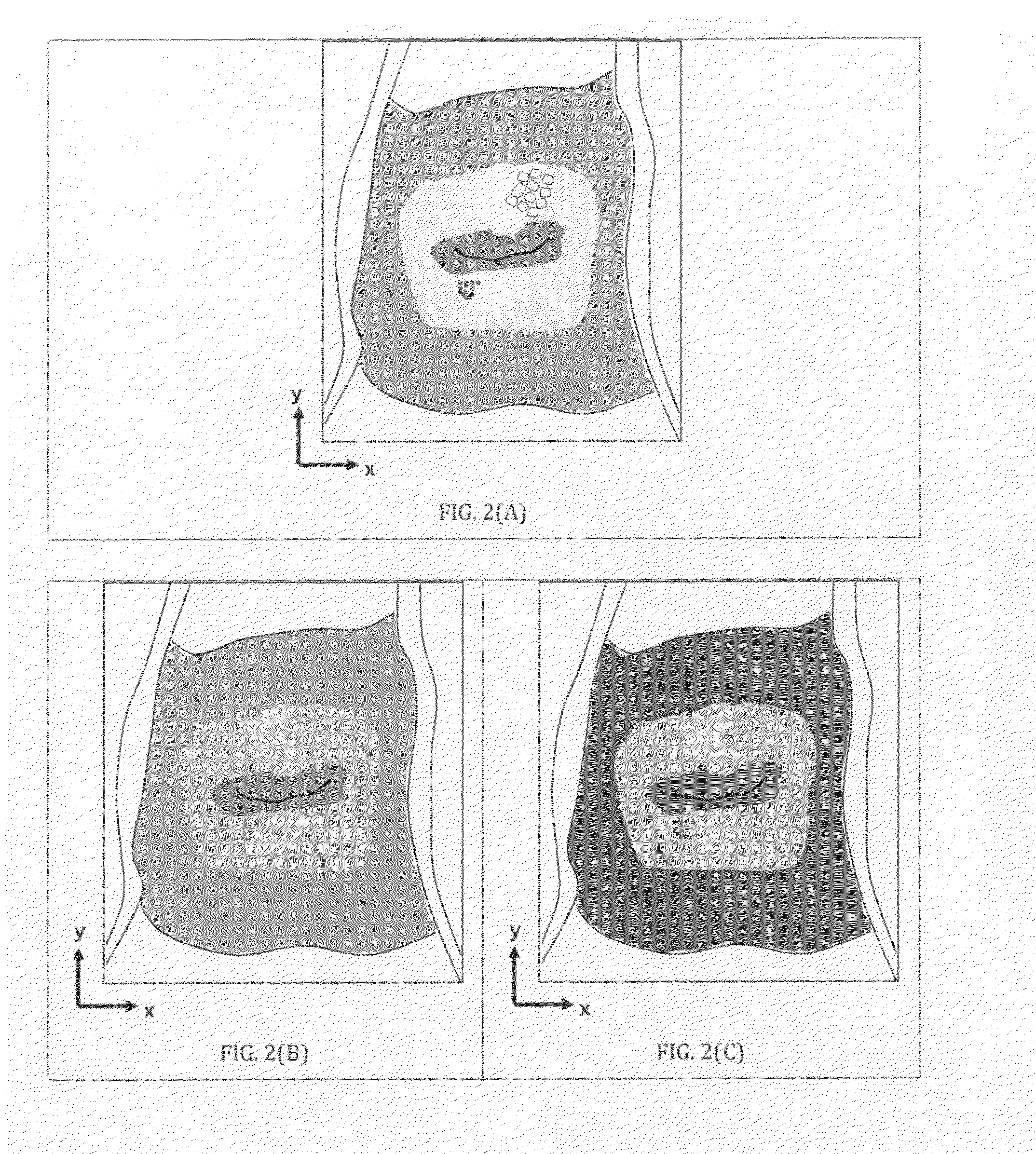

Process for preserving three dimensional orientation to allow registering histopathological diagnoses of tissue to images of that tissue

InactiveUS20100093023A1Keep the distanceAccurately determinePreparing sample for investigationBiological testingPathology diagnosisFixed Specimen

A process for maintaining 3 dimensional orientation between a tissue specimen and images of the area of investigation, to register histopathologic diagnoses of multiple locations within the specimen with corresponding locations on the surface of said area of investigation, by marking at least two fiduciary lines on the area of investigation; acquiring a fiduciary image of the tissue with the fiduciary lines; excising the tissue to form a tissue specimen; inserting at least two parallel needles through said specimen; acquiring a specimen image of the specimen with inserted needles over an alignment grid; fixing the specimen by immersing the specimen; acquiring a fixed image of the fixed specimen with the inserted needles over the alignment grid; forming a paraffin mold containing the fixed specimen and inserted needles; injecting different colored inks through the needles while withdrawing them from the fixed specimen, so that different colored needle tracks are formed in the specimen; sectioning the specimen to create specimen blocks having different colored needle tracks; further sectioning the specimen to cut the specimen blocks into specimen slices having different colored ink dots corresponding to the different colored needle tracks; forming pathology images from the specimen slices; performing histopathology analyses on the pathology images; annotating the pathology images with histopathology annotations; aligning the annotations with the fixed image using the colored ink dots; determining shrinkage between the fixed image and the annotations by using the grid to compare the distance between the needles in the fixed image with the distance between the ink dots on the specimen slices; registering the fixed image to the specimen image to account for shrinkage caused by fixation, using locations of the needles in both of the images as landmarks; registering the specimen image to the fiduciary image to account for tissue translation and soft tissue movement using the fiduciary lines and geographical features of said area of investigation as landmarks; registering the fiduciary image to the reference image to account for tissue translation and soft tissue movement using said geographical features; whereby annotations of histopathologic diagnoses are provided for multiple locations on or under the surface of the specimen that are registered to images of the specimen.

Owner:CADES SCHUTTE A LIMITED LIABILITY LAW PARTNERSHIP

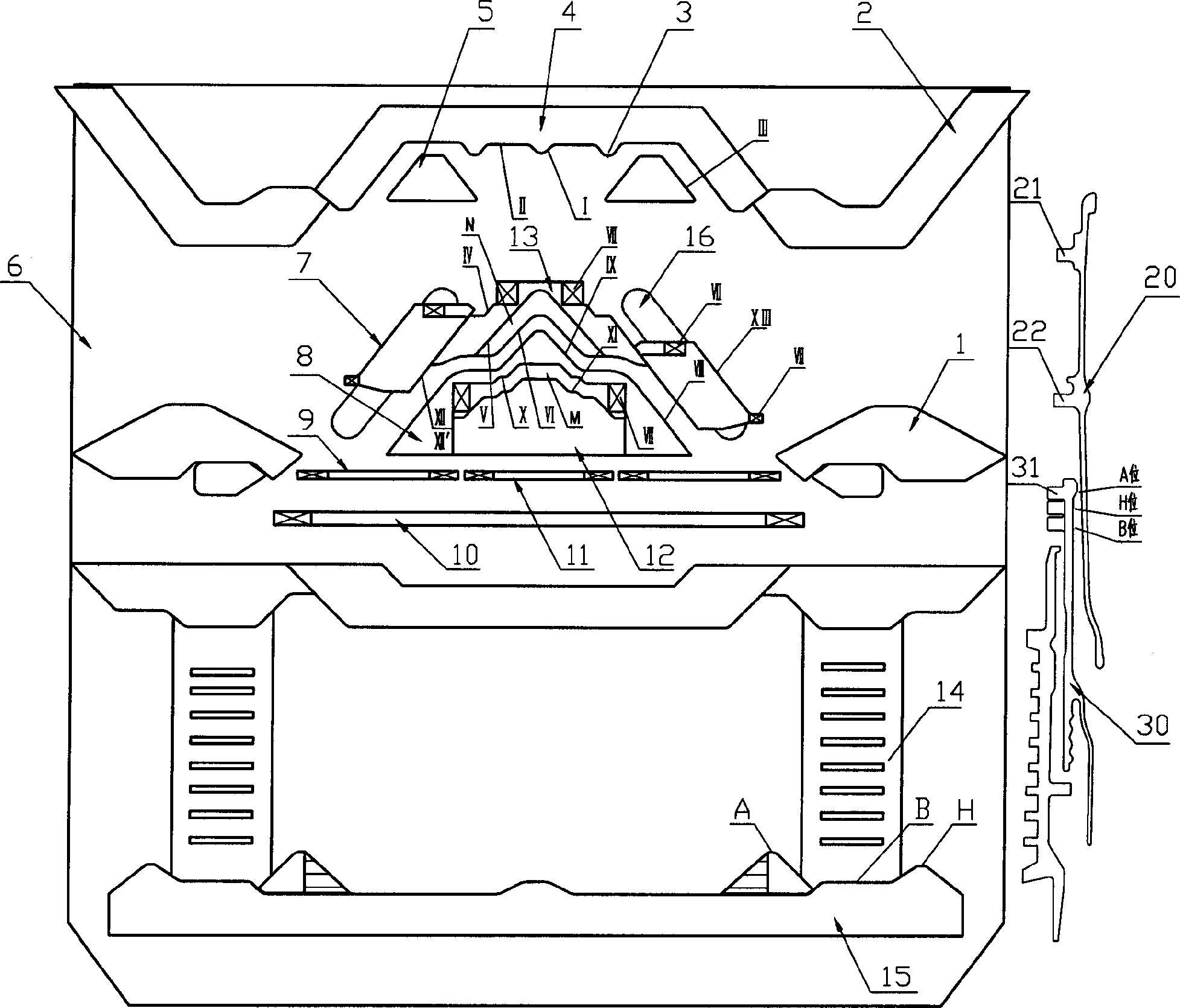

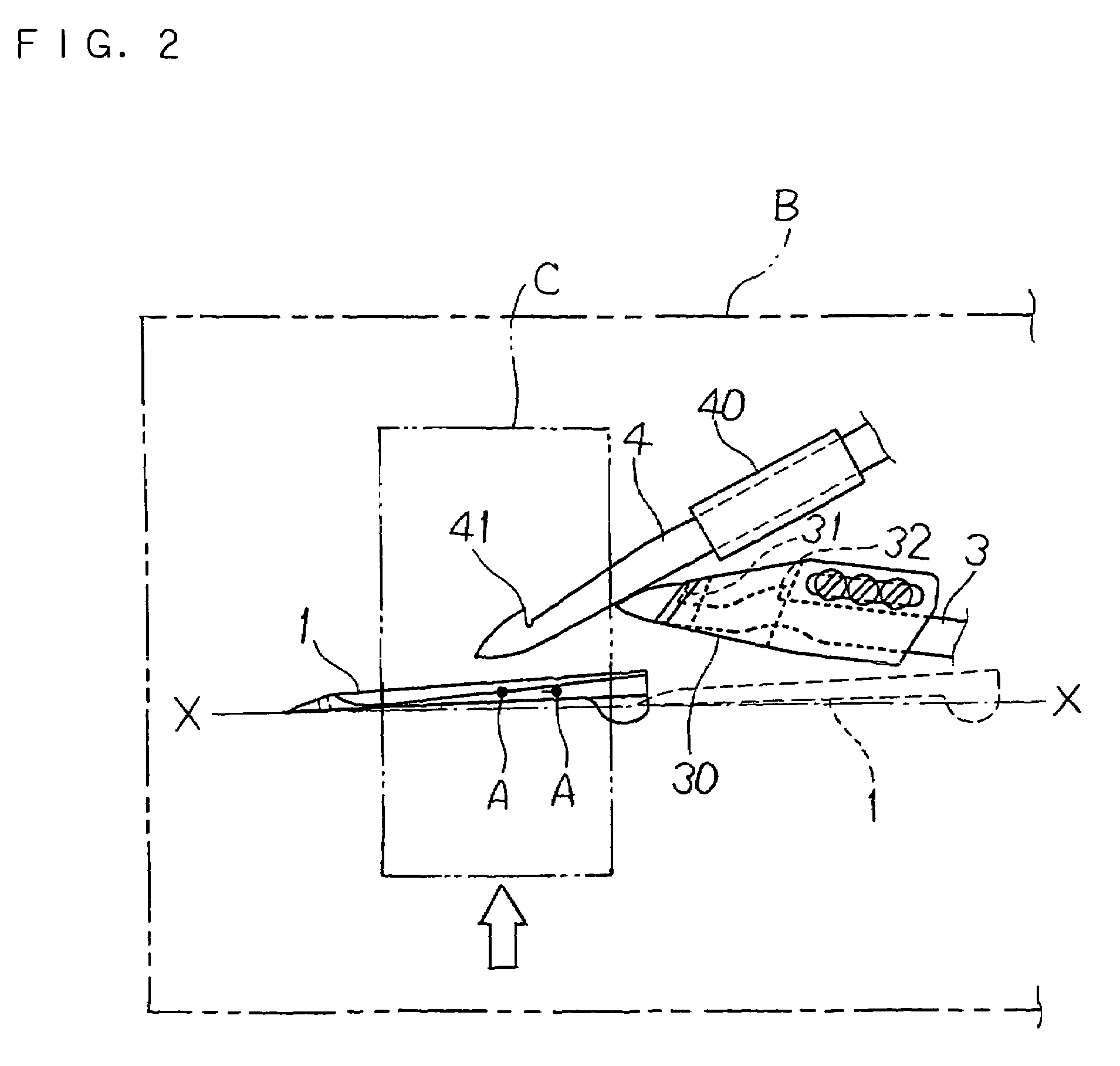

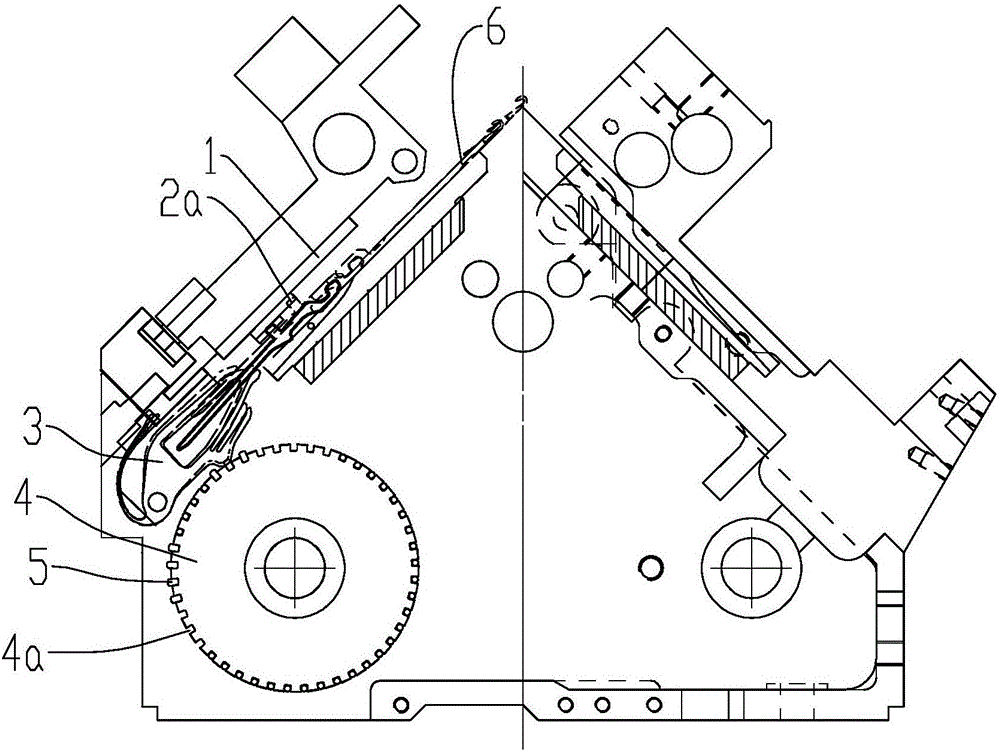

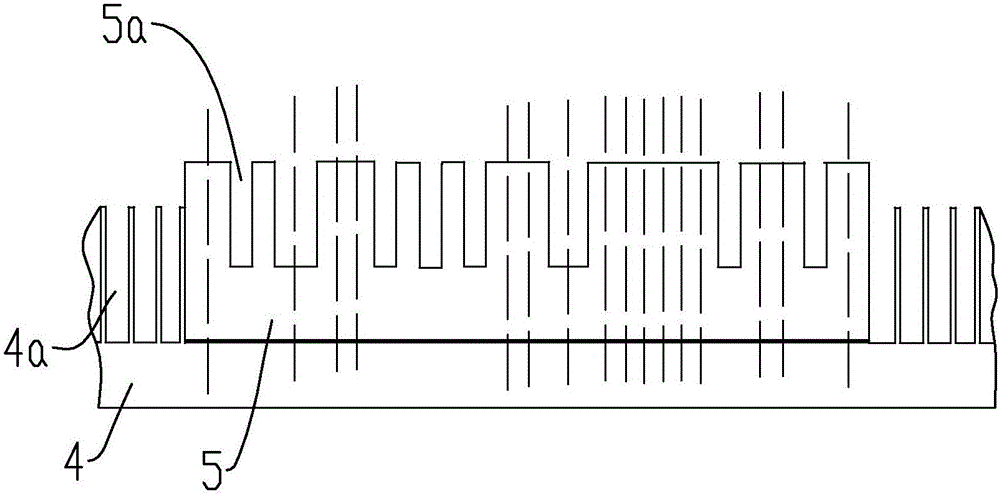

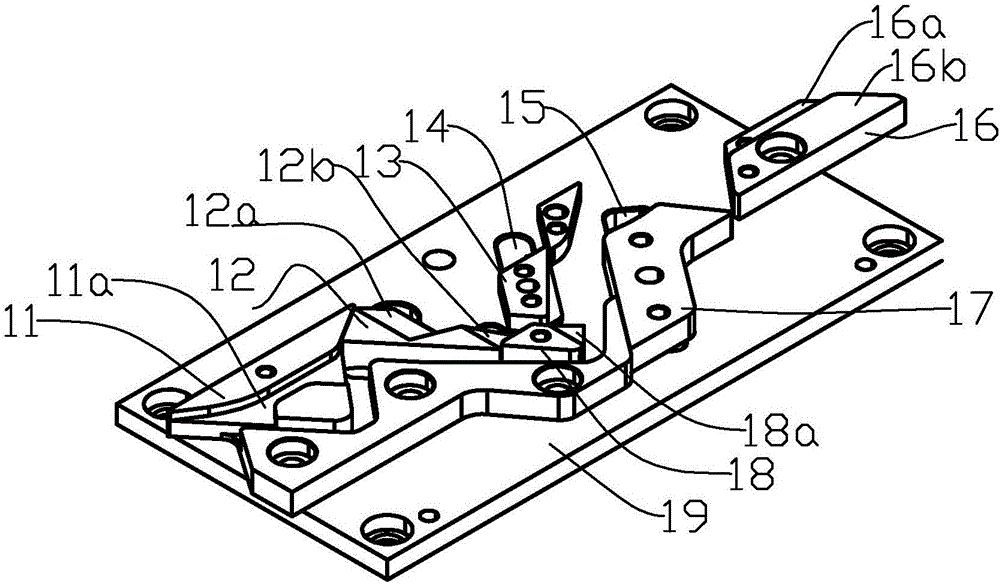

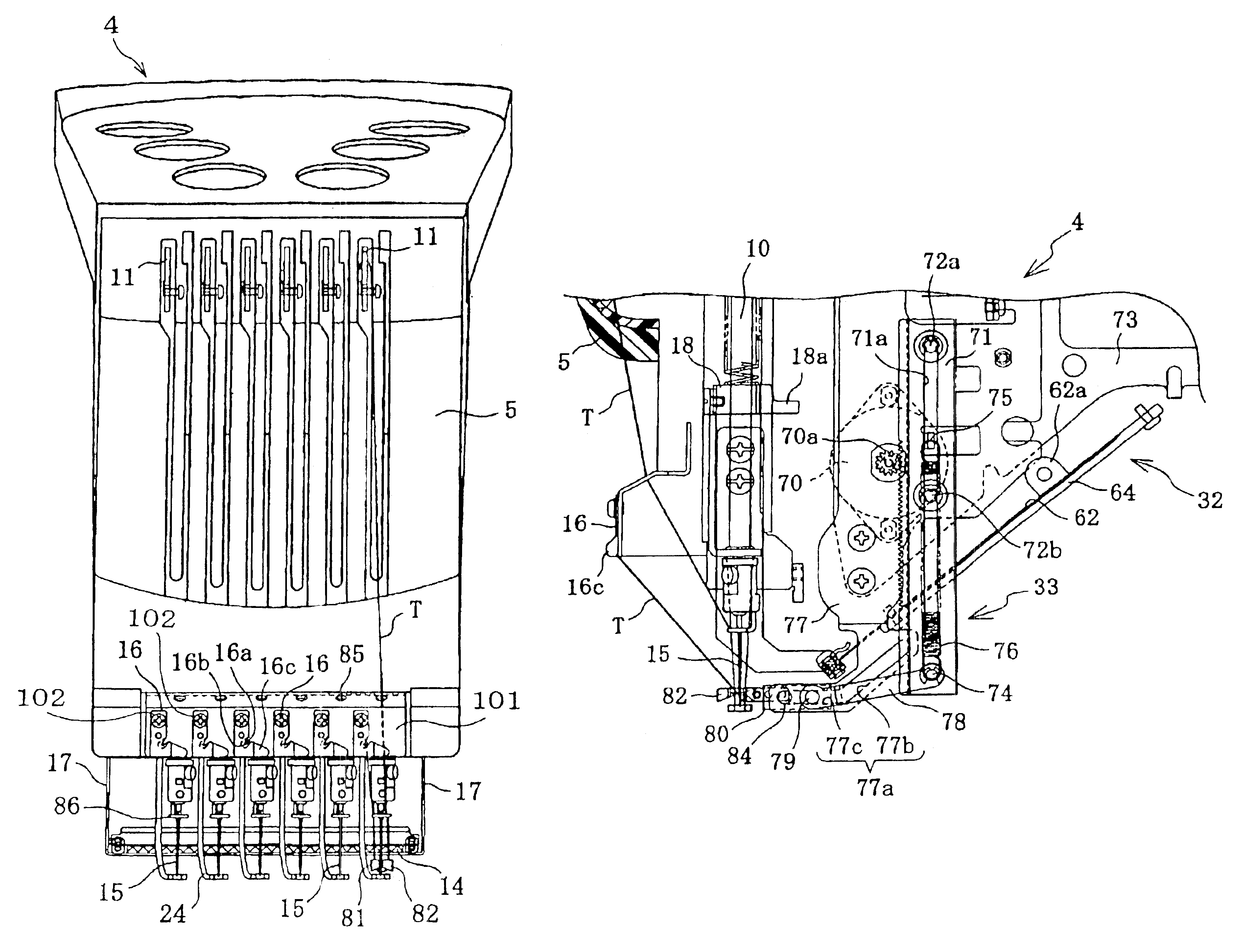

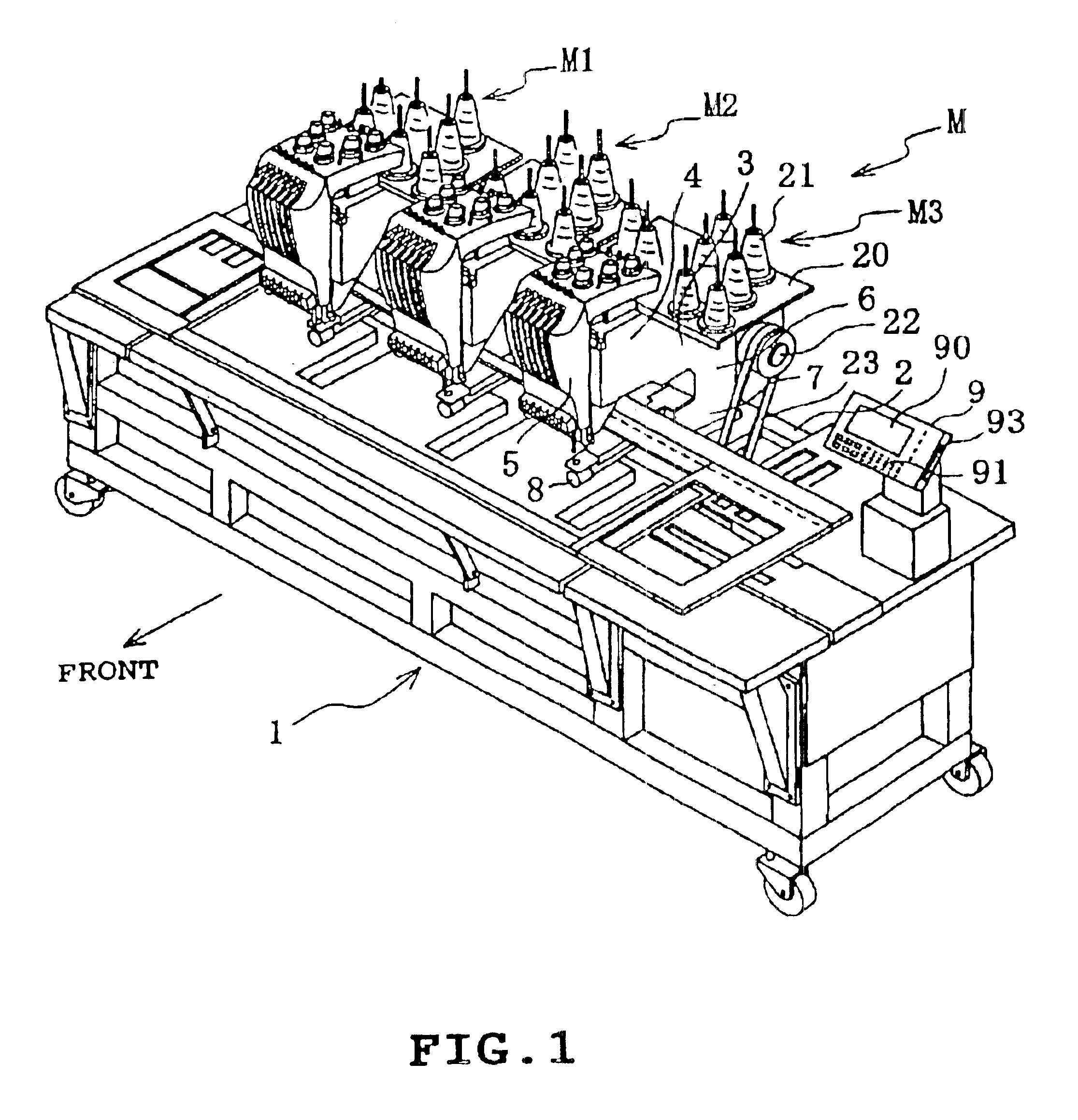

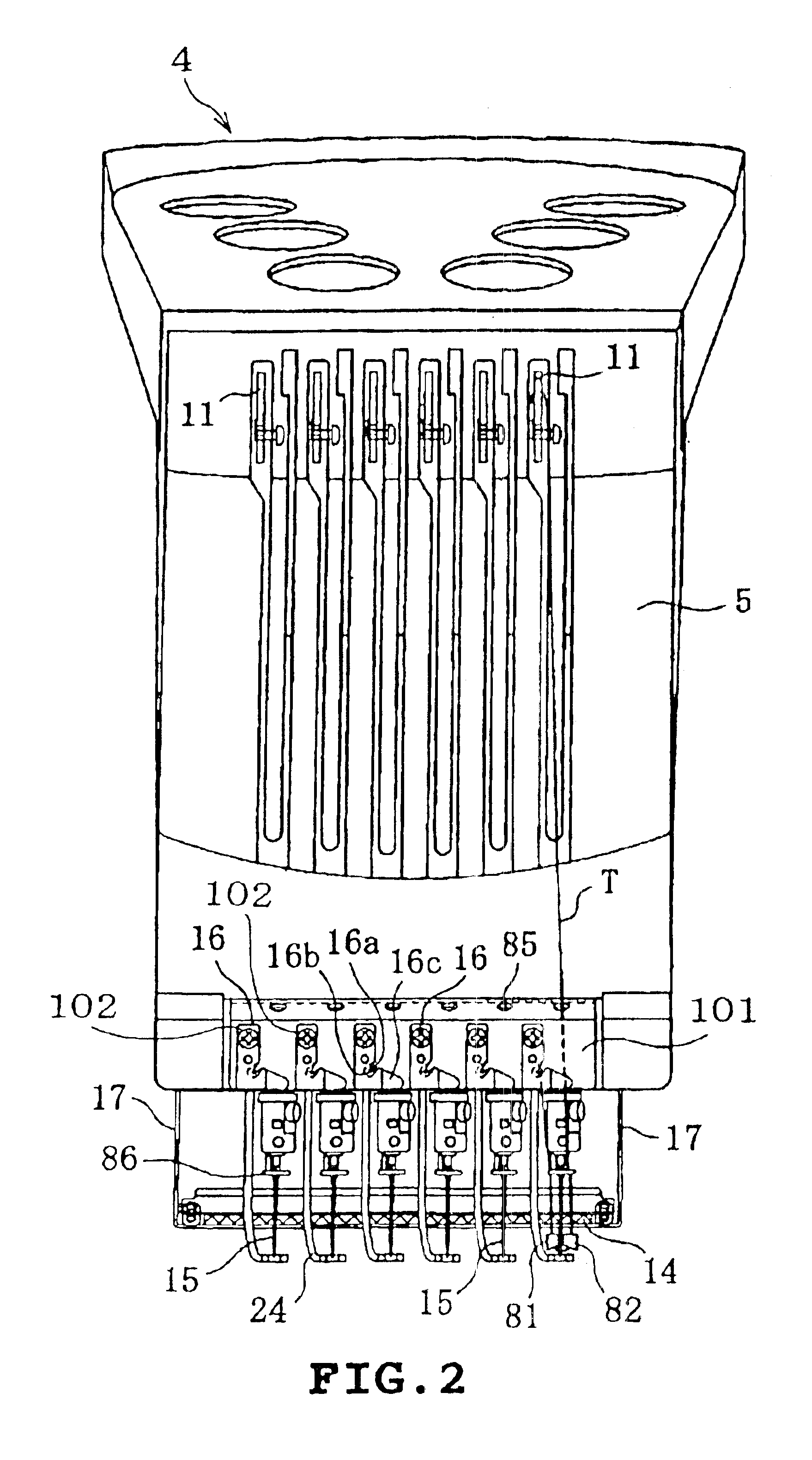

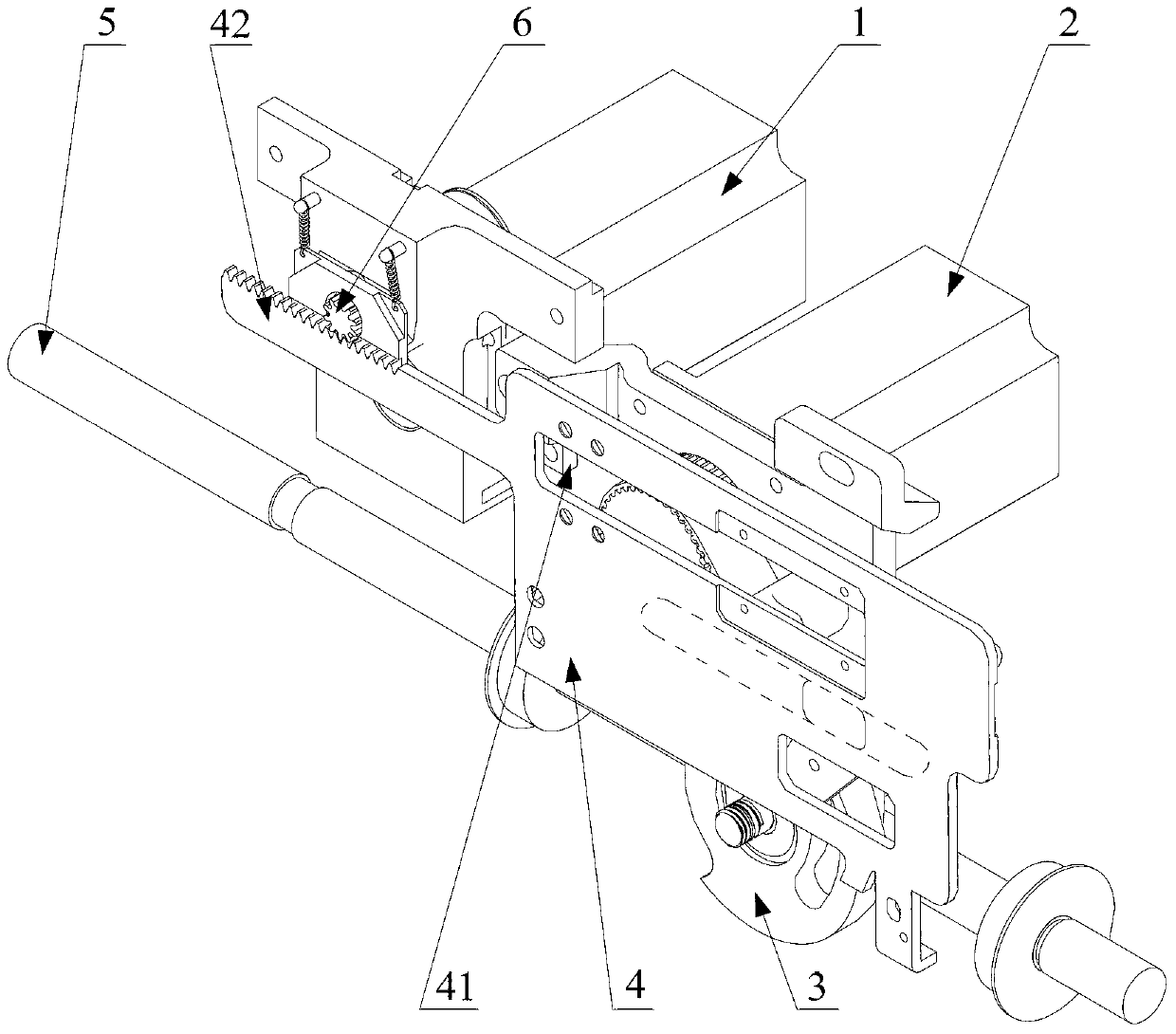

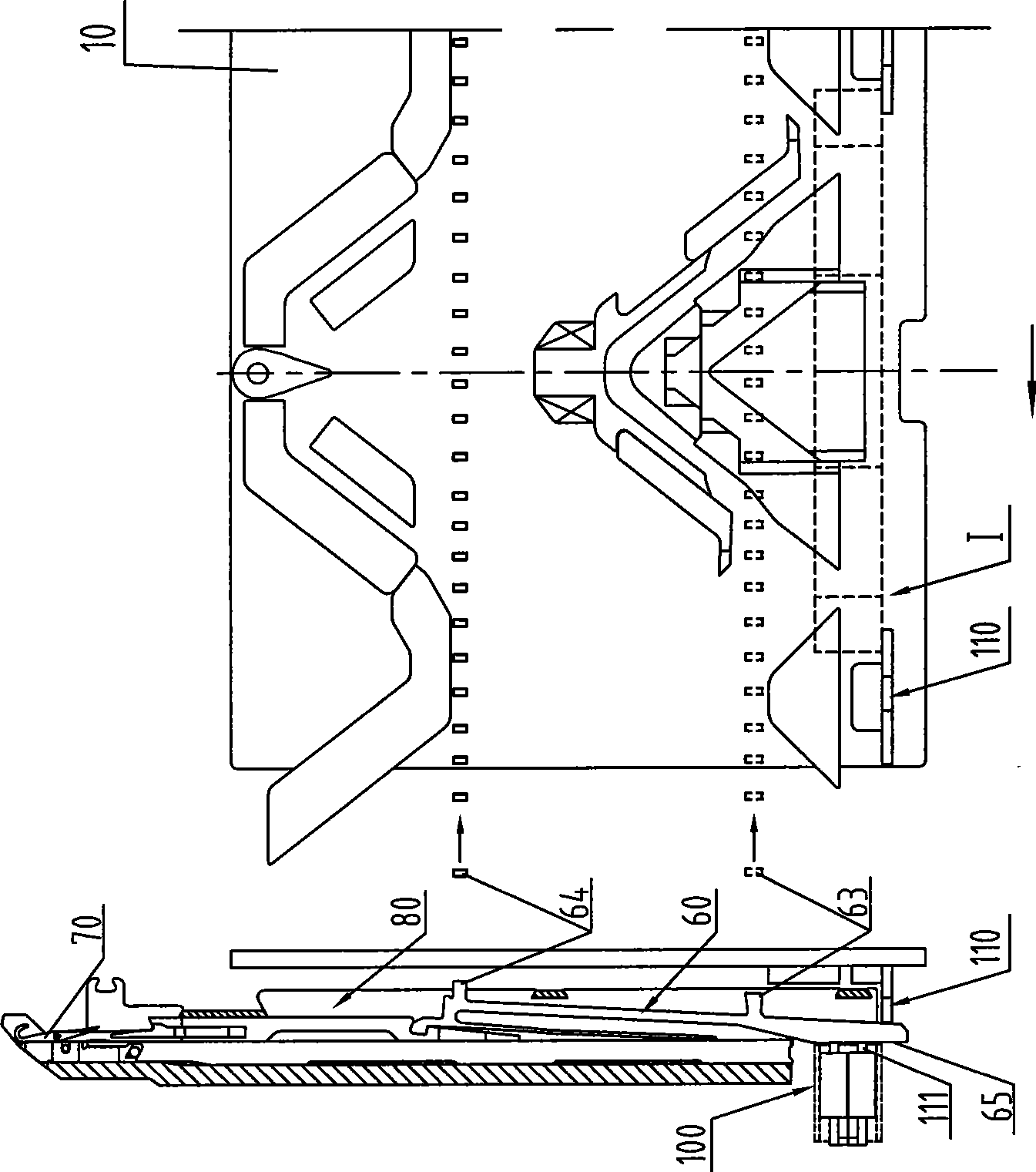

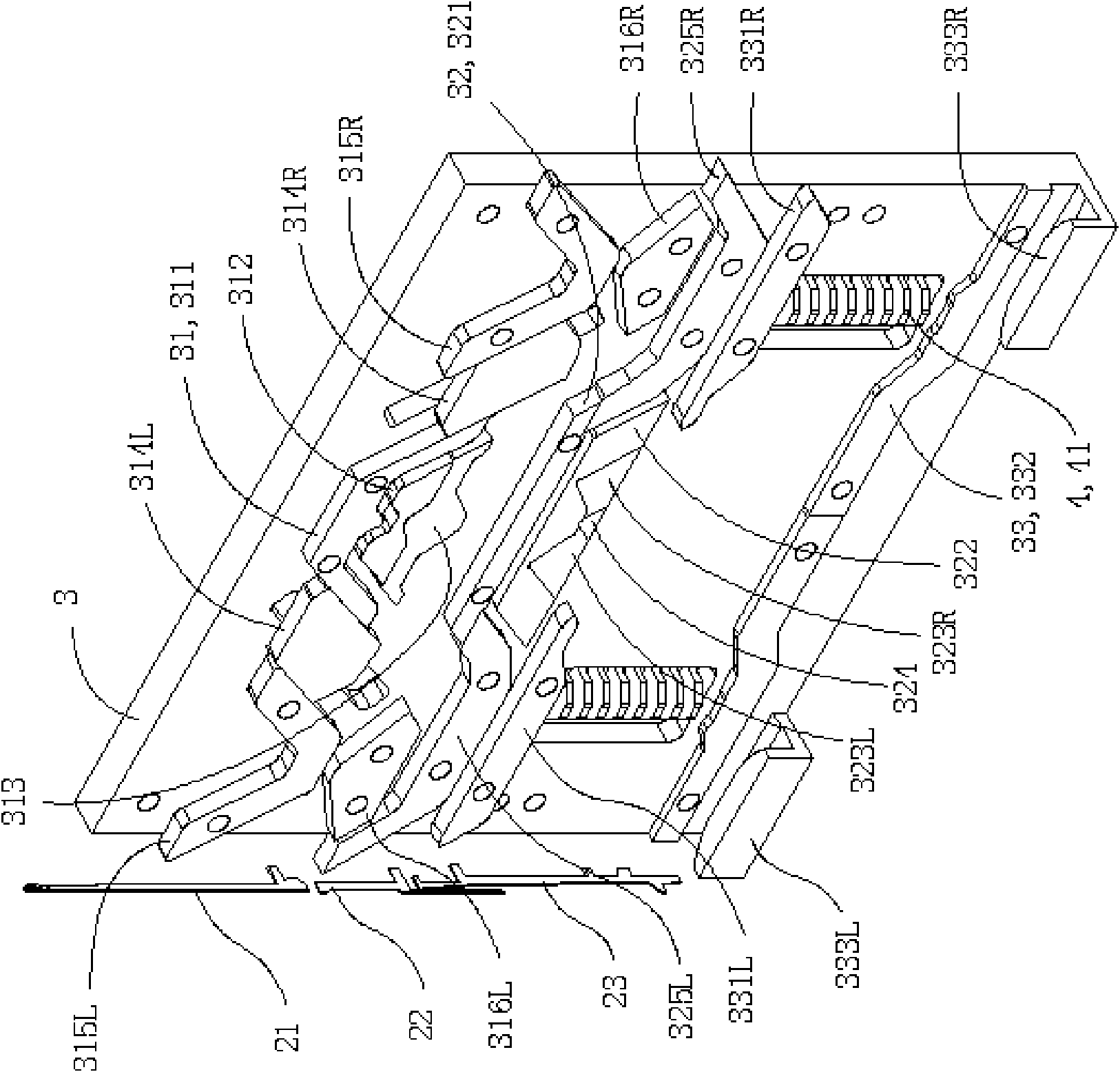

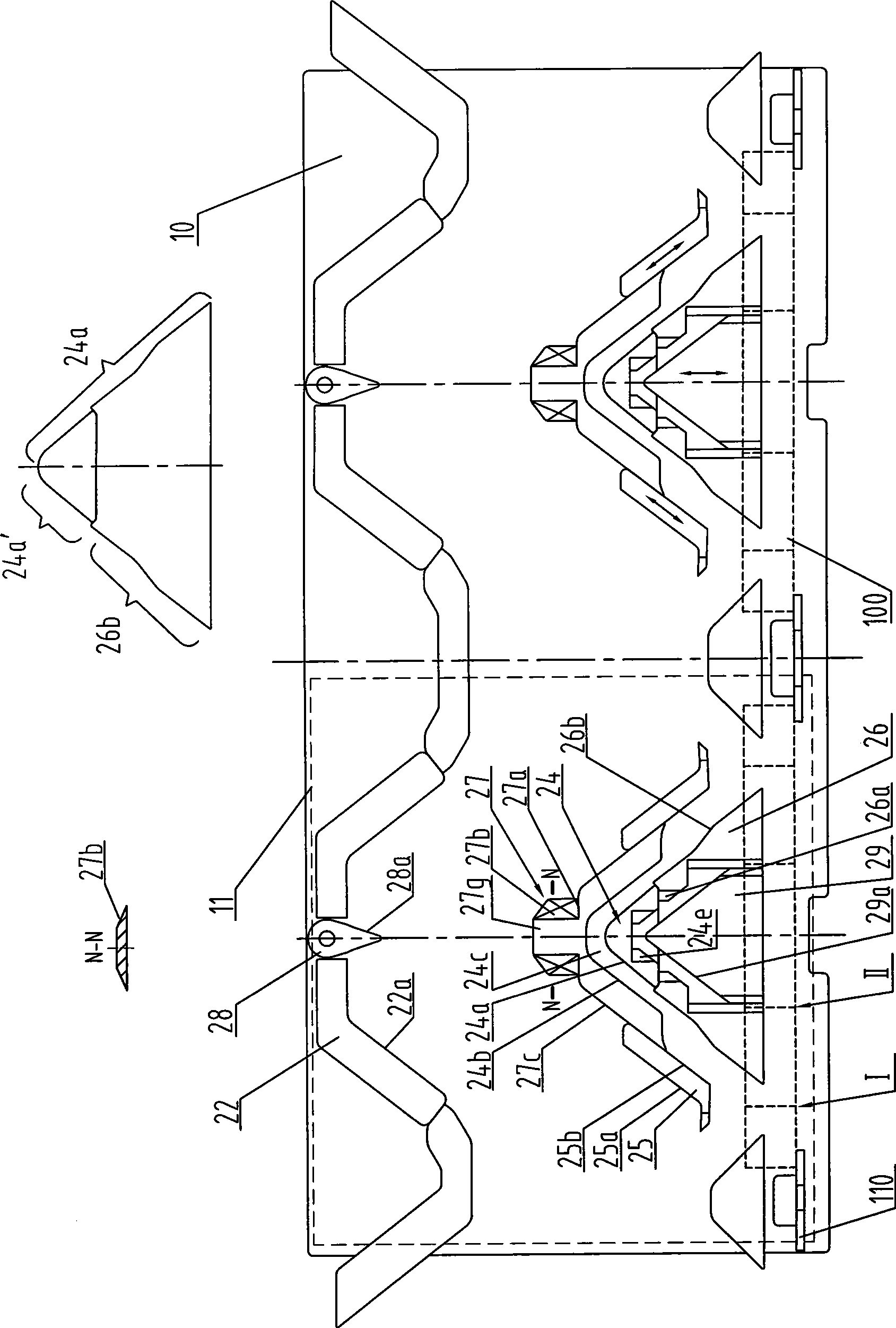

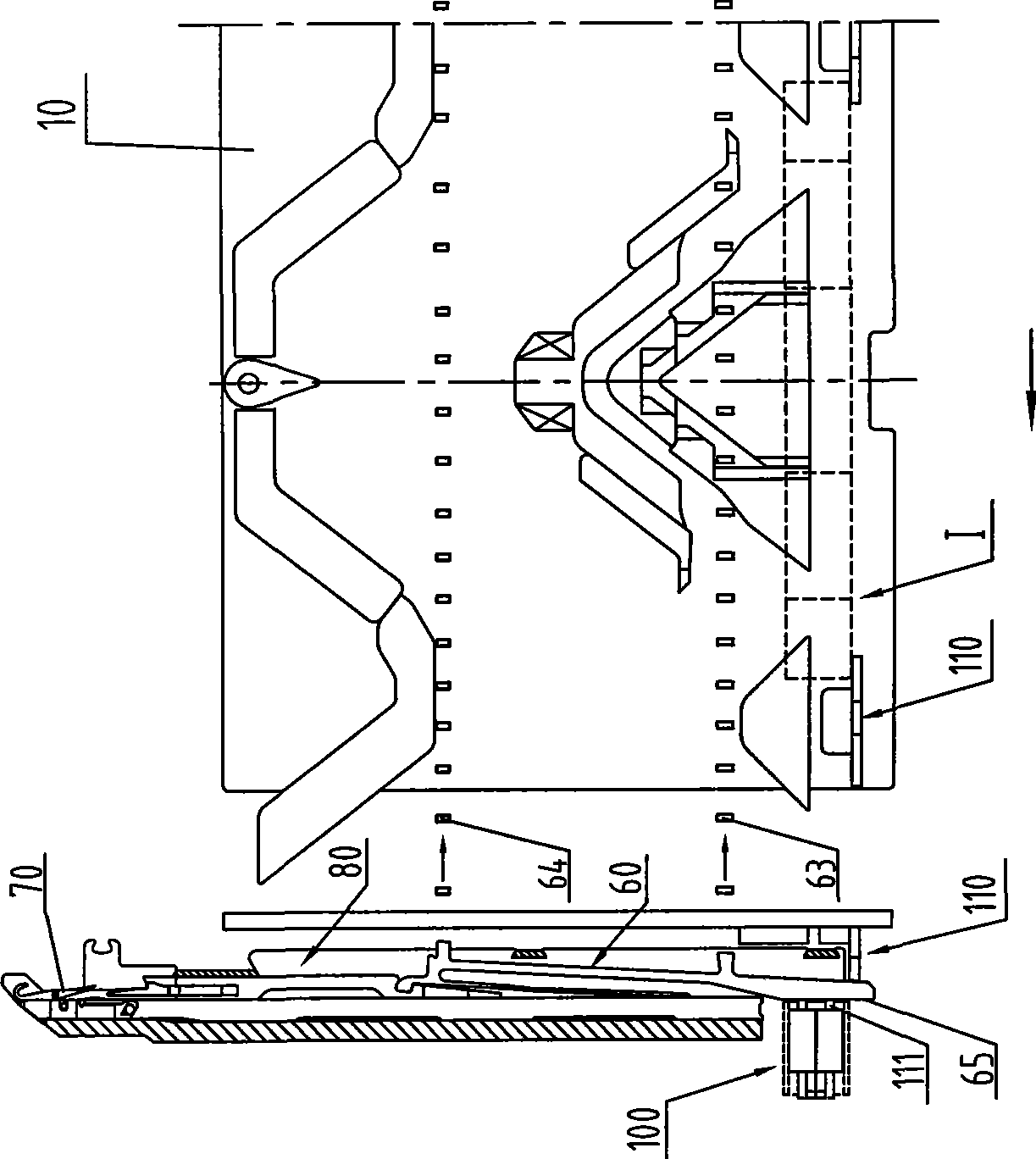

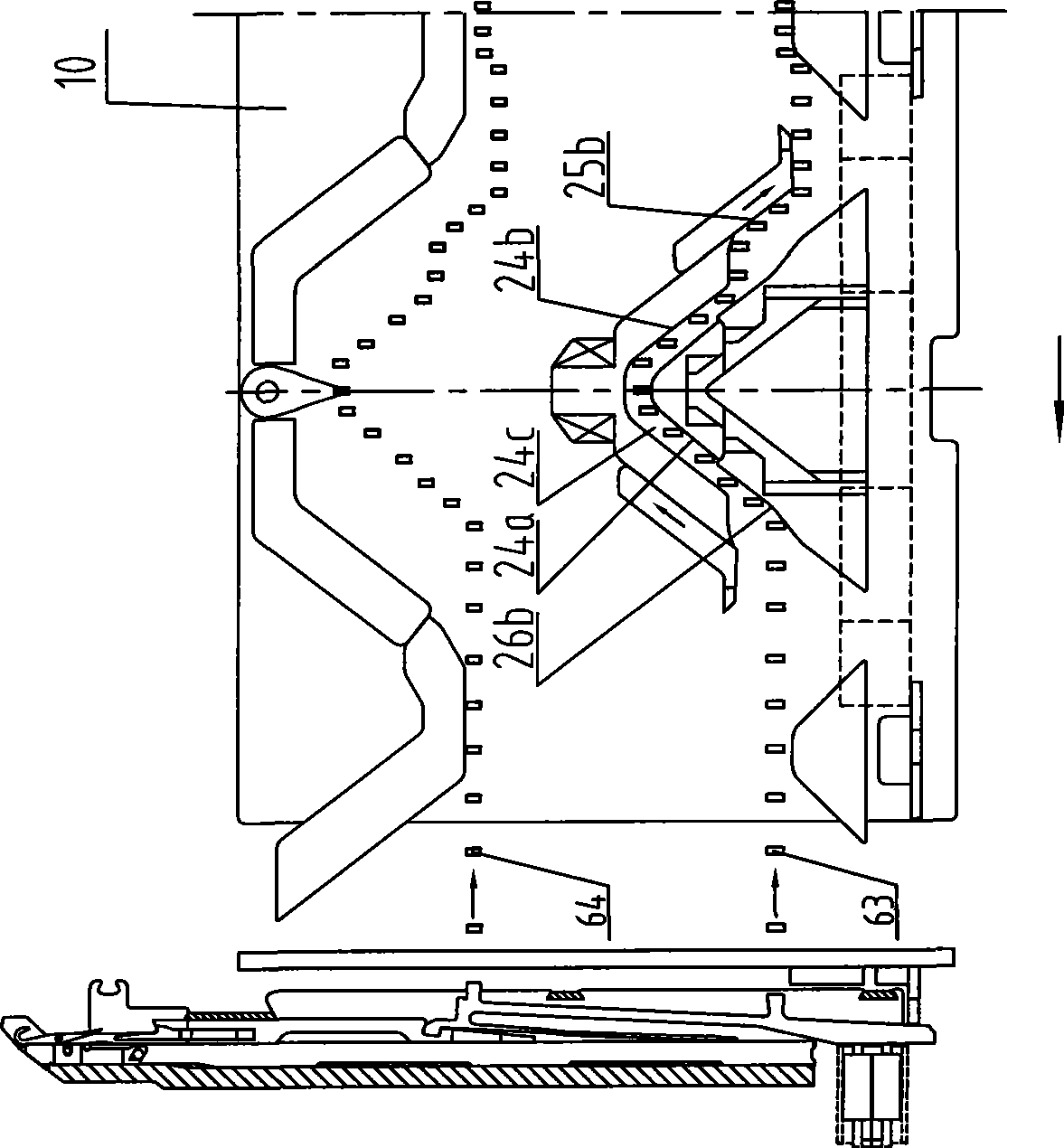

Braiding controlling mechanism of flat braiding machine

InactiveCN1793467AHigh operational reliabilityReasonable optimization of trajectoryWeft knittingEngineeringCam

The invention relates to a cross braider braiding control mechanism. Its technical proposal is as follows: it is set at cam plate, and made up of at least one braiding units; each of them is set at one unit area of the cam plate; and it contains control cam, needle gating machine, middle, left and right moving clamping plates, fixing clamping plate, selection jack needle lifting cam including one delivering needle retracting cam, two delivering collating cams, one delivering cam, one loop formation needle lifting cam, one delivering joining needle cam and two depressing cam; all of them are fixed on cam plate except depressing cam. Its advantages are that delivering needle track is more reasonable and optimizing to ensure delivering and needle jointing more exact, stable, and reliable; control cam is fixedly connected to make its action more reliable; needle butt will no happen; each of the braiding units only need two needle gating machines to reduce cost and cross direction size of the braiding control mechanism.

Owner:冯加林

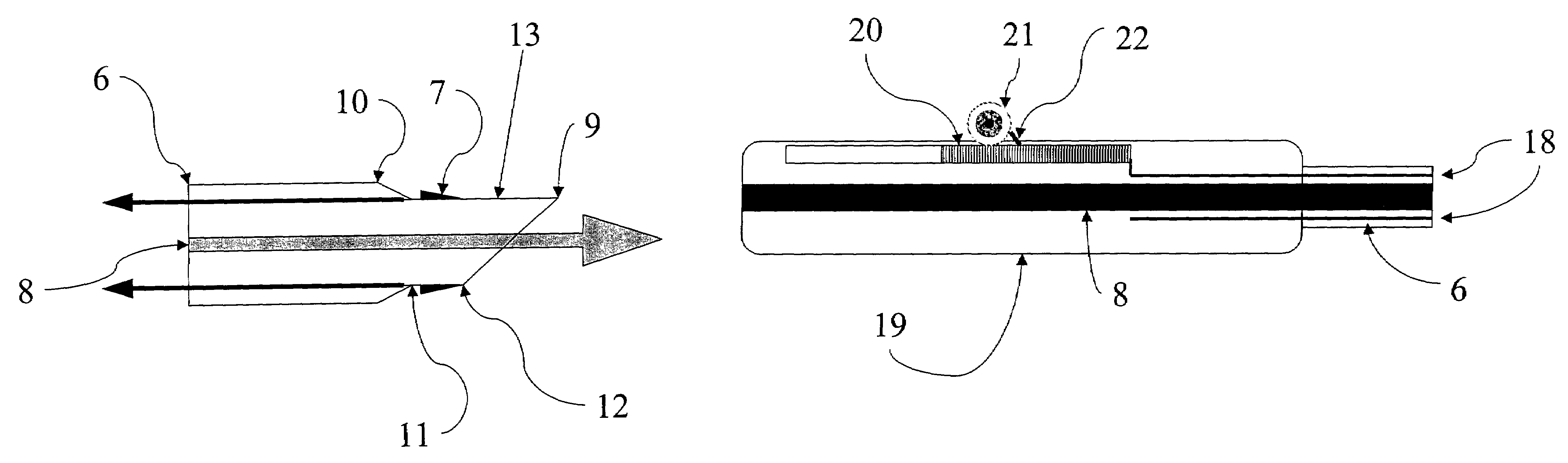

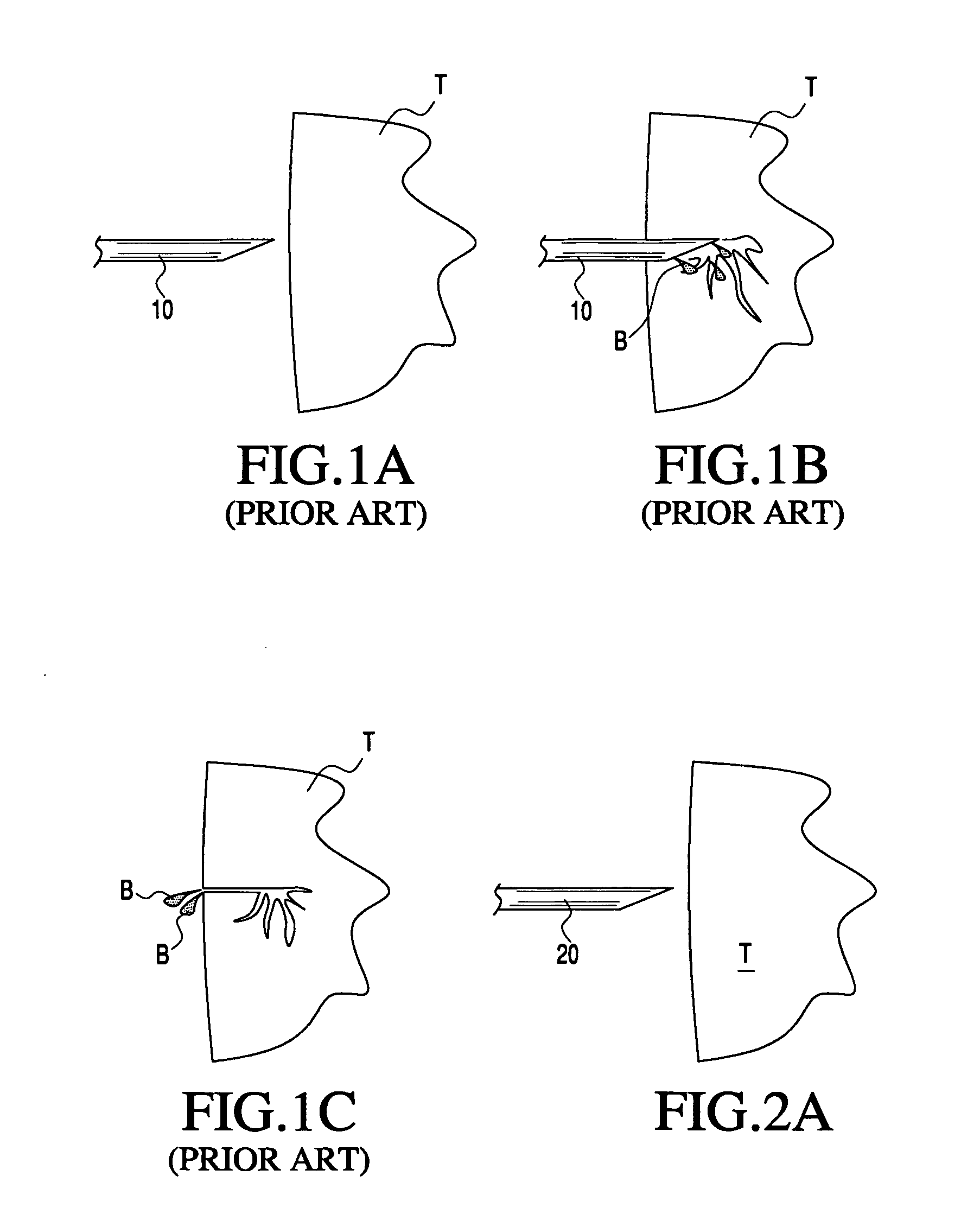

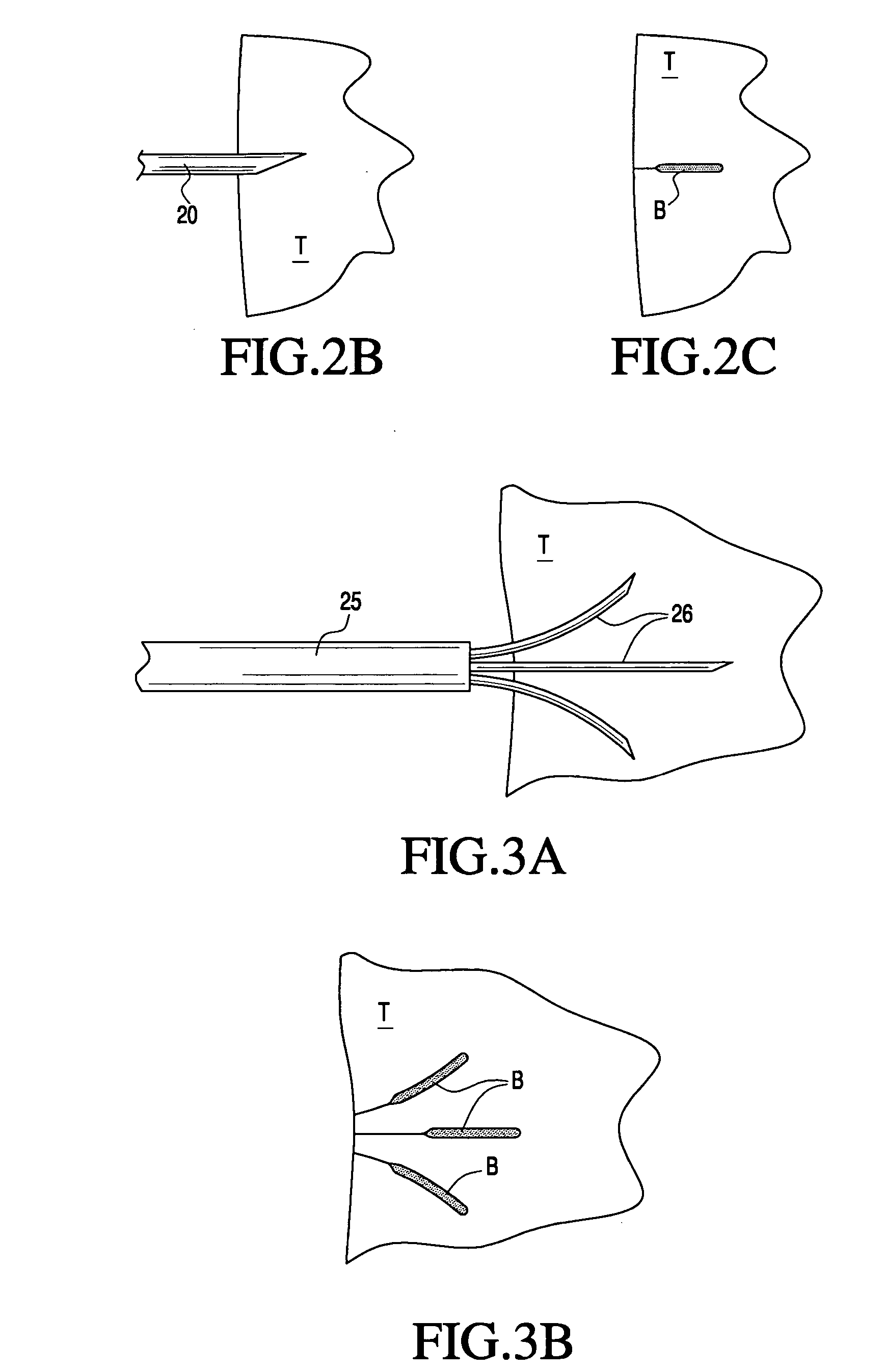

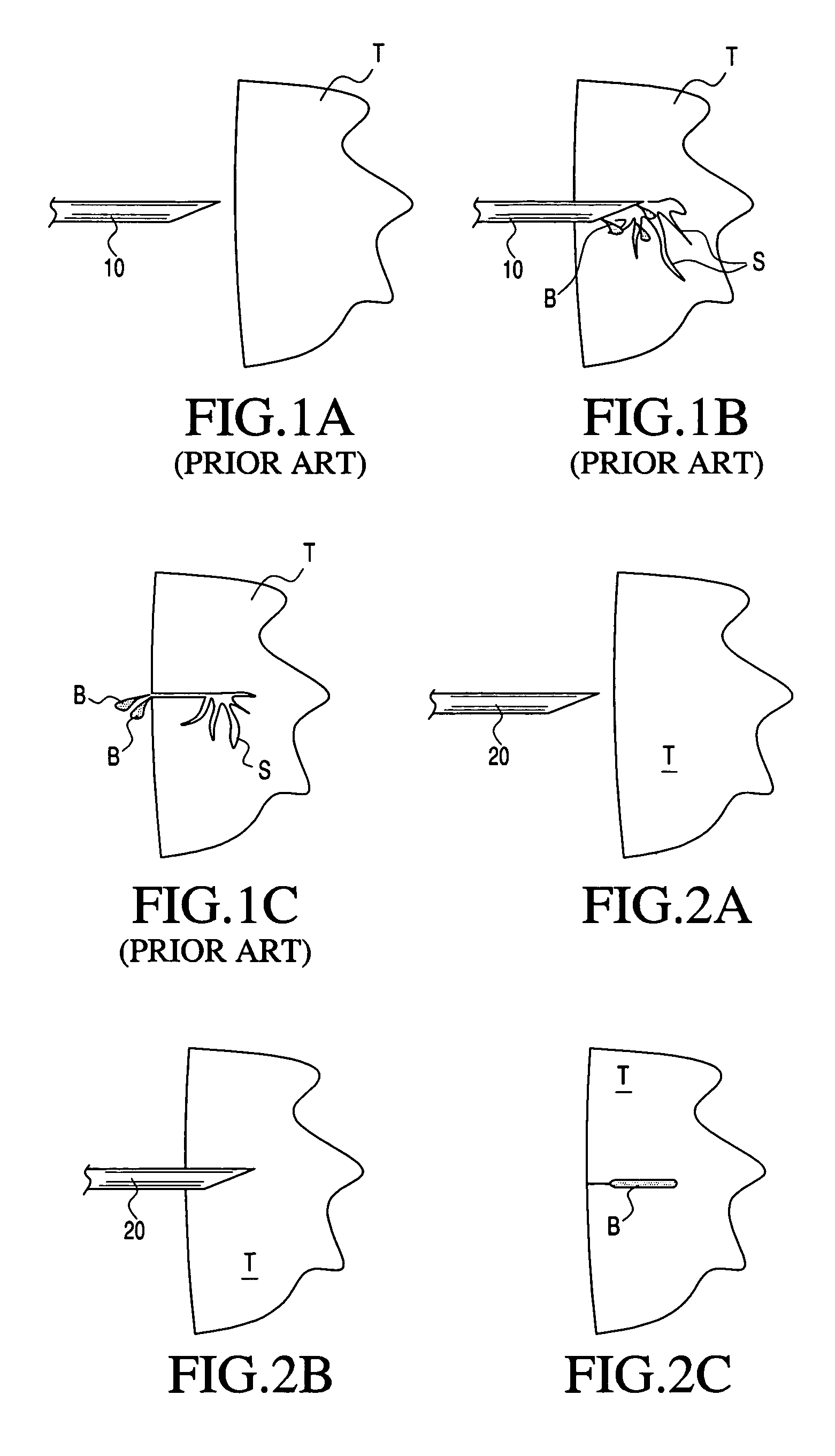

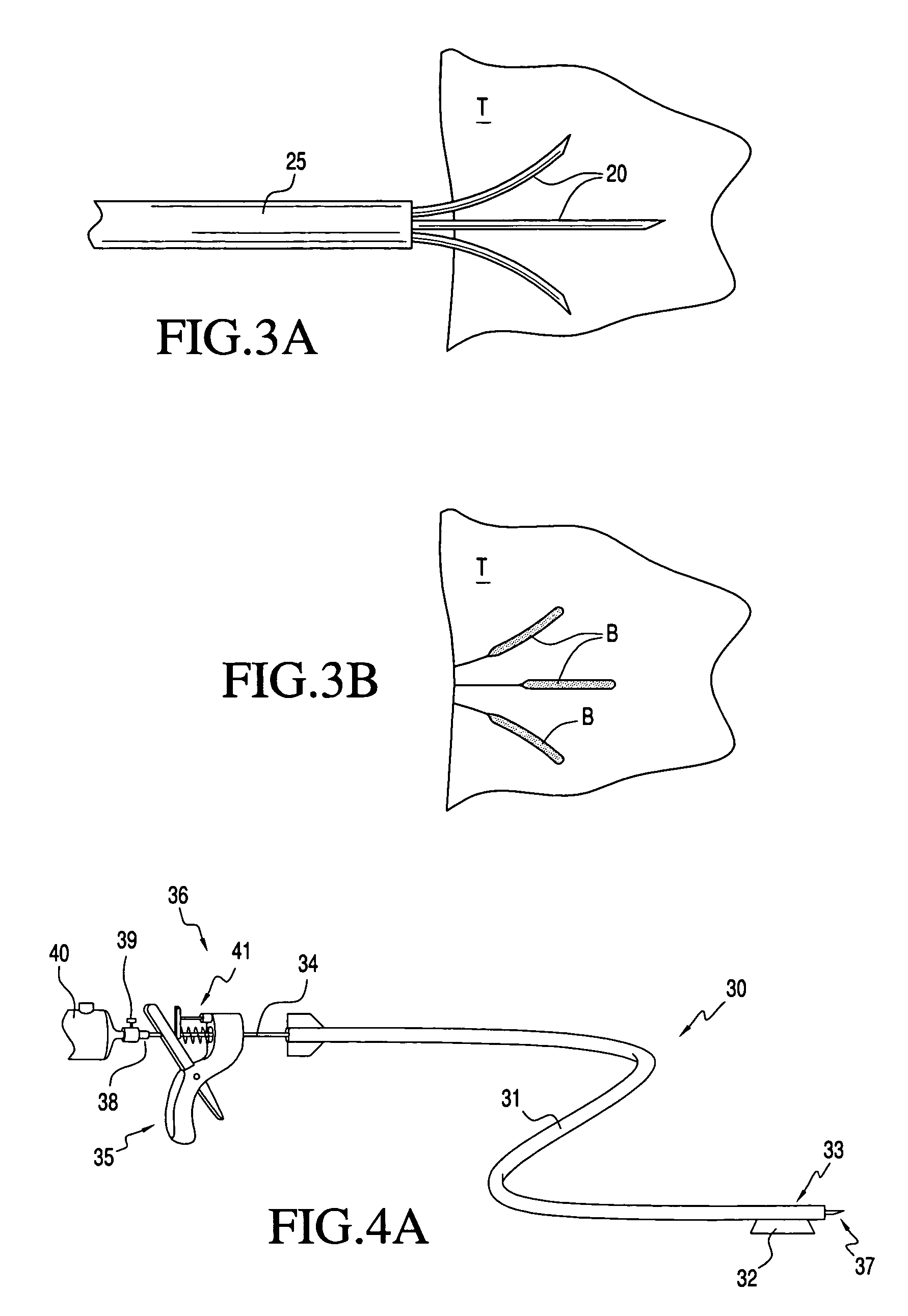

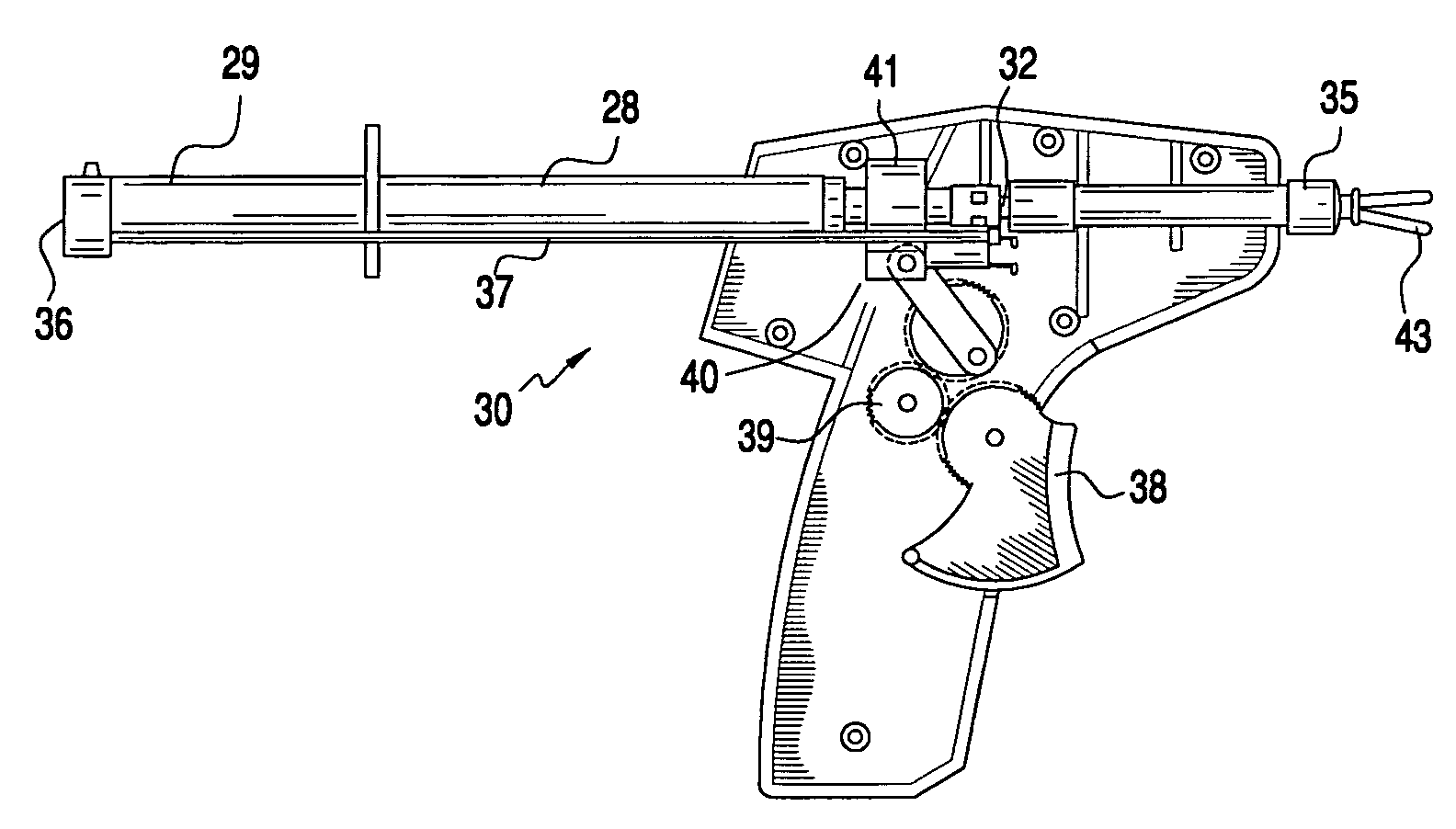

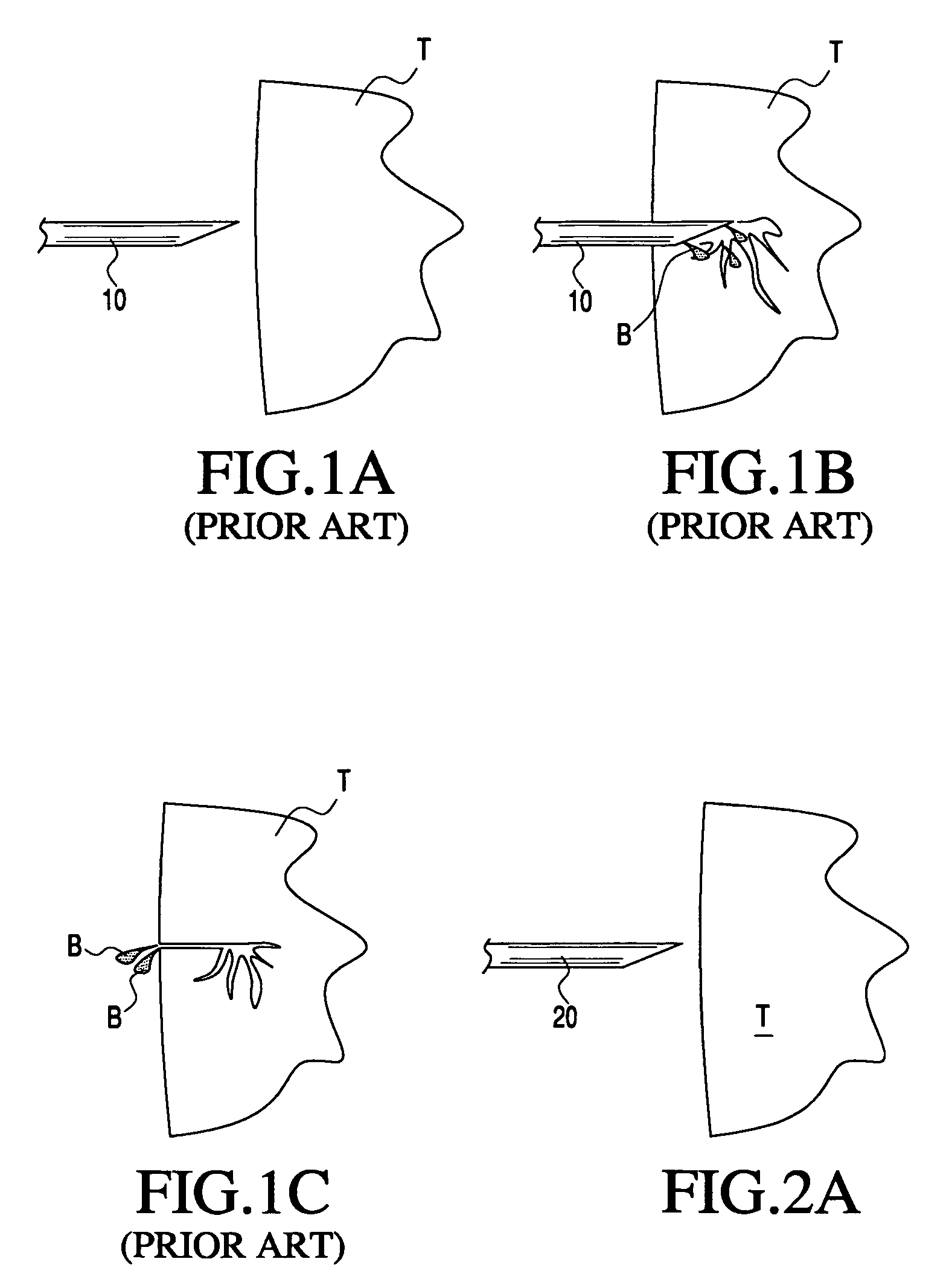

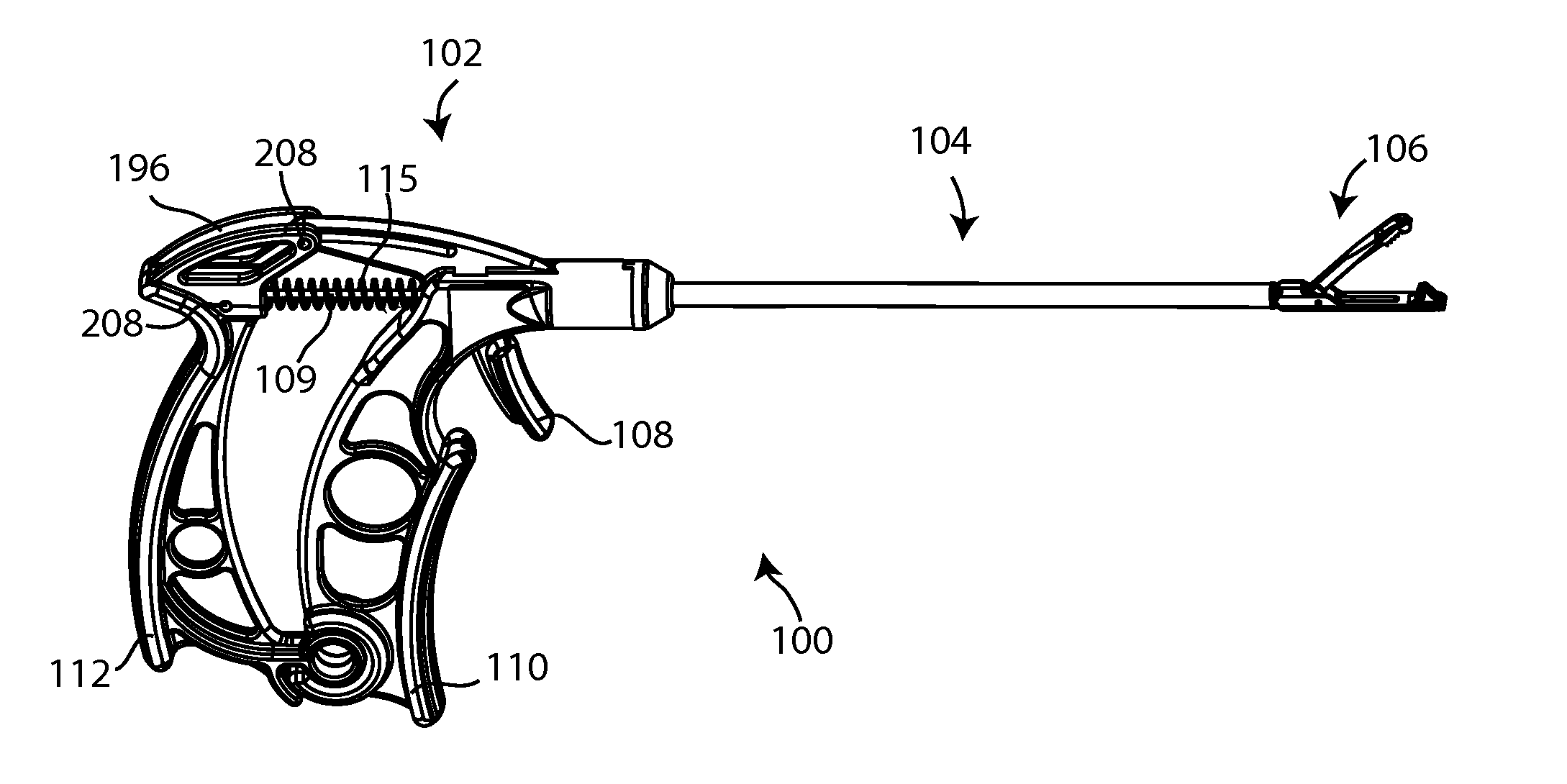

Apparatus and methods for treating tissue using passive injection systems

ActiveUS20060015067A1Reduce riskPromote tissue regenerationSurgical needlesMedical devicesDamages tissueActive agent

Methods and apparatus are provided for treating damaged tissue using apparatus that atraumatically delivers a bioactive agent within the tissue, wherein the apparatus provides a column of stem cells may be advanced simultaneously with a needle during needle insertion, and then held stationary or injected at low pressure while retracting the needle. Alternatively, the needle may employ electromotive forces, or to change a dimension of the needle, to expel the bioactive agent into the needle track.

Owner:COOK MEDICAL TECH LLC

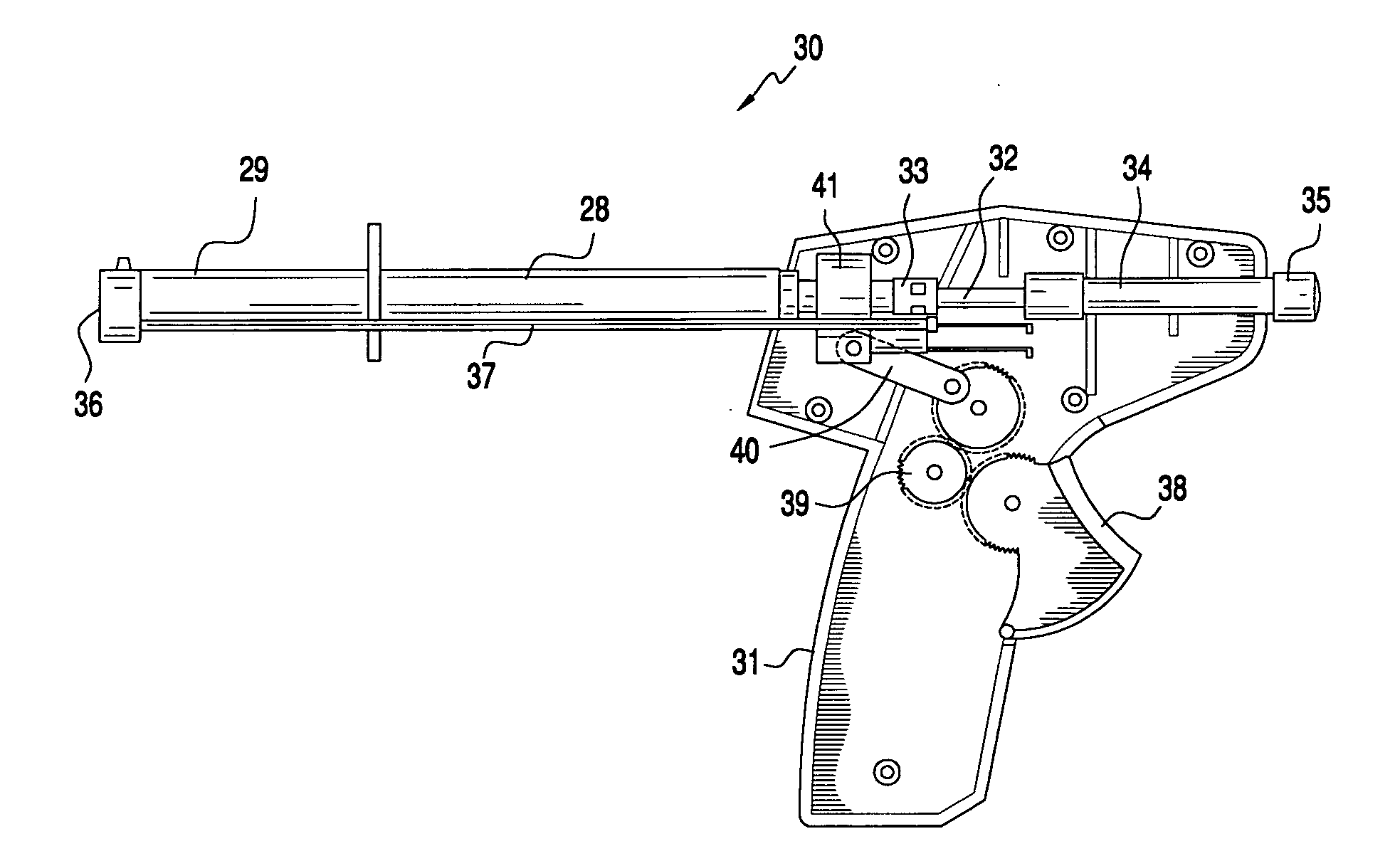

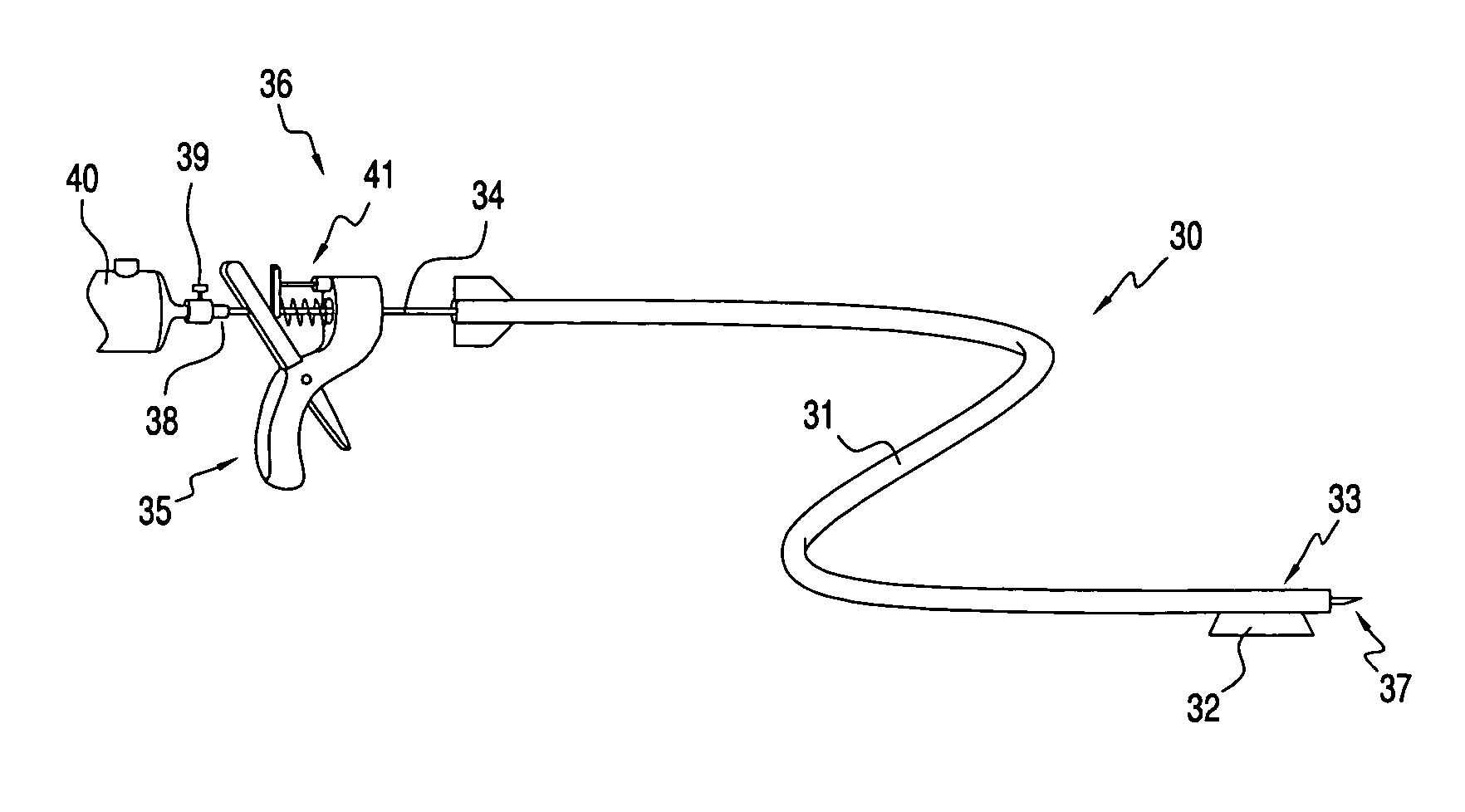

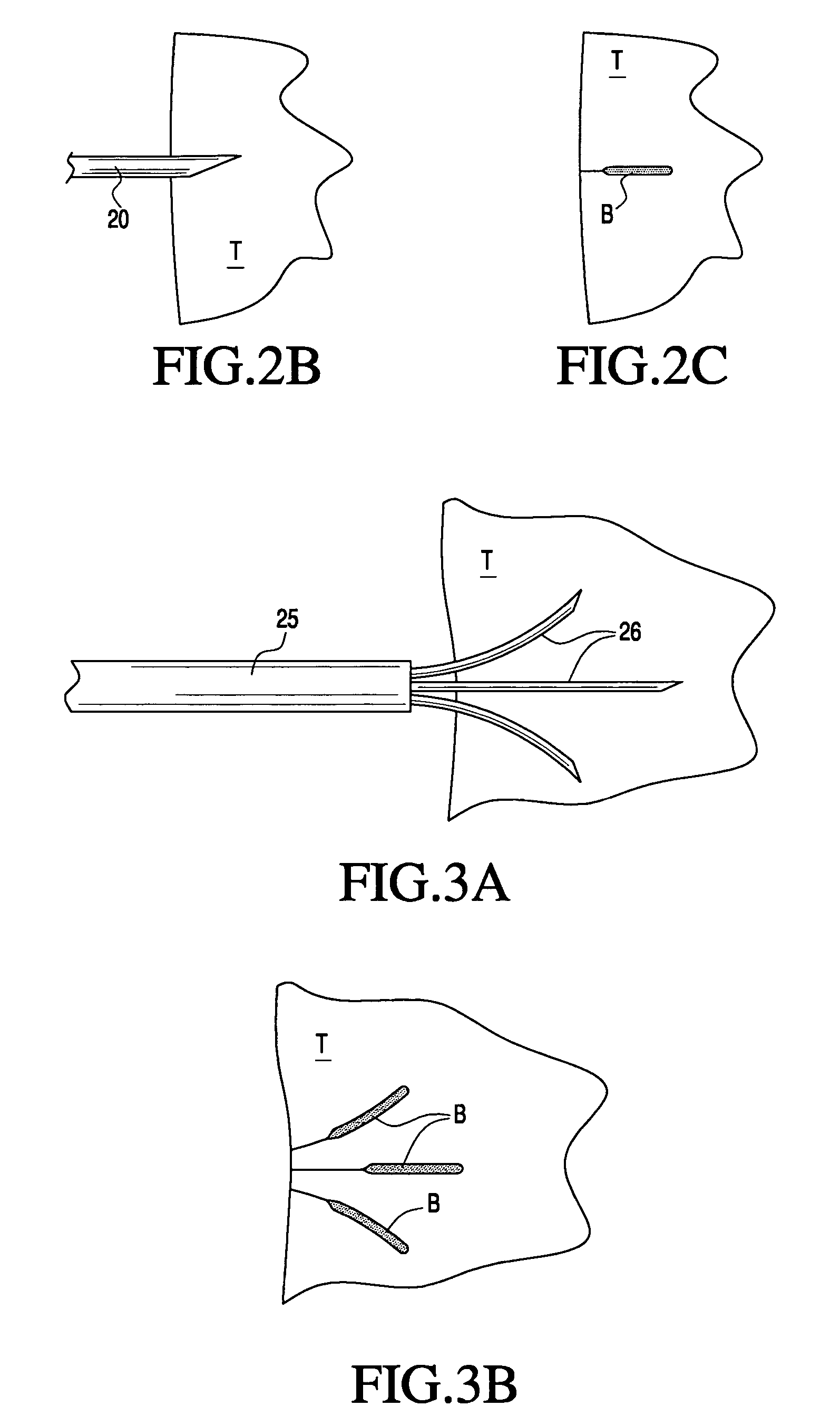

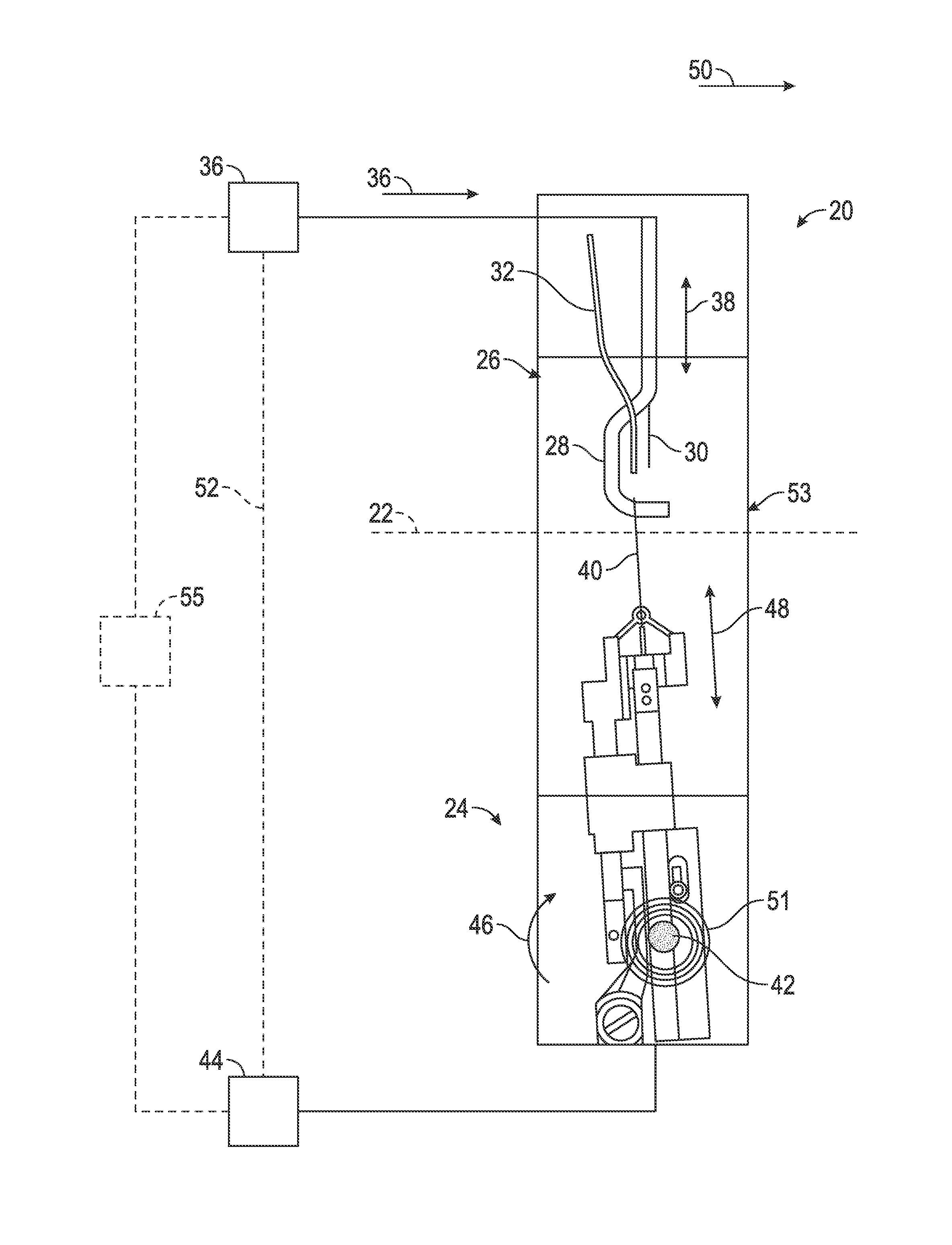

Systems and methods for atraumatic implantation of bio-active agents

ActiveUS20060015085A1Reduce riskReduce needInfusion syringesSurgical needlesActive agentCapillary action

Methods and apparatus are provided for delivering a bioactive agent in a needle track formed in a target tissue mass, following formation of the needle track, by avoiding impingement of the agent against target tissue at high velocity or by using capillary action to draw the bioactive agent out of the needle during needle withdrawal. The apparatus comprises a catheter and a needle disposed within the catheter and configured to be selectively extended into the tissue mass to a predetermined depth, while dispensing the agent simultaneously with retraction of the needle along the needle track. Alternatively, or in addition, the needle may be configured to create a tissue space surrounding a distal or lateral surface of the needle, into which the bioactive agent to be infused.

Owner:COOK MEDICAL TECH LLC

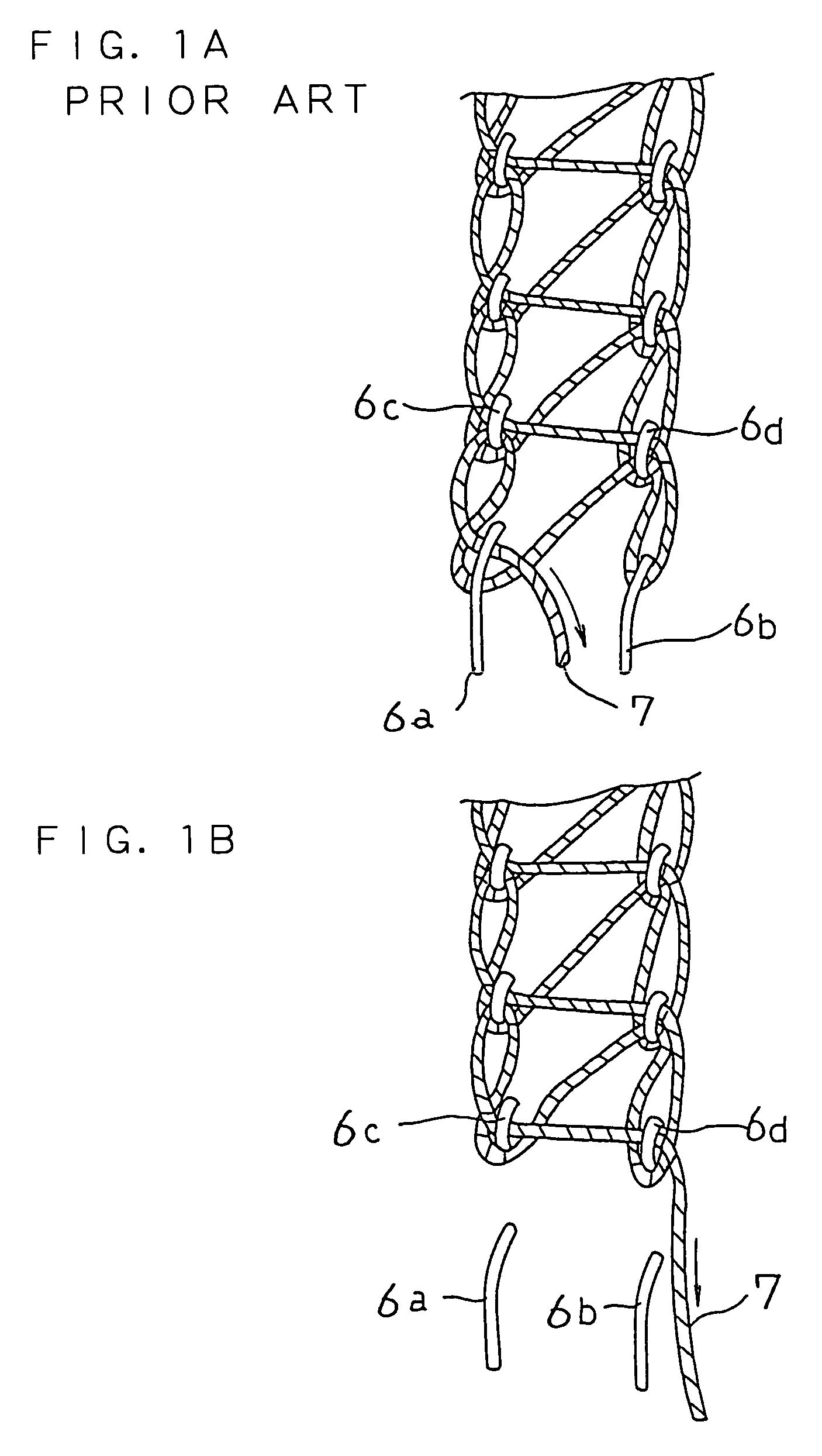

Seam ravel preventing apparatus and ravel preventing method

InactiveUS7497177B2Stable executionPreventing ravelingNeedle severing devicesLoop takersEngineeringScrew thread

A looper is brought into an advance state at the end of sewing, and a looper thread hanging hook arranged on the right rear side of a needle drop position is forced to advance and retreat to catch a looper thread running to the rear side of the looper and hold it on the rear side of the needle drop position. After performing sewing for one stitch in this state, the thread cutting hook arranged on the right side of the needle drop position is forced to advance and retreat to catch the looper thread running to the rear side of the looper with a first hold section and catch needle threads and the looper thread held by the looper thread hanging hook with a second hook section, and then these threads are collectively cut by bringing them into slide-contact with a thread cutting knife.

Owner:YAMATO SEWING MASCH MFG CO LTD

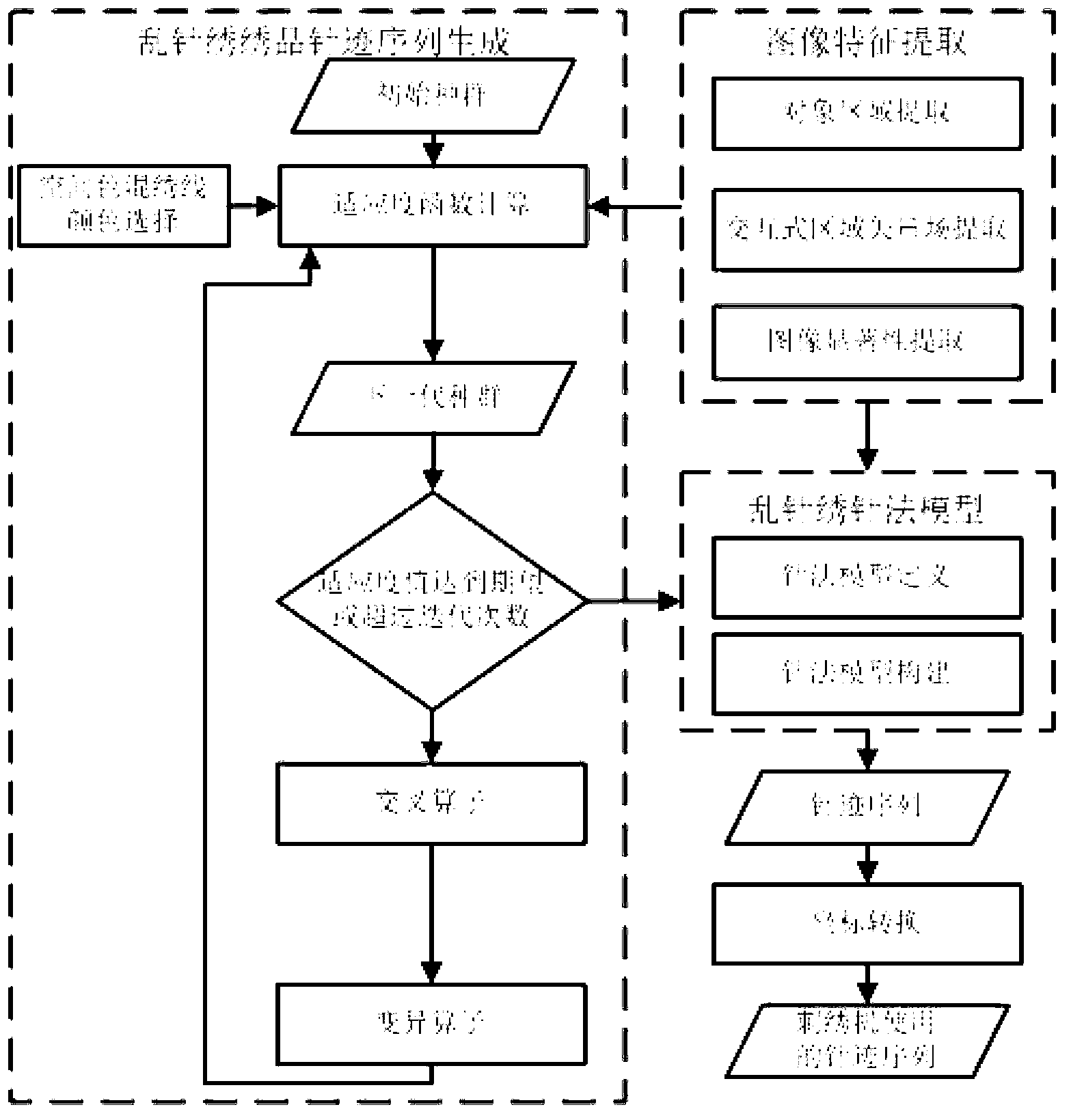

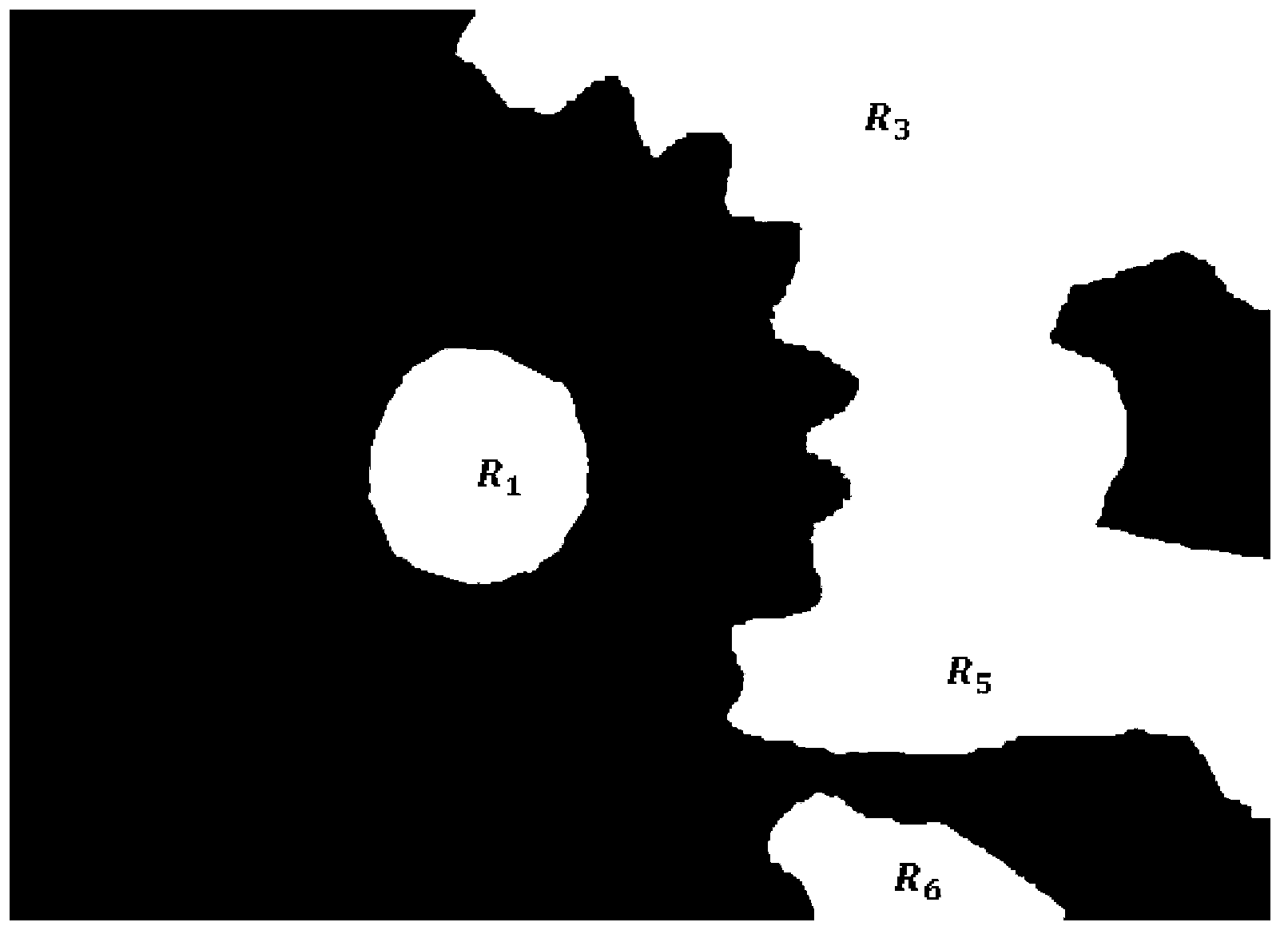

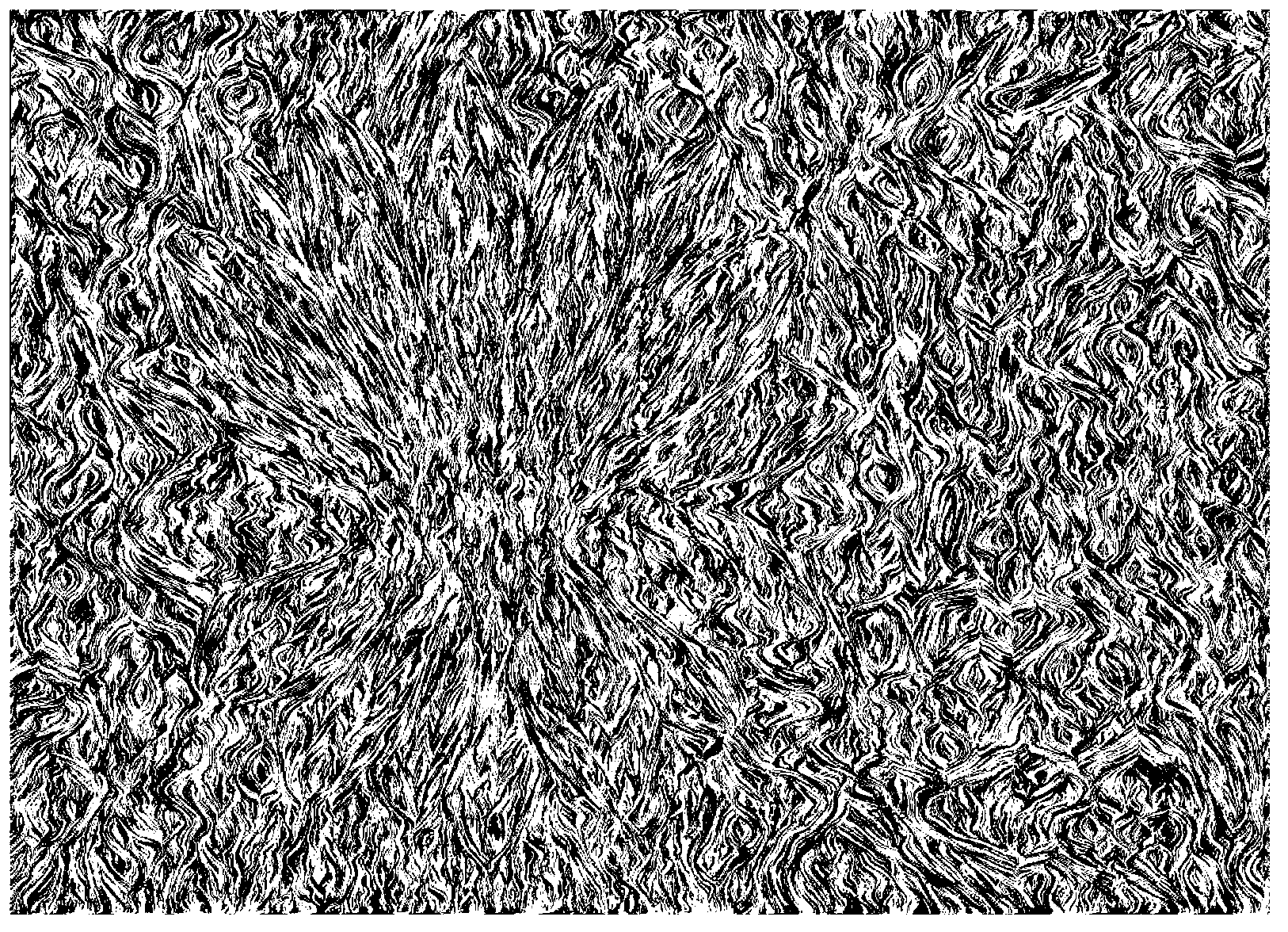

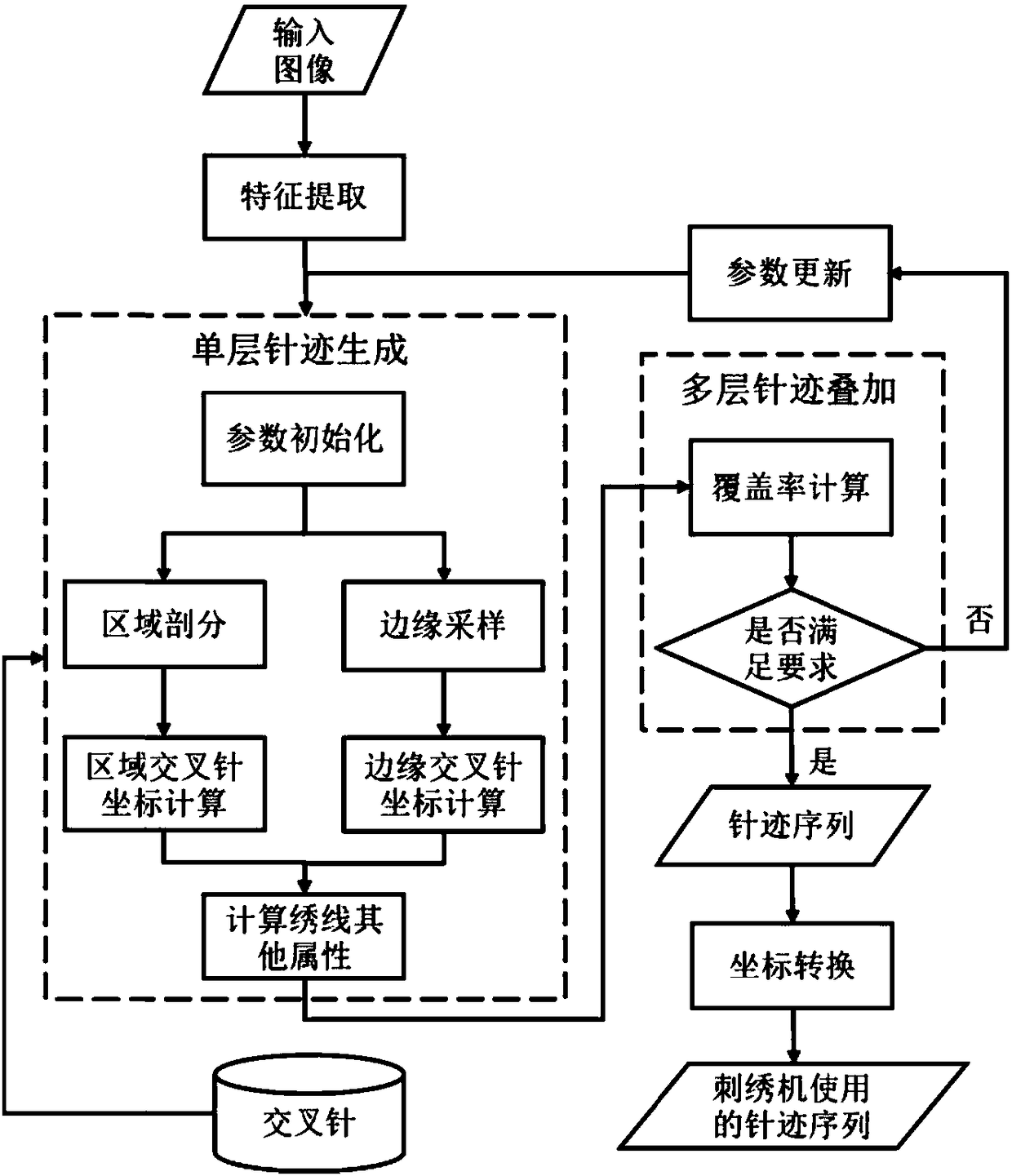

Computer-aided disordered needlework manufacture method using genetic algorithms

InactiveCN103294864AImprove production efficiencyReduce manual workCharacter and pattern recognitionSpecial data processing applicationsColor imageGenetic algorithm

The invention discloses a computer-aided disordered needlework manufacture method using genetic algorithms. The method includes the steps of firstly, using an input color image as a reference image, and using imaging segmentation, area vector field extraction and image consistency line extraction to extract image features such as different object areas, area vector fields and image saliency; secondly, defining three-layer parameterized knitting models including each embroidery thread, each cross needle and cross needle arrangement according to features of disordered needlework, and describing a method for obtaining embroidery thread collection according to the parameterized knitting models; thirdly, using the genetic algorithms to obtain disordered needlework needle tracking sequence according to knitting model parameters determined according to image features; fourthly, converting needle tracking coordinates into coordinates required by a computerized embroidery machine, and inputting the coordinates into the computerized embroidery machine to obtain the corresponding disordered needlework. The method is significant to mechanical standardized production of the disordered needlework.

Owner:NANJING UNIV

Apparatus and methods for treating tissue using passive injection systems

ActiveUS7338471B2Reduce riskRaise the ratioSurgical needlesMedical devicesDamages tissueActive agent

Methods and apparatus are provided for treating damaged tissue using apparatus that atraumatically delivers a bioactive agent within the tissue, wherein the apparatus provides a column of stem cells may be advanced simultaneously with a needle during needle insertion, and then held stationary or injected at low pressure while retracting the needle. Alternatively, the needle may employ electromotive forces, or to change a dimension of the needle, to expel the bioactive agent into the needle track.

Owner:COOK MEDICAL TECH LLC

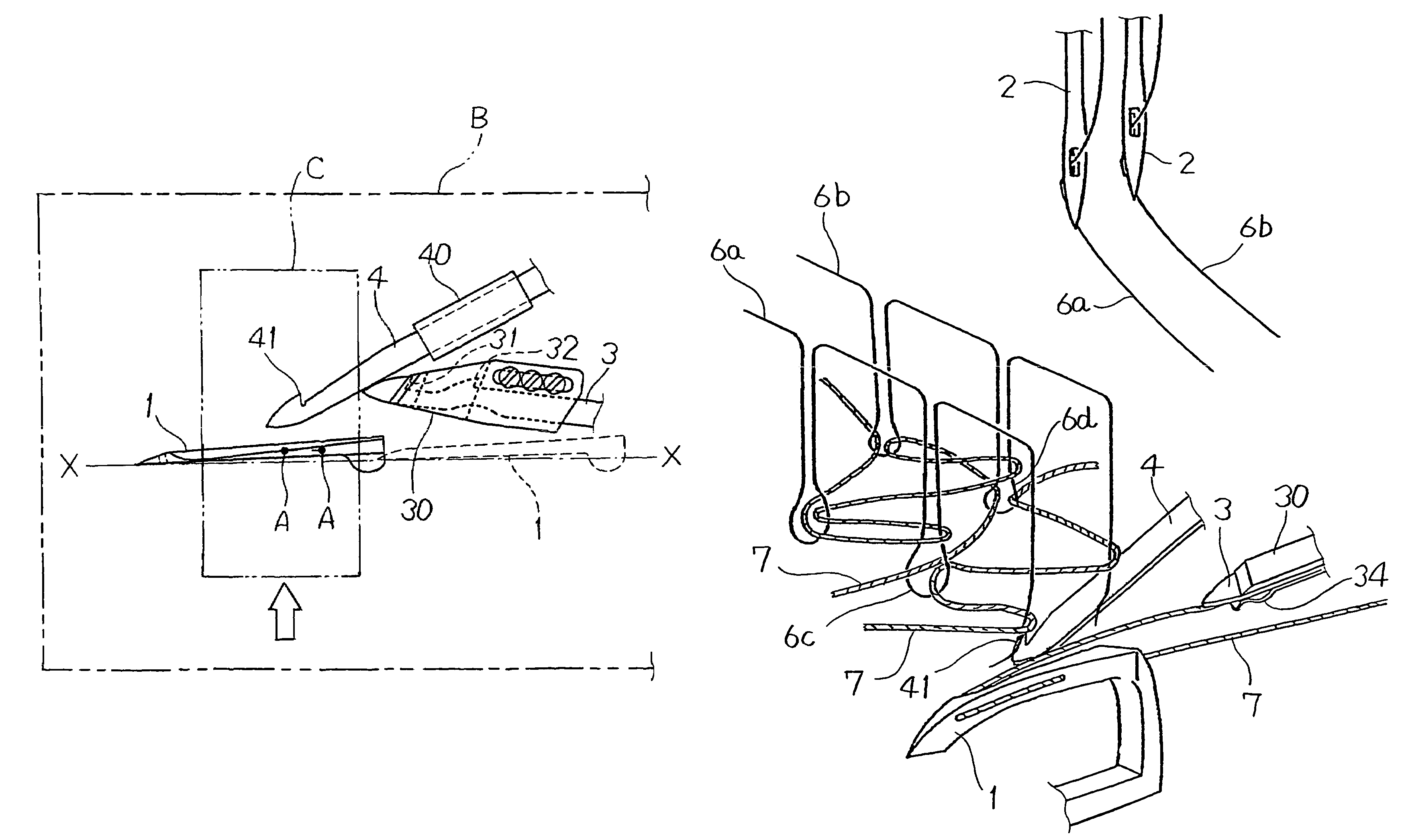

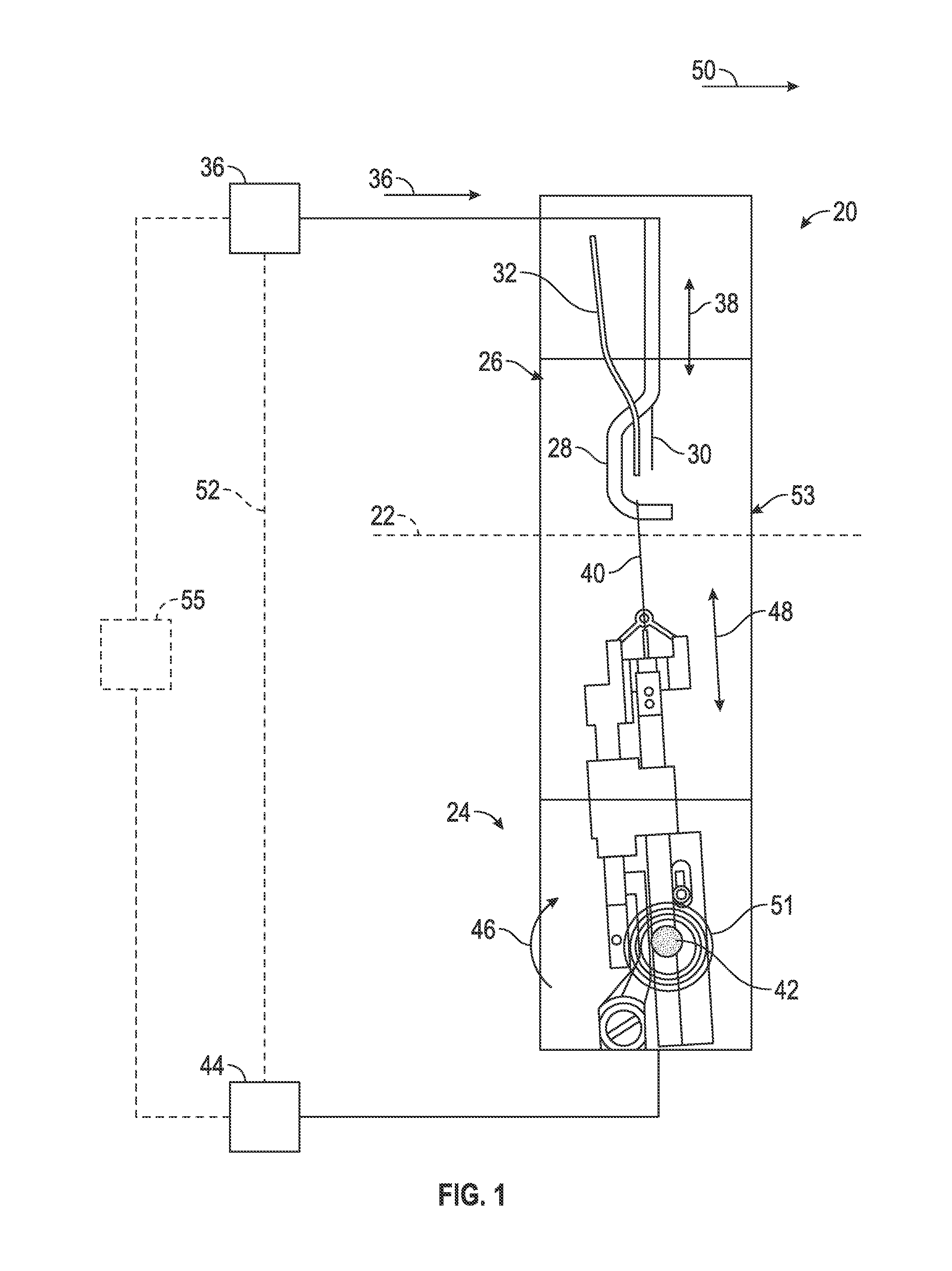

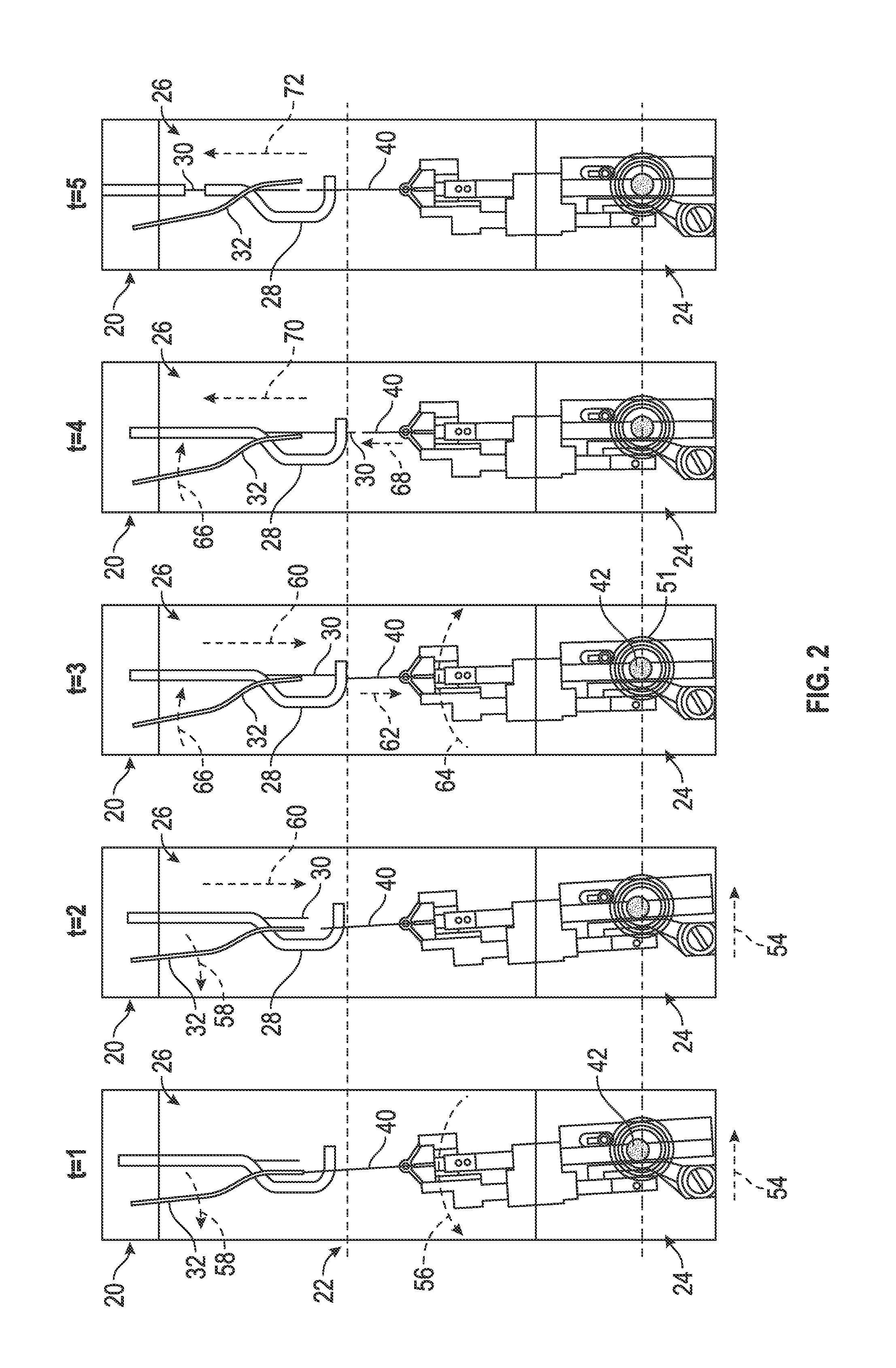

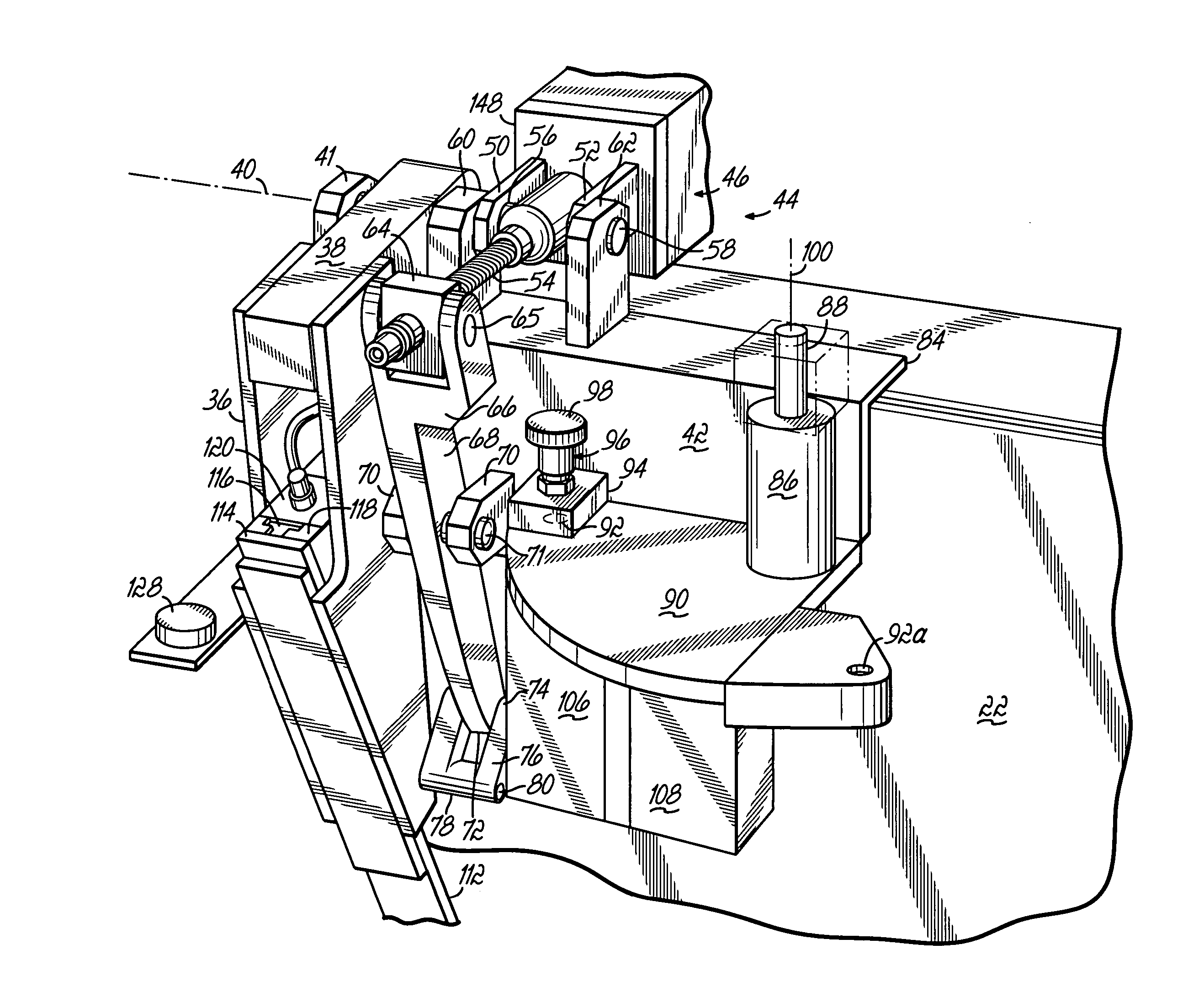

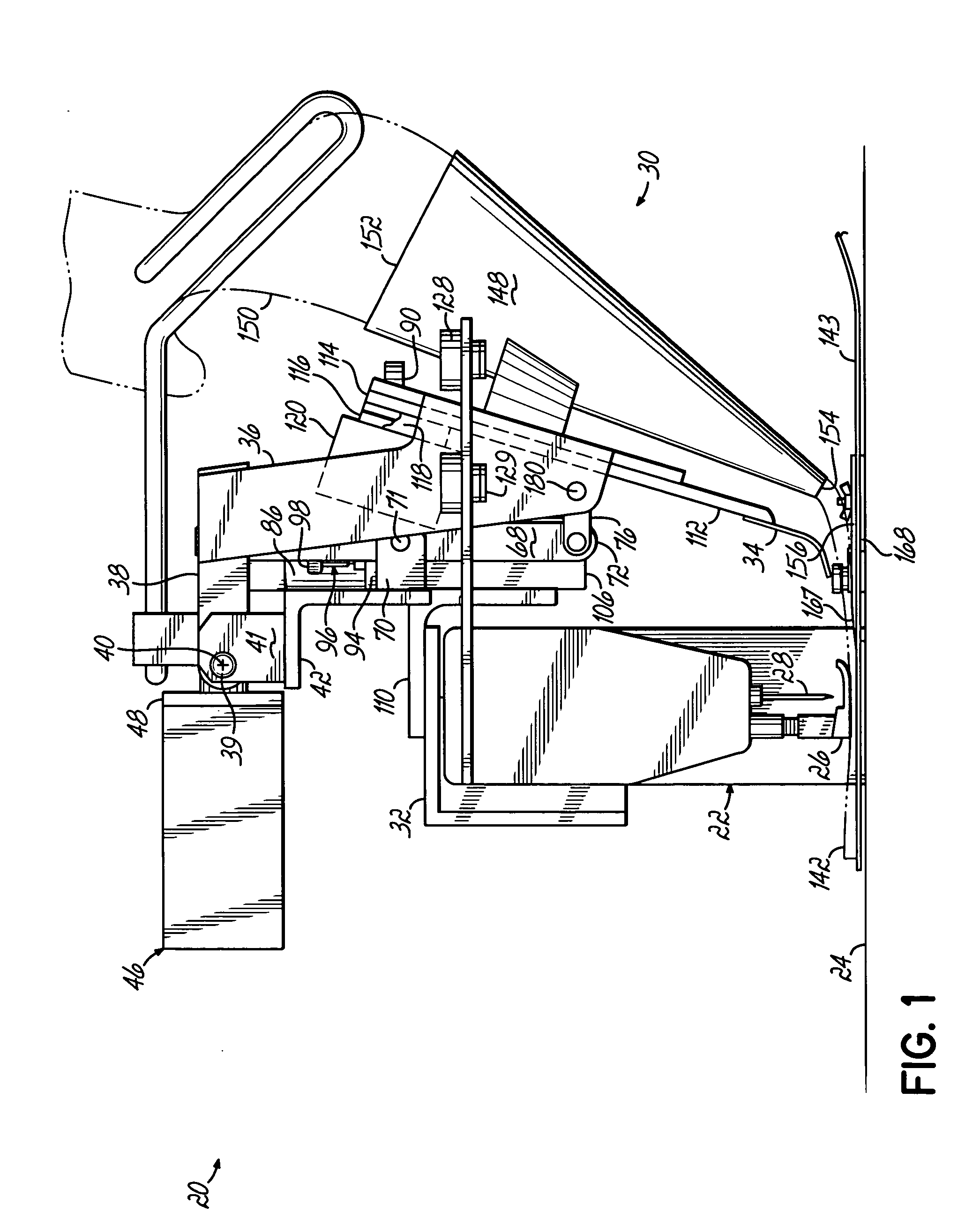

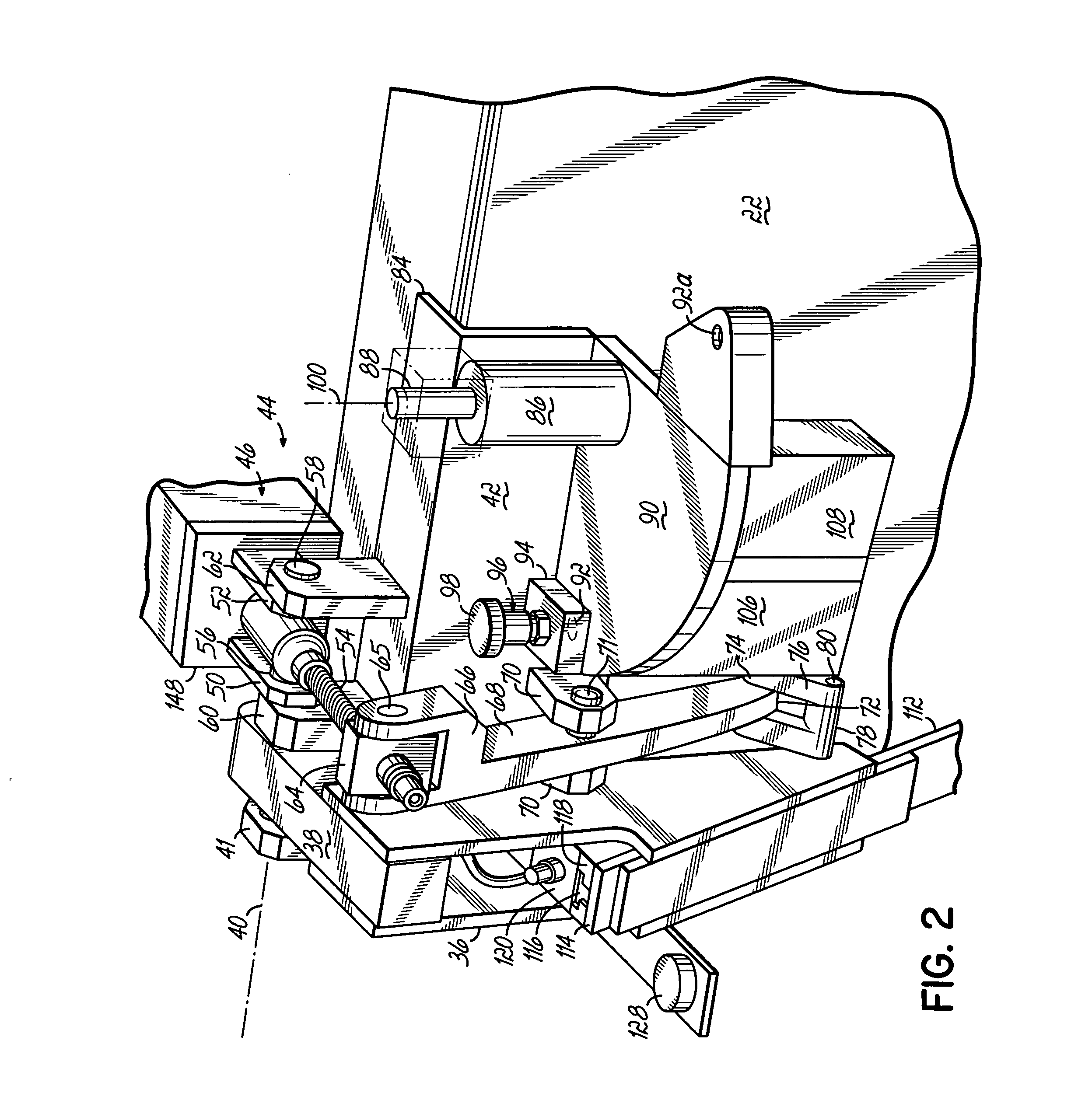

Apparatus for stitching vehicle interior components

An apparatus for stitching a component is provided. The apparatus includes an awl bar assembly coupled to a first drive device. The awl bar assembly is moved from a first position to a second position along the stitch path with an external drive device. A second drive device is coupled to the first drive device. A needle bar assembly is provided having a needle. The needle moves between an inserted and a withdrawn position, the needle bar assembly being pivotally coupled to the second drive device, the needle bar assembly moves from the first position to the second position with the same external drive device driving the awl bar assembly. A biasing member is coupled to the needle bar assembly, the biasing member being arranged to pivot and align the needle bar assembly in the second position in response to the needle bar being moved to the withdrawn position.

Owner:INTEVA PRODUCTS LLC

Glove machine needle selection system

ActiveCN106521790AImprove stabilityRich diversityFlat-bed knitting machinesSelection systemBiomedical engineering

The invention provides a glove machine needle selection knitting system, which belongs to the field of glove machine, which comprises a needle selection roller, a roller pin, a selected bird blade, a jacking needle, a knitting needle and a triangular plate. The needle roller surface is provided with a groove. Triangle board is equipped with a needle track, and the pin on the needle plate coordinates with needle track. The groove is provided with a plurality of knitting pins, the knitting pin and the roller pin being distributed according to the knitting demand. The triangular plate comprises a bottom plate and a rubber triangular angle, a needle triangle, a zigzag triangle, a middle triangle, a degree adjustment block and a pressure pin triangle provided on the front surface of the bottom plate. The middle triangle, the rubber triangle and the pressure pin are fixed to the bottom plate. The seam triangle is arranged in conjunction with the degree adjustment block. The system can change the knitting pattern quickly and easily by replacing the knitting pin, and fixes the needle track on the triangular plate to reduce the use and control of the movement mechanism of the triangular plate, greatly improve the efficiency of the glove machine for needle selection, jacquard, weaving and other operations.

Owner:ZHEJIANG HAISEN KNITTING MACHINE TECHN

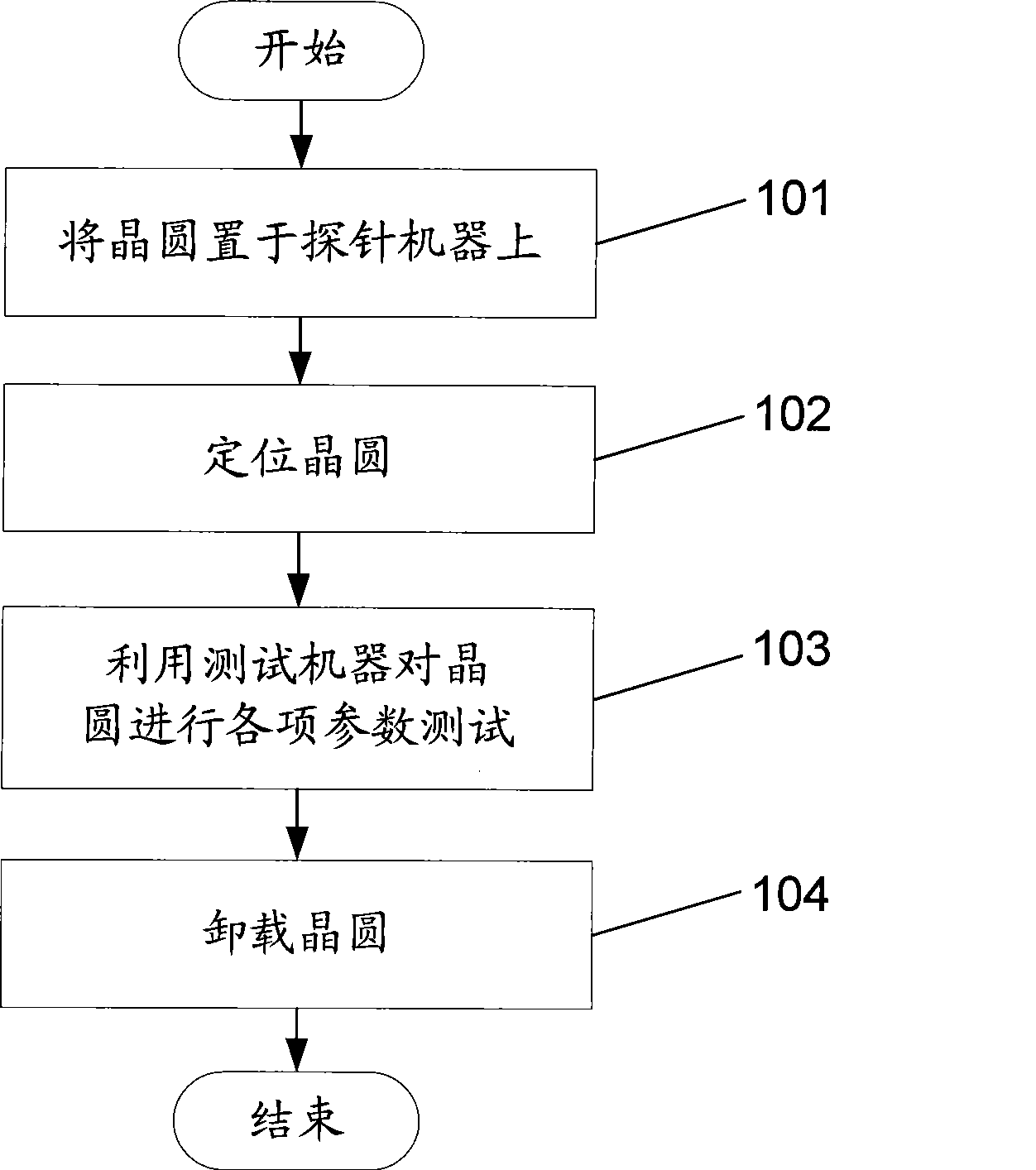

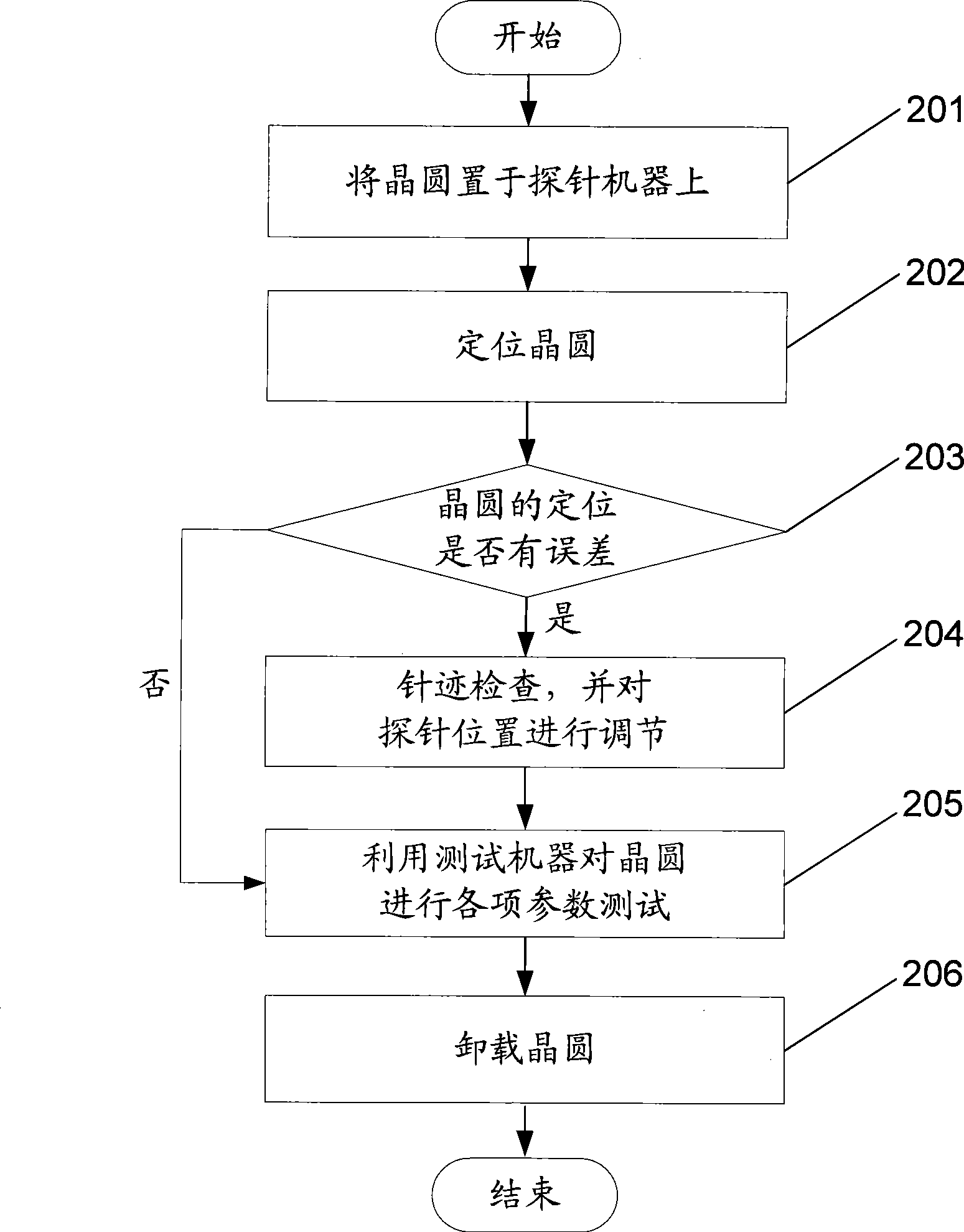

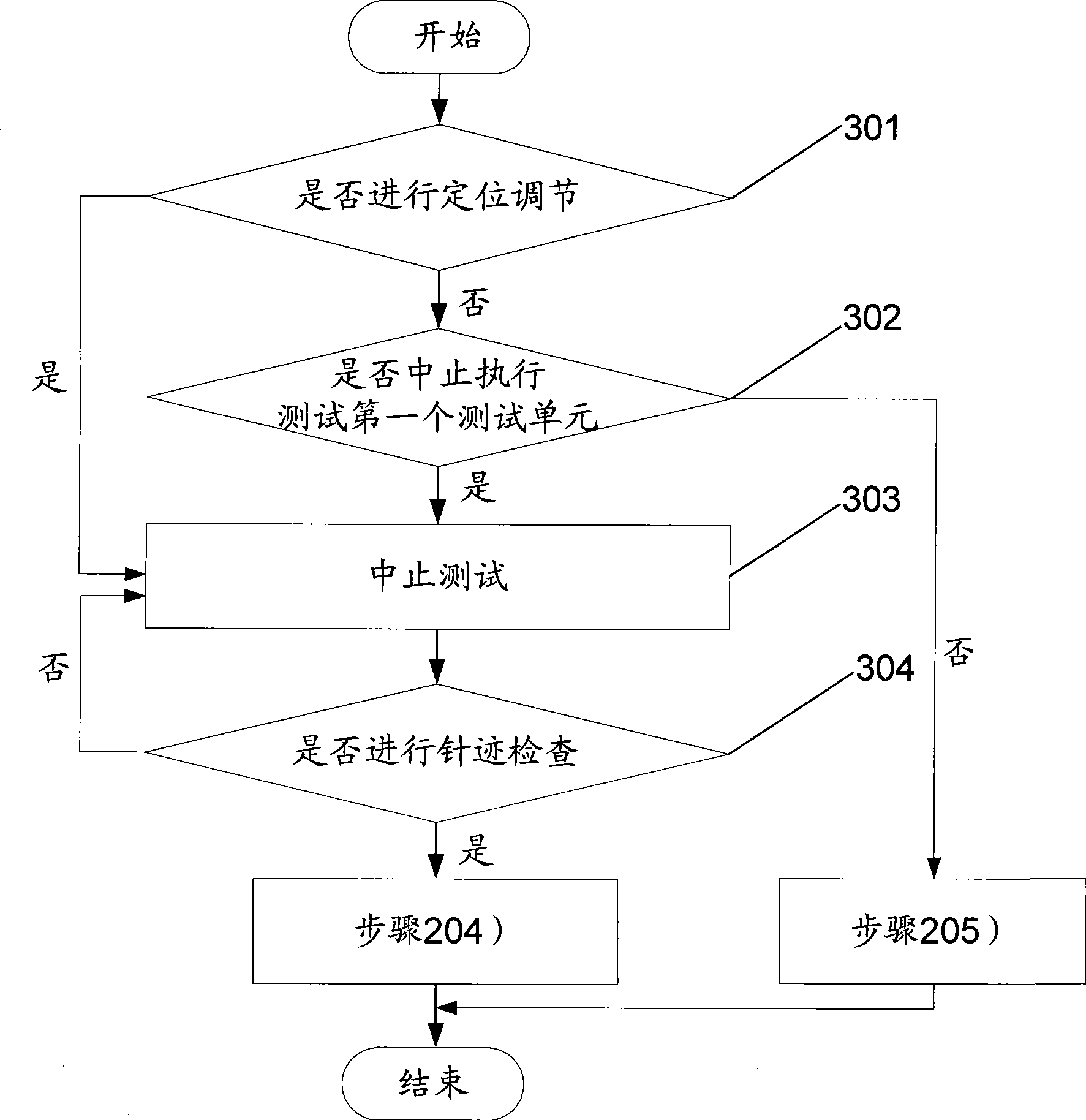

Method for eliminating probe needle track bias

InactiveCN101368990AEliminate offsetHigh measurement accuracySemiconductor/solid-state device testing/measurementIndividual semiconductor device testingNeedle trackIntegrated circuit

The invention discloses a method for eliminating probe track offset, which is characterized in that the method comprises following steps: A) a wafer can be arranged on a probe device; B) the wafer is positioned; C) whether the wafer position has errors or not is judged, if yes, and then step D can be executed; if no error exists, step E is executed; D) the probe trace is detected, and the probe position can be adjusted; E) all parameters of the wafer can be tested through a test machine; F) the wafer is unloaded. The method belongs to the integration circuit manufacturing, can greatly reduce error of the measuring result of electrical parameter, and can prevent the wafer from being discarded.

Owner:SEMICON MFG INT (SHANGHAI) CORP

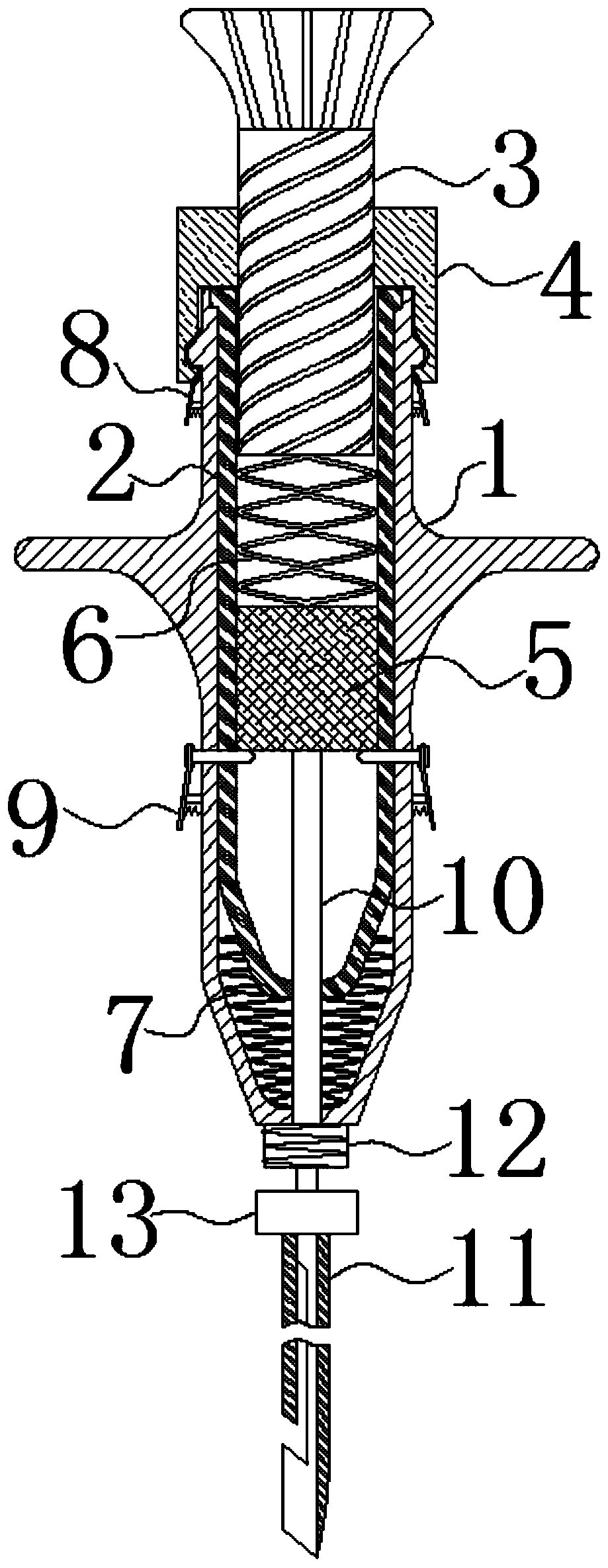

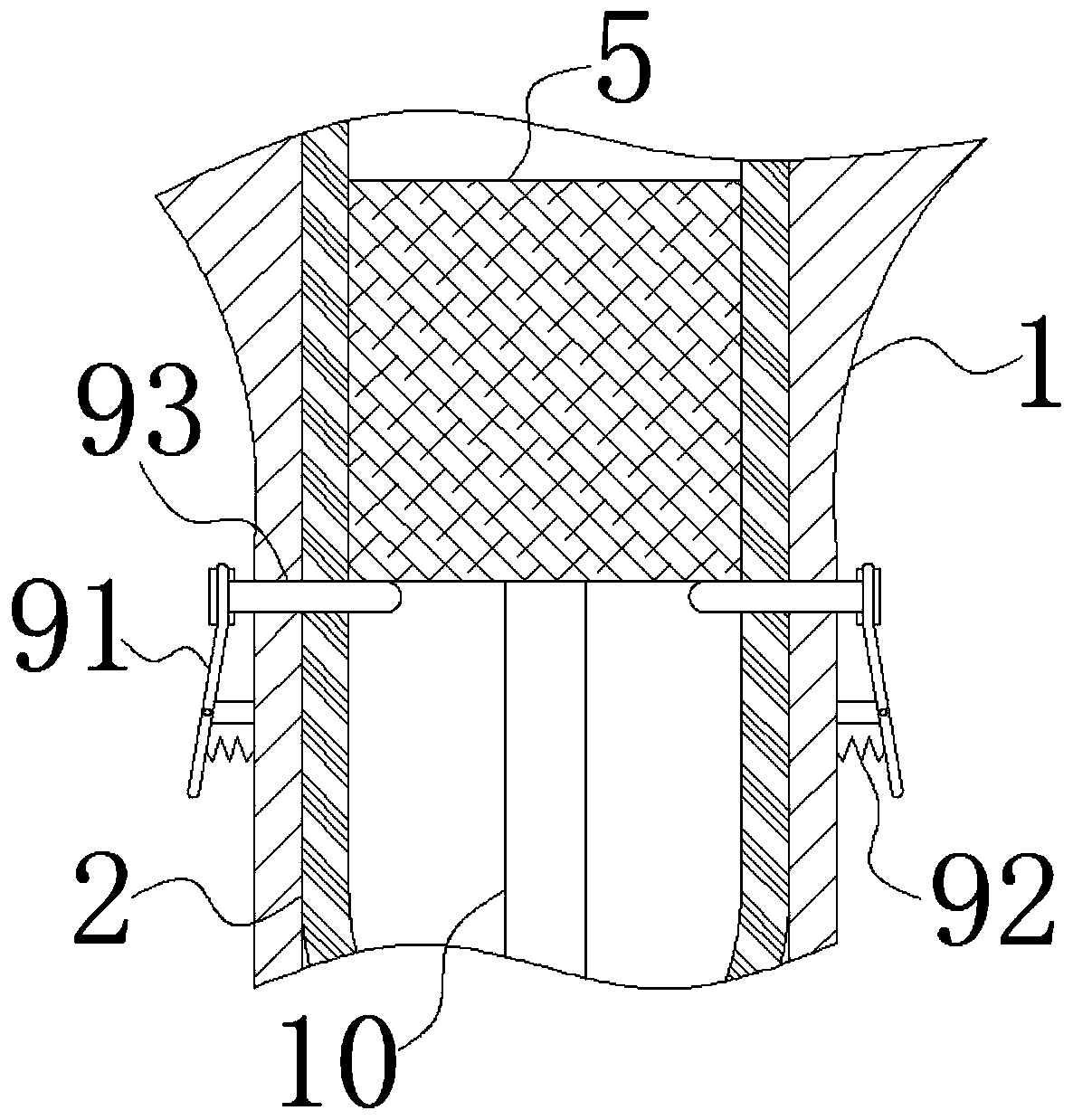

Internal-cooling microwave ablation needle provided with implanted balloon

ActiveCN105640642AEasy to fixAdvantages of high temperature controlSurgical instruments for heatingSurgical instruments for coolingMicrowaveCold injury

The invention relates to an internal-cooling microwave ablation needle provided with an implanted balloon. A microwave antenna is insulated from an internal cooling system through a microwave antenna liner tube, the internal cooling system is in positioning connection with an outer tube through an adapter tube and a sealing tube, and the balloon is located between a targeted area and a non-targeted area of the microwave ablation needle and connected with a J-T spray tube through the adapter tube; the J-T spray tube is connected with a finned tube, the balloon is filled with fluid through the adapter tube, the balloon after filling of the cooling fluid is expanded and has a fastening effect with surrounding tissue; when low-temperature gas is introduced, small frozen areas are produced around the balloon under the action of the throttling effect of the J-T spray tube, and the fixing function is realized; a vacuum wall is arranged on the inner side of the outer tube, so that the fluid in the outer tube is in heat insulation from biological tissue outside the outer tube, and normal tissue is protected from cold injuries. The internal-cooling microwave ablation needle can be effectively prevented from displacement with shrinking deformation of heated biological tissue in an ablation process, and has the advantages that an ablation area is positioned more accurately, fewer normal tissue injuries are caused, the risk of the needle track implantation of tumors is lower and the like.

Owner:ACCUTARGET MEDIPHARMA (SHANGHAI) CO LTD

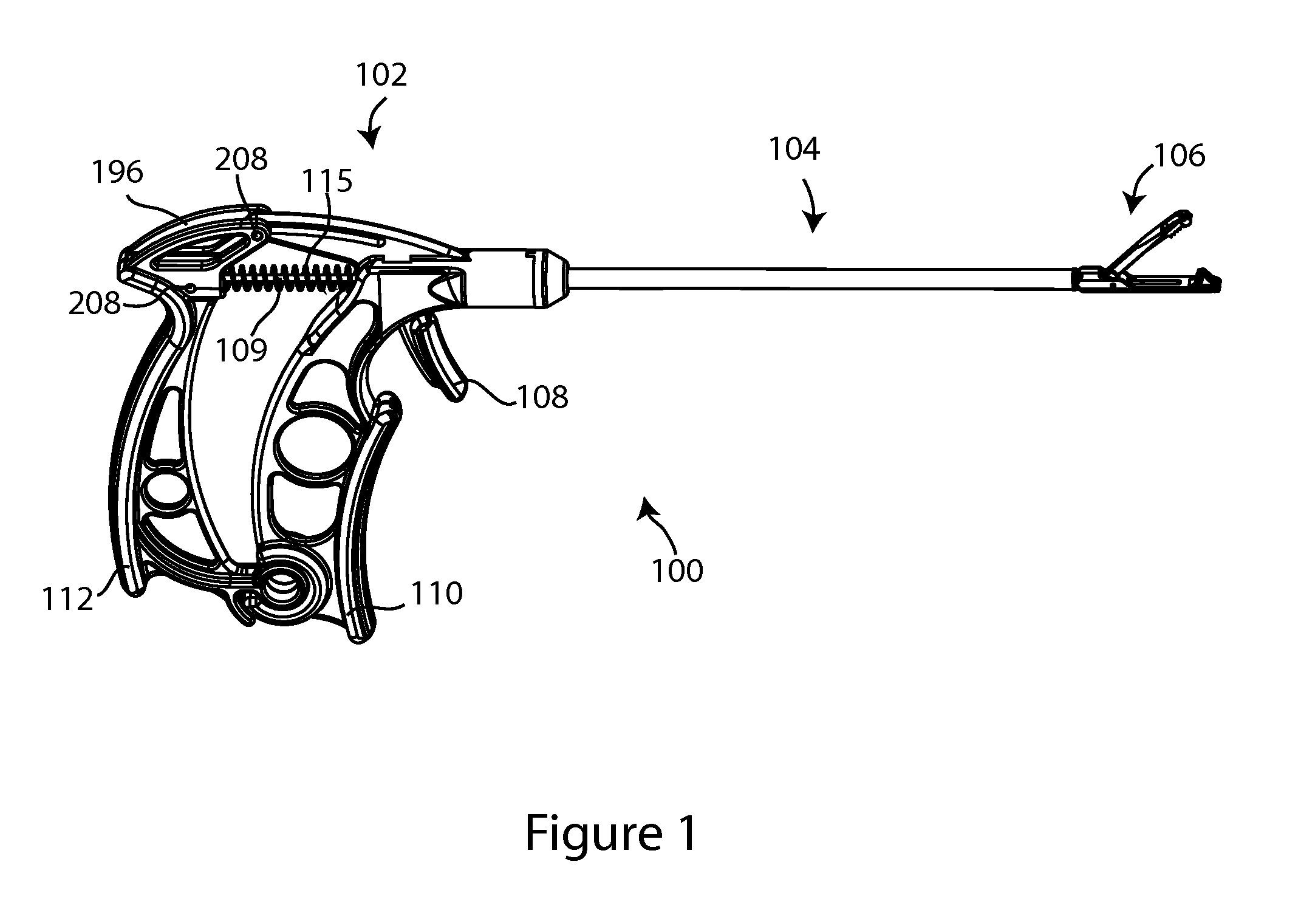

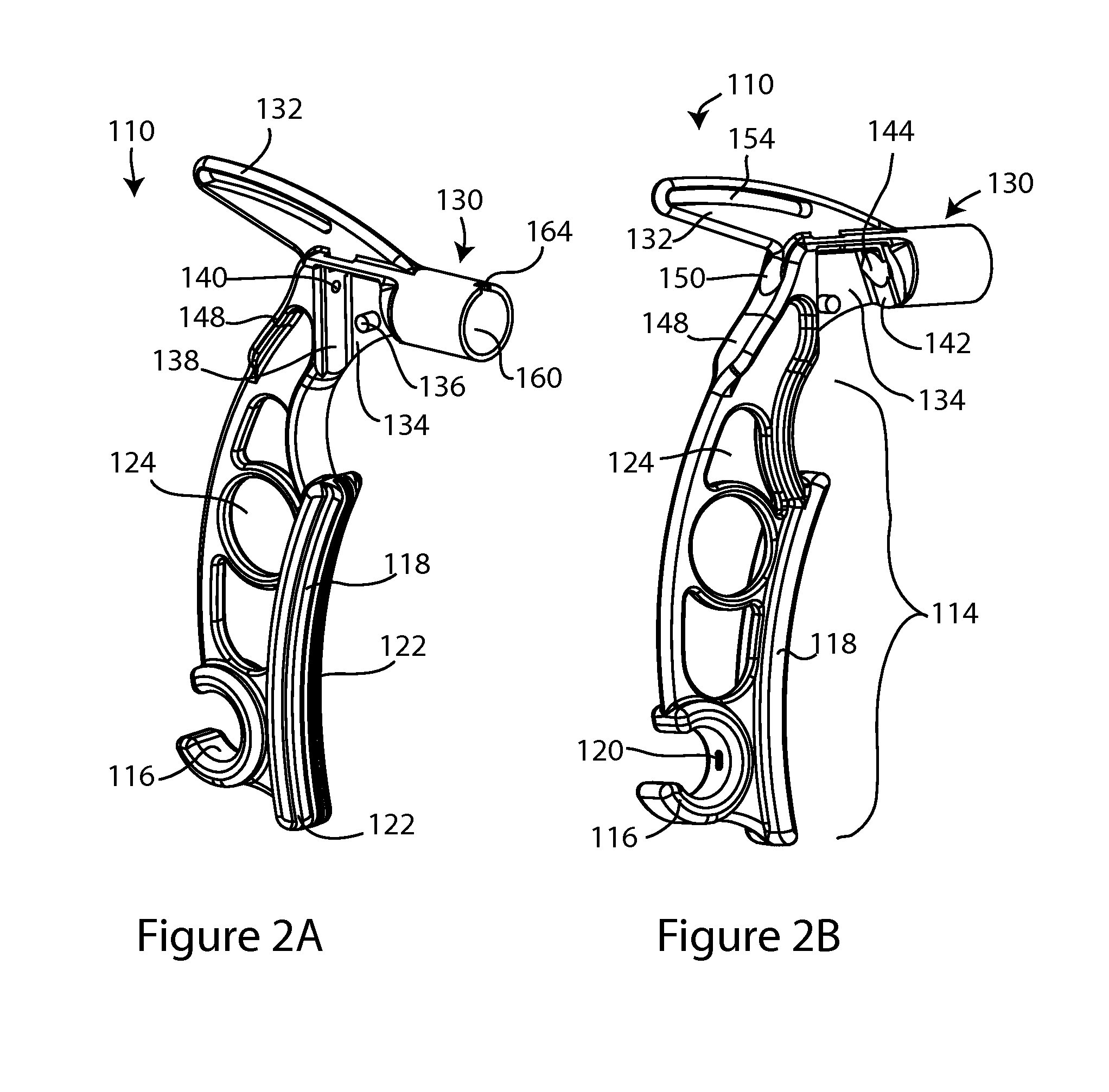

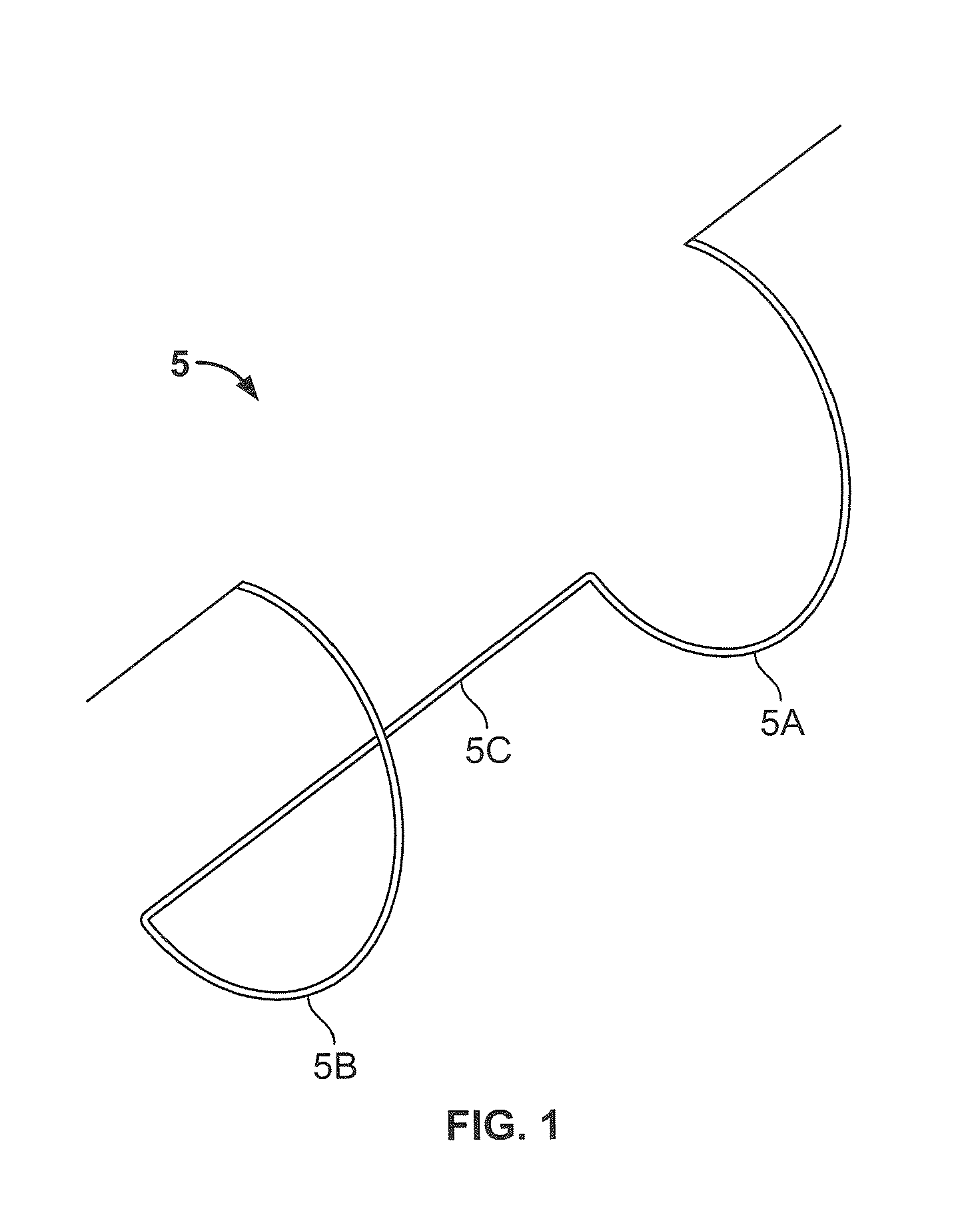

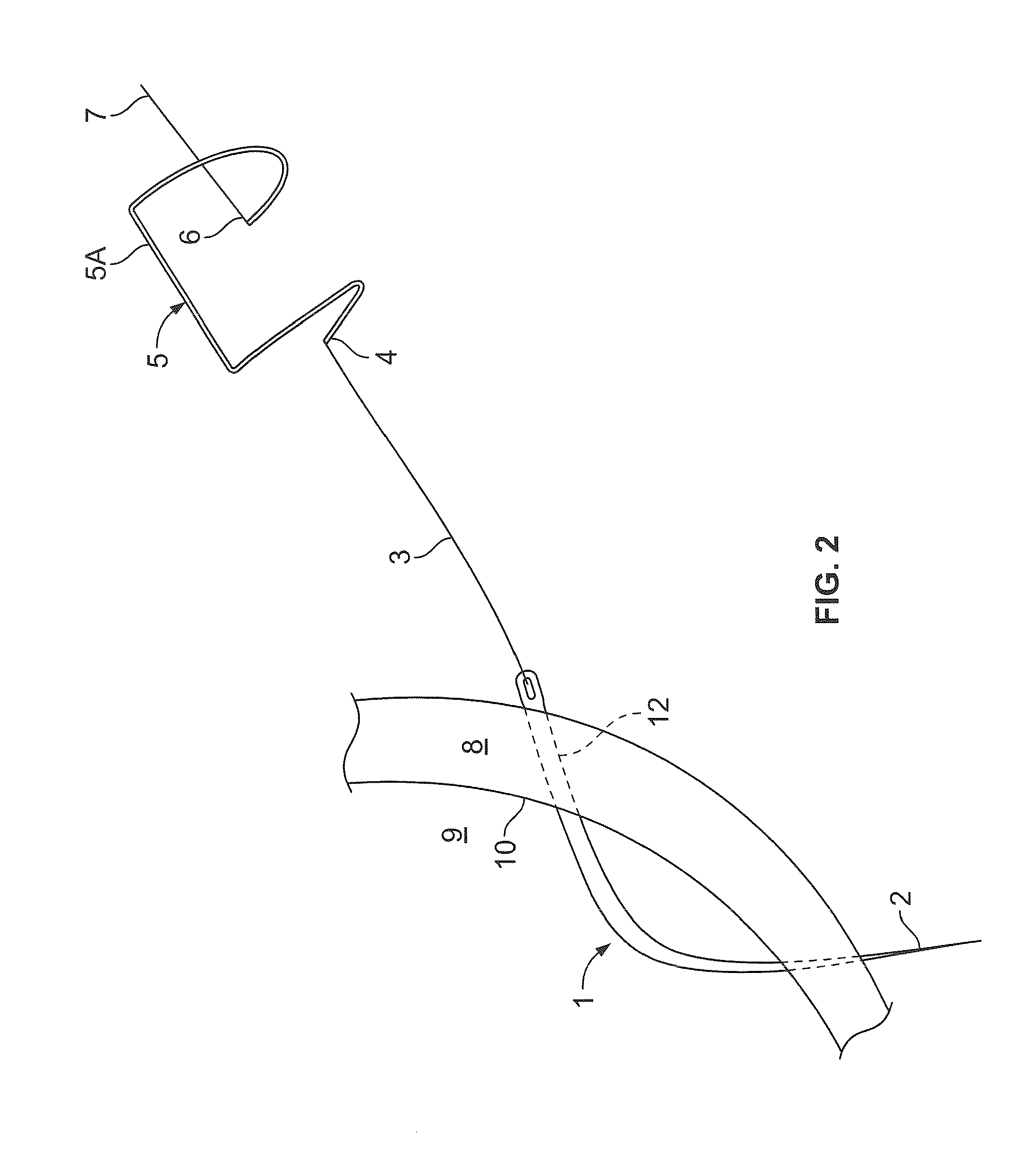

Suture passers

Suture passers which include a handle assembly, shaft assembly, and jaw assembly. In one embodiment, the handle assembly includes first and second handles joined at a hinge, the second handle pivotable relative to the first handle and guided by an arcuate guiding feature concentric to the hinge. The jaw assembly includes upper and lower jaws, the lower jaw including an open needle track. The open needle track includes entry, tangential and exit segments, each of which is directly visible, directly accessible, and directly inspectable. The lower jaw can be manufactured as a single piece, using a single manufacturing process, which may be injection molding or multi-axis machining. When manufactured by multi-axis machining, all features of the lower jaw may be machined without removal of the jaw piece from the multi-axis machine. Methods of suture passer manufacture and assembly which may provide significant cost savings are disclosed.

Owner:IMDS CORPORATION

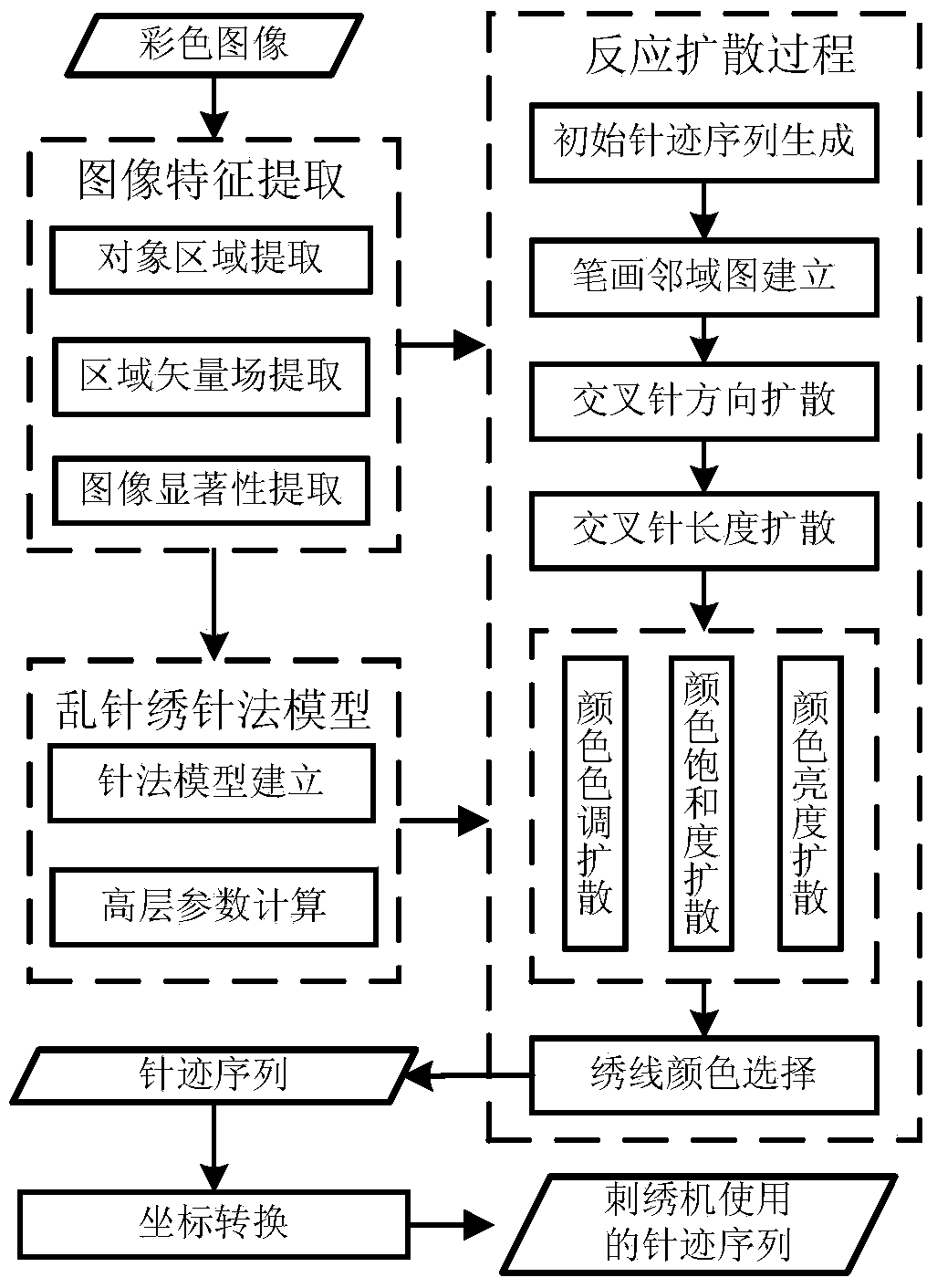

Computer-assisted disordered needlework manufacture method based on reaction diffusion process

InactiveCN103473433AReduce workloadImprove production efficiencyImage enhancementSpecial data processing applicationsDiffusionColor image

The invention discloses a computer-assisted disordered needlework manufacture method based on a reaction diffusion process. The manufacture method comprises the following steps of a step 1 that a color image is taken as an input, and different object regions, regional vector fields and image obviousness of the input color image are extracted by adopting image segmentation, regional vector field extraction and image obviousness computation methods; a step 2 that a three-layer parameterization stitch model comprising single embroidery threads, single cross needles and cross needle distribution is built according to the characteristic of a disordered needlework, and a parameter value computation method of a cross needle distribution layer in the model is described; a step 3 that a stroke neighbourhood graph is built according to the initial needle tracking sequence generated by each object region, the direction, the length, the color hue, the color saturation and the color brightness of the generated needle tracking sequence are respectively controlled by adopting five reaction diffusion processes, the colors of embroidery threads are selected, and the final needle tracking sequences of all object regions are obtained; a step 4 that coordinates of the needle tracking sequences are converted into coordinates of a computerized embroidery machine.

Owner:NANJING UNIV

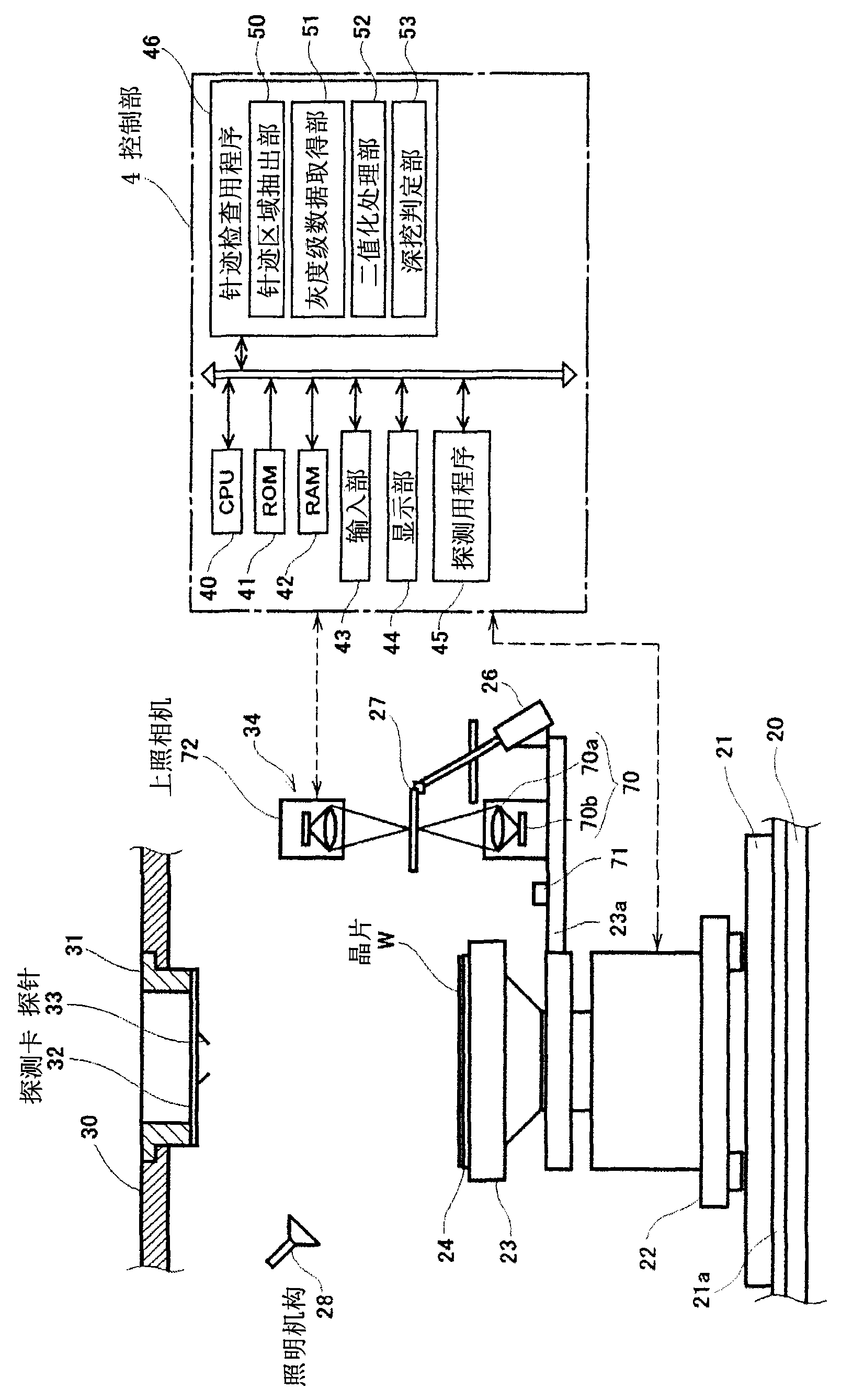

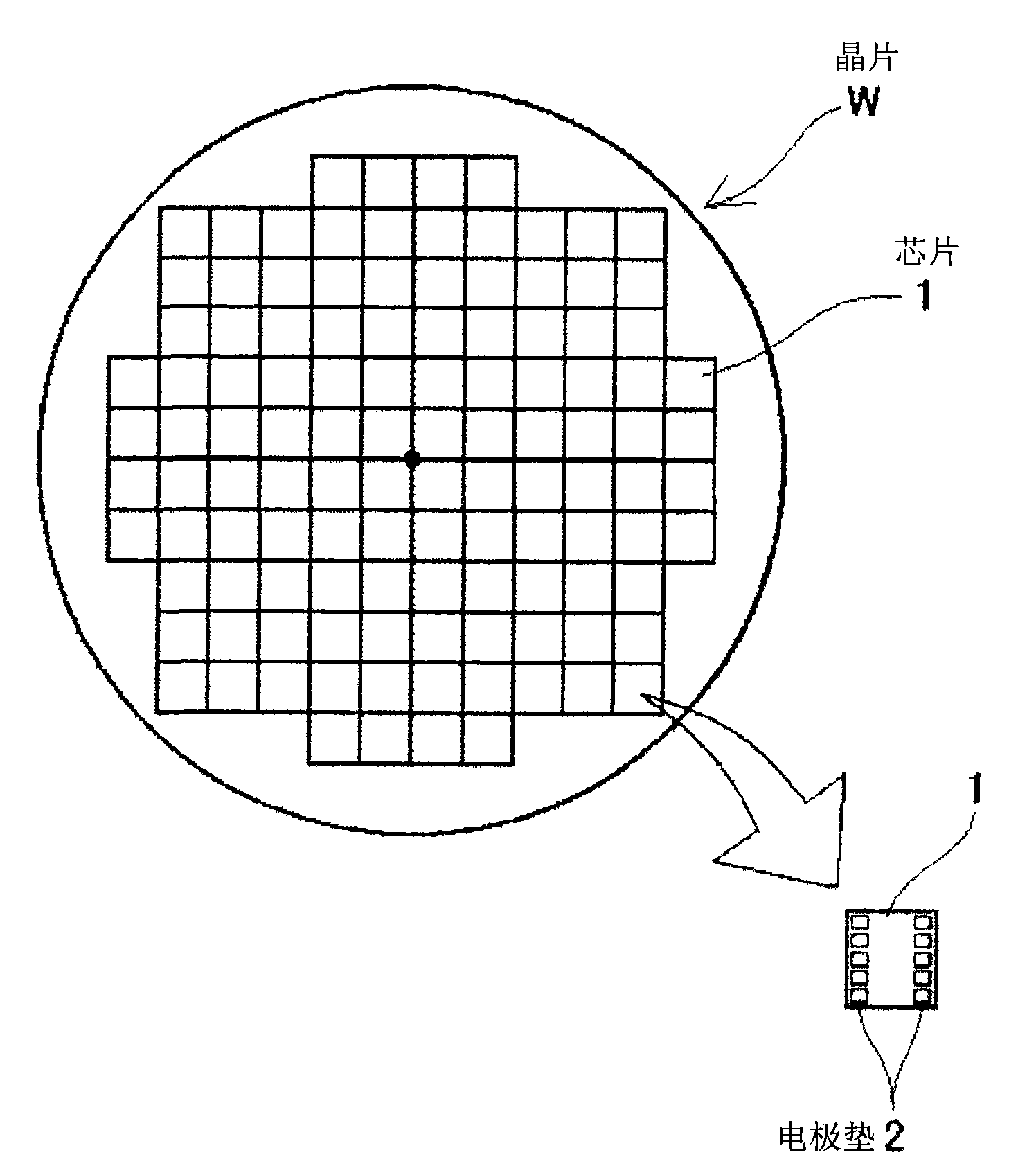

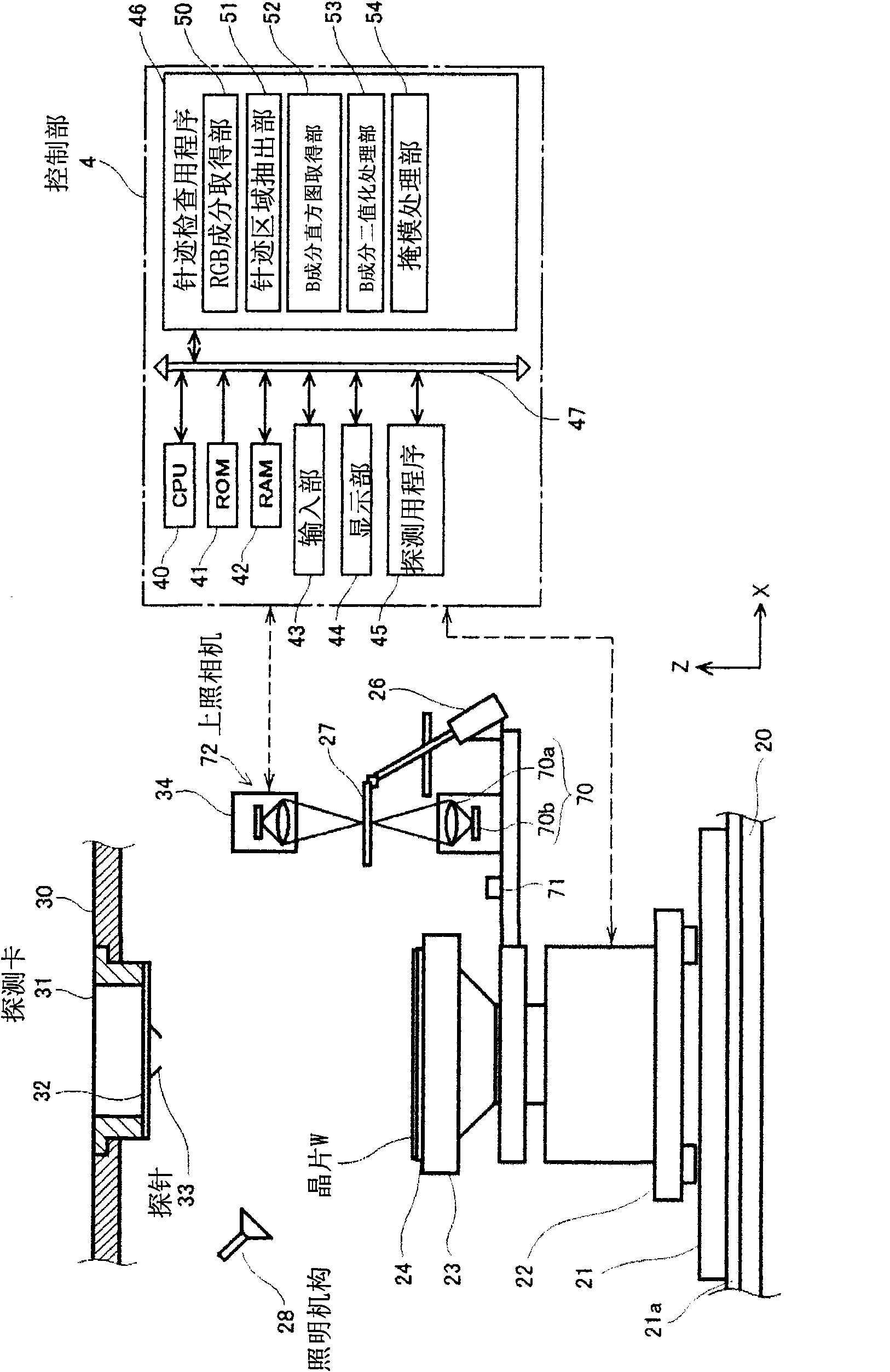

Needle track inspection device, detecting device and needle track checking procedure

ActiveCN101587084AReduce the burden onGrasp the exception quicklyImage analysisElectrical measurement instrument detailsReference patternsGrey level

Owner:TOKYO ELECTRON LTD

Smooth memory knitted fabric and preparation method

ActiveCN103556377AFunction increaseThe preparation process is scientific and environmentally friendlyWeft knittingDeodorantEngineering

The invention relates to a smooth memory knitted fabric and a preparation method thereof. The smooth memory knitted fabric comprises an outer layer and an inner layer, the outer layer is composed of super fine denier polyester fibers, and the inner layer is composed of Modal fiber staple yarns and polyurethane fiber filaments. The preparation method includes that (1) after structural design, a weft knitting single-sided multi-needle-track high needle pitch knitting machine is used for weaving with weft knitting number 28-32G to obtain a knitted fabric, and (2) the obtained knitted fabric is subjected to presetting, pre-processing, polyester fiber dyeing, Modal fiber overdyeing, color fixing, water scrubbing, repeatedly setting and finally drying. The smooth memory knitted fabric has the advantages that the smooth memory knitted fabric is highly elastic, fine, smooth, quickly dry when absorbing water, antimicrobial, deodorant, not prone to deformation after washed, light, convenient and comfortable if a user wears clothes made of the fabric, and capable of overcoming defects of poor hand feel, creased cloth surfaces, insufficient wet permeability, tendency to stink and the like in terms of traditional fabrics.

Owner:NINGBO DAQIAN TEXTILE

Sewing machine

A sewing machine includes a head on which a needle bar for fixing a needle is mounted, a thread cutting blade mounted in the head so as to be capable of cutting an end of a thread which is threaded so as to be passed through an eye of the needle, and a holder mounted in the head so as to be capable of holding the thread end after the thread end has been cut by the thread cutting blade. The thread cutting blade is positioned so that a first amount of thread from the eye of the needle mounted in the head to the thread end held by the holder equals a second amount of thread by which the thread end is drawn to an underside of a cloth in a stitch formed immediately after start of a sewing operation.

Owner:BROTHER KOGYO KK

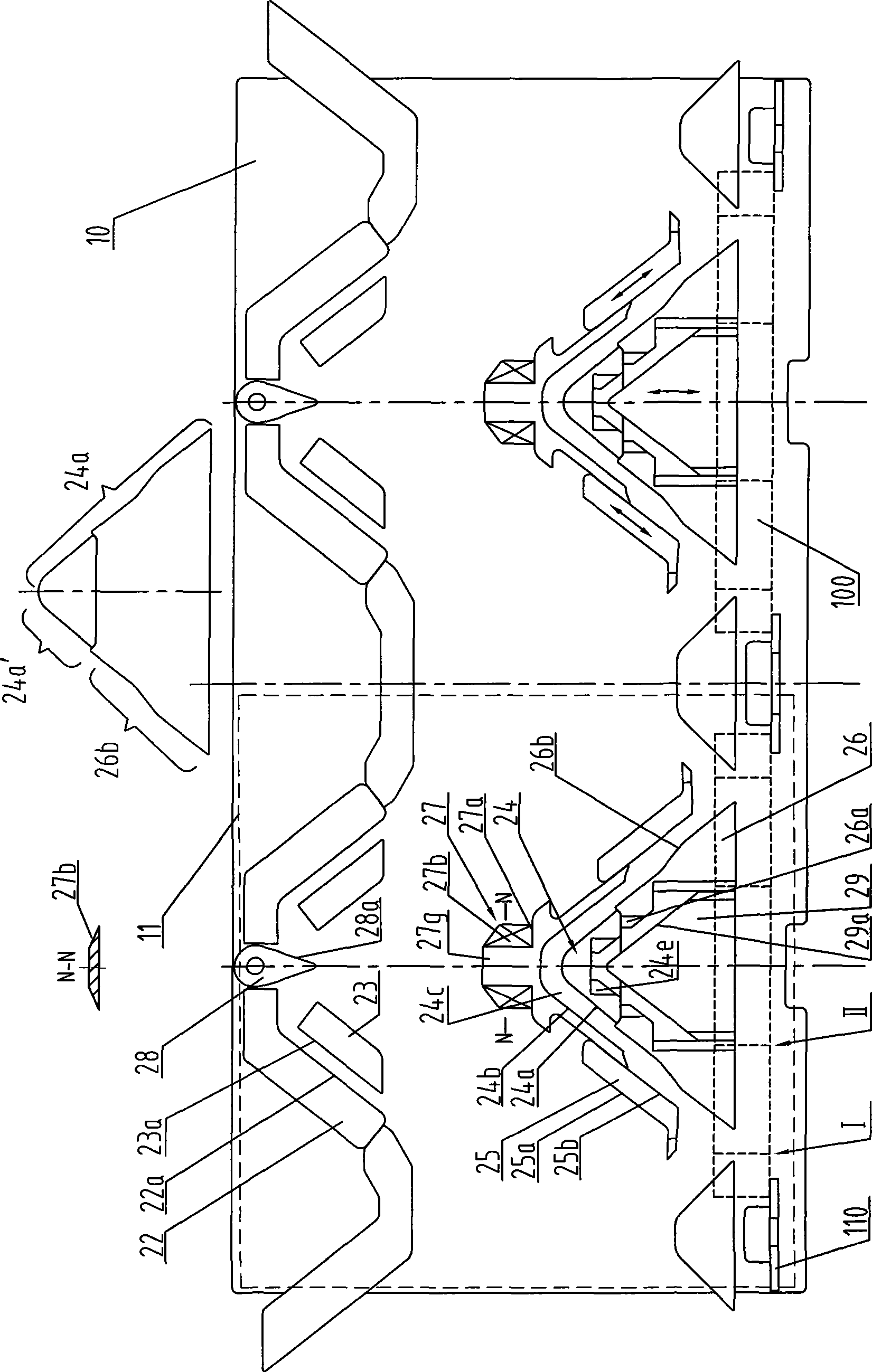

Mock button hole machine and feeding device thereof

ActiveCN103343427AFast replacementEliminates the need for manual parts replacementWork-feeding meansSewing-machine control devicesEngineeringCam

The invention provides a feeding device of a mock button hole machine. The mock button hole machine comprises a machining platform, a first motor, a second motor, a gear, a sliding block, a rotating piece and a cam, wherein the machining platform is provided with a rack and a strip-shaped hole extending in the extension direction of the rack, the axis of the output shaft of the first motor and the axis of the output shaft of the second motor are both perpendicular to the extension direction of the rack, the gear is connected with the first motor and matched with the rack, the sliding block is limited in the strip-shaped hole in a slidable mode, the rotating piece can change the position, in the direction perpendicular to the extension direction, of the sliding block when rotating, the rotating piece is provided with a rotating shaft, the sliding block is arranged on the rotating piece, and the cam is matched with the rotating piece, can drive the rotating piece to rotate when rotating and is connected with the second motor. The feeding device drives the machining platform to move in the Y direction and in the X direction through the two motors, when different needle tracks need to be obtained, the tracks can be obtained through changing of the rotating speeds and the rotating directions of the two motors, the procedure of replacing parts through manual work is saved, and the replacing speed of different needle tracks is improved. The invention further provides the mock button hole machine with the feeding device.

Owner:WENZHOU GUTAI MACHINERY TECH CO LTD

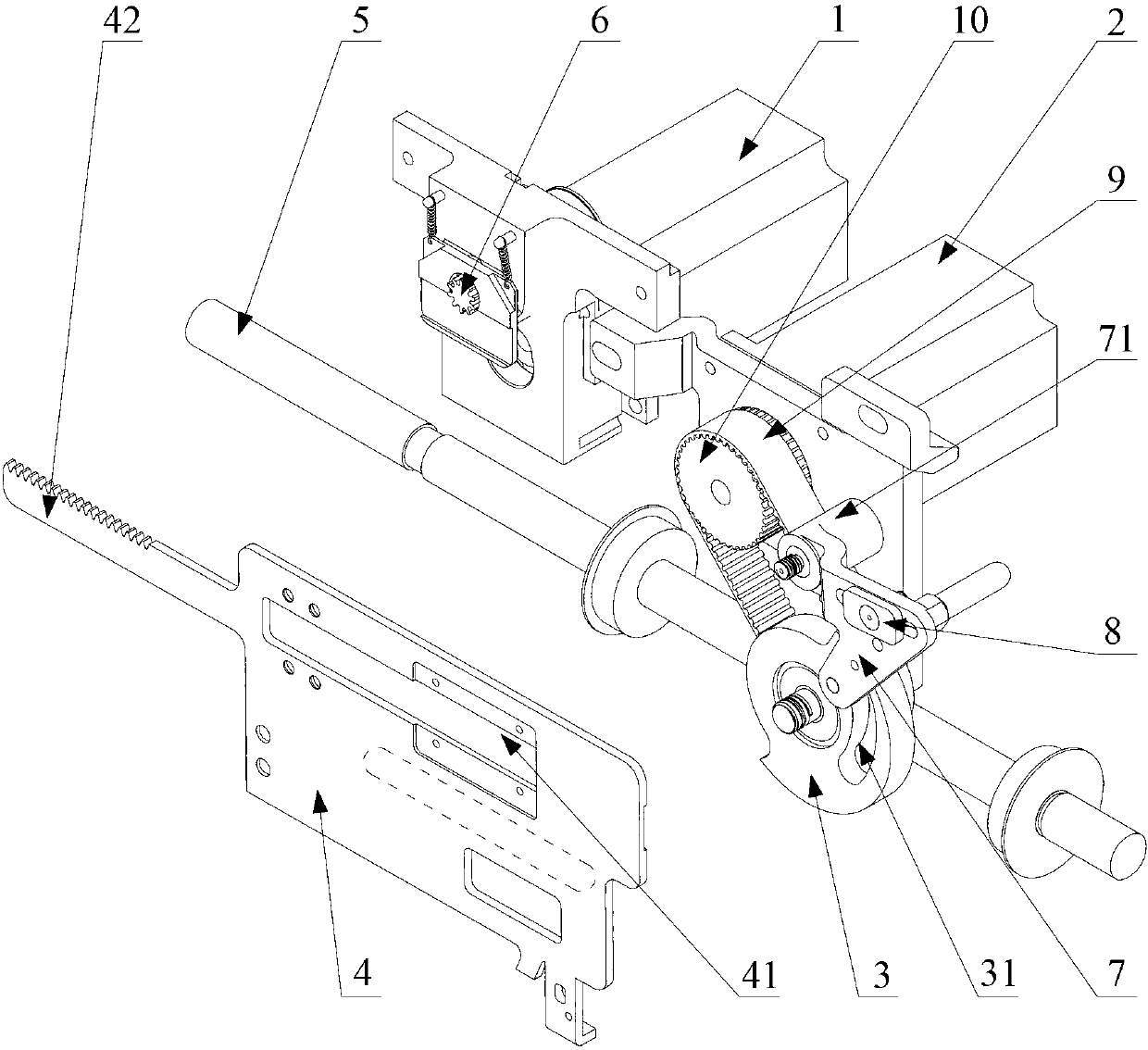

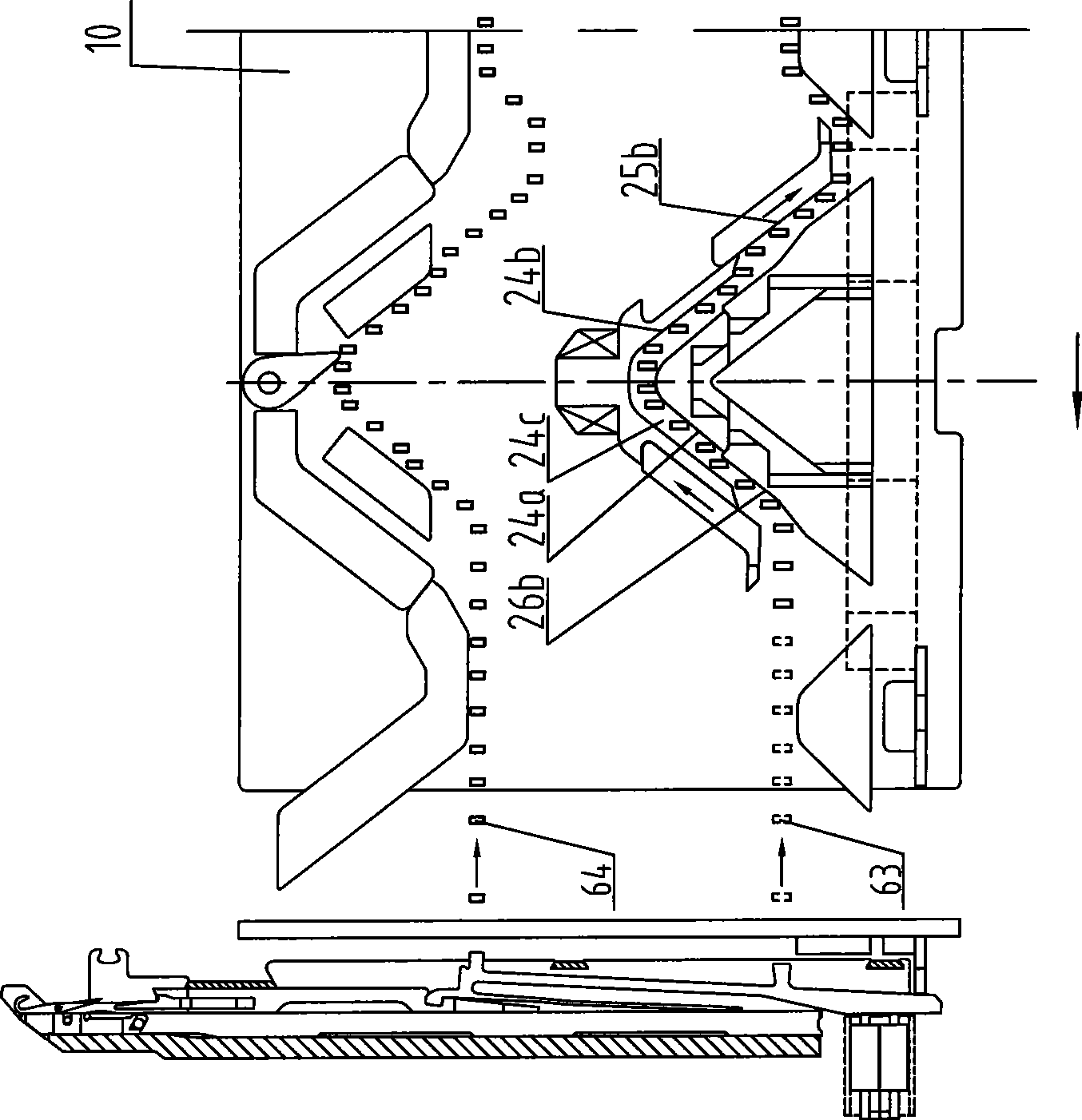

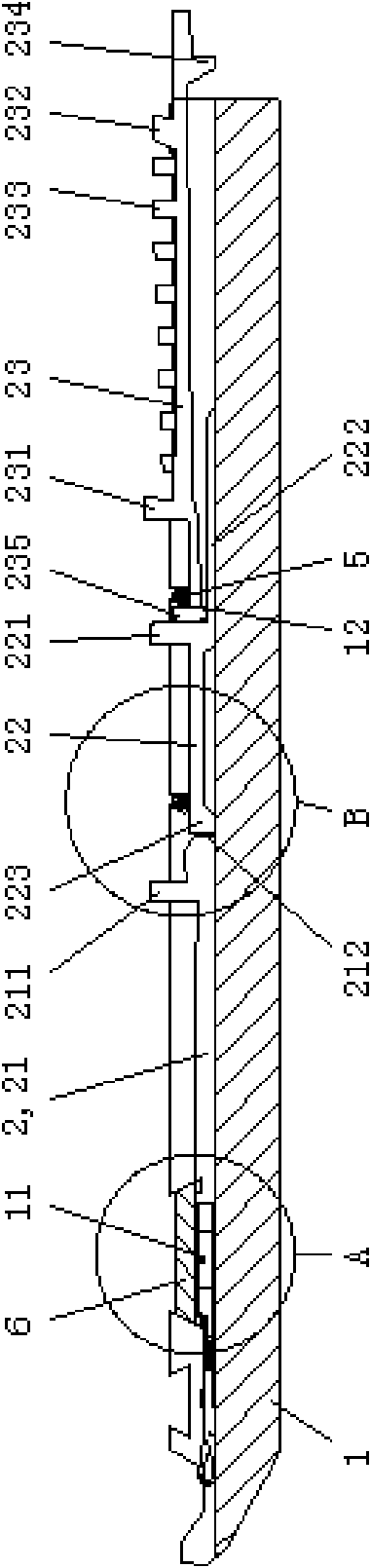

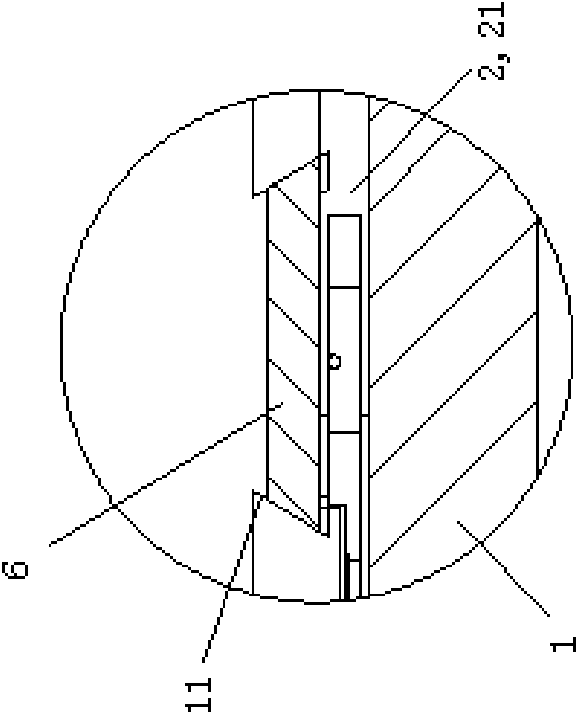

Triangular weaving mechanism

The invention relates to a triangular weaving mechanism, which is provided with a triangular base plate and at least one weaving unit; the weaving unit is provided with a plurality of needle surfaces which are positioned on corresponding weaving triangles; a loop transfer surface of each weaving unit consists of a first loop transfer running surface, a second loop transfer running surface and a loop transfer needle stabilizing surface; the first loop transfer running surface is positioned on the outside of a needle pressing surface; the second loop transfer running surface is positioned on the inside of a loop transfer needle blocking surface; the loop transfer needle stabilizing surface is positioned at the upper end of a loop forming back stitching surface; a loop transfer back stitching surface consists of swinging loop transfer back stitching surfaces and the loop forming back stitching surface; two swinging loop transfer back stitching surfaces are attached on a swinging back stitching triangle and rotatably positioned in the center of the corresponding weaving unit; and when the two swinging loop transfer back stitching surfaces rotate to one side, a loop transfer needle track consisting of the first loop transfer running surface, the second loop transfer running surface, the loop transfer needle stabilizing surface, the swinging loop transfer back stitching surfaces and the loop forming back stitching surface is formed. The triangular weaving mechanism has the advantages of shortening stroke, improving the weaving efficiency, capable of shortening the length of the triangular base plate, consuming less materials and reducing the manufacturing cost.

Owner:冯加林 +1

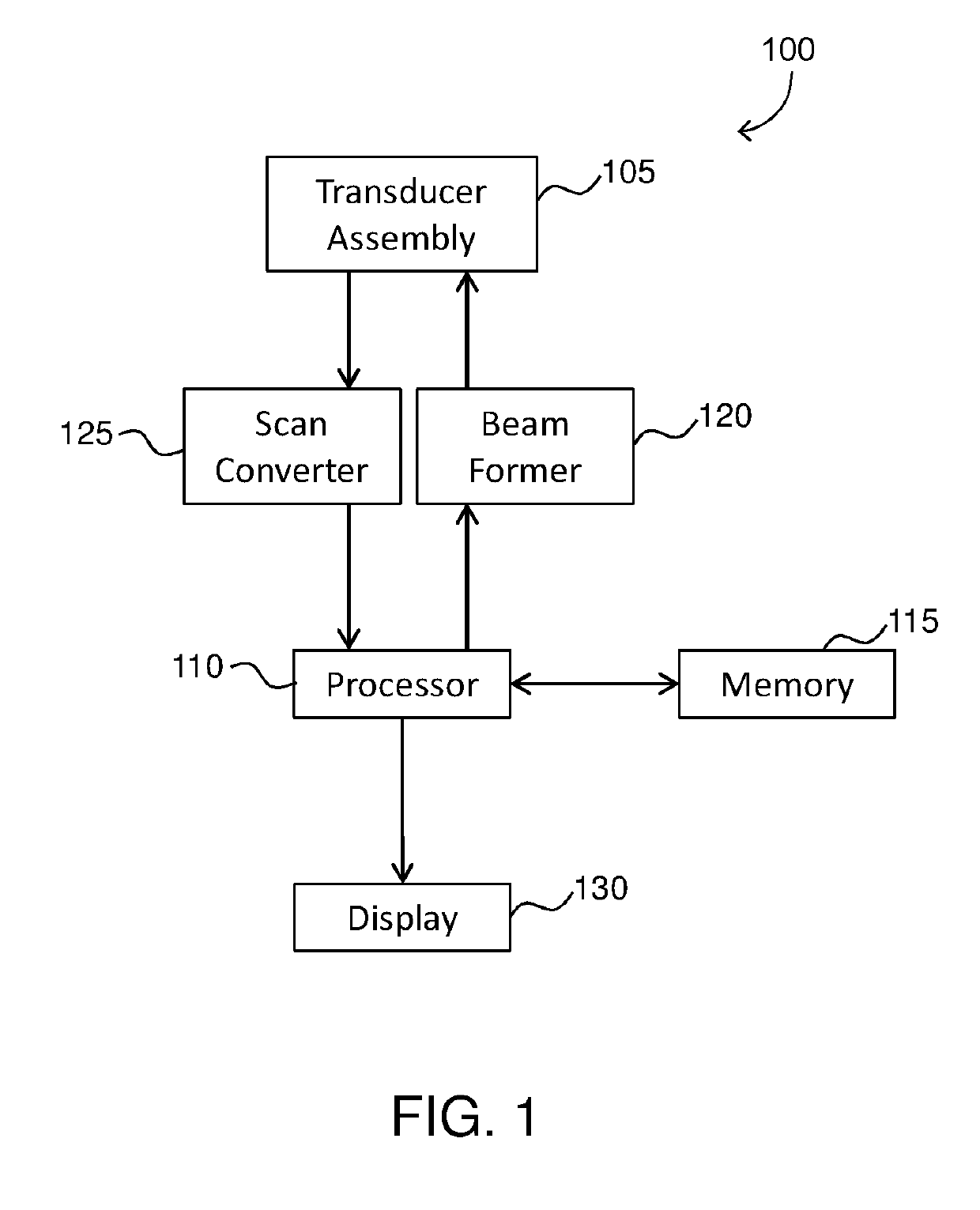

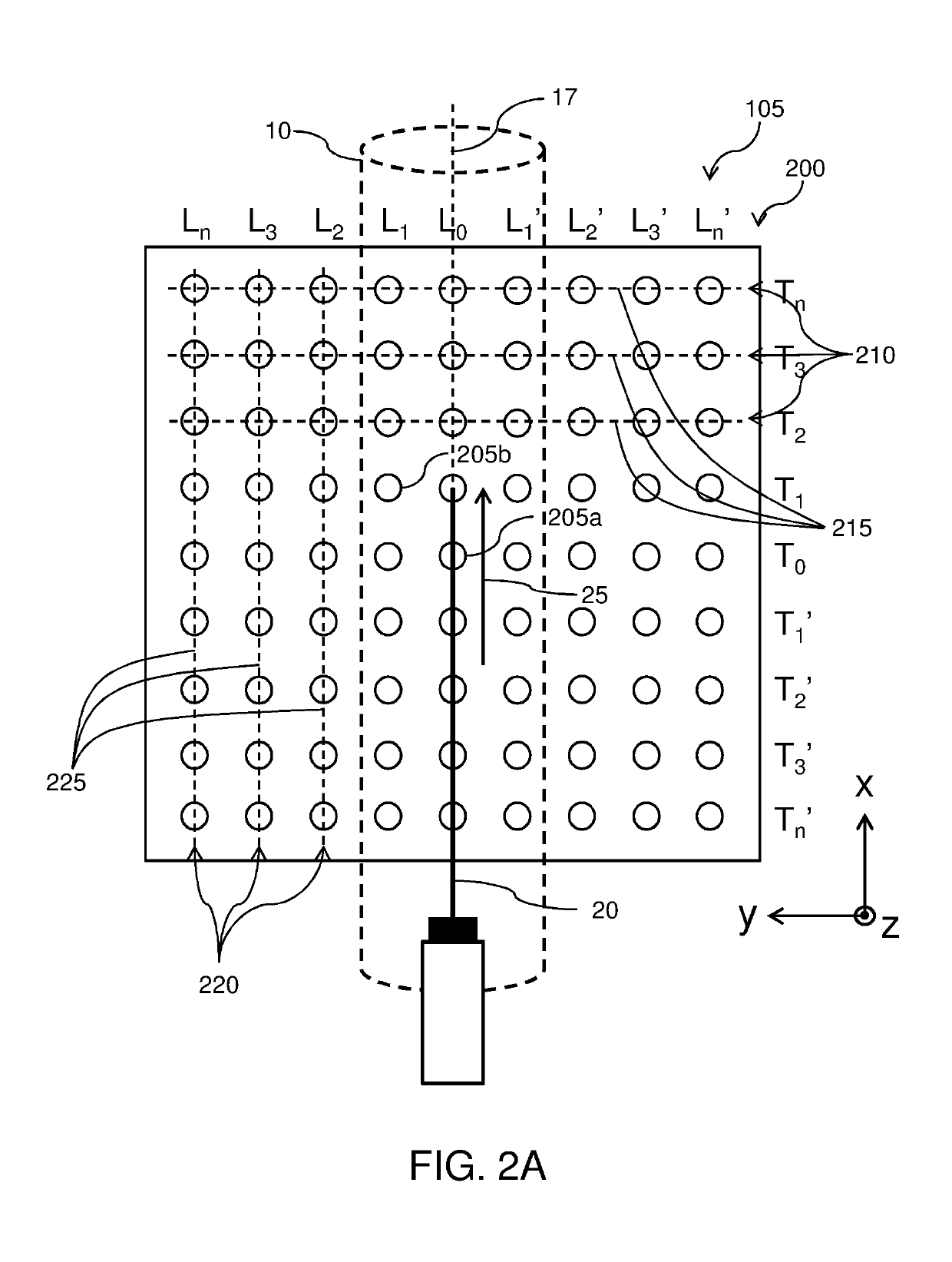

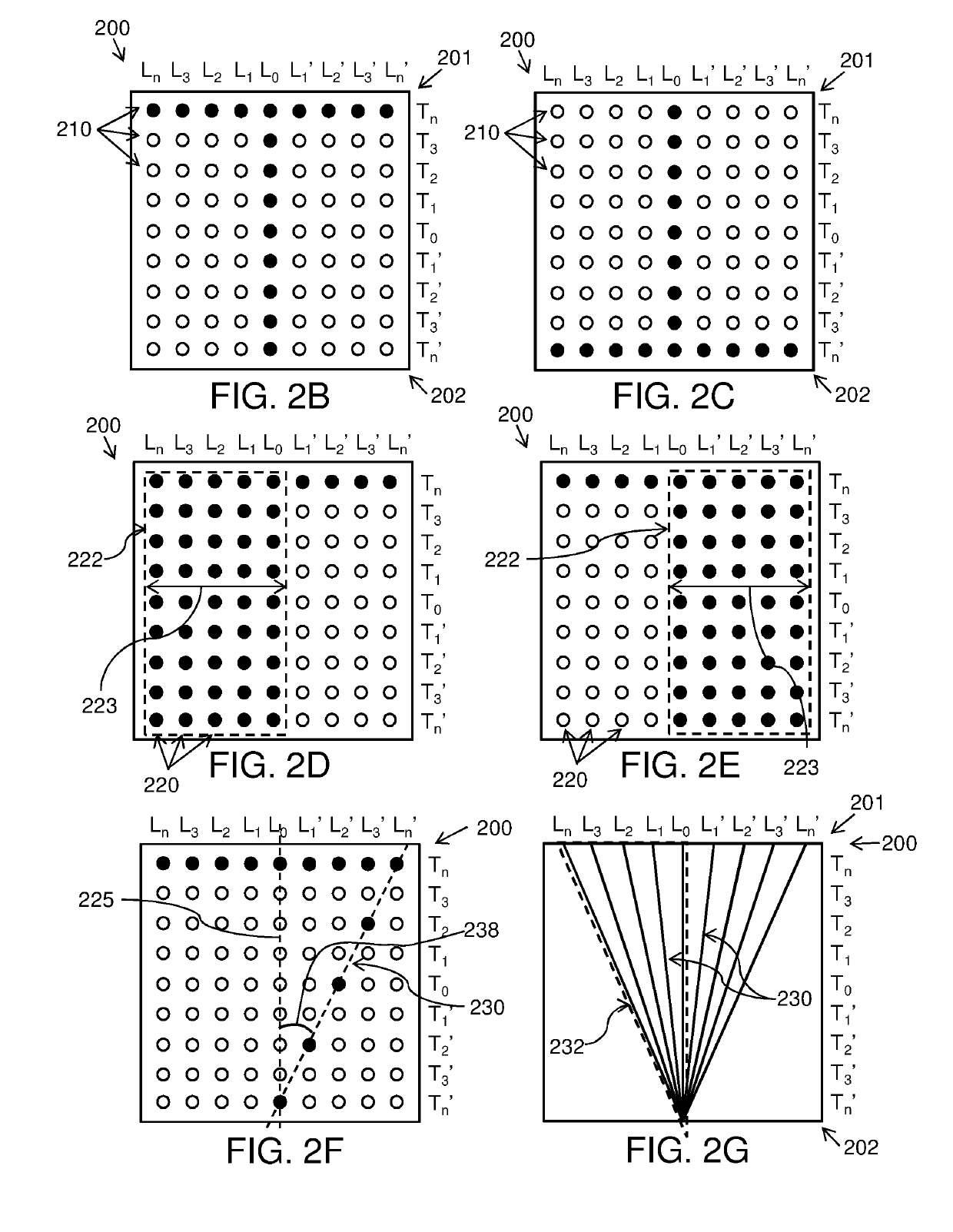

Needle tracking transducer array methods and apparatus

InactiveUS20190200951A1Easy to trackOrgan movement/changes detectionSurgeryTransverse axisTransducer

Disclosed herein are systems and methods for providing real-time monitoring of a probe within a target zone. An apparatus for tracking the probe comprises a transducer assembly comprising a two-dimensional array of transducer elements. The two-dimensional array comprises a plurality of transverse arrays and a plurality of longitudinal arrays. The monitoring system further comprises a processor configured to activate and receive data from at least one transverse array extending along a transverse axis that is transverse to the target zone and to a direction of travel of the probe, and two or more longitudinal arrays extending along longitudinal axes that are transverse to the transverse axis. The two or more longitudinal arrays may be activated sequentially in a programmed sequence. Based on the data, the processor can determine the position of the probe within the target zone, and display the probe on a transverse cross-section view of the target zone via a software-generated special effect.

Owner:GLO TIP LLC

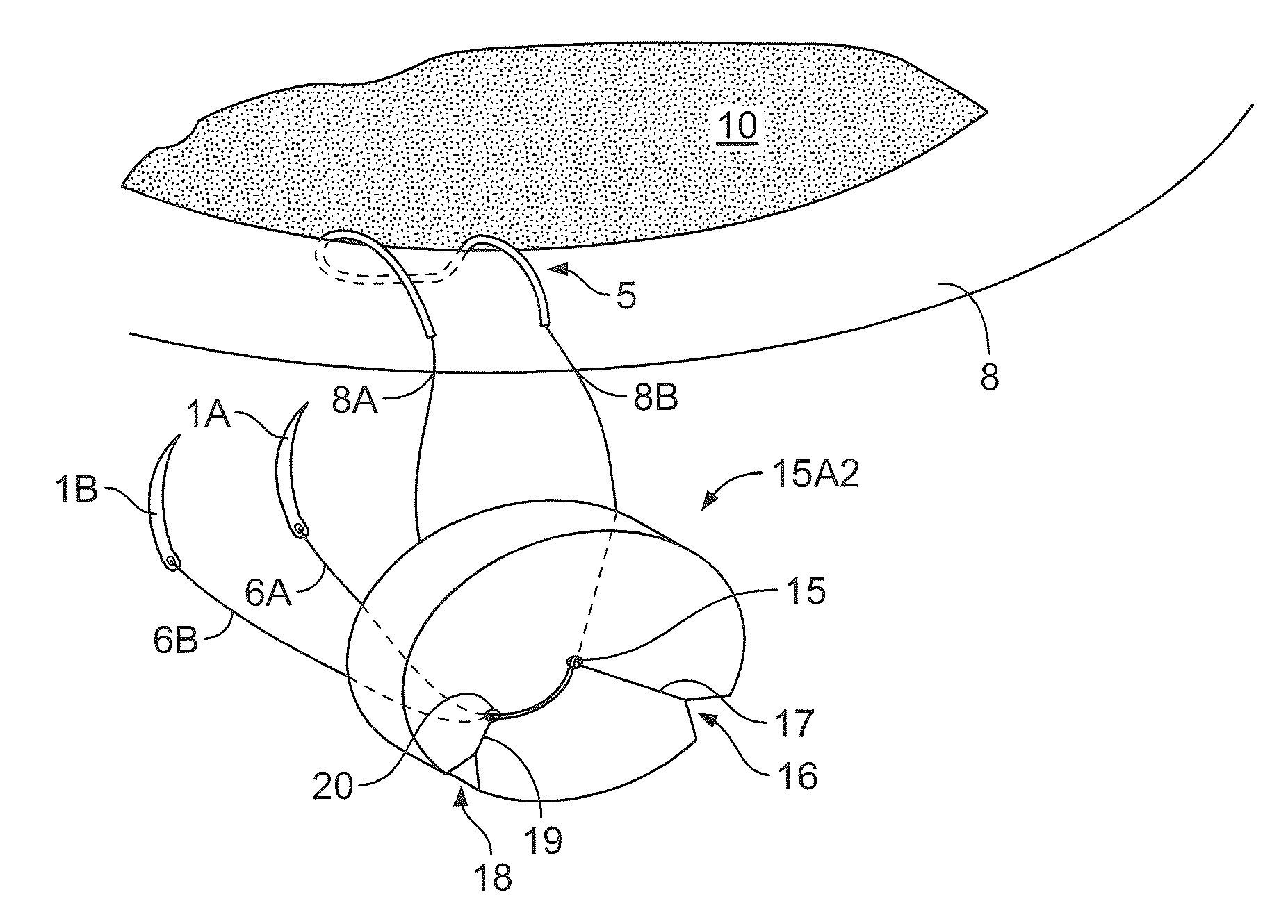

Apparatus and method for performing ocular surgery

A method and apparatus for performing eye surgery. A deformable body having shape memory retentive properties is formed with one or more open loops. The body is longitudinally stretched so that it can follow a needle through a small caliber needle track formed in the cornea, into the anterior chamber in front of the iris. There, the body has relaxed and reverted to its original shape. The needle is of such size that the needle track self-closes and no closure stitch is needed. Two sutures are connected to opposite ends of the body and one of the sutures connects the body to the needle. After the body is in the pupil of the iris, the loop openings face the wall of the iris and then the sutures are pulled to displace the body and press it against the wall of the iris to dilate the pupil.

Owner:PRYWES ARNOLD S

Programmable tucking attachment for a sewing machine and method

InactiveUS20050183646A1Material is facilitatedEasy to controlProgramme-controlled sewing machinesWork-feeding meansEngineeringNeedle track

A tucking attachment for a sewing machine having a tucking blade with one end positioned adjacent material and a tucking blade drive with an output shaft mechanically coupled to the tucking blade. A control, connected to the tucking blade drive, is operable to command the tucking blade drive to move the tucking blade through a programmable displacement to form a tuck in the material adjacent a presser foot of the sewing machine. Thereafter, the sewing machine is operated to sew a number of stitches in the tuck, and the tucking blade is then retracted. Repeating the above cycle of operation permits successive tucks of different lengths to be formed in the material.

Owner:L & P PROPERTY MANAGEMENT CO

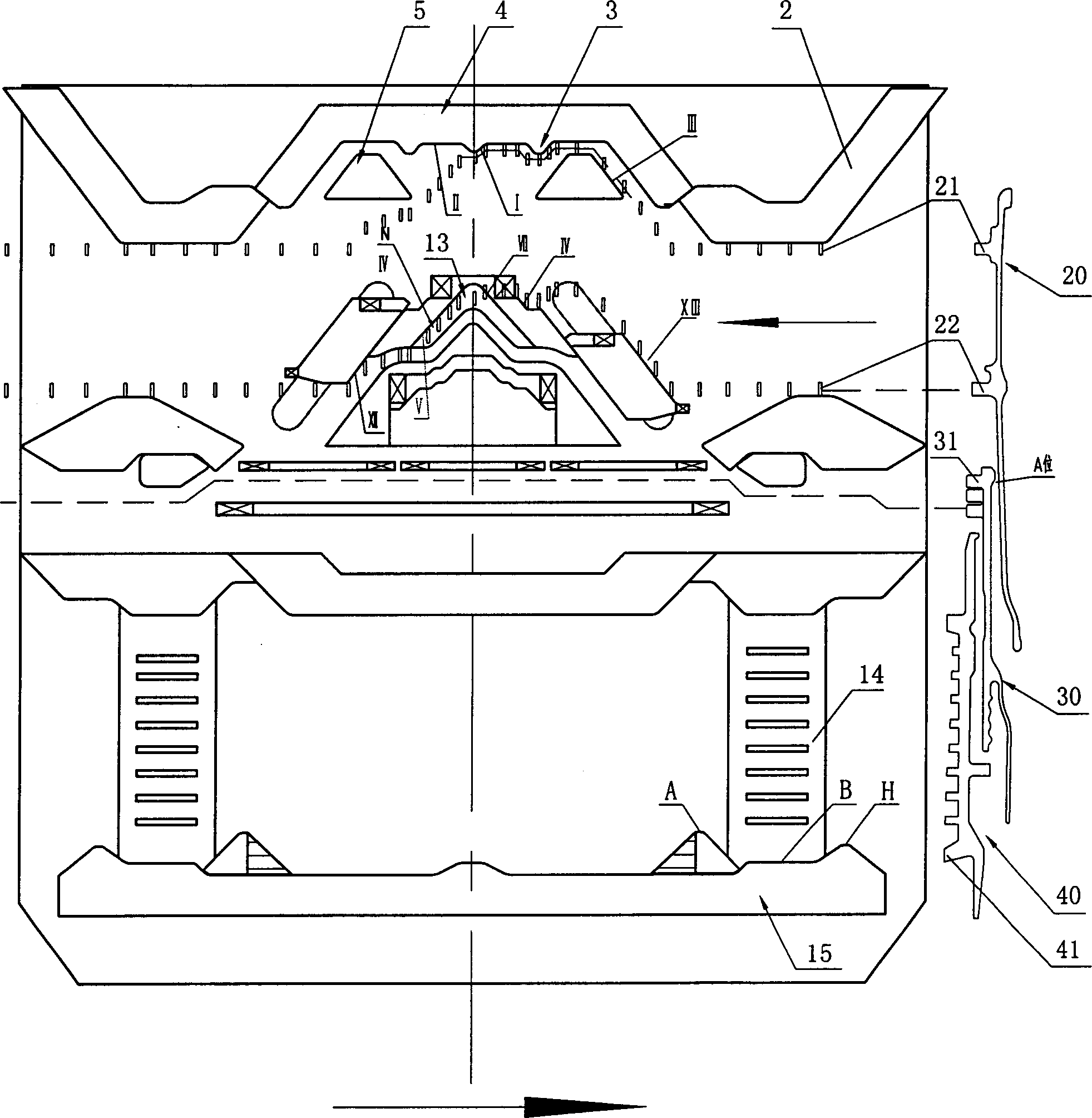

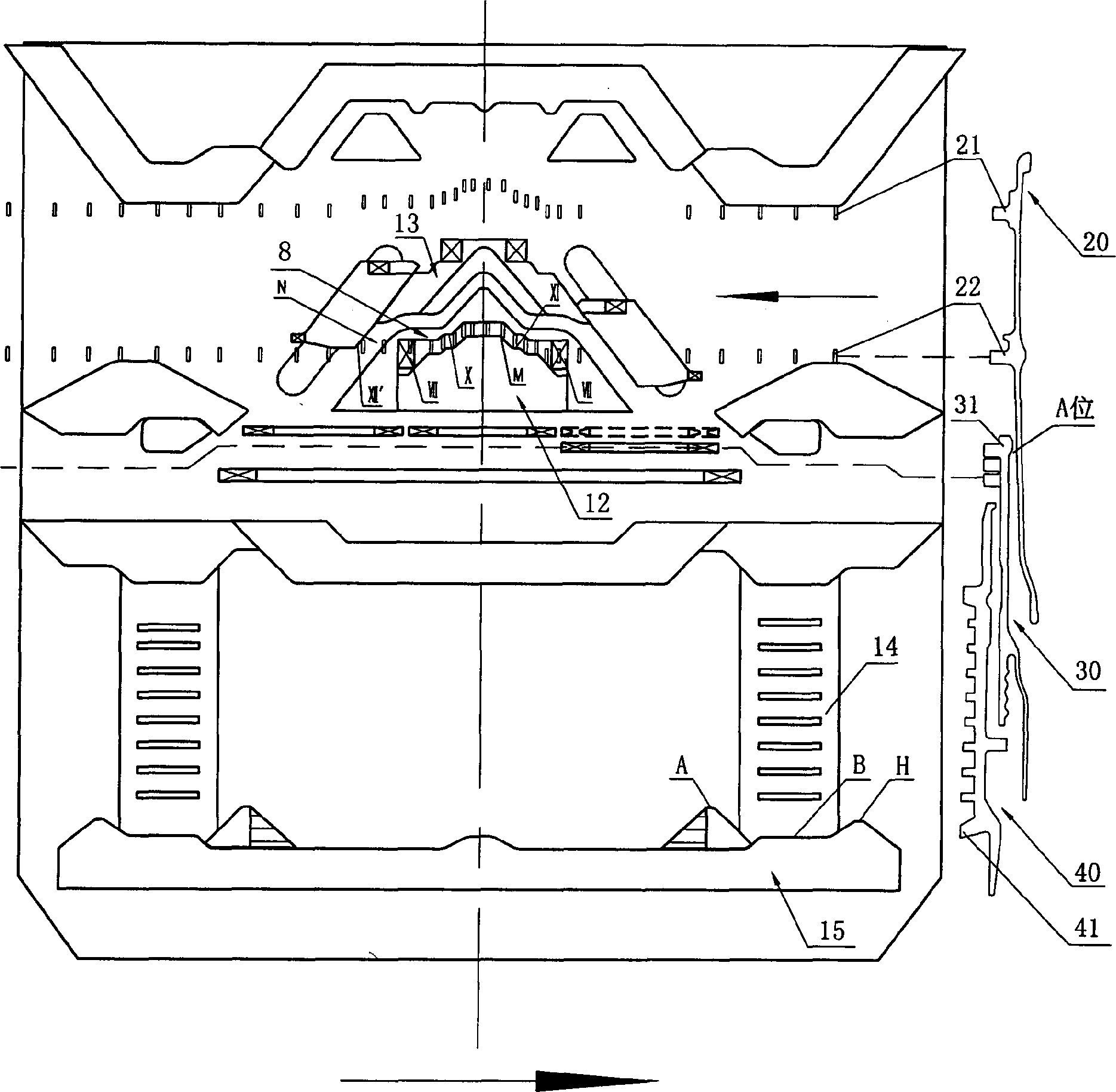

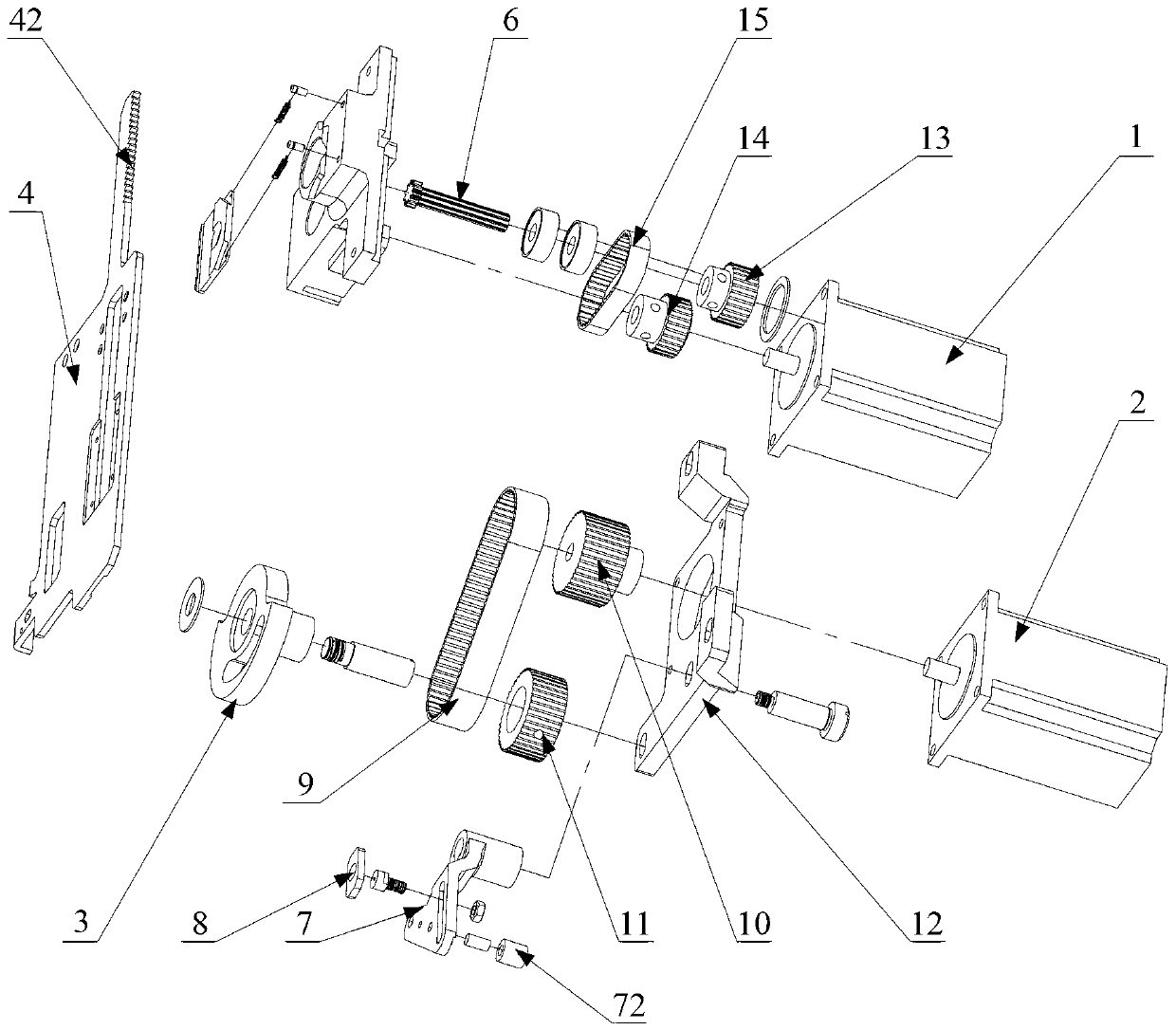

Walk-needle control mechanism of computer transversal knitting machine

InactiveCN101654841ASimplify the control problemReduce unnecessary wear and tearWeft knittingControllabilityBiomedical engineering

The invention relates to a walk-needle control mechanism of a computer transversal knitting machine, provided with a needle bed and a plurality of needle slots transversally arranged on the needle bed. Each needle slot is internally provided with a knitting needle component and a triangular soleplate, wherein the knitting needle component can longitudinally move; the triangular soleplate is arranged above the needle bed and matched with the knitting needle component; each knitting needle component comprises a knitting needle, a needle-pushing sheet and a needle-selecting sheet which are sequentially arranged; the triangular soleplate is provided with a needle selector; a needle heel is arranged at the lower part of the knitting needle; the triangular soleplate is provided with a knitting needle control component, a needle-pushing control component and a needle-selecting control component; the knitting needle control component controls the moving track of the knitting needle; the needle-pushing control component controls the moving track of the needle-pushing sheet; and the needle-selecting control component controls the moving track of the needle-selecting sheet. The walk-needle control mechanism of the computer transversal knitting machine can singly control the movement of the knitting needle, the needle-pushing sheet and the needle-selecting sheet, radically solves the problems of overlong motion distances of the needle-pushing sheet and the needle-selecting sheet, lessens the unnecessary abrasion of the needle-selecting sheet and the needle-pushing sheet, effectively prolongs the service life, simplifies the control problem of the triangular soleplate and has stronger walk-needle track controllability, high working stability and reasonable design.

Owner:JIANGSU SHENGTIAN IND

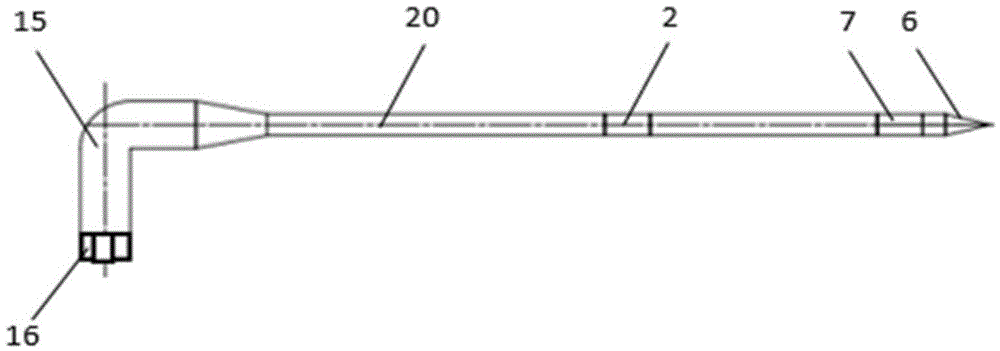

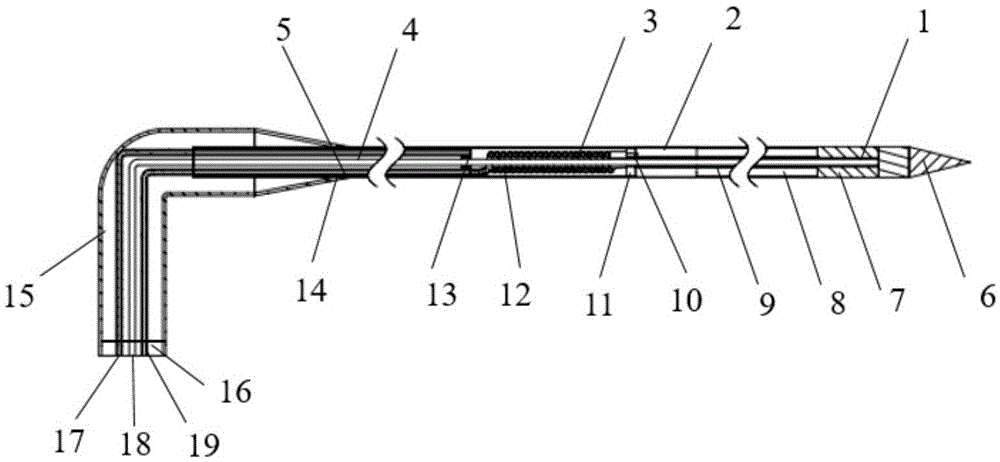

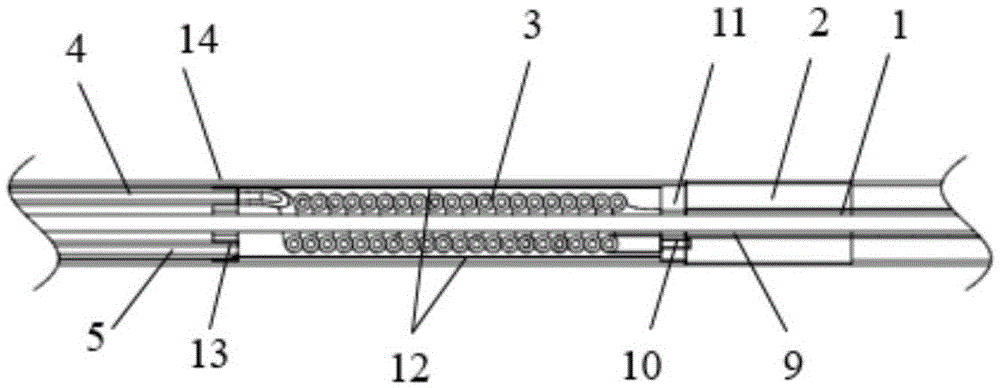

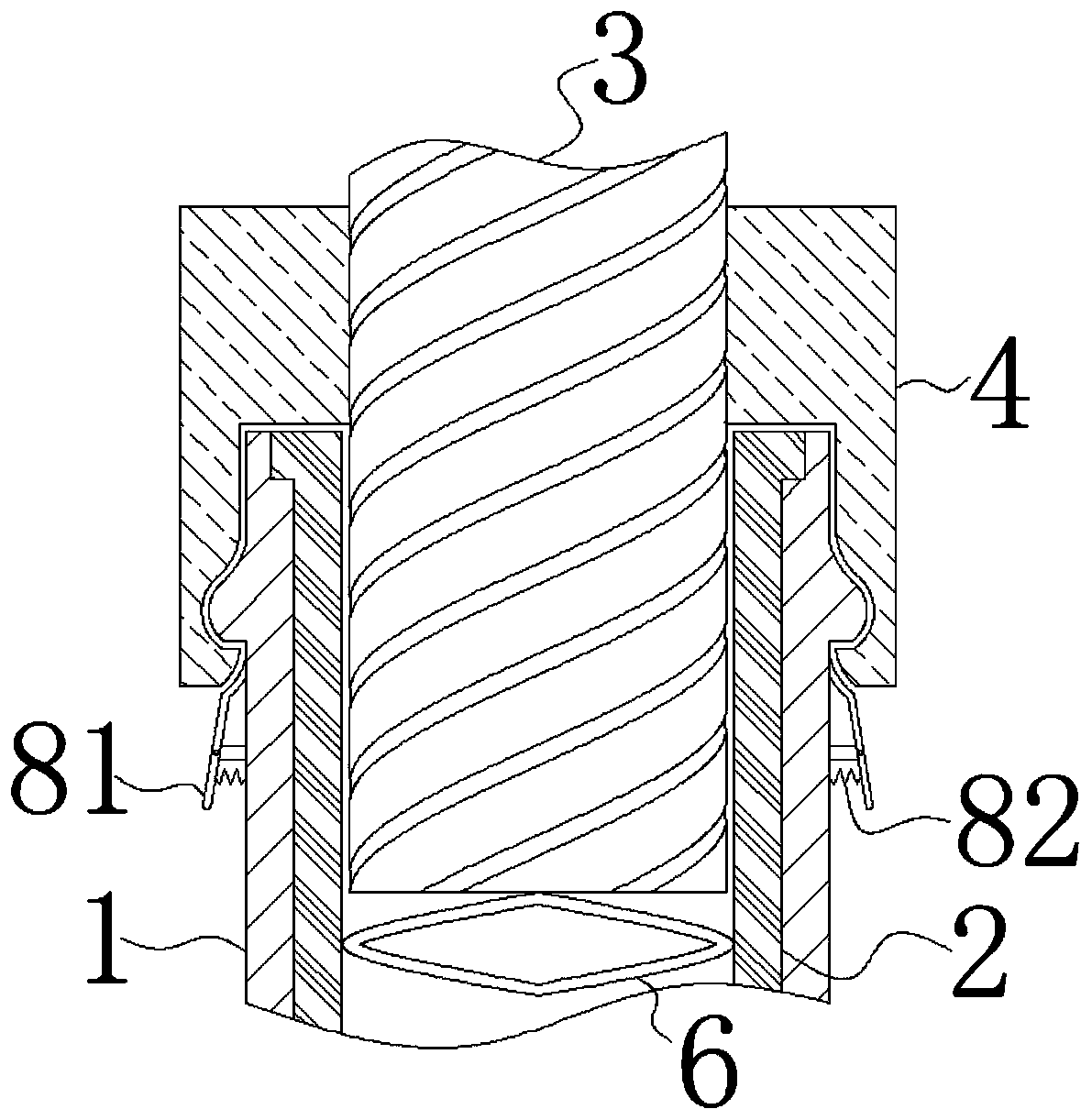

Puncture needle

The present invention discloses a puncture needle, relates to the technical field of medical biopsy sampling devices, and solves technical problems that when a biopsy puncture operation is performed by a puncture needle in the prior art, organs or tissues around a target tissue are easily damaged, and tumor metastasis along a needle track is also liable to occur. The puncture needle comprises a needle tube, a pusher, a needle core and a needle head; the needle tube is screwedly connected with the pusher; the needle tube is connected with the needle head; the pusher is movably connected with the needle core; and the pusher is in screw rotation cooperation with the needle tube to drive the needle core to move forward or backward. Since the pusher is in the screw rotation cooperation with theneedle tube to drive the needle core to move forward or backward, any puncture length of the needle core of the puncture needle can be adjusted and the puncture needle is not limited by puncture interval lengths. Compared with puncture needles in the prior art, the puncture length of the needle core can be accurately controlled to avoid damages to the organs or tissues and reduce probability of the tumor metastasis along the needle track.

Owner:吴忠隐

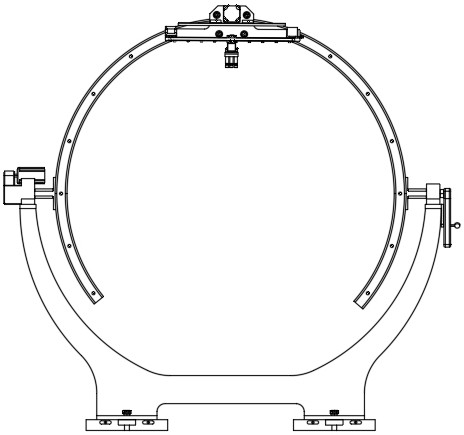

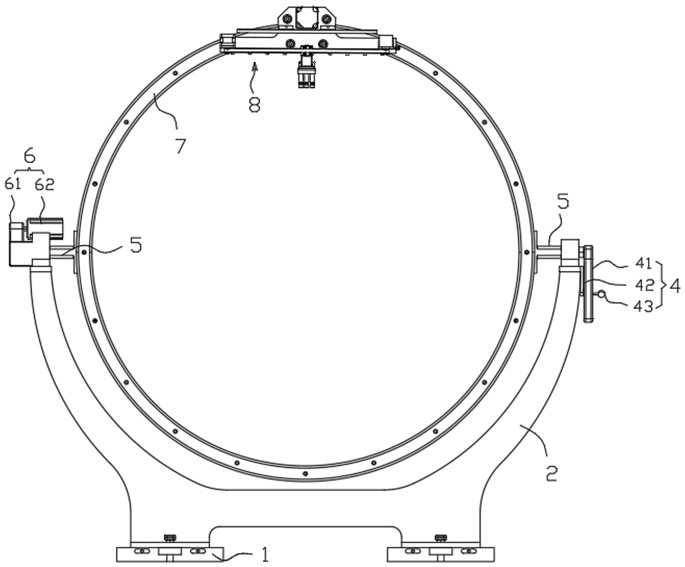

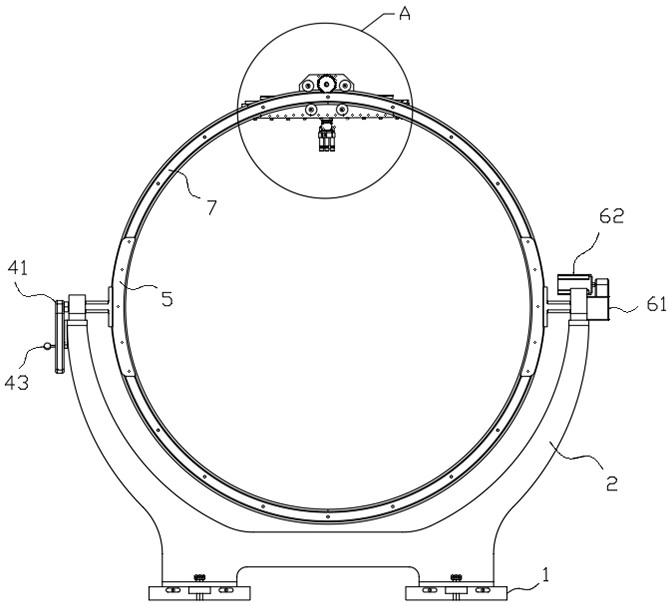

An auxiliary guiding and positioning device for CT puncture

The present application discloses a positioning device for CT puncture auxiliary guidance, which is composed of a control mechanism and an actuator. The actuator includes a base, a support frame, and any end of the support frame is provided with a locking mechanism; the positioning device It includes a first guide rail arranged in an arc, on which a guide device for indicating different puncture angles in the same plane is slidably installed, and the guide device includes a deflection drive mechanism that slides along the first rail, vertically A first translation mechanism and a second translation mechanism are installed; the second translation mechanism is slidably installed with a guide mechanism that uses visible laser space to indicate puncture. The present invention can be used in conjunction with existing detection equipment, such as CT, MRI, and PET-CT. The puncture needle path information determined by the image can be obtained through the imaging equipment, and the present invention can be used to accurately position and indicate in space to assist doctors. The operation avoids misalignment and error caused by experience or bare-handed puncture.

Owner:锐德泰医疗科技(成都)有限公司

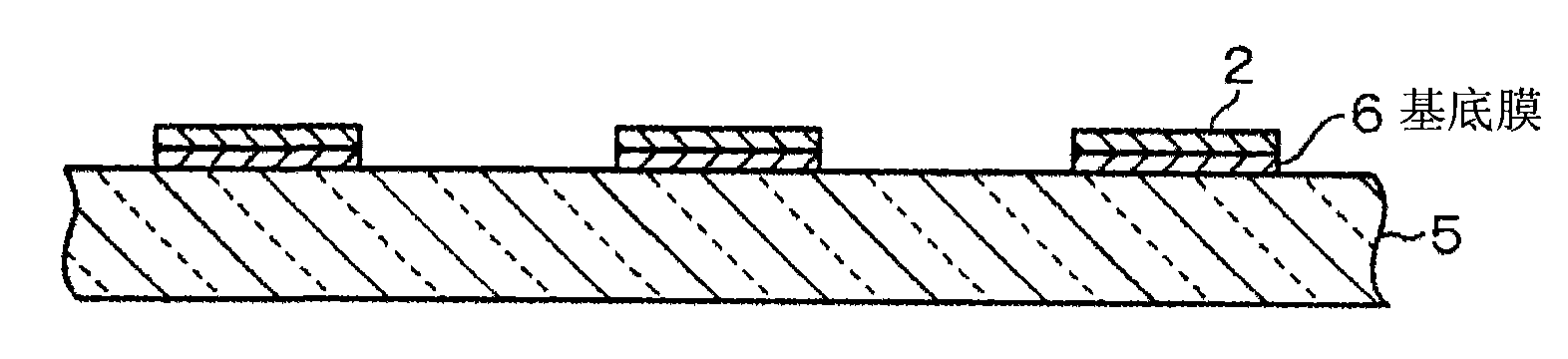

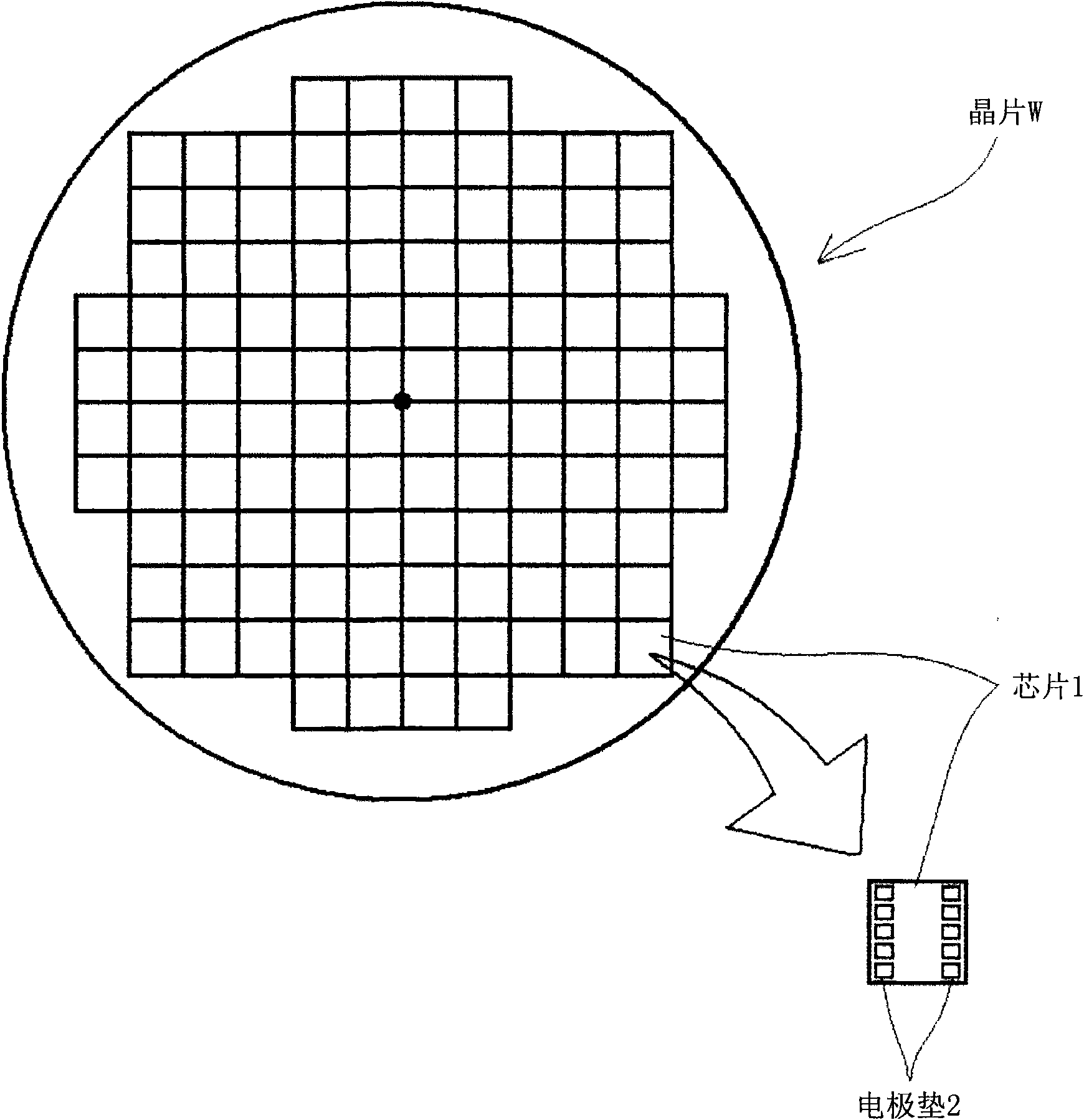

A needle tracking inspection device, a detecting device and a needle tracking inspection method

ActiveCN101593714AReduce the burden onSemiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationAdditive ingredientGrey level

The invention provides a needle tracking inspection device, a detecting device with the device and a needle tracking inspection method that can detect protrusion condition of a base layer of an electrode mat to a cardinal plate after detection automatically with high precision, wherein the needle tracking inspection device comprises the following procedures: obtain a R ingredient data (D2), a G ingredient data (D3) and a B ingredient data (D4), then a RGB ingredient obtaining part (50) of the B ingredient data (D4) is selected according to the difference of the reflection index of material quality of an electrode mat (2) and that of a basal layer (6); and to the B ingredient data (D4), in order to obtain image of the basal layer (6) distinguished from the electrode mat (2), a set grey level and a B ingredient histogram obtaining part (52) as relation data having pixels of the grey level, then according to the obtained histogram judge the existence of protrusion of the basal layer (6) in the needle tracking.

Owner:TOKYO ELECTRON LTD

Triangular weaving mechanism

The invention relates to a triangular weaving mechanism, which is provided with a triangular base plate and at least one weaving unit; the weaving unit is provided with a plurality of needle surfaces which are positioned on corresponding weaving triangles; a loop transfer surface of each weaving unit consists of a first loop transfer running surface, a second loop transfer running surface and a loop transfer needle stabilizing surface; the first loop transfer running surface is positioned on the outside of a needle pressing surface; the second loop transfer running surface extends upward from the inside of the first loop transfer running surface to the loop transfer needle stabilizing surface; the loop transfer needle stabilizing surface is positioned at the upper end of a loop forming back stitching surface; a loop transfer back stitching surface consists of swinging loop transfer back stitching surfaces and the loop forming back stitching surface; two swinging loop transfer back stitching surfaces are attached on a swinging back stitching triangle and rotatably positioned in the center of the corresponding weaving unit; and when the two swinging loop transfer back stitching surfaces rotate to one side, a loop transfer needle track consisting of the first loop transfer running surface, the second loop transfer running surface, the loop transfer needle stabilizing surface, the swinging loop transfer back stitching surfaces and the loop forming back stitching surface is formed. The triangular weaving mechanism has the advantages of shortening stroke, improving the weaving efficiency, having short triangular base plate and low manufacturing cost, and consuming smaller materials.

Owner:冯加林 +1

Process-type computer-assisted random-needle embroidery production method

ActiveCN108170907AEasy to understandImprove textureImage analysisDesign optimisation/simulationObject structureColor image

The invention discloses a process-type computer-assisted random-needle embroidery production method. The method comprises the steps that 1, an image partitioning method and a region vector field extraction method are adopted to extract different object regions and region vector fields of an input color image; 2, a digital stitching model comprising every single embroidery thread and every single cross stitch is established according to the characteristics of a random-needle embroidery; 3, a single-layer needle track is generated inside and at the edge of each object region, a region needle track which contains uniformly distributed embroidery threads and can show a region texture direction is generated inside each region, a fitting needle track which can show an object structure is generated at the edge of each region, and the operation is executed on all the object regions to obtain a final needle track sequence; 4, the coverage of each object region is calculated, whether the currentcoverage meets a designated requirement is judged, if not, parameters are updated, and needle tracks continue to be generated, and otherwise needle track generation in the current region is ended; and 5, coordinates of the needle track sequence are converted into coordinates of a computer embroidery machine.

Owner:NANJING UNIV

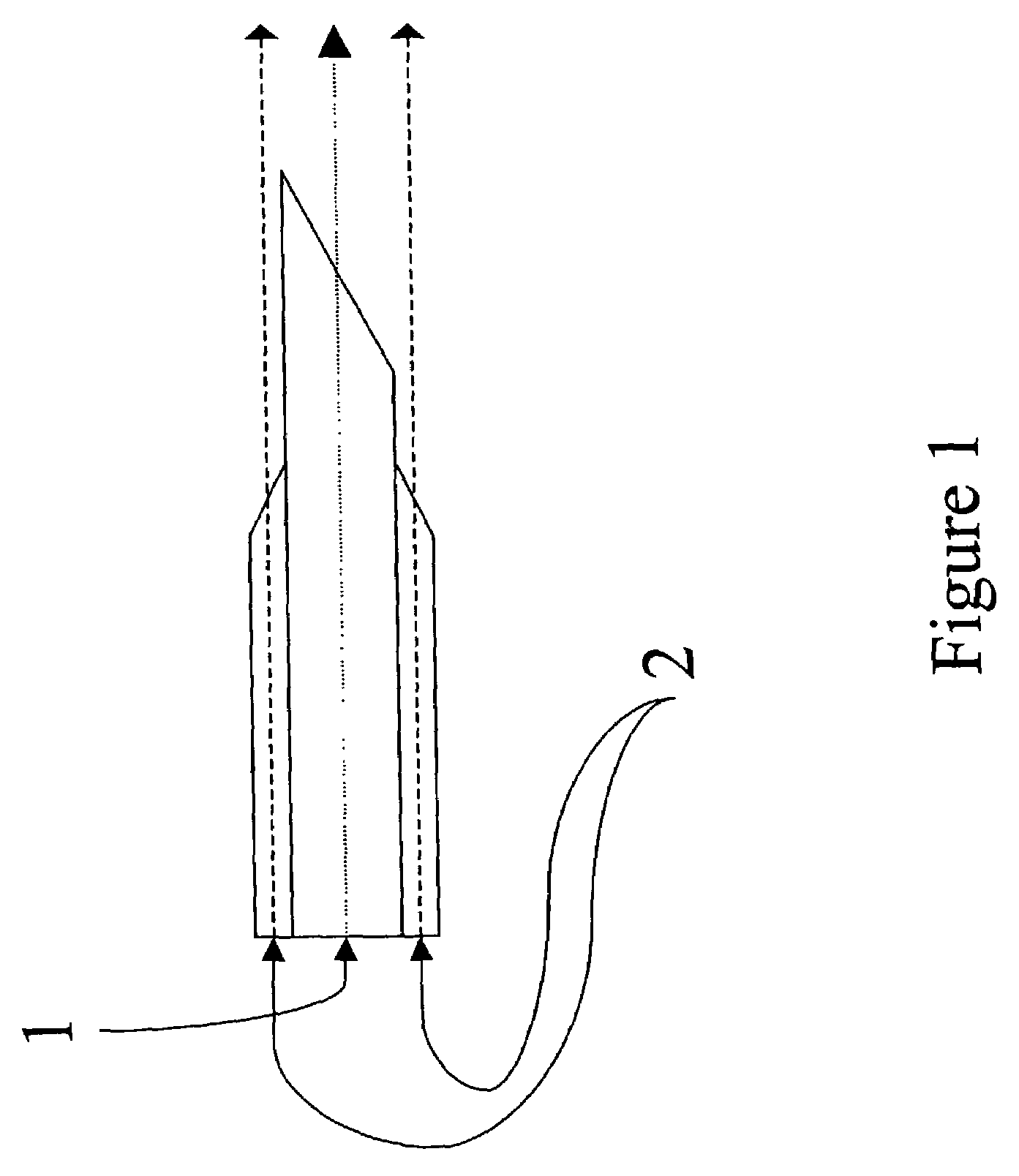

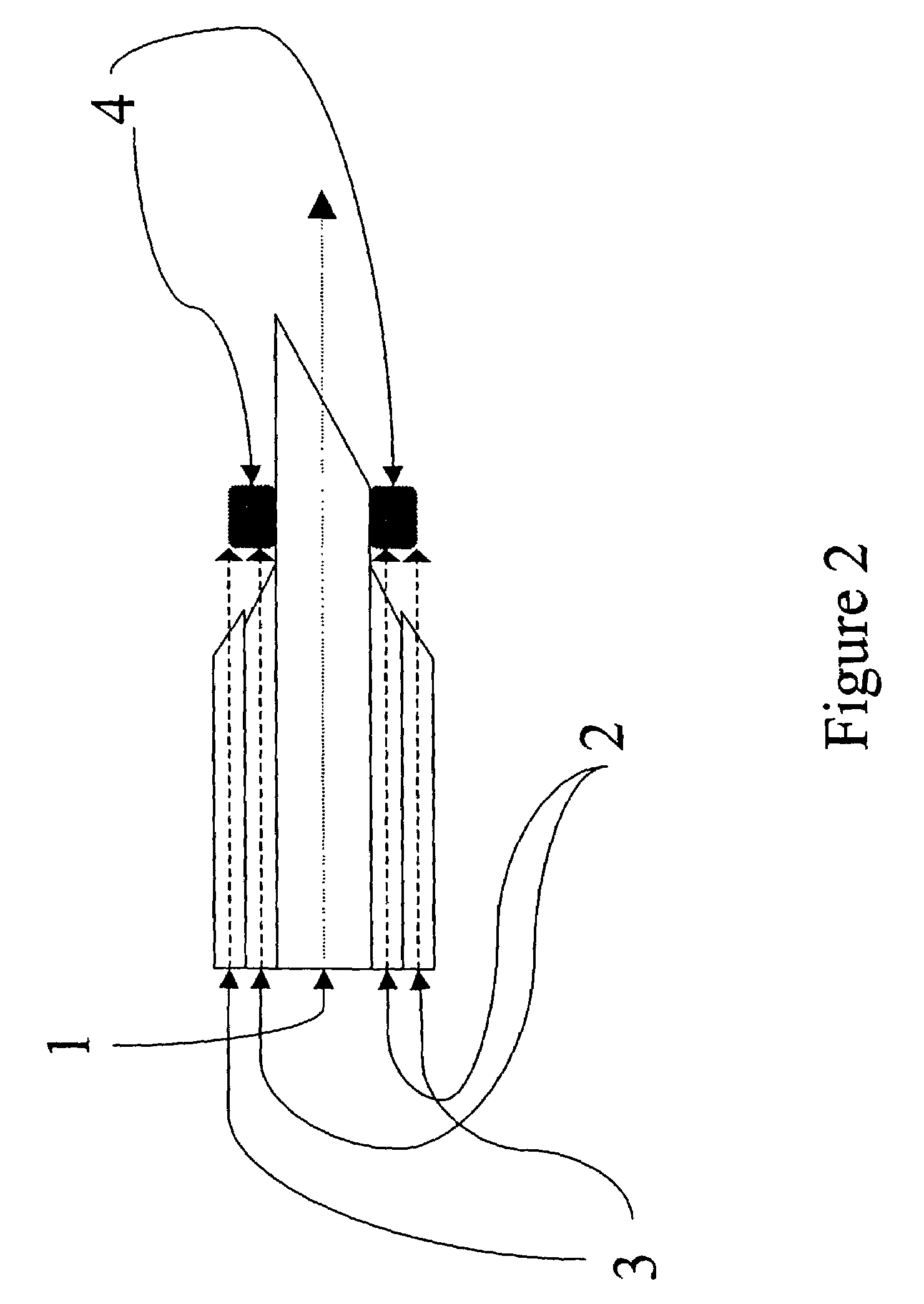

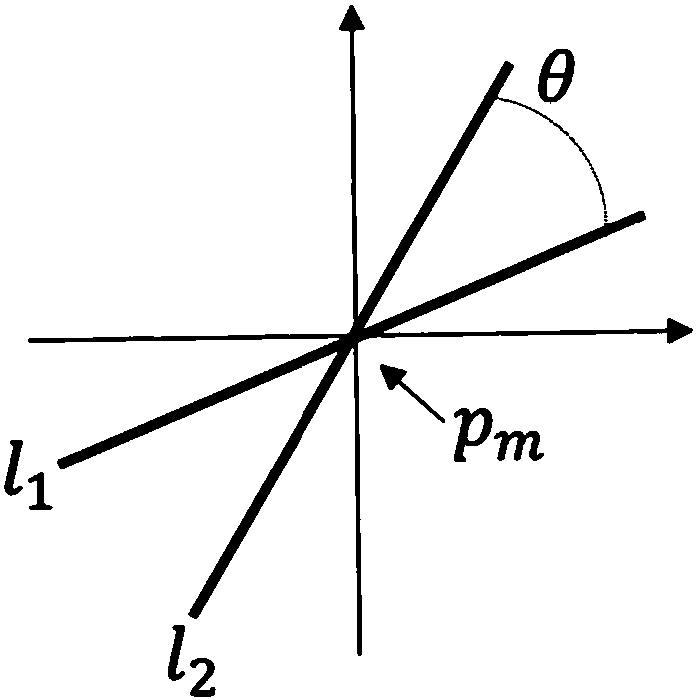

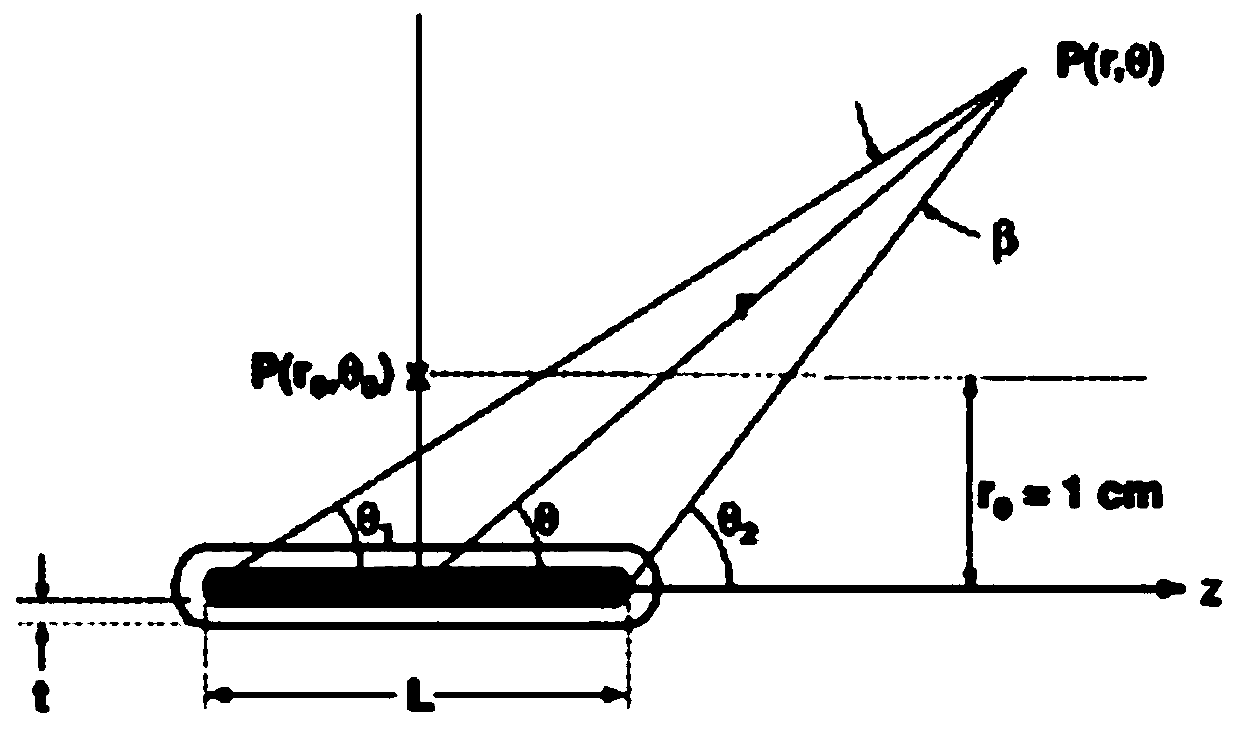

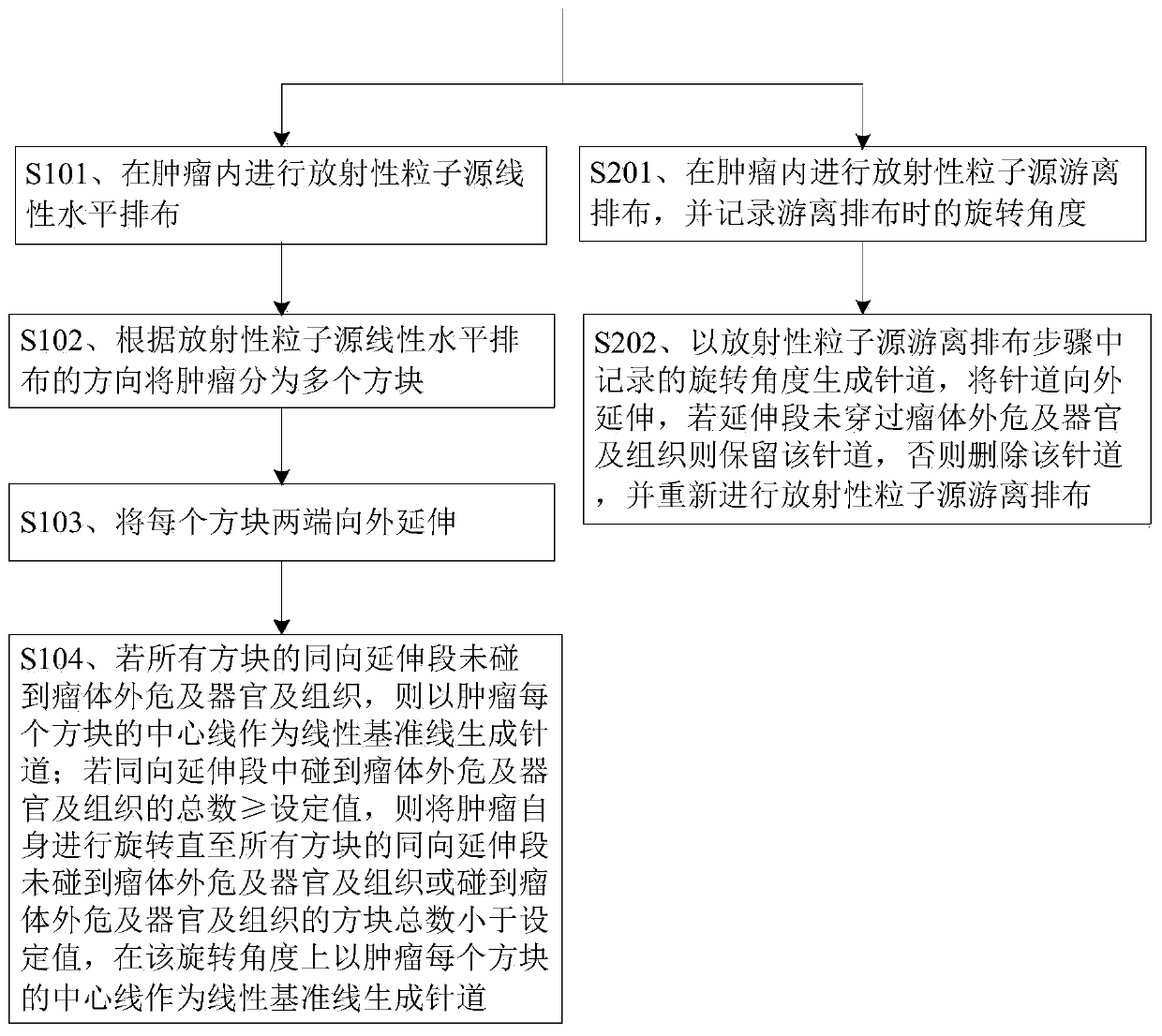

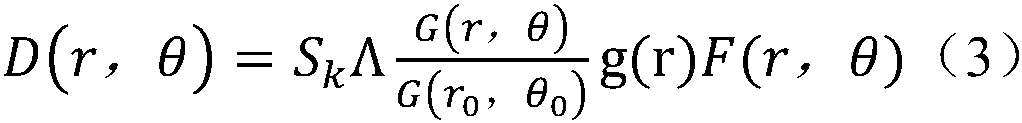

Method for planning path of radioactive particle source transplant needle track in tumor bodies and generating needle track

InactiveCN110141771AAvoid harmReduce damageX-ray/gamma-ray/particle-irradiation therapyRadiologyNuclear medicine

The invention discloses a method for planning a path of a radioactive particle source transplant needle track in tumor bodies and generating a needle track. The method comprises the steps of planninga parallel needle track path, and generating a needle track; S101, enabling radioactive particle sources to be in linear and horizontal distribution in tumors; S102, according to the linear and horizontal distribution of the radioactive particle sources, dividing the tumors into a plurality of rectangular blocks; S103, enabling two ends of each of the rectangular blocks to extend outwards; and S104, if the equidirectional extension segment of each of the rectangular blocks does not come across damaged organs and tissue outside the tumors, generating the needle track by using the center line ofeach rectangular block of the tumors as a reference line, if the total quantity of the damaged organs and tissue outside the tumors in the equidirectional extension segments is greater than or equalto a set value, rotating the tumors to the best angle, generating the needle track by using the center line of each of the rectangular blocks of the tumors at the rotating angle as the linear reference line, and planning the free-angle needle track path and generating the needle track. According to the method disclosed by the invention, the needle tracks are reasonably planned, and additional damage to other tissue in bodies can be avoided.

Owner:成都真实维度科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com