Braiding controlling mechanism of flat braiding machine

A technology of flat knitting machine and control mechanism, which is applied in weft knitting, knitting, textiles and papermaking, etc. It can solve the problems of increased manufacturing cost, more triangles and more needle selectors in Stoll machines, and increase the reliability of operations. , Reasonable optimization of the trajectory, and the effect of accurate needle movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

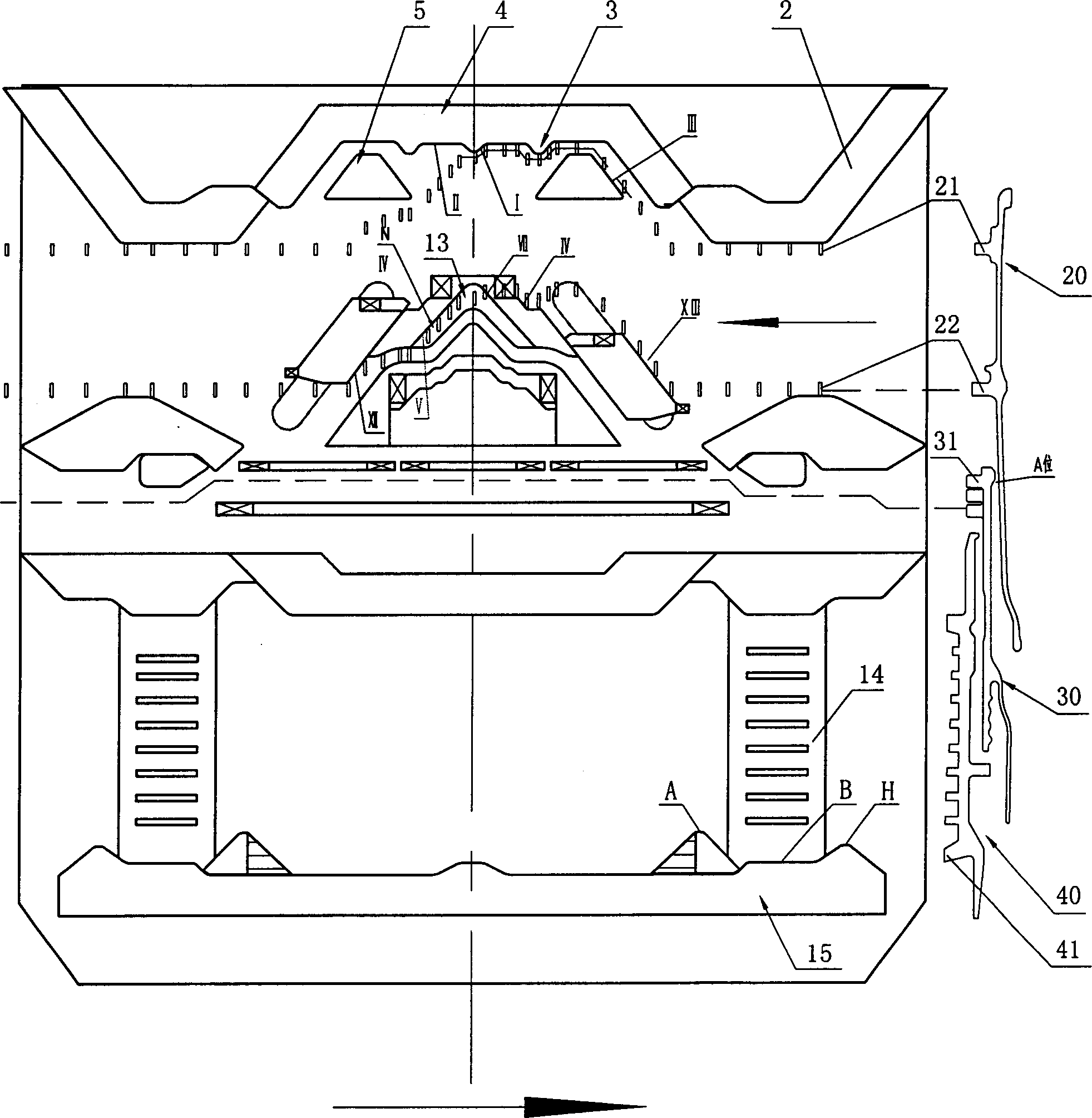

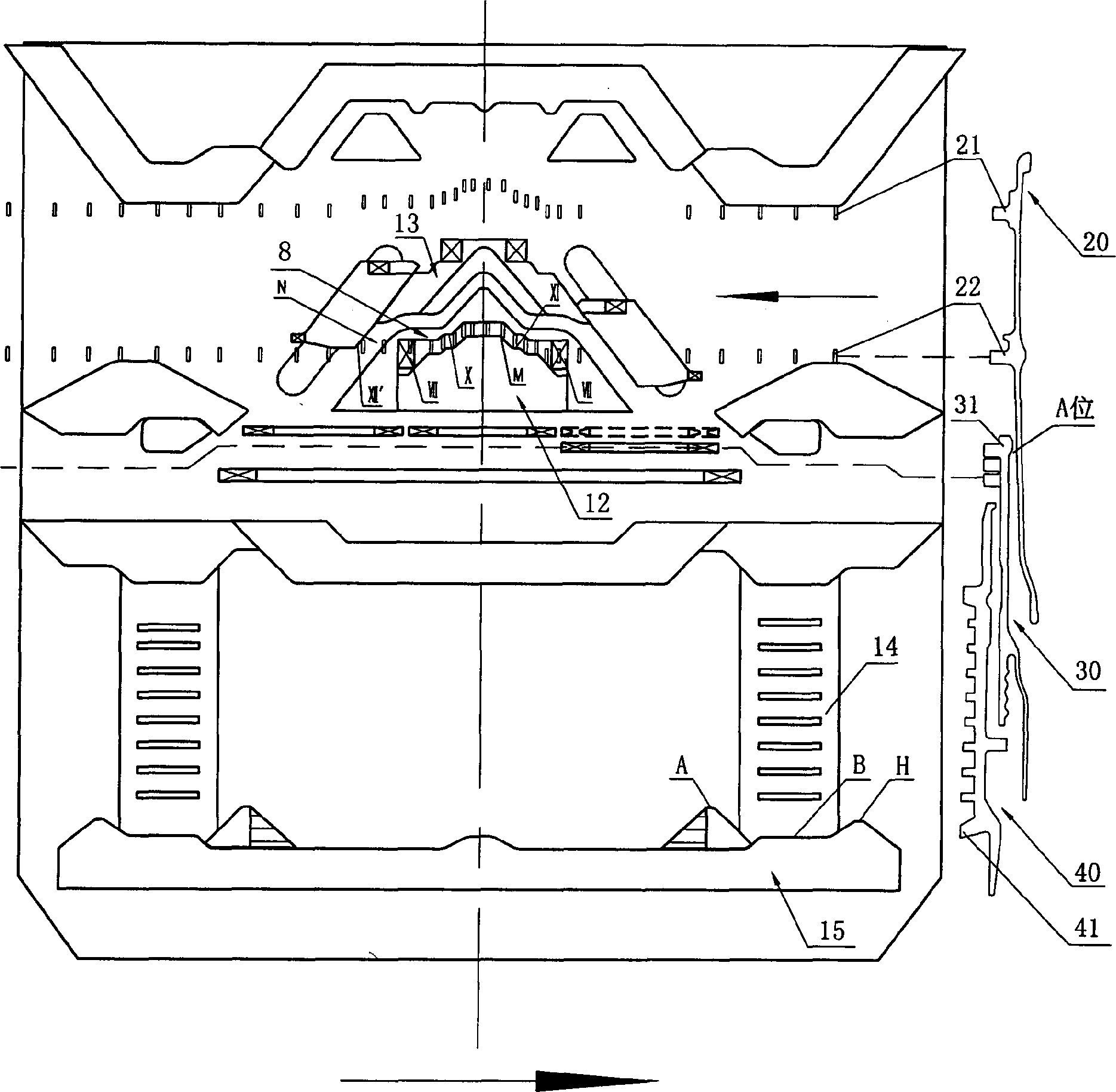

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0037] In this embodiment, a knitting unit is taken as an example, and the knitting unit is set to move rightward at random, and the butts of the sliders in each needle groove on the needle bed move leftward relative to the machine head.

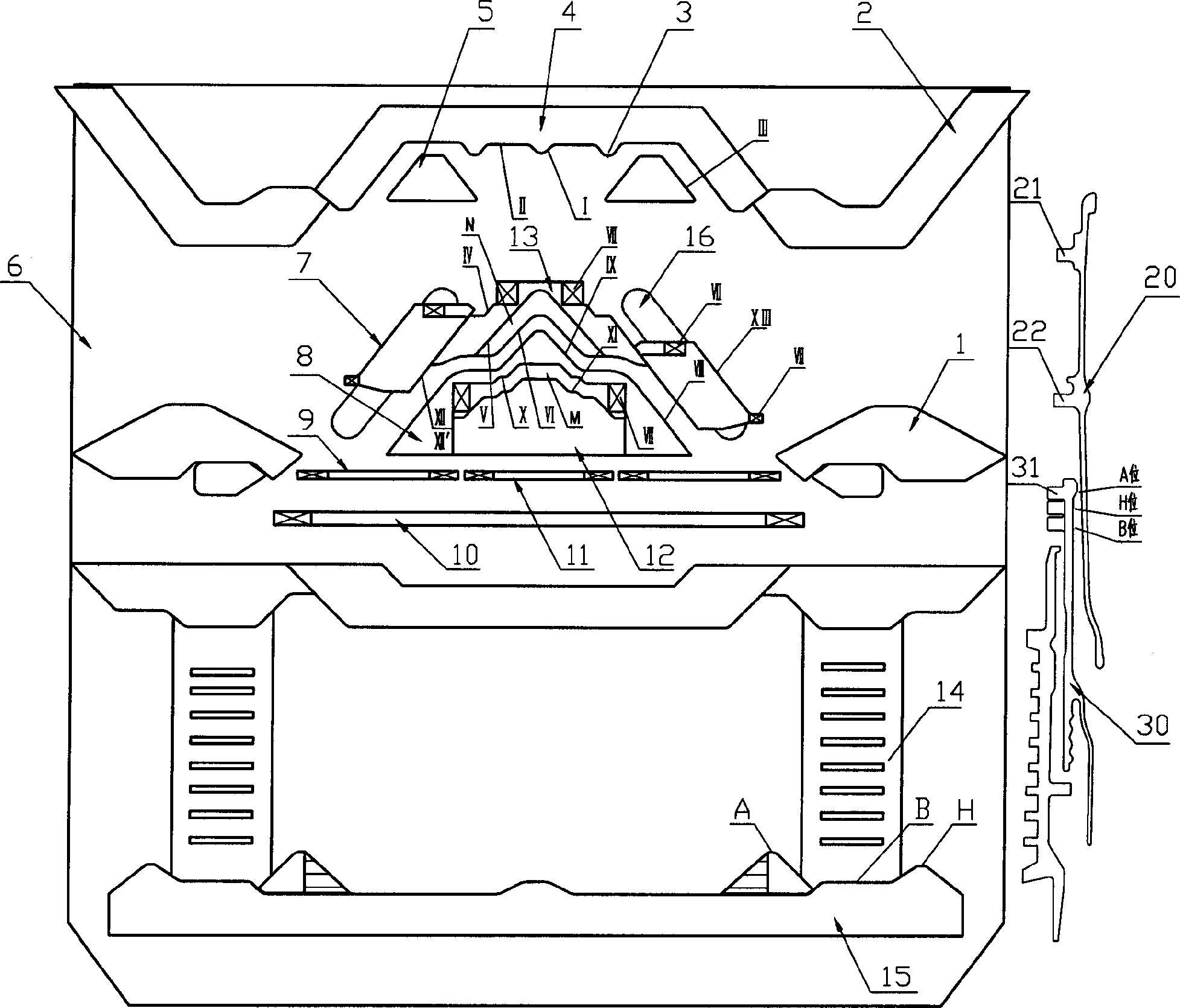

[0038] control figure 1 , the knitting unit is placed in a unit area on the triangular bottom plate 6, which includes the middle movable press plate 11, the left and right movable press plates 9, the fixed press plate 10, the needle selector 14, the control triangle for controlling the corresponding needle butt of the guide pin and the control needle selection The needle selector of sheet corresponding needle butt starts the needle triangle 15. Needle selector starting needle triangle 15 places the lower end of each unit area, and it has A, H, B three needle selection starting needle surfaces. The control triangle i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com